Exhibit 99.84

TIMMINS GOLD CORP.

NI 43-101 F1 TECHNICAL REPORT

UPDATED RESOURCES AND RESERVES

AND MINE PLAN FOR THE

SAN FRANCISCO GOLD MINE

SONORA, MÉXICO

November 30, 2010

Amended August 3, 2011

Prepared by:

William J. Lewis, B.Sc., P.Geo.

Ing. Alan J. San Martin, MAusIMM

Mani Verma, P.Eng.

Christopher A. Jacobs, CEng,l MIMMM

Richard M. Gowans, B.Sc. P.Eng.

SUITE 900 - 390 BAY STREET, TORONTO ONTARIO, CANADA M5H 2Y2

Telephone (1) (416) 362-5135 Fax (1) (416) 362 5763

Table of Contents

i

ii

iii

APPENDIXES

| APPENDIX I | Glossary of Mining and Other Related Terms | At end of Report |

| | | |

| APPENDIX 2 | 2008 to June, 2010, Summary of Significant Drill Assays in the NW, S-SW and E-SE Areas around the San Francisco Pit | At end of Report |

iv

List of Tables

Page

v

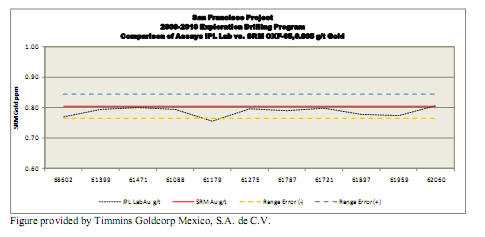

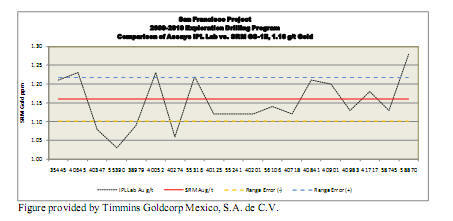

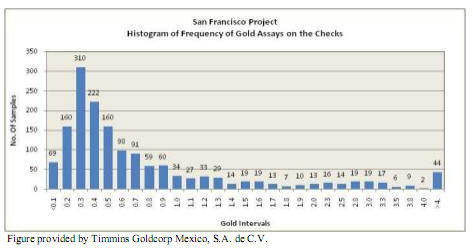

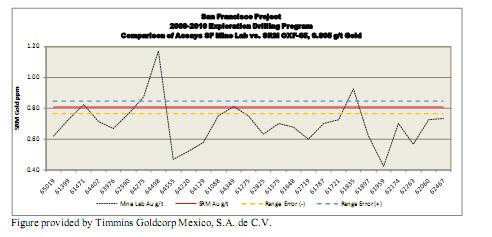

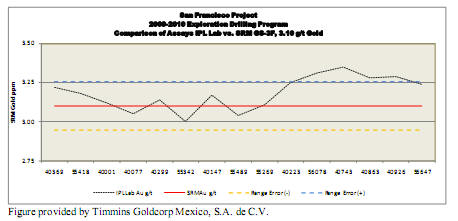

| Table 13.9 | Summary of the Comparison of the San Francisco Mine and IPL Laboratories Assay Results against the SRM CDN-GS-P8 | 107 |

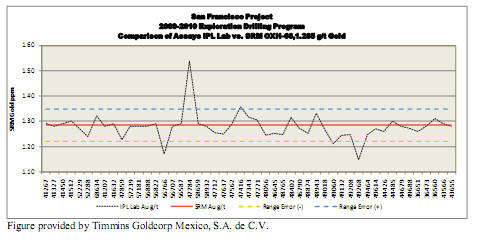

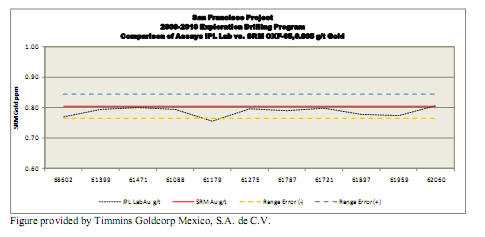

| Table 13.10 | Summary of the Comparison of the San Francisco Mine and IPL Laboratories versus the SRM OXF-65 | 108 |

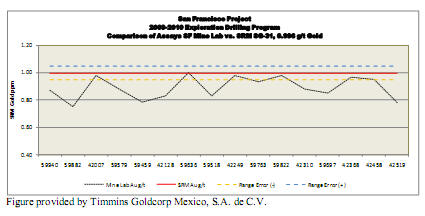

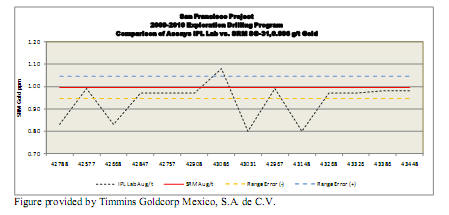

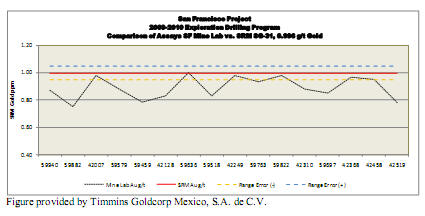

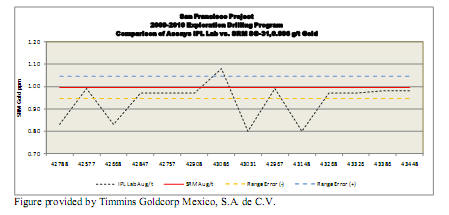

| Table 13.11 | Summary of the Comparison of the San Francisco Mine and IPL Laboratories versus SRM SG-31 | 109 |

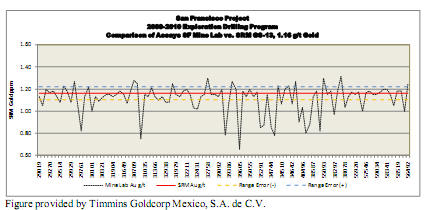

| Table 13.12 | Summary of the Comparison of the San Francisco Mine and IPL Laboratories versus the SRM CDN-GS-1E | 110 |

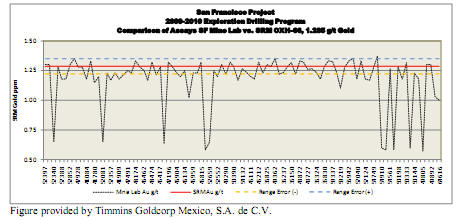

| Table 13.13 | Summary of the Comparison of the San Francisco Mine and IPL Laboratories against the SRM OXH-66 | 111 |

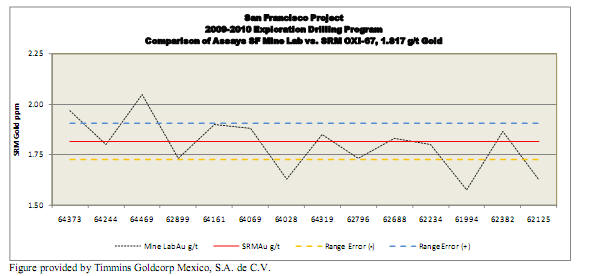

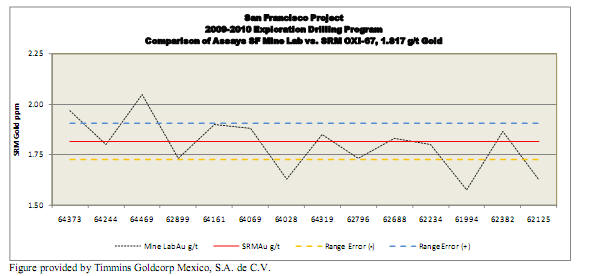

| Table 13.14 | Summary of the Comparison of the San Francisco Mine Laboratory against SRM OXI-67 | 112 |

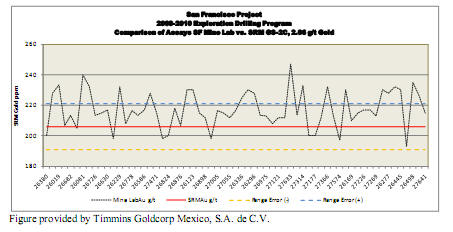

| Table 13.15 | Summary of the Comparison of the San Francisco Mine Laboratory against SRM CDN-GS-2C | 113 |

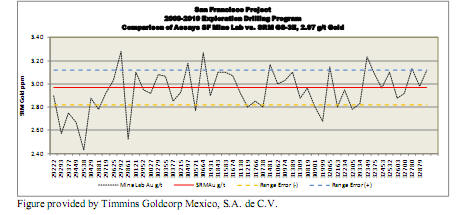

| Table 13.16 | Summary of the Comparison of the San Francisco Mine Laboratory against SRM CDN-GS-3E | 113 |

| Table 13.17 | Summary of the Comparison of the San Francisco Mine Laboratory against SRM CDN-GS-3FN | 114 |

| Table 13.18 | Summary of the Comparison of the San Francisco Mine Laboratory against the SRM CDN-GS-5C | 115 |

| Table 13.19 | Summary of Blank Assay Data for the September, 2009 to March, 2010 Drill Program (San Francisco Laboratory) | 116 |

| Table 13.20 | Summary of Blank Assay Data for the September, 2009 to March, 2010 Drill Program (IPL and IPL-Inspectorate Laboratory) | 116 |

| Table 13.21 | Summary of the Results for the Duplicate Samples, September, 2009 to June, 2010 Drilling Program | 117 |

| Table 14.1 | Summary of April to June, 2010, Quarter Production | 121 |

| Table 16.1 | Summary of the Two Composites | 125 |

| Table 16.2 | Summary of the Leach Column Tests September, 2009 to July, 2010 | 126 |

| Table 16.3 | Summary of the Mineralization Type and Corresponding Test Gold Recoveries | 127 |

| Table 17.1 | Mineral Resource Estimate for the San Francisco Project (Inclusive of Mineral Reserves) | 128 |

| Table 17.2 | 3-D Block Model Limits and Dimensions | 130 |

| Table 17.3 | Rock Domain Code and Specific Gravity | 131 |

| Table 17.4 | Measured, Indicated and Inferred Resource Blocks, August, 2010 | 133 |

vi

vii

List of Figures

Page

viii

ix

x

xi

xii

1.0 SUMMARY

1.1 GENERAL

Timmins Gold Corp. (TSX-V:TMM) (TMM) has retained Micon International Limited (Micon) to conduct an audit of its resource and reserve estimation and prepare an update of its 2008/2009 preliminary feasibility study on the San Francisco project in the state of Sonora, Mexico. The purpose of this Technical Report is to support disclosure of the results of Micon’s resource and reserve audit and the updated preliminary feasibility study, compliant with Canadian National Instrument (NI) 43-101.

Previously, Micon prepared a Technical Report, entitled “NI 43-101 Technical Report on the Preliminary Feasibility Study for the San Francisco Gold Property, Estación Llano, Sonora, Mexico”, describing the preliminary feasibility study on the San Francisco project, dated March 31, 2008 and amended January 13, 2009.

At the request of the British Columbia Securities Commission (BCSC) the certificates in this report were amended on August 3, 2011.

1.2 PROPERTY DESCRIPTION AND LOCATION

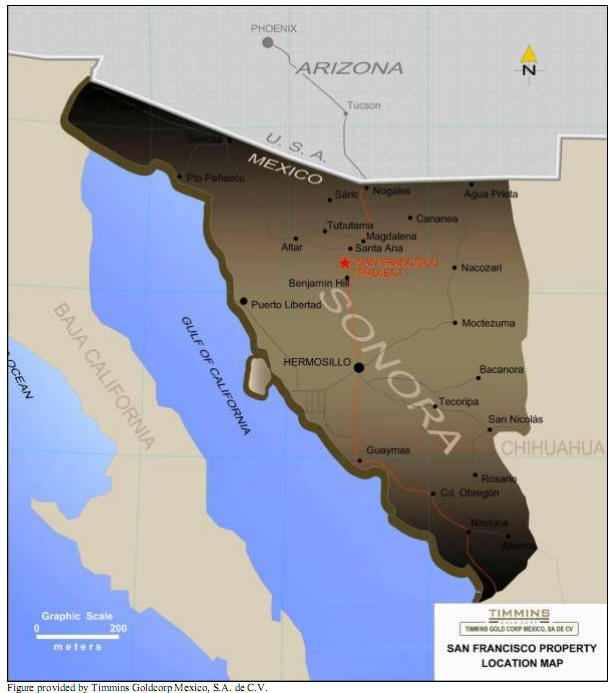

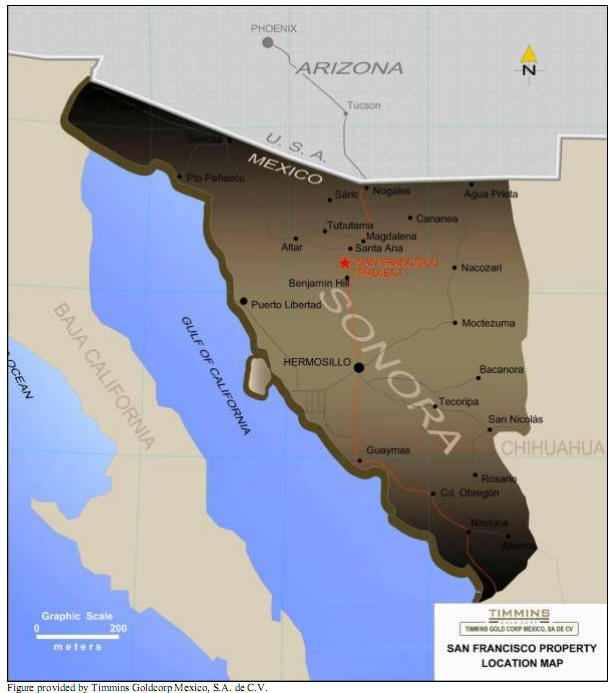

The San Francisco property is situated in the north central portion of the state of Sonora, Mexico, approximately 150 km north of the state capital, Hermosillo. In this report, the term San Francisco project (the project) refers to the area within the exploitation or mining concessions optioned by TMM, while the term San Francisco property (the property) refers to the entire land package (mineral exploitation and exploration concessions) optioned and owned by TMM.

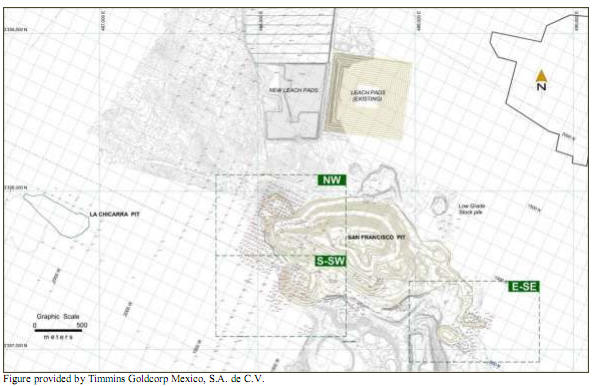

The project is comprised of two previously mined open pits (San Francisco and La Chicharra), together with heap leach processing facilities and associated infrastructure located close to the San Francisco pit.

TMM advises that it holds its interest in the San Francisco property through its wholly-owned Mexican subsidiary Timmins Goldcorp Mexico, S.A. de C.V. (Timmins). Timmins originally acquired the rights to the exploitation concessions on April 18, 2005, upon signing an option agreement with Geomaque de Mexico, S.A. de C.V. (Geomaque de Mexico). The option agreement has now been superseded by an acquisition agreement. The purchase price was set at USD 5,000,000 plus 10,000,000 shares at a deemed price of USD 0.50 per share. The existing equipment had an additional purchase price of USD 3,500,000 plus value added tax (VAT), which amount is due without interest at the end of the three years from May, 2007. A portion of the equipment purchase price remains outstanding. The security documentation to place a lien against the equipment is being finalized.

In 2005, Timmins staked a number of exploration concessions surrounding the exploitation concessions. Interspersed within the Timmins concessions were four mineral concessions controlled by other parties, but these do not impact the main area of interest covering the San Francisco project. All concessions are subject to a semi-annual fee and the filing of reports in May of each year covering the work accomplished on the property between January and December of the preceding year. The total semi-annual fee payable to the Mexican government for the group of concessions is presently estimated to be USD 72,929.

1

The Mexican mining laws were changed in 2005 and, as a result of these changes, all mineral concessions granted by the Dirección General de Minas (DGM) became mining concessions and there are no longer separate specifications for a mineral exploration or exploitation concession. A second change to the mining laws was that all mining concessions are granted for 50 years provided that the concessions remain in good standing. As part of this change, all former exploration concessions which were previously granted for 6 years became eligible for the 50-year term.

In 2006, Timmins concluded an access agreement with an agrarian community (an “Ejido” in Mexico) called Los Chinos whereby Timmins was granted access privileges to 674 ha, the use of the Ejido’s roads, as well as being able to perform all exploration work on the area covered by the agreement. The agreement is for a period of 10 years with an option to extend the access beyond the 10-year period. In consideration for the Ejido granting the access privileges to a portion of its land, Timmins paid the Ejido the sum of USD 30,000.

1.3 ACCESSIBILITY, CLIMATE, PHYSIOGRAPHY, LOCAL RESOURCES AND INFRASTRUCTURE

The project is located in the Arizona-Sonora desert in the northern portion of the Mexican state of Sonora, 2 km west of the town of Estación Llano (Estación), approximately 150 km north of Hermosillo and 120 km south of the United States/Mexico border city of Nogales along Highway 15 (Pan American highway). The closest accommodations are located in Santa Ana, a small city located 21 km to the north on Highway 15.

The climate at the project site ranges from semi-arid to arid. The average ambient temperature is 21°C, with minimum and maximum temperatures of -5ºC and 50ºC, respectively. The average rainfall for the area is 330 millimetres (mm) with an upper extreme of 880 mm. The desert vegetation surrounding the San Francisco mine is composed of low lying scrub, thickets and various types of cacti, with the vegetation type classified as Sarrocaulus Thicket.

Physiographically, the San Francisco property is situated within the southern Basin and Range Province, characterized by elongate, northwest-trending ranges separated by wide alluvial valleys. The San Francisco mine is located in a relatively flat area of the desert with the topography ranging between 700 and 750 m above sea level.

2

1.4 HISTORY

After conducting exploration on the project between 1983 and 1992, Compania Fresnillo S.A. de C.V. (Fresnillo) sold the property in 1992 to Geomaque Explorations Ltd. (Geomaque). After conducting further exploration, Geomaque decided to bring the project into production in 1995. Due to economic conditions, mining ceased and the operation entered into the leach-only mode in November, 2000. In May, 2002, the last gold pour was conducted; the plant was mothballed, and clean-up activities at the mine site began.

In 2003, Geomaque sought and received shareholder approval to amalgamate the corporation under a new Canadian company, Defiance Mining Corporation (Defiance). On November 24, 2003, Defiance sold its Mexican subsidiaries (Geomaque de Mexico and Mina San Francisco), which held the San Francisco gold mine, to the Astiazaran family of Sonora and their private company for a total consideration of USD 235,000.

Since June, 2006, the Astiazaran family and their company Desarrollos Prodesa S.A. de C.V. have been extracting sand and gravel intermittently from both the waste dumps and the leach pads for use in highway construction as well as other construction projects.

Timmins acquired an option to earn an interest in the property in early 2005, whereupon Timmins conducted a review of the available data and started a reverse circulation drilling program in August and September, 2005. This was followed by a second drilling program comprised of both reverse circulation and diamond drilling in 2006, based on the results of the 2005 drilling program.

1.5 GEOLOGICAL SETTING AND MINERALIZATION

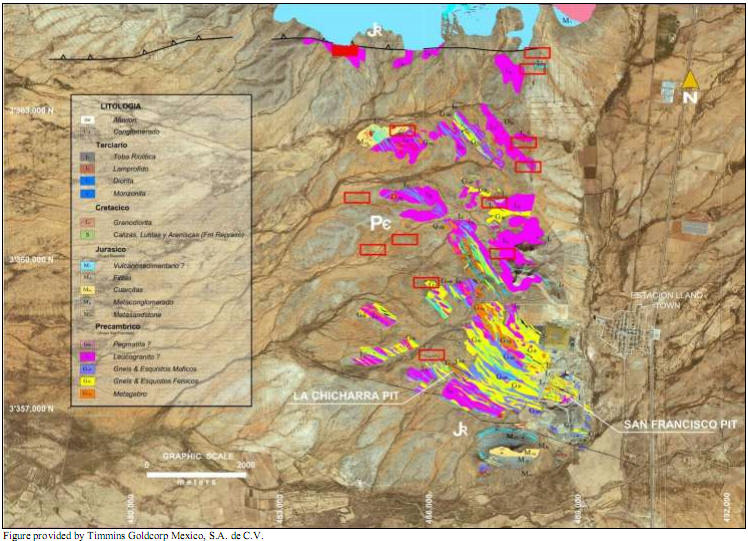

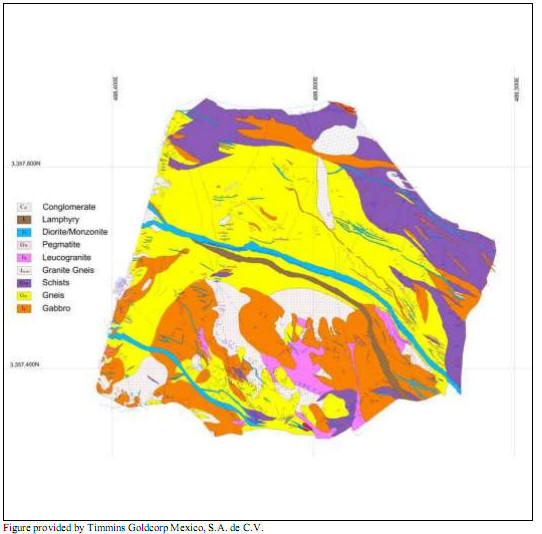

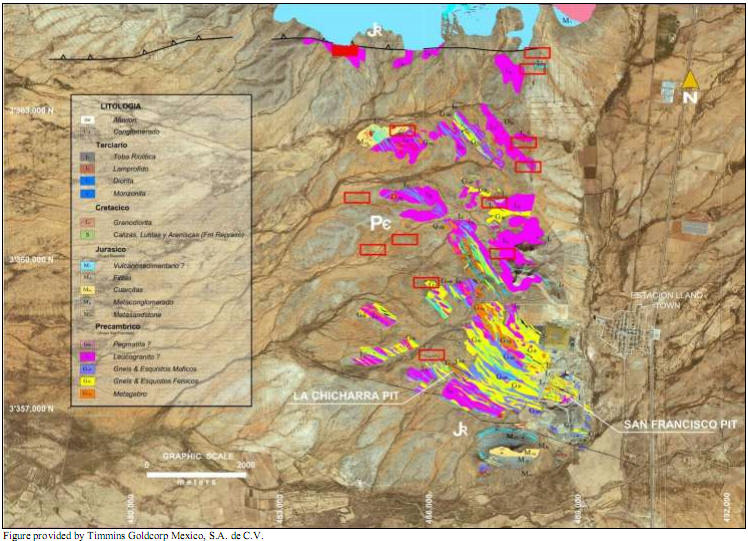

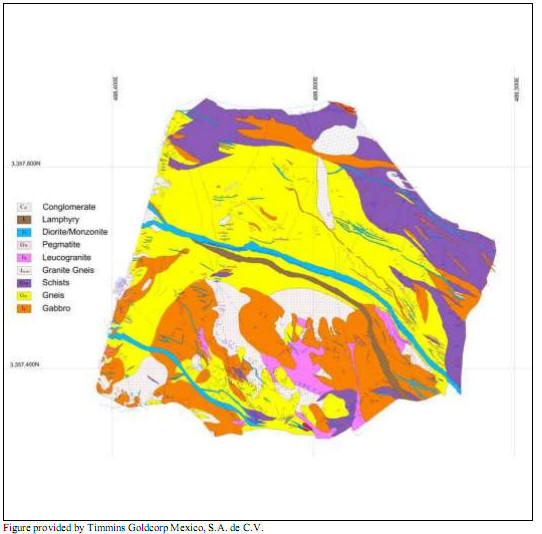

The San Francisco project is a gold occurrence with trace to small amounts of other metallic minerals. The gold occurs in granitic gneiss and the deposit contains principally free gold and occasionally electrum. The associated mineralogy, the possibility of associated tourmaline, the style of mineralization, and fluid inclusion studies suggest that the San Francisco deposits may be of mesothermal origin.

The San Francisco deposits are roughly tabular with multiple phases of gold mineralization. The deposits strike 60° west to 65° west, dip to the northeast, range in thickness from 4 to 50 m, extend over 1,500 m along strike and are open ended. Another deposit, the La Chicharra zone, was mined during the last two years of production, as a separate pit.

1.6 EXPLORATION AND OTHER PROGRAMS

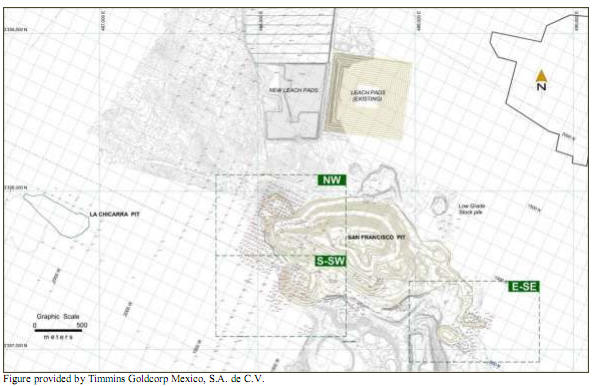

After acquiring the project, Timmins undertook a review of all available geological data surrounding the previous mining areas and identified a number of immediate exploration targets both to the northwest and to the southeast of the San Francisco pit which required further work. Timmins also spent the first few months staking the surrounding area and laying out an appropriate drilling program with the objective of confirming and extending the known mineralization around the open pit.

3

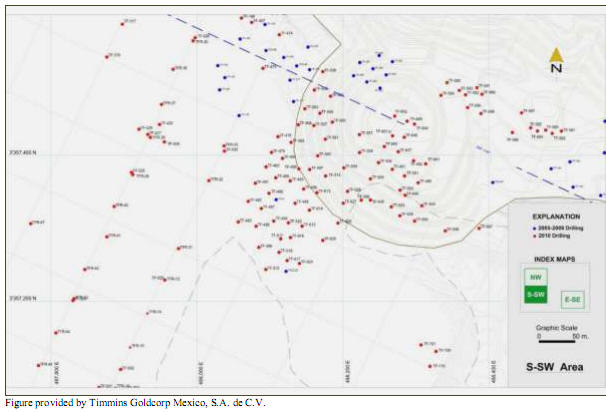

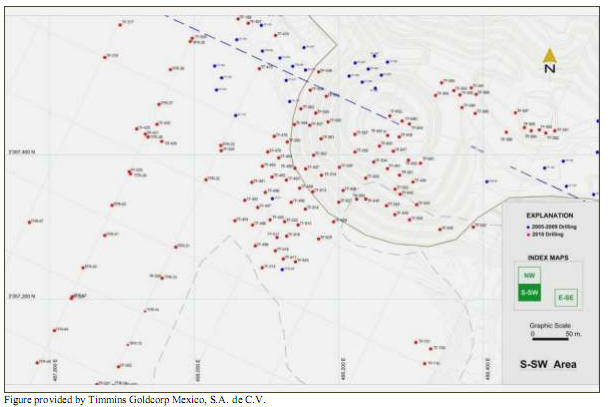

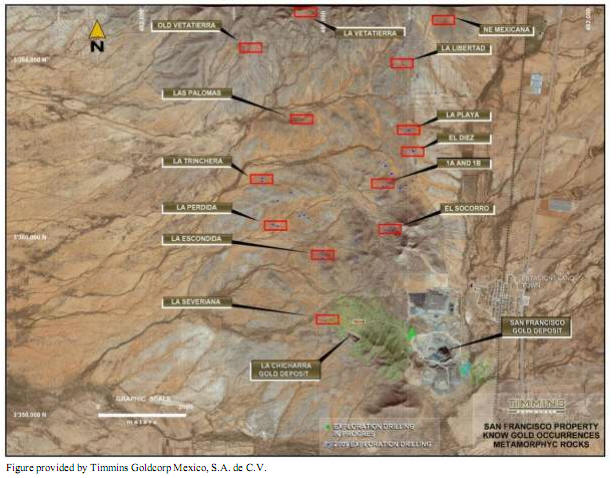

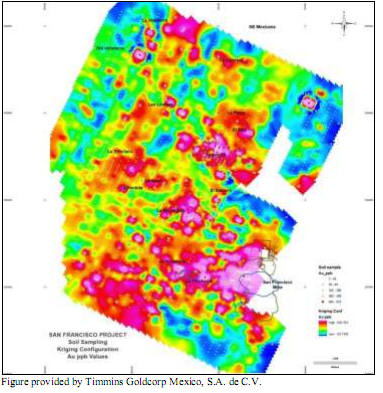

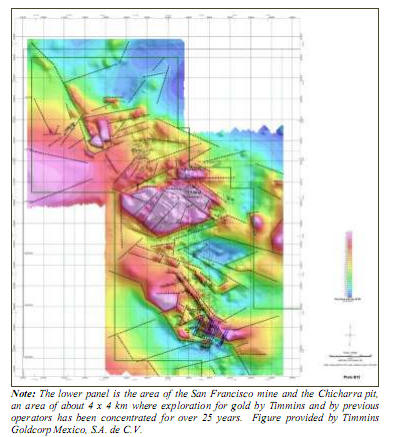

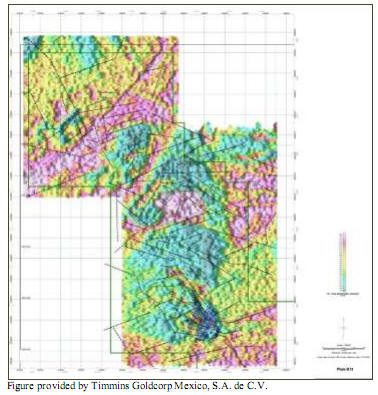

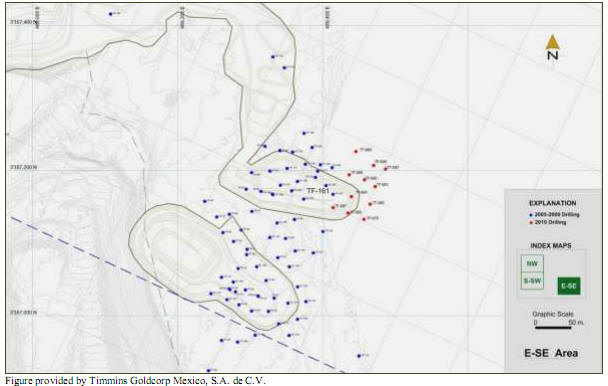

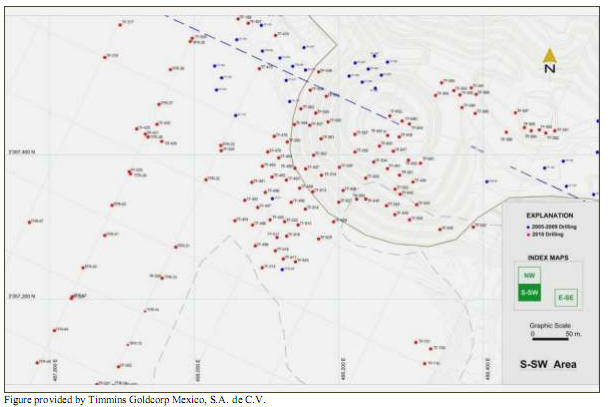

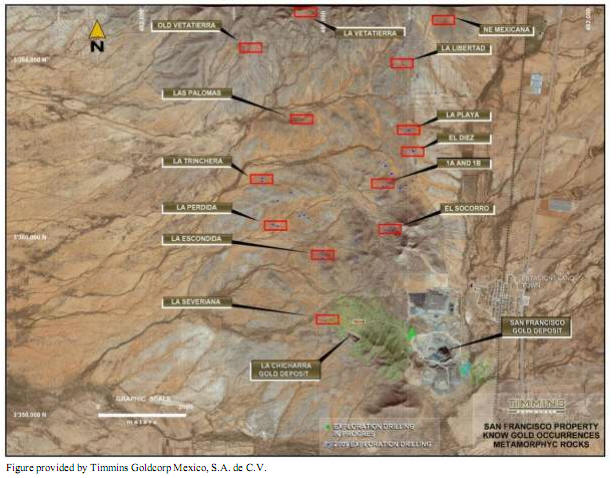

Beginning in 2005 and continuing to the present time, TMM/Timmins has been conducting aggressive exploration programs to delineate and expand on the known mineralization at the San Francisco mine. The exploration drilling programs have primarily been concentrated around the existing pits but other mineral exposures previously identified by Geomaque, as well as new areas identified by TMM/Timmins, been have targeted as well.

As a result of the successful exploration campaigns around the existing pits, TMM/Timmins has been able to expand on the previously known mineralization, to re-open the San Francisco mine and expand the resources and reserves.

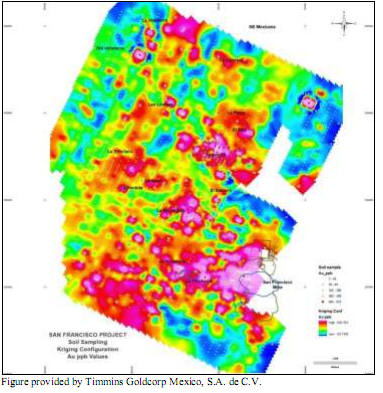

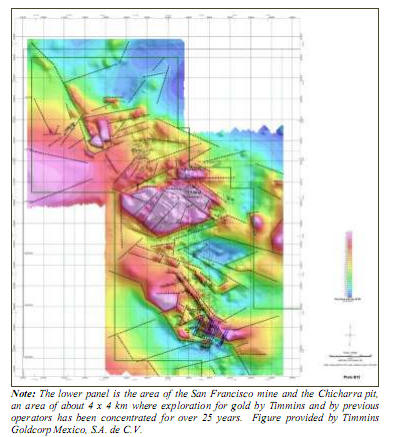

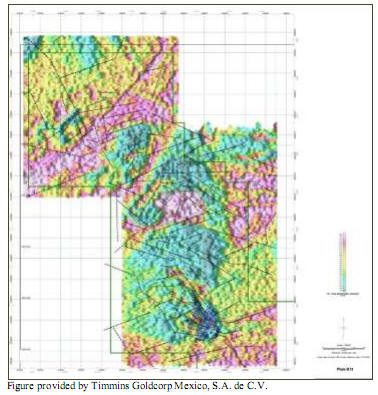

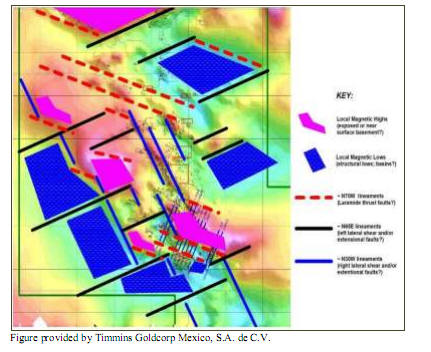

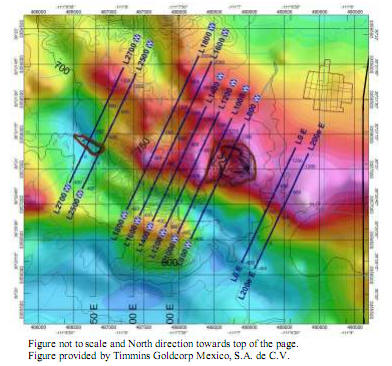

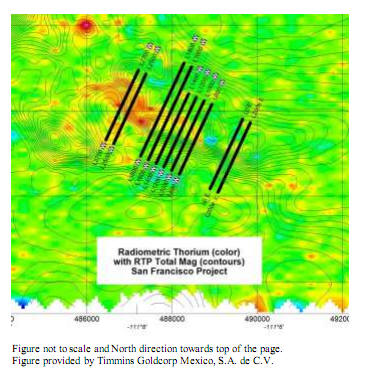

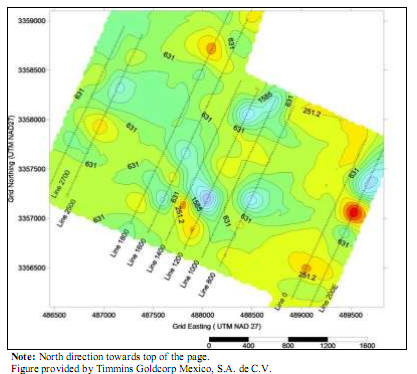

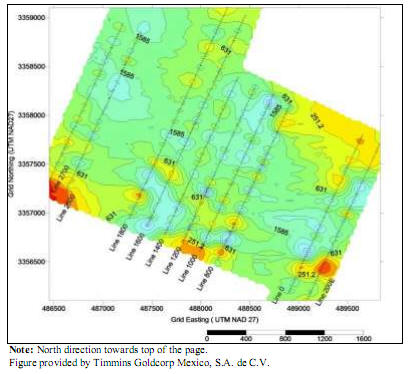

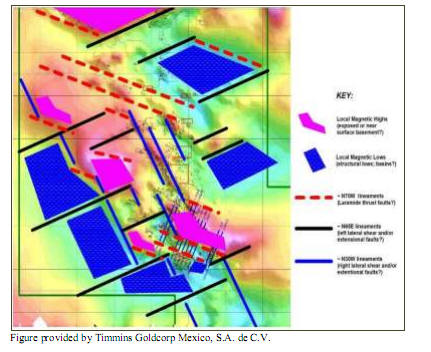

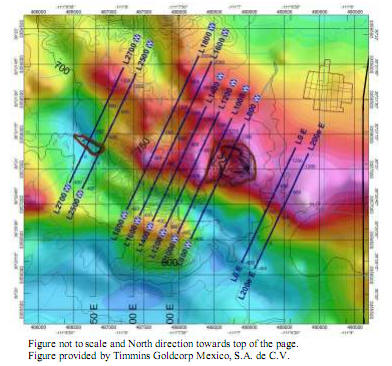

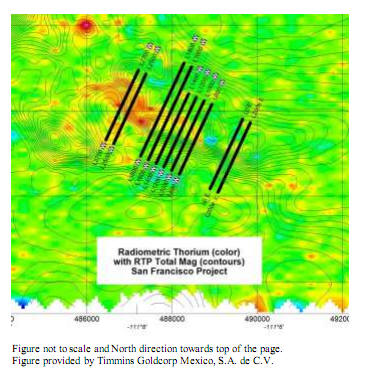

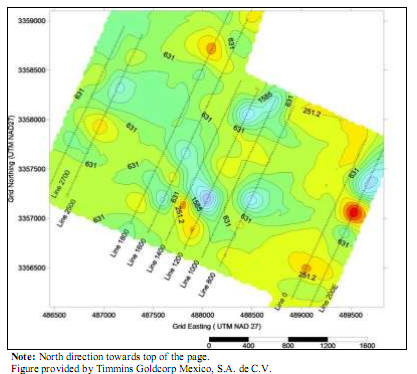

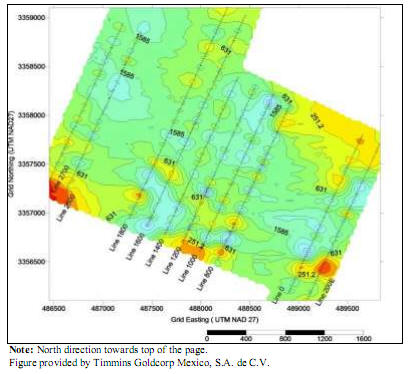

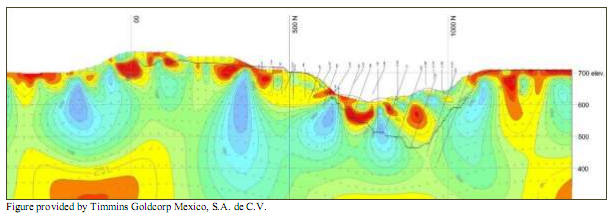

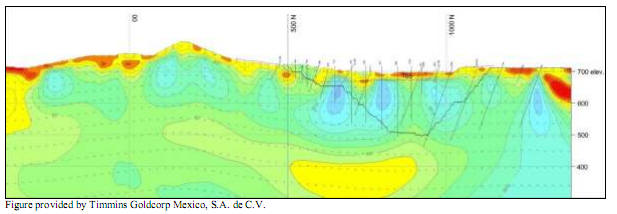

Between 2008 and 2010 Timmins also conducted a number of other exploration programs such as geochemical soil and chip sampling, an air magnetic and radiometric survey, a natural source audio-frequency magnetotelluric survey (NSAMT) and a structural review of the San Francisco gold deposit.

The TMM/Timmins budget for the next phase of exploration for the San Francisco mine is the result of the successful 2009-2010 drilling program. Infill and exploration drilling will continue for the remainder of 2010 and into 2011 in order to expand the mineral resources and reserves.

Of particular interest is the southeast extension where the last section line of drilling (200E) contained three RC holes which were drilled to maximum depth of 170 m. Two of the three holes intersected mineralization, with hole TF-810 intersecting three mineralized intervals of low grade and narrow thickness: 1.52 m grading 0.31 g/t gold; 1.52 m grading 0.24 g/t gold and 1.52 m grading 0.41 g/t gold. Hole TF-812, located 50 m to the north on the same section line intersected 9.12 m grading 0.98 g/t gold and 6.08 m grading 0.52 g/t gold. All mineralized intervals were located within the first 60 m from surface and are related to a chargeability anomaly open at depth for a further 300 m. TMM/Timmins has outlined a further core drilling program totalling 5,000 m.

Near the perimeter of the pit, infill drilling has been planned to follow-up previous mineralized intersections that could increase the resources immediately east and north of the San Francisco pit and the new pit limit which resulted from the recent resource update. The infill drill program outlined by Timmins is comprised of approximately 30,000 m of reverse circulation drilling.

A program of exploration has been also outlined to define and test at least 4 of the 13 targets to the north of the San Francisco pit: these are the most favourable targets when geochemistry, lithology, structural lineament and relationship with the northwest mineral trend are considered. Timmins has estimated that this program will be approximately 30,000 m, involving a combination of reverse circulation drilling and a mobile RAB drill to acquire fast samples to outline drill targets for the RC drill.

4

The total expenditures for the next phase of exploration, including other related payments such as access, are estimated to USD 6.1 million.

1.7 RESOURCE AND RESERVE ESTIMATES

1.7.1 Mineral Resource Estimate

The resource estimate completed by Timmins in July, 2010 and audited by Micon in August/September, 2010 is compliant with the current CIM standards and definitions specified by NI 43-101, and supersedes the March, 2008 resource estimate for the San Francisco mine.

Both Canadian NI 43-101 and the Australasian Joint Ore Reserves Committee (JORC) code state that mineral resources must meet the condition of “a reasonable prospect for eventual economic extraction.” For open pit material, Timmins utilized Lerchs Grossman pit shell geometry at reasonable long term prices, and reasonable costs and recovery assumptions, as meeting this condition for mineral resources. The resource is based on a pit shell at a gold price of USD 1,100/oz and additional cost and recovery parameters developed by Timmins which meet the conditions for classification of the material as a mineral resource. Pit optimization was based on Measured, Indicated and Inferred resources.

Table 1.1 summarizes the economic parameters used for the analysis. The parameters are a combination of Independent Mining Consultants, Inc. (IMC) and Timmins inputs taking into account the actual costs obtained from the first year of operation.

Pit bench heights were set at 6.0 m (the block height of the 3-D block model). Base case slope angles used for the pit optimization were based on inter-ramp angles recommended by Golder Associates (December, 1996 report) and adjusted to allow for haul roads of 25 m width.

Table 1.1

Pit Optimization Parameters for the San Francisco Project

| Costs (USD) | Rock Densities and Recoveries |

| Description | Units | Amount | Name | Code | Density | Recovery % |

| Waste mining cost | $/t | 1.70 | Diorite | 2 | 2.72 | 60.50 |

| Ore mining cost | $/t ore | 1.70 | Gneiss | 4 | 2.75 | 70.70 |

| Process cost | $/t ore | 2.83 | Granite | 5 | 2.76 | 84.50 |

| G & A cost | $/t ore | 0.42 | Schist | 6 | 2.75 | 65.37 |

| Total Cost | $/t ore | 4.95 | Lamprophrite Dyke | 8 | 2.76 | 60.50 |

| Gold price | $/oz | 1,100 | Gabbro | 11 | 2.81 | 60.53 |

| | General Recovery | | 70.00 |

Table provided by Timmins Goldcorp Mexico, S.A. de C.V.

The mineral resource, as estimated by Timmins, is presented in Table 1.2. This resource estimate includes the undiluted mineral reserve material as of August 31, 2010.

5

Table 1.2

Mineral Resource Estimate for the San Francisco Project (Inclusive of Mineral Reserves)

(Cut-off Grade of 0.131 g/t Gold, USD 1,100 Gold Price)

| Resource Classification | Tonnes (x 1,000) | Gold Grade (g/t) | Contained Gold (oz) |

| Measured | 19,089 | 0.797 | 489,000 |

| Indicated | 23,442 | 0.658 | 495,000 |

| Total Measured and Indicated | 42,531 | 0.720 | 984,000 |

| Inferred | 10,308 | 0.628 | 208,000 |

Micon believes that no environmental, permitting, legal, title, taxation, socio-economic, marketing or political issues exist which would adversely affect the Mineral Resources estimated above, at this time. However, Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. The figures in Table 1.2 have been rounded to reflect that they are an estimate.

The Mineral Resource estimate has been reviewed and audited by Micon. It is Micon’s opinion that the August 31, 2010 Mineral Resource estimate has been prepared in accordance with the CIM standards and definitions for Mineral Resource estimates and that TMM/Timmins can use this estimate as a basis for further exploration and economic evaluation of the San Francisco mine project.

1.7.2 Mineral Reserve

Having established a Measured and Indicated mineral resource estimate from the initial pit optimization analysis, Timmins then designed an open pit with haul roads capable of accepting trucks in the 91-t class, and prepared a production schedule and second pit optimization for the extraction of the measured and indicated mineral resources.

Mining recovery for the San Francisco deposit has been assumed to be 99% based on open pit mining methods. Micon agrees with the mining recovery as initially presented, although this number may change based on actual year-to-year reconciliation studies.

The dilution for the San Francisco deposit is defined according to the type of mineralization and the size of the modelled blocks. The deposit varies in size and shape of the mineralization from one bench to another. The potential dilution varies for each of the blocks due to the proportion of waste in contact with the economic material. Therefore, the larger economic zones carry a lower percent of dilution than the smaller zones.

Timmins believes that its current method for estimating dilution is a close approximation of what can be expected during the operational period of the mine. The method consists of identifying sub-economic blocks in contact with ore blocks and adding 30% of this material as mining dilution.

An overall average of 12% dilution was estimated for the pit. Table 1.3 presents the total reserves estimated within the pit design outline, including the mine recovery and dilution factors.

6

Table 1.3

Mineral Reserves within the San Francisco Pit Design (August 31, 2010) at USD 900/oz and after Mining

Recovery and Dilution

| In Pit Reserves | In Pit Waste |

| Classification | Tonnes

(x 1,000) | Grade (g/t) | Contained

Ounces | Waste Tonnes

(x 1,000) | Total Tonnes

(x 1,000) | Stripping

Ratio |

| Proven | 17,194 | 0.756 | 418,000 | | | |

| Probable | 17,738 | 0.635 | 362,000 | | | |

| Total | 34,932 | 0.695 | 780,000 | 60,417 | 95,349 | 1.73 |

The Proven and Probable Reserves in Table 1.3 have been derived from the Measured and Indicated mineral resources summarized in Table 1.2 and account for mining recovery and dilution. The figures in Table 1.3 have been rounded to reflect that they are an estimate.

The Mineral Reserve estimate has been reviewed and audited by Micon. It is Micon’s opinion that the August 31, 2010 Mineral Reserve estimate has been prepared in accordance with the CIM standards and definitions for Mineral Reserve estimates and that TMM/Timmins can use this estimate as a basis for further exploration and economic evaluation of the San Francisco mine project.

The San Francisco mine commenced commercial production in April, 2010. To the end of September, 2010, the mine had sold 26,999 ounces of gold.

1.8 OPERATIONAL DATA

1.8.1 Open Pit Design

1.8.1.1 Geotechnical Studies and Pit Design Criteria

The most recent geotechnical study carried out on the San Francisco pit was conducted by Golder Associates in December, 1996 for the previous owners of the property, Geomaque de Mexico. Golder’s scope of work was to carry out site investigations, testing and analysis to develop final slope angle recommendations for the pit design.

The recommended overall slope angles ranged from 37° for single 6 m benches along the northeast facing slopes to a maximum slope of 56° for double benching in schist units. In its report Golder presented a table of recommended inter-ramp slope angles and catch bench widths to achieve the recommended overall slope angles.

Timmins used this information when carrying out the pit optimization analysis and included an allowance for 25 m ramp widths in the overall slope angles.

7

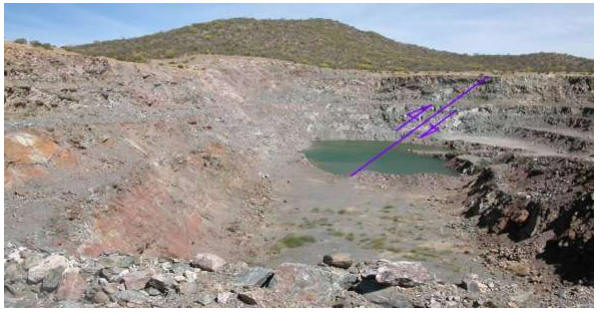

1.8.1.2 Hydrological Considerations

Micon has no information on hydrology in the pit area. At the time of Micon’s visit, the pit floor was under water but this was understood to represent accumulated precipitation rather than inflows of groundwater. The existing pit walls were generally dry, with a few minor seepages along shear zones.

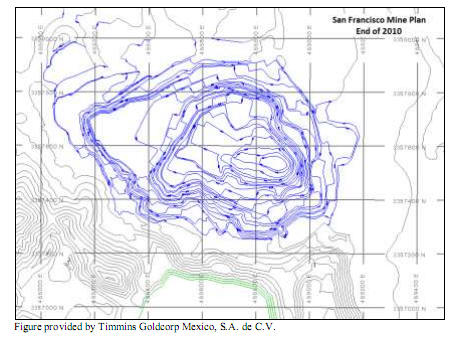

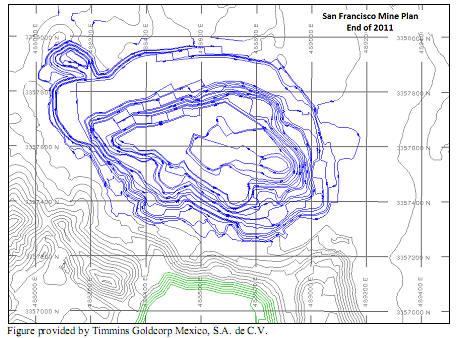

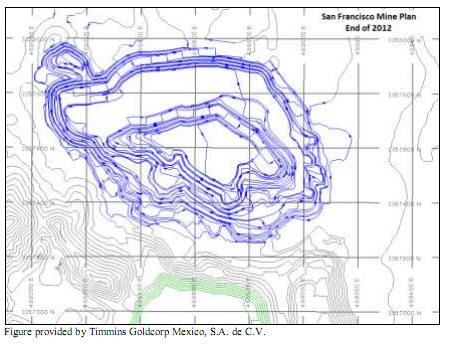

1.8.1.3 Phased Pit Designs

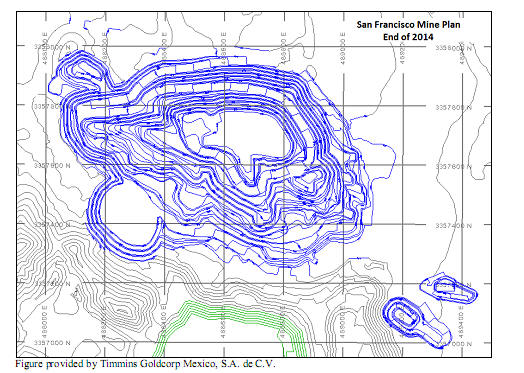

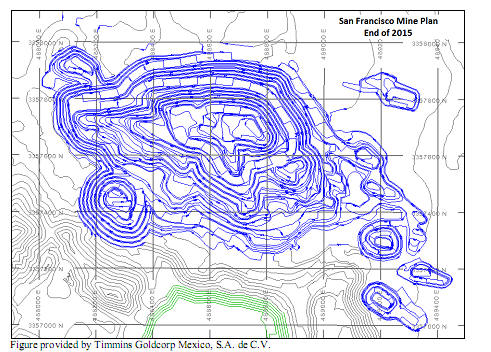

In 2010, the three-phase open pit design was extended to incorporate additional, recently discovered resources to the northwest of the existing pit outline. The ultimate pit design is based on the USD 900/oz gold optimized pit shell.

Both the ultimate pit design and interim mining phases conform to the current topography, including the existing pit outline. The interim phase boundaries were adjusted to ensure mineable bench widths and include ramps for access and haulage by 91-t trucks.

Mining phases were designed to have a balanced waste distribution during the mine life and continuous availability of ore.

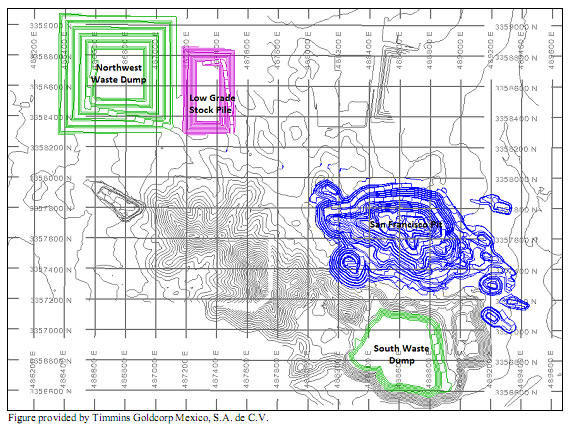

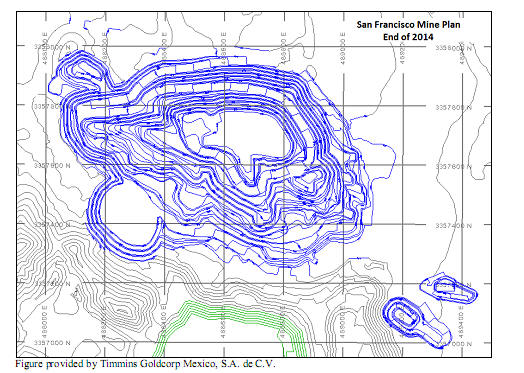

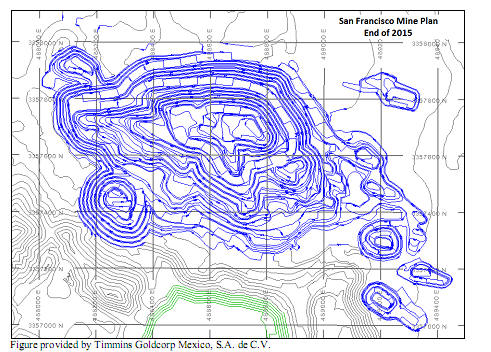

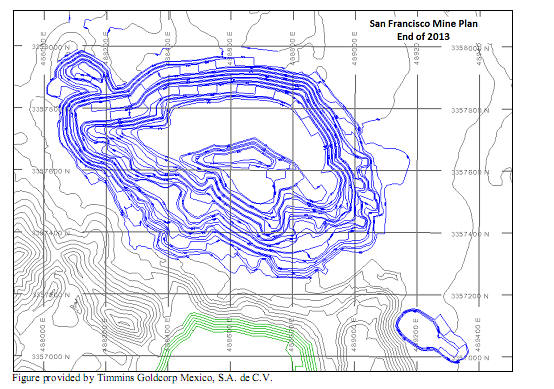

For the mine plan and production schedule, tonnages within the initial mining phase were adjusted to match the current pit outline. Phase one extends down to the bench on elevation 590. Then, the phase two push back will expand the pit about 280 m west and deepen the pit to the bench at elevation 536. The third phase and ultimate pit outline has a 120 m push back on the north wall and the final pit bottom is at bench elevation 464.

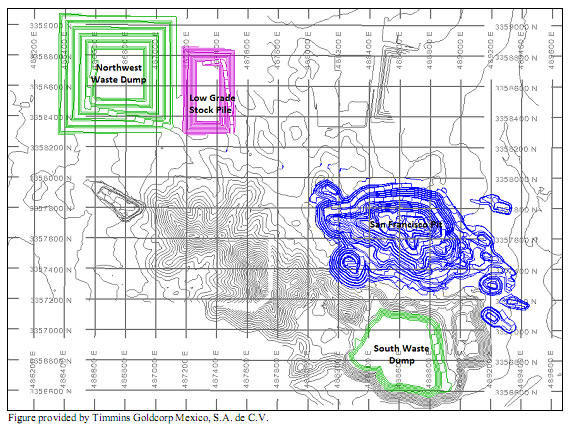

1.8.1.4 Waste Rock Management

Existing waste rock dumps are located to the south of the San Francisco open pit, close to the pit rim and the dumps cannot be extended to the north. They are also limited to the east by a property boundary and to the west by ground not yet condemned by exploration drilling. With the re-establishment of the operations, these existing dumps will be extended further south, where adequate space does exist. For the expansion of the reserves, additional waste dump volume is required and a site located northwest of the pit has been identified that would contain the majority of waste rock produced during the mine life. Currently, a condemnation drilling program is underway in this area.

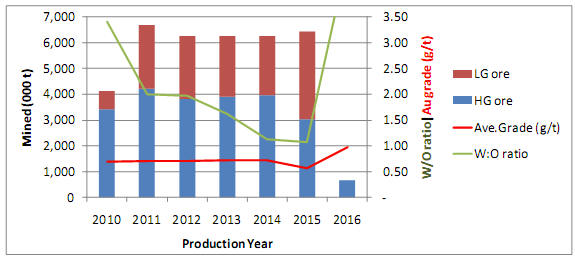

1.8.2 Mine Production Schedule

Using the phased pit designs described above, Timmins has developed a mine production schedule that is based on producing a minimum of 18,000 tonnes of ore per day. The mine plan has been developed on monthly intervals for the initial 16-month period to December 2011, on a quarterly basis for 2012 and annually for the remainder of the mine life to 2015.

8

The mine schedule considers ore between the internal cut-off of 0.16 g/t gold and 0.5 g/t gold as low grade, and high grade ore to be above 0.5 g/t gold. Blended ore will be fed to the crusher.

1.8.3 Mine Operations

All mining activities are being carried out by the contractor, Peal Mexico, S.A. de C.V., of Navojoa, Mexico. The contractor provides all the mining equipment and personnel required to produce the tonnage mandated by Timmins, in accordance with the mining plan.

1.8.3.1 Mining Contract

Under the contract dated May 23, 2007 and updated August 14, 2008, the contractor’s performance of mining operations at the San Francisco mine includes the following: drilling and blasting, loading and transportation of waste rock and ore, pit drainage, building slopes and roads as needed, scaling of pit walls to design limits, maintenance of equipment, and providing safe and orderly working conditions. The contractor is obliged to supply and maintain appropriate principal and auxiliary mining equipment and personnel.

1.8.3.2 Owner Mining Requirements

Mining engineering and design services are provided by Timmins. These services include:

- Obtaining of all permits and licences for mining.

- Mine design and planning, grade control and surveying services.

- Supply of electric power, water and telecommunications.

- Security services, safety plans and personnel and first aid stations.

Timmins provides contract supervision, geology, engineering, planning and survey services using its own employees.

1.8.4 Conclusion

Micon has reviewed the resource and reserve estimates, the mine design, the mining schedule and the contract terms, including the contractor’s ability to meet the mining schedule, and concludes that the estimations and designs have been properly carried out and that the contractor is capable of meeting the schedule.

1.9 PROCESSING

1.9.1 Crushing and Conveying

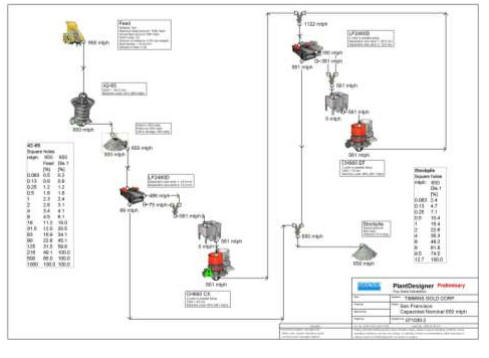

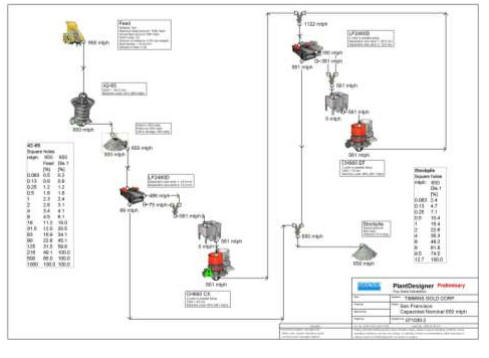

Ore extracted from the pit is transported in haulage trucks with a capacity of 91 tonnes, which feed directly into the gyratory primary crusher with dimensions of 42” x 65”. The crusher has nominal capacity of 1,200 t/h. The crushed product is then transported on conveyor belts to a stockpile with a capacity of 10,000 tonnes.

9

Two feeders beneath the stockpile deliver the ore to a conveyor belt for transport to the secondary crushing circuit. The ore is screened at ½”. Screen undersize reports to the final product, while screen oversize is fed to two secondary crushers.

Product from the secondary crushers is transported on conveyor belts to the tertiary crushing circuit, which consists of two tertiary crushers operating in closed circuit with ½” screens. Undersize from the screens is delivered to the leach pad.

An additional crusher and screen, both for the tertiary circuit and with the same specifications as the existing ones, are planned to be installed to increase throughput from 12,000 t/d to 18,000 t/d.

1.9.2 Leach Pad

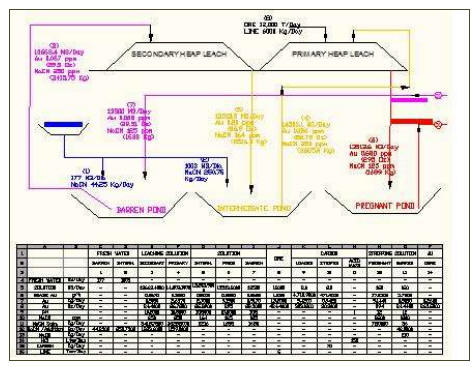

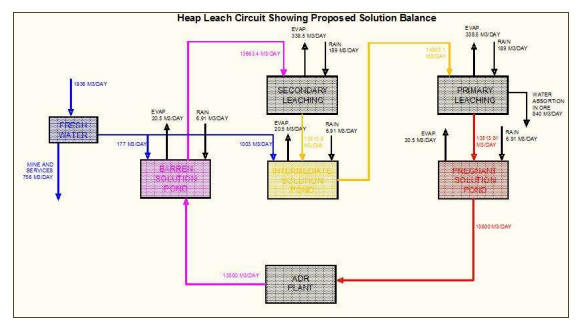

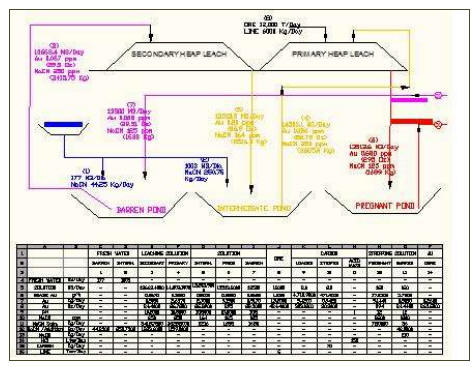

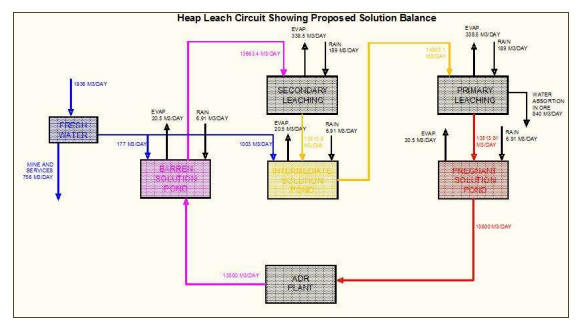

The current leach pad occupies approximately 40 ha and is divided into 7 sections. Material from the crushing plant is transported to the leach pad on overland conveyors and deposited on the pad with a stacker forming 6 m lifts. A bulldozer passes on top of the lifts to level the surface. The irrigation pipelines are then installed, through which the leach solution is distributed over the entire surface of the lift.

Leach solution infiltrates the crushed ore, dissolving gold and silver. The solution percolates to the bottom of the lift and flows to the canal that carries the pregnant solution to the storage pond from which it is pumped to the ADR plant.

Barren solution exiting the ADR plant flows to a storage pond. Fresh water is added to the barren solution to replace losses during the process, and sodium cyanide is added before the solution is pumped back to the leach pad.

Due to the increase in mineral reserves and the planned increase in production capacity, an additional 35.2 ha will be prepared to construct a new leach pad.

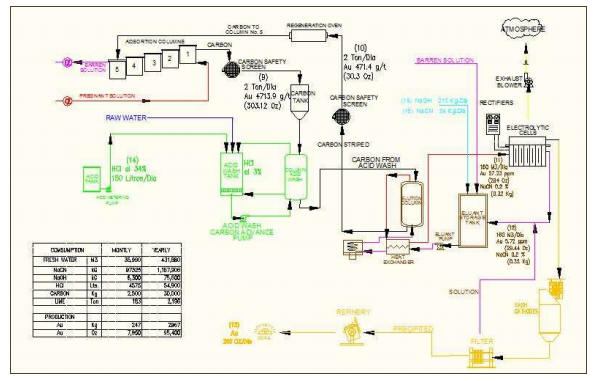

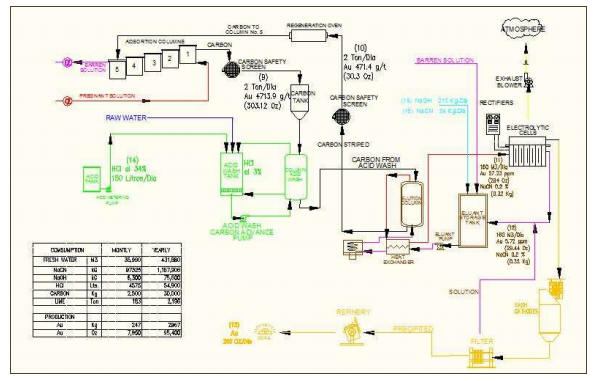

1.9.3 Absorption/Desorption/Recovery Plant

Pregnant solution is fed to the adsorption plant which consists of 2 lines of carbon columns each with 5 tanks through which the carbon is advanced counter-currently. Gold is adsorbed on the carbon to a concentration of approximately 5,000 g/t. Desorption of the carbon is achieved in a Zedra circuit using stainless steel electrodes in a stainless steel electrolytic cell.

A new line of carbon columns with 5 tanks and a flow of 3,500 g/m is planned to be installed to accommodate the increase in production capacity.

Manpower for the processing section of the project is currently 147.

10

1.9.4 General Manpower and Infrastructure

The current total workforce for the San Francisco mine stands at 267.

Office space for the mine is provided in a structure of approximately 450 m2 located southeast of the ADR plant. The building has adequate working space for the on-site mine administration and also provides basic catering and ablution facilities.

A vehicle workshop south of the ADR plant and north of the open pit occupies more than 660 m2 and accommodates the off-road haul trucks, excavators and ancillary vehicles used in the mining operation.

A general warehouse of approximately 200 m2 located north of the ADR plant accommodates process reagents and mechanical spares. Bulk lime for the heap leach process is stored in a silo near the crushing plant.

1.9.5 Electrical Power Supply

Electrical power to the mine is delivered through a 33 kV overhead line from the utility company, Comisión Federal de Electricidad (CFE). From the main metering point, the power is distributed to the crushing and screening plant and other site infrastructure at 480/220/110 V. At the crushing and screening plant, separate transformers feed the principal equipment.

The current electrical power supply is sufficient for the planned production capacity of 18,000 t/d of ore.

1.9.6 Water Supply

The current demand of fresh water is 2 000 m3/d, of which 1,100 m3/d are for the leach area and ADR plant and 900 m3/d for the mine and services.

The Comisión Nacional del Agua (CONAGUA) authorized the total and definitive transfer of the rights for two concession titles to exploit and use national water previously held by Geomaque de Mexico, to Timmins’ Mexican subsidiary Molimentales del Noroeste, S. A. de C. V. (Molimentales) on May 30, 2008. Molimentales acquired an additional 2 water rights concessions in August, 2010

1.9.7 Environmental Considerations

The Secretaría de Medio Ambiente y Recursos Naturales (SEMARNAT) determined that the project as described in the environmental impact assessment (Manifiesto de Impacto Ambiental – Modalidad Particular) and a level 2 environmental risk study (Estudio de Riesgo Ambiental Nivel 2) for San Francisco mine submitted on December 17, 2007, is environmentally viable, and authorized the project with conditions specifically regarding reforestation and groundwater monitoring on August 1, 2008. Groundwater monitoring is currently being performed monthly on four monitoring wells to determine the level of cyanide. Reforestation activities have continued every month with three specific species: palo fierro, palo verde and mezquite.

11

On May 30, 2008, SEMARNAT registered Molimentales as a generator of hazardous waste. Molimentales is complying with hazardous waste management standards using an on-site storage facility exclusively for hazardous waste which is collected by an accredited company. The mine contractor, Peal Mexico, was registered by SEMARNAT as a generator of hazardous waste on August 26, 2010, and is responsible for the management of the hazardous waste generated by the mining operations.

Due to the proposed increase in in production capacity from 12,000 t/d to 18,000 t/d of ore, Molimentales will update all of its environmental permits to include the additional use of land.

1.10 ECONOMIC EVALUATION

Micon conducted the economic evaluation of the San Francisco project based on the information supplied to it by TMM and its subsidiary Timmins.

1.10.1 Macro-Economic Assumptions

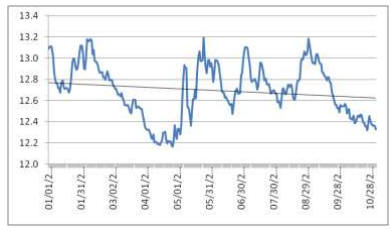

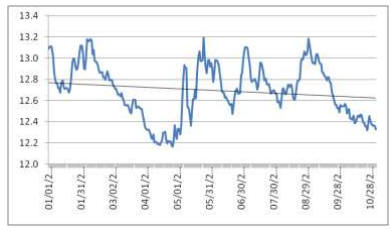

Economic analysis of the San Francisco project has been carried out in United States dollars (USD). Conversion of local Mexican costs, principally labour and power, has been made at the rate of MXN 12.50/:USD 1.00, which is considered appropriate given recent trends in actual rates (see Figure 1.1) .

Figure 1.1

Exchange Rate (MXN/USD) 2010

The cash flow projection has been made in constant, third quarter 2010 money terms. The net cash flows have been discounted to year-end 2010 for the purposes of calculating net present value (NPV). A base discount rate of 8.0% per year has been selected as most likely to represent the weighted average cost of capital to the project. Other rates are provided for ease of comparison.

12

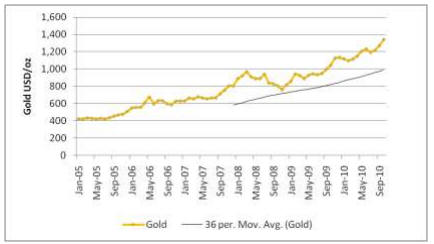

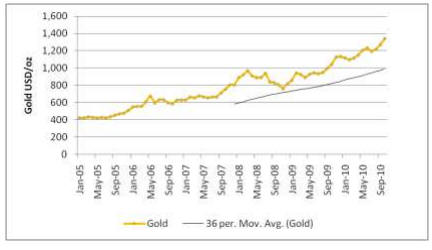

1.10.2 Metal Price Forecast

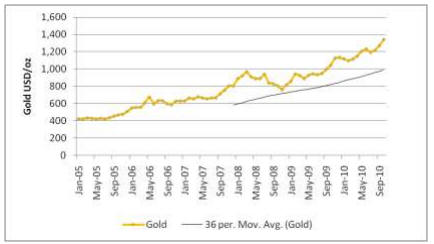

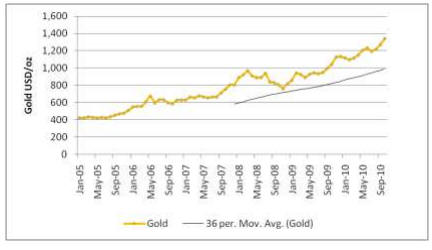

Revenue projections are based on a constant gold price of USD 1,000/oz in real terms, closely approximating the 3-year trailing average price but significantly lower than spot prices at the time of writing (see Figure 1.2) .. Accordingly, the sensitivity of the project to gold price in a range of up to USD 1,400/oz has also been evaluated. A price of USD 17/oz has been used for the minor amount of silver produced.

Figure 1.2

Spot Gold Price

1.10.3 Royalties and Taxes

Micon understands that no liability for NSR royalty interests in the San Francisco mine has extended to the present owners. Therefore, no royalty has been provided for.

Mexican corporate taxation has been provided for at the base rate of 28%, with provision for temporary rates of 30% up to the end of 2012 and 29% during 2013, which Timmins expects to be applicable. The World Bank/IFC website estimates a typical effective rate of tax on profits in Mexico of 22.9% ..

1.10.4 Working Capital

Provision has been made for working capital represented by 7 and 30 days of accounts receivable and payable, respectively, as well as 45 days of stores and 30 days of product inventory. The life-of-mine cash flow assumes that an amount of $9 million presently in working capital will be released once operations cease.

13

1.10.5 Base Case

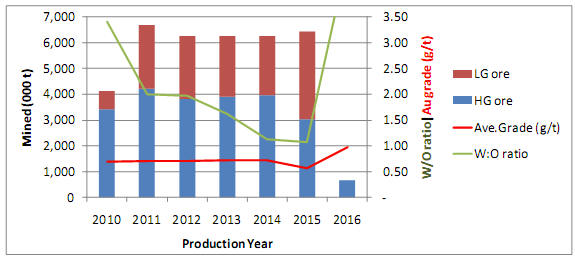

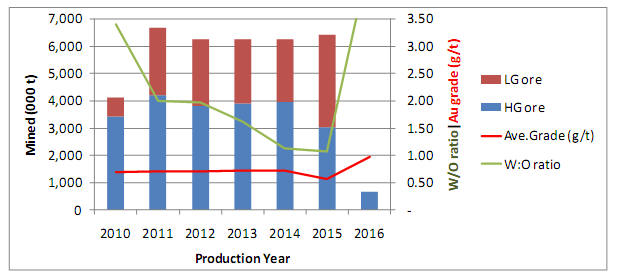

The base case evaluation of the San Francisco project has been made using the nominal treatment rate of 18,000 t/d, which is expected to be achieved from July, 2011. The mining schedule that supports this production plan is given in Figure 1.3.

Figure 1.3

Mining Schedule

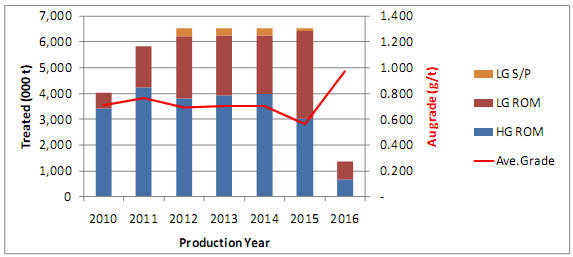

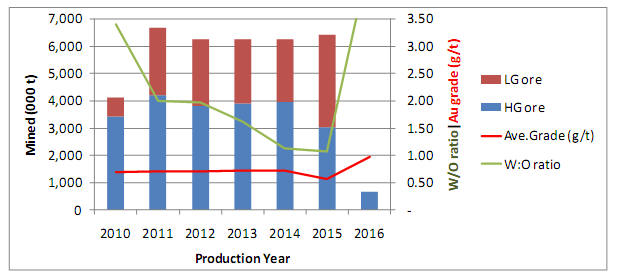

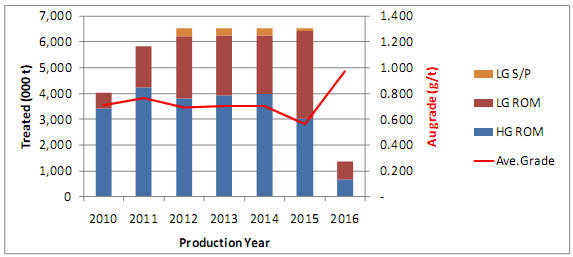

Open pit mining ceases early in 2016 and, as shown in Figure 1.4, processing of both high grade and low grade run-of-mine (ROM) material is carried out in parallel, with a small tonnage of low grade material (< 1 million tonnes) stockpiled during 2011/2012 treated later in the operating period. The cost for rehandling this low grade material has been conservatively estimated at USD 0.50/t.

Figure 1.4

Processing Schedule

14

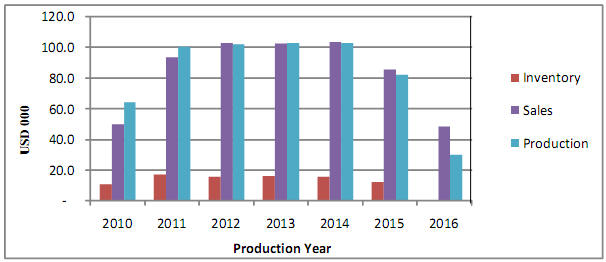

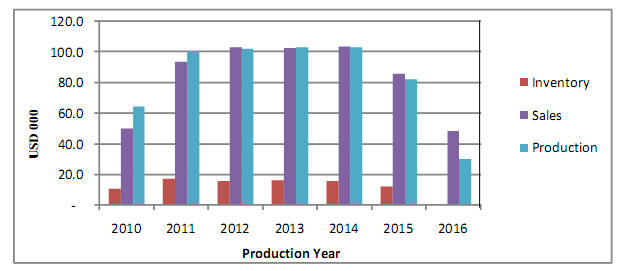

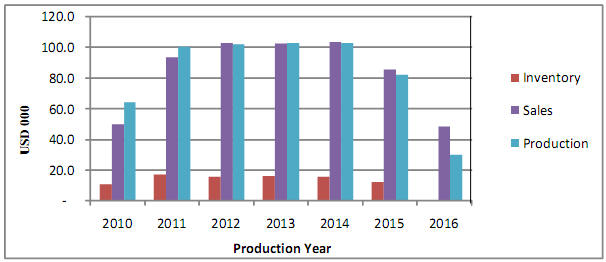

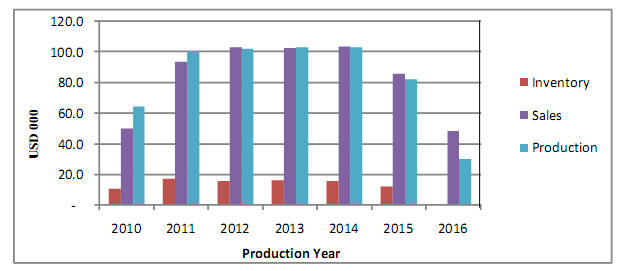

Overall process recovery averages 70% of contained gold in ore treated. Sales forecasts take into consideration the lockup of gold in the heap, as shown in Figure 1.5.

Figure 1.5

Gold Production, Sales and Inventory

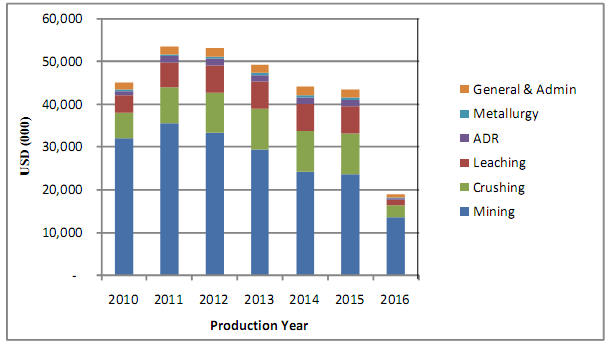

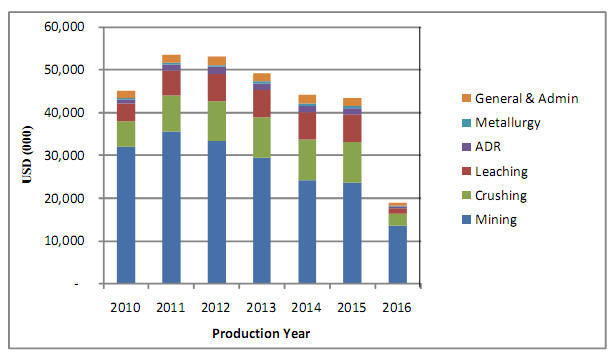

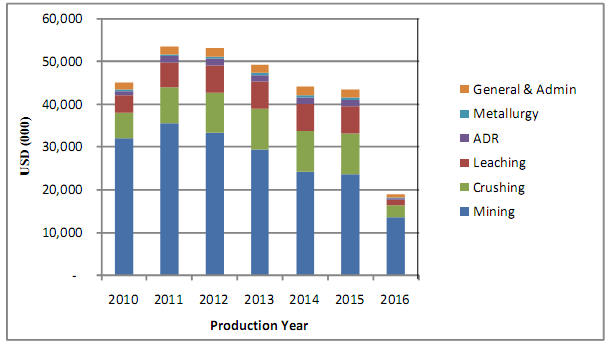

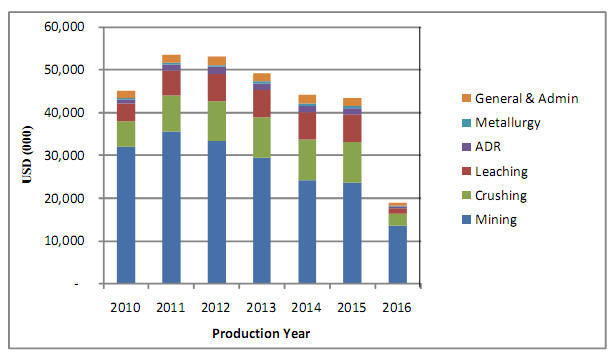

Cash operating costs are forecast to remain steady over the open pit mining period. Annual cash operating costs are shown in Figure 1.6.

Figure 1.6

Operating Costs Schedule

15

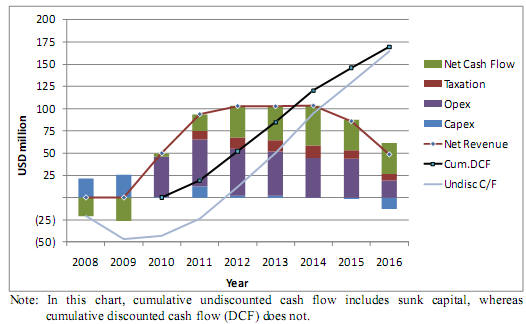

Pre-production capital costs for re-establishment of mining operations, refurbishment of the crushing and ADR plants and for extension of the heap leach pad at the San Francisco mine were all incurred in the period prior to the re-commencement of commercial production in April, 2010. As such, these costs have been treated as sunk costs for the purposes of the economic evaluation and, where shown in the project cash flow schedules and charts, are included for illustration of pay-back period only.

Sustaining capital expenditures are included in the cash flow projections at a level which allows for the overhaul of plant and equipment on an as-required basis. Additional capital expenditure to be incurred in the expansion from 12,000 t/d to 18,000 t/d has been estimated at USD 11.2 million and is provided for in the cash flow model. The costs of rehabilitation and mine closure bonding have also been included in sustaining capital.

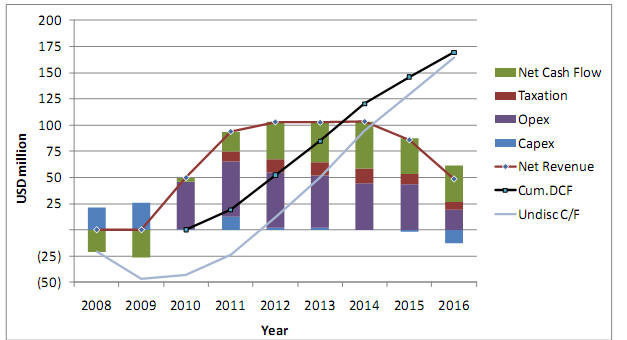

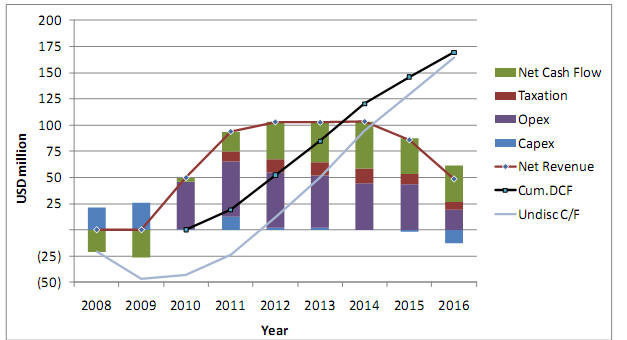

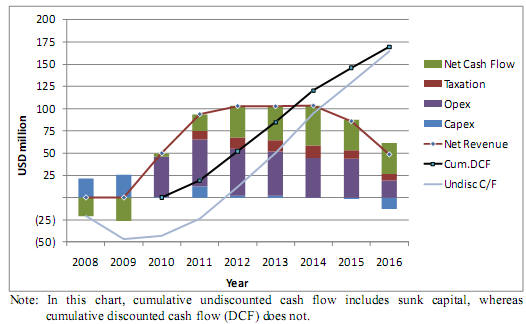

A summary of the base case life-of-mine statistics is provided in Table 1.4. Annual cash flows for the base case are summarized in Table 1.5. The base case cash flow profile is presented graphically in Figure 1.7. The calculated NPV and cumulative DCF exclude sunk costs, but sunk costs are included in the cumulative undiscounted cash flow.

It will be seen that, for the base case, the net present value of the project cash flow at a discount rate of 8%/y (NPV8) evaluates to approximately USD 216.8 million before tax and USD 163.1 million after tax. Since capital costs have been treated as sunk, no internal rate of return can be calculated. The average cash cost of production equates to USD 489.05/oz gold, or USD 7.88/t treated.

Table 1.4

Summary Life-of-Mine Statistics

| | Life-of-Mine Cash Flow

(US$ millions) | Life-of-Mine Averages |

| Undiscounted | NPV at 8.0% | Unit Cost | Margin | USD/oz |

| US$/t | % | Gold |

| Net Revenue | 537.6 | 438.5 | 16.13 | 100.0% | 1,001.54 |

| | | | | | |

| Mining costs | 159.8 | 132.3 | 4.79 | 29.7% | 297.68 |

| Crushing costs | 49.0 | 40.1 | 1.47 | 9.1% | 91.36 |

| Leach costs | 32.4 | 26.6 | 0.97 | 6.0% | 60.37 |

| ADR costs | 8.2 | 6.7 | 0.25 | 1.5% | 15.22 |

| Metallurgy and Lab costs | 2.4 | 2.0 | 0.07 | 0.5% | 4.53 |

| General & Admin costs | 10.7 | 8.7 | 0.32 | 2.0% | 19.88 |

| Total cash operating cost | 262.5 | 216.3 | 7.88 | 48.8% | 489.05 |

| | | | | | |

| Cash operating margin | 275.1 | 222.1 | 8.25 | 51.2% | 512.48 |

| | | | | | |

| Capital Expenditure | 1.5 | 5.4 | 0.04 | 0.3% | 2.71 |

| | | | | | |

| Net Cash Flow (before tax) | 273.6 | 216.8 | 8.21 | 50.9% | 509.78 |

| | | | | | |

| Taxation | 66.5 | 53.7 | 2.00 | 12.4% | 123.94 |

| | | | | | |

| Net Cash Flow (after tax) | 207.1 | 163.1 | 6.21 | 38.5% | 385.84 |

16

Table 1.5

Project Base Case Annual Cash Flows

| | USD 000 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | LOM total |

| Revenue | Gross Sales | 94,272 | 103,502 | 103,042 | 103,913 | 86,217 | 48,744 | 539,689 |

| | Bullion delivery | 274 | 305 | 278 | 280 | 236 | 124 | 1,497 |

| | Bullion refining | 112 | 123 | 120 | 121 | 101 | 52 | 629 |

| | Net Sales Revenue | 93,885 | 103,074 | 102,644 | 103,513 | 85,880 | 48,567 | 537,564 |

| | | | | | | | | |

| Cash Op. Costs | Mining costs | 35,528 | 33,279 | 29,418 | 24,260 | 23,722 | 13,572 | 159,779 |

| | Crushing costs | 8,525 | 9,455 | 9,454 | 9,454 | 9,439 | 2,709 | 49,036 |

| | Leach costs | 5,666 | 6,340 | 6,340 | 6,340 | 6,337 | 1,380 | 32,405 |

| | ADR costs | 1,442 | 1,576 | 1,576 | 1,576 | 1,570 | 428 | 8,168 |

| | Metallurgy & Lab costs | 441 | 451 | 451 | 451 | 446 | 193 | 2,434 |

| | G&A costs | 1,923 | 1,997 | 1,997 | 1,997 | 1,977 | 781 | 10,672 |

| | Total Cash Operating Costs | 53,526 | 53,098 | 49,236 | 44,077 | 43,491 | 19,065 | 262,494 |

| | | | | | | | | |

| Net Cash Operating Margin (EBITDA) | 40,359 | 49,975 | 53,408 | 59,435 | 42,389 | 29,502 | 275,070 |

| | | | | | | | | |

| Capital | Initial/expansion capital | - | - | - | - | - | - | - |

| | Sustaining capital | 6,143 | 690 | 2,729 | 393 | 302 | 302 | 10,559 |

| | Changes in working capital | 5,915 | 1,013 | -375 | -321 | -2,247 | -13,090 | -9,107 |

| | | | | | | | | |

| Net cash flow before tax | 28,302 | 48,273 | 51,055 | 59,363 | 44,335 | 42,291 | 273,618 |

| Taxation payable | 9,082 | 12,706 | 13,195 | 14,370 | 9,512 | 7,658 | 66,523 |

| Net cash flow after tax | 19,220 | 35,567 | 37,859 | 44,993 | 34,823 | 34,633 | 207,095 |

| | | | | | | | | |

| Discounted Cash Flow (8 %/y) Pre-Tax | 27,234 | 43,010 | 42,119 | 45,345 | 31,357 | 27,696 | 216,760 |

| Cumulative DCF (8 %/y) Pre-tax | 27,234 | 70,243 | 112,362 | 157,707 | 189,064 | 216,760 | |

| | | | | | | | | |

| Discounted Cash Flow (8 %/y) After tax | 18,494 | 31,689 | 31,233 | 34,369 | 24,630 | 22,681 | 163,096 |

| Cumulative DCF (8 %/y) After tax | 18,494 | 50,183 | 81,416 | 115,785 | 140,415 | 163,096 | |

17

Figure 1.7

Cash Flow Projection

Note: In this chart, cumulative undiscounted cash flow includes sunk capital, whereas cumulative discounted cash flow (DCF) does not.

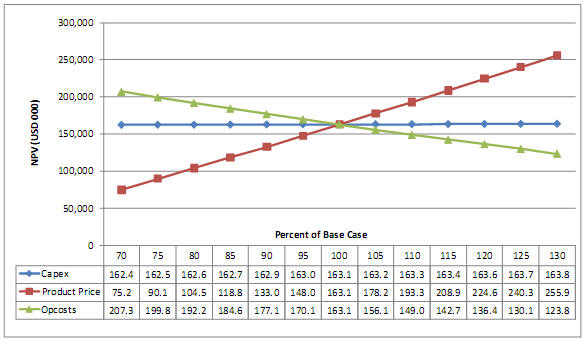

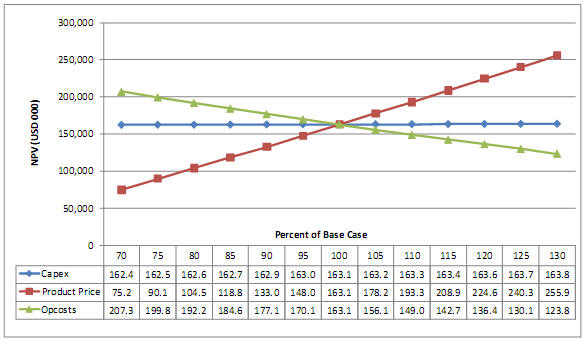

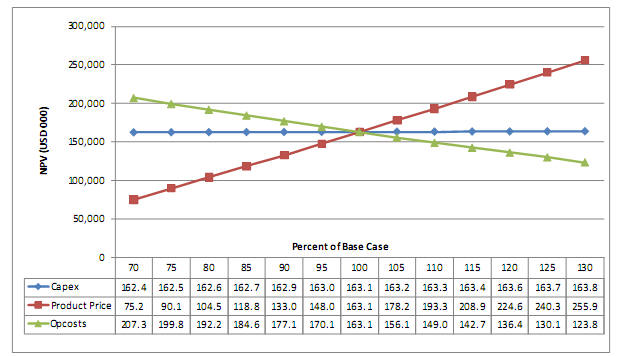

1.11 SENSITIVITY STUDY

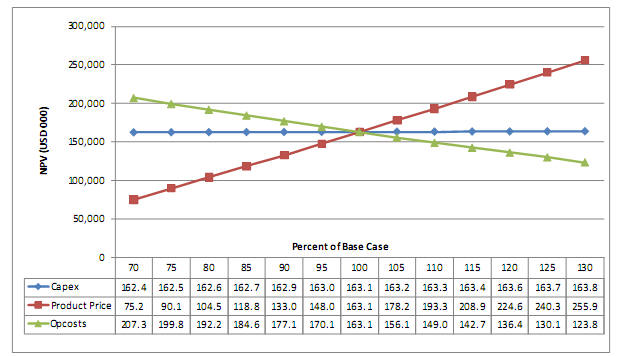

Sensitivity of the NPV8 to changes in gold price, operating and capital costs has been analyzed (Figure 1.8) . Project revenues are directly proportional to process recovery and grade, and hence gold price may also be used as a proxy in this model for changes in both recovery and reserve grade as revenue drivers.

The sensitivity results show that, as expected, the project is most sensitive to the revenue drivers described above. However, even with an adverse change of 30% (i.e., a reduction in price to USD 700/oz), NPV8 remains strongly positive; economic break-even occurs with a gold price of around USD 510/oz. At the time of writing, the spot gold price was in excess of USD 1,300/oz, at which price NPV8 is estimated at approximately USD 256 million.

The project is also moderately sensitive to operating costs, with a 30% adverse change sufficient to reduce NPV8 by approximately USD 40 million. With the bulk of project capital costs already sunk, however, sensitivity to capital expenditure is negligible.

18

Figure 1.8

Sensitivity of NPV8 to Prices, Operating and Capital Costs

Micon selected a discount rate of 8% as representing an expected cost of capital for the project in its base case. Sensitivity of the project NPV has been determined for a range of discount rates from 5% to 10%, as shown in Table 1.6.

Table 1.6

Sensitivity of NPV to Discount Rate

| Discount Rate | NPV before tax

(US$ 000) | NPV after tax

(US$ 000) |

| 5% | 235,655 | 177,696 |

| 6% | 229,070 | 172,605 |

| 7% | 222,778 | 167,743 |

| 8% | 216,760 | 163,096 |

| 9% | 211,003 | 158,651 |

| 10% | 205,491 | 154,399 |

Sensitivity of the project NPV8 has also been determined for a specified range of gold prices, as shown in Table 1.7.

19

Table 1.7

Sensitivity of NPV to Gold Price

Gold Price

US$/oz | NPV before tax

(US$ 000) | NPV after tax

(US$ 000) |

| 600 | 40,309 | 39,764 |

| 700 | 84,422 | 75,151 |

| 800 | 128,535 | 104,487 |

| 900 | 172,648 | 132,981 |

| 1,000 | 216,760 | 163,096 |

| 1,100 | 260,873 | 193,292 |

| 1,200 | 304,986 | 224,666 |

| 1,300 | 349,099 | 256,040 |

| 1,400 | 393,211 | 287,415 |

1.12 �� CONCLUSIONS AND RECOMMENDATIONS

Micon has reviewed the proposed exploration program for the San Francisco property and, in light of the observations made in this report, supports the concepts as outlined by TMM/Timmins. Given the prospective nature of the property, it is Micon’s opinion that the San Francisco project and property merit further exploration and that TMM/Timmins’ proposed exploration plans are properly conceived and justified.

Micon agrees with the general direction of TMM/Timmins’ exploration and development program for the property and makes the following additional recommendations:

| | 1) | Micon recommends that TMM/Timmins reviews its criteria for the classification of resources in the areas outside of the existing pit limits. |

| | | |

| | 2) | Micon recommends that TMM/Timmins proceeds with its economic studies to increase the crushing capacity at the San Francisco project. |

| | | |

| | 3) | Micon recommends that Timmins has an independent consultant review the laboratory operations and procedures in order to improve the quality of its results. |

Given the known extent of mineralization on the property, compared to the amount of mining activity, the San Francisco project has the potential to host further deposits or lenses of gold mineralization, similar in character and grade to those exploited in the past, outside the present resource base.

Additionally, Micon has reviewed TMM/Timmins’ operational plans for the San Francisco mine and believes that the mine plan and operational parameters have been well thought out. It is Micon’s opinion that the San Francisco mine is a well-run operation. Micon supports the further economic studies to determine the impact of increasing the crusher throughput to 18,000 t/d.

20

2.0 INTRODUCTION AND TERMS OF REFERENCE

At the request of Mr. Arturo Bonillas, President and Mr. Bruce Bragagnolo, CEO of Timmins Gold Corp. (TSX-V:TMM) (TMM), Micon International Limited (Micon) has been retained to provide an audit of the current internal resource and reserve estimates and an update to its previous 2008/2009 preliminary feasibility study for the San Francisco gold project located in the state of Sonora, Mexico. The previous Micon Technical Report was entitled “NI 43-101 F1 Technical Report on the Preliminary Feasibility Study for the San Francisco Gold Project, Sonora, Mexico” dated March 31, 2008 and amended January 13,2009.

At the request of the British Columbia Securities Commission (BCSC) the certificates in this report were amended on August 3, 2011.

TMM advises that it holds its interest in the San Francisco property through its wholly-owned Mexican subsidiary Timmins Goldcorp Mexico, S.A. de C.V. (Timmins) which holds two mining concessions, three exploration concessions, and seven exploitation concessions through a wholly-owned subsidiary, Molimentales del Noroeste de S.A. de C.V. (Molimentales).

In this Technical Report, TMM and its subsidiary Timmins are used interchangeably and for the purposes of the report are considered to be one and the same.

The current study is based on the internal resource and reserve estimates and mine plan prepared in-house by Timmins and Molimentales personnel and their consultants. Micon has audited the resource and reserve estimates as well as conducting a review of the mine plan and its various components. The material in this report was derived from a number of sources in addition to the material provided by TMM/Timmins and these sources are noted in Section 21 of this report. A site visit was conducted by Micon between August 3 and 6, 2010, during which the resources and reserves as well as various aspects of the operation and mine plan were discussed. The current and future exploration programs were discussed as well. The site visit included a tour through the open pit, leach pad, crushing circuit and the process plant.

The qualified persons responsible for the preparation of this report are Mr.William J. Lewis, B.Sc., P.Geo., Ing. Alan J. San Martin, MAusIMM., Mr. Mani Verma, P.Eng., Mr. Christopher A. Jacobs, CEng., MIMMM, and Mr. Richard M./ Gowans, P.Eng.

Messrs. Verma and Lewis conducted the August, 2010 site visit. Messrs. Jacobs, San Martin, Gowans conducted their desk top reviews in Toronto based on the information provided to them by TMM/Timmins.

Mr. Lewis, a Senior Geologist with Micon, is responsible for the independent summary and review of the exploration on the San Francisco project, the comments on the propriety of Timmins’ exploration drilling program, the plans and budget for the next phase of exploration and the review of Timmins Quality Assurance/Quality Control (QA/QC) program at the mine site. Mr. Lewis and Mr. San Martin, a Mineral Resource Modeller with Micon, conducted the review and audit of the resource estimate.

21

Mr Verma, an Associate Mining Engineer with Micon, is responsible for the review of the mine plan, production scheduling, operations and the terms of the existing mining contract and related cost estimates. Mr. Jacobs, a Vice President and Senior Mineral Economist with Micon, has reviewed the capital and operating cost estimates for the project and compiled the discounted cash flow analysis and sensitivity studies used to evaluate project economics. Mr. Gowans, President and Principal Metallurgist of Micon, reviewed the metallurgical aspect of the San Francisco project.

All currency amounts are stated in US dollars (USD) or Mexican pesos (MXN), as specified, with costs and commodity prices typically expressed in US dollars. Quantities are generally stated in metric units, the standard Canadian and international practice, including metric tons (tonnes, t) and kilograms (kg) for weight, kilometres (km) or metres (m) for distance, hectares (ha) for area, grams (g) and grams per metric tonne (g/t) for gold and silver grades (g/t Au, g/t Ag). Wherever applicable, imperial units have been converted to Système International d’Unités (SI) units for reporting consistency. Precious metal grades may be expressed in parts per million (ppm) or parts per billion (ppb) and their quantities may also be reported in troy ounces (ounces, oz), a common practice in the mining industry. A list of abbreviations is provided in Table 2.1. Appendix 1 contains a glossary of mining and other related terms.

The review of the San Francisco project was based on published material researched by Micon, as well as data, professional opinions and unpublished material submitted by the professional staff of TMM/Timmins or its consultants. Much of these data came from reports prepared and provided by TMM/Timmins.

Micon does not have nor has it previously had any material interest in TMM, Timmins or related entities or interests. The relationship with TMM and Timmins is solely a professional association between the client and the independent consultant. This report is prepared in return for fees based upon agreed commercial rates and the payment of these fees is in no way contingent on the results of this report.

This report includes technical information which requires subsequent calculations or estimates to derive sub-totals, totals and weighted averages. Such calculations or estimations inherently involve a degree of rounding and consequently introduce a margin of error. Where these occur, Micon does not consider them to be material.

22

Table 2.1

List of Abbreviations

| Name | Abbreviation | Name | Abbreviation |

| Accurassay Laboratories | Accurassay | Metre(s) | m |

| Acme Analytical Laboratories Ltd. | ACME | Mexican peso | MXN |

| Adsorption/desorption/reactivation | ADR | Micon International Limited | Micon |

| ALS Chemex Laboratories | ALS Chemex | Million (eg Million tonnes, Million ounces, Million years) | M (Mt, Moz, Ma) |

| Canadian Institute of Mining, Metallurgy and Petroleum | CIM | Milligram(s) | mg |

| Canadian National Instrument 43-101 | NI 43-101 | Millimetre(s) | mm |

| Centimetre(s) | Cm | Molimentales del Noroeste de S.A. de C.V. | Molimentales |

| Compania Fresnillo S.A. de C.V. | Fresnillo | North American Datum | NAD |

| Defiance Mining Corporation | Defiance | Net present value, at discount rate of 8%/y | NPV, NPV8 |

| Degree(s), Degrees Celsius | o ,o C | Net smelter return | NSR |

| Digital elevation model | DEM | Not available/applicable | n.a. |

| Dirección General de Minas | DGM | Ounces (troy)/ounces per year | oz, oz/y |

| Discounted cash flow | DCF | Parts per billion, part per million | ppb, ppm |

| Diversified Drilling, S.A. de C.V. | Diversified | Percent(age) | % |

| Explotaciones Mineras Del Noroeste S.A. de C.V. | Explotaciones Mineras | Quality Assurance/Quality Control | QA/QC |

| Geomaque de Mexico, S.A. de C.V. | Geomaque de Mexico | Run of mine | ROM |

| Geomaque Explorations Inc. | Geomaque | Servicios Industriales Peñoles, S.A. de C.V. | Peñoles |

| Golder Associates Ltd. | Golder Associates | SGS Mineral Services | SGS |

| Grams per metric tonne | g/t | Sol & Adobe Ingenieros Asociados S.A. de C.V. | Sol & Adobe. |

| Hectare(s) | Ha | Specific gravity | SG |

| Inch(es) | In | Square kilometre(s) | km2 |

| Independent Mining Consultants, Inc. | IMC | Three-dimensional | 3-D |

| Inductively Coupled Plasma – Emission Spectrometry | ICP-ES | Timmins Gold Corp. | TMM |

| Internal diameter | ID | Timmins Goldcorp Mexico, S.A. de C.V. | Timmins |

| Internal rate of return | IRR | Tonne (metric)/tonnes per day | t, t/d |

| Impuesto al Valor Agregado (or VAT) | IVA | Tonne-kilometre | t-km |

| Kappes, Cassiday and Associates | Kappes Cassiday | Tonnes per cubic metre | t/m3 |

| Kilogram(s) | Kg | TSL Laboratories Inc. | TSL |

| Kilometre(s) | Km | United States Dollar(s) | USD |

| Life of mine | LOM | Universal Transverse Mercator | UTM |

| Litre(s) | L | Value Added Tax or Impuesto al Valor Agregado | VAT or IVA |

| McCelland Laboratories Inc. | McCelland | Year | y |

| METCON Research Inc. | METCON | | |

23

3.0 RELIANCE ON OTHER EXPERTS

Micon has reviewed and analyzed data provided by TMM/Timmins, its consultants and the previous operator of the project, and has drawn its own conclusions therefrom, augmented by its direct field examination. Micon has not carried out any independent exploration work, drilled any holes or carried out an extensive program of sampling and assaying on the property. However, previous sampling (Lewis, 2006) was conducted to independently substantiate the mineralization at the San Francisco project and further samples were not obtained during the 2006, 2007, 2010 site visits.

Micon has reviewed and audited the work conducted on the resource and reserve estimates, the mine plan and other material related to the operating San Francisco mine which was supplied by TMM and Timmins.

While exercising all reasonable diligence in checking, confirming and testing it, Micon has relied upon Timmins’ presentation of the project data, including data from the previous operator, in formulating its opinion with respect to the San Francisco property.

The English translations for the various agreements under which TMM and its wholly-owned Mexican subsidiary, Timmins, hold title to the mineral concessions for this project have been previously reviewed by Micon. Micon, however, offers no legal opinion as to the validity of the mineral title claimed. A description of the property, and ownership thereof, is provided for general information purposes only. A legal opinion regarding the mineral concessions was provided to Micon by Timmins in conjunction with the publication of the previous Technical Report. Micon has continued to rely on this expert opinion as Timmins validation regarding title to the mineral concessions. The legal opinion regarding the mineral title was undertaken by Roberto Herrera Piñon, a mining lawyer and master in corporate law, located in Hermosillo, Mexico. The legal opinion regarding the mineral concessions was dated April 26, 2007.

Micon has relied also upon a legal opinion dated April 25, 2007 and prepared by Francisco Manuel Cordova Celaya, Dr. En Derecho regarding the transfer of the San Francisco project to Molimentales and Timmins. The legal opinion was prepared and executed in Hermosillo, Mexico.

The existing environmental conditions, liabilities and remediation have been described where required by NI 43-101 regulations. However, these statements are provided for information purposes only and Micon offers no opinion in this regard.

24

The descriptions of geology, mineralization and exploration used in this report are taken from reports prepared by various companies or their contracted consultants, as well as from various government and academic publications. The conclusions of this report rely in part on data available in published and unpublished reports supplied by the companies which have conducted the exploration on the property, and information supplied by Timmins. The information provided to Timmins was supplied by reputable companies and Micon has no reason to doubt its validity.

Micon is pleased to acknowledge the helpful cooperation of Timmins management and consulting field staff, all of whom made any and all data requested available and responded openly and helpfully to all questions, queries and requests for material.

Some of the figures and tables for this report were reproduced or derived from historical reports written on the property by various individuals and/or supplied to Micon by TMM and Timmins. Most of the photographs were taken by the authors of this report during their respective site visits. In the cases where photographs, figures or tables were supplied by other individuals or TMM and Timmins they are referenced below the inserted item.

25

4.0 PROPERTY DESCRIPTION AND LOCATION

Timmins’ San Francisco property is located in the north central portion of the Mexican state of Sonora, which borders on the American state of Arizona, and is approximately 150 km north of the city of Hermosillo, the capital of Sonora. The latitude and longitude for the project site are approximately 30°21’13” N, 111°06’52” W. The UTM coordinates are 3,357,802 N, 489,017 E and the datum used was NAD 27 Mexico. The project is located 2 km west of the town of Estación Llano (Estación) and is accessed via Mexican State Highway 15 (Pan American highway) from Hermosillo.

The term San Francisco project refers to the area related to the exploitation concessions optioned by TMM, while the term San Francisco property refers to the entire land package (mineral exploitation and exploration concessions) optioned and owned by TMM. The location of the San Francisco property is shown in Figure 4.1.

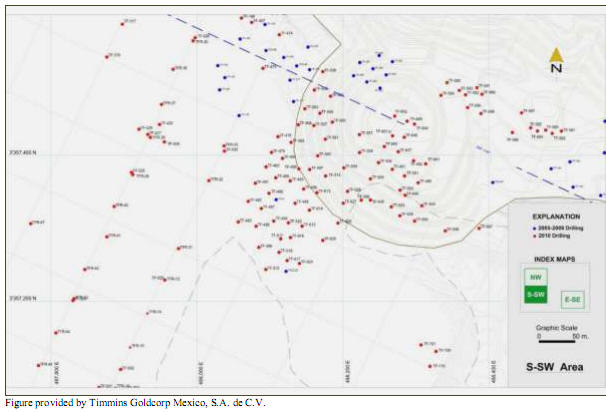

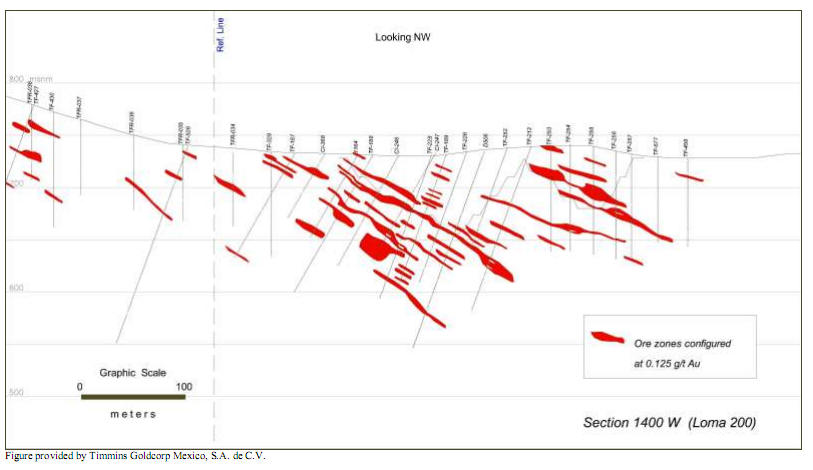

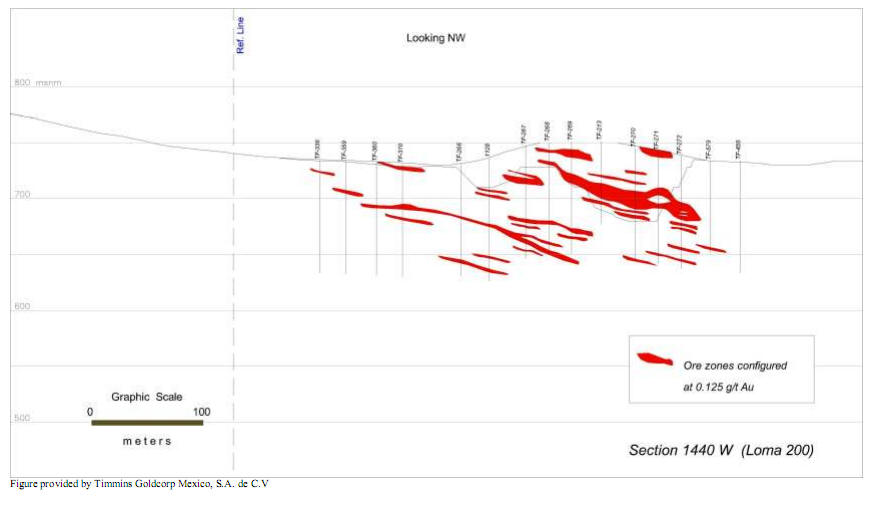

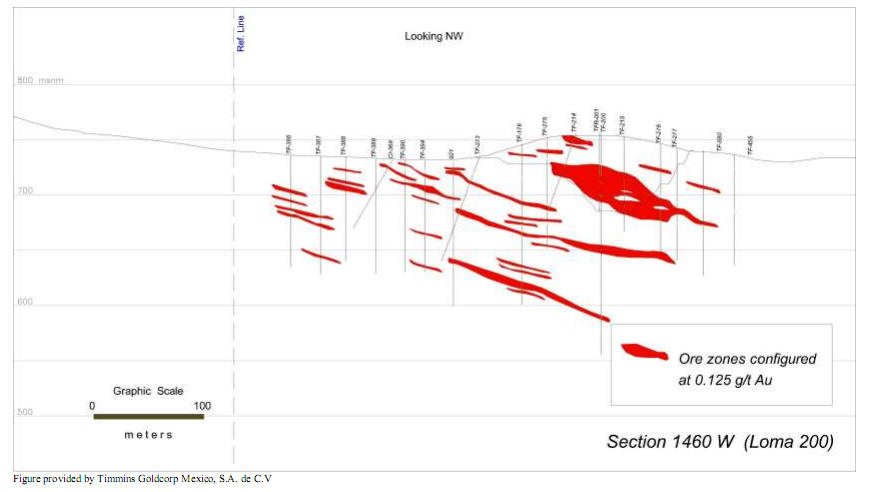

The exploration program carried out by Timmins during the last three years (2008 to 2010) has been focused primarily on exploring the extension, both along strike and in the dip direction, of the mineralization related to the San Francisco gold deposit. Secondary exploration programs have been undertaken at the La Chicharra gold deposit located 2 km west of the San Francisco pit. The exploration programs have been accelerated on the targets located to the north of the San Francisco project, including a short drill exploration program to confirm the presence of gold and favourable lithology. The results have proven to be favourable and further exploration is planned over the next two years on these targets.

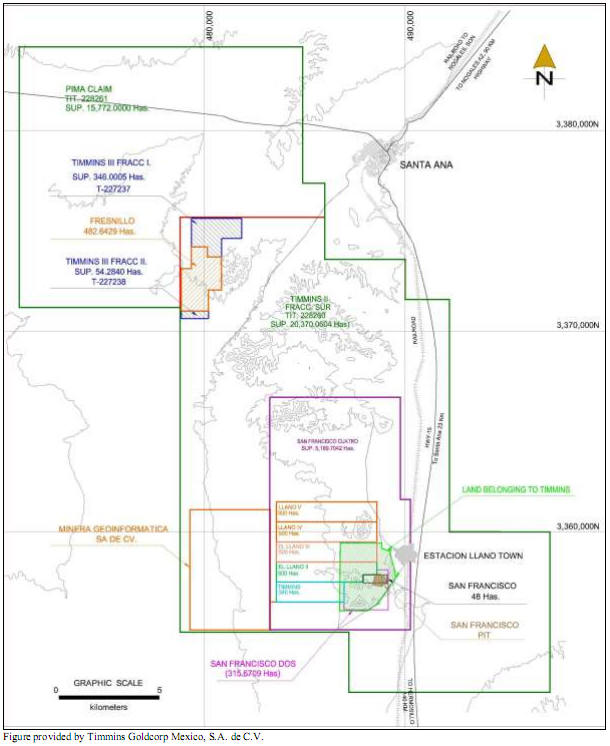

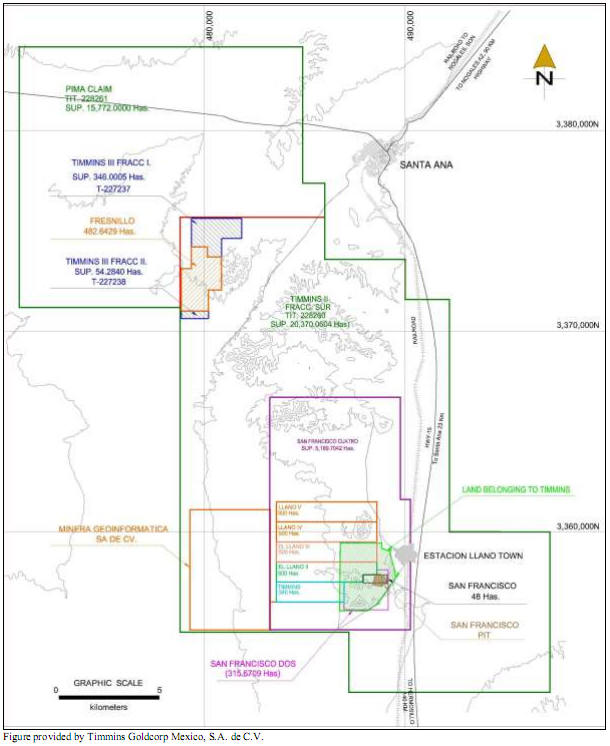

TMM advises that it holds the San Francisco property, which consists of 12 mining concessions, through its wholly-owned Mexican subsidiary. All the concessions are contiguous and each varies in size for a total property area of 43,432.72 hectares (ha). In late 2005, the original Timmins II concession was subdivided into two concessions (Timmins II Fraccion Sur and Pima) as part of separate exploration strategies for the original Timmins II concession. All concessions are subject to a bi-annual fee and the filing of reports in May of each year covering the work accomplished on the property between January and December of the preceding year.

The information for the twelve concessions is summarized in Table 4.1. A map of the mineral concessions for the San Francisco property is provided in Figure 4.2.

Timmins advises that it acquired the first seven concessions shown in Table 4.1, covering the San Francisco mine, through its purchase of Molimentales in April, 2007.

26

Figure 4.1

San Francisco Project Location Map

27

Table 4.1

San Francisco Project, Summary of Mineral Concessions

| Mineral Concession Name | Title Number | Owner | Location (UTM Nad 27 Mex) | Mineral Concession Type3 | Area (hectares) | Location Date | Expiry Date3 | Bi-Annual Fee (USD)4 |

| San Francisco | 198971 | Molimentales del Noroeste, S.A de C.V. | 488,675.174 E 3,359,396.801 N | Mining Concession | 48.0000 | Nov 13, 1993 | Feb. 10, 2044 | 450 |

| San Francisco Dos | 209618 | Molimentales del Noroeste, S.A de C.V. | 488,675.174 E 3,359,396.801 N | Mining Concession | 315.6709 | Dec 4, 1996 | Aug. 2, 2049 | 2,810 |

| San Francisco Cuatro | 219301 | Molimentales del Noroeste, S.A de C.V. | 488,675.174 E 3,359,396.801 N | Mining Concession | 5,189.7041 | Aug 18, 2000 | Feb. 25, 2053 | 13,128 |

| Llano II | 197203 | Molimentales del Noroeste, S.A. de C.V. | 483,652.702 E 3,356,290.081 N | Mining Concession | 500.0000 | Oct 23, 1986 | Aug. 18, 2043 | 4,450 |

| Llano III | 197202 | Molimentales del Noroeste, S.A de C.V. | 483,652.702 E 3,356,290.081 N | Mining Concession | 500.0000 | Oct 23, 1986 | Aug. 26, 2043 | 4.450 |

| Llano IV | 222787 | Molimentales del Noroeste, S.A. de C.V. | 488,675.174 E 3,359,396.801 N | Mining Concession | 500.0000 | May 17, 2004 | Aug 30, 2054 | 630 |

| Llano V | 222788 | Molimentales del Noroeste, S.A. de C.V. | 483,652.702 E 3,356,290.081 N | Mining Concession | 500.0000 | May 17, 2004 | Aug 30, 2054 | 630 |

| Timmins | 226519 | Timmins Goldcorp México, S.A. de C.V. | 488,675.174 E 3,359,396.801 N | Mining Concession | 337.0000 | Aug. 26, 2005 | Jan. 23, 2056 | 424 |

| Timmins III Fraccion 1 | 227237 | Timmins Goldcorp México, S.A. de C.V. | 481,529.246 E 3,371,837.280 N | Mining Concession | 346.0004 | Feb. 15, 2006 | May 25, 2056 | 436 |

| Timmins III Fraccion 2 | 227238 | Timmins Goldcorp México, S.A. de C.V. | 481,529.246 E 3,371,837.280 N | Mining Concession | 54.2835 | Feb. 15, 2006 | May 25, 2056 | 69 |

| Timmins II Fraccion Sur2 | 228260 | Timmins Goldcorp México, S.A. de C.V. | 488,675.174 E 3,359,396.801 N | Mining Concession | 20,370.0604 | Nov. 17, 2005 | Mar. 13, 2056 | 25,617 |

| Pima2 | 228261 | Timmins Goldcorp México, S.A. de C.V. | 486,058.775 E 3,375,493.728 N | Mining Concession | 15,772.0000 | Nov. 17, 2005 | Mar. 13, 2056 | 19,835 |

| Total: | - | - | - | - | 44,792.7193 | - | - | 72,929 |

Table provided by Timmins Goldcorp Mexico, S.A. de C.V.

Notes:

2 The Timmins II claim, originally staked with a surface of 39.403.0000 ha., was titled for the Direccion General de Minas (DGM), after survey works, with a surface of 36,142.0604 ha. In 2008, due to a change in exploration strategy, the Timmins II claim was divided into two claims, Timmins II Fraccion Sur and Pima.

3 In 2006 the mining law was modified and the distinction between exploitation concessions and exploration concessions was abolished. Therefore all concessions granted by the DGM as of 2006 are legally “mining concessions”. The amendment to the mining law also granted the new mining concessions for a term of 50 years which is the same length of time granted to the old exploitation concessions under the mining law before the amendment.

4 Fees are estimated in US dollars based on payments in 2010. Inflation and other factors are considered by the Mexican government each year.

28

Figure 4.2

San Francisco Property (Concessions) Map

29

In 2006, Timmins signed a temporary occupancy agreement with an agrarian community (Ejido) in Mexico called Los Chinos whereby Timmins was granted access privileges to 674 ha, the use of the Ejido’s roads, as well as being able to perform all exploration work on the area covered by the agreement. The agreement is for a period of 10 years with an option to extend the access beyond the 10-year period. As consideration for the ejido granting access to a portion of its land, Timmins paid it the sum of USD 30,000.

During August and September, 2009, Molimentales acquired the 800 hectares on which the San Francisco mine is currently located, by means of five purchase agreements covering every one of the Ejido Jesus Garcia Heroe de Nacozari’s five former parcels that altogether form the 800 ha. Timmins and/or Molimentales paid the former Ejido members, as consideration for the purchase and acquisition of the 5 parcels, the amount of USD 1 million.

Other parties control four mineral concessions which are contained within the area of the mineral concessions owned by Timmins but none of these concessions impacts the main area of the San Francisco project.

When the Mexican mining law was amended in 2006, all mineral concessions granted by the Dirección General de Minas (DGM) became simple mining concessions and there was no longer a distinction between mineral exploration or exploitation concessions. A second change to the mining law resulted in all mining concessions being granted for a period of 50 years, provided that the concessions remained in good standing. As part of the second change all former exploration concessions which were previously granted for a period of 6 years became eligible for the 50-year term.

For any concession to remain valid, the bi-annual fees must be paid and a report has to be filed during the month of May of each year which covers the work conducted during the preceding year (This report is commonly known in Mexico as “Comprobacion de Obras”). Concessions are extendable provided that the application is made within the five-year period prior to the expiry of the concession and the bi-annual fee and work requirements are in good standing. The bi-annual fee, payable to the Mexican government for Timmins to hold the group of contiguous mining concessions under exploitation or exploration is USD 72,929.

All mineral concessions must have their boundaries orientated astronomically north-south and east-west and the lengths of the sides must be one hundred metres or multiples thereof, except where these conditions cannot be satisfied because they border on other mineral concessions. The locations of the concessions are determined on the basis of a fixed point on the land, called the starting point, which is either linked to the perimeter of the concession or located thereupon. Prior to being granted a concession, the company must present a topographic survey to the DGM within 60 days of staking. Once this is completed the DGM will usually grant the concession. The starting point (white cairn on the hilltop) for one of the mineral concessions comprising the San Francisco project is shown in Figure 4.3.

30

Figure 4.3

View of the Starting Point for One of the Concessions on the San Francisco Property

Since the San Francisco project is located on a number of mining concessions upon which mining has previously been conducted, all exploration work continues to be covered by the environmental permitting already in place and no further notice is required to be given to any division of the Mexican government. The specific environmental permitting of the San Francisco mine site was obtained in December, 2007, via an environmental assessment, and it is valid for the duration of the seven mining concessions that comprise the mine, provided that Molimentales keeps the permitting in good standing. Water for any drilling programs at the San Francisco project is obtained from the on-site water wells.

Micon is unaware of any outstanding environmental liabilities attached to the San Francisco project and is unable to comment on any remediation which may have been undertaken by previous owners.

31

5.0 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

5.1 ACCESSIBILITY

The San Francisco property is readily accessible from Hermosillo, the state capital of Sonora, via Mexican State Highway 15 (Pan American Highway), north from Hermosillo for 150 km. The property is 120 km south of the United States/Mexico border city of Nogales, also on Highway 15. The San Francisco mine site is 2 km west of the town of Estación. The major population centre for the region is Magdalena de Kino (Magdalena) to the north with a population of over 50,000 inhabitants.

The mineral concessions are located approximately due west and north of Estación, with the closest accommodations located in Santa Ana, a small city located to the north on Highway 15.

5.2 LOCAL RESOURCES AND INFRASTRUCTURE

Timmins maintains guarded gates across the access road to the mine and immediate project area. Exploration can be conducted year round, with the desert monsoon season occurring between July and September. Materials needed to supply the mine are transported by either truck (utilizing Mexican State Highway 15) or by rail (utilizing the Ferrocarril del Pacifico railway), both of which pass through the community of Estación.

Timmins has been granted the temporary occupation of surface rights at the San Francisco mine by the DGM for the duration of the exploitation concessions. In the case of an exploration concession, the holder is granted temporary occupancy for creation of land easements needed to carry out exploration for the duration of the mineral concession. In order to commence mining, the holder of the concession is required to negotiate the surface rights with the legal holder of these rights or to acquire the surface rights through a temporary expropriation.

Water for the drilling programs is available from wells located on the mine site. The water table in the area of the mine is approximately 25 m below the surface. A typical water well is shown in Figure 5.1.

The surrounding cities and towns supply the majority of the workers, with the professional staff coming from other parts of Mexico.

The site consists of all the necessary infrastructure to maintain and operate the equipment and mine.

32

Figure 5.1

View of the Water Well Located on the San Francisco Project

5.3 CLIMATE AND PHYSIOGRAPHY

The project is located in the Arizona-Sonora desert in the northern portion of the Mexican state of Sonora. The climate at the project site ranges from semi-arid to arid. The average ambient temperature is 21°C, with minimum and maximum temperatures of -5ºC and 50ºC, respectively. The average rainfall for the area is 330 mm with an upper extreme of 880 mm.

The wet season or desert monsoon season is between July and September and heavy rainfall can hamper exploration at times.

The San Francisco property is situated within the southern Basin and Range physiographic province, which is characterized by elongate, northwest-trending ranges separated by wide alluvial valleys. San Francisco is located in a relatively flat area of the desert with the topography ranging between 700 and 750 m above sea level.

The desert vegetation surrounding the San Francisco mine is composed of low lying scrub, thickets and various types of cacti, with the vegetation type classified as Sarrocaulus Thicket. The state of Sonora is well known for its mining and cattle industries, although US manufacturing firms are starting to move into the larger centres as a result of the North American Free Trade Agreement (NAFTA). See Figure 5.2 for a view of the desert surrounding the San Francisco property.

33

Figure 5.2

View of the Sonora Desert Surrounding the Property

34

6.0 HISTORY

6.1 SAN FRANCISCO PROPERTY AND GOLD MINE

The San Francisco gold mine is a past producing heap leach operation which was in production originally between 1995 and 2002. However, during the last two years of operation, gold was being recovered from the leach pads only, with no mining being conducted from the San Francisco and La Chicharra open pits.

Placer mining and small scale underground mining began in the San Francisco mine area during the early 1940s. This limited work drew Fresnillo to the area in 1983. In 1985, three diamond drill holes and 30 conventional percussion drill holes were completed on the property. The results of these drill holes were encouraging enough to warrant drilling additional diamond drill holes during 1986. In 1987, 540 m of underground development was conducted, including a decline and a number of drifts and cross-cuts. The decline was completed to the 685 m elevation above sea level, where numerous 1.8 by 1.5 m drifts and cross-cuts were developed. Fresnillo drilled 10 diamond drill holes and 25 reverse circulation drill holes in 1988, and an additional 226 reverse circulation drill holes in 1989. In addition, metallurgical testing and an induced polarization survey were completed in 1989. In 1990 and 1991, Fresnillo completed an additional 108 reverse circulation drill holes. Fresnillo decided to sell the property in 1992, at which time it was acquired by Geomaque. See Figure 6.1 for an example of one of the rotary drill site locations southeast of the main pit. As part of the Geomaque purchase, Fresnillo retained a 3% NSR royalty and the option to re-acquire a 50% interest by paying Geomaque twice the amount which it had expended. Geomaque completed a feasibility study in 1993 and drilled a further 69 reverse circulation drill holes in 1994. Geomaque acquired the NSR royalty and option back from Fresnillo in 1995 for USD 4,700,000.

Geomaque conducted its activities in Mexico through its subsidiaries, Geomaque de Mexico, S.A. de C.V. (Geomaque de Mexico) and Mina San Francisco, S.A. de C.V. (Mina San Francisco).

Geomaque began construction of the San Francisco mine in 1995, with production beginning in late 1995. Production began at the rate of 3,000 t/d of ore or 30,000 oz/y of gold. However, as a result of the discovery of additional reserves, an expansion of the mining fleet, crushing system and gold recovery plant was undertaken in an effort to increase production to 10,000 t/d of ore. Due to the prevailing market conditions in February, 2000, Geomaque announced a revised mine plan whereby higher grade ore with a lower stripping ratio would be mined from the San Francisco pit and the La Chicharra deposit, which is located west of the San Francisco pit.

The San Francisco deposits consisted of the El Manto, the San Francisco, the En Medio and the El Polvorin deposits. All of these deposits were later incorporated into the main San Francisco pit. Another deposit, the La Chicharra zone, was mined during the last two years of production as a second pit.

35

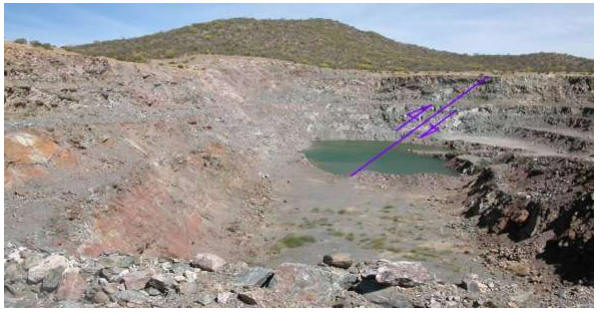

Mining ended and the operation entered into a leach only mode in November, 2000. In May, 2002, the last gold pour was conducted, the plant was mothballed, and clean-up activities at the mine site began. See Figure 6.2 for a photographic overview of the San Francisco pit and leach pad taken from a hill to the southwest of the mine site prior to the current phase of production.

Figure 6.1

Location of One of the Rotary Drill Sites Located to Southeast of the Main Pit

Figure 6.2

View of the San Francisco Gold Mine with Estación Llano in the Background

36

In 2001, to settle debts related to lease arrangements of construction equipment to Geomaque de Mexico, Butler Machinery Co. (Butler) accepted a payment of USD 500,000, the proceeds in excess of USD 500,000 on the sale of certain equipment from the San Francisco mine and a 1% net smelter return (NSR) royalty on any future gold production from the unmined resources in the main pit of the San Francisco mine. No present value was ascribed to the rights at the time of the agreement. Micon has been advised by Timmins that the agreement between Geomaque and Butler has ended and has received an opinion that the property was transferred to Molimentales free of any royalties. It is the opinion of Timmins solicitors that Timmins has free and clear title to the equipment on the property and no obligations to pay any NSR royalties.

Geomaque signed a Surface Rights Agreement with a group of rights holders (the Ejido Jesus Garcia Heroe De Nacozari (Ejido Jesus Garcia)). Based on a letter agreement dated July 7, 1999, the Ejido Jesus Garcia agreed to transfer to the company a surface area of 800 ha, for a total consideration of USD 1,000,000, of which USD 75,000 was due and payable on signing of the agreement. The letter agreement and its efficacy were the subject of litigation between Geomaque and the Ejido Jesus Garcia, whereby the company sought to have the agreement declared void, its deposit returned and other remedies, and the Ejido Jesus Garcia sought to have the agreement held effective and sought, inter alia, the payment of the balance of the purchase price and other relief.

In the summer of 2003, Geomaque sought and received shareholder approval to amalgamate the corporation under a new Canadian company, Defiance Mining Corporation (Defiance).

On November 24, 2003, Defiance sold its Mexican subsidiaries, Geomaque de Mexico and Mina San Francisco, to the Astiazaran family and their private Mexican company for a total consideration of USD 235,000. The Mexican subsidiaries held the San Francisco gold mine and the sale relieved Defiance of long-term liabilities totalling USD 1,900,000, including a USD 925,000 surface rights purchase obligation, approximately USD 760,000 in reclamation provisions and other payables totalling USD 263,000. The litigation of the surface rights between the Ejido Jesus Garcia and Geomaque de Mexico was settled in favour of Geomaque de Mexico on January 20, 2005. Geomaque de Mexico has been granted by the DGM the temporary occupation of surface rights at the San Francisco mine for the duration of the exploitation concessions.

Since June, 2006, the Astiazaran family and their company, Desarrollos Prodesa S.A. de C.V. (Prodesa) retained ownership of the waste dumps and the original leach pads, and have been extracting sand and gravel intermittently for use in highway construction and other construction projects. Timmins is continuing to negotiate the purchase of these heap leach piles and waste rock dumps. See Figure 6.3 for a view of the gravel extraction from the old leach pads at the San Francisco mine site.

37

Figure 6.3

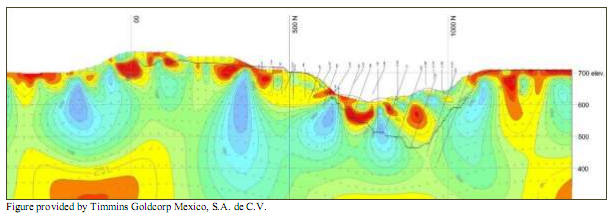

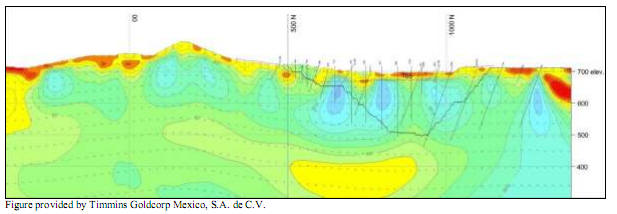

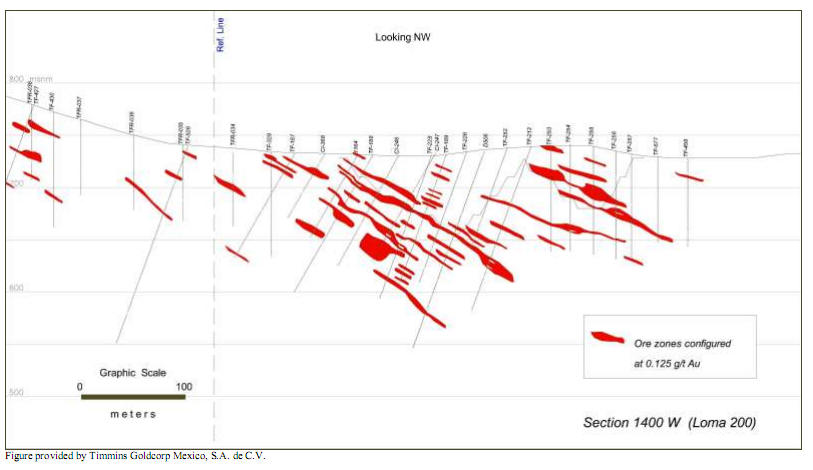

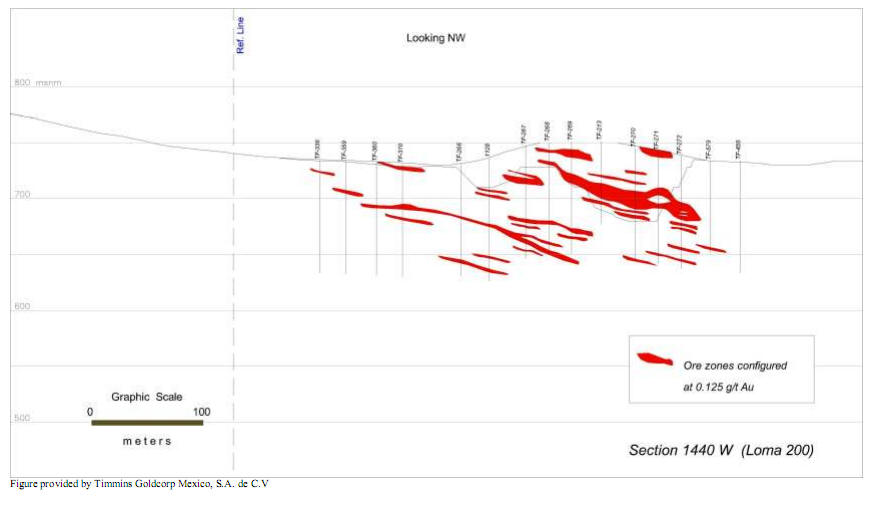

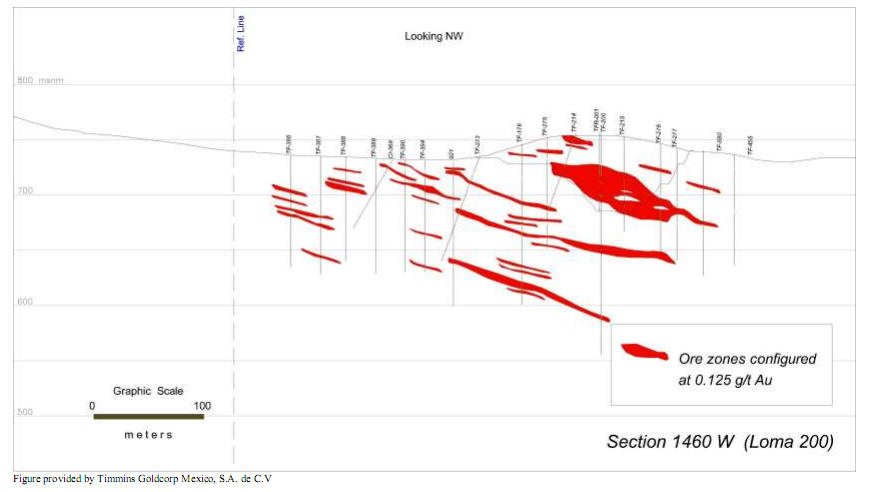

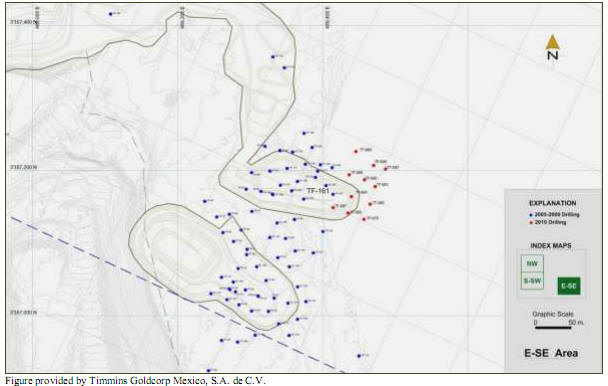

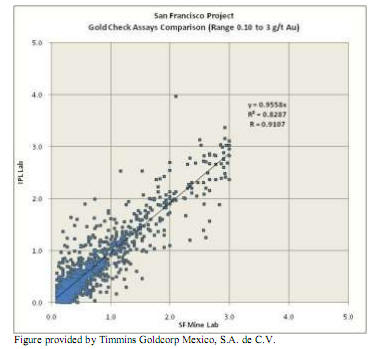

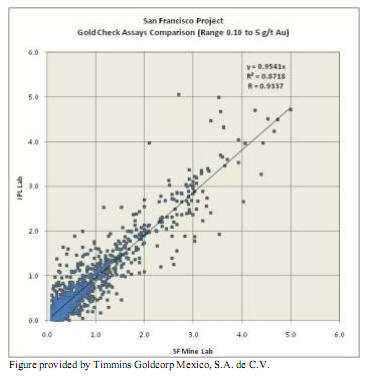

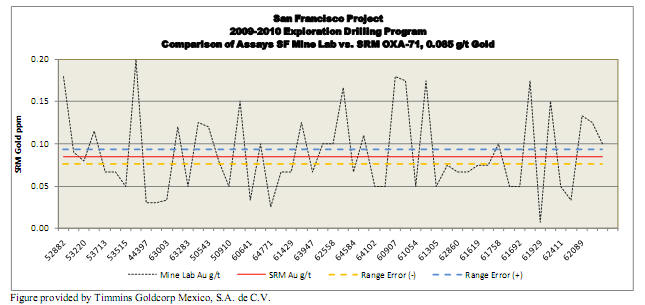

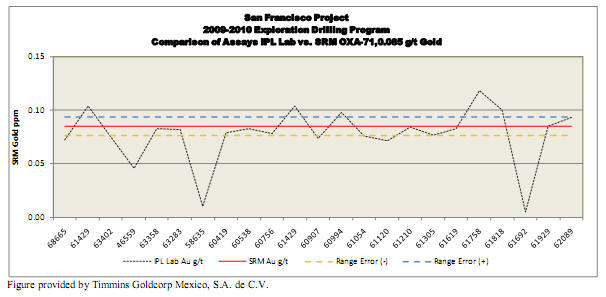

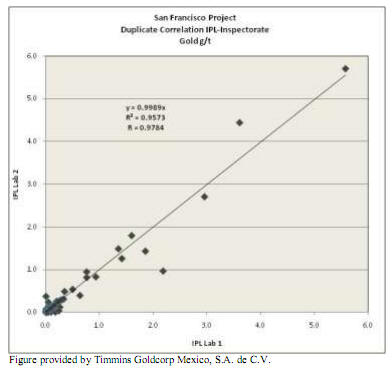

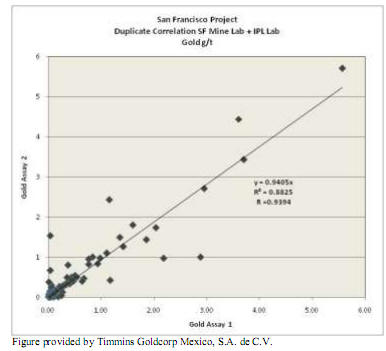

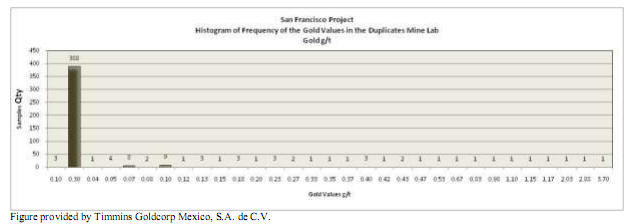

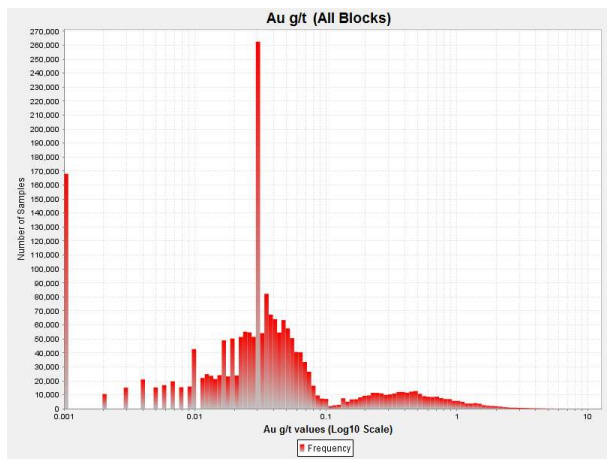

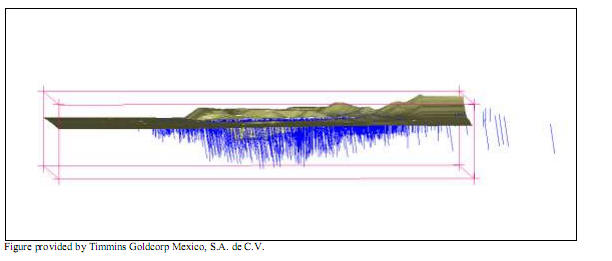

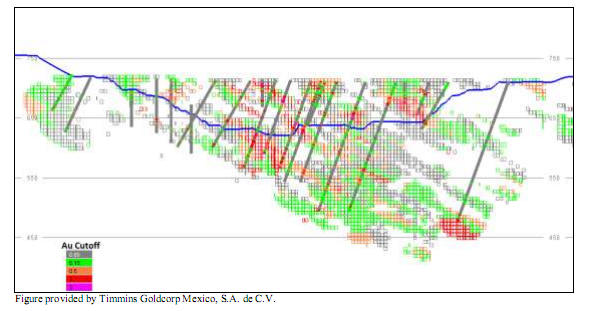

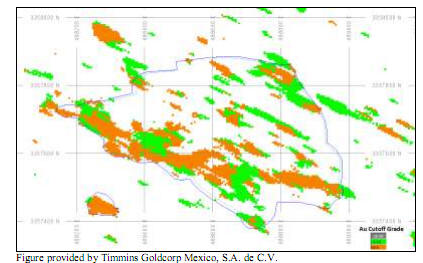

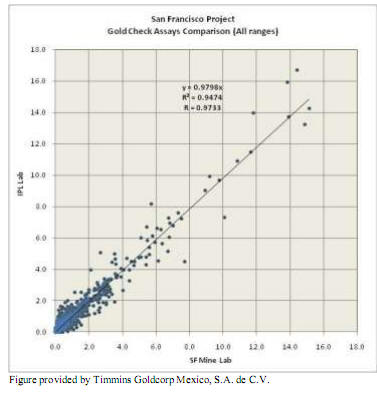

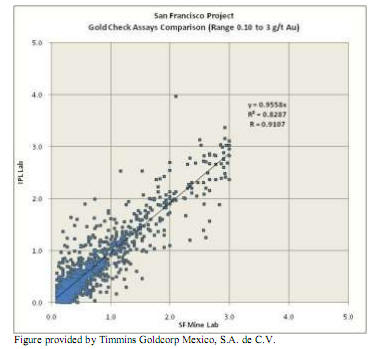

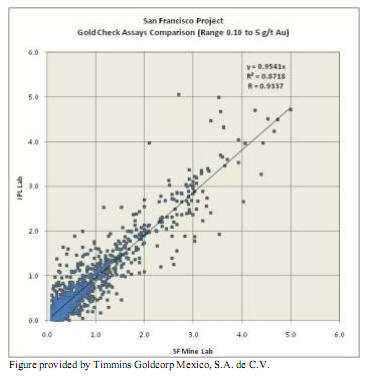

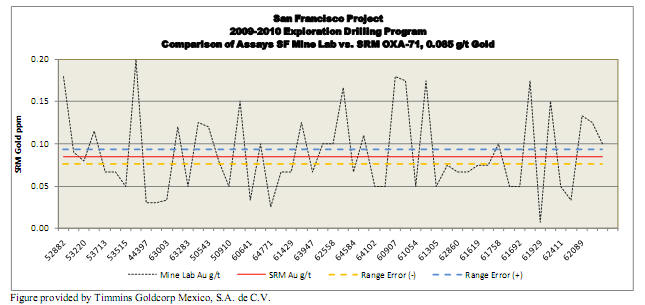

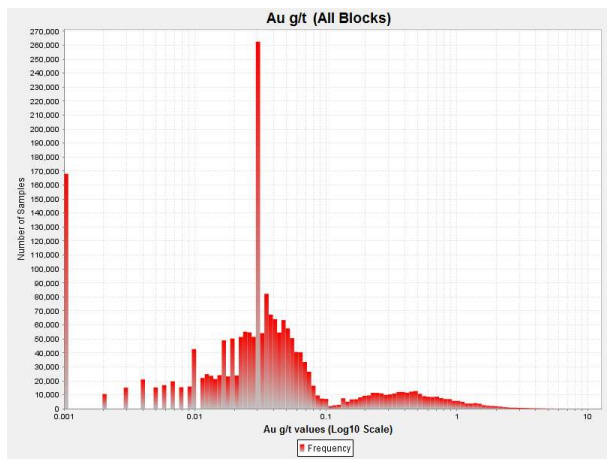

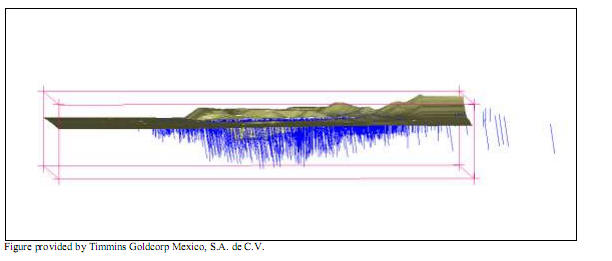

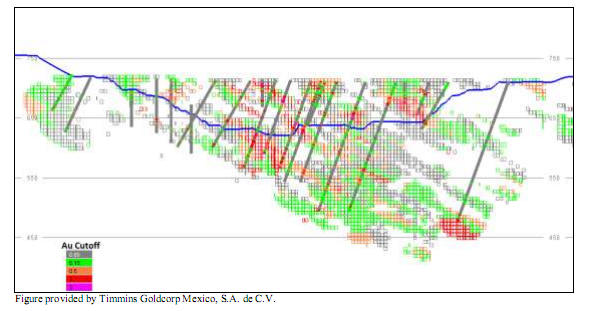

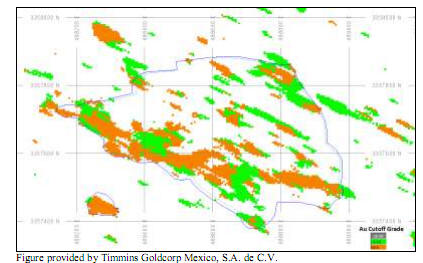

Extraction of Gravel from the Leach Pad for Construction Use