Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 20-F

(Mark One)

| REGISTRATION STATEMENT PURSUANT TO SECTION 12(B) OR 12(G) OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

| ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2007.

OR

| TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

| SHELL COMPANY REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934 |

Date of event requiring this shell company report

For the transition period from to

Commission file number:

WSP HOLDINGS LIMITED

(Exact name of Registrant as specified in its charter)

N/A

(Translation of Registrant’s name into English)

Cayman Islands

(Jurisdiction of incorporation or organization)

No. 38 Zhujiang Road

Xinqu, Wuxi,

Jiangsu Province

People’s Republic of China

(Address of principal executive offices)

Yip Kok Thi

WSP Holdings Limited

No. 38 Zhujiang Road

Xinqu, Wuxi,

Jiangsu Province

People’s Republic of China

Phone: +86-510-8536-0401

Email: info@wsphl.com

(Name, Telephone, Email and/or Facsimile number and Address of Company Contact Person)

Securities registered or to be registered pursuant to Section 12(b) of the Act:

| Title of each class | Name of exchange on which each class is to be registered | ||

| American Depositary Shares, each representing 2 ordinary shares, par value $0.0001 per share | New York Stock Exchange |

Securities registered or to be registered pursuant to Section 12(g) of the Act:

None

(Title of Class)

Securities for which there is a reporting obligation pursuant to Section 15(d) of the Act:

None

(Title of Class)

Indicate the number of outstanding shares of each of the Issuer’s classes of capital or common stock as of the close of the period covered by the annual report.

200,000,000 ordinary shares, par value $0.0001 per share, as of December 31, 2007.

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

Yes ![]() No

No ![]()

If this report is an annual or transition report, indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934.

Yes ![]() No

No ![]()

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

Yes ![]() No

No ![]()

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definition of ‘‘accelerated filer and large accelerated filer’’ in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated Filer | Accelerated filer | Non-accelerated filer |

Indicate by check mark which basis of accounting the registrant has used to prepare the financial statements included in this filing:

| US GAAP | International Financial Reporting Standards as issued by the International Accounting Standards Board | Other |

If ‘‘Other’’ has been checked in response to the previous question indicate by check mark which financial statement item the registrant has elected to follow.

Item 17 ![]() Item 18

Item 18 ![]()

If this is an annual report, indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

Yes ![]() No

No ![]()

(APPLICABLE ONLY TO ISSUERS INVOLVED IN BANKRUPTCY PROCEEDINGS DURING THE PAST FIVE YEARS)

Indicate by check mark whether the registrant has filed all documents and reports required to be filed by Sections 12, 13 or 15(d) of the Securities Exchange Act of 1934 subsequent to the distribution of securities under a plan confirmed by a court.

Yes ![]() No

No ![]()

TABLE OF CONTENTS

i

Table of Contents

INTRODUCTION

Unless the context otherwise requires, in this annual report on Form 20-F,

| • | ‘‘we,’’ ‘‘us,’’ ‘‘our company,’’ ‘‘our’’ or ‘‘WSP Holdings’’ refers to WSP Holdings Limited, which, unless otherwise required under the context, includes its predecessor entities and its consolidated subsidiaries; |

| • | ‘‘ADSs’’ refers to our American depositary shares, each of which represents two ordinary shares; |

| • | ‘‘China’’ or ‘‘PRC’’ refers to the People’s Republic of China, excluding, for the purpose of this annual report on Form 20-F only, Taiwan, Hong Kong and Macau; |

| • | ‘‘Oil Country Tubular Goods,’’ or ‘‘OCTG,’’ refers to pipes and other tubular products used in the exploration, drilling and extraction of oil, gas and other hydrocarbon products. OCTG mainly consist of casing, tubing and drill pipes. Unless otherwise indicated, discussions relating to OCTG in this annual report on Form 20-F are limited to these three types of OCTG; |

| • | ‘‘Production capacity’’ refers to the maximum production capacity that can be achieved at the optimal level of operations of a production line, calculated using an estimated product mix for such production line, which may differ from its actual product mix; |

| • | ‘‘RMB’’ or ‘‘Renminbi’’ refers to the legal currency of China, ‘‘HK$’’ refers to the legal currency of Hong Kong, and ‘‘$,’’ ‘‘US$’’ or ‘‘U.S. dollars’’ refers to the legal currency of the United States; and |

| • | ‘‘shares’’ or ‘‘ordinary shares’’ refers to our ordinary shares, par value $0.0001 per share. |

Some names of companies given in this annual report are translated or transliterated from Chinese if the original legal name is only in Chinese.

Discrepancies in any table between the amounts identified as total amounts and the sum of the amounts listed therein are due to rounding.

This annual report on Form 20-F includes our audited consolidated financial statements for the years ended December 31, 2005, 2006 and 2007.

We use U.S. dollars as our reporting currency in our financial statements and in this annual report. When reporting our operating results and financial position, we use the monthly average exchange rate for the year and the exchange rate at the balance sheet date, respectively, as published by the People’s Bank of China. With respect to amounts not recorded in our consolidated financial statements included elsewhere in this annual report, all translations from Renminbi amounts into U.S. dollars were made at the noon buying rate in The City of New York for cable transfers in Renminbi per U.S. dollar as certified for customs purposes by the Federal Reserve Bank of New York, or the noon buying rate, on December 31, 2007, which was RMB7.2946 to $1.00. We make no representation that the Renminbi amounts in this annual report could have been or could be converted into U.S. dollars or Renminbi, as the case may be, at any particular rate or at all. See & lsquo;‘Item 3. Key Information—D. Risk Factors—Risks Related to Doing Business in China—Fluctuations in exchange rates could adversely affect our business as well as result in foreign currency exchange losses.’’ On June 10, 2008, the noon buying rate was RMB6.9248 to $1.00.

We completed the initial public offering of 25,000,000 ADSs on December 6, 2007. On December 6, 2007, we listed our ADSs on the New York Stock Exchange under the symbol ‘‘WH.’’ In January 2008, the underwriters exercised their over-allotment option for the purchase of an additional 2,894,900 ADSs.

1

Table of Contents

PART I

Item 1. Identity of Directors, Senior Management and Advisers

Not Applicable.

Item 2. Offer Statistics and Expected Timetable

Not Applicable.

Item 3. Key Information

A. Selected Financial Data

The following selected consolidated financial should be read in conjunction with our consolidated financial statements and notes to those consolidated financial statements included elsewhere in this annual report and ‘‘Item 5. Operating and Financial Review and Prospects.’’ The selected consolidated statement of operations data for the years ended December 31, 2005, 2006 and 2007 and the selected consolidated balance sheet data as of December 31, 2006 and 2007 are derived from our audited consolidated financial statements, which are included elsewhere in this annual report. The selected consolidated statement of operations data for the years ended December 31, 2004 and the selected consolidated balance sheet data as of December 31, 2004 and 2005 are derived from our audited consolidated financial statements, which are not included in this annual report. Our audited condensed consolidated financial s tatements are prepared and presented in accordance with U.S. GAAP.

We have not included financial information for the year ended December 31, 2003, as such information is not available on a basis that is consistent with the consolidated financial information for the years ended December 31, 2004, 2005, 2006 and 2007. Wuxi Seamless Oil Pipes Company Limited, or WSP China, historically prepared limited unconsolidated financial statements under PRC accounting standards for internal purposes and to support tax return information only. Such financial information for the year ended December 31, 2003 cannot be provided on a U.S. GAAP basis without unreasonable effort or expense.

| For the year ended December 31, | ||||||||||||||||||||||||

| 2004 | 2005 | 2006 | 2007 | |||||||||||||||||||||

| (in thousands, except for share and per share data) | ||||||||||||||||||||||||

| Selected Consolidated Income Statement Data: | ||||||||||||||||||||||||

| Net revenues | $ | 128,497 | $ | 241,012 | $ | 366,501 | $ | 483,783 | ||||||||||||||||

| Cost of revenues | (116,943 | ) | (198,550 | ) | (281,106 | ) | (357,997 | ) | ||||||||||||||||

| Gross profit | 11,554 | 42,462 | 85,395 | 125,786 | ||||||||||||||||||||

| Selling and marketing expenses | (1,032 | ) | (2,056 | ) | (4,102 | ) | (8,578 | ) | ||||||||||||||||

| General and administrative expenses | (2,243 | ) | (6,356 | ) | (9,799 | ) | (13,591 | ) | ||||||||||||||||

| Other operating income (expenses) | 706 | (499 | ) | (549 | ) | (32 | ) | |||||||||||||||||

| Income from operations | 8,985 | 33,551 | 70,945 | 103,585 | ||||||||||||||||||||

| Interest income (expense), net | (1,241 | ) | (1,901 | ) | (1,735 | ) | (10,541 | ) | ||||||||||||||||

| Other income (expense) | (3 | ) | (86 | ) | 4 | 212 | ||||||||||||||||||

| Exchange differences | (32 | ) | 741 | 357 | (1,898 | ) | ||||||||||||||||||

| Income from continuing operations | 7,709 | 32,305 | 69,571 | 91,358 | ||||||||||||||||||||

| Provision for income taxes | (630 | ) | (4,198 | ) | (10,582 | ) | (15,188 | ) | ||||||||||||||||

| Earnings in equity investments | 260 | 266 | 67 | — | ||||||||||||||||||||

| Minority interest | — | 47 | (371 | ) | (1,609 | ) | ||||||||||||||||||

| Net income from continuing operations | 7,339 | 28,420 | 58,685 | 74,561 | ||||||||||||||||||||

| Net income (expense) from discontinued operations | (862 | ) | (4,104 | ) | 233 | — | ||||||||||||||||||

2

Table of Contents

| For the year ended December 31, | ||||||||||||||||||||||||

| 2004 | 2005 | 2006 | 2007 | |||||||||||||||||||||

| (in thousands, except for share and per share data) | ||||||||||||||||||||||||

| Net income | 6,477 | 24,316 | 58,918 | 74,561 | ||||||||||||||||||||

| Net income per share—basic | ||||||||||||||||||||||||

| Income from continuing operations | 0.08 | 0.31 | 0.40 | 0.49 | ||||||||||||||||||||

| Loss on discontinued operations | (0.01 | ) | (0.04 | ) | — | — | ||||||||||||||||||

| Net income per share | 0.07 | 0.27 | 0.40 | 0.49 | ||||||||||||||||||||

| Net income per share—diluted | ||||||||||||||||||||||||

| Income from continuing operations | 0.08 | 0.31 | 0.40 | 0.48 | ||||||||||||||||||||

| Loss on discontinued operations | (0.01 | ) | (0.04 | ) | — | — | ||||||||||||||||||

| Net income per share | 0.07 | 0.27 | 0.40 | 0.48 | ||||||||||||||||||||

| Weighted average ordinary shares outstanding: | ||||||||||||||||||||||||

| Basic | 86,447,932 | 91,315,420 | 145,954,406 | 153,561,644 | ||||||||||||||||||||

| Diluted | 86,447,932 | 91,315,420 | 145,954,406 | 153,738,133 | ||||||||||||||||||||

| As of December 31, | ||||||||||||||||||||||||

| 2004 | 2005 | 2006 | 2007 | |||||||||||||||||||||

| (in thousands) | ||||||||||||||||||||||||

| Consolidated balance sheet data | ||||||||||||||||||||||||

| Cash and cash equivalents | $ | 2,465 | $ | 10,475 | $ | 23,505 | $ | 179,973 | ||||||||||||||||

| Restricted cash | 17,683 | 35,437 | 55,657 | 120,759 | ||||||||||||||||||||

| Accounts and bills receivable, net | 34,078 | 34,054 | 56,947 | 137,497 | ||||||||||||||||||||

| Advances to suppliers | 16,465 | 13,598 | 15,684 | 18,167 | ||||||||||||||||||||

| Inventories | 28,468 | 75,892 | 86,562 | 163,246 | ||||||||||||||||||||

| Total current assets | 110,641 | 175,551 | 248,719 | 626,042 | ||||||||||||||||||||

| Property and equipment, net | 24,830 | 82,301 | 153,143 | 185,136 | ||||||||||||||||||||

| Acquired intangible assets | — | 325 | 231 | 187 | ||||||||||||||||||||

| Total assets | 147,848 | 272,041 | 413,334 | 827,221 | ||||||||||||||||||||

| Accounts payable | 48,271 | 65,796 | 112,806 | 179,065 | ||||||||||||||||||||

| Borrowings—due within one year | 49,417 | 76,654 | 104,967 | 208,356 | ||||||||||||||||||||

| Total current liabilities | 124,511 | 170,304 | 259,859 | 423,032 | ||||||||||||||||||||

| Total liabilities | 124,789 | 215,155 | 314,371 | 482,095 | ||||||||||||||||||||

| Minority interest | — | 996 | 2,813 | 4,002 | ||||||||||||||||||||

| Total shareholders’ equity | 23,059 | 55,890 | 96,150 | 341,124 | ||||||||||||||||||||

| Total liabilities, minority interest, and shareholders’ equity | $ | 147,848 | $ | 272,041 | $ | 413,334 | $ | 827,221 | ||||||||||||||||

Exchange rate information

We use U.S. dollars as our reporting currency in our financial statements and in this annual report. When reporting our operating results and financial position, we use the monthly average exchange rate for the year and the exchange rate at the balance sheet date, respectively, as published by the People’s Bank of China. With respect to amounts not recorded in our consolidated financial statements included elsewhere in this annual report, all translations from Renminbi amounts into U.S. dollars were made at the noon buying rate in The City of New York for cable transfers in Renminbi per U.S. dollar as certified for customs purposes by the Federal Reserve Bank of New York, or the noon buying rate, on December 31, 2007, which was RMB7.2946 to $1.00. We make no representation that any RMB or U.S. dollar amounts could have been, or could be, converted into U.S. dollars or RMB, as the case may be, at any particular rate, the rates stated below, o r at all. The PRC government imposes control over its foreign currency reserves in part through direct regulation of the conversion of RMB into foreign exchange and through restrictions on foreign trade. See ‘‘Item 3. Key Information—D. Risk factors—Risks Related

3

Table of Contents

to Doing Business in China—Fluctuations in exchange rates could adversely affect our business as well as result in foreign currency exchange losses.’’ On June 10, 2008, the noon buying rate was RMB6.9248 to $1.00.

The following table sets forth information concerning exchange rates between the RMB and the U.S. dollar for the periods indicated. These rates are provided solely for your convenience and are not necessarily the exchange rates that we used in this annual report or will use in the preparation of our periodic reports or any other information to be provided to you. The source of these rates is the Federal Reserve Bank of New York.

| Period | Period end | Average(1) | Low | High | ||||||||||||||||||||

| (RMB per $1.00) | ||||||||||||||||||||||||

| 2002 | 8.2800 | 8.2772 | 8.2800 | 8.2700 | ||||||||||||||||||||

| 2003 | 8.2767 | 8.2771 | 8.2800 | 8.2765 | ||||||||||||||||||||

| 2004 | 8.2765 | 8.2768 | 8.2774 | 8.2764 | ||||||||||||||||||||

| 2005 | 8.0702 | 8.1826 | 8.2765 | 8.0702 | ||||||||||||||||||||

| 2006 | 7.8041 | 7.9579 | 8.0702 | 7.8041 | ||||||||||||||||||||

| 2007 | 7.2946 | 7.5806 | 7.8127 | 7.2946 | ||||||||||||||||||||

| 2008 | ||||||||||||||||||||||||

| January | 7.1818 | 7.2405 | 7.2946 | 7.1818 | ||||||||||||||||||||

| February | 7.1115 | 7.1644 | 7.1973 | 7.1100 | ||||||||||||||||||||

| March | 7.0120 | 7.0722 | 7.1110 | 7.0105 | ||||||||||||||||||||

| April | 6.9870 | 7.0000 | 7.0185 | 6.9840 | ||||||||||||||||||||

| May | 6.9400 | 6.9725 | 7.0000 | 6.9377 | ||||||||||||||||||||

| June (through June 10, 2008) | 6.9248 | 6.9352 | 6.9633 | 6.9230 | ||||||||||||||||||||

| (1) | Annual averages are calculated from month-end rates. Monthly averages are calculated using the average of the daily rates during the relevant period. |

B. Capitalization and Indebtedness

Not Applicable.

C. Reasons for the Offer and Use of Proceeds

Not Applicable.

D. Risk Factors

Risks related to our business

Declines in domestic and international oil and natural gas prices, or domestic and international exploration, drilling and production activities, would adversely affect our profitability.

Demand for our OCTG products depends significantly on the number of domestic and worldwide oil and gas wells drilled, completed and reworked, as well as the depth and drilling conditions of these wells. The level of such drilling activities in turn depends on the level of capital spending by major oil and gas companies. A decline in domestic and worldwide oil and gas exploration, drilling and production activities would adversely affect our results of operations. Decreased demand for our products would be expected to result not only from periods of decreased capital spending and activities in exploration, drilling and production, but also from the resulting build up of customer inventory, as certain OCTG products associated with idle rigs such as tubing can be reused on active rigs, making new purchases unnecessary.

Capital spending on OCTG used for oil and natural gas exploration, drilling and production activities is driven in part by the prevailing prices for oil and natural gas and the perceived stability and sustainability of those prices. Our revenues and net income have increased significantly in the past three years, due in part to increases in oil and natural gas prices, which have also reached historically high levels during this period. However, oil and natural gas prices are also subject to significant volatility due to numerous factors beyond our control, including, but not limited to, changes in the supply and demand

4

Table of Contents

for oil and natural gas, market uncertainty, world events, regulatory control (including by the PRC government), political developments in petroleum producing regions and the price and availability of alternative energy sources.

We can provide no assurance that oil and natural gas prices will not decline from the historical highs reached in recent periods or that such prices will otherwise remain at sufficiently high levels to support demand for our products. Any declines in the price of oil and natural gas, even for a short period of time, may reduce or curtail expenditures by oil and gas companies in connection with exploration, drilling and production activities, which may result in lower sales volumes and prices for our products in the PRC and overseas and materially and adversely affect our results of operations and financial condition.

Our results of operations may be adversely affected by increases in steel prices.

Steel is the principal raw material for our products. Raw materials accounted for 91.5%, 86.1% and 80.9% of our cost of revenues in 2005, 2006 and 2007, respectively. Any increase in the steel price could reduce our profit margin if we are unable to pass such increased costs on to our customers. Since the end of 2003, the price of steel has increased substantially due in part to increasing demand which has significantly affected our gross margin. We experienced a substantial increase in steel prices also in 2007, and we expect the steel price to continue to rise in 2008. The price of steel has had, and will continue to have, a significant impact on our cost of revenues. If we are unable to manage our purchases of steel at prices acceptable to us or if the prices of steel increase significantly and we are not able to pass on all or part of any such price increases to our customers, our profit margins may decrease and our results of operations would be materially and adversely affected.

Our operating results may be subject to seasonal fluctuations, which may result in significant volatility in, and otherwise adversely affect, our revenue and profitability.

Our operating results may fluctuate as a result of a number of factors, many of which are beyond our control. Our net revenues have generally decreased in the first quarter and the third quarter of the year. Our customers tend to build up their inventories of our products during the fourth quarter in anticipation of the Chinese New Year holiday which generally takes place in late January or early February of the following year. In addition, business activities in China generally slow down in the first quarter of each year during the Chinese New Year period, which adversely affects our sales and results of operations during that period. Hot summer months may also impact the productivity of the employees working in our production facilities. The above-described seasonal trends that we have experienced in the past may not apply to, or be indicative of, our future operating results. If we do not meet financial expectations of securities analysts or investors, the pr ice of our ADSs may decline.

We depend on a limited number of customers, and any loss of these customers could materially and adversely affect our revenue and profitability.

Our customers include oil and gas companies in the PRC and abroad. Aggregate sales attributable to our five largest customers represented approximately 71.4%, 60.5% and 55.8% of our net revenues for the years ended December 31, 2005, 2006 and 2007, respectively. We cannot assure you that we will be able to maintain or improve our relationships with these customers, or that we will be able to continue to supply products to these customers at current levels or at all. In addition, our business is affected by competition in the oil and gas industry, and any decline in our major customers’ businesses in these markets could lead to a decline in purchase orders from these customers. If any of our key customers were to substantially reduce the size or amount of the orders they place with us or were to terminate their business relationship with us entirely, we cannot assure you that we would be able to obtain orders from other customers to replace any su ch lost sales on comparable terms or at all. If any of these relationships were to be so altered and we were unable to obtain replacement orders, our business, results of operations and financial condition would be materially and adversely affected.

5

Table of Contents

Our sales contracts typically have a term of less than six months and, as a result, customers may reduce their orders or terminate their relationships with us almost immediately.

Sales of our products are typically conducted either through purchase orders or sales contracts with a term less than six months. As a result, our customers may choose to terminate their relationship with us after completion of the shipment or expiration of the contract, as the case may be. Our customers are also not obligated in any way to continue placing orders with us at historical levels or at all. If any of our customers, particularly our key customers, were to materially reduce their orders with us or were to terminate entirely their business relationship with us with short notice, we might not have sufficient time to locate alternative customers and our business and results of operations could be materially and adversely affected.

We cannot assure you that our products will pass the periodic inspection by API or the qualification process of potential customers, and our failure to pass such inspection or qualification will adversely affect our business prospects and results of operations.

We have obtained certificates from API to use the official API monogram on our products to demonstrate that our products meet the API standards. These certificates are subject to periodic inspections by API. Furthermore, our growth strategies include increasing our sales in the PRC domestic market, as well as expanding into international markets such as North America, the Middle East, Asia, Africa and Russia. It is standard industry practice that an OCTG manufacturer must first pass a qualification process to become an approved supplier of an oil and gas company before providing OCTG products to that company. We cannot assure you that we will be able to obtain the necessary certifications from API or approvals for new products from our existing customers or approvals from any new customers. Even if we can ultimately secure such approvals or certifications, we cannot assure you that such certifications and approvals can be obtained in a timely manner or can be ma intained. If we fail to become an approved supplier of our potential customers, or if we are unable to obtain or maintain such approval in a timely manner, we may not be able to execute our expansion plans and our business prospects and results of operations may be materially and adversely affected.

If we are unable to compete effectively in the OCTG industry, our revenue and profits may decrease.

We face intense competition in the domestic and international markets in which we operate. Domestically, we face competition from a number of manufacturers that produce OCTG that are similar to ours. Our major domestic competitors include Tianjin Pipe (Group) Corporation, Shanghai Baosteel Group Corporation, and Pangang Group Chengdu Iron & Steel Co., Ltd, which are mostly state-owned enterprises. We also face competition from international manufacturers, such as Tenaris in Argentina, Vallourec & Mannesmann Tubes in France, TMK in Russia, Sumitomo and JFE in Japan, and U.S. Steel in the United States. Our major competitors may have longer operating history, larger customer base, stronger customer relationships, greater brand or name recognition and greater financial, technical, marketing and public relations resources than we do. Some of our competitors may also be better positioned to develop superior product features and technological innovations and b e able to better adapt to market trends than we are.

Our ability to compete depends on, among other things, high product quality, short lead-time, timely delivery, competitive pricing, range of product offerings and superior customer service and support. Increased competition may require us to reduce our prices or increase our costs and may have a material adverse effect on our financial condition and results of operations. Any decrease in the quality of our products or level of our service to our customers or any occurrence of a price war among our competitors and us may adversely affect our business and results of operations. If we are unable to remain competitive, we may not be able to increase or even maintain our current share of the OCTG market in China or overseas or continue to achieve our current level of profitability.

We cannot assure you that we will be successful in implementing our future expansion plans, in particular our plans for international expansion and overseas sales, or in managing our growth.

A principal component of our future strategy is to continue to grow by expanding our production capacity and further developing our overseas sales. Our future growth will depend on a number of factors,

6

Table of Contents

including, but not limited to, our ability to manage expansion and overseas operations, obtain any required financing, achieve operational efficiencies, and secure sufficient access to raw materials. Some of these factors are beyond our control. As a result, we may not be able to successfully manage our growth or expand our operations, which could have a material adverse effect on our business, financial condition and results of operations.

In addition, we may need to increase the number of our employees and enhance our operational and financial systems to handle the increased complexity and the expanded geographical coverage of our operations associated with our growth. We cannot assure you that we will be able to attract and retain qualified management staff and employees or that our current operational and financial systems and controls will be adequate to accommodate future growth. This could have a material adverse effect on our business, financial condition and results of operations.

We face risks associated with the marketing, distribution and sale of our products internationally, and if we are unable to manage these risks effectively, they could impair our ability to expand our business overseas.

Our international expansion targets are mature markets in terms of OCTG production. In order for us to succeed, we need to take market share away from the existing suppliers of seamless OCTG in these markets. We cannot assure you that we will be able to do so in these competitive markets.

Moreover, our plans for international expansion may be hindered by the following:

| • | cultural differences and other difficulties in staffing and managing overseas operations; |

| • | inherent difficulties and delays in contract enforcement and collection of receivables through the use of foreign legal systems; |

| • | volatility in currency exchange rates; |

| • | the risk that foreign countries may impose withholding taxes (or otherwise tax our foreign income or place restrictions on repatriation of profit); |

| • | the risk of barriers, such as anti-dumping and other tariffs or other restrictions being imposed on foreign trade; |

| • | changes in the political, regulatory, or economic conditions in a foreign country or region; and |

| • | the burden of complying with foreign laws and regulations. |

If we are unable to manage these risks effectively, our ability to conduct or expand our business overseas would be impaired, which may in turn materially and adversely affect our business, financial condition, results of operations and prospects.

Our business depends on our ability to attract and retain members of our senior management team and other key personnel.

Our future success is dependent on the efforts, performance and abilities of our key management team, particularly Mr. Piao Longhua, our chairman and chief executive officer. Mr. Piao founded our company and has extensive industry experience. We do not maintain key man insurance on any of our management personnel. As the OCTG industry in the PRC continues to become more competitive, we expect the competition for management and other skilled personnel to intensify. Failure to attract and retain qualified employees or the loss of any member of our senior management may result in a loss of organizational focus, poor operating execution or an inability to identify and execute potential strategic initiatives such as overseas expansion and new product offerings. This could, in turn, materially and adversely affect our business, financial condition and results of operations.

Our business relies on our ability to retain and attract experienced sales staff and our ability to maintain and expand our existing sales networks both domestically and overseas.

Our experienced sales staff constitutes an essential part of our business. In the domestic PRC market, our sales staff possesses strong technical backgrounds in the OCTG industry, which enable them to

7

Table of Contents

provide and deliver on-site technical support to our customers. We rely on our four sales offices located in the Daqing, Changqing, Xinjiang and Sichuan oilfields to directly sell our products to major oilfields in the PRC. In addition to providing on-site services to our customers throughout the sales process and after-sales support, our sales staff also helps us maintain good relationships with our customers. Internationally, we sell our products through our distributors and sales agents. The loss of services of any of our experienced sales staff without timely replacement, the inability to attract and retain sales personnel, or the loss of any of our major distributors or sales agents may have an adverse effect on our business. If we are unable to maintain our existing sales network, our operations may be materially and adversely affected.

We depend on a limited number of suppliers for a majority of our raw material requirements, and interruption of raw material delivery could prevent us from delivering our products in a timely manner to our customers in the required quantities, and in turn result in order cancellations, decreased revenue and loss of market share.

Our operations depend on our ability to obtain adequate and quality supplies of our primary raw materials, namely round steel billets and green pipes, in a timely manner. If our suppliers fail to meet our quality standards or our quantity demands, our production and sales volume and our results of operation will be adversely affected. We currently rely on two major suppliers to supply round billets to us with which we have entered into long-term arrangements. See ‘‘Item 4. Information on the Company—B. Business Overview—Manufacturing—Suppliers of raw materials.’’ However, we cannot guarantee that our long-term arrangements with these two suppliers will provide us with a reliable supply of raw materials we need. If there is any supply shortage, we may be unable to deliver our products in a timely manner to our customers in the required quantities, which in turn could result in order cancellations, decreased revenue and lo ss of market share.

We may be unable to prevent possible resales or transfers of our products to countries, governments, entities, or persons targeted by United States economic sanctions, especially when we sell our products to distributors over which we have limited control.

The U.S. Department of the Treasury’s Office of Foreign Assets Control, or OFAC, administers certain laws and regulations, or U.S. Economic Sanctions Laws, that impose restrictions upon U.S. persons and, in some instances, foreign entities owned or controlled by U.S. persons, with respect to activities or transactions with certain countries, governments, entities and individuals that are the subject of U.S. Economic Sanctions Laws, or Sanctions Targets. U.S. persons are also generally prohibited from facilitating such activities or transactions. We will not use any proceeds from the sale of our ADSs to fund any activities or business with any Sanctions Targets with respect to activities or transactions prohibited by U.S. Economic Sanctions Laws. We sell our products in international markets primarily through independent non-U.S. distributors which are responsible for interacting with the end customers of our products. In the three years ended Dec ember 31, 2007, we did not have any direct sales to Sanctions Targets, but we indirectly sold a portion of our products to them. To the best of our knowledge, in 2006 and 2007, our indirect sales to Sanctions Targets, including Burma, Cuba, Sudan and Syria, accounted for approximately 9% and 2.8%, respectively, of our net revenues. While we believe that U.S. Economic Sanctions Laws under their current terms are not applicable to our activities, we have nonetheless decided to take measures to prevent any future sales of our products, either directly or indirectly, to Sanctions Targets. See ‘‘Item 5. Operating and Financial Review and Prospects—A. Operating Results—Internal control over distribution of our products.’’ However, we cannot assure you that our measures will be able to prevent all sales of our products, directly or indirectly, to Sanctions Targets in the future. We do not always know the end customers to whom our distributors resell our products, and ou r distributors may breach their covenant to us not to resell our products to Sanctions Targets. If such resales occur in the future, our reputation could be adversely affected, some of our U.S. investors may be required to sell their interests in our company under the laws of certain U.S. states or under internal investment policies or may decide for reputational reasons to sell such interests, and some U.S. institutional investors may forego the purchase of our ADSs, all of which could materially and adversely affect the value of our ADSs and your investment in us.

8

Table of Contents

Measures such as initiation of anti-dumping and anti-subsidy proceedings and imposition of anti-dumping and/or countervailing duties by governments in our overseas markets could materially and adversely affect our export sales.

Anti-dumping and anti-subsidy proceedings have been initiated by some countries in relation to steel products, resulting in anti-dumping and/or countervailing duties being imposed by those countries on steel products. Those and other similar measures could trigger trade disputes in the international steel product markets that could adversely affect our exports.

The Canada Border Services Agency, or CBSA, initiated an investigation on August 13, 2007 on the alleged dumping and subsidizing of certain seamless carbon and alloy steel oil and gas well casings from China after receiving a complaint from Tenaris Algoma Tubes Inc., a Canadian manufacturer. We were named as one of the 30 exporters of the goods from China subject to the investigation. On November 9, 2007, the CBSA made its preliminary determination that exports of carbon and alloy steel seamless oil and gas well casings were being dumped and were subsidized. These preliminary findings resulted in the imposition of a 44% preliminary duty on our products imported into Canada. In February 2008, CBSA made a final determination which imposed anti-dumping and countervailing duties on the subject goods imported into Canada from China subsequent to CBSA’s initial determination in November 2007. In March 2008, the Canadian Interna tional Trade Tribunal, or CITT, which adjudicates whether dumped goods or subsidized imports have caused a material injury to the Canadian industry, did not find present material injury, and ordered that any anti-dumping and countervailing duties paid by the importers on exports of oil and gas well casings from China subsequent to November 2007 be refunded to importers. However, CITT also reached a conclusion that the domestic industry is threatened with injury by future imports, thus imposing anti-dumping and countervailing duties from March 10, 2008. Accordingly, should the Company seek to sell products into Canada in the future, the Company is obligated to comply with price guidance provided by the CBSA in order to avoid any anti-dumping or countervailing duties.

In addition, there is no assurance that there will not be similar actions taken in the future in other countries against Chinese-made seamless OCTG products. For example, in March 2002, the U.S. government imposed certain quotas and tariffs on imports of a range of steel products. Although the United States lifted those tariffs in December 2003, there can be no assurance that the United States or other countries will not impose other quotas or tariffs. Furthermore, some U.S. producers of welded steel pipes have recently filed petitions with the U.S. Department of Commerce and the U.S. International Trade Commission alleging that exports of welded steel pipe products by Chinese companies into the United States were subsidized by the Chinese government. We do not currently produce any welded steel pipe products. However, if there is any similar action filed against us regarding products we sell in the future, even without merits, it will divert sign ificant company resources and management’s attention and could have an adverse impact on the prices and sales of our products in such countries, which could adversely affect our business prospects and results of operations. If any judgment is entered into against us in such an action, we may be subject to fines and penalties and restrictions on sales activities, and our overseas sales would be materially and adversely affected.

If we are unable to continue developing our production technology or adopt new production technology, our business and prospects may be harmed.

The OCTG industry is competitive and the production technology underlying the industry is evolving. As customers’ needs, related technologies and market trends are subject to change, we cannot assure you that we will be able to correctly predict the trends in a timely manner. If we fail to correctly predict changes in the production technology or develop or adopt competitive technology on a timely basis, we may not be able to respond effectively to competitive industry conditions and changing customer demands.

Responding and adapting to technological developments and changes in the OCTG industry and the integration of new technologies or industry standards, may require substantial investment of resources, time and capital. Even if we implement such measures, there can be no assurance that we will succeed in adequately responding and adapting to such technological and industry changes. In the event that we are

9

Table of Contents

unable to respond successfully to technological and industry changes, our business, results of operations and competitiveness may be materially and adversely affected.

Failure to protect our intellectual property rights may materially and adversely affect our competitive position and operations, and we may be exposed to infringement or misappropriation claims by third parties.

Our success is in part attributable to the technologies, know-how and other intellectual properties that we have developed or acquired. See ‘‘Item 4. Information on the Company—B. Business Overview —Intellectual property rights’’ for information relating to our patents and trademarks. Although we rely upon a combination of trade secrets, confidentiality policies, non-disclosure and other contractual arrangements, and patent and trademark laws to protect our intellectual property rights, there can be no assurance that the steps we have taken to protect our intellectual property rights are adequate to prevent or deter infringement or other misappropriation of our intellectual property. We may not be able to detect unauthorized uses or take appropriate and timely steps to enforce our intellectual property rights. Any significant infringement of our proprietary technologies and processes or our intellectual property rights could w eaken our competitive position and have an adverse effect on our operations. To protect our intellectual property rights, we may have to commence legal proceedings against any misappropriation or infringement. However, there can be no assurance that we will prevail in such proceedings. Furthermore, as we only hold PRC patents, if third parties manufacture and sell products using our technology outside of the PRC in competition against us, we would not have a legal cause of action against them.

Furthermore, we may be subject to litigation involving claims of patent infringement or the violation of other intellectual property rights of third parties. The defense of intellectual property suits, patent opposition proceedings and related legal and administrative proceedings can be both costly and time-consuming and may significantly divert the efforts and resources of our technical and management personnel. An adverse determination in any such litigation or proceedings to which we may become a party could subject us to significant liability to third parties, require us to seek licenses from third parties, to pay ongoing royalties, or to redesign our products or subject us to injunctions prohibiting the manufacture and sale of our products or the use of our technologies, which could materially and adversely affect our business, financial condition or results of operations. Protracted litigation could also result in our customers or potential customers defer ring or limiting their purchase or use of our products until resolution of such litigation, which could adversely affect our business.

Failure to maintain an effective quality control system at our manufacturing facilities could have a material adverse effect on our business and operations.

The performance, quality and safety of our products are critical to the success of our business. These factors depend significantly on the effectiveness of our quality control systems, which in turn depend on a number of factors, including the design of our quality control systems, our quality-training program, and our ability to ensure that our employees adhere to the quality control policies and guidelines. Any significant failure or deterioration of our quality control systems could have a material adverse effect on our business reputation, results of operations and financial condition.

Significant product liability claims made against us, regardless of their success, could harm our business reputation, results of operations and financial condition.

Our OCTG products are sold primarily for use in oil and gas exploration, drilling and extraction activities. These activities are subject to inherent risks, including well failures, line pipe leaks and fires, that could result in death, personal injury, property damage, pollution or loss of production, all of which could result in liability claims made against us. We typically offer warranties on our products for a period of up to one year. During the warranty period, faulty products are repaired or replaced by us, or returned to us. Actual defects or allegations of defects in our products may give rise to claims against us for losses and expose us to claims for damages. Any such claims, regardless of their merits, could cause us to incur significant costs, divert our management’s attention, harm our business reputation or cause significant disruption to our operations. Furthermore, we can provide no assurance that we will be able to successfully defend ag ainst such claims, and we do not have any product liability insurance covering our products, except insurance covering those products sold in North America. If any such claims were successful, we could be subject to substantial liabilities, which could materially and adversely affect our results of operations and our financial condition.

10

Table of Contents

If disruptions in our transportation network occur or our shipping costs substantially increase, we may be unable to deliver our products in a timely manner and our cost of revenues could increase.

We are highly dependent upon the transportation systems, including train, truck and ocean shipping, to ship our products. The transportation network is potentially exposed to disruption from a variety of causes, including labor disputes or port strikes, acts of war or terrorism and natural disasters. If our delivery times increase unexpectedly for any reasons, our ability to deliver products on time could be materially and adversely affected and result in delayed or lost revenue.

Our growth strategies require significant capital investments and may require us to seek external financing, which may not be available on terms favorable to us.

Our business operations and growth strategies require substantial capital investments, the availability of which depends on our ability to generate cash flow from operations, borrow funds on satisfactory terms and raise funds in the capital markets. Our ability to arrange for financing to support our capital expenditures and the cost of such financing are dependent on numerous factors, including general economic and capital markets conditions, interest rates and credit availability from banks or other lenders, many of which are beyond our control. In addition, increases in interest rates or failure to obtain external financing on terms favorable to us will affect our financing costs and our results of operations.

As of December 31, 2007, our total bank and other borrowings amounted to $263.1 million. In the event we are unable to obtain extensions of these borrowings when they become due, or if we are unable to obtain sufficient alternative funding at reasonable terms to make repayments, we will have to repay these borrowings with cash generated by our operating activities. Our business might not generate sufficient cash flow from operations to repay these borrowings, some of which are secured by significant amounts of our assets. In addition, repaying these borrowings with cash generated by our operating activities will divert our financial resources from the requirements of our ongoing operations and future growth, and would have a material adverse effect on our business, financial condition and future prospects.

Our financial leverage may hamper our ability to expand and may materially affect our results of operations.

Our ability to make scheduled payments under our financing agreements and any future financing transactions and our ability to refinance our debts, if necessary, will depend, among other things, on our future operating performance. From time to time, we will be required to repay our short-term borrowings and, as a result, we may need to allocate a portion of our cash flow to service these obligations. This could impair our ability to make necessary capital expenditures, develop business opportunities or make strategic acquisitions. We cannot assure you that our business will generate sufficient cash flow from operations in the future to service our debts and make necessary capital expenditures, in which case we may seek additional financing, dispose of certain assets or seek to refinance some or all of our debts. We cannot assure you that any of these alternatives can be implemented on satisfactory terms, if at all, or without breach of the terms and conditions of existing or future financing transactions. In the event that we are unable to meet our liabilities when they are due or if our creditors take legal action against us for payment, we may have to liquidate our long-term assets to repay our creditors. We may have difficulty converting our long-term assets into current assets in such a situation and may suffer losses upon the sale of our long-term assets. This would materially and adversely affect our operations and prevent us from successfully implementing our business strategy.

As a holding company, our ability to make distributions and other payments to our shareholders depends to a significant extent upon the distribution of earnings and other payments made by WSP China.

We declared a dividend of $15.0 million in January 2005, which was in turn contributed by our shareholders to increase the registered capital of WSP China. We declared dividends in the aggregate of $28.8 million in June and August 2006 and $32.5 million in October 2007. On November 30, 2006, our board of directors announced that it intended to approve an annual dividend up to 50% of our annual profits. However, our ability to distribute future dividends will be subject to various factors including, but not limited to, available cash and distributable reserves, investment requirements, and cash flow and

11

Table of Contents

working capital requirements, as well as the withholding tax obligations for dividend distribution under the tax taw. These factors depend on other factors that are beyond our control, including a possible economic downturn and delays in the payments made by customers. If we encounter any of these problems or others, we may not be able to declare and pay dividends in the future as currently planned. In addition, we are currently evaluating the impacts of the new PRC tax law on our dividend plan in 2008. Depending on future events and other changes in the regulatory environment or the business climates, our board of directors may determinate at a later time to change our dividend policy.

Our ability to make distributions or other payments to our shareholders depends primarily on payments from WSP China, whose ability to make such payments is subject to PRC regulations. Under PRC laws and accounting rules, dividends may be paid only out of distributable profits. Distributable profits with respect to WSP China refers to its after-tax profits as determined under PRC GAAP, less any recovery of accumulated losses and allocations to statutory funds that it is required to make. Any distributable profits that are not distributed in a given year are retained and are available for distribution in subsequent years. WSP China is required under PRC laws and regulations to allocate a portion of its annual after-tax profits, if any, to certain statutory reserves and funds prior to declaring and remitting dividends. For example, it is required to allocate 10% of its after-tax profit to statutory reserves until such reserves reach 50% of WSP China’s regist ered capital. Allocations to these statutory reserves and funds can only be used for specific purposes and are not transferable to us in the form of loans, advances or cash dividends. The calculation of distributable profits of WSP China under PRC GAAP differs in many respects from the equivalent calculation under U.S. GAAP. As a result, WSP China may not be able to pay dividends to us in any given year if it does not have distributable profits as determined under PRC GAAP, even if we have profits for the relevant year as determined under U.S. GAAP. Accordingly, if we do not receive dividend distributions from WSP China, our liquidity, financial condition and ability to make dividend distributions will be materially and adversely affected.

We may not be successful in our future acquisitions and investments.

If we are presented with appropriate opportunities, we may acquire additional businesses or assets as part of our growth strategy. Future acquisitions, investments and joint ventures may expose us to potential risks, and the success of our acquisitions, investments and joint ventures depend on a number of factors, including:

| • | our ability to identify suitable opportunities for acquisitions, investments or joint ventures; |

| • | whether we are able to reach an acquisition, investment or joint venture agreement on terms that are satisfactory to us; |

| • | the extent to which we are able to exercise control over the acquired company or business; |

| • | the economic, business or other strategic objectives and goals of the acquired company or business compared to those of our company; |

| • | the diversion of management attention and resources from our existing business; |

| • | our ability to finance the acquisition, investment or joint venture; and |

| • | our ability to integrate successfully the acquired company or business. |

If we fail to make acquisitions or investments or form joint ventures that are strategically important to us, our growth and business prospects may be limited. If we encounter difficulties in integrating the business we acquired, our financial condition and results of operations may be materially and adversely affected.

There have been material weaknesses and deficiencies in our internal control over financial reporting and there remain areas of our internal and disclosure controls that require improvement. If we fail to establish or maintain an effective system of internal controls, we may be unable to accurately report our financial results or prevent fraud, and investor confidence and the market price of our ADSs may be adversely impacted.

We are subject to reporting obligations under U.S. securities laws. The U.S. Securities and Exchange Commission, or the SEC, as required by Section 404 of the Sarbanes-Oxley Act of 2002, adopted rules

12

Table of Contents

requiring every public company to include a management report on such company’s internal control over financial reporting in its annual report, which contains management’s assessment of the effectiveness of the company’s internal control over financial reporting. In addition, an independent registered public accounting firm must audit and report on the effectiveness of the company’s internal control over financial reporting. These requirements will first apply to our annual report on Form 20-F for the fiscal year ending on December 31, 2008. Our reporting obligations as a public company will place a significant strain on our management, operational and financial resources and systems for the foreseeable future.

Prior to our initial public offering in December 2007, we were a private company with limited accounting personnel and other resources with which to address our internal controls and procedures. Our independent registered public accounting firm has not conducted an audit of our internal control over financial reporting. However, in connection with the audits of our consolidated financial statements included in this annual report on Form 20-F, we and our auditors, an independent registered public accounting firm, identified two material weaknesses in our internal control over financial reporting, as defined in the standards established by the Public Company Accounting Oversight Board. The material weaknesses identified relate to (i) our inadequate accounting personnel with a good understanding of U.S. GAAP and SEC reporting requirements, and (ii) our lack of a comprehensive accounting policies and procedures manual. In addition, our auditors also identi fied a significant deficiency relating to the lack of certain accounting controls in one of our subsidiaries, Jiangsu Fanli Pipe Co., Ltd., or Jiangsu Fanli. If we had performed a thorough assessment of our internal control over financial reporting or if our independent registered public accounting firm had performed an audit of our internal control over financial reporting, additional material weaknesses, significant deficiencies or control deficiencies might be identified.

If we fail to timely achieve and maintain the adequacy of our internal controls, our management may conclude that our internal control over financial reporting is not effective. Moreover, effective internal control over financial reporting is necessary for us to produce reliable financial reports and is important to help prevent fraud. As a result, our failure to achieve and maintain effective internal control over financial reporting could result in the loss of investor confidence in the reliability of our financial statements, which in turn could harm our business and negatively impact the market price of our ADSs.

Our business is substantially dependent on the continuing devotion of our chairman and chief executive officer, and our business may be materially and adversely affected if we lose his service.

Mr. Piao Longhua, our chairman and chief executive officer, is a director and controlling shareholder of several private companies, including Eastar Industries, Inc., Expert Master Holdings Limited, or EMH, Lianyungang Eastar Photonics Technologies Co., Ltd., Regalia Investments Holdings Ltd., WSP Canada Ltd., or WSPC, WSP Pipe LLC, Wuxi Huayi Investment Company Limited, Wuxi Longhua Steel Pipes Company Limited and Cambodia Iron and Steel Mining Industry Group. We cannot assure you that Mr. Piao will be able to devote substantially all of his time to our business given his duties to other companies and the changing business environment that may demand more of his time outside of our company. For example, in November, 2007, EMH completed a round of financing and loaned the money to Mr. Piao in relation to his purchase of a controlling equity interest in Cambodia Iron and Steel Mining Industry Group, an iron ore mining company, and Mr. Pia o became a director of that company. In addition, although none of these companies currently engages in the production and sale of OCTG products, we cannot assure you that they will not enter into such business in the future. See ‘‘Item 6. Directors, Senior Management and Employees—C. Board Practices—Code of business conduct and ethics’’ for more details on our code of business conduct and ethics with respect to conflict of interests. If Mr. Piao is not able to devote a substantial amount of his time to our business, or if any dispute arises between Mr. Piao and us, we cannot assure you that we will be able to find a suitable replacement timely or at all, and our business may be adversely and materially affected.

Control or significant influence by our existing shareholders may limit your ability to affect the outcome of decisions requiring the approval of shareholders.

EMH owned approximately 50.6% of our issued share capital as of the date of this annual report. Mr. Piao, our chairman and chief executive officer, is the sole shareholder of EMH, and has control over

13

Table of Contents

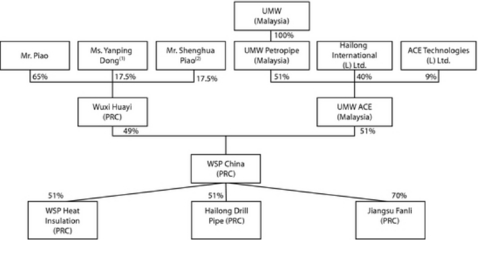

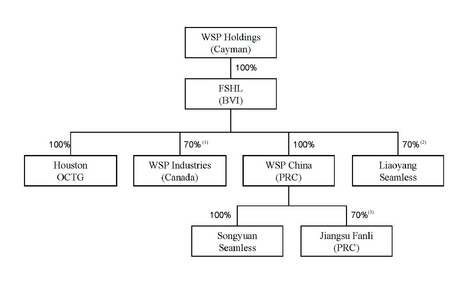

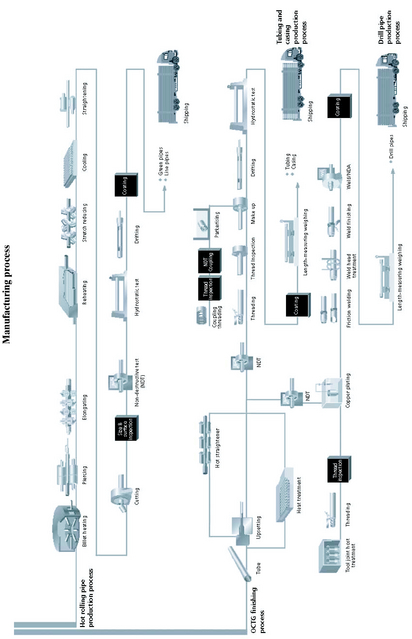

our business, including matters relating to our management and policies and certain matters requiring the approval of our shareholders, such as election of directors, approval of significant corporate transactions and the timing and distribution of dividends. Furthermore, our articles of association contain a quorum requirement of at least a majority of our total outstanding shares present in person or by proxy. EMH, with an aggregate shareholding sufficient to constitute a quorum, could approve by itself actions that require a majority vote at shareholder meetings, which may not be in the best interest of our other shareholders. Furthermore, UMW China Ventures (L) Ltd., or UMW Ventures, which beneficially owns approximately 22.3% of our issued share capital as of the date of this annual report will have significant influence over our business. UMW Ventures was a wholly-owned subsidiary of UMW Holdings Berhad, or UMW. Our vice chairman, Abdul Halim bin Harun, was appointed by UMW. To the extent the interests of EMH or UMW conflict with the interests of other shareholders, the interests of other shareholders may be disadvantaged and harmed. Moreover, we have in the past entered into related party transactions with the affiliates of EMH and UMW, and we expect to continue to enter into related party transactions, subject, if applicable, to our audit committee’s review and approval.

We have limited insurance coverage in China.

The insurance industry in China is still at an early stage of development. Insurance companies in China offer limited commercial insurance products. We have determined that balancing the risks of disruption or liability from our business, or the loss or damage to our property, including our facilities, equipment and office furniture, the cost of insuring for these risks on the one hand, and the difficulties associated with acquiring such insurance on commercially reasonable terms on the other hand, makes it impractical for us to have such insurance. As a result, we only maintain property insurance with respect to our operations that covers general property, plant and equipment, and shipping and transportation. We do not have any product liability insurance covering our products, except for property liability insurance covering our products sold in North America. We do not maintain business interruption or key-man insurance in China. Consequently, any uninsured o ccurrence of loss or damage to property, litigation or business disruption may result in our incurring substantial costs and the diversion of resources, which could have an adverse effect on our operating results. The occurrence of certain incidents including fire, severe weather, earthquake, war, flooding, power outages and the consequences resulting from them may not be covered adequately, or may not be covered at all, by our insurance policies. If we were to incur substantial liabilities that were not covered by our insurance, or if our business operations were interrupted for more than a short period of time, we could incur costs and losses that could materially and adversely affect our results of operations.

We may not be able to obtain the necessary PRC government authorization, the land use rights certificate or the building ownership certificate for one of our properties.

We have not obtained PRC government authorization, the land use rights certificate or the building ownership certificate with respect to one of our warehouse facilities with a gross floor area of approximately 1,000 square meters. There is no assurance that we will be able to obtain PRC government authorization, the land use rights certificate or the building ownership certificate for this property. If we fail to obtain such authorization or certificates in a timely manner, or at all, we may be required to relocate this warehouse facility, which could materially and adversely affect our financial condition and results of operations.

Risks related to doing business in China

The PRC’s economic, political and social conditions, as well as governmental policies, could affect the financial markets in China, our liquidity and access to capital and our ability to operate our business.

Substantially all of our business operations are conducted in China. Accordingly, our results of operations, financial condition and prospects are subject to a significant degree to economic, political and legal developments in China. China’s economy differs from the economies of developed countries in many respects, including with respect to the amount of government involvement, level of development, growth rate, control of foreign exchange and allocation of resources. While the PRC economy has experienced

14

Table of Contents

significant growth in the past 30 years, growth has been uneven across different regions and among various economic sectors of China. The PRC government has implemented various measures to encourage economic development and guide the allocation of resources. Some of these measures benefit the overall PRC economy, but may have a negative effect on us. For example, our financial condition and results of operations may be adversely affected by government control over capital investments or changes in tax regulations that are applicable to us. More generally, if the business environment in China deteriorates from the perspective of domestic or international investors, our business in China may also be adversely affected.

Uncertainties with respect to the PRC legal system could materially and adversely affect us.

We conduct our business primarily through our subsidiaries and affiliated entities in China. PRC laws and regulations govern our operations in China. Our subsidiaries are generally subject to laws and regulations applicable to foreign investments in China and, in particular, laws applicable to wholly foreign-owned enterprises. The PRC legal system is based on written statutes. Prior court decisions may be cited for reference but have limited precedential value.

Since 1979, PRC legislation and regulations have significantly enhanced the protections afforded to various forms of foreign investments in China. However, China has not developed a fully integrated legal system and recently enacted laws and regulations that may not sufficiently cover all aspects of economic activities in China. In particular, because these laws and regulations are relatively new, and because of the limited volume of published decisions and their non-binding nature, the interpretation and enforcement of these laws and regulations involve uncertainties. In addition, the PRC legal system is based in part on government policies and internal rules (some of which are not published on a timely basis or at all) that may have a retroactive effect. As a result, we may not be aware of our violation of these policies and rules until some time after the violation. In addition, any litigation in China, regardless of outcome, may be protracted and result in substantial costs and diversion of resources and management attention.

Recent PRC regulations relating to offshore investment activities by PRC residents may increase our administrative burden and restrict our overseas and cross-border investment activity. If our shareholders who are PRC residents fail to make any required applications and filings under such regulations, we may be unable to distribute profits and may become subject to liability under PRC laws.

Regulations were recently promulgated by the PRC National Development and Reform Commission and the PRC State Administration of Foreign Exchange, or SAFE, that require registrations with, and approvals from, PRC government authorities in connection with direct or indirect offshore investment activities by PRC residents, including PRC individuals and PRC corporate entities. These regulations apply to our shareholders who are PRC residents and may also apply to certain of our offshore acquisitions as well.

In the event that a PRC shareholder with a direct or indirect stake in an offshore parent company fails to make the required SAFE registration, the PRC subsidiaries of that offshore parent company may be prohibited from making distributions of profit to the offshore parent and from paying the offshore parent proceeds from any reduction in capital, share transfer or liquidation in respect of the PRC subsidiaries. Furthermore, failure to comply with the various SAFE registration requirements described above could result in liability under PRC law for foreign exchange evasion.

Our current beneficial owner who is PRC resident has registered with the local SAFE branch as required under these regulations relating to offshore investment activities. However, the failure of our beneficial owner to timely amend his SAFE registrations pursuant to regulations or the failure of future beneficial owners of our company who are PRC residents to comply with the registration procedures may subject such beneficial owners to fines and legal sanctions and may also limit our ability to contribute additional capital into our PRC subsidiaries, limit our PRC subsidiaries’ ability to distribute dividends to our company or otherwise adversely affect our business.

The New M&A Rule may delay or inhibit our ability to complete certain mergers and acquisitions which could affect our ability to expand our business or maintain our market shares.

On August 8, 2006, six PRC regulatory agencies, namely, the PRC Ministry of Commerce, the State Assets Supervision and Administration Commission, or SASAC, the State Administration for

15

Table of Contents

Taxation, the State Administration for Industry and Commerce, the China Securities Regulatory Commission, or CSRC, and SAFE, jointly adopted the Regulations on Mergers and Acquisitions of Domestic Enterprises by Foreign Investors, or the New M&A Rule, which became effective on September 8, 2006. This New M&A Rule purports, among other things established additional procedures and requirements that could make merger and acquisition activities by foreign investors more time-consuming and complex, including requirements in some instances that the Ministry of Commerce be notified in advance of any change-of-control transaction in which a foreign investor takes control of a PRC domestic enterprise. In the future, we may grow our business in part by acquiring complementary businesses. Complying with the requirements of the New M&A Rule to complete such transactions could be time-consuming, and any required approval processes, including obtaining approval from the Ministry of Commerce, may dela y or inhibit our ability to complete such transactions, which could affect our ability to expand our business or maintain our market share.

Restrictions on currency exchange may limit our ability to utilize our revenues effectively.

The PRC government imposes controls on the convertibility of Renminbi into foreign currencies and, in certain cases, the remittance of currency out of China. We receive much of our revenues in Renminbi. Under our current structure, our income is primarily derived from dividend payments from our PRC subsidiaries. Shortages in the availability of foreign currency may restrict the ability of our PRC subsidiaries to remit sufficient foreign currency to pay dividends or other payments to us, or otherwise satisfy their foreign currency denominated obligations. Under existing PRC foreign exchange regulations, payments of current account items, including profit distributions, interest payments and expenditures from trade-related transactions, can be made in foreign currencies without prior approval from the SAFE by complying with certain procedural requirements. However, approval from appropriate government authorities is required where Renminbi is to be converted into foreign currency and remitted out of China to pay capital expenses such as the repayment of bank loans denominated in foreign currencies. The PRC government may also at its discretion restrict access in the future to foreign currencies for current account transactions. If the foreign exchange control system prevents us from obtaining sufficient foreign currency to satisfy our currency demands, we may not be able to pay dividends in foreign currencies to our shareholders, including holders of our ADSs.

Fluctuations in exchange rates could adversely affect our business as well as result in foreign currency exchange losses.

Our financial statements are expressed in U.S. dollars. The functional currency of WSP Holdings is U.S. dollars and the functional currency of our PRC operating subsidiaries is Renminbi. The change in value of the Renminbi against the U.S. dollar and other currencies is affected by, among other things, changes in China’s political and economic conditions. See ‘‘Item 5. Operating and Financial Review and Prospects—A. Operating Results—Quantitative and qualitative disclosure about market risks—Foreign currency risks’’ for a description of the recent PRC foreign exchange policy changes. A substantial portion of our sales is denominated in U.S. dollars and Renminbi, while substantially all of our costs and expenses are denominated in Renminbi. As a result, appreciation of Renminbi since July 2005 has increased, and further appreciation of Renminbi could further increase, our costs. If we were to increase our prices to compensate for the increased costs, we may decrease the market competitiveness of our products. This could result in a decrease in our international sales and materially and adversely affect our business.

In addition, as we rely primarily on dividends paid to us by WSP China, our operating subsidiary in the PRC for our cash requirement, any significant revaluation of the Renminbi may have a material adverse effect on our financial condition and results of operations. The value of, and any dividends payable on, our ADSs in foreign currency terms will also be affected. For example, if we decide to convert our Renminbi into U.S. dollars for the purpose of making payments for dividends on our ordinary shares or ADSs or for other business purposes, an appreciation of the U.S. dollar against the Renminbi would have a negative effect on the U.S. dollar amount available to us. Conversely, when converting the U.S. dollars we received from our financing activities and oversea sales into Renminbi for our operations, any appreciation of the Renminbi against the U.S. dollar will decrease the Renminbi amount we receive from the conversion.

16

Table of Contents

There are only limited hedging transactions available in the PRC to reduce our exposure to exchange rate fluctuations. We are in the process of entering into hedging transactions to reduce our exposure to foreign currency exchange risk, but the availability and effectiveness of these transactions may be limited and we may not be able to successfully hedge our exposure at all.

Our business benefits from certain PRC government incentives, and expiration of, or changes to, these incentives could have a material adverse effect on our results of operations.

The PRC government has provided various incentives to foreign invested enterprises. Prior to December 31, 2007, as a foreign-invested enterprise and a high and new technology enterprise located in the Wuxi National High-Tech Industrial Development Zone, WSP China was subject to a foreign enterprise income tax, or FEIT, of 15%. In addition, WSP China enjoyed a five-year tax holiday that ended in 2004, pursuant to which it paid a FEIT at the rate of 7.5% in 2004. See ‘‘Item 5. Operating and Financial Review and Prospects—A. Operating Results—Taxation’’ for more details.

In March 2007, the PRC National People’s Congress passed the PRC Enterprise Income Tax Law, or the New Tax Law, and in December 2007, the State Council promulgated the implementing rules of the New Tax Law, both of which became effective on January 1, 2008. Under the New Tax Law, foreign invested enterprise, or FIE, and domestic companies are subject to a uniform income tax rate of 25%. According to the New Tax Law, entities that qualify as ‘‘high and new technology enterprises supported by the state’’ are expected to benefit from a reduced tax rate of 15% as compared to the uniform tax rate of 25%. Our effective income tax rate will increase unless we are otherwise eligible for preferential treatment. However, there can be no assurance that WSP China will qualify as a ‘‘high and new technology enterprise’’ and benefit from a preferential tax rate under the New Tax Law.