May 12, 2016 Morgan Stanley Refining Corporate Access Day Filed by Northern Tier Energy LP Pursuant to Rule 425 under the Securities Act of 1933 And deemed filed pursuant to Rule 14a-12 Under the Securities Exchange Act of 1934 Subject Company: Northern Tier Energy LP Form S-4 File No.: 333-209031 On May 12, 2016, Northern Tier Energy LP made the following presentation available on its website, which it presented later that day at the Morgan Stanley Refining Corporate Access Day in New York City.

Forward Looking Statements Forward-Looking Statements This presentation contains forward-looking statements. The forward-looking statements contained herein include statements about, among other things, future: advantageous access to crude oil supplies and the attractiveness of our refined product outlets; safe operations; integration of refining, marketing, retail and logistics assets; flexibility of our refinery; safe operations; leverage and financial flexibility; ability to identify growth opportunities and complete accretive acquisitions; incentives of our management team; entity structure; amount & type of crude oil we’ll run at our refinery and yields; location of our assets; redundancy of our operations and assets, refinery utilization and increased maintenance flexibility; ability to process a variety of light, heavy, sweet and sour crude oils and the pricing thereof; fuel quality requirements and regulations, our ability to comply therewith and capex required for and financial impacts of such compliance; liquid volume yield; FCC capacity; increases in NDL and/or WCS crude oil production; adjusted gross margin per barrel of throughput; number of company-operated & franchised stores, the locations thereof and the ability of such stores to sell any or all of our refinery’s gasoline; commitments for supply of third party retail networks; improved netbacks; increases in total fuel gallons sold to the SuperAmerica network; brand presence of SuperAmerica including its benchmark against national top tier fuel retailers; new stores and franchise growth; organic growth opportunities and our ability to identify and/or complete high return projects successfully or at all, and the expected results of such projects; replacement of desalters including the costs, timing, EBITDA, IRR and payback thereof including increases in crude oil input flexibility and optionality, replacement of Syncrude with higher valued crude oils up to 10 MPD or at all, margin benefit of $4.50/bbl or at all, improved process reliability, reduction in salt-related corrosion and diesel v. gasoline recovery flexibility, annual net income, depreciation and amortization; modification of our crude units and distillate hydrotreaters and the timing, costs, IRR, payback and results thereof including increases in distillate yield, increases in crude capacity, crude margin benefits and diesel recovery incentive, annual net income, depreciation and amortization; installation of a solvent deasphalting unit including costs, EBITDA, , annual net income, depreciation and amortization, timing, expected product spread benefit, product yields, pitch yields and its ability to fill excess FCC capacity; optimization of first purchaser barrels in the Bakken and utilization of crude oil transport fleet; ability to source some or all Bakken crude oil from the field and associated increases in gross margins and crude oil quality; growth of the SuperAmerica brand by building new stores, expanding our franchise network or otherwise; acquisition of refining assets, including assets that are well-maintained and/or have access to advantaged crude oil and attractive refined product dynamics; Bakken growth; the announced merger with Western Refining, Inc. (“Western” or “WNR”), including the financing thereof, the timing and likelihood of completion thereof and the management team of the combined company following the merger, the continued pipeline access to advantaged crude oil and strength of refined product regions following the merger; the existence and value of financial and operational synergies of the combined company; the flexibility and pace of asset drop-downs, if any; costs of capital and acquisition currency; organizational and financial structure of the combined company; percentage of products comparable to a 3-2-1 crack spread and the 6-3-2-1 crack spread; and cash available for distribution. The words “believe,” “expect,” “anticipate,” “plan,” “intend,” “foresee,” “should,” “would,” “could,” “attempt,” “appears,” “forecast,” “outlook,” “estimate,” “project,” “potential,” “may,” “will,” “are likely” or other similar expressions are intended to identify forward-looking statements. These forward-looking statements are based on management’s current expectations and beliefs concerning future developments and their potential effect on us. While management believes that these forward-looking statements are reasonable as and when made, there can be no assurance that future developments affecting us will be those that we anticipate, and any and all of our forward-looking statements in this presentation may turn out to be inaccurate. Our forward-looking statements involve significant risks and uncertainties (some of which are beyond our control) and assumptions that could cause actual results to differ materially from our historical experience and our present expectations or projections. These statements are subject to the general risks inherent in our business, and our statements about the merger are also subject to risks related to the merger generally (including the risk that is it not completed when expected or at all) as well as general risks inherent in the business of Western. In addition, if the merger with Western is consummated, it may impact the operation of our business, including with respect to future growth plans and strategies. These expectations may or may not be realized, and may be based upon assumptions or judgments that prove to be incorrect. In addition, our business and operations involve numerous risks and uncertainties, many of which are beyond our control, which could result in our expectations not being realized, or otherwise materially affect our financial condition, results of operations and cash flows. Other known, unknown or unpredictable factors could have material adverse effects on our future results. Additional information regarding such factors and our uncertainties, risks and assumptions are contained in our filings with the Securities and Exchange Commission. All forward-looking statements are only as of the date hereof, and we do not undertake any obligation to (and expressly disclaim any obligation to) update any forward looking statements to reflect events or circumstances after the date such statements were made, or to reflect the occurrence of unanticipated events. Important Notice to Investors This communication does not constitute an offer to sell or the solicitation of an offer to buy any securities or a solicitation of any vote or approval in any jurisdiction where such an offer or solicitation is unlawful. Any such offer will be made only by means of a prospectus meeting the requirements of Section 10 of the Securities Act of 1933, pursuant to a registration statement filed with the SEC. The proposed transaction between Western Refining, Inc. (“Western”) and Northern Tier Energy LP (“NTI”) will be submitted to the unitholders of NTI for their consideration. On January 19, 2016, Western filed a registration statement on Form S-4 with the SEC that included a preliminary prospectus of Western and a preliminary proxy statement of NTI. Western and NTI will also file other documents with the SEC regarding the proposed transaction, including a definitive prospectus and proxy statement. INVESTORS AND SECURITY HOLDERS OF NTI ARE URGED TO READ THE DEFINITIVE PROXY STATEMENT/PROSPECTUS AND ANY OTHER RELEVANT DOCUMENTS THAT WILL BE FILED WITH THE SEC CAREFULLY AND IN THEIR ENTIRETY WHEN THEY BECOME AVAILABLE BECAUSE THEY WILL CONTAIN IMPORTANT INFORMATION ABOUT THE PROPOSED TRANSACTION. Investors and security holders may obtain free copies of the definitive proxy statement/prospectus and other documents containing important information about Western and NTI once such documents are filed with the SEC through the website maintained by the SEC at www.sec.gov. Copies of the documents filed with the SEC by Western will be available free of charge on Western’s website at www.wnr.com under the “Investor Relations” section or by contacting Western’s Investor Relations Department at (602) 286-1530. Copies of the documents filed with the SEC by NTI will be available free of charge on NTI’s website at www.northerntier.com under the “Investors” section or by contacting NTI’s Investor Relations Department at (651) 769-6700. Participants in Solicitation Relating to the Merger Western, NTI and certain of their respective directors and executive officers may be deemed to be participants in the solicitation of proxies from the unitholders of NTI in connection with the proposed transaction. Information about the directors and executive officers of Western is set forth in the Proxy Statement on Schedule 14A for Western’s 2015 annual meeting of shareholders, which was filed with the SEC on April 22, 2015. Information about the directors and executive officers of the general partner of NTI is set forth in the 2015 Annual Report on Form 10-K for NTI, which was filed with the SEC on February 26, 2016. These documents can be obtained free of charge from the sources indicated above. Other information regarding the participants in the proxy solicitation and a description of their direct and indirect interests, by security holdings or otherwise, will be contained in the proxy statement/prospectus and other relevant materials to be filed with the SEC when they become available.

Key Business Highlights Strategically-Located Refinery with Advantaged Access to Crude Oil Supplies and Attractive Refined Product Outlets Integrated Refining, Marketing, Retail, and Logistics Operations Flexible Refinery with Operational Redundancies Refinery Track Record of Safe Operations Low Leverage with Financial Flexibility Focused on Organic Growth Opportunities and Potential for Accretive Acquisitions Experienced, Proven and Incentivized Management Team

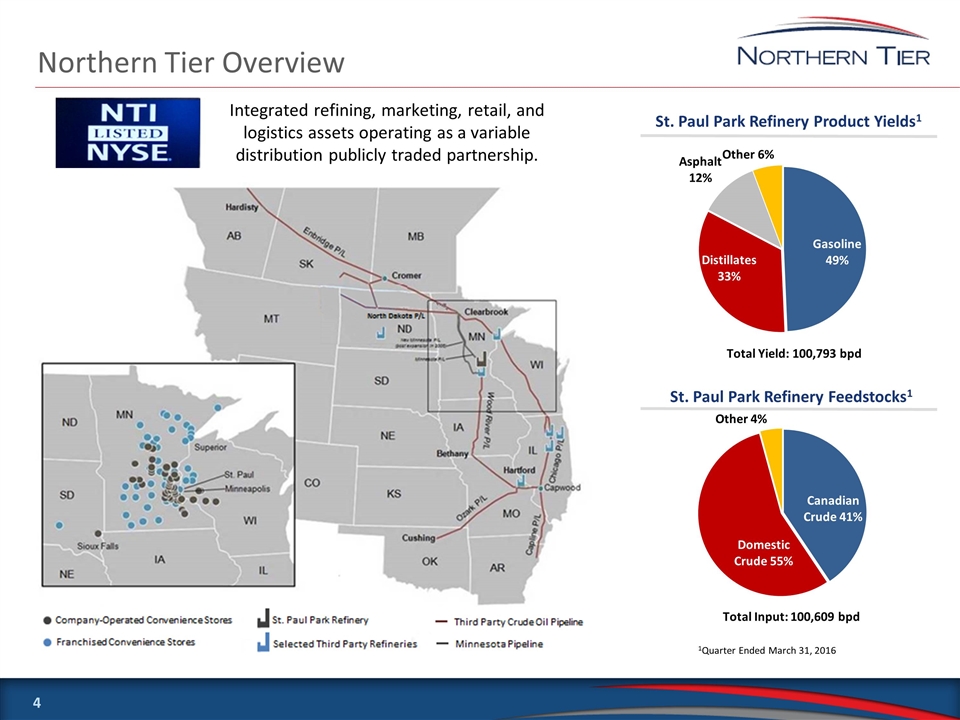

Gasoline 46% Northern Tier Overview Integrated refining, marketing, retail, and logistics assets operating as a variable distribution publicly traded partnership. St. Paul Park Refinery Product Yields1 St. Paul Park Refinery Feedstocks1 Total Input: 100,609 bpd Total Yield: 100,793 bpd 1Quarter Ended March 31, 2016

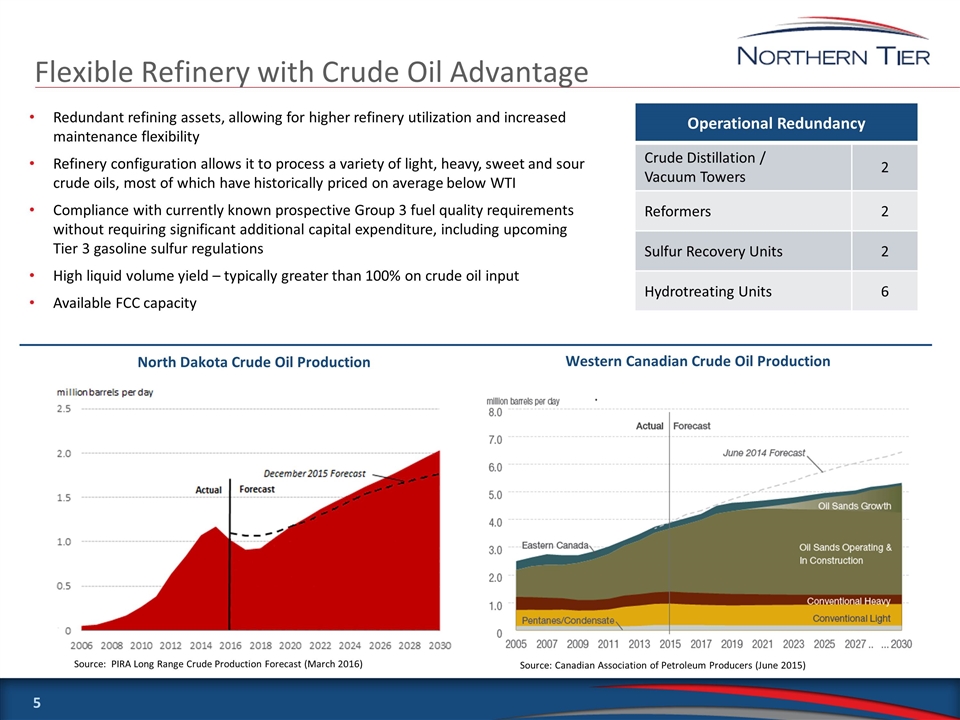

Redundant refining assets, allowing for higher refinery utilization and increased maintenance flexibility Refinery configuration allows it to process a variety of light, heavy, sweet and sour crude oils, most of which have historically priced on average below WTI Compliance with currently known prospective Group 3 fuel quality requirements without requiring significant additional capital expenditure, including upcoming Tier 3 gasoline sulfur regulations High liquid volume yield – typically greater than 100% on crude oil input Available FCC capacity Flexible Refinery with Crude Oil Advantage Operational Redundancy Crude Distillation / Vacuum Towers 2 Reformers 2 Sulfur Recovery Units 2 Hydrotreating Units 6 North Dakota Crude Oil Production Western Canadian Crude Oil Production Source: PIRA Long Range Crude Production Forecast (March 2016) Source: Canadian Association of Petroleum Producers (June 2015)

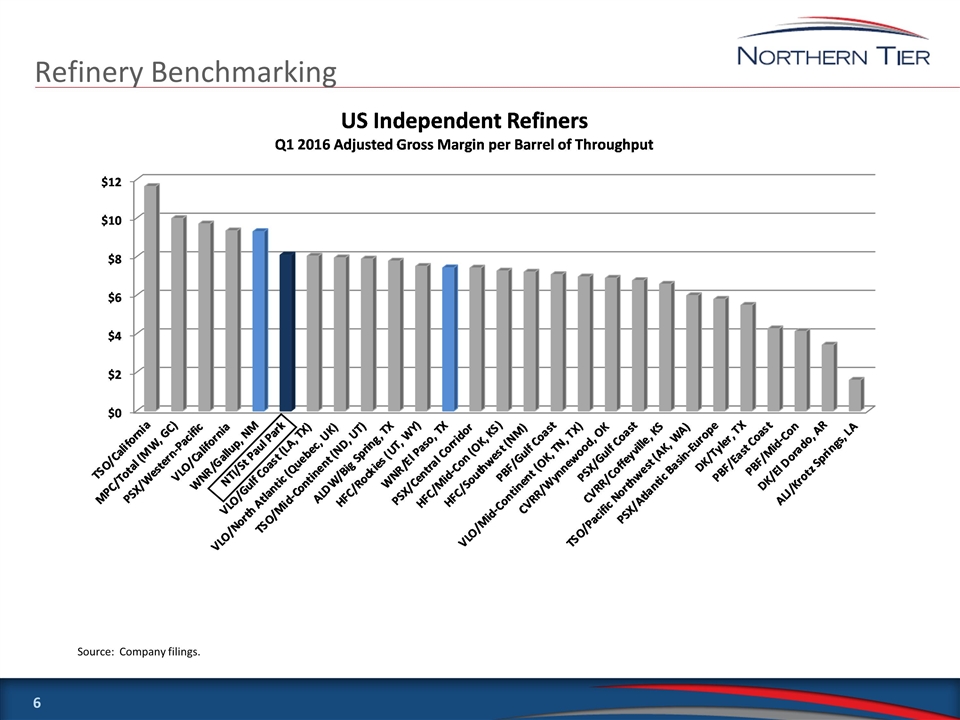

Refinery Benchmarking Source: Company filings.

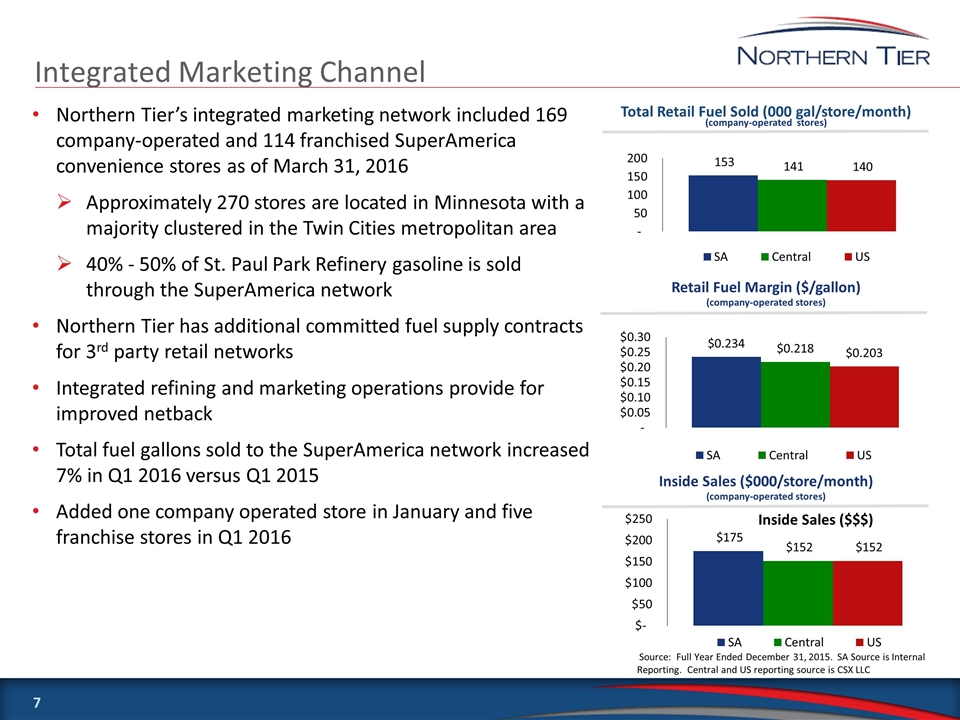

Integrated Marketing Channel Northern Tier’s integrated marketing network included 169 company-operated and 114 franchised SuperAmerica convenience stores as of March 31, 2016 Approximately 270 stores are located in Minnesota with a majority clustered in the Twin Cities metropolitan area 40% - 50% of St. Paul Park Refinery gasoline is sold through the SuperAmerica network Northern Tier has additional committed fuel supply contracts for 3rd party retail networks Integrated refining and marketing operations provide for improved netback Total fuel gallons sold to the SuperAmerica network increased 7% in Q1 2016 versus Q1 2015 Added one company operated store in January and five franchise stores in Q1 2016 Total Retail Fuel Sold (000 gal/store/month) (company-operated stores) Retail Fuel Margin ($/gallon) (company-operated stores) Inside Sales ($000/store/month) (company-operated stores) Source: Full Year Ended December 31, 2015. SA Source is Internal Reporting. Central and US reporting source is CSX LLC

Growth Strategy Organic Slate of high return projects (IRR in excess of 30%) which should improve yields of higher value light products, efficiency of operations, and/or crude oil slate flexibility: Projects underway intended to: replace the desalters to increase crude oil input flexibility No. 1 crude unit desalter commissioned in April 2016 No. 2 crude unit desalter expected to be complete in fall of 2016 modify the No. 2 crude unit and diesel hydrotreater to increase distillate yield and crude oil throughput capacity install a solvent deasphalting unit to utilize available FCC capacity Optimize first purchaser crude oil barrels in the Bakken with flexible utilization of crude oil transport fleet Grow the SuperAmerica brand by opening new stores and expanding franchise network Acquisitions Evaluate well-maintained refining assets with access to advantaged crude oil and attractive refined product dynamics Grow the SuperAmerica brand by acquiring existing retail assets

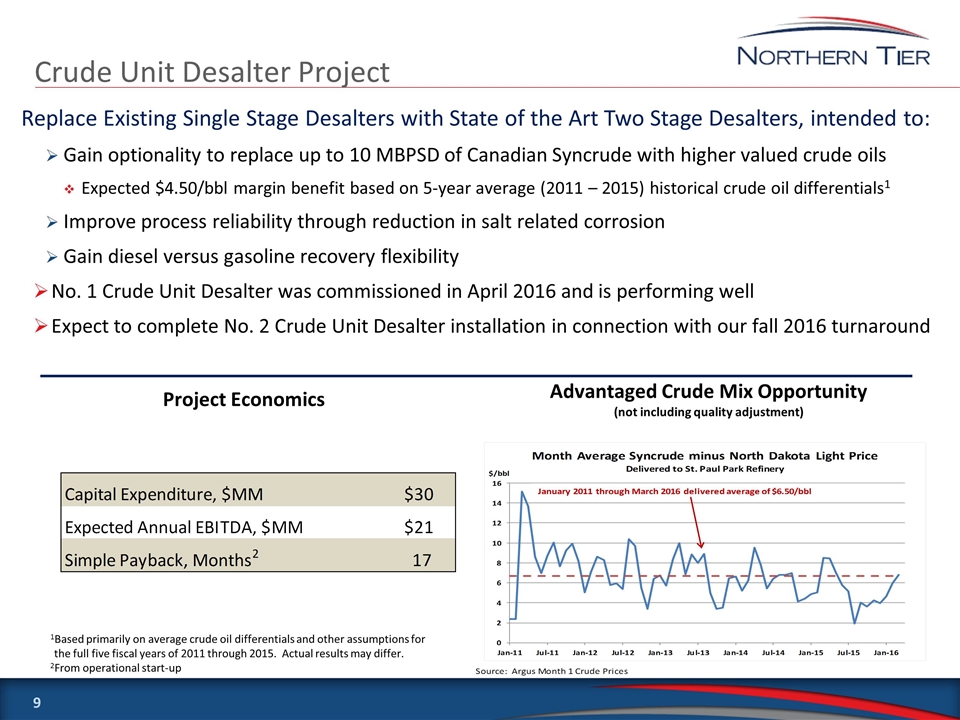

Crude Unit Desalter Project Replace Existing Single Stage Desalters with State of the Art Two Stage Desalters, intended to: Gain optionality to replace up to 10 MBPSD of Canadian Syncrude with higher valued crude oils Expected $4.50/bbl margin benefit based on 5-year average (2011 – 2015) historical crude oil differentials1 Improve process reliability through reduction in salt related corrosion Gain diesel versus gasoline recovery flexibility No. 1 Crude Unit Desalter was commissioned in April 2016 and is performing well Expect to complete No. 2 Crude Unit Desalter installation in connection with our fall 2016 turnaround Advantaged Crude Mix Opportunity (not including quality adjustment) Project Economics 1Based primarily on average crude oil differentials and other assumptions for the full five fiscal years of 2011 through 2015. Actual results may differ. 2From operational start-up

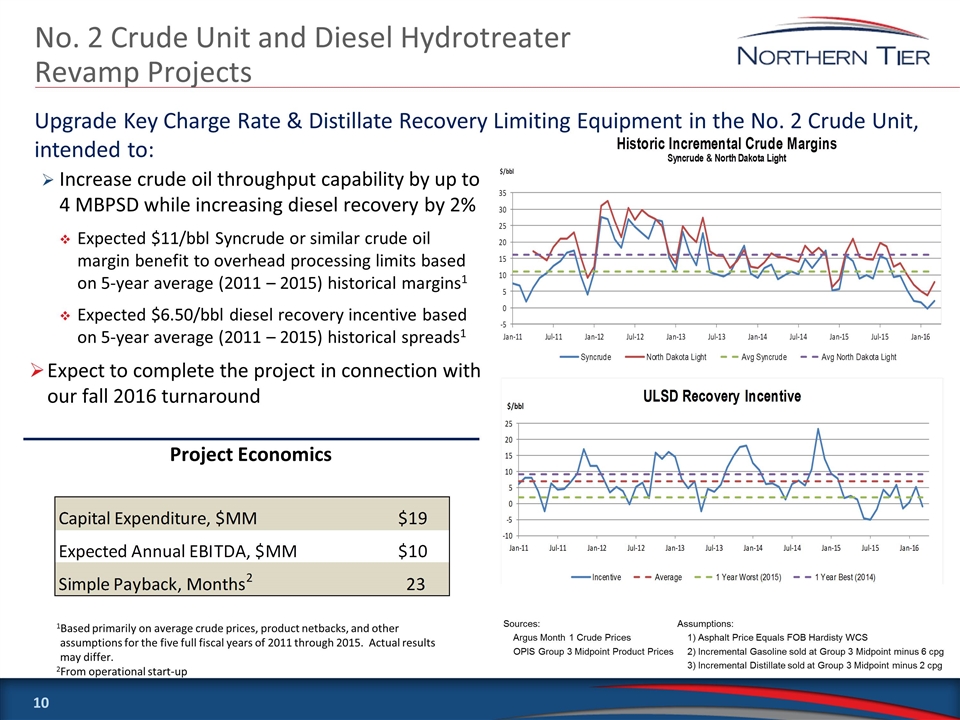

No. 2 Crude Unit and Diesel Hydrotreater Revamp Projects Increase crude oil throughput capability by up to 4 MBPSD while increasing diesel recovery by 2% Expected $11/bbl Syncrude or similar crude oil margin benefit to overhead processing limits based on 5-year average (2011 – 2015) historical margins1 Expected $6.50/bbl diesel recovery incentive based on 5-year average (2011 – 2015) historical spreads1 Expect to complete the project in connection with our fall 2016 turnaround Project Economics 1Based primarily on average crude prices, product netbacks, and other assumptions for the five full fiscal years of 2011 through 2015. Actual results may differ. 2From operational start-up Upgrade Key Charge Rate & Distillate Recovery Limiting Equipment in the No. 2 Crude Unit, intended to: Sources: Assumptions: Argus Month 1 Crude Prices 1) Asphalt Price Equals FOB Hardisty WCS OPIS Group 3 Midpoint Product Prices 2) Incremental Gasoline sold at Group 3 Midpoint minus 6 cpg 3) Incremental Distillate sold at Group 3 Midpoint minus 2 cpg

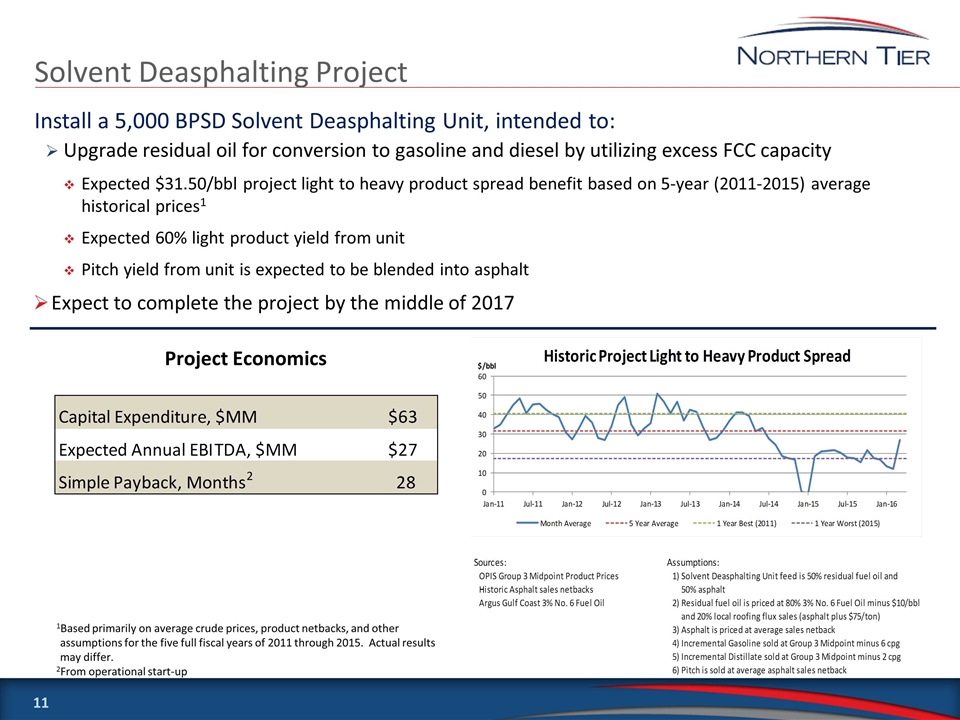

Solvent Deasphalting Project Upgrade residual oil for conversion to gasoline and diesel by utilizing excess FCC capacity Expected $31.50/bbl project light to heavy product spread benefit based on 5-year (2011-2015) average historical prices1 Expected 60% light product yield from unit Pitch yield from unit is expected to be blended into asphalt Expect to complete the project by the middle of 2017 Project Economics 1Based primarily on average crude prices, product netbacks, and other assumptions for the five full fiscal years of 2011 through 2015. Actual results may differ. 2From operational start-up Install a 5,000 BPSD Solvent Deasphalting Unit, intended to:

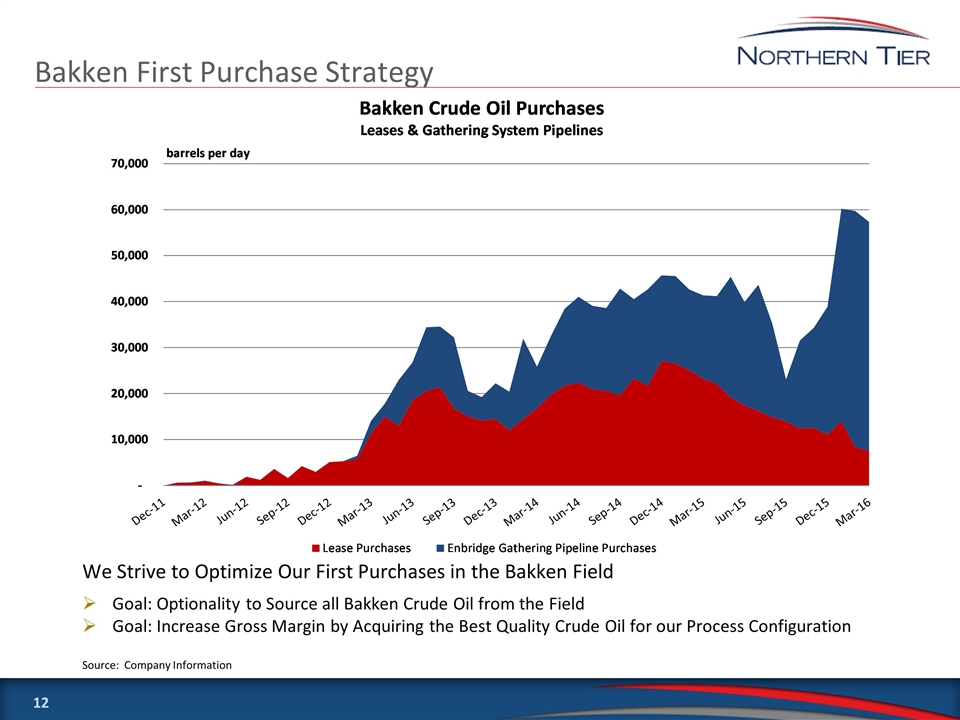

Bakken First Purchase Strategy Source: Company Information We Strive to Optimize Our First Purchases in the Bakken Field Goal: Optionality to Source all Bakken Crude Oil from the Field Goal: Increase Gross Margin by Acquiring the Best Quality Crude Oil for our Process Configuration

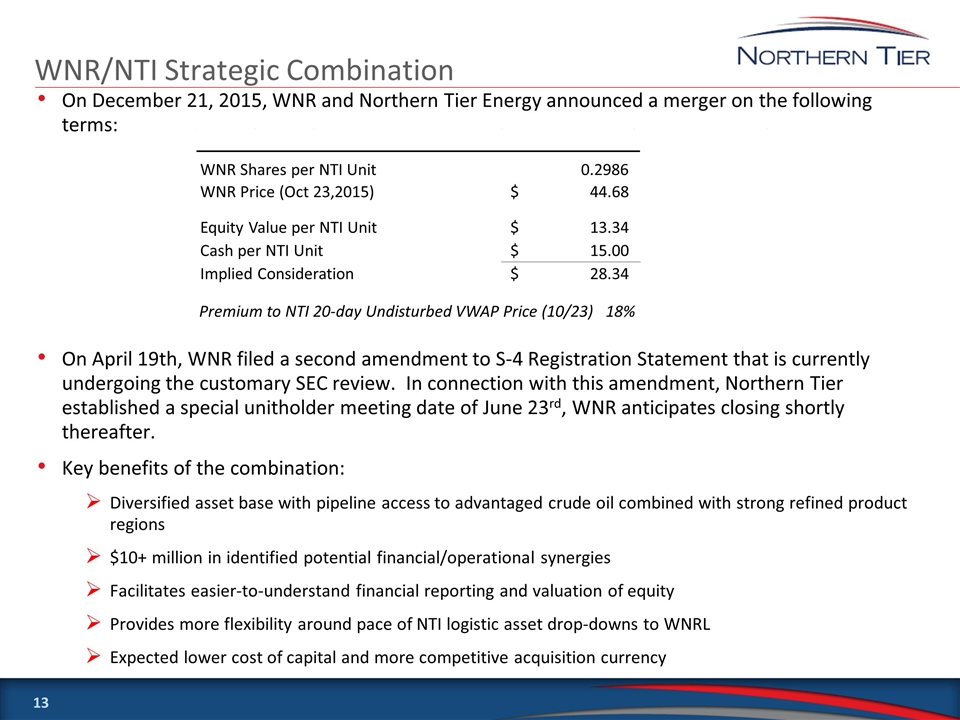

WNR/NTI Strategic Combination On December 21, 2015, WNR and Northern Tier Energy announced a merger on the following terms: On April 19th, WNR filed a second amendment to S-4 Registration Statement that is currently undergoing the customary SEC review. In connection with this amendment, Northern Tier established a special unitholder meeting date of June 23rd, WNR anticipates closing shortly thereafter. Key benefits of the combination: Diversified asset base with pipeline access to advantaged crude oil combined with strong refined product regions $10+ million in identified potential financial/operational synergies Facilitates easier-to-understand financial reporting and valuation of equity Provides more flexibility around pace of NTI logistic asset drop-downs to WNRL Expected lower cost of capital and more competitive acquisition currency WNR Shares per NTI Unit 0.2986 WNR Price (Oct 23,2015) 44.68 $ Equity Value per NTI Unit 13.34 $ Cash per NTI Unit 15.00 $ Implied Consideration 28.34 $ Premium to NTI 20-day Undisturbed VWAP Price (10/23) 18%

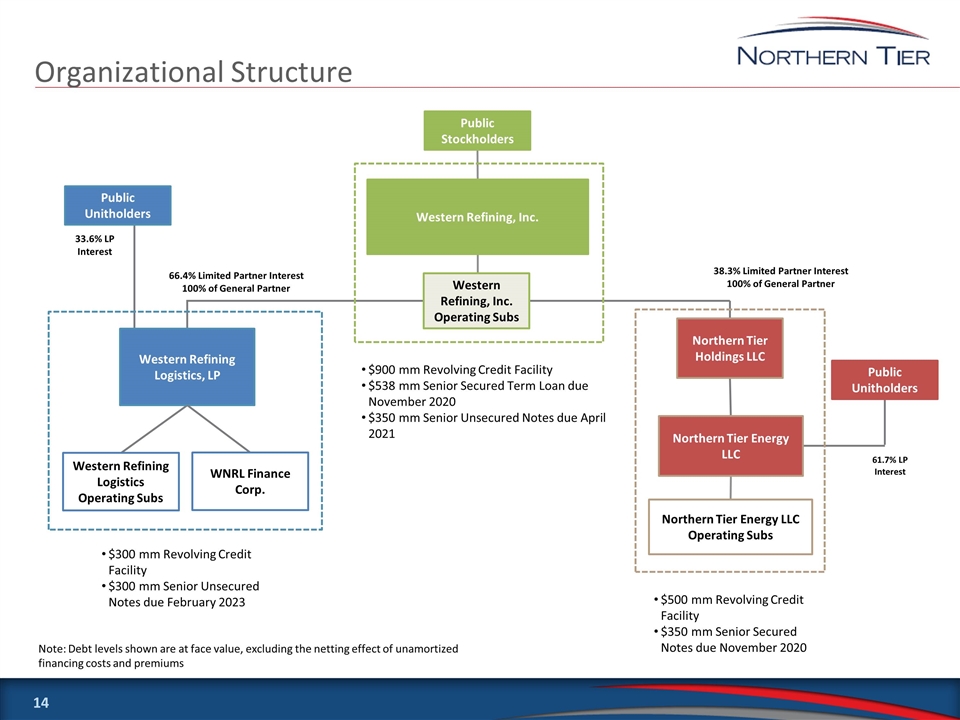

Organizational Structure $300 mm Revolving Credit Facility $300 mm Senior Unsecured Notes due February 2023 Northern Tier Energy LLC Northern Tier Energy LLC Operating Subs Western Refining Logistics Operating Subs Western Refining Logistics, LP $500 mm Revolving Credit Facility $350 mm Senior Secured Notes due November 2020 Western Refining, Inc. Western Refining, Inc. Operating Subs $900 mm Revolving Credit Facility $538 mm Senior Secured Term Loan due November 2020 $350 mm Senior Unsecured Notes due April 2021 Public Unitholders 38.3% Limited Partner Interest 100% of General Partner 66.4% Limited Partner Interest 100% of General Partner Public Unitholders Public Stockholders 33.6% LP Interest 61.7% LP Interest Northern Tier Holdings LLC WNRL Finance Corp. Note: Debt levels shown are at face value, excluding the netting effect of unamortized financing costs and premiums

Key Business Highlights Strategically-Located Refinery with Advantaged Access to Crude Oil Supplies and Attractive Refined Product Outlets Integrated Refining, Marketing, Retail, and Logistics Operations Flexible Refinery with Operational Redundancies Refinery Track Record of Safe Operations Low Leverage with Financial Flexibility Focused on Organic Growth Opportunities and Potential for Accretive Acquisitions Experienced, Proven and Incentivized Management Team

Appendix

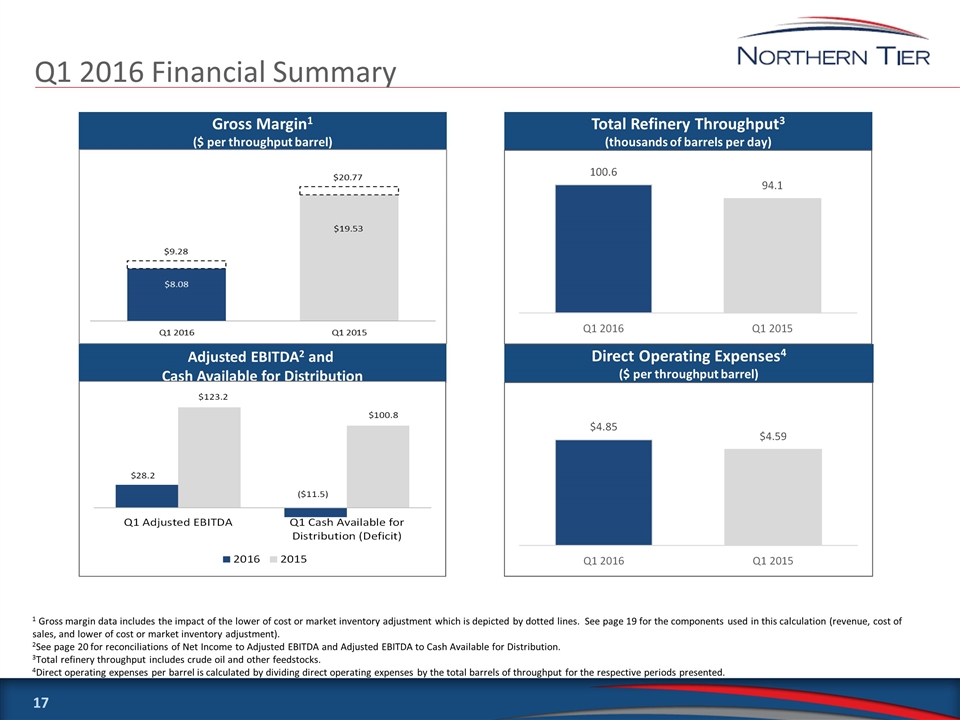

Q1 2016 Financial Summary 1 Gross margin data includes the impact of the lower of cost or market inventory adjustment which is depicted by dotted lines. See page 19 for the components used in this calculation (revenue, cost of sales, and lower of cost or market inventory adjustment). 2See page 20 for reconciliations of Net Income to Adjusted EBITDA and Adjusted EBITDA to Cash Available for Distribution. 3Total refinery throughput includes crude oil and other feedstocks. 4Direct operating expenses per barrel is calculated by dividing direct operating expenses by the total barrels of throughput for the respective periods presented. Gross Margin1 ($ per throughput barrel) Direct Operating Expenses4 ($ per throughput barrel) Total Refinery Throughput3 (thousands of barrels per day) Adjusted EBITDA2 and Cash Available for Distribution

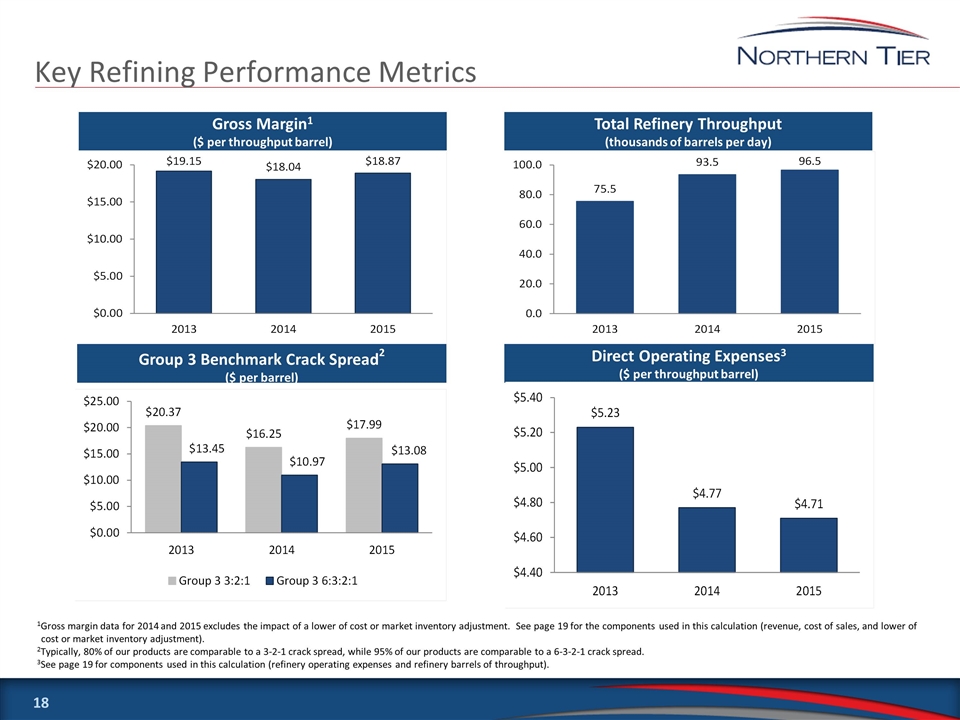

Key Refining Performance Metrics 1Gross margin data for 2014 and 2015 excludes the impact of a lower of cost or market inventory adjustment. See page 19 for the components used in this calculation (revenue, cost of sales, and lower of cost or market inventory adjustment). 2Typically, 80% of our products are comparable to a 3-2-1 crack spread, while 95% of our products are comparable to a 6-3-2-1 crack spread. 3See page 19 for components used in this calculation (refinery operating expenses and refinery barrels of throughput). Gross Margin1 ($ per throughput barrel) Group 3 Benchmark Crack Spread2 ($ per barrel) Direct Operating Expenses3 ($ per throughput barrel) Total Refinery Throughput (thousands of barrels per day)

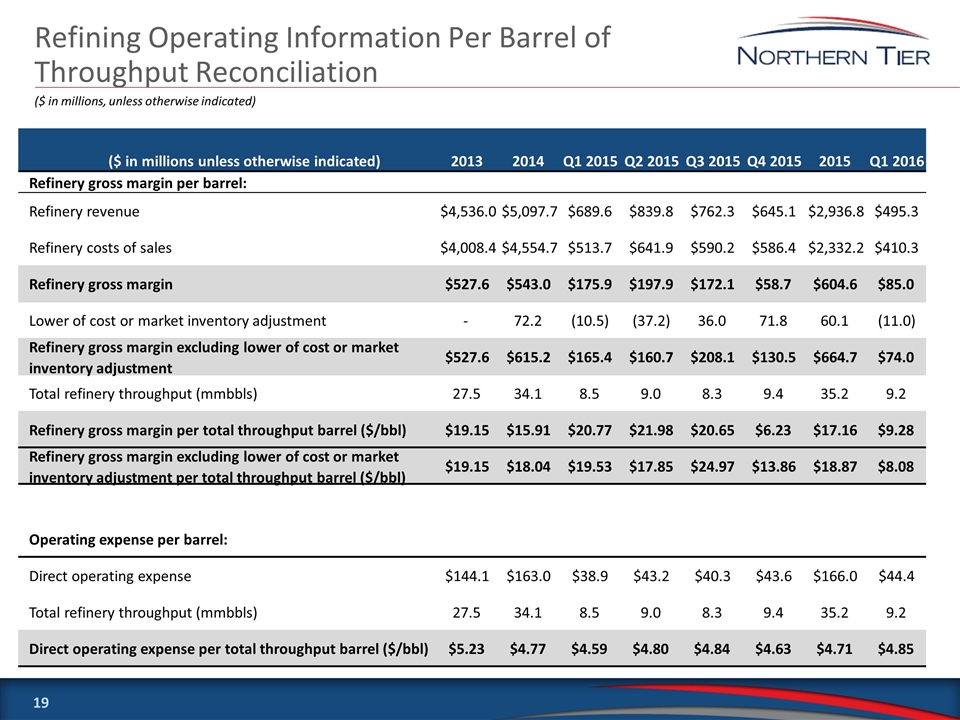

Refining Operating Information Per Barrel of Throughput Reconciliation ($ in millions, unless otherwise indicated) ($ in millions unless otherwise indicated) 2013 2014 Q1 2015 Q2 2015 Q3 2015 Q4 2015 2015 Q1 2016 Refinery gross margin per barrel: Refinery revenue $4,536.0 $5,097.7 $689.6 $839.8 $762.3 $645.1 $2,936.8 $495.3 Refinery costs of sales $4,008.4 $4,554.7 $513.7 $641.9 $590.2 $586.4 $2,332.2 $410.3 Refinery gross margin $527.6 $543.0 $175.9 $197.9 $172.1 $58.7 $604.6 $85.0 Lower of cost or market inventory adjustment - 72.2 (10.5) (37.2) 36.0 71.8 60.1 (11.0) Refinery gross margin excluding lower of cost or market inventory adjustment $527.6 $615.2 $165.4 $160.7 $208.1 $130.5 $664.7 $74.0 Total refinery throughput (mmbbls) 27.5 34.1 8.5 9.0 8.3 9.4 35.2 9.2 Refinery gross margin per total throughput barrel ($/bbl) $19.15 $15.91 $20.77 $21.98 $20.65 $6.23 $17.16 $9.28 Refinery gross margin excluding lower of cost or market inventory adjustment per total throughput barrel ($/bbl) $19.15 $18.04 $19.53 $17.85 $24.97 $13.86 $18.87 $8.08 Operating expense per barrel: Direct operating expense $144.1 $163.0 $38.9 $43.2 $40.3 $43.6 $166.0 $44.4 Total refinery throughput (mmbbls) 27.5 34.1 8.5 9.0 8.3 9.4 35.2 9.2 Direct operating expense per total throughput barrel ($/bbl) $5.23 $4.77 $4.59 $4.80 $4.84 $4.63 $4.71 $4.85

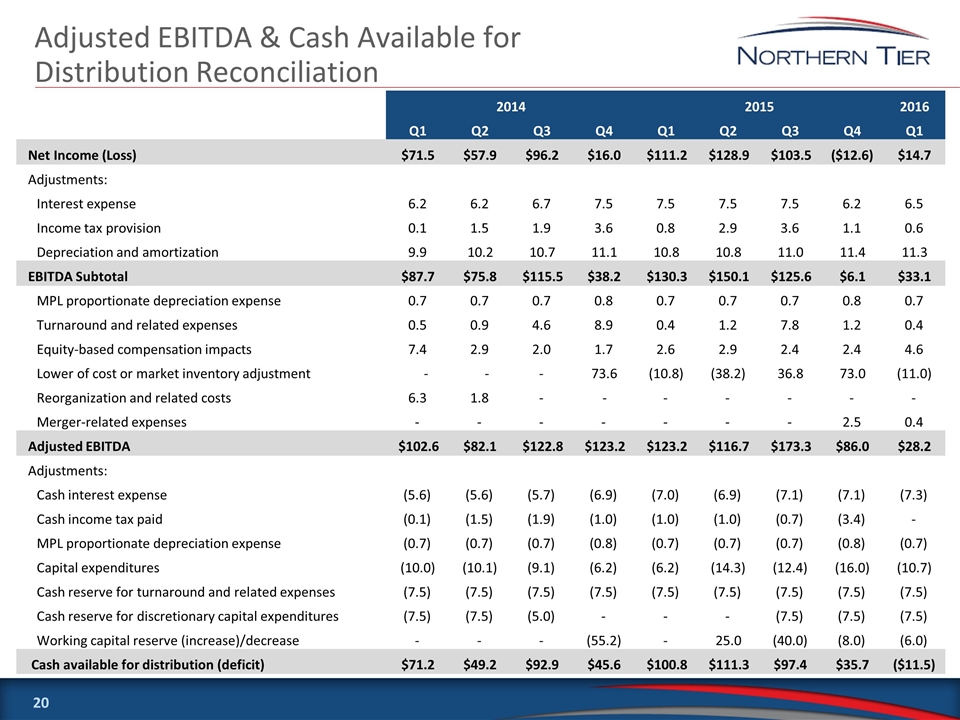

Adjusted EBITDA & Cash Available for Distribution Reconciliation 2016 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Net Income (Loss) $71.5 $57.9 $96.2 $16.0 $111.2 $128.9 $103.5 ($12.6) $14.7 Adjustments: Interest expense 6.2 6.2 6.7 7.5 7.5 7.5 7.5 6.2 6.5 Income tax provision 0.1 1.5 1.9 3.6 0.8 2.9 3.6 1.1 0.6 Depreciation and amortization 9.9 10.2 10.7 11.1 10.8 10.8 11.0 11.4 11.3 EBITDA Subtotal $87.7 $75.8 $115.5 $38.2 $130.3 $150.1 $125.6 $6.1 $33.1 MPL proportionate depreciation expense 0.7 0.7 0.7 0.8 0.7 0.7 0.7 0.8 0.7 Turnaround and related expenses 0.5 0.9 4.6 8.9 0.4 1.2 7.8 1.2 0.4 Equity-based compensation impacts 7.4 2.9 2.0 1.7 2.6 2.9 2.4 2.4 4.6 Lower of cost or market inventory adjustment - - - 73.6 (10.8) (38.2) 36.8 73.0 (11.0) Reorganization and related costs 6.3 1.8 - - - - - - - Merger-related expenses - - - - - - - 2.5 0.4 Adjusted EBITDA $102.6 $82.1 $122.8 $123.2 $123.2 $116.7 $173.3 $86.0 $28.2 Adjustments: Cash interest expense (5.6) (5.6) (5.7) (6.9) (7.0) (6.9) (7.1) (7.1) (7.3) Cash income tax paid (0.1) (1.5) (1.9) (1.0) (1.0) (1.0) (0.7) (3.4) - MPL proportionate depreciation expense (0.7) (0.7) (0.7) (0.8) (0.7) (0.7) (0.7) (0.8) (0.7) Capital expenditures (10.0) (10.1) (9.1) (6.2) (6.2) (14.3) (12.4) (16.0) (10.7) Cash reserve for turnaround and related expenses (7.5) (7.5) (7.5) (7.5) (7.5) (7.5) (7.5) (7.5) (7.5) Cash reserve for discretionary capital expenditures (7.5) (7.5) (5.0) - - - (7.5) (7.5) (7.5) Working capital reserve (increase)/decrease - - - (55.2) - 25.0 (40.0) (8.0) (6.0) Cash available for distribution (deficit) $71.2 $49.2 $92.9 $45.6 $100.8 $111.3 $97.4 $35.7 ($11.5) 2014 2015

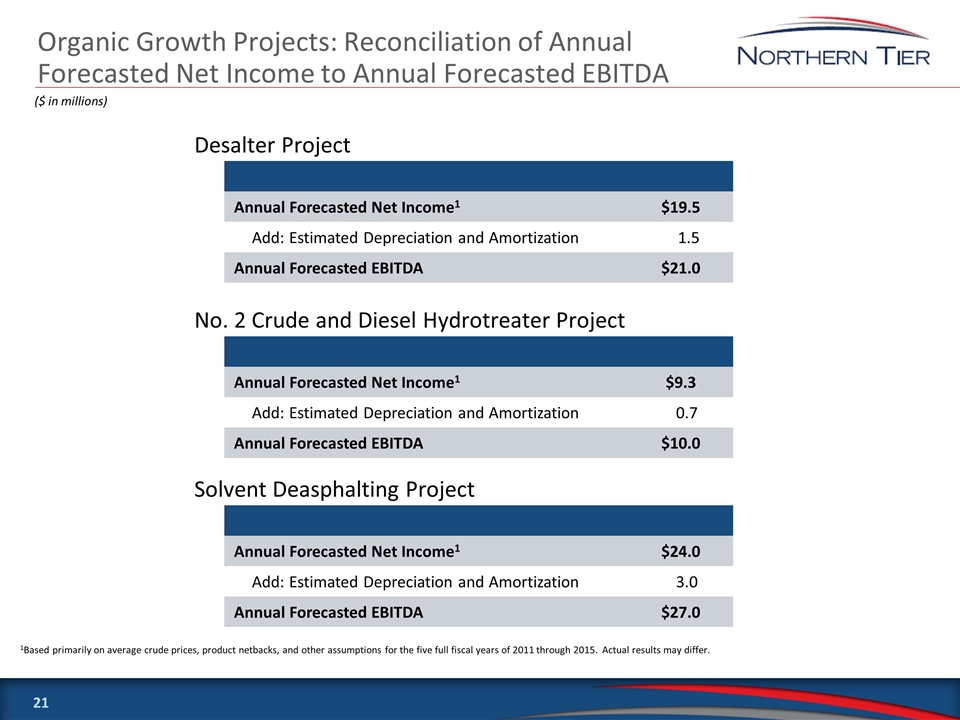

Organic Growth Projects: Reconciliation of Annual Forecasted Net Income to Annual Forecasted EBITDA Annual Forecasted Net Income1 $24.0 Add: Estimated Depreciation and Amortization 3.0 Annual Forecasted EBITDA $27.0 ($ in millions) 1Based primarily on average crude prices, product netbacks, and other assumptions for the five full fiscal years of 2011 through 2015. Actual results may differ. Annual Forecasted Net Income1 $9.3 Add: Estimated Depreciation and Amortization 0.7 Annual Forecasted EBITDA $10.0 Annual Forecasted Net Income1 $19.5 Add: Estimated Depreciation and Amortization 1.5 Annual Forecasted EBITDA $21.0 Desalter Project No. 2 Crude and Diesel Hydrotreater Project Solvent Deasphalting Project

Non-GAAP Measures This presentation includes Non-GAAP financial and performance measures, including: EBITDA and Adjusted EBITDA Adjusted EBITDA is defined as net income (loss) before interest expense, income taxes and depreciation and amortization, adjusted for depreciation from the Minnesota Pipe Line operations, lower of cost or market inventory adjustments, turnaround and related expenses, equity-based compensation expense, and merger-related expenses. Adjusted EBITDA is not a presentation made in accordance with GAAP and our computation of Adjusted EBITDA may vary from others in our industry. In addition, Adjusted EBITDA contains some, but not all, adjustments that are taken into account in calculating the components of various covenants in the agreements governing our 2020 Secured Notes and the ABL Facility. We believe the presentation of Adjusted EBITDA is useful to investors because it is frequently used by securities analysts, investors and other interested parties in the evaluation of companies in our industry. The calculation of Adjusted EBITDA generally eliminates the effects of financings, income taxes and the accounting effects of significant turnaround activities which many of our peers capitalize and therefore exclude from Adjusted EBITDA. Adjusted EBITDA should not be considered as an alternative to operating income or net income as measures of operating performance. In addition, Adjusted EBITDA is not presented as, and should not be considered, an alternative to cash flow from operations as a measure of liquidity. Adjusted EBITDA has limitations as an analytical tool and should not be considered in isolation, or as a substitute for analysis of the results as reported under GAAP. Cash Available for Distribution Cash available for distribution is a non-GAAP performance measure that we believe is important to investors in evaluating our overall cash generation performance. Cash available for distribution should not be considered as an alternative to operating income or net income as measures of operating performance. In addition, cash available for distribution is not presented as, and should not be considered, an alternative to cash flow from operations as a measure of liquidity. As shown in the tables in this Appendix, we have reconciled cash available for distribution to Adjusted EBITDA and in addition reconciled Adjusted EBITDA to net income. Cash available for distribution has limitations as an analytical tool and should not be considered in isolation, or as a substitute for analysis of the results as reported under GAAP. Our calculation of cash available for distribution may differ from similar calculations of other companies in our industry, thereby limiting its usefulness as a comparative measure. Cash available for distribution for each quarter will be determined by the board of directors of our general partner following the end of such quarter. Refining Gross Margin Refining gross margin is calculated by subtracting refining costs of sales from total refining revenues. Refining gross margin excluding lower of cost or market (“LCM”) inventory adjustment is calculated by adding back the non-cash LCM inventory adjustment to refining gross margin. Refining gross margin and refining gross margin excluding LCM are non-GAAP measures that we believe are important to investors in evaluating our refining segment performance as a general indication of the amount above its cost of products that is able to sell refined products. NTI’s calculation of refining gross margin and refining gross margin excluding LCM may differ from similar calculations by other companies in our industry, thereby limiting its usefulness as a comparative measure.