Exhibit 99.12

Global Mineral Resource Services #603 – 131 East Third Street North Vancouver Canada V7L 0E3 — T 1 778 882 3761 E greg.mosher@gmrs.rocks W gmrs.rocks | |

Technical Report

Almaden Gold Property

GoldMining Inc.

Washington County, Idaho, USA

In accordance with the requirements of National Instrument 43-101 “Standards of Disclosure for Mineral Projects” of the Canadian Securities Administrators

Qualified Persons:

G. Mosher, P.Geo., M.Sc. Applied

GMRS Project 02-02-2020

Effective Date: 01 April 2020

Serving the mining industry

GoldMining Inc. (GMI) has acquired the Almaden gold property (Almaden or Property) in southwestern Idaho, USA, and has retained Global Mineral Resource Services (GMRS) to prepare an independent technical report documenting, amongst other items, an updated resource estimate for the Property compliant with National Instrument 43-101. This report is to support the resource estimate announced in the news release dated June 3, 2020 and for public disclosure of information on the Project as a result of its acquisition from Sailfish Royalty Corp. on March 3, 2020.

Almaden is a low-sulphidation epithermal gold deposit that was initially identified as a mercury deposit in 1936 and was exploited for mercury between 1939 and 1972. The Property was subsequently explored for its gold content starting in 1980 and in addition to geological mapping, geochemical and geophysical surveying, and several metallurgical bulk samples, the Property has been tested over a period of 32 years by 934 drillholes with an aggregate length of over 70,000 m.

The Property is located in Washington County, southwestern Idaho, approximately 20 kilometers (km) east of Weiser, the county seat of Washington County, and 120 km northwest of Boise, the state capital. The center of the Property is at approximately 116° 42.8’W longitude and 44° 14.3’N latitude and the Property extends along the crest and western slopes of Nutmeg Mountain.

The Property is approximately 1,724 hectares in area and is comprised of 210 federal unpatented lode mining claims, 12 patented claims, and 2 leases of private land. The claims and leases are located in Sections 28, 29, 32, and 33, T 11 N, R 3 W, and Sections 4 and 5, T 10 N, R 3 W, Boise Base and Meridian.

Exploration programs have been completed by several operators during the period 1980 to 2012 with drill programs summarized in Table 1.1.

Table 1.1 identifies the operators, their years of activity and the type of drilling they carried out on the Property.

Table 1.1 Almaden Historical Drilling by Year

Company | Year | Rotary | Reverse Circulation | Core | Total Meters |

Homestake | 1980-1981 | | 36 | 6 | 2,448 |

Freeport | 1983 | | | | 1,495 |

Ican Resources | 1985-1986 | 510 | | | 27,866 |

Western States | 1986 | | 3 | | 274 |

Hycroft | 1987 | | 42 | | 1,940 |

Ican Resources | 1988 | | | 10 | 667 |

Amax | 1991-1993 | | 58 | 10 | 7,124 |

Ican Resources | 1993-1994 | | 51 | 5 | 3,499 |

Amax | 1996-1997 | | | 10 | 538 |

Freegold | 2006-2007 | | 103 | 42 | 16,150 |

Terraco | 2011 | | | 16 | 5,492 |

Terraco | 2012 | | | 32 | 2,761 |

Total | | 510 | 293 | 131 | 70,254 |

The drill programs have delineated four tabular zones of epithermal gold mineralization: Main, North, Stinking Water and Cove Creek Zones. The Main Zone is constrained within a graben. North Zone mineralization was deposited on the eastern flank of the graben, approximately 600 m north of the Main Zone. The Stinking Water Zone is located 600 m west of the North Zone and is interpreted to be a slumped landslide portion of that zone. The Cove Creek Zone is located approximately 600 m south of the Main Zone and is inferred to be a slumped landslide continuation of the Main Zone.

The characteristics of gold-mercury mineralization at Almaden are consistent with a low-sulfidation, epithermal, hot spring deposit type. Almaden mineralization is similar to occurrences and deposits of gold, silver, and mercury elsewhere in Nevada, Oregon, and Idaho, although Almaden is unusual for this deposit type because of the elevated presence of molybdenum.

The Property is underlain, from oldest to youngest, by Miocene-age basalt, Payette Formation sandstone and siltstone, and lacustrine sedimentary rocks of the Pliocene-age Idaho Group, all of which are exposed in an erosional window through the Weiser Basalt.

Most gold mineralization that has been identified within the Property to date occurs within a north-trending graben and most of the drilling has been concentrated within and peripheral to that graben. The graben is bounded on the east by the Main Fault and on the west by the B Fault and sedimentary units change in thickness and character across the bounding faults. Mineralization is associated with multi-phase hydrothermal brecciation and veining, strong silicification, acid alteration, and faulting. Much of the surface alteration is composed primarily of opaline silica and appears to be replacement of Payette Formation siltstone and sandstone. Mercury was introduced late in the hydrothermal events that deposited the gold.

There are four principal zones of mineralization. As the name implies, the Main Zone is the most significant in size and contained quantity of gold. Gold mineralization is hosted primarily in silicified Payette Formation sandstone that has been subjected to multiple phases of hydrothermal alteration, brecciation, and veining. Main Zone mineralization occurs over a north-south distance of approximately 1,200 m a width from 250 to 500 m, and a vertical thickness of up to 180 m, although most mineralization occurs within 60 m of surface. The North Zone underlies the narrow ridge crest at the north end of Nutmeg Mountain, approximately 600 meters northeast of the Main Zone. In the North Zone, gold occurs as an oval, north-trending, tabular body that is less than 60 m thick, approximately 335 m long (N-S) and 150 m wide. The Stinking Water Zone lies approximately 400 m west of the North Zone and 600 m north of the Main Zone (Figure 7.4). At Stinking Water, a large, tabular, northeast-trending oval shaped, highly-fractured slump block is covered by a veneer of silicified and veined boulders derived from the North Zone. Mineralization in the Stinking Water Zone is up to 60 m thick. The Cove Creek area is located 600 m southeast of, and approximately 170 m lower than, the Main Zone. Here, gold mineralization occurs in a nearly horizontal zone with a sharp upper contact and in association with oxidized opal, chalcedony, and quartz vein stockworks that are hosted by silicified, pyritized arkosic sandstone and chalcedonic sinter. The Cove Creek Zone has little to no surface expression.

Numerous metallurgical tests have been conducted on mineralization from the Property; most tests were designed with the expectation that gold would be recovered by heap leach processing.

This report contains a mineral resource estimate that was carried out using the assay data from the drill programs that were conducted between 1981 and 2012. The estimate was done by ordinary kriging on blocks that measured 20 feet east-west, 30 feet north-south and 10 feet vertically. The resultant block model was then constrained by a conceptual pit because most of the deposit occurs at and near surface. Base case for the estimate is taken at a cutoff grade of 0.3 grams / tonne gold. At that cutoff, the deposit is estimated to contain an Indicated resource of 43,470,000 tonnes with an average grade of 0.65 grams / tonne for 910,000 contained ounces of gold, and an Inferred resource of 9,150,000 tonnes with an average grade of 0.56 grams / tonne for 160,000 contained ounces.

GMRS concludes that technical risks with respect to the mineral resource estimate may include underestimation of gold grades because of loss of gold in faults and fractures. Equally however, those same faults and fractures may be sufficiently abundant that they could exert a negative effect on the estimated volume of rock, thereby leading to an overestimation of the tonnage of mineralized rock present. The economic viability of the deposit may be affected by metal recoveries. There are no known risk factors that may affect access, title, or the right or ability to perform work on the Property.

In summary, the Almaden low-sulphidation epithermal deposit, which includes the Main, North, Stinking Water and Cove Creek Zones. GMRS is of the opinion, that the Almaden Property has enough merit to warrant further exploration expenditures and sufficiently advanced to undertake a Preliminary Economic Assessment (PEA). The deposit has been tested by relatively shallow drilling (average drill hole length of 75 m) with many of these holes ending in mineralization. Additionally, most of the drill holes were drilled vertically, which would not adequately test for high-angle or vertical fractures and faults that could potentially host high-grade feeder veins.

GMRS is recommending an exploration program to better define the outside limits of mineralization as well as to test for high-grade feeder veins that could potentially underlie the flat-lying mineralization outlined to date. A comprehensive metallurgical program that builds on the studies completed to date should be undertaken to determine the optimal processing method. This work along with an updated resource estimate incorporating the above drill results should then be incorporated into a scoping level PEA to determine if the project should be advanced further through a pre-feasibility and feasibility studies.

GMRS recommends a Two-Phase Program to advance the Almaden Project. The Phase One Program will consist of geophysics, alteration mapping and diamond drilling to define the limits of mineralization and to identify high-grade feeder-style mineralization that could potentially underly existing lower-grade near surface mineralization. The Phase One program is estimated to cost approximately C$2,060,290.

The Phase Two Program will consist of various metallurgical studies, modelling of ore types and oxidation states to complete an updated resource estimate and a Preliminary Economic Assessment (PEA). The Phase Two Program is estimated to cost approximately C$1,909,000.

The above programs are independent of each other and results from the Phase One Program do not affect the decision on whether to proceed with the Phase Two Program. However, results from the Phase One program could determine some of the input parameters for the Preliminary Economic Assessment.

Contents

1 | Summary | 2 |

| | | |

2 | Introduction | 9 |

| | | |

3 | Reliance on Other Experts | 10 |

| | | |

4 | Property Description and Location | 11 |

| | 4.1 | Property Location | 11 |

| | 4.2 | Property Description | 11 |

| | 4.3 | Royalties Payable | 12 |

| | 4.4 | Environmental Liabilities | 13 |

| | 4.5 | Permits | 13 |

| | 4.6 | Risk Factors | 13 |

| | | |

5 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 14 |

| | | |

6 | History | 15 |

| | 6.1 | Geological Programs | 15 |

| | 6.2 | Geochemical Programs | 18 |

| | 6.3 | Geophysical Programs | 19 |

| | 6.4 | Historical Resource Estimates | 19 |

| | 6.5 | Historical Engineering Studies | 21 |

| | 6.6 | Production from the Property | 21 |

| | 6.7 | Current Status of the Property | 21 |

| | | |

7 | Geological Setting and Mineralization | 22 |

| | 7.1 | Regional Geology | 22 |

| | 7.3 | Property Geology | 24 |

| | | 7.3.1 | Stratigraphy | 24 |

| | | 7.3.2 | Structure | 26 |

| | | 7.3.3 | Alteration | 28 |

| | | 7.3.4 | Mineralization | 28 |

| | | |

8 | Deposit Types | 31 |

| | | |

9 | Exploration | 33 |

| | | |

10 | Drilling | 34 |

| | | |

11 | Sample Preparation, Analyses and Security | 38 |

| | 11.1 | Sampling Methods | 38 |

| | | 11.1.1 | Reverse Circulation and Rotary | 38 |

| | | 11.1.2 | Core Drilling | 38 |

| | | 11.1.3 | Bulk Sampling | 39 |

| | 11.2 | Sample Preparation, Analysis and Security | 39 |

| | 11.3 | Quality Control/Quality Assurance (“QA/QC”) | 41 |

| | | 11.3.1 | Check Assays | 41 |

| | | 11.3.2 | Standards and Blanks | 42 |

| | | |

12 | Data Verification | 44 |

| | | |

13 | Mineral Processing and Metallurgical Testing | 45 |

14 | Mineral Resource Estimates | 49 |

| | 14.1 | Introduction | 49 |

| | 14.2 | Capping | 49 |

| | 14.3 | Composites | 49 |

| | 14.4 | Bulk Density | 49 |

| | 14.5 | Geological Interpretation | 50 |

| | 14.6 | Analysis of Spatial Continuity | 52 |

| | 14.7 | Block Model | 53 |

| | 14.8 | Interpolation Plan | 53 |

| | 14.9 | Reasonable Prospects of Eventual Economic Extraction | 53 |

| | 14.10 | Mineral Resource Classification | 55 |

| | 14.11 | Mineral Resource Tabulation | 56 |

| | 14.12 | Block Model Validation | 56 |

| | 14.13 | Comparison With Previous Estimates | 58 |

| | | |

15 | Mineral Reserve Estimates | 59 |

| | | |

16 | Mining Methods | 60 |

| | | |

17 | Recovery Methods | 61 |

| | | |

18 | Project Infrastructure | 62 |

| | | |

19 | Market Studies and Contracts | 63 |

| | | |

20 | Environmental Studies, Permitting and Social or Community Impact | 64 |

| | | |

21 | Capital and Operating Costs | 65 |

| | | |

22 | Economic Analysis | 66 |

| | | |

23 | Adjacent Properties | 67 |

| | | |

24 | Other Relevant Data and Information | 68 |

| | | |

25 | Interpretation and Conclusions | 69 |

| | | |

26 | Recommendations | 71 |

| | 26.1 | Phase One Program – Drill Program to identify potential high-grade feeder mineralization | 71 |

| | 26.2 | Phase Two Program – Metallurgical Study and Preliminary Economic Assessment | 72 |

| | | |

27 | References | 73 |

| | | |

28 | Date and Signature Page | 74 |

| | | |

29 | Certificate of Qualified Person | 75 |

| | | |

30 | Appendix 1 Property Status | 77 |

| | | |

31 | Appendix 2 Almaden Drillhole Locations | 82 |

Tables

Table 1.1 | Almaden Historical Drilling by Year | 2 |

Table 6.1 | Almaden Historical Drilling by Year | 17 |

Table 6.2 | Almaden Historical Mineral Resource Estimates1 | 20 |

Table 10.1 | Almaden Drilling by Operator | 34 |

Table 10.2 | Almaden Gold Assay Descriptive Statistics | 36 |

Table 10.3 | Almaden Drill Samples by Operator and Drilling Method | 36 |

Table 11.1 | Freegold Standard Reference Material Specifications | 42 |

Table 11.2 | Terraco Standard Reference Material Specifications | 42 |

Table 12.1 | Almaden Check Assays | 44 |

Table 13.1 | Almaden Mineral Processing and Metallurgical Testing | 45 |

Table 14.1 | Almaden Lithological Units and Average Gold Content | 50 |

Table 14.2 | Almaden Variogram Parameters | 52 |

Table 14.3 | Almaden Search Ellipse | 52 |

Table 14.4 | Almaden Block Model Parameters | 53 |

Table 14.5 | Almaden Conceptual Pit Parameters | 54 |

Table 14.6 | Almaden Mineral Resource Estimate Classification Criteria | 55 |

Table 14.7 | Almaden Mineral Resource Estimate at 0.3 g/t Au Cutoff | 56 |

Table 14.8 | Almaden Current Resource Estimate Compared to MDA 2009 Estimate | 58 |

Table 26.1 | Phase One Program – Drill Budget to Identify Potential High-grade Feeder Mineralization | 71 |

Table 26.2 | Phase Two Program – Metallurgical Study and Preliminary Economic Study | 72 |

Table 30.1 | Almaden Property Land Status Summary | 78 |

Table 30.2 | Almaden Unpatented Claims | 78 |

Figures

Figure 4.1 | Almaden Property Location | 11 |

Figure 4.2 | Almaden Property Claim Map | 12 |

Figure 6.1 | Almaden Soil Sampling Grid and Gold Anomalies | 18 |

Figure 6.2 | Almaden Property IP Resistivity Map | 19 |

Figure 7.1 | Almaden Property Location and Geological Provinces, Idaho | 23 |

Figure 7.2 | Almaden Property Location: Western Snake River Plain | 24 |

Figure 7.3 | Almaden Schematic Cross-Section | 25 |

Figure 7.4 | Almaden Faults and Grade-Thickness Gold Accumulations | 27 |

Figure 7.5 | Almaden Principal Zones of Gold Mineralization | 29 |

Figure 10.1 | Almaden Property Drillhole Plan by Type | 35 |

Figure 10.2 | Almaden Gold Assay Population By Operator and Drill Technique | 37 |

Figure 11.1 | Terraco Standard Reference Material Assays | 43 |

Figure 14.1 | Almaden Cumulative Probability Plot for Gold Assays (oz/st) | 49 |

Figure 14.2 | Almaden Gradeshell 0.001 Ounces per Short Ton | 51 |

Figure 14.3 | Almaden Variogram | 52 |

Figure 14.4 | Almaden Block Model | 54 |

Figure 14.5 | Almaden Mineral Resource by Classification | 55 |

Figure 14.6 | Almaden Swath Plots | 57 |

GoldMining Inc. (GMI) has acquired the Almaden gold property (Almaden or Property) in southern Idaho, USA, and has retained Global Mineral Resource Services (GMRS) to prepare a technical report, compliant with National Instrument 43-101. This report is to support the resource estimate announced in the news release dated June 3, 2020 and for public disclosure of information on the Project as a result of its acquisition from Sailfish Royalty Corp. on March 3, 2020.

Almaden is a low-sulphidation epithermal gold deposit that was initially identified as a mercury deposit in 1936 and was exploited for mercury between 1939 and 1972. The Property was explored for its gold content starting in 1979 and in addition to geological mapping, geochemical and geophysical surveying, and several metallurgical bulk samples, the Property has been tested by 934 drillholes, with an aggregate length of approximately 70,000 meters.

In addition to a description of the deposit and its history of exploration, this report contains a mineral resource estimate of the gold content based upon data obtained from those drill campaigns. Information and data used in the preparation of this report were obtained from GMI and include drillhole collar locations, downhole survey data, assays and lithological descriptions as well as various supporting data. Additional information about regional geology was obtained from public domain sources. The data used is listed in Section 27 References, and where appropriate, within the report.

The author of this technical report inspected the Property on February 24, 2020 and February 25, 2020 for a period of 1.5 days.

3 | Reliance on Other Experts |

GMRS has relied upon GMI for the legal description of the Property as well as terms of acquisition and the permits and other obligations that must be obtained or fulfilled in order for GMI to retain the Property and conduct any planned activities on the Property. As well, GMRS has relied upon GMI with respect to the identification and description of political, environmental and other risks with respect to the Property. GMRS is not qualified to and has not verified the data referenced above. All information was obtained from Mr. Garnet Dawson, CEO of GMI.

4 | Property Description and Location |

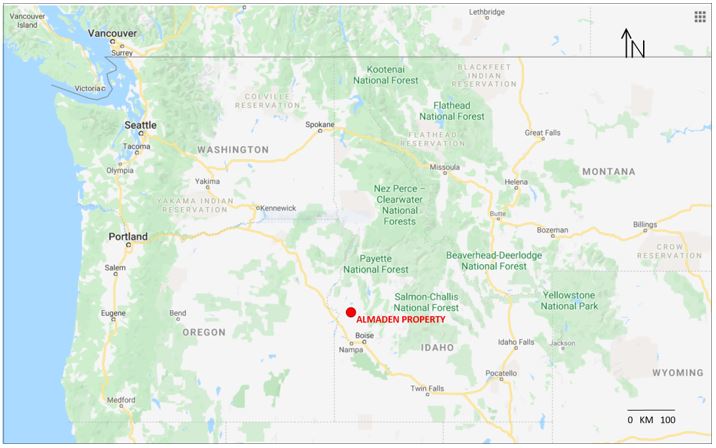

The Property is located in Washington County, southwestern Idaho, approximately 20 km east of Weiser, the county seat of Washington County, and 120 km northwest of Boise, the state capital, (Figure 4.1). The center of the Property is at approximately 116° 42.8’W longitude and 44° 14.3’N latitude and the Property extends along the crest and western slopes of Nutmeg Mountain.

Figure 4.1 Almaden Property Location

Source: GMRS 2020

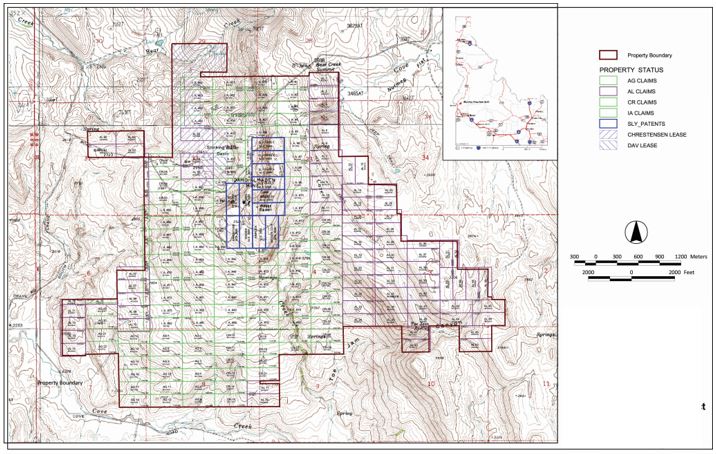

The Property is approximately 1,724 hectares in area and is comprised of 210 federal unpatented lode mining claims, 12 patented claims, and 2 leases of private land (Figure 4.2). Twelve patented claims are leased from Dean and Harold Davies and others and are approximately 97 ha in area (240 acres) in area (Dav Lease on Figure 4.12.)

Figure 4.2 Almaden Property Claim Map

(Source Terraco, 2013)

Approximately 97 ha (240 acres) of private ground (16 ha / 40 acres of surface rights and 81 ha / 200 acres of surface and mineral rights) are leased from Frank R. Chrestesen and others (Chrestesen Lease Figure 4.2). Another 16 ha / 40 acres of surface and mineral rights are leased from Harold Davies and others. With the exception of this parcel, GMI does not hold any surface rights on the Property. Property status, including details regarding the unpatented claims, is summarized in Appendix 1.

The patented claim boundaries were surveyed by the Bureau of Land Management (BLM) in 2006. The unpatented claims have not been surveyed by a registered land or mineral surveyor, and there is no state or federal law or regulation requiring such surveying. Survey plats for all patented mining claims are open to public inspection at the BLM.

GMI owns indirectly through its subsidiary 100% of the 210 unpatented mining claim and has lease agreements with Davies and Chrestesen on the 12 patented mining claim and two leases of private land. Yearly costs to maintain the above lease agreements and unpatented mining claims is approximately US$70,000 per year.

The Property is subject to a production royalty of 4% Net Returns payable to Harold Davies and the other owners of the Davies Lease and a production royalty of 4% Net Returns payable to Frank R. Chrestesen and the other owners of the Chrestesen Lease. Annual payments for the Davies lease are US$24,000 and for the Chrestesen lease are US$3,360, which can be deducted from future production royalties.

A royalty of 1% Net Smelter Return (“NSR”) is payable on the unpatented claims to Royal Gold, Inc. if the average price of gold is less than $425 per ounce and 2% if the average price of gold is equal to or greater than $425 per ounce. The same royalty applies to an area of interest outside of the current property boundaries that is comprised of the following area: Sections: 24, 25 and 36 – Township 11 North, Range 4 West; Sections: 1 and 12 – Township 10 North, Range 4 West; Sections: 19-22 and 27-34 – Township 11 North, Range 3 West; and Sections: 3-10, Township 10 North, Range 3 West, all relative to the Boise Meridian.

A 0.5% NSR royalty is held on the sale of all metallic elements from the Property by EXP2 LLC. A purchase agreement for 30% of the gold and silver produced on the Property is held by an affiliate company, EXP T1 Ltd.

4.4 | Environmental Liabilities |

On January 28, 2020, HDR Engineering Inc. (HDR), conducted an Environmental Site Assessment of the Property on behalf of GMI. HDR concluded that the Property is the site of former underground and open pit mining as well as processing of mercury and therefore, there is some surface disturbance, mine tailings, and remains of the processing plant, as well as roads and drill pads from prior mining and exploration. The abandoned open pits represent potential hazards because their walls are not barricaded, and the tailings may contain residual mercury that could leach into the groundwater. However, as the area is semi-arid, if leaching of mercury is occurring it must necessarily be at a low rate and the area into which any such leachate might migrate is a topographic depression that is remote from human habitation. The Idaho Department of Environmental Quality (IDEQ) inspected the Property in 2002 on behalf of the Environmental Protection Agency (EPA) and concluded that following the initial investigation, the contamination was not serious enough to require federal Superfund action or National Priorities List (NPL) consideration, and the remnants of the Idaho Almaden Mine operations are currently not a regulatory concern.

Exploration programs that are conducted on private lands do not require any permits. Drilling on BLM land is covered by BLM Case Number File IDI-35-690. A $500 bond was posted along with this authorization. Further drilling on the unpatented claims may require further permitting with the BLM.

There are no known risk factors that may affect access, title, or the right or ability to perform work on the Property.

5 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

The town of Weiser is located approximately 120 kilometers (km) northwest of Boise and is linked to it by Interstate 84 and US Highway 95. From Weiser, access to the Property is by 20 km of well-maintained, paved county road (Cove Road) and then for three km on an all-season gravel road (South Crane Creek Road).

Summers in this area are hot and dry and winters are cold, with most of the annual precipitation as snow. Average annual precipitation is 33 centimeter (cm), with evaporation rates generally exceeding precipitation rates. The average January temperature is 2.5° Celsius (C), and the average high in July is 34°C. Exploration and mining can be conducted year-round.

Weiser, where the field office for the Property is located, has a population of about 5,400 and basic services and supplies can be obtained here. Ontario, Oregon, located about 55 km southwest of Almaden, has a population of about 11,000 and can provide most required supplies and services. Boise, approximately 120 km southeast of the Property, has a population of over 200,000, and is a regional transportation and commercial hub.

The closest high-voltage power transmission lines are 230-kilovolt lines that pass within 10 km of the Property and may be a possible source of electrical power for a future mining operation.

There are no surface sources of water on the Property and no water wells capable of supplying a mining operation have been drilled within or in the immediate vicinity of the Property. Two irrigation reservoirs located nine and eighteen km from Almaden, and the Weiser River, with a potential diversion site about five km from the Property, are the nearest sources of surface water. Options for obtaining water for a possible mining operation would be to purchase or lease and pipe surface water from these sources or possibly to locate sufficient groundwater on or near the Property. The ultimate source(s) of water would depend on the quantity required.

The Property has sufficient area to accommodate potential mining operations and infrastructure, including processing plant sites, as well as potential storage of tailings and disposal of waste, and heap leach pads. With the exception of 16 ha, GMI does not hold any surface rights on the Property and, in the event that a mining operation was contemplated, would have to acquire them.

Mining operations are common in this part of United States and it is reasonable to assume that appropriate mining personnel could be recruited from within Idaho or adjacent states.

The Property is located at and near the top of Nutmeg Mountain. Elevations on the Property range from 800 meters above sea level (masl) on the west side of the Property to 1,140 masl at the top of Nutmeg Mountain, with moderate to steep topography. Range grasses and scattered sagebrush comprise the limited vegetation.

Cinnabar was discovered on Nutmeg Mountain in 1936 by Harry Brown, a sheep herder and amateur mineralogist. Claims were staked in 1937 and exploration, by shallow shafts and drill holes, began in 1938. By 1939, Idaho Almaden Mines Co. had begun mercury production. From then until the mine closed in December 1942, 3,958 flasks of mercury were produced at a recovered grade of 6.27 pounds (lbs) per short ton (0.34%). Mercury mineralization at Almaden cropped out at the surface and was mined in a broad open cut which eventually reached a length of 80 metres (m) and a width of 40 m and a maximum depth of 9 m. Mining also extended underground to follow irregular zones too deep to mine by open cut. Although one shaft extended to 50 m in a fault, most of the workings were shallow. Other small, high-grade cinnabar occurrences were found on the northern crest of Nutmeg Mountain, but the Almaden Mine was the most extensively developed mercury occurrence in the area.

Rare Metals Corporation of America re-opened the Property in September 1955 and at full capacity, the mill processed approximately 175 short tons (160 tonnes) of ore per day. In 1957, the mine produced 2,200 flasks of mercury, but in 1959 the production rate began to decrease in response to the removal by the US government of the floor price of $225 per 76-pound (34.5-kilogram (kg)) flask. A temporary shutdown occurred in December 1961 when the price of mercury dropped to $183 per flask. Mining resumed in 1965 with mercury production reaching 100 flasks per month. Mining rates varied from 90 to 120 flasks per month until October 1968, when 81 flasks of mercury, valued at that time at over US$44,000, were stolen. The operation never recovered and closed in March 1972.

Between 1939 and 1972, the Idaho Almaden Mine produced approximately 22,600 flasks (779,000 kg) of mercury from a minimum of 506,600 short tons of ore. Mercury ore was processed onsite by crushing and retorting to collect the mercury vapours extracted from the crushed rock.

Although the presence of gold was known during the mercury mining operations, grades were considered too low (0.01 to 0.02 ounces per short ton (oz/sT)), to be of commercial interest besides which the recovery of gold was incompatible with the process used to recover mercury.

In 1979, Homestake Mining Limited (Homestake) leased the Davies and Chrestesen properties and staked the IA claims (See Appendix 1 Tables 1 and 2 for details on the Davies and Chrestesen Leases, and the IA unpatented mineral claims). Homestake explored the Property for two years and in 1981 drilled 19 reverse-circulation (RC) and six diamond drill core (core) holes. Four of the RC holes were angled at 60 degrees to the east or northeast; the rest were vertical.

Freeport Resources (Freeport) optioned the Property from Homestake in 1983 and drilled 17 vertical RC holes before dropping their option in 1984.

In 1985, Canu Resources Inc. (Canu) acquired control of the Property through a joint venture with Homestake and during 1985-1986, drilled 512 rotary holes. Data exists for 510 of these holes.

Most of these holes were drilled on a 50 by 75-foot (ft) (15 by 23 m) grid in the area now named the Main Zone and all were vertical. Canu merged with Ican Minerals (Ican), in 1986.

From 1986 to 1994, Western States Minerals Corp. (Western States), Hycroft Resources and Development (Hycroft), and Amax Gold Exploration Inc. (Amax) each worked on the Property through agreements with Ican.

Western States drilled three RC holes in 1986, but these holes are poorly documented and are not included the drillhole database. Hycroft drilled 42 RC holes in 1987 and in 1988, Ican drilled 10 core holes.

Amax leased the property in March 1991 and staked an additional 114 lode claims. Amax drilled 58 RC and 10 core holes in the period 1991-1992, carried out detailed geologic mapping, compiled all previous drill-hole data, conducted cyanide-solubility tests on drill cuttings and core, and conducted 21 column-leach tests on drill core material. Longyear Drilling was the contractor for the core holes and used a Longyear 44 PQ wireline drill rig and drilled 2.5 inch (in) (6.35 cm) diameter core for the first four holes and 4 in(10 cm) diameter core for the final six holes. A track-mounted drill with 5 in (12.7 cm) diameter, 15 ft-long (4.57 m) rods was used for the RC drilling. The core holes and 37 of the RC holes were drilled at angles less than 90°, with depths ranging from 150 to 600 ft (46 to 183 m). Although drilling was moderately difficult because of open fractures and variable hardness, recovery was generally good.

Amax returned the Property to Ican in early 1994. Ican then drilled 39 RC holes (2,300 m / 7,547 ft) and five core holes for a total of 430 m (1,416 ft) in the Stinking Water Basin area, about 600 m north the Main Zone. Ican drilled an additional 12 RC holes totalling 766 m (2,514 ft) in the Cove Creek area, immediately south of the Main Zone. This drilling intersected mineralization in both areas.

Cambior USA, Inc. (Cambior) conducted an evaluation of the Property in 1995, which included five bottle-roll tests that were completed by McClelland Laboratories Inc. on drill cuttings from Ican’s 1994 drilling.

Freegold Ventures Ltd. (Freegold) optioned the Property in 1995 and by 2001, had acquired 100% interest in it as well as 100% of the shares of Ican and Canu. Freegold began metallurgical test work in 1995 with material from four bulk-sample pits within the Main and North Zones. In late 1996 and early 1997, Freegold collected three additional bulk samples and also conducted further metallurgical test work on pre-existing core samples. In late 1996, Freegold drilled ten, 10 cm diameter core holes to supply material for additional metallurgical testing. Boyles Brothers Drilling was the contractor for the ten core holes. These metallurgical tests are described in Section 13.0 of this report.

During 1995 and 1996, Freegold undertook geologic mapping and generated geologic cross sections based on that mapping and in 1997 retained Watts, Griffis and McOuat (WGM) to complete a feasibility study including a resource estimate (see Section 6.4 of this report).

No further exploration work was conducted on the Property from 1998 through 2004.

In December 2004, Freegold investigated the potential for the presence of bonanza-grade mineralization beneath the near-surface, tabular mineralization and, in late 2005, conducted a review of the 1997 WGM feasibility study and filed a National Instrument (NI) 43-101-compliant technical report, including a resource estimate (see Section 6.4 of this report).

In 2006, Freegold commenced RC and core drilling to increase the density of holes in areas that had been tested previously to expand the resource, and to provide additional material for metallurgical testing. Through the end of 2007, 145 RC and core holes were completed for a total of 16,150 m (52,985.5 ft). The first six holes completed in 2006 were large-diameter (PQ) core holes (2,990 ft / 911 m) drilled for metallurgical testing. All other core holes were HQ diameter.

Core drilling was conducted by Ruen Drilling, Inc. of Clark Fork, Idaho. Until early 2007, the drill used was a trailer-mounted Longyear Fly Model 70. Thereafter, a trailer-mounted CS 1000 was used. No significant drilling problems were encountered. The RC contractor was Diversified Drilling LLC of Missoula, Montana, who used a Foremost W-750 rig with a down-hole hammer, conventional interchange, and cyclone for sample recovery. Drill-hole diameter varied from 4.75 in. to 5.5 in.(12 to 14 cm). RC drilling was wet, as required by Idaho health and safety regulations, so water was injected into the holes until groundwater was reached. The groundwater level within the Main and North zones is at a depth of greater than 500 ft (150 m) so most holes terminated above the groundwater table and did not encounter any significant groundwater flows. In the Stinking Water area which is at elevations 600 ft to 700 ft (183 to 213 m) lower than the Main Zone, groundwater was encountered within 100 ft (30 m) of surface. Deeper drilling (>500 ft / 150 m) along the north side of the Main Zone encountered hot water with temperatures reaching up to 77° C. The extreme temperatures created both a safety hazard and a sampling problem resulting in three holes being abandoned.

A major part of the 2006-2007 program was the drilling of three east-west fences of core holes across the Main Zone as all previous core had been consumed in metallurgical testing. Data obtained from the new core drilling was used to improve the interpretation of stratigraphy, structure and mineralization. The 2006-2007 drilling intersected gold mineralization at depths below those drilled by previous operators.

Freegold also began multi-element assaying for all sample intervals; prior operators had only assayed for gold. As a result, drill intercepts of molybdenum (Mo) mineralization grading up to 0.5% Mo were found in the North Zone and portions of the Main Zone. Drilling intersected a 1.5 m (five ft) interval of 1.3% Mo associated with weakly anomalous gold within a structural zone that is a potential feeder structure to the North Zone molybdenum mineralization.

In 2006, Freegold drilled, blasted and extracted approximately 40 tons of material from three surface pits in the Main and North zones for use in metallurgical testing and commissioned additional metallurgical work on core composites, as discussed in Section 16.0 of this report.

In 2009, Western Standard Metals Ltd. (Western Standard) acquired the Property from Freegold. Western Standard did no physical work on the Property.

In January 2011, Terraco Gold Corp. (Terraco) merged with Western Standard and drilled 16 core holes (5,492 m / 18,020 ft) to test for bonanza-style mineralization at depth beneath the Main Zone near-surface mineralization, as well as to test other near-surface targets. In 2012, Terraco drilled 28 HQ core holes for exploration purposes, and four P-diameter holes to acquire sample material for metallurgical testing. The 32 holes had a total length of 2,761m / 9,059 ft.

There are no down-hole survey data for any holes drilled prior to 2011 as most of the pre-2011 holes were reverse-circulation and rotary for which downhole surveying is not a normal practice, and most were less than 150 m in length so that deviations are not likely to have been significant.

Core recovery data are available for core holes SW-40 through SW-44 and all the core holes drilled in the 1996-1997, 2006-2007 and 2011-2012 drill campaigns. A review by Mine Development Associates (MDA) (2009) of recoveries up to the end of 2007 indicated average project-wide core recovery, as calculated from 3,328 recovery intervals, of 94%. Core recovery from the 2011 and 2012 drill campaigns was approximately 83% based on records from 36 core holes. Recoveries for those holes ranged from 71% to 95% and core loss was generally attributed to broken ground with the greatest core losses generally occurring near surface.

Table 6.1 is a chronological summary of drilling completed on the Property.

Table 6.1 Almaden Historical Drilling by Year

Company | Year | Rotary | Reverse Circulation | Core | Total Meters |

Homestake | 1981 | | 36 | 6 | 2,448 |

Freeport | 1983 | | | | 1,495 |

Ican Resources | 1985-1986 | 510 | | | 27,866 |

Western States | 1986 | | 3 | | 274 |

Hycroft | 1987 | | 42 | | 1,940 |

Ican Resources | 1988 | | | 10 | 667 |

Amax | 1991-1993 | | 58 | 10 | 7,124 |

Ican Resources | 1993-1994 | | 51 | 5 | 3,499 |

Amax | 1996-1997 | | | 10 | 538 |

Freegold | 2006-2007 | | 103 | 42 | 16,150 |

Terraco | 2011 | | | 16 | 5,492 |

Terraco | 2012 | | | 32 | 2,761 |

Total | | 510 | 293 | 131 | 70,254 |

Freegold collected 1,250 soil samples at 25 m stations on 14 east-west lines spaced 200 m apart. This grid covered the main areas of known gold mineralization. No information from Freegold is available for this sampling program, but when Terraco acquired the Property they had the Freegold results interpreted by DIR Exploration Inc. (DIR) of Palisade, Colorado. DIR produced plans and profiles of eleven elements, including gold, silver, molybdenum, arsenic and mercury, for each of the sampling lines. The DIR interpretation suggested that gold mineralization extends beyond the Stinking Water Zone to the north and the Cove Creek Zone to the south of the main area of known gold mineralization and recommended that the sampling grid be expanded to evaluate those areas.

Terraco extended the grid as recommended and collected 1,714 more samples by adding lines, extending existing lines, and sampling the Cove Creek area in greater detail. These samples were analysed by ALS Global (ALS) for gold (Au-TL42, aqua regia digestion and ICP-MS finish) and for 41 additional elements by aqua regia digestion and ICP finish (MEMS 41). ALS geochemical laboratories are accredited to ISO/IEC17025:2017 for specific analytical procedures. The ALS quality program includes quality control steps through sample preparation and analysis, inter-laboratory test programs, and regular internal audits. This additional sampling confirmed the presence of gold in soil in the areas previously identified. The linear nature of these anomalies suggests a possible structural influence. Figure 6.1 shows the extent of both Freegold and Terraco soil sampling. The figure can be enlarged for clarity.

Figure 6.1 Almaden Soil Sampling Grid and Gold Anomalies

(Source: Terraco 2013)

The only documented geophysical surveying of the Property was done by Freegold who carried out a 100 m dipole induced polarization (IP) survey on 24 east-west lines spaced 200 m apart (Figure 6.2). Freegold did not generate any documentation for the survey, but Terraco had the data compiled by Zonge International of Tucson, Arizona and then interpreted by Abraham Emond of Salt Lake City, Utah. Mr. Emond generated a series of plans and sections.

Resistivity identified the main, highly siliceous areas of mineralization. The Stinking Water and Cove Creek Zones have very weak resistivity responses, probably because they are superficial slump deposits. Emond recommended the drill testing of a number of the resistivity anomalies and Terraco did subsequently drill some of these, although it is not known whether their selection of target areas for drill testing was guided by the geophysical responses. Note: Figure 6.2 can be enlarged for clarity.

Figure 6.2 Almaden Property IP Resistivity Map

(Source: Terraco 2011)

6.4 | Historical Resource Estimates |

There are seven known historical mineral resource estimates for the Property; these are summarized in Table 6.2. All except the last two estimates pre-date NI 43-101 reporting requirements, therefore the resource terminology is not consistent with CIM Best Practice guidelines. The estimates are of unknown reliability and are presented here only as historical information but are considered relevant because they demonstrate the similarity of interpretations and estimation outcomes over time.

In 1986, Bechtel Inc. (Bechtel) calculated “geologic reserve” and “preliminary mineable reserve” estimates for Ican using a database that included the first 499 holes drilled at Almaden (predominantly rotary holes with limited RC and core drilling) with 17,764 assays from samples collected at 5 ft (1.5 m) intervals. The Bechtel estimate included three mineralized zones, the Main, North, and Nutmeg, and was based on ordinary kriging, a block model with a block sizes of 50 x 50 x 20 ft and a search ellipse with a radius of 200 ft. For the “preliminary mineable reserve” estimate, Bechtel developed a constraining pit using a gold price of $400/oz, 45% gold recovery, and mining, milling, and other costs of $3.75/sT, but did not include capital costs. Bechtel calculated that the break-even cutoff grade was about 0.02 oz/sT gold, at which cutoff they estimated “mineable reserves” of 12,452,000 tons at 0.034 oz/sT gold and a 0.55 stripping ratio.

Table 6.2 Almaden Historical Mineral Resource Estimates1

Company | Year | Classification2 | Cut-off | Short Tons | Grade | Ounces Au |

| | | (Oz Au/Short Ton) | | (Oz Au/ Short Ton) | |

Ican | 1986 | Geologic Reserve | 0.010 | 38,472,000 | 0.024 | 923,328 |

(Bechtel) | 1986 | Mineable Reserve | 0.010 | 16,232,000 | 0.030 | 486,960 |

Ican (Gray Assoc) | 1988 | Resource | 0.010 | 43,676,000 | 0.021 | 917,196 |

Amax | 1993 | Resource | 0.010 | 39,855,431 | 0.022 | 876,819 |

| 1993 | Mineable Resource | 0.010 | 31,000,000 | 0.024 | 729,000 |

Ican | 1994 | Resource | | 45,800,000 | 0.023 | 1,058,000 |

| 1997 | Measured Geologic Resource | 0.010 | 41,593,000 | 0.021 | 873,453 |

| 1997 | Indicated Geologic Resource | 0.010 | 2,499,000 | 0.016 | 39,984 |

Freegold (WGM) | 1997 | Total Resource | 0.010 | 44,092,000 | 0.020 | 881,840 |

| 1997 | Proven Reserve | 0.010 | 37,903,000 | 0.021 | 795,963 |

| 1997 | Probable Reserve | 0.010 | 1,657,000 | 0.016 | 26,512 |

| 1997 | Total Reserve | 0.010 | 39,560,000 | 0.021 | 822,475 |

Freegold | 2006 | Indicated | 0.011 | 24,778,000 | 0.021 | 520,338 |

(Freeman) | 2006 | Inferred | 0.011 | 19,989,000 | 0.018 | 359,802 |

Freegold (MDA) | 2009 | Measured + Indicated | 0.010 | 43,050,000 | 0.020 | 864,000 |

| 2009 | Inferred | 0.009 | 5,270,000 | 0.016 | 84,000 |

Table Notes:

1The QP has not done sufficient work to classify the historical estimate as a current mineral resource or mineral reserve and GMI is not treating the historical estimate as current mineral resource or mineral reserve.

2Classification designations in the historical estimates completed from 1986 to 1997 predate and do not conform to CIM Best Practice Guidelines for resource classification terminology.

In 1988, R. E. Gray & Associates calculated a resource estimate for Ican using the same data as Bechtel used. No information is available regarding the procedures used to arrive at this estimate, other than the search ellipse had a radius of 200 ft.

Amax completed a mineral inventory estimate in November 1992. This estimate used an updated database with additional drill data and a cross-sectional estimation method based on east-west sections spaced 100 ft apart. The estimate included “ore”, “waste” and “dilution”. The “ore” portion amounted to approximately 31 million short tons with an average grade of 0.0235 oz/sT.

In 1994, Ican completed an in-house an unclassified resource estimate of 1,058,000 contained ounces that included mineralization north (Stinking Water) and south (Cove Creek) of the main deposit area. No details of the estimation methodology or assumptions are available.

In 1997, WGM prepared a feasibility study for Freegold including a reserve estimate that was based on the same drillhole information used by Amax for their 1992 resource estimate. The estimate utilized over 24,000 fire assays for gold from approximately 680 drillholes. WGM used inverse distance squared interpolation within a 0.01 oz/sT gold grade shell and a search ellipse of 300ft. The block model estimate was then constrained using a pit shell.

In 2006, J. D. Graham & Associates prepared a NI 43-101 technical report, including a mineral resource estimate, for Freegold. The resource estimate was based on the same drill-hole information and database used by Amax in 1993 and WGM in 1997 and used Surpac Vision® software. The model used was similar in orientation and block size to WGM’s model, with blocks measuring 40 ft by 40 ft in plan and 20 ft high. Grades were estimated using inverse distance interpolation. The search ellipse had a major axis of 170 ft, oriented at 337°, and the minor axis with a length of 142 ft. Gold assay values were not cut because of the low incidence of higher-grade values in the assay database. The Graham estimate used a density of 13ft3/ton and a resource cutoff of 0.011 oz/sT gold.

In 2009, MDA completed a NI 43-101 compliant resource estimate and technical report for Western Standard. The database contained 886 drill holes, 36,361 gold assays and 15,571 cyanide-soluble leach analyses. The database also contains 255 specific gravity measurements from Freegold 1996 and 2006-2007 drill core. Modelling was done on 50 ft-spaced, east-west oriented, cross-sections. Assays were capped and composited into 10 ft lengths. Blocks measured 25 ft north-south by 20 ft east-west by 20 ft vertical. The CN-ratio model contained three domains, defined primarily by drill sample cyanide-soluble leach extraction data and logged silicification and oxidation codes: low-extraction, from <10% to ~40% cyanide-soluble extraction; high-extraction from ~70% to 100% gold extraction; and between these two end-member groups, a mixed population with cyanide extraction values ranging from ~40% to ~70%. Gold grades were estimated into the block model by inverse-distance interpolation in two passes. Estimation criteria were defined by variograms as well as inferred geologic controls of the mineralization. Resource classification considered distance to the nearest sample, number of samples, geologic confidence, and mineral domain continuity. MDA used different cutoff grades for oxide, mixed and sulphide resources and classified the resource into measured, indicated and inferred categories.

NOTE: All of the information pertaining to the historical resource estimates described in Section 6.4 have been obtained from the 2009 MDA Technical Report prepared by Paul Tietz and Michael Gustin and dated December 8, 2009. GMI is not treating any of these historical resource estimates as current and the author has not determined what work would be required to verify or upgrade any of these estimates or if such verification or upgrading would be possible.

6.5 | Historical Engineering Studies |

In 1997, WGM prepared a feasibility study for Freegold. The WGM study envisioned an open-pit mine with cyanide-leach processing. The overall mineable zone was approximately 1,500 m (5,000 ft) long with a maximum width of 450 m (1,500 ft). Design plant throughput was 8,000,000 sT per year and mining of approximately 4,800,000 sT waste per year in addition to ore. No significant pre-stripping was required because of the near-surface nature of the mineralization. Project life was five years. WGM concluded that a minimum average gold recovery of 55% would be needed to make the project economically attractive, with an average recoverable gold grade of 0.013 oz/short ton and an average estimated recovery for the mineable reserve portion of the deposit of 63%. Estimated recovery was 526,800 ounces of gold.

6.6 | Production from the Property |

There has been no recorded gold production from the Property, but as noted at the beginning of this section, between 1939 and 1972, the Idaho Almaden Mine produced approximately 22,600 flasks (779,000 kg) of mercury from a minimum of 506,615 sT of ore.

6.7 | Current Status of the Property |

In August 2019, Terraco was acquired by Sailfish Royalty Corp. (Sailfish). In March 2020, GMI acquired the Almaden Property from Sailfish. There has been no physical work on the Property since 2012.

7 | Geological Setting and Mineralization |

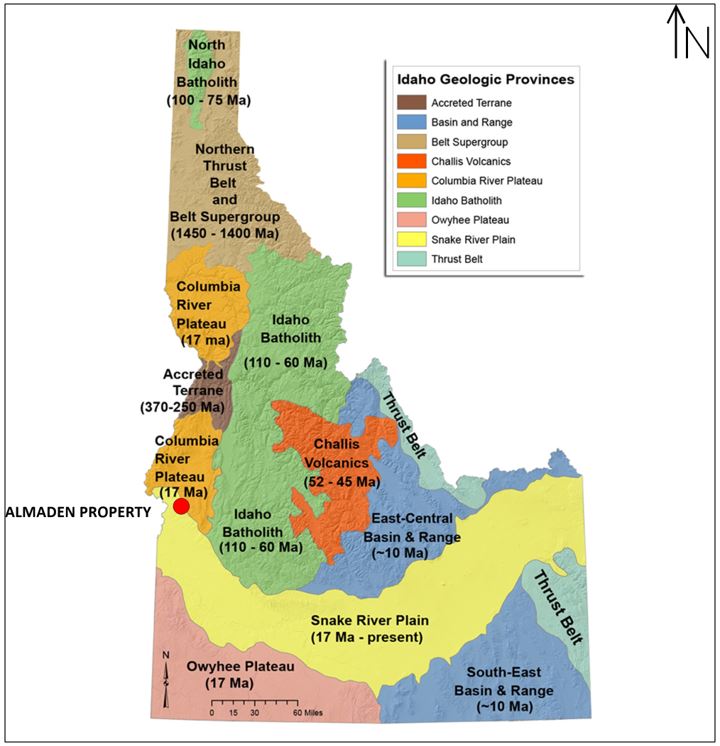

The Almaden Property is located within the Basin and Range Geological Province of western United States, on the north-western margin of the Snake River Plain. The deposit is contained within sedimentary rocks of Miocene age that were deposited on accreted terrane of the Paleozoic to Mesozoic-age Blue Mountains. Most of the suture zone and accreted terranes in Idaho were subsequently covered by Columbia River basalt flows during Miocene time. The Property area is exposed in an embayment on the margin of the Columbia River basalts (Figure 7.1).

The Blue Mountains are comprised of three terranes, the Wallowa, Baker, and Olds Ferry, of Permian to Triassic age, that are comprised of fragments of oceanic island arcs, continental fringing arcs, and various subduction-related mélange that were amalgamated and underwent Late Triassic metamorphism and Triassic-Jurassic sedimentation before collision with the North American margin. Following suturing, deformation and intrusion continued as subduction was re-established. The Idaho batholith was intruded during the Late Cretaceous, east of the suture zone, followed by the extrusion of volcanic rocks (Challis magmatic event) during the Eocene.

Basin and Range extension began during the Miocene (~17 million years (Ma)) and has continued through to the present as a result of the cessation of compression and crustal thickening during the Cordilleran Orogeny. Prior to Basin and Range extension, the Pacific Plate was subducted beneath the North American Plate in a compressional regime that included about 200 million years of orthogonal compression. In Eocene time, plate interactions changed from orthogonal compression to oblique strike-slip (transform) along the San Andreas Fault system in California. When compressional forces ceased, the stressed continental crust of the North American Plate relaxed, isostatic rebound began, and extensional forces gave rise to the Basin and Range Province.

In Idaho, the Basin and Range Province is cross-cut by the Snake River Plain. Figure 7.1 shows the geological provinces in the State of Idaho, the extent of the Basin and Range Province in southern Idaho, and the extent of the Snake River Plain that cuts across the Basin and Range Province.

7.2 Local Geology

The Almaden Property is located within the western part of the Snake River Plain, which is divided into eastern and western portions that although contiguous, have different geological histories. The eastern part of the plain is a down warp that forms a low topographic corridor across the Basin and Range Province. The hotspot that currently resides beneath Yellowstone was crossed by the eastern Snake River Plain starting approximately 16 million years before present. As a consequence of its migration over the hotspot, the eastern Snake River Plain is underlain by silicic and mafic volcanic rocks with local interbeds of continental sediments, and by Quaternary-age basalt flows that cover approximately 95% of the surface. The tuffs at Yellowstone (0.6 to 2 Ma) represent the youngest pulse of silicic volcanic activity associated with the hotspot.

The western part of the Snake River Plain (WSRP) is a normal-fault bounded basin about 70 km wide and 300 km long, with relief due to both tilting toward the center of the basin and active normal fault systems. The rocks that occupy the western Snake River Plain are rhyolitic tuffs and ash flows of the Idavada Volcanic Group (15 to 11 Ma), and fluvial and lacustrine sediments, with interbedded basalt flows of the Idaho Group. Lake Idaho occupied the WSRP during the Pliocene epoch as the graben subsided in response to the hotspot migrating to the east. Displacement of these sedimentary and volcanic units where they outcrop is clearly visible in the field. Figure 7.2 shows the structural and tectonic setting of the western portion of the Snake River Plain with the location of the Property on the eastern margin of the WSRP graben.

Figure 7.1 Almaden Property Location and Geological Provinces, Idaho

Source: GMRS 2020

Figure 7.2 Almaden Property Location: Western Snake River Plain

Source GMRS 2020

7.3 Property Geology

7.3.1 Stratigraphy

The Property is underlain, from oldest to youngest, by Miocene-age basalt, Payette Formation sandstone and siltstone, and lacustrine sedimentary rocks of the Pliocene-age Idaho Group, all of which are exposed in an erosional window through the Weiser Basalt. Most gold mineralization that has been identified to date occurs within and peripheral to a north-trending graben. The graben is bounded on the east by the Main Fault and on the west by the B Fault, and sedimentary units change in thickness and character across the bounding faults (Figure 7.3).

The deepest unit encountered in drilling is the Cambridge unit of the Colombia River Basalt. The thickness of the Cambridge basalts In the Almaden area is unknown but a geothermal well drilled approximately 1.6 km north of Almaden penetrated approximately 2,000 m of basalt. Within the Property area, the basalts have been variably propylitically altered and locally contain pyrite in amounts ranging from <0.5% to 3%. The basalt is rarely silicified. Chalcopyrite and sphalerite were noted in the basalt in drillhole TAL-765C, but to date, no significant gold mineralization has been found in the basalt.

The Payette Formation, defined as sediments interbedded with Colombia River basalt flows, is comprised of arkosic sandstone with minor siltstone, and underlying claystone. The stratigraphically lowest unit of the Payette Formation that is exposed on the Property is grey, thin-bedded claystone that crops out in roadcuts west of the deposit and has been encountered in drillholes beneath the entire resource area. The claystone contains fine-grained disseminated pyrite but is otherwise unmineralized and often represents the lower limit of disseminated gold mineralization. The thickness of the claystone in the Property area is unknown as drilling to date has yet to pass completely through the unit.

Figure 7.3 Almaden Schematic Cross-Section

(Source: Terraco, 2012)

Arkosic sandstone overlies the claystone. This is the most extensive sedimentary unit within the Property and is the primary host for gold mineralization. This unit includes both arkose and tuffaceous arkose, with lesser inter-bedded conglomerate, siltstone, shale, and rhyolitic crystal tuff. The sandstone is grey, commonly coarse-grained, contains abundant grains of feldspar and other non-quartz materials, and is well-bedded and commonly cross-bedded. This unit can be up to 150 m thick within the graben but is generally 60 m to 120 m thick outside the graben. Bedding orientation indicates a shallow easterly dip (5 to 15 degrees). Minor local folding, commonly associated with fault movement and offset, is present. Within the area of mineralization, the sandstone is silicified and contains quartz stockworks, hydrothermal breccia, and argillic alteration. The banded, chalcedonic quartz veins up to 15 cm in width, show variable orientations, are discontinuous and irregular, and locally may be re-brecciated. Certain beds in this unit are completely altered to white clay, probably due to acid leaching.

Within the graben, a sub-horizontal chalcedonic debris-breccia unit unconformably overlies the arkosic sandstone. This unit is typically a dense, multi-lithologic, siliceous breccia that is characterized by angular to sub-angular fragments up to approximately 25cm in the longest dimension. Fragments commonly include opalite, silicified sandstone, siltstone, chalcedonic vein material, and sand-sized fragments of both clear and dark quartz. Finer-grained sedimentary rocks composed of similar lithologies are associated with the breccia. The breccia exhibits multiple episodes of veining, brecciation, and silicification and in some areas, sandstone is totally replaced by silica, with no original sedimentary textures remaining. Blocks of less-altered sandstone occur within the chalcedonic breccia. The breccia and associated sedimentary units are interpreted to have formed synchronously with hydrothermal activity and to have been shed off of the fault scarp formed by movement along the Main fault. Opal veins cut the silica breccia and are more common near the contact with the overlying sinter. The chalcedonic breccia is approximately 3 to 15m thick with the greatest thickness immediately west of the Main fault.

A layer of sub-horizontal, opalized siltstone and sandstone and local sinter, caps the chalcedonic breccia and the arkosic sandstone and is exposed at surface in pits and excavations. This unit is the host of the mercury mineralization (cinnabar) that was exploited in the past. The opalized sandstone unit is characterized by light grey to white, thin-layered, locally brecciated opal with varying amounts of clay. Fossil reeds, indicative of the hot pool origin of the sinter, are locally preserved in some outcrops. The sinter unit contains minor gold, but is the main host of mercury mineralization.

Overburden is comprised of brown soil, fanglomerate, colluvium, and alluvium. The soil and alluvium are relatively thin, and parts of the deposit have no cover. Landslide deposits shedding off Nutmeg Mountain occur along all sides of the mountain but are especially common in the Stinking Water Basin area to the north of the main deposit area. Down-slope movement post-dates alteration and mineralization associated with hot spring activity. Transported material is commonly comprised of large silicified blocks that are difficult to distinguish from in-situ rock.

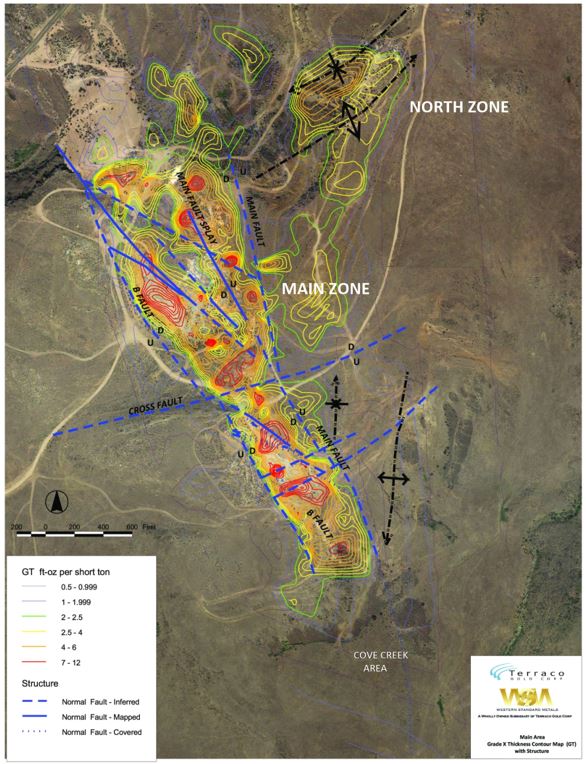

7.3.2 Structure

The principal structures within the Property are faults that trend northwest and north-northeast, with both trends appearing to have been active both before and during the introduction of gold mineralization. Main Zone mineralization occurs within a graben bounded by syn-mineralization northwest-trending faults, the Main Fault on the east and the B-Fault on the west. The Main Fault dips steeply to the west and the B-Fault dips steeply to the east. Although no drillholes have penetrated deep enough to determine the behaviour of these two faults at depth, it is reasonable to assume that they converge, with the Main Fault being the controlling structure. The North Zone is bounded by northwest and north-trending structures. Smaller northeast-trending structures also localize mineralization in the North Zone. Hot-spring alteration and gold mineralization are strongest at structural intersections. Figure 7.4 shows the major structures in the Main and North Zone areas as well as the concentration of gold mineralization, expressed as contours of gold grade-thickness, adjacent to faults and at fault intersections. The Stinking Water Zone is located just off the map to the northwest in Figure 7.4.

The Main Fault separates relatively strong alteration and mineralization within the graben from weaker alteration and mineralization to the east and is interpreted to have exerted fundamental controls on the distribution of mineralizing fluids, alteration and deposition of gold. The topographic and stratigraphic changes across the fault are consistent with steep, west-side-down movement along the fault and variations in thickness of Payette sandstone across the fault indicate that the fault was active during deposition.

The B-Fault forms the western boundary of the graben and movement along the B-fault is indicated by offset across the fault of the contact between the arkosic sandstone and underlying claystone units of the Payette Formation. As well, the opalized sandstone thins to the west of the B-Fault, suggesting movement on the fault during the opalizing event.

Pre-mineralization, east-northeast-trending folds are exposed on the western slopes of Nutmeg Mountain immediately south of the North Zone mineralization. The folds are truncated to the north by a northwest-trending fault that defines the southern limit of the North Zone mineralization and are truncated to the west by a north-trending fault zone that extends north and marks the western limit of the North Zone mineralization. This fold set may predate the northwest-trending Paddock Valley structural zone, which is associated with gold mineralization at Almaden. The influence of these pre-mineralization folds on mineralization is not known.

Figure 7.4 Almaden Faults and Grade-Thickness Gold Accumulations

Source: Terraco 2012

7.3.3 Alteration

Alteration associated with mineralization includes silicification, argillization (acid alteration), and carbonatization. Silicification is by far the most common and widespread form of alteration and ranges from silica (chalcedonic) veining through silica flooding (amorphous silica) to total silica replacement (opal) of the host rock. Argillic alteration is common, ranging from weak to nearly total replacement of the arkosic sandstone by clay. Below and in the lower part of the mineralized zone, calcite-quartz alteration is common.

7.3.4 Mineralization

Gold mineralization within the Property occurs in four physically separate areas, the Main, North, Stinking Water and Cove Creek Zones (Figure 7.4).

Mineralization was deposited in a hot spring environment and is associated with multi-phase hydrothermal brecciation and veining, strong silicification, acid alteration, and faulting. Much of the alteration exposed at surface is composed primarily of opalized sandstone. Cinnabar deposition was present late in the hydrothermal events that deposited gold.

Gold occurs most commonly as particles of native gold ranging from less than one to nine microns in size, although visible gold was noted in drillhole TAL-794C. Some gold is encapsulated in silica or is intimately associated with framboidal pyrite that is in turn silica encapsulated. Silver content of the gold averages 25%. Very fine-grained cinnabar occurs primarily in opalized sandstone and sinter that overlies the gold mineralization and is typically deposited along fractures, in veinlets, and as surface coatings in cavities. Molybdenum is present at low concentrations throughout the Almaden deposit, with increased concentrations of between 0.03% and 0.05% Mo over thicknesses of 45 to 65 meters within the northern parts of the Main Zone and the North Zone. Molybdenum values as high as 1.39% Mo were encountered in drilling at depth beneath the North Zone. The relationship between gold and molybdenum mineralization, if any, has not been determined.

Mineralization is variably oxidized, with oxidized intervals ranging from a few meters to greater than 100 meters in thickness. Stacked, alternating sequences of oxidized, partially oxidized, and unoxidized material are common, particularly in the Main Zone. The shallow sulfidic material often occurs within strongly silicified, less fractured rock that is less permeable to circulating oxidizing fluids.

Figure 7.5 Almaden Principal Zones of Gold Mineralization

Source: Terraco 2019

As the name implies, the Main Zone is the most significant in size and contained quantity of gold. Gold mineralization is hosted primarily in silicified Payette Formation sandstone that has been subjected to multiple phases of hydrothermal alteration, brecciation, and veining. Main Zone mineralization occurs over a north-south distance of approximately 1,200 m a width from 250 to 500 m, and a vertical thickness of up to 180 m, although most mineralization occurs within 60 m of surface. In the historic mercury pit area, the northwest trend is complicated by splays or parallel structures that result in a wider mineralized zone that extends eastward from the Main Fault. Siliceous sinter may have acted as an impermeable cap during the emplacement of gold mineralization.

Peripheral to the graben, Main Zone mineralization occurs within preferentially mineralized silicified sandstone horizons that contain weak hydrothermal brecciation and veining. This generally stratabound gold mineralization weakens away from the graben, although localized areas of higher grade are commonly associated with high-angle structures.

The North Zone underlies the narrow ridge crest at the north end of Nutmeg Mountain, approximately 600 meters northeast of the Main Zone (Figure 7.4). Gold in the North Zone occurs as an oval, north-trending, tabular body that is less than 60 m thick, approximately 335 m long (N-S) and 150 m wide. The North Zone contains more sulphide than the Main Zone and surface exposures are notably rusty. Gold occurs within silicified sandstone and arkosic sandstone with only minor hydrothermal breccia development. Thin, sheeted quartz veins and vein stockworks occur within near-vertical, northwest and northeast-trending structures that cut the silicified sandstone and arkose. Gold mineralization is thickest and generally of higher grade along the western side of the zone. Mineralization is overlain by a gold-poor, silicified-pyritized sandstone cap.

The Stinking Water Zone lies approximately 400 m west of the North Zone and 600 m north of the Main Zone (Figure 7.4). At Stinking Water, a large, tabular, northeast-trending oval shaped, highly-fractured slump block is covered by a veneer of silicified and veined boulders derived from the North Zone. Mineralization in the Stinking Water Zone is up to 60 m thick.

The Cove Creek area is located 600 m southeast of, and approximately 170 m lower than, the Main Zone. Here, gold mineralization occurs in a nearly horizontal zone with a sharp upper contact and in association with oxidized opal, chalcedony, and quartz vein stockworks that are hosted by silicified, pyritized arkosic sandstone and chalcedonic sinter. The Cove Creek Zone is overlain by a weakly silicified sandstone cap cut by only a few narrow veins with low-grade gold values. The Cove Creek Zone has little to no surface expression.

The characteristics of gold-mercury mineralization at Almaden are consistent with a low-sulfidation, epithermal, hot spring deposit type. Almaden mineralization is similar to time-stratigraphically equivalent occurrences and deposits of gold, silver, and mercury elsewhere in Nevada, Oregon, and Idaho, although the association of molybdenum at Almaden is unusual for this deposit type. Salient aspects of this type of deposit, modified from Panteleyev 1996, are listed below.

Commodities (By-products): Au, Ag (Pb, Zn, Cu)

Geological Characteristics: Quartz veins, stockworks and breccias carrying gold, silver, electrum, argentite and pyrite with lesser and variable amounts of sphalerite, chalcopyrite, galena, rare tetrahedrite and sulphosalt minerals form in high- level (epizonal) to near-surface environments. Mineralization commonly exhibits open- space filling textures and is associated with volcanic-related hydrothermal to geothermal systems.

Tectonic Setting: Volcanic island and continent-margin magmatic arcs and continental volcanic fields with extensional structures.

Geological setting: High-level hydrothermal systems from depths of approximately one km to surficial hot spring settings. Regional-scale fracture systems related to grabens, (resurgent) calderas, flow-dome complexes and rarely, maar diatremes. Extensional structures in volcanic fields (normal faults, fault splays, ladder veins and cymoid loops, etc.) are common; locally graben or caldera-fill clastic rocks are present. High-level (subvolcanic) stocks and/or dikes and pebble breccia diatremes occur in some areas. Locally resurgent or domal structures are related to underlying intrusive bodies.

Age of Mineralization: Any age.

Host/Associated Rock Types: Most types of volcanic rocks; calcalkaline andesitic compositions predominate. Some deposits occur in areas with bimodal volcanism and extensive subaerial ashflow deposits. A less common association is with alkalic intrusive rocks and shoshonitic volcanics. Clastic and epiclastic sediments occur in intra-volcanic basins and structural depressions.

Deposit form: Mineralized zones are typically localized in structures but may occur in permeable lithologies. Upward-flaring ore zones centred on structurally-controlled hydrothermal conduits are typical. Large (> 1 m wide and hundreds of metres in strike length) to small veins and stockworks are common with lesser disseminations and replacements. Vein systems can be laterally extensive, but ore shoots have relatively restricted vertical extent. High-grade ores are commonly found in dilational zones in faults at flexures, splays and in cymoid loops.

Texture/Structure: Open-space filling, symmetrical and other layering, crustification, comb structure, colloform banding and multiple brecciation.

“Ore” Mineralogy: Pyrite, electrum, gold, silver, argentite; chalcopyrite, sphalerite, galena, tetrahedrite, silver sulphosalt and/or selenide minerals. Deposits can be strongly zoned along strike and vertically. Deposits are commonly zoned vertically over 250 to 350 m from a basemetal poor, Au-Ag-rich top to a relatively Ag-rich basemetal zone and an underlying basemetal rich zone grading at depth into a sparse basemetal, pyritic zone. In alkalic hostrocks, tellurides, V mica (roscoelite) and fluorite may be abundant, with lesser molybdenite.

Gangue Mineralogy: Quartz, amethyst, chalcedony, quartz pseudomorphs after calcite, calcite; adularia, sericite, barite, fluorite, Ca- Mg-Mn-Fe carbonate minerals such as rhodochrosite, hematite and chlorite.

Alteration Mineralogy: Silicification is extensive in ores as multiple generations of quartz and chalcedony are commonly accompanied by adularia and calcite. Pervasive silicification in vein envelopes is flanked by sericite-illite- kaolinite assemblages. Intermediate argillic alteration formed adjacent to some veins; advanced argillic alteration (kaolinite-alunite) may form along the tops of mineralized zones. Propylitic alteration dominates at depth and peripherally.

Weathering: Weathered outcrops are often characterized by resistant quartz ± alunite 'ledges' and extensive flanking bleached, clay-altered zones with supergene alunite, jarosite and other limonite minerals.

Mineralization Controls: In some districts the epithermal mineralization is tied to a specific metallogenetic event, either structural, magmatic, or both. The veins are emplaced within a restricted stratigraphic interval generally within one km of the paleosurface. Mineralization near surface occurs in hot spring systems, or the deeper, underlying hydrothermal conduits. At greater depth it can be postulated to occur above, or peripheral to, porphyry and possibly skarn mineralization. Normal faults, margins of grabens, coarse clastic caldera moat-fill units, radial and ring dike fracture sets and both hydrothermal and tectonic breccias are all ore fluid channeling structures. Through going, branching, bifurcating, anastamosing and intersecting fracture systems are commonly mineralized. Ore shoots form where dilational openings and cymoid loops develop, typically where the strike or dip of veins change. Hangingwall fractures in mineralized structures are particularly favourable for high-grade ore.

Genetic Model: These deposits form in both subaerial, predominantly felsic, volcanic fields in extensional and strike-slip structural regimes and island arc or continental andesitic stratovolcanoes above active subduction zones. Near- surface hydrothermal systems, ranging from hot spring at surface to deeper, structurally and permeability focused fluid flow zones are the sites of mineralization. The ore fluids are relatively dilute and cool solutions that are mixtures of magmatic and meteoric fluids. Mineral deposition takes place as the solutions undergo cooling and degassing by fluid mixing, boiling and decompression.

Exploration work to date on the Property has outlined extensive near surface stockwork, replacement, and sinter alteration and mineralization that formed in a hot spring environment. However, the relatively shallow drilling and mostly vertical drill holes has not intersected the steeply dipping fault structures that would potentially host high-grade gold mineralization and acted as conduits for the extensive near surface low-grade gold mineralization. Future exploration and drill programs will look to identify these potential high-grade feeders and use alteration and mineralogical vectoring and geophysics to identify vectors to this mineralization.

GMI has done no exploration on the Property. All exploration conducted on the Property was done by previous operators and is described in Section 6 this report.

GMI has done no drilling on the Property. Drilling performed by previous operators is described in Section 6 of this report, but because the assays obtained from those historical drill programs have been used as the basis of the resource estimate described in Section 14 of this report, salient aspects of those drill programs are described here.

Table 10.1 is a summary by operator of all the documented drillholes within the Property and demonstrates that there have been numerous drill campaigns over a period of 32 years and three different drilling methods: rotary, reverse circulation and core. Drillhole collar locations are tabulated in Appendix 2 in which the locations are referenced in Idaho State Plane NAD 83 coordinates.

Table 10.1 Almaden Drilling by Operator

Company | Year | Reverse Circulation | Rotary | Core |

| | No. | Meters | No. | Meters | No. | Meters |

Homestake | 1980 | 19 | 2,038 | | | | |

Homestake | 1981 | | | | | 6 | 410 |

Freeport | 1983 | 17 | 1,495 | | | | |

Ican | 1985-1986 | | | 512 | 27,866 | | |

Ican | 1988 | | | | | 10 | 667 |

Ican | 1994 | 51 | 3,067 | | | | |

Ican | 1994 | | | | | 5 | 432 |

Western States | 1986 | 3 | 274 | | | | |

Hycroft | 1987 | 42 | 1,940 | | | | |

Amax | 1991-1992 | 58 | 6,318 | | | | |

Amax | 1991-1993 | | | | | 10 | 806 |

Amax | 1996-1997 | | | | | 10 | 538 |

Freegold | 2006-2007 | 103 | 11,271 | | | | |

Freegold | 2006-2007 | | | | | 42 | 4,879 |

Terraco | 2011 | | | | | 16 | 5,492 |

Terraco | 2012 | | | | | 32 | 2,761 |

Sub-Total | | 293 (31%) | 26,403 | 512 (55%) | 27,866 | 131 (14%) | 15,985 |

Total Holes | 936 | | | | | | |

Total Meters | 70,254 | | | | | | |

Figure 10.1 shows the disposition of the holes within the Property and the general locations of the major zones of mineralization that have been identified. Holes are color-coded by type. Approximately 14% of the holes are core, 31% are reverse circulation and 55% are rotary. Grid locations are Idaho State Plane NAD 83 coordinates.

Collectively, the drill programs have delineated four tabular zones of epithermal gold mineralization, the Main, North, Stinking Water and Cove Creek. The Main Zone is constrained within a graben that is bounded by the northwest-trending Main and B Faults. The North Zone mineralization was deposited on the eastern flank of the graben, approximately 600m north of the Main Zone. The Stinking Water Zone is located east of the North Zone and is interpreted to be a slumped portion of that zone. The Cove Creek Zone is located approximately 600m south of the Main Zone and is inferred to be a slumped portion of the Main Zone.

Most mineralization occurs in tabular, near-horizontal zones and most drillholes are vertical with the result that most intercepts of mineralization represent true thicknesses. However, some gold mineralization occurs in steep veins and stockworks and vertical holes through that mineralization have resulted in intercepts greater than true thicknesses, but as vein geometry can only be measured in core and core holes represent only approximately 14% of all holes drilled, the extent of stockwork and vein type mineralization is not fully known.

Figure 10.1 Almaden Property Drillhole Plan by Type

Source: GMRS 2020

Table 10.2 summarized the descriptive statistics for all gold assays in the database that were accompanied by a sample number or were greater than zero. Descriptive statistics for rotary, reverse-circulation and core subsets are also given in Table 10.2.

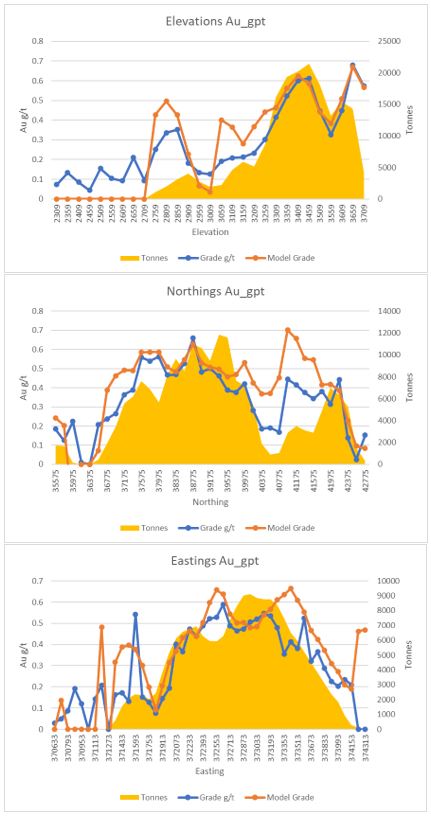

Table 10.2 Almaden Gold Assay Descriptive Statistics