- GMDAQ Dashboard

- Financials

- Filings

-

Holdings

- Transcripts

-

ETFs

- Insider

- Institutional

- Shorts

-

F-1 Filing

Gamida Cell (GMDAQ) F-1Registration statement (foreign)

Filed: 24 Jun 19, 4:04pm

As filed with the Securities and Exchange Commission on June 24, 2019.

Registration No. 333-

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM F-1

REGISTRATION STATEMENT

UNDER

THE SECURITIES ACT OF 1933

Gamida Cell Ltd.

(Exact name of Registrant as specified in its charter)

Not Applicable

(Translation of Registrant’s name into English)

State of Israel | 2834 | Not Applicable |

(State or other jurisdiction of incorporation or organization) | (Primary Standard Industrial Classification Code Number) | (I.R.S. Employer Identification Number) |

5 Nahum Heftsadie Street

Givaat Shaul, Jerusalem 91340 Israel

Tel: +972 (2) 659-5666

(Address, including zip code, and telephone number, including area code, of Registrant’s principal executive offices)

Gamida Cell Inc.

673 Boylston Street

Boston, MA 02116

Telephone: (617) 892-9080

(Name, address, including zip code, and telephone number, including area code, of agent for service)

Divakar Gupta Daniel I. Goldberg Joshua A. Kaufman Cooley LLP 1114 Avenue of the Americas New York, NY 10036 Telephone: (212) 479-6000 Facsimile: (212) 479-6275 | Haim Gueta Shachar Hadar Meitar Liquornik Geva Leshem Tal 16 Abba Hillel Road Ramat Gan 5250608, Israel Telephone: +972 (3) 610-3100 Facsimile: +972 (3) 610-3111 | Michael Kaplan Derek Dostal Davis Polk & Wardwell LLP 450 Lexington Avenue New York, NY 10017 Telephone: (212) 450-4000 Facsimile: (212) 701-5800 |

Approximate date of commencement of proposed sale to the public: As soon as practicable after the effective date of this Registration Statement.

If any of the securities being registered on this Form are to be offered on a delayed or continuous basis pursuant to Rule 415 under the Securities Act of 1933, check the following box. o

If this Form is filed to register additional securities for an offering pursuant to Rule 462(b) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. o

If this Form is a post-effective amendment filed pursuant to Rule 462(c) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. o

If this Form is a post-effective amendment filed pursuant to Rule 462(d) under the Securities Act, check the following box and list the Securities Act registration statement number of the earlier effective registration statement for the same offering. o

Indicate by check mark whether the registrant is an emerging growth company as defined in Rule 405 of the Securities Act of 1933.

Emerging growth company ☒

If an emerging growth company that prepares its financial statements in accordance with U.S. GAAP, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 7(a)(2)(B) of the Securities Act. o

CALCULATION OF REGISTRATION FEE

Title of Each Class of Securities To Be Registered | Proposed Maximum Aggregate Offering Price(1) | Amount of Registration Fee | ||||

Ordinary Shares, par value NIS 0.01 per share | $ | 34,730,000 | $ | 4,209.28 | ||

| (1) | Estimated solely for the purpose of calculating the amount of the registration fee in accordance with Rule 457(o) under the Securities Act of 1933, as amended. Includes the ordinary shares that the underwriters have the option to purchase. |

The Registrant hereby amends this Registration Statement on such date or dates as may be necessary to delay its effective date until the Registrant shall file a further amendment which specifically states that this Registration Statement shall thereafter become effective in accordance with Section 8(a) of the Securities Act of 1933 or until the Registration Statement shall become effective on such date as the Commission, acting pursuant to said Section 8(a), may determine.

The information in this preliminary prospectus is not complete and may be changed. These securities may not be sold until the registration statement filed with the Securities and Exchange Commission is effective. This preliminary prospectus is not an offer to sell nor does it seek an offer to buy these securities in any jurisdiction where the offer or sale is not permitted.

Preliminary Prospectus | Subject to Completion. Dated June 24, 2019 |

4,040,000 Ordinary Shares

Gamida Cell Ltd.

All of the 4,040,000 ordinary shares in this offering are being sold by the company. Our ordinary shares are traded on The Nasdaq Global Market under the symbol “GMDA.” On June 20, 2019, the last reported sale price of our ordinary shares on The Nasdaq Global Market was $7.47 per ordinary share.

We are an “emerging growth company” as that term is used in the Jumpstart Our Business Startups Act of 2012 and, as such, have elected to comply with certain reduced public company reporting requirements for this prospectus and future filings.

Investing in our ordinary shares involves a high degree of risk. See “Risk Factors” on page 10 to read about factors you should consider before buying our ordinary shares.

Per Share | Total | |||||

Public offering price | $ | $ | ||||

Underwriting discount(1) | $ | $ | ||||

Proceeds to Gamida Cell Ltd., before expenses | $ | $ | ||||

| (1) | See “Underwriting” beginning on page 158 for additional information regarding underwriting compensation. |

To the extent that the underwriters sell more than 4,040,000 ordinary shares, the underwriters have the option to purchase up to an additional 606,000 ordinary shares from us at the public offering price less the underwriting discount. If the underwriters exercise the option in full, the total underwriting discounts and commissions payable by us will be $ , and the total proceeds to us, before expenses, will be $ .

Neither the Securities and Exchange Commission nor any other regulatory body has approved or disapproved of these securities or passed upon the accuracy or adequacy of this prospectus. Any representation to the contrary is a criminal offense.

The underwriters expect to deliver the ordinary shares against payment in New York, New York on or about , 2019.

Joint Book-Running Managers

RBC Capital Markets | JMP Securities |

Lead Manager

Oppenheimer & Co.

Prospectus dated , 2019

TABLE OF CONTENTS

Neither we nor the underwriters have authorized anyone to provide you with information that is different from that contained in this prospectus, any amendment or supplement to this prospectus, or in any free writing prospectus we may authorize to be delivered or made available to you. Neither we nor the underwriters take responsibility for, and can provide no assurance as to the reliability of, any other information that others may give you. We and the underwriters are offering to sell ordinary shares and seeking offers to purchase ordinary shares only in jurisdictions where offers and sales are permitted. The information contained in this prospectus is accurate only as of the date on the front of this prospectus, regardless of the time of delivery of this prospectus or any sale of ordinary shares. Our business, financial condition, results of operations and prospects may have changed since the date on the front cover of this prospectus.

Neither we nor any of the underwriters have taken any action to permit this offering or possession or distribution of this prospectus in any jurisdiction where action for that purpose is required, other than in the United States. You are required to inform yourselves about and to observe any restrictions relating to this offering and the distribution of this prospectus.

Gamida Cell and NiCord are trademarks of ours that we use in this prospectus. This prospectus also includes trademarks, tradenames and service marks that are the property of other organizations. Solely for convenience, our trademarks and tradenames referred to in this prospectus appear without the ® or ™ symbols, but those references are not intended to indicate, in any way, that we will not assert, to the fullest extent under applicable law, our rights, or the right of the applicable licensor to our trademark and tradenames. We do not intend to use or display other companies’ trademarks and trade names to imply a relationship with, or endorsement or sponsorship of us by, any other companies.

The unaudited consolidated financial statements as of March 31, 2019 and 2018 and the audited consolidated financial statements for the years ended December 31, 2018, 2017 and 2016 included

i

elsewhere in this prospectus have been prepared in accordance with the international financial reporting standards, or IFRS, as issued by the international accounting standards board, or the IASB. None of the financial information in this prospectus has been prepared in accordance with accounting principles generally accepted in the United States, or GAAP.

Unless the context otherwise requires, references in this prospectus to the “Company,” “Gamida Cell,” “we,” “us,” “our” and other similar designations refer to Gamida Cell Ltd. The terms “shekel,” “Israeli shekel” and “NIS” refer to New Israeli Shekels, the lawful currency of the State of Israel, and the terms “dollar,” “U.S. dollar” or “$” refer to United States dollars, the lawful currency of the United States of America. All references to “shares” in this prospectus refer to ordinary shares of Gamida Cell Ltd., par value NIS 0.01 per share.

MARKET, INDUSTRY AND OTHER DATA

This prospectus contains estimates, projections and other information concerning our industry, our business, and the markets for our product candidates. Information that is based on estimates, forecasts, projections, market research or similar methodologies is inherently subject to uncertainties, and actual events or circumstances may differ materially from events and circumstances that are assumed in this information. Unless otherwise expressly stated, we obtained this industry, business, market and other data from our own internal estimates and research as well as from reports, research surveys, studies and similar data prepared by market research firms and other third parties, industry, medical and general publications, government data and similar sources.

In addition, assumptions and estimates of our and our industry’s future performance are necessarily subject to a high degree of uncertainty and risk due to a variety of factors, including those described in “Risk Factors.” These and other factors could cause our future performance to differ materially from our assumptions and estimates. See “Special Note Regarding Forward-Looking Statements.”

ii

This summary highlights selected information contained elsewhere in this prospectus and does not contain all of the information that you should consider in making your investment decision. Before deciding to invest in our ordinary shares, you should read this entire prospectus carefully, including the sections of this prospectus entitled “Risk Factors” and “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and our consolidated financial statements and the related notes included elsewhere in this prospectus.

Goal

To deliver curative cell therapies to patients with serious and life-threatening medical conditions.

Overview

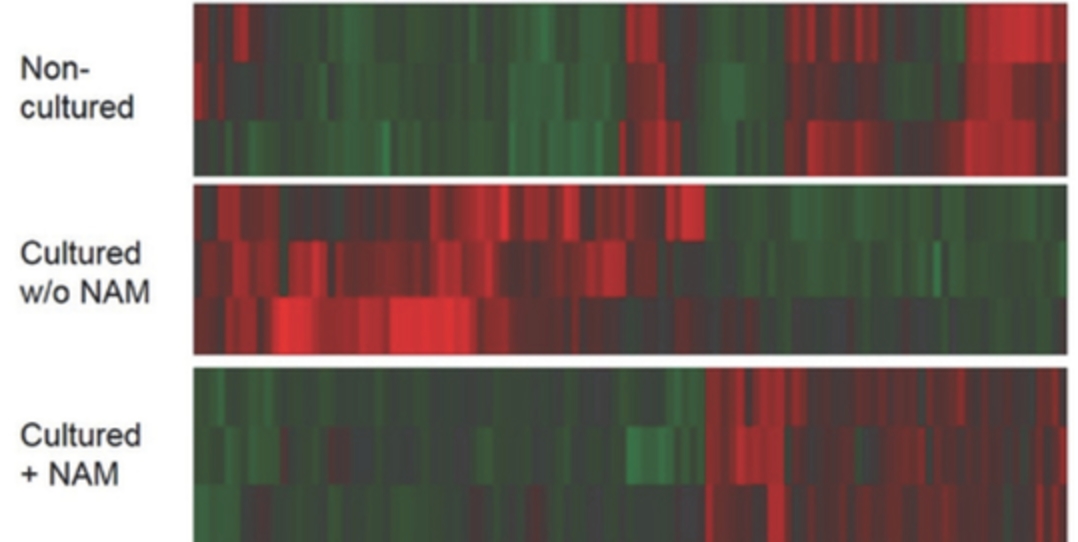

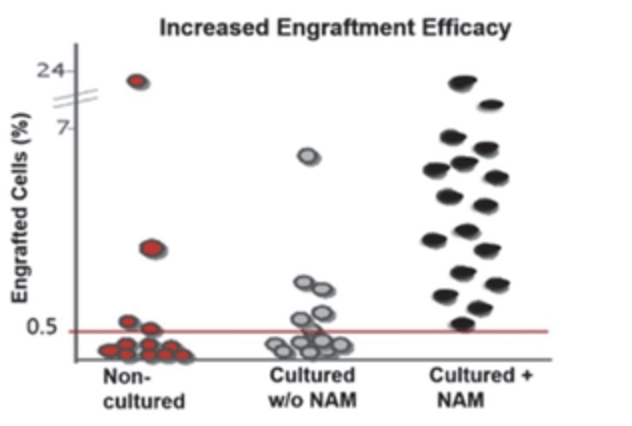

We are a clinical-stage biopharmaceutical company committed to developing advanced cell therapies with the potential to cure cancer and rare, serious hematologic diseases. While cell therapies have the potential to address a variety of diseases, they are limited by availability of donor cells, matching a donor to the patient, and the decline in donor cell functionality when expanding the cells to achieve a therapeutic dose. We have leveraged our nicotinamide-based, or NAM-based, cell expansion technology to develop a pipeline of products designed to address the limitations of cell therapies. Our proprietary technology is designed to allow for the proliferation of donor cells while maintaining the cells’ functional therapeutic characteristics, which, if approved, will provide a treatment alternative for patients.

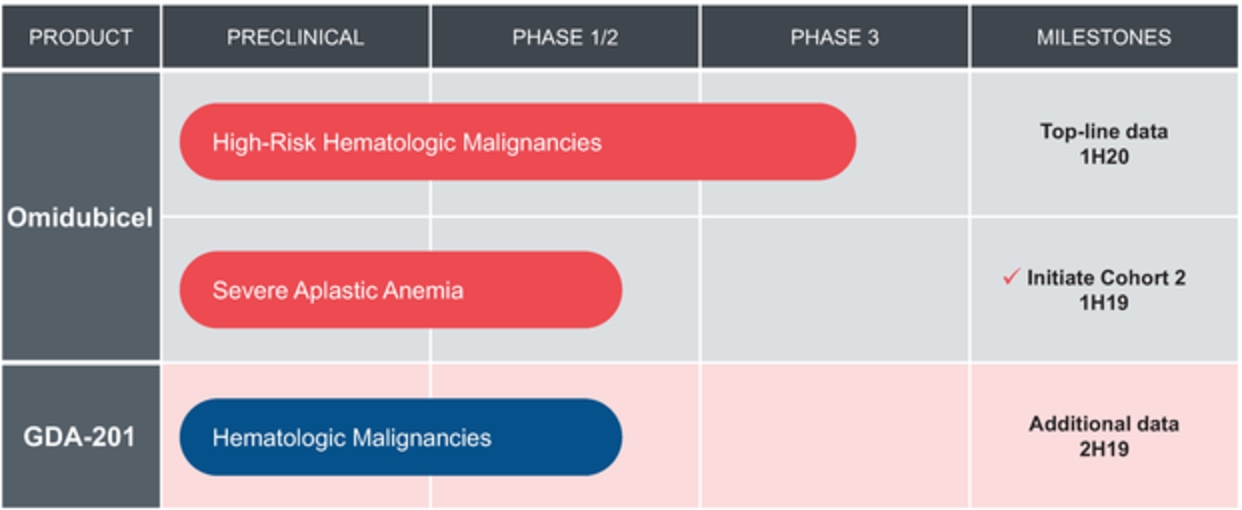

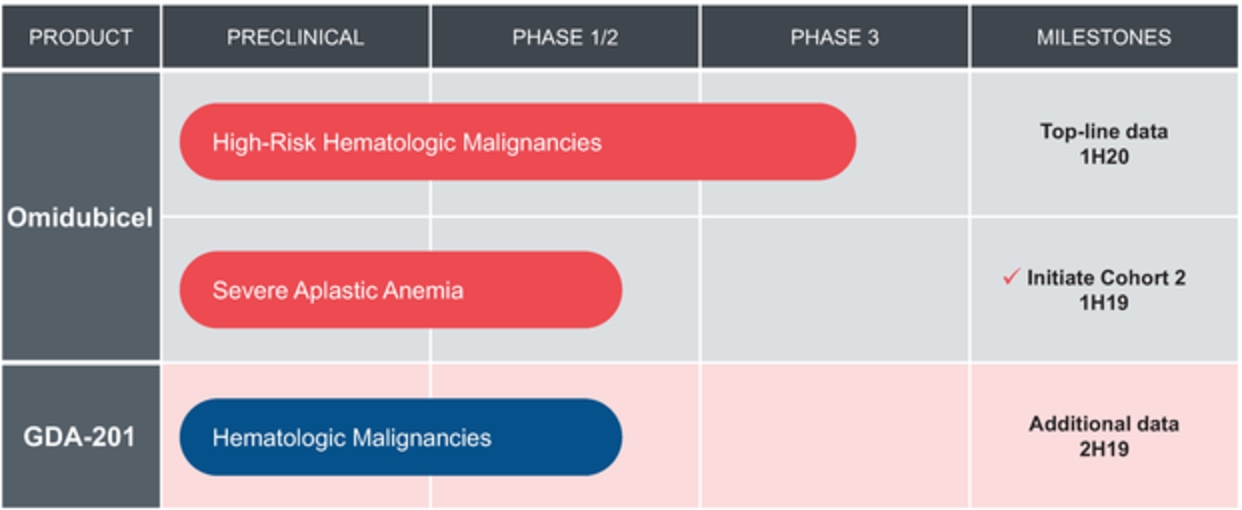

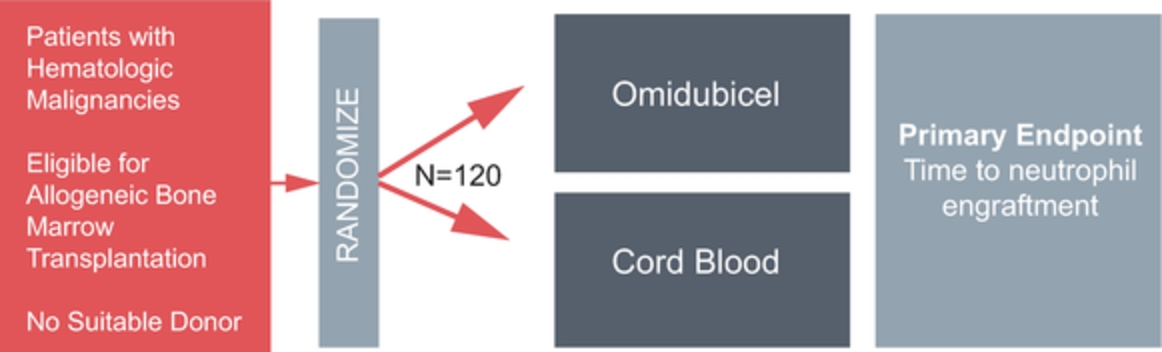

Our most advanced product candidate, omidubicel (formerly known as NiCord), is an investigational advanced cell therapy designed to expand the life-saving benefits of hematopoietic stem cell (bone marrow) transplant, or HSCT. The Company is currently enrolling patients in a pivotal Phase 3 clinical trial in approximately 120 patients with various hematologic malignancies, including high risk leukemias such as acute myeloid leukemia, or AML, acute lymphocytic leukemia, or ALL, chronic myeloid leukemia, or CML, myelodysplastic syndrome, or MDS and lymphomas. We anticipate reporting top-line data from this trial in the first half of 2020. In our Phase 1/2 clinical trials, patients who were transplanted with omidubicel achieved rapid engraftment and immune reconstitution, which are key indicators of clinical benefits. Data from the Phase 1/2 clinical study were published in the Journal of Clinical Oncology in December 2018. Based on the results of our Phase 1/2 clinical trials, we received Breakthrough Therapy Designation for omidubicel in the United States from the U.S. Food and Drug Administration, or the FDA. Furthermore, we received orphan drug designation from both the FDA and the European Medicines Agency.

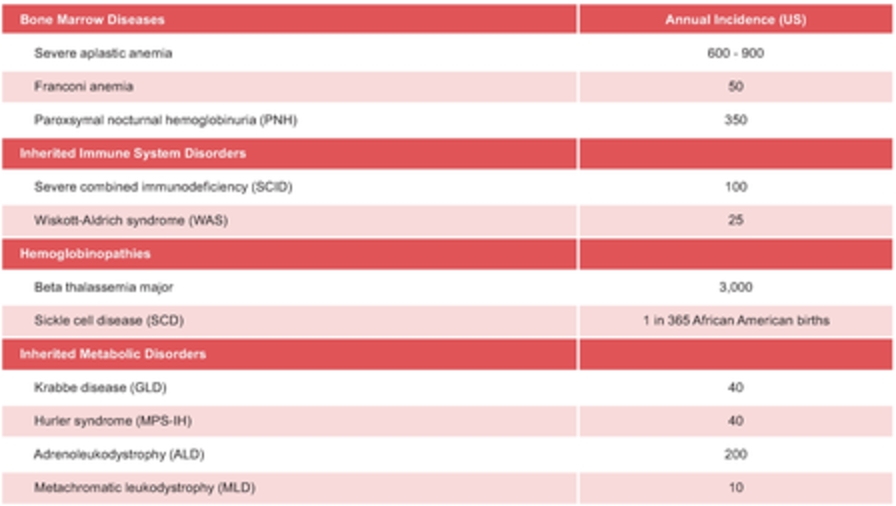

In addition to hematologic malignancies, we are pursuing the development of omidubicel for the treatment of bone marrow failure disorders. Omidubicel is currently being evaluated in a Phase 1/2 clinical trial sponsored by the National Institutes of Health in patients with severe aplastic anemia, a rare, life-threatening hematological disorder. This study is designed to evaluate the safety and effectiveness of transplantation with omidubicel to overcome the high incidence of graft rejection associated with conventional cord blood for severe aplastic anemia. We reported initial data from this study at the 2019 Transplantation & Cellular Therapy Meetings of American Society for Blood and Marrow Transplantation and Center for International Blood and Marrow Transplant Research, or the TCT Annual Meeting, in February 2019.

Beyond omidubicel, we have leveraged our NAM technology to develop another product candidate, GDA-201 (formerly known as NAM-NK), an investigational, natural killer, or NK, cell-based cancer immunotherapy to be used in combination with standard-of-care therapeutic antibodies. NK cells have potent anti-tumor properties and have the advantage over other oncology cell therapies of not requiring genetic matching, potentially enabling NK cells to serve as a universal donor-based therapy when combined with certain antibodies. GDA-201 addresses a key limitation in the therapeutic potential of NK cells by increasing the cytotoxicity and in vivo retention and proliferation of NK cells expanded in culture conditions. GDA-201 is currently in an investigator-sponsored Phase 1 trial for the treatment of relapsed or refractory non-Hodgkin lymphoma, or NHL, and multiple myeloma, or MM.

1

The figure below summarizes key information about our current pipeline of product candidates:

Omidubicel for the Treatment of Hematologic Malignancies

Limitations of Allogeneic HSCT

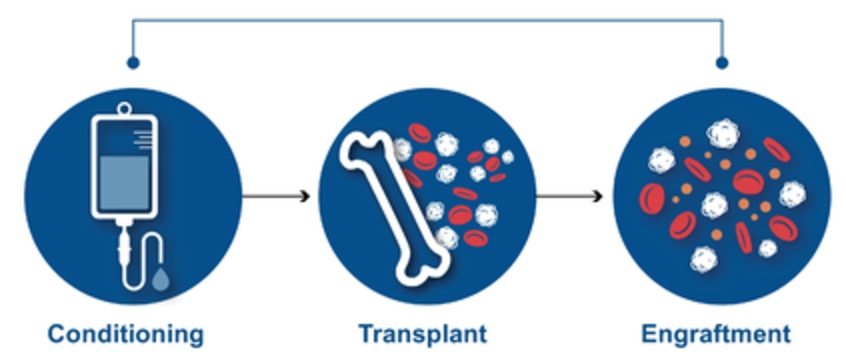

Cell therapies involve the delivery of human cells to replace or repair damaged tissue or cells in order to treat a variety of cancers and other diseases. HSCT, commonly known as bone marrow transplantation, is the most frequently used cell therapy and is used to treat a variety of hematologic malignancies and other serious conditions. A person’s entire blood and bone marrow can be reconstituted from a seed population of stem cells obtained from an allogeneic, or non-self, donor whose blood-forming and immune-system-forming cells are both free of cancer and effective at carrying out their functions. Approximately 90% of HSCT procedures performed in the United States are for patients with hematologic malignancies. There are approximately 30,000 patients per year receiving allogeneic HSCT in the United States, Europe and Japan, of which 8,500 are in the United States. The number of these procedures increased by 5% per year in the United States from 2006 to 2016. By 2021, the Company expects that approximately 11,000 individuals with a hematologic malignancy will be a candidate for HSCT, and the Company further projects that omidubicel, if approved, will be used to treat approximately 30% of these patients.

Despite the curative potential of HSCT, it is estimated that more than 40% of eligible patients do not receive one for various reasons, including finding a matched donor. The best source for donor cells is a sibling who is a matched related donor, or MRD, but the chances of having a sibling match in the United States are only 25% to 30%. The majority of patients rely on alternate sources of donor cells, including matched unrelated donor, or MUD, haploidentical, or “half-matched” donors, and umbilical cord blood. Notwithstanding the various potential sources of donor cells, HSCT is subject to a number of significant limitations, including: (i) delays in finding a suitable match, during which disease progression may make patients ineligible for transplant; (ii) an insufficient number or delayed engraftment of donor cells, leaving patients without a functioning immune system and leading to potentially life-threatening immune deficiency following transplant; and (iii) a lack of long-term compatibility between the donor cells and the patient’s own cells, resulting in potentially fatal graft versus host disease, or GvHD.

Umbilical cord blood offers promise as a readily available source of stem cells for patients who need HSCT and do not have a MRD source. It is easier to find a match when using stem cells derived from cord blood, since a full match is not required for a successful transplant using cord blood. This broadens the pool of potential donors and shortens the process of finding a suitable match. However, on average, a typical cord blood graft contains approximately one-tenth the number of stem and progenitor cells compared to stem cell grafts from adult bone marrow or peripheral blood donors. This lower number of cells may delay engraftment of the donor cells and reconstitution of the immune system. This, in turn, increases both time in the hospital and the likelihood that a patient might contract a life-threatening infection.

2

Omidubicel as a Universal Stem Cell Graft for Allogeneic HSCT

Omidubicel, our lead product candidate, is designed to address the limitations of HSCT. Omidubicel is composed of cord blood that has been manufactured using our proprietary NAM-based cell expansion technology, which is designed to increase engraftment efficiency in HSCT and enable rapid engraftment and immune system reconstitution. This reduces the risk of infections and other complications after transplant. In addition, the donor T cells in cord blood are naïve, meaning that they have not matured and may more readily adapt to the recipient. This results in greater immunologic compatibility, or the matching of the donor cells with the recipient’s cells, reducing the frequency and severity of GvHD. In light of these advantages, omidubicel, if approved, may serve as a universal, readily available, reliable and effective alternative to existing sources of donor cells for HSCT.

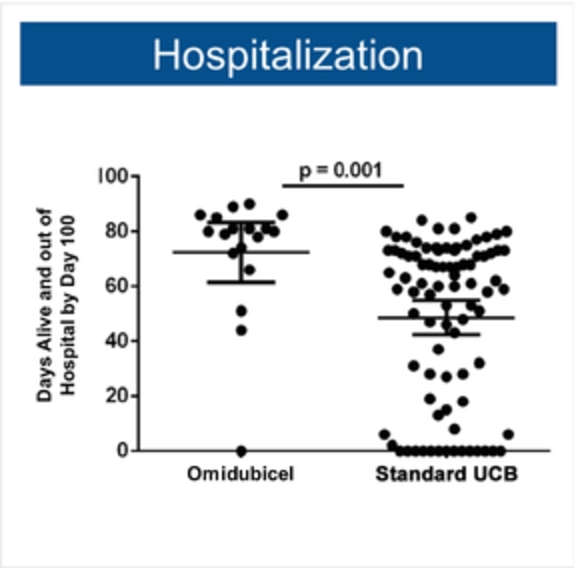

We are currently enrolling patients in an international, multicenter, randomized, pivotal Phase 3 clinical trial in 120 patients with hematologic malignancies, AML, ALL, CML, MDS and lymphomas. We anticipate reporting top-line data from this trial in the first half of 2020. In our Phase 1/2 clinical trial, sponsored by us, we enrolled 36 patients with hematologic malignancies who did not have a suitable matched donor. For comparison, we identified 146 patients as historic controls from data collected by the Center for International Blood and Marrow Transplant Research, or CIBMTR. The primary endpoint of neutrophil engraftment was met based on recovery of neutrophils, which are infection-fighting white blood cells. Neutrophil engraftment is defined as achieving a minimum neutrophil count of at least 0.5 x 109 per liter on three consecutive measurements on different days. There was a median recovery time of 11.5 days after transplantation in omidubicel treated patients, compared to 21 days observed in the historic controls. A key secondary endpoint, platelet engraftment, was also met with a median recovery time of 34 days in omidubicel treated patients, compared to 46 days in historic controls. Platelets are required for normal blood clotting and low platelet counts are associated with life-threatening hemorrhage. Platelet engraftment is defined as achieving a platelet count of at least 20 x 109 per liter on three consecutive measurements on different days, with no platelet transfusion in the preceding seven days. Efficient engraftment and robust immune reconstitution likely contributed to an observed reduction of 20 days in the number of days, post-transplant, that patients were hospitalized as compared to similar patients treated with standard cord blood. Based on the results of this Phase 1/2 trial, we received Breakthrough Therapy Designation from the FDA.

Our Strategy

Our goal is to deliver curative cell therapies to patients with serious and life-threatening medical conditions. The key strategies to achieve our goal are the following:

| • | Complete Phase 3 clinical development and obtain regulatory approval for omidubicel in hematologic malignancies. Assuming positive results from the Phase 3 clinical trial, we plan to seek regulatory approval for omidubicel in the United States, the European Union and other geographies. We have entered into an agreement with Lonza Netherlands B.V., or Lonza, pursuant to which Lonza will supplement our anticipated capacity for commercial production. |

| • | Advance omidubicel for the treatment of severe aplastic anemia in an ongoing Phase 1/2 clinical trial. We reported preliminary data from our Phase 1/2 clinical trial at the 2019 TCT Annual Meeting. All three patients enrolled in the first cohort were successfully treated with reduced intensity conditioning regimens and underwent an HSCT bone marrow transplant consisting of omidubicel plus a haploidentical stem cell graft. |

| • | Investigate the potential of GDA-201 in conjunction with therapeutic antibodies in additional cancer indications. Data reported from the first 14 patients in the ongoing investigator-sponsored Phase 1 trial of GDA-201 in patients with NHL and MM demonstrated that GDA-201 was highly active, with three complete responses observed in patients with NHL and one complete response in a patient with MM. |

| • | Maximize commercial value of our product candidates. If omidubicel is approved for stem cell transplantation, we intend to independently pursue the commercialization of omidubicel in the United States. Outside of the United States, we may pursue the approval and commercialization of omidubicel in collaboration with a partner. |

3

| • | Centralize manufacturing capabilities to deliver a pharmaceutical grade product to meet commercial demand. We currently have limited in-house GMP manufacturing capabilities. We are building additional manufacturing infrastructure at an identified site to diversify production of omidubicel and as we prepare for commercialization. |

| • | Demonstrate omidubicel’s value through Health Economics Outcomes Research. We believe that a favorable outcome of our ongoing Health Economics Outcomes Research analysis will inform price, reimbursement and adoption. Additionally, we are developing a reimbursement strategy modeled upon recently approved cell therapies in oncology through the New Technology Add-on Payment program. |

| • | Expand our pipeline of cell therapy product candidates by leveraging our cell expansion technology. We are utilizing our platform technology to develop GDA-201. Additionally, we plan to leverage our NAM-based expansion technology for the discovery of additional product candidates. |

Management Team, Board and Investor Base

We are led by an experienced management team with extensive expertise in developing oncology therapies and manufacturing cell therapies and other complex biologics. Our director and chief executive officer, Julian Adams, played a central role in the discovery and development of bortezomib, or Velcade®, a widely used therapy for MM and other blood cancers approved by the FDA in 2003. Dr. Adams also led research and development, or R&D, efforts at Infinity Pharmaceuticals, Inc., which helped lead to the 2018 FDA approval of duvelisib, also known as Copiktra®, for the treatment of certain leukemias and lymphomas. We are also backed by a strong board of directors and an investor base that includes Novartis, Clal Biotechnology Industries and Israel Biotech Fund.

Risks Associated With Our Business

Our business is subject to a number of risks of which you should be aware before making an investment decision. These risks are discussed more fully in the “Risk Factors” section of this prospectus immediately following this prospectus summary. These risks include, among others, the following:

| • | We have incurred significant losses since our inception. We anticipate that we will continue to incur significant losses for the foreseeable future, and we may never achieve or maintain profitability. |

| • | We have never generated any revenue from product sales and may never be profitable. |

| • | We are heavily dependent on the success of our product candidates, including obtaining regulatory approval to market our product candidates in the United States, the European Union and other geographies. |

| • | Our product candidates are based on novel technologies, which makes it difficult to predict the time and cost of development and of subsequently obtaining regulatory approval. |

| • | Our product candidates and the administration process may cause undesirable side effects or have other properties that could delay or prevent their regulatory approval, limit the commercial profile of an approved label or result in significant negative consequences following marketing approval, if any. |

| • | Our recurring losses from operations have raised substantial doubt regarding our ability to continue as a going concern absent access to sources of liquidity. |

| • | We rely on third parties to conduct certain elements of our preclinical studies and clinical trials and perform other tasks for us. If these third parties do not successfully carry out their contractual duties, meet expected deadlines or comply with regulatory requirements, we may not be able to obtain regulatory approval for or commercialize our product candidates. |

| • | We rely on a limited number of third parties or, in some cases, a sole third party, for some of our raw materials or certain equipment that we use to create our product candidates, and may not be able to find replacements in the event our supplier no longer provides sufficient quantities or fails to do so at acceptable quality levels or prices. |

4

| • | We rely upon a combination of patents, trade secret protection and confidentiality agreements to protect the intellectual property related to our technologies and product candidates, and we may not be able to compete effectively in our markets if we are unable to maintain sufficient intellectual property protection for our product candidates. |

| • | We currently have no marketing and sales organization. If we are unable to establish sales and marketing capabilities, or enter into agreements with third parties to market and sell our product candidates, if approved, we may be unable to generate any product revenue. |

| • | We do not anticipate that we will be classified as a passive foreign investment company for the current taxable year; however, if we are so classified, our U.S. shareholders could suffer adverse tax consequences. |

Corporate Information

We are an Israeli corporation based in Jerusalem, Israel, and were incorporated in 1998. Our principal executive offices are located at 5 Nahum Heftsadie St., Givaat Shaul, Jerusalem 91340, Israel and our U.S. subsidiary’s executive headquarters are in Boston, Massachusetts. Our telephone number is +972 (2) 659-5666. Our website address is www.gamida-cell.com. The information contained on our website and available through our website is an inactive textual reference only.

Implications of Being an “Emerging Growth Company” and a Foreign Private Issuer

As a company with less than $1.07 billion in revenue during our last fiscal year, we qualify as an “emerging growth company” as defined in the Jumpstart Our Business Startups Act of 2012, or the JOBS Act. An emerging growth company may take advantage of specified reduced reporting and other burdens that are otherwise applicable generally to public companies. These provisions include:

| • | a requirement to include only two years of audited financial statements and only two years of related Management’s Discussion and Analysis of Financial Condition and Results of Operations disclosure in our initial registration statement; |

| • | reduced executive compensation disclosure; |

| • | exemptions from the requirement to hold a non-binding advisory vote on executive compensation, including golden parachute compensation; and |

| • | an exemption from the auditor attestation requirement in the assessment of our internal control over financial reporting pursuant to the Sarbanes-Oxley Act of 2002. |

We may take advantage of these provisions for up to five years or such earlier time that we are no longer an emerging growth company. We would cease to be an emerging growth company upon the earlier to occur of: (1) the last day of the fiscal year in which we have total annual gross revenue of $1.07 billion or more; (2) the date on which we have issued more than $1.0 billion in nonconvertible debt during the previous three years; or (3) the date on which we are deemed to be a large accelerated filer under the rules of the Securities and Exchange Commission, or the SEC. We may choose to take advantage of some but not all of these reduced burdens, and therefore the information that we provide holders of our ordinary shares may be different than the information you might receive from other public companies in which you hold equity. In addition, Section 107 of the JOBS Act also provides that an emerging growth company can take advantage of an extended transition period for complying with new or revised accounting standards applicable to public companies. However, given that we currently report and expect to continue to report under IFRS as issued by the IASB, the extended transition period available to emerging growth companies that report under GAAP is inapplicable to us.

We report under the Securities Exchange Act of 1934, as amended, or the Exchange Act, as a non-U.S. company with foreign private issuer status. Even after we no longer qualify as an emerging growth company, as long as we continue to qualify as a foreign private issuer under the Exchange Act, we will be exempt from certain provisions of the Exchange Act that are applicable to U.S. domestic public companies, including:

| • | the sections of the Exchange Act regulating the solicitation of proxies, consents or authorizations with respect to a security registered under the Exchange Act; |

5

| • | the sections of the Exchange Act requiring insiders to file public reports of their share ownership and trading activities and liability for insiders who profit from trades made in a short period of time; and |

| • | the rules under the Exchange Act requiring the filing with the SEC of quarterly reports on Form 10-Q containing unaudited financial statements and other specified information, and current reports on Form 8-K upon the occurrence of specified significant events (although we intend to report our results of operations voluntarily on a quarterly basis). |

Both foreign private issuers and emerging growth companies are also exempt from certain more stringent executive compensation disclosure rules. Thus, even if we no longer qualify as an emerging growth company, but remain a foreign private issuer, we will continue to be exempt from the more stringent compensation disclosures required of companies that are neither an emerging growth company nor a foreign private issuer.

We would cease to be a foreign private issuer at such time as more than 50% of our outstanding voting securities are held by U.S. residents and any of the following three circumstances applies: (i) the majority of our executive officers or directors are U.S. citizens or residents, (ii) more than 50% of our assets are located in the United States or (iii) our business is administered principally in the United States.

In this prospectus, we have taken advantage of certain of the reduced reporting requirements as a result of being an emerging growth company and a foreign private issuer. Accordingly, the information contained herein may be different than the information you receive from other public companies in which you hold equity securities.

6

THE OFFERING

We intend to use the net proceeds from this offering, together with our existing cash and cash equivalents, available for sale and short-term deposits: (i) to fund clinical development of our product candidates, including the completion of our pivotal Phase 3 clinical trial of our lead product candidate, omidubicel, and the preparation of a Biologics Licensing Application for omidubicel; (ii) to expand our commercial and manufacturing capabilities; and (iii) for general corporate purposes and working capital.

See “Use of Proceeds” for more information about the intended use of proceeds from this offering.

7

Unless otherwise stated, the number of ordinary shares to be outstanding after this offering is based on 25,140,048 ordinary shares outstanding as of March 31, 2019, and excludes:

| • | 3,742,416 ordinary shares reserved for issuance upon the exercise of outstanding options as of March 31, 2019, at a weighted average exercise price of $4.21 per share; |

| • | 456,344 ordinary shares reserved for future issuance under our 2017 Share Incentive Plan, as of March 31, 2019, as well as any automatic increases in the number of common shares reserved for future issuance under this plan; |

| • | 466,375 ordinary shares issued upon the exercise of options after March 31, 2019; and |

| • | 3,313,512 ordinary shares issuable upon the exercise of outstanding warrants to purchase ordinary shares, at a weighted average exercise price of $6.72 per share, which warrants are expected to remain outstanding at the consummation of this offering. |

Unless otherwise indicated, all information in this prospectus assumes that the underwriters do not exercise their option to purchase up to an additional 606,000 ordinary shares.

8

SUMMARY CONSOLIDATED FINANCIAL DATA

The following tables summarize our consolidated financial data. We have derived the following statements of operations data for the years ended December 31, 2018, 2017 and 2016 from our audited consolidated financial statements included elsewhere in this prospectus. The following statements of operations data for the three months ended March 31, 2019 and 2018 and the balance sheet data as of March 31, 2019 have been derived from our unaudited condensed interim consolidated financial statements included elsewhere in this prospectus. Our historical results are not necessarily indicative of the results that may be expected in the future and our interim period results are not necessarily indicative of results to be expected for a full year or any other interim period. The following consolidated summary financial data should be read in conjunction with “Selected Consolidated Financial Data,” “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and our consolidated financial statements and related notes included elsewhere in this prospectus.

Year ended December 31, | Three months ended March 31, | ||||||||||||||

2018 | 2017 | 2016 | 2019 | 2018 | |||||||||||

(unaudited) | |||||||||||||||

(in thousands, except share and per share amounts) | |||||||||||||||

Statements of Operations Data: | |||||||||||||||

Research and development expenses, net | $ | 22,045 | $ | 15,018 | $ | 19,095 | $ | 7,283 | $ | 5,060 | |||||

General and administrative expenses | 11,599 | 4,472 | 4,614 | 3,813 | 1,653 | ||||||||||

Operating loss | 33,644 | 19,490 | 23,709 | 11,096 | 6,713 | ||||||||||

Financial expenses | 20,259 | 718 | 155 | 4,734 | 974 | ||||||||||

Financial income | (1,042 | ) | (1,197 | ) | (1,193 | ) | (349 | ) | (296 | ) | |||||

Loss before taxes on income | 52,861 | 19,011 | 22,671 | 15,481 | 7,391 | ||||||||||

Taxes on income | 70 | — | — | 26 | — | ||||||||||

Net Loss | 52,931 | 19,011 | 22,671 | 15,507 | 7,391 | ||||||||||

Basic and diluted net loss per ordinary share | $ | 10.53 | $ | 27.56 | $ | 32.86 | $ | 0.62 | $ | 10.78 | |||||

Weighted average number of ordinary shares, basic and diluted | 5,025,213 | 689,898 | 689,898 | 25,038,261 | 689,898 | ||||||||||

As of March 31, 2019 | ||||||

Actual | As Adjusted(1)(2) | |||||

(unaudited) | ||||||

(in thousands) | ||||||

Balance Sheet Data: | ||||||

Cash and cash equivalents, available-for-sale financial assets and short-term deposits | $ | 50,406 | $ | 78,074 | ||

Working Capital(3) | 43,124 | 70,792 | ||||

Total Assets | 61,047 | 88,715 | ||||

Total Shareholders’ Equity | 13,145 | 40,813 | ||||

| (1) | Data presented on an as adjusted basis to give effect to the sale of 4,040,000 ordinary shares in this offering at the assumed public offering price of $7.47 per ordinary share, which was the last reported sale price of our ordinary shares on The Nasdaq Global Market on June 20, 2019, and after deducting the underwriting discounts and commissions and estimated offering expenses payable by us. |

| (2) | Each $1.00 increase (decrease) in the assumed public offering price of $7.47 per ordinary share, which was the last reported sale price of our ordinary shares on The Nasdaq Global Market on June 20, 2019, would increase (decrease), respectively, each of cash and cash equivalents, working capital, total assets and total shareholders’ equity on an as adjusted basis by approximately $3.80/(3.80) million, assuming the number of ordinary shares offered by us, as set forth on the cover of this prospectus, remains the same, and after deducting the underwriting discounts and commissions and estimated offering expenses payable by us. Similarly, each increase (decrease) of 1.0 million in the number of ordinary shares we are offering would increase (decrease), respectively, each of cash and cash equivalents, working capital, total assets and total shareholders’ equity on an as adjusted basis by approximately $7.02/(7.02) million, assuming the assumed public offering price per ordinary share remains the same, and after deducting the underwriting discounts and commissions and estimated offering expenses payable by us. The as adjusted information is illustrative only, and we will adjust this information based on the actual public offering price and other terms of this offering determined at pricing. |

| (3) | Working capital is defined as total current assets minus total current liabilities. |

9

Investing in our ordinary shares involves a high degree of risk. You should carefully consider the risks and uncertainties described below, in addition to the other information set forth in this prospectus, including the consolidated financial statements and the related notes included elsewhere in this prospectus, before purchasing our ordinary shares. If any of the following risks actually occurs, our business, financial condition, cash flows and results of operations could be negatively impacted. In that case, the trading price of our ordinary shares would likely decline and you might lose all or part of your investment. Additional risks and uncertainties not presently known to us or that we currently deem immaterial also may impair our business operations.

Risks Related to Our Financial Condition and Capital Requirements

We have incurred significant losses since our inception. We anticipate that we will continue to incur significant losses for the foreseeable future, and we may never achieve or maintain profitability.

We are a clinical-stage biopharmaceutical company. We have incurred net losses each year since our inception in 1998, including net losses of $15.5 million and $7.4 million for the three months ended March 31, 2019 and 2018, respectively, and $52.9 million, $19.0 million and $22.7 million for the years ended December 31, 2018, 2017 and 2016, respectively. As of March 31, 2019, we had an accumulated deficit of $184.7 million.

We have devoted substantially all of our financial resources to designing and developing our product candidates, including conducting preclinical studies and clinical trials and providing general and administrative support for these operations. We expect to continue to incur significant expenses and increasing operating losses for the foreseeable future. Our ability to ultimately achieve recurring revenue and profitability, which we do not expect to occur for at least several years, is dependent upon our ability to successfully complete the development of our product candidates, obtain necessary regulatory approvals for and successfully manufacture, market and commercialize our products.

We anticipate that our expenses will increase substantially based on a number of factors, including to the extent that we:

| • | continue our clinical development of omidubicel for the treatment of hematologic malignancies and other rare, serious hematologic diseases; |

| • | seek regulatory and marketing approvals for our product candidates that successfully complete clinical studies; |

| • | identify, assess, acquire, license and/or develop other product candidates; |

| • | establish and validate our commercial-scale current good manufacturing practices, or cGMP, manufacturing facilities; |

| • | establish a sales, marketing and distribution infrastructure to commercialize any products for which we may obtain marketing approval; |

| • | hire personnel and invest in additional infrastructure to support our operations as a public company and expand our product development; |

| • | enter into agreements to license intellectual property from, or to, third parties; |

| • | develop, maintain, protect and expand our intellectual property portfolio; and |

| • | experience any delays or encounter issues with respect to any of the above, including but not limited to, failed studies, complex results, safety issues or other regulatory challenges that require longer follow-up of existing studies, additional major studies or additional supportive studies in order to pursue marketing approval. |

To date, we have financed our operations primarily through our initial public offering of equity securities, private placements of equity securities and royalty-bearing grants that we received from the Israeli Innovation Authority, or the IIA, formerly known as the Office of the Chief Scientist of the Ministry of Economy and Industry. The amount of our future net losses will depend, in part, on the rate of our future expenditures and our ability to obtain funding through equity or debt financings, strategic collaborations,

10

or grants. Even if we obtain regulatory approval to market one or more product candidates, our future revenue will depend upon the size of any markets in which such product candidates receive approval, and our ability to achieve sufficient market acceptance, pricing, reimbursement from third-party payors for such product candidates. Further, the net losses that we incur may fluctuate significantly from quarter to quarter and year to year, such that a period-to-period comparison of our results of operations may not be a good indication of our future performance. We may also incur other unanticipated costs from our operations.

We will need to raise substantial additional funding, which may not be available on acceptable terms, or at all. Failure to obtain funding on acceptable terms and on a timely basis may require us to curtail, delay or discontinue our product development efforts or other operations.

Our audited consolidated financial statements for each of the three years in the period ended December 31, 2018 and our unaudited financial statements for the three months ended March 31, 2019, included elsewhere in this prospectus, note that there is substantial doubt about our ability to continue as a going concern, absent sources of additional liquidity. In order to fund further operations, we will need to raise capital. We may seek these funds through a combination of private and public equity offerings, debt financings, government grants, strategic collaborations and licensing arrangements. Additional financing may not be available when we need it or may not be available on terms that are favorable to us. These conditions raise substantial doubt about our ability to continue as a going concern, and we will be required to raise additional funds, seek alternative means of financial support, or both, in order to continue operations. The accompanying audited consolidated financial statements have been prepared assuming that we will continue as a going concern and do not include adjustments that might result from the outcome of this uncertainty. If we are unable to raise the requisite funds, we will need to curtail or cease operations.

Developing our product candidates is expensive, and we expect our research and development expenses to increase substantially in connection with our ongoing activities, particularly as we advance our product candidates through preclinical studies and clinical development in an effort to obtain regulatory approval. We are conducting a Phase 3 clinical trial of our lead product candidate, omidubicel, for the treatment of hematologic malignancies. We expect to report top-line data in the first half of 2020. Assuming positive results from the Phase 3 clinical trial, we plan to seek regulatory approval for omidubicel in the United States and the European Union, and we may seek such approvals in other geographies. We also plan to continue our Phase 1/2 investigator-sponsored clinical trial of omidubicel for the treatment of severe aplastic anemia and our Phase 1 investigator-sponsored clinical trial of our GDA-201 product candidate for the treatment of relapsed or refractory non-Hodgkin lymphoma, or NHL, and multiple myeloma, or MM. We also incur additional ongoing costs associated with operating as a public company.

As of March 31, 2019, we had cash and cash equivalents and available-for-sale financial assets of $50.3 million. We currently believe that our existing capital resources will be sufficient to meet our projected operating requirements through March 2020. We will require significant additional financing in the future to fund our operations. Our future funding requirements will depend on many factors, including, but not limited to:

| • | the progress, results and costs of our current and planned clinical trials of omidubicel and our other future product candidates; |

| • | the cost, timing and outcomes of regulatory review of omidubicel and our other future product candidates; |

| • | the costs of establishing and maintaining one or more of our planned commercial-scale cGMP manufacturing facilities, including in Kiryat Gat, Israel, and/or engaging third-party manufacturers; |

| • | the scope, progress, results and costs of product development, laboratory testing, manufacturing, preclinical development and clinical trials for any other product candidates that we may develop or otherwise obtain in the future; |

11

| • | the cost of our future activities, including establishing sales, marketing and distribution capabilities for any product candidates in any particular geography where we receive marketing approval for such product candidates; |

| • | the terms and timing of any collaborative, licensing and other arrangements that we may establish; |

| • | the costs of preparing, filing and prosecuting patent applications, maintaining and enforcing our intellectual property rights and defending intellectual property-related claims; and |

| • | the level of revenue, if any, received from commercial sales of any product candidates for which we receive marketing approval. |

Identifying potential product candidates and conducting preclinical testing and clinical trials is a time-consuming, expensive and uncertain process that takes years to complete, and we may never generate the necessary data or results required to obtain marketing approval and achieve product sales. In addition, our product candidates, if approved, may not achieve commercial success. Our product revenue, if any, will be derived from or based on sales of product candidates that may not be commercially available for many years, if at all. Accordingly, we will need to continue to rely on additional financing to achieve our business objectives. Any additional fundraising efforts may divert our management from their day-to-day activities, which may adversely affect our ability to develop and commercialize our product candidates.

We cannot guarantee that future financing will be available in sufficient amounts or on terms acceptable to us, if at all, and the terms of any financing may adversely affect the interests or rights of our shareholders. Even if we believe that we have sufficient funds for our current or future operating plans, we may seek additional capital if market conditions are favorable or if we have specific strategic considerations. The issuance of additional securities, whether equity or debt, by us, or the possibility of such issuance, may cause the market price of our shares to decline.

Raising additional capital may cause dilution to our shareholders, restrict our operations or require us to relinquish rights to our technologies or product candidates.

Until such time, if ever, as we can generate substantial product revenue, we expect to obtain additional capital through a combination of equity offerings, debt financings and collaborations and strategic and licensing arrangements. To the extent that we raise additional capital through the sale of equity or convertible debt securities, your ownership interest will be diluted, and the terms of such securities may include liquidation or other preferences that adversely affect your rights as a shareholder. Debt financing, if available, may involve covenants restricting our operations or our ability to incur additional debt. If we raise additional funds through collaboration and licensing arrangements with third parties, it may be necessary to relinquish certain rights to our technologies or our product candidates, or to grant licenses on terms that are not favorable to us.

If we are unable to obtain funding on acceptable terms and on a timely basis, we may be required to significantly curtail, delay or discontinue one or more of our research, development or manufacturing programs or the commercialization of any approved product, or be unable to expand our operations or otherwise capitalize on our business opportunities, as desired, which could materially affect our business, financial condition and results of operations.

We have never generated any revenue from product sales and may never be profitable.

We have no products approved for marketing in any jurisdiction, and we have never generated any revenue from product sales. Our ability to generate revenue and achieve profitability depends on our ability, alone or with strategic collaboration partners, to successfully complete the development of, and obtain the regulatory and marketing approvals necessary to commercialize one or more of our product candidates. We do not anticipate generating revenue from product sales for at least the next several years. Our ability to generate future revenue from product sales will depend heavily on our ability to:

| • | complete research and preclinical and clinical development of our product candidates in a timely and successful manner; |

12

| • | obtain regulatory and marketing approval for those of our product candidates for which we complete clinical studies; |

| • | develop and obtain regulatory approval for a sustainable and scalable in-house and/or third-party manufacturing process that meets all applicable regulatory standards for our approved product candidates; |

| • | establish and maintain supply and, if applicable, manufacturing relationships with third parties that can provide adequate, in both amount and quality, products to support clinical development and the market demand for our product candidates, if and when approved; |

| • | launch and commercialize our product candidates for which we obtain regulatory and marketing approval, either directly by establishing a sales force, marketing and distribution infrastructure, and/or with collaborators or distributors; |

| • | expose, educate and train physicians and other medical professionals to use our products; |

| • | obtain market acceptance, if and when approved, of our product candidates from the medical community and third-party payors; |

| • | ensure procedures utilizing our product candidates are approved for coverage and adequate reimbursement from governmental agencies, private insurance plans, managed care organizations, and other third-party payors in jurisdictions where they have been approved for marketing; |

| • | address any competing technological and market developments that impact our product candidates or their prospective usage by medical professionals; |

| • | identify, assess, acquire and/or develop new product candidates; |

| • | negotiate favorable terms in any collaboration, licensing or other arrangements into which we may enter and perform our obligations under such collaborations; |

| • | maintain, protect and expand our portfolio of intellectual property rights, including patents, patent applications, trade secrets and know-how; |

| • | avoid and defend against third-party interference, infringement or other intellectual property related claims; |

| • | attract, hire and retain qualified personnel; and |

| • | locate and lease or acquire suitable facilities to support our clinical development, manufacturing facilities and commercial expansion. |

Even if one or more of our product candidates is approved for marketing and sale, we anticipate incurring significant incremental costs associated with commercializing such product candidates. Our expenses could increase beyond expectations if we are required by the U.S. Food and Drug Administration, or the FDA, the European Medicines Agency, or the EMA, or other regulatory agencies or ethical committees in medical centers, to change our manufacturing processes or assays or to perform clinical, nonclinical, or other types of studies in addition to those that we currently anticipate. Even if we are successful in obtaining regulatory approvals to market one or more of our product candidates, our revenue earned from such product candidates will be dependent in part upon the size of the markets in the territories for which we gain regulatory approval for such products, the accepted price for such products, our ability to obtain reimbursement for such products at any price, whether we own the commercial rights for that territory in which such products have been approved and the expenses associated with manufacturing and marketing such products for such markets. Therefore, we may not generate significant revenue from the sale of such products, even if approved. Further, if we are not able to generate significant revenue from the sale of our approved products, we may be forced to curtail or cease our operations. Due to the numerous risks and uncertainties involved in product development, it is difficult to predict the timing or amount of increased expenses, or when, or if, we will be able to achieve or maintain profitability.

13

Risks Related to the Discovery, Development and Clinical Testing of Our Product Candidates

We are heavily dependent on the success of our product candidates, including obtaining regulatory approval to market our product candidates in the United States, the European Union and other geographies.

To date, we have deployed all of our efforts and financial resources to: (i) research and develop our nicotinamide-based, or NAM-based, cell expansion technology, our lead product candidate, omidubicel, for the treatment of hematologic malignancies, and our other product candidates, including conducting preclinical and clinical studies and providing general and administrative support for these operations; and (ii) develop and secure our intellectual property portfolio for our product candidates. Our future success is dependent on our ability to successfully develop, obtain regulatory approval for and commercialize one or more of our current and future product candidates. Our product candidates’ marketability is subject to significant risks associated with successfully completing current and future clinical trials and commercializing our product candidates that receive regulatory approval, including:

| • | completion of our ongoing international, multicenter, randomized, pivotal Phase 3 clinical trial of omidubicel for the treatment of hematologic malignancies and the clinical trials of our other product candidates, and for any other product candidates for which we may file an Investigational New Drug, or IND, application, without which we would be unable to commence such clinical trials; |

| • | acceptance by the FDA, EMA or other regulatory agencies of our parameters for regulatory approval relating to omidubicel and our other product candidates, including our proposed indications, primary and secondary endpoint assessments and measurements, safety evaluations and regulatory pathways; |

| • | the acceptance by the FDA, EMA or other regulatory agencies of the number, design, size, conduct and implementation of our clinical trials, our trial protocols and the interpretation of data from preclinical studies or clinical trials; |

| • | our ability to successfully complete the clinical trials of our product candidates, including timely patient enrollment and acceptable safety and efficacy data and our ability to demonstrate the safety and efficacy of the product candidates undergoing such clinical trials; |

| • | our ability to complete our Phase 3 clinical trial of omidubicel for the treatment of hematologic malignancies in the United States in a timely fashion, and that such single pivotal Phase 3 clinical trial, even if successfully completed, will be sufficient to support approval of a Biologics License Application, or BLA; |

| • | the FDA’s acceptance of the sufficiency of the data we collect from our preclinical studies and our investigator-sponsored Phase 1/2 clinical trial of omidubicel for the treatment of severe aplastic anemia and of GDA-201 for the treatment of NHL and MM; |

| • | the willingness of the FDA, EMA or other regulatory agencies to schedule an advisory committee meeting in a timely manner to evaluate and decide on the approval of our regulatory filings, if such advisory committee meetings are required; |

| • | the recommendation of the FDA’s advisory committee to approve our applications to market omidubicel and our other product candidates in the United States, and the EMA in the European Union, if such advisory committee reviews are scheduled, without limiting the approved labeling, specifications, distribution or use of the products, or imposing other restrictions; |

| • | the satisfaction of the FDA, EMA or other regulatory agencies with the safety and efficacy of our product candidates; |

| • | the prevalence and severity of adverse events associated with our product candidates; |

| • | the timely and satisfactory performance by third-party contractors, trial sites and principal investigators of their obligations in relation to our clinical trials; |

| • | our success in educating medical professionals and patients about the benefits, administration and use of our product candidates, if approved; |

14

| • | the availability, perceived advantages, relative cost, safety and efficacy of alternative and competing treatments for the indications addressed by our product candidates; |

| • | the effectiveness of our marketing, sales and distribution strategy, and operations, as well as that of any current and future licensees; |

| • | the extent to which third-party payors provide coverage and adequate reimbursement for procedures utilizing our products; |

| • | our ability to develop, validate and maintain a commercially viable manufacturing process that is compliant with cGMP; |

| • | our ability to obtain, maintain, protect and enforce our intellectual property rights with respect to our product candidates; and |

| • | changes to regulatory guidelines. |

Many of these clinical, regulatory and commercial risks are beyond our control. Accordingly, we cannot assure you that we will be able to advance any of our product candidates through clinical development, or to obtain regulatory approval of or commercialize any of our product candidates. If we fail to achieve these objectives or overcome the challenges presented above, we could experience significant delays or an inability to successfully commercialize our product candidates. Accordingly, we may not be able to generate sufficient revenue through the sale of our product candidates to enable us to continue our business.

We may be unable to obtain regulatory approval for our product candidates.

The research, development, testing, manufacturing, labeling, packaging, approval, promotion, advertising, storage, recordkeeping, marketing, distribution, post-approval monitoring and reporting and export and import of drug products are subject to extensive regulation by the FDA, the EMA and by regulatory authorities in other countries. These regulations differ from country to country. To gain approval to market our product candidates, we must provide data from well-controlled clinical trials that adequately demonstrate the safety and efficacy of the product for the intended indication to the satisfaction of the FDA, EMA or other regulatory authority. We have not yet obtained regulatory approval to market any of our product candidates in the United States or any other country. The FDA, EMA or other regulatory agencies can delay, limit or deny approval of our product candidates for many reasons, including:

| • | regulatory requests for additional analyses, reports, data, non-clinical and preclinical studies and clinical trials; |

| • | our inability to demonstrate that the product candidates are safe and effective for the target indication to the satisfaction of the FDA, EMA or other regulatory agencies; |

| • | the FDA’s, EMA’s, or other regulatory agencies’ disagreement with our clinical trial protocol, the interpretation of data from preclinical studies or clinical trials, or adequacy of the conduct and control of clinical trials; |

| • | clinical holds, other regulatory objections to commencing or continuing a clinical trial or the inability to obtain regulatory approval to commence a clinical trial in countries that require such approvals; |

| • | the population studied in the clinical trial may not be sufficiently broad or representative to assess safety in the patient population for which we seek approval; |

| • | unfavorable or inconclusive results of clinical trials and supportive non-clinical studies, including unfavorable results regarding safety or efficacy of our product candidates observed in clinical trials; |

| • | our inability to demonstrate that clinical or other benefits of our product candidates outweigh any safety or other perceived risks; |

| • | any determination that a clinical trial presents unacceptable health risks to subjects; |

15

| • | our inability to obtain approval from institutional review boards, or IRBs, to conduct clinical trials at their respective sites; |

| • | the non-approval of the formulation, labeling or the specifications of our product candidates; |

| • | the failure to accept the manufacturing processes or facilities at our manufacturing site or those of third-party manufacturers with which we contract; |

| • | the potential for approval policies or regulations of the FDA, EMA or other regulatory agencies to significantly change in a manner rendering our clinical data insufficient for approval; or |

| • | resistance to approval from the advisory committees of the FDA, EMA or other regulatory agencies for any reason including safety or efficacy concerns. |

In the United States, we will be required to submit a BLA, to obtain FDA approval before marketing any of our product candidates. A BLA must include extensive preclinical and clinical data and supporting information to establish the product candidate’s safety, purity and potency, or efficacy, for each desired indication. The BLA must also include significant information regarding the chemistry, manufacturing and controls for the product. The FDA may further inspect our manufacturing facilities to ensure that they can manufacture our product candidates and our products, if and when approved, in compliance with the applicable regulatory requirements, as well as inspect our clinical trial sites to ensure that our studies are properly conducted. Obtaining approval of a BLA is a lengthy, expensive and uncertain process, and approval may not be obtained. Upon submission of a BLA, the FDA must make an initial determination that the application is sufficiently complete to accept the submission for filing. We cannot be certain that any submissions will be accepted for filing and review by the FDA, or ultimately be approved. If the application is not accepted for review or approval, the FDA may require that we conduct additional clinical or preclinical trials, or take other actions before it will reconsider our application. If the FDA requires additional studies or data, we would incur increased costs and delays in the marketing approval process, which may require us to expend more resources than we have available. In addition, the FDA may not consider any additional information to be complete or sufficient to support approval.

Regulatory authorities outside of the United States, such as in the European Union, also have requirements for approval of biologics for commercial sale with which we must comply prior to marketing in those areas. Regulatory requirements can vary widely from country to country and could delay or prevent the introduction of our product candidates. Clinical trials conducted in one country may not be accepted by regulatory authorities in other countries, and obtaining regulatory approval in one country does not mean that regulatory approval will be obtained in any other country. However, the failure to obtain regulatory approval in one jurisdiction could have a negative impact on our ability to obtain approval in a different jurisdiction. Approval processes vary among countries and can involve additional product candidate testing and validation and additional administrative review periods. Seeking additional regulatory approvals outside the United States and European Union could require additional non-clinical studies or clinical trials, which could be costly and time consuming. These regulatory approvals may include all of the risks associated with obtaining FDA or EMA approval. For all of these reasons, if we seek such regulatory approvals for any of our other product candidates, we may not obtain such approvals on a timely basis, if at all.

Even if we eventually complete clinical testing and receive approval of any regulatory filing for our product candidates, the FDA may grant approval contingent on the performance of costly and potentially time-consuming additional post-approval clinical trials or subject to contraindications, black box warnings, restrictive surveillance or a Risk Evaluation and Mitigation Strategy, or REMS. Further, the FDA, EMA or other regulatory authorities may also approve our product candidates for a more limited indication or a narrower patient population than we originally requested, and these regulatory authorities may not approve the labeling that we believe is necessary or desirable for the successful commercialization of our product candidates. Following any approval for commercial sale of our product candidates, certain changes to the product, such as changes in manufacturing processes and additional labeling claims, as well as new safety information, will be subject to additional FDA notification, or review and approval. Also, regulatory approval for any of our product candidates may be withdrawn. To the extent we seek regulatory approval in jurisdictions outside of the United States and European Union, we may face challenges similar to those described above with regulatory authorities in applicable jurisdictions.

16

Any delay in obtaining, or inability to obtain, applicable regulatory approval for any of our product candidates would delay or prevent commercialization of our product candidates and would thus negatively impact our business, results of operations and prospects.

Clinical development is difficult to design and implement and involves a lengthy and expensive process with uncertain outcomes.

Clinical testing is expensive and can take many years to complete, and its outcome is inherently uncertain. Bone marrow transplant and cell-based therapies that appear promising in the early phases of development may fail to reach the market. Further, a failure of one or more of our clinical trials can occur at any time during the clinical trial process. We do not know whether future clinical trials, if any, will begin on time, need to be redesigned, enroll an adequate number of patients on time or be completed on schedule, if at all. Clinical trials can be delayed, suspended or terminated for a variety of reasons, including failure to:

| • | generate sufficient preclinical, toxicology, or other in vivo or in vitro data to support the initiation or continuation of clinical trials; |

| • | obtain regulatory approval, or feedback on trial design, in order to commence a trial; |

| • | identify, recruit and train suitable clinical investigators; |

| • | reach agreement on acceptable terms with prospective contract research organizations, or CROs, and clinical trial sites, the terms of which can be subject to extensive negotiation and may vary significantly among CROs and clinical trial sites, and have such CROs and sites effect the proper and timely conduct of our clinical trials; |

| • | obtain and maintain IRB approval at each clinical trial site; |

| • | identify, recruit and enroll suitable patients to participate in a trial; |

| • | have a sufficient number of patients complete a trial or return for post-treatment follow-up; |

| • | ensure clinical investigators and clinical trial sites observe trial protocol or continue to participate in a trial; |

| • | address any patient safety concerns that arise during the course of a trial; |

| • | address any conflicts with new or existing laws or regulations; |

| • | add a sufficient number of clinical trial sites; |

| • | manufacture sufficient quantities at the required quality of product candidate for use in clinical trials; or |

| • | raise sufficient capital to fund a trial. |

We may also experience numerous unforeseen events during, or as a result of, clinical trials that could delay or prevent our ability to receive marketing approval or commercialize our product candidates, including:

| • | we may receive feedback from regulatory authorities that requires us to modify the design of our clinical trials; |

| • | clinical trials of our product candidates may produce negative or inconclusive results, and we may decide, or regulators may require us, to conduct additional clinical trials or abandon development programs; |

| • | the number of patients required for clinical trials of our product candidates may be larger than we anticipate, enrollment in these clinical trials may be slower than we anticipate or participants may drop out of these clinical trials at a higher rate than we anticipate; |

| • | our third-party contractors may fail to comply with regulatory requirements or meet their contractual obligations to us in a timely manner, or at all; |

17

| • | regulators or IRBs may not authorize us or our investigators to commence a clinical trial or conduct a clinical trial at a prospective trial site or amend a trial protocol; |

| • | we may have delays in reaching or fail to reach agreement on acceptable clinical trial contracts or clinical trial protocols with prospective trial sites and CROs; |

| • | we or our investigators might have to suspend or terminate clinical trials of our product candidates for various reasons, including non-compliance with regulatory requirements, a finding that our product candidates have undesirable side effects or other unexpected characteristics, or a finding that the participants are being exposed to unacceptable health risks; |

| • | the cost of clinical trials of our product candidates may be greater than we anticipate; |

| • | the supply or quality of our product candidates or other materials necessary to conduct clinical trials of our product candidates may be insufficient or inadequate; |

| • | there may be changes in government regulations or administrative actions; |

| • | our product candidates may have undesirable adverse effects or other unexpected characteristics; |

| • | we may not be able to demonstrate that a produce candidate’s clinical and other benefits outweigh its safety risks; |

| • | we may not be able to demonstrate that a product candidate provides an advantage over current standards of care of future competitive therapies in development; |

| • | regulators may revise the requirements for approving our product candidates, or such requirements may not be as we anticipate; and |

| • | any future collaborators that conduct clinical trials may face any of the above issues, and may conduct clinical trials in ways they view as advantageous to them but that are suboptimal for us. |

We may also encounter delays if a clinical trial is suspended or terminated by us, by the IRBs of the institutions in which such trials are being conducted, by the trial’s data safety monitoring board, by the FDA, EMA or other regulatory agencies. Such authorities may suspend or terminate one or more of our clinical trials due to a number of factors, including our failure to conduct the clinical trial in accordance with relevant regulatory requirements or clinical protocols, inspection of the clinical trial operations or trial site by the FDA, EMA or other regulatory agencies resulting in the imposition of a clinical hold, unforeseen safety issues or adverse side effects, failure to demonstrate a benefit from using a drug, changes in governmental regulations or administrative actions or lack of adequate funding to continue the clinical trial. In particular, while we currently expect to report top-line data in the first half of 2020 for our Phase 3 clinical trial comparing transplantation with omidubicel versus standard cord blood, no assurance can be given that we will be able to maintain that timing.

Further, conducting clinical trials in countries outside of the United States and European Union, as we plan to do for our product candidates, presents additional risks that may delay completion of our clinical trials. These risks include the failure of enrolled patients in foreign countries to adhere to clinical protocol as a result of differences in healthcare services or cultural customs, managing additional administrative burdens associated with jurisdiction-specific regulatory schemes, as well as political and economic risks relevant to such jurisdictions.

If we experience delays in carrying out or completing any clinical trial of our product candidates, the commercial prospects of our product candidates may be harmed, and our ability to generate product revenue from any of these product candidates will be delayed. In addition, any delays in completing our clinical trials will increase our costs, slow down our product candidate development and approval process and jeopardize our ability to commence product sales and generate revenue. Any of these occurrences may significantly harm our business and financial condition. In addition, many of the factors that cause, or lead to, a delay in the commencement or completion of clinical trials may also ultimately lead to the denial of regulatory approval of our product candidates.

18

The results of earlier studies and trials may not be predictive of future trial results, and our clinical trials may fail to adequately demonstrate the safety and efficacy of our product candidates.