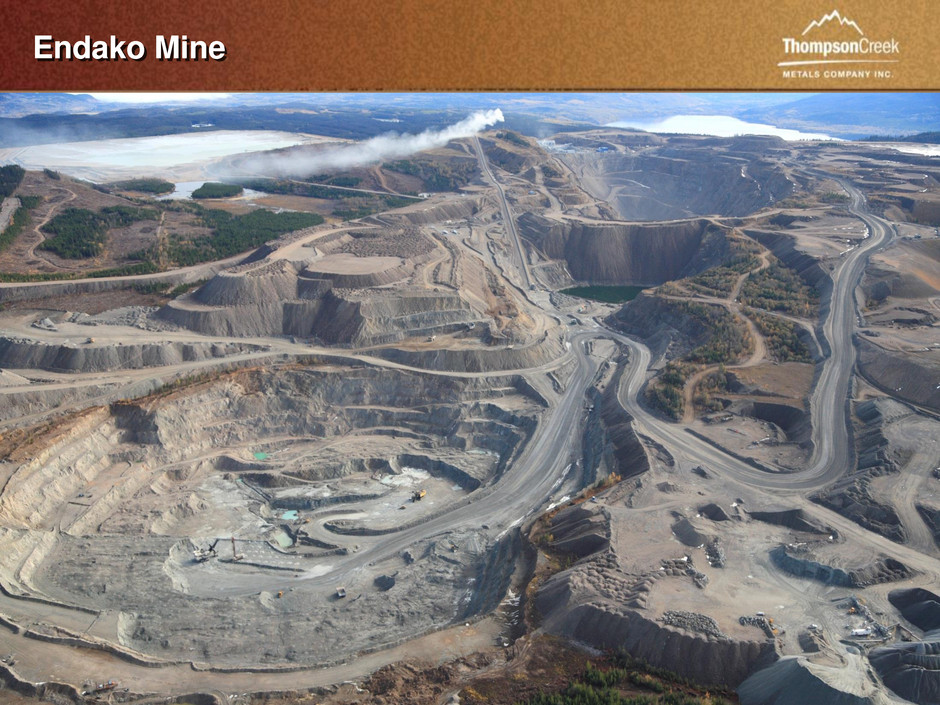

1 Endako Mine 1

2 Endako Mine Safety Performance 0 5 5 4 4 0 4 1 0 0 3.1 2.4 1.4 1.98 0 1 2 3 4 5 6 7 2010 2011 2012 2013 2014 YTD 2 AIRR – All Incident Recordable Rate Medical Aids Lost Time Injury AIRR – Rolling 12 Month Average --- AIRR Max/Min Average

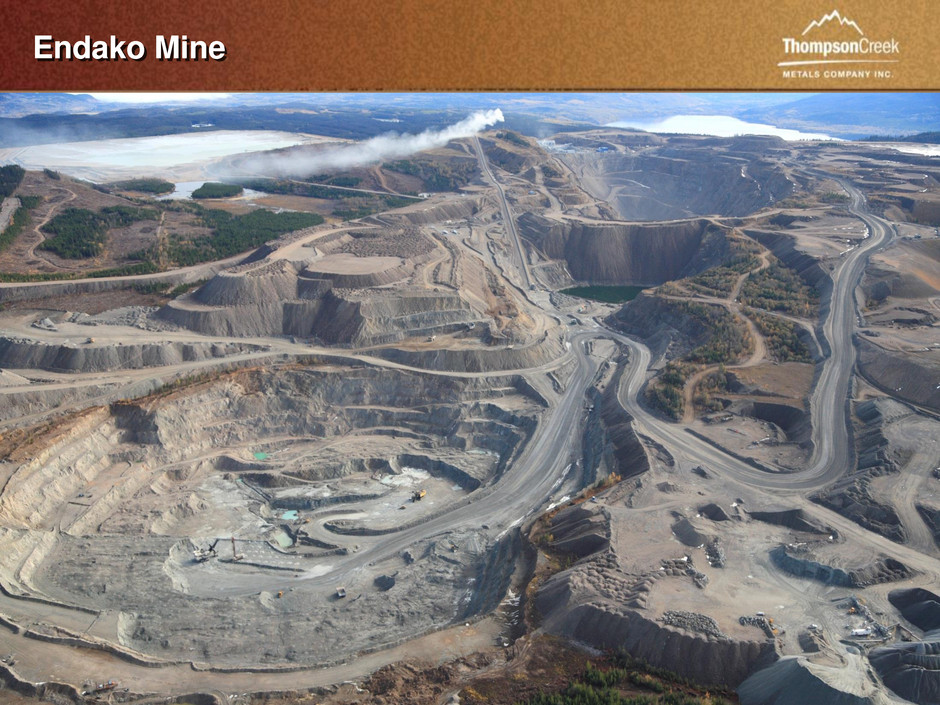

3 Endako Mine

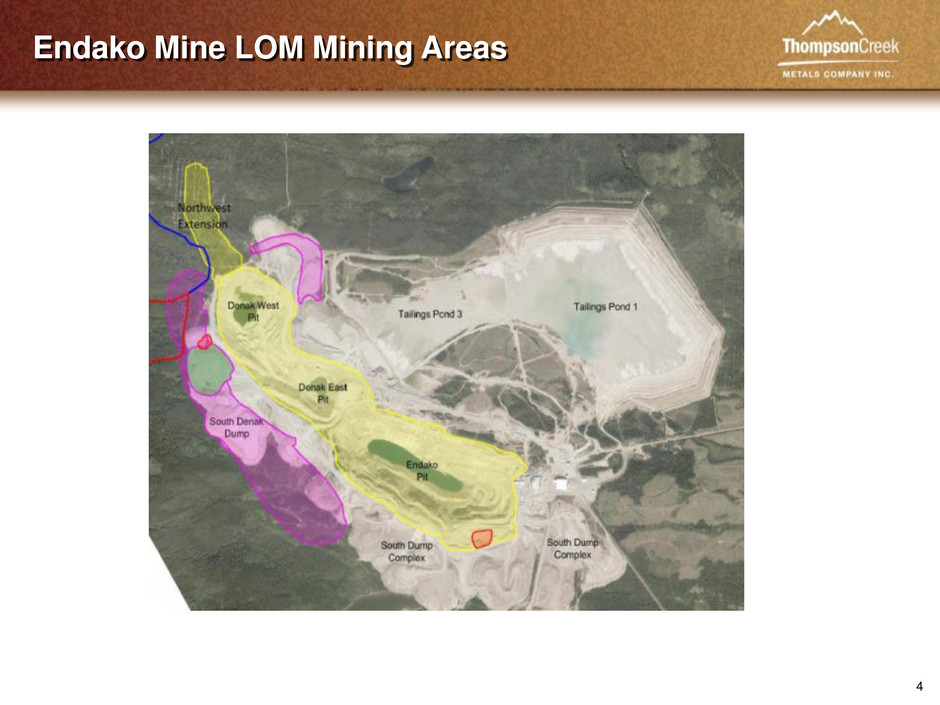

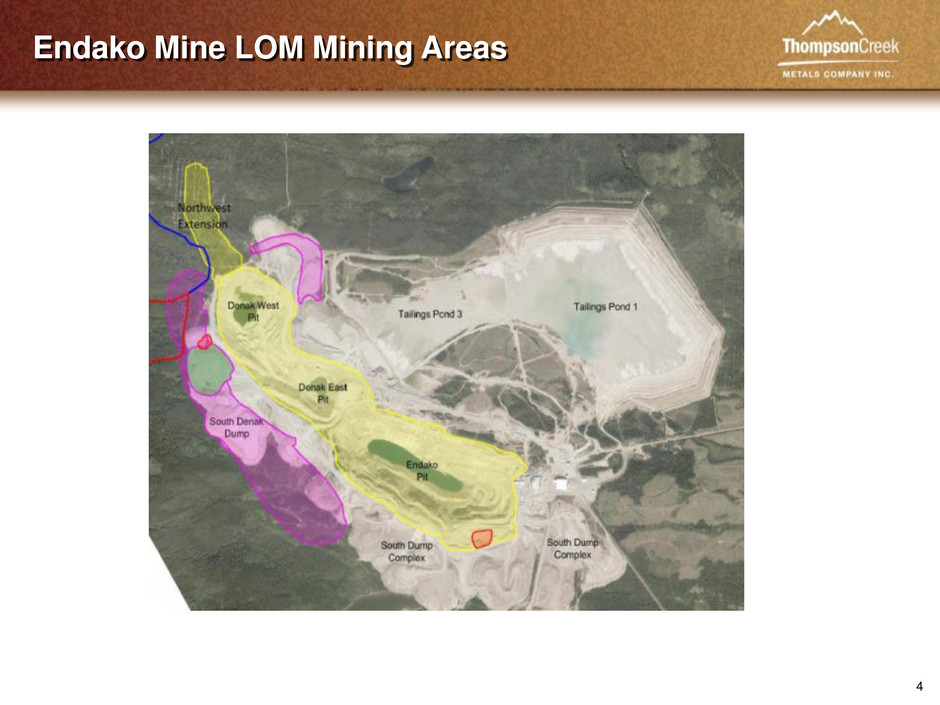

4 Endako Mine LOM Mining Areas 4

5 Endako Mill Facility and Flow Sheet Grinding SAG 2x Ball Roughers Regrind + Cleaning Concentrate Storage Leaching + Drying Roasting 5

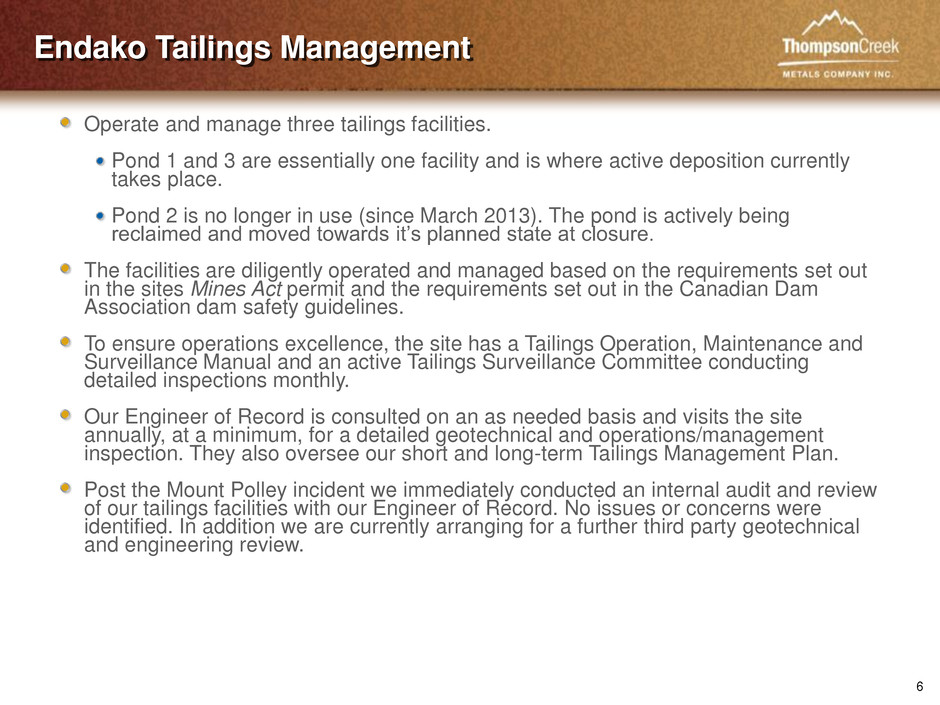

6 Endako Tailings Management 6 Operate and manage three tailings facilities. Pond 1 and 3 are essentially one facility and is where active deposition currently takes place. Pond 2 is no longer in use (since March 2013). The pond is actively being reclaimed and moved towards it’s planned state at closure. The facilities are diligently operated and managed based on the requirements set out in the sites Mines Act permit and the requirements set out in the Canadian Dam Association dam safety guidelines. To ensure operations excellence, the site has a Tailings Operation, Maintenance and Surveillance Manual and an active Tailings Surveillance Committee conducting detailed inspections monthly. Our Engineer of Record is consulted on an as needed basis and visits the site annually, at a minimum, for a detailed geotechnical and operations/management inspection. They also oversee our short and long-term Tailings Management Plan. Post the Mount Polley incident we immediately conducted an internal audit and review of our tailings facilities with our Engineer of Record. No issues or concerns were identified. In addition we are currently arranging for a further third party geotechnical and engineering review.

7 Endako Operating Statistics 2.4 4.6 2.1 3.9 $11.17 $10.87 $11.93 $11.85 1 Please refer to Appendix for non-GAAP reconciliation. Q214 Q213 H114 H113 Q214 Q213 H114 H113 Mo Production (75%) (millions lbs) Cash Costs1 (US $/lb)

8 Endako Updated 2014 Production and Cash Cost Guidance Updated 2014 Estimate Previous 2014 Estimate Molybdenum (000’s lb): Endako Mine Production (75%) 1 9,000 – 10,000 10,000 – 12,000 Cash Costs ($/lb produced) 2 10.50 – 12.00 9.00 – 10.50 1 Molybdenum production pounds represented are molybdenum oxide and high performance molybdenum disulfide (“HPM”) from our share of production from the mines, but exclude molybdenum processed from purchased product. 2 Estimates for cash costs assume a foreign exchange rate of US$1.00 = C$1.05.

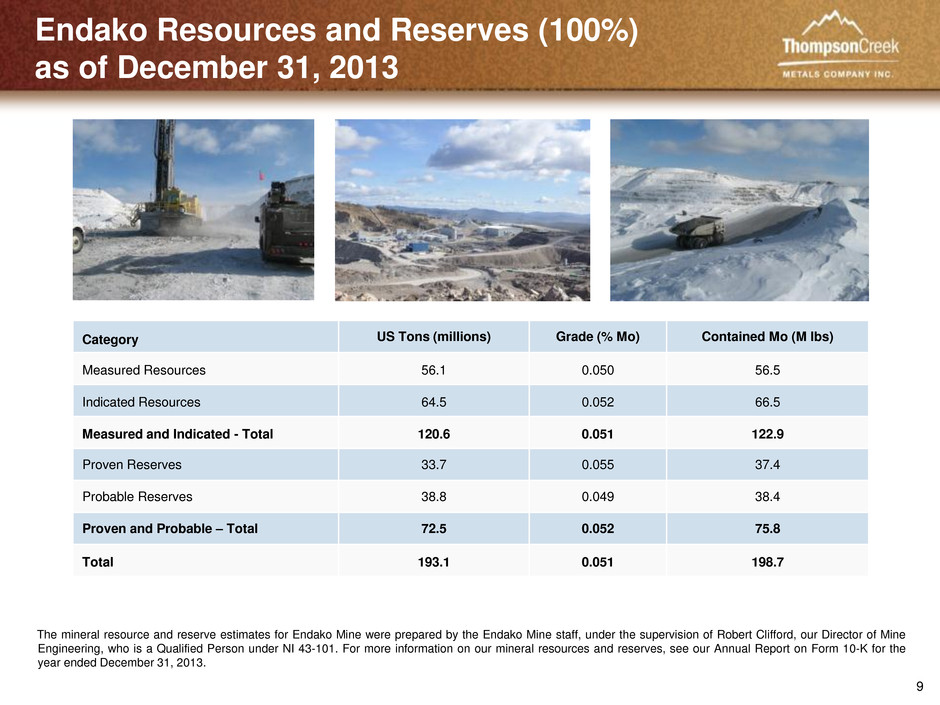

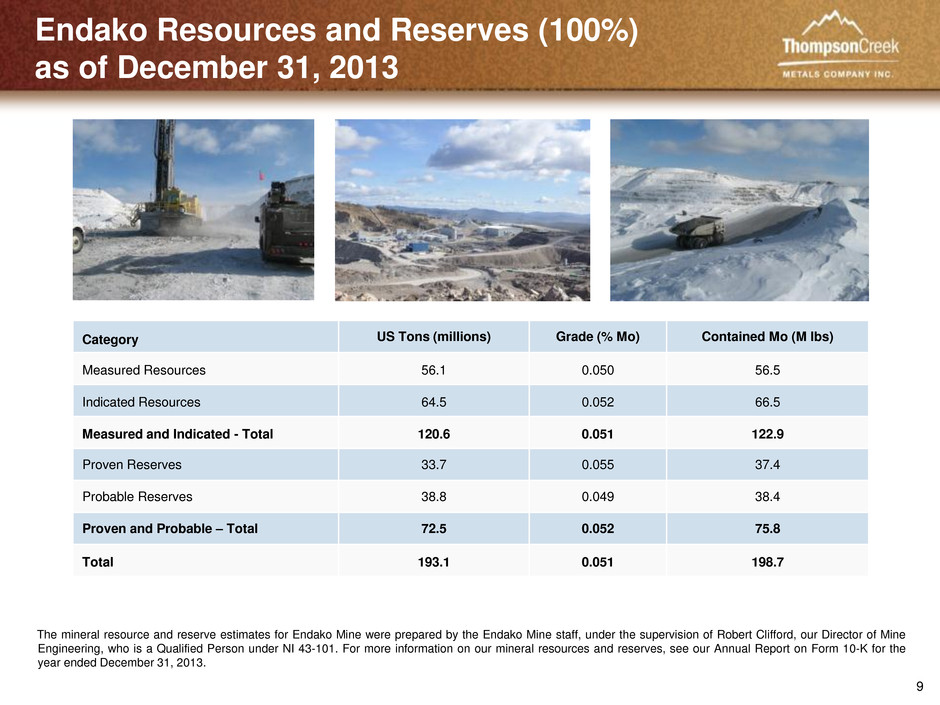

Endako Resources and Reserves (100%) as of December 31, 2013 Category US Tons (millions) Grade (% Mo) Contained Mo (M lbs) Measured Resources 56.1 0.050 56.5 Indicated Resources 64.5 0.052 66.5 Measured and Indicated - Total 120.6 0.051 122.9 Proven Reserves 33.7 0.055 37.4 Probable Reserves 38.8 0.049 38.4 Proven and Probable – Total 72.5 0.052 75.8 Total 193.1 0.051 198.7 The mineral resource and reserve estimates for Endako Mine were prepared by the Endako Mine staff, under the supervision of Robert Clifford, our Director of Mine Engineering, who is a Qualified Person under NI 43-101. For more information on our mineral resources and reserves, see our Annual Report on Form 10-K for the year ended December 31, 2013. 9

10 Endako Mine 2014 Optimization Activities Crusher Optimization Reliability & Engineering Focus Operating Strategy, Systems and Procedures Mine Improvement Fleet Availability Blast Movement Technology Operator Efficiencies & Mine Planning Reduced Haulage Distance Recovery Improvement Projects Causeway Ore Reagents Expert System 10

11 Appendix

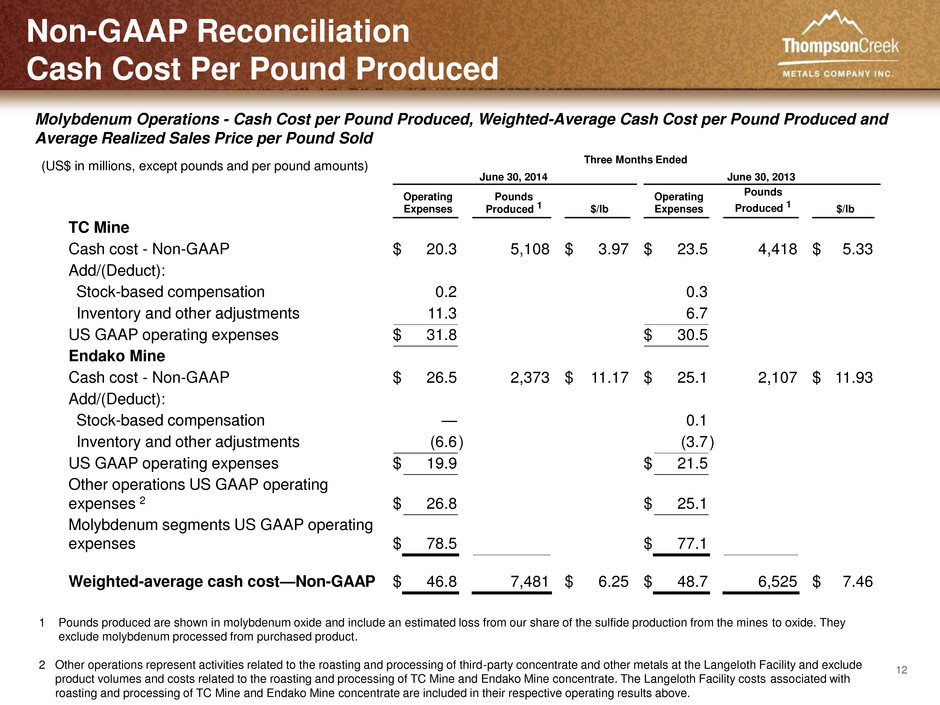

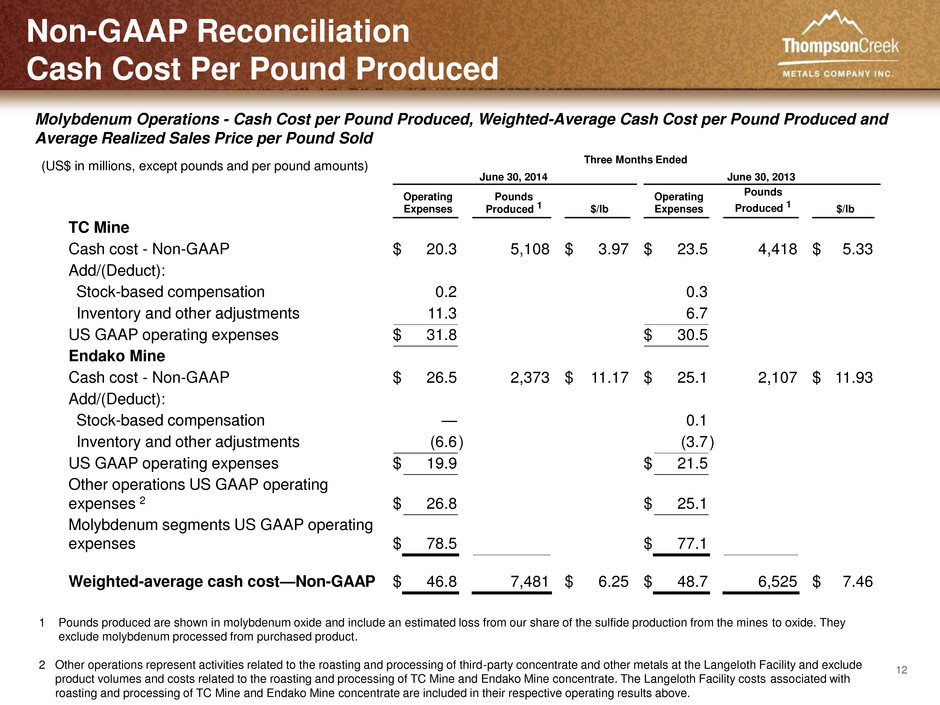

12 Molybdenum Operations - Cash Cost per Pound Produced, Weighted-Average Cash Cost per Pound Produced and Average Realized Sales Price per Pound Sold Three Months Ended June 30, 2014 June 30, 2013 Operating Expenses Pounds Produced 1 $/lb Operating Expenses Pounds Produced 1 $/lb TC Mine Cash cost - Non-GAAP $ 20.3 5,108 $ 3.97 $ 23.5 4,418 $ 5.33 Add/(Deduct): Stock-based compensation 0.2 0.3 Inventory and other adjustments 11.3 6.7 US GAAP operating expenses $ 31.8 $ 30.5 Endako Mine Cash cost - Non-GAAP $ 26.5 2,373 $ 11.17 $ 25.1 2,107 $ 11.93 Add/(Deduct): Stock-based compensation — 0.1 Inventory and other adjustments (6.6 ) (3.7 ) US GAAP operating expenses $ 19.9 $ 21.5 Other operations US GAAP operating expenses 2 $ 26.8 $ 25.1 Molybdenum segments US GAAP operating expenses $ 78.5 $ 77.1 Weighted-average cash cost—Non-GAAP $ 46.8 7,481 $ 6.25 $ 48.7 6,525 $ 7.46 (US$ in millions, except pounds and per pound amounts) Non-GAAP Reconciliation Cash Cost Per Pound Produced 1 Pounds produced are shown in molybdenum oxide and include an estimated loss from our share of the sulfide production from the mines to oxide. They exclude molybdenum processed from purchased product. 2 Other operations represent activities related to the roasting and processing of third-party concentrate and other metals at the Langeloth Facility and exclude product volumes and costs related to the roasting and processing of TC Mine and Endako Mine concentrate. The Langeloth Facility costs associated with roasting and processing of TC Mine and Endako Mine concentrate are included in their respective operating results above.

13 Six Months Ended June 30, 2014 June 30, 2013 Operating Expenses Pounds Produced 1 $/lb Operating Expenses Pounds Produced 1 $/lb TC Mine Cash cost - Non-GAAP $ 42.1 10,766 $ 3.91 $ 48.3 10,347 $ 4.67 Add/(Deduct): Stock-based compensation 0.4 0.5 Inventory and other adjustments 15.3 10.0 US GAAP operating expenses $ 57.8 $ 58.8 Endako Mine Cash cost - Non-GAAP $ 50.0 4,602 $ 10.87 $ 45.8 3,868 $ 11.85 Add/(Deduct): Stock-based compensation — 0.2 Inventory and other adjustments (0.4 ) (8.9 ) US GAAP operating expenses $ 49.6 $ 37.1 Other operations US GAAP operating expenses 2 $ 41.9 $ 49.9 Molybdenum segments US GAAP operating expenses $ 149.3 $ 145.8 Weighted-average cash cost—Non- GAAP $ 92.1 15,368 $ 5.99 $ 94.1 14,215 $ 6.62 Molybdenum Operations - Cash Cost per Pound Produced, Weighted-Average Cash Cost per Pound Produced and Average Realized Sales Price per Pound Sold (US$ in millions, except pounds and per pound amounts) 1 Pounds produced are shown in molybdenum oxide and include an estimated loss from our share of the sulfide production from the mines to oxide. They exclude molybdenum processed from purchased product. 2 Other operations represent activities related to the roasting and processing of third-party concentrate and other metals at the Langeloth Facility and exclude product volumes and costs related to the roasting and processing of TC Mine and Endako Mine concentrate. The Langeloth Facility costs associated with roasting and processing of TC Mine and Endako Mine concentrate are included in their respective operating results above. Non-GAAP Reconciliation Cash Cost Per Pound Produced