North American Lithium DFS Technical Report Summary – Quebec, Canada Exhibit 96.3 North American Lithium DFS Technical Report Summary – Quebec, Canada 2 DOCUMENT ISSUES AND APPROVALS Document Information Project: North American Lithium S-K 1300 Technical Report Summary Document Name: OMS_2024_Sayona_NAL_TRS_Final_241114 Title: S-K 1300 Technical Report Summary for Mineral Resource and Mineral Reserves at North American Lithium Client: Sayona Date: 9th December 2024 Report Effective Date: 30th June 2024 Contributors Name Position Signature Prepared by: Tony O’Connell M AusIMM Principal Mining Engineer Steve Andrews M AusIMM Principal Consultant - Corporate Advisory Alan Hocking M AusIMM Principal Consultant Simon O’Leary M AusIMM Principal Process Engineer Approved by: Tony O’Connell M AusIMM Principal Mining Engineer North American Lithium DFS Technical Report Summary – Quebec, Canada 3 TABLE OF CONTENTS 1. Executive Summary ...................................................................................................................... 21 1.1 Introduction .......................................................................................................................... 21 1.2 Forward Looking Notice ........................................................................................................ 21 1.3 Background ........................................................................................................................... 22 1.4 Property Description and Ownership ................................................................................... 23 1.4.1 Surface Rights ................................................................................................................ 26 1.4.2 Property History ............................................................................................................ 26 1.5 Geology and Mineralization .................................................................................................. 27 1.6 Exploration ............................................................................................................................ 27 1.7 Mineral Reserve Estimates ................................................................................................... 28 1.8 Mineral Resource Estimate ................................................................................................... 29 1.9 Material Development and Operations ................................................................................ 30 1.10 Mine Design .......................................................................................................................... 30 1.11 Recovery Methods ................................................................................................................ 32 1.11.1 Metallurgical Testing ..................................................................................................... 33 1.12 Project Infrastructure ............................................................................................................ 33 1.13 Capital and Operating Cost Estimates .................................................................................. 35 1.13.1 Capital Costs .................................................................................................................. 35 1.13.2 Operating Costs ............................................................................................................. 35 1.14 Market Studies ...................................................................................................................... 36 1.14.1 Market Balance ............................................................................................................. 36 1.14.2 Spodumene Price Forecast ........................................................................................... 36 1.15 Environmental, Social and Permitting .................................................................................. 37 1.15.1 Environmental Studies .................................................................................................. 37 1.15.2 Status of Negotiations with Stakeholders ..................................................................... 37 1.15.3 Permitting ..................................................................................................................... 38 1.15.4 Reclamation and Closure .............................................................................................. 38 1.16 Economic Analysis ................................................................................................................. 38 1.17 ConcLUsions and Recommendations .................................................................................... 40 1.17.1 Key Outcomes ............................................................................................................... 40 1.17.2 QP Recommendations .................................................................................................. 41 North American Lithium DFS Technical Report Summary – Quebec, Canada 4 1.18 Revision Notes ...................................................................................................................... 41 2. Introduction ................................................................................................................................. 42 2.1 Terms of Reference and Purpose of the Report ................................................................... 42 2.2 Qualifications of Qualified Persons/Firms ............................................................................ 43 2.2.1 Contributing Authors .................................................................................................... 43 2.2.2 Site Visit ......................................................................................................................... 43 2.3 Source of information ........................................................................................................... 46 2.4 Units of Measure & Glossary of Terms ................................................................................. 46 3. Property Description .................................................................................................................... 52 3.1 Property Location, Country, Regional and Government Setting .......................................... 52 3.2 Mineral Tenure, Agreement and Royalties ........................................................................... 55 3.2.1 Surface Rights ................................................................................................................ 55 3.2.2 Mineral Rights and Permitting ...................................................................................... 57 3.2.3 Agreements and Royalties ............................................................................................ 58 3.3 Environmental Liabilities and Other Permitting Requirements ............................................ 58 3.4 Mineral and Surface Purchase Agreements .......................................................................... 60 3.5 Other Significant Factors and Risks ....................................................................................... 60 4. Accessibility, Climate, Physiography, Local Resources, and Infrastructure ................................. 61 4.1 Accessibility ........................................................................................................................... 61 4.2 Topography, Elevation, Vegetation and Climate .................................................................. 62 4.2.1 Physiography ................................................................................................................. 62 4.2.2 Climate .......................................................................................................................... 66 4.2.3 Vegetation ..................................................................................................................... 66 4.3 Local Infrastructure and Resources ...................................................................................... 67 4.3.1 Airports, Rail Terminals, and Bus Services .................................................................... 67 4.3.2 Local Workforce ............................................................................................................ 67 4.3.3 Additional Support Services .......................................................................................... 68 5. History .......................................................................................................................................... 69 5.1 General .................................................................................................................................. 69 5.2 Historical Production ............................................................................................................ 70 5.2.1 Ownership and Activities .............................................................................................. 70 5.2.2 Historical Production..................................................................................................... 72 5.2.3 2021 Acquisition to Present .......................................................................................... 75

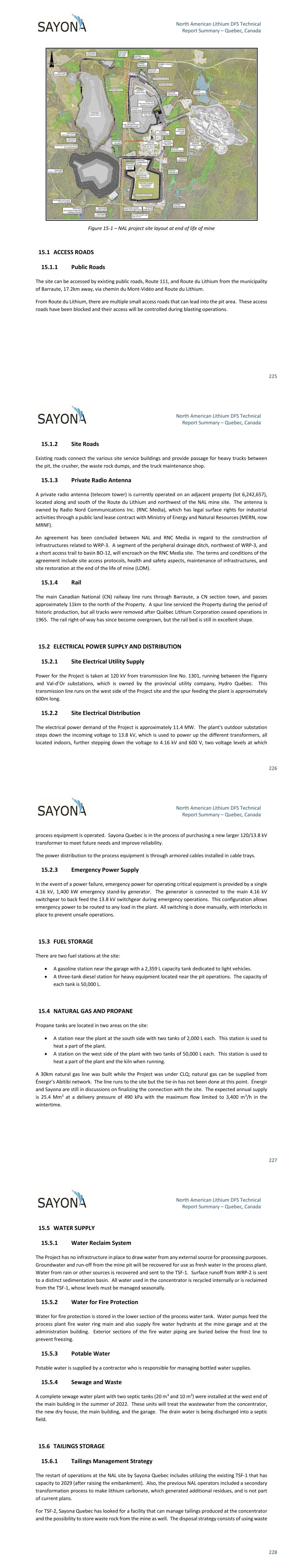

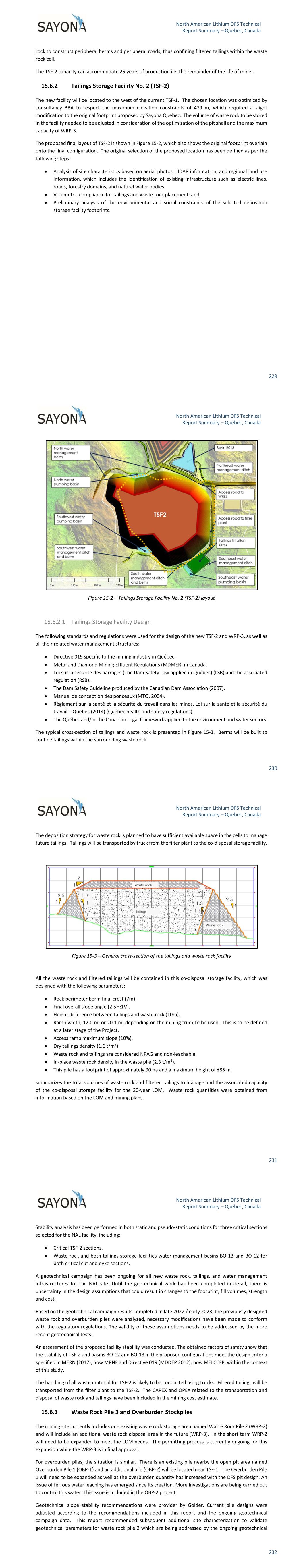

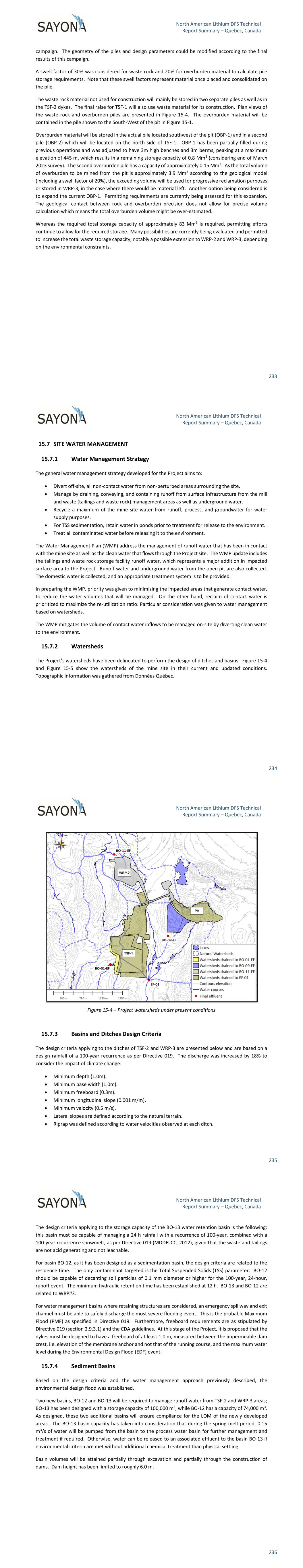

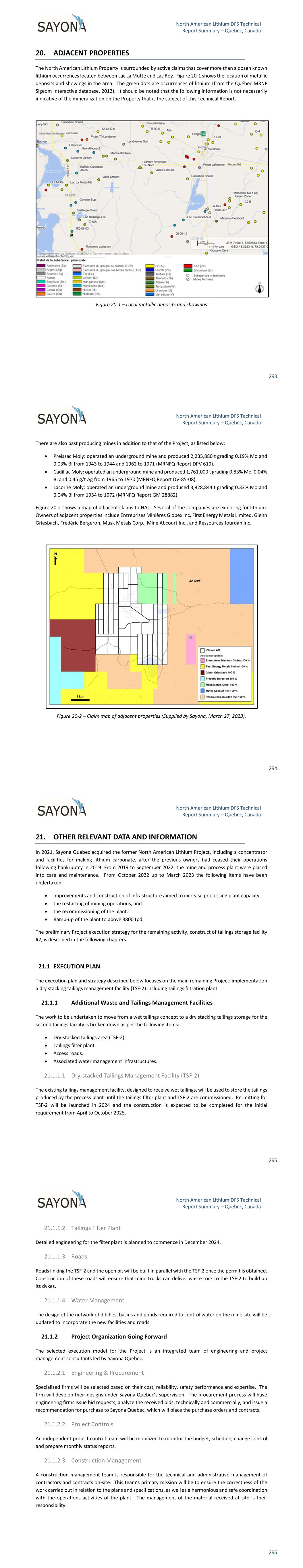

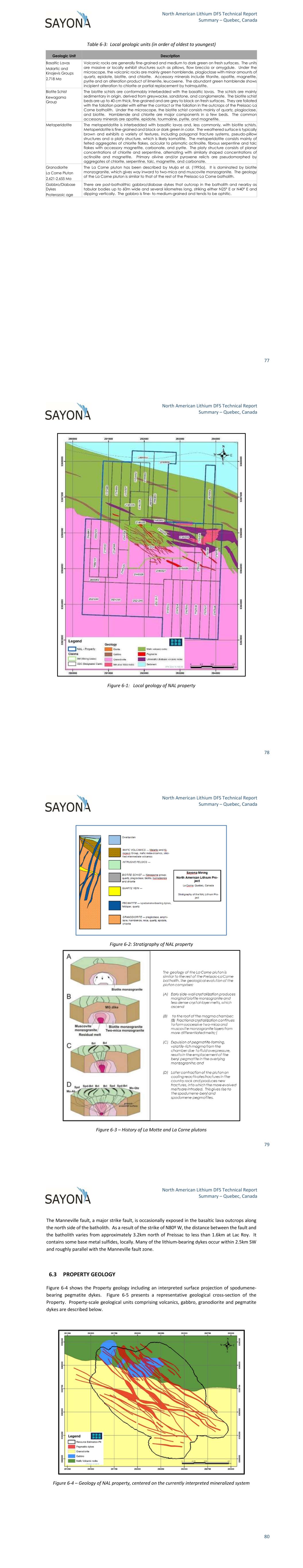

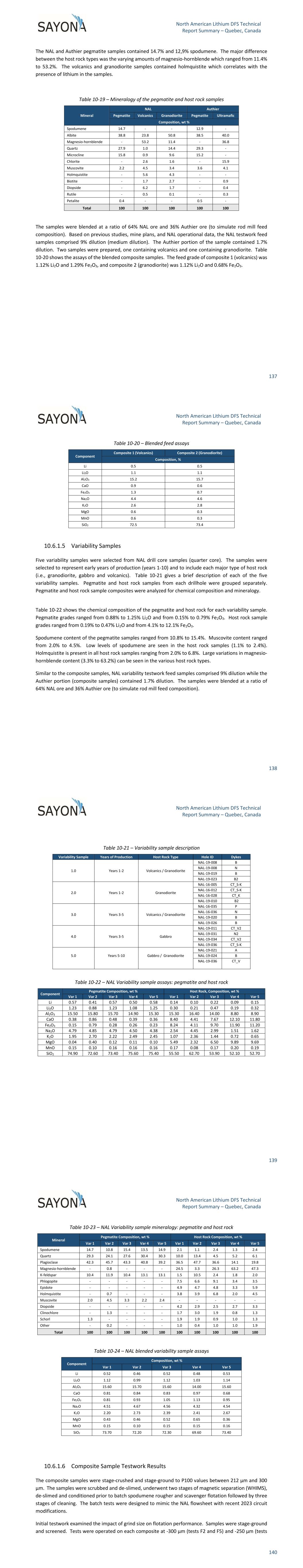

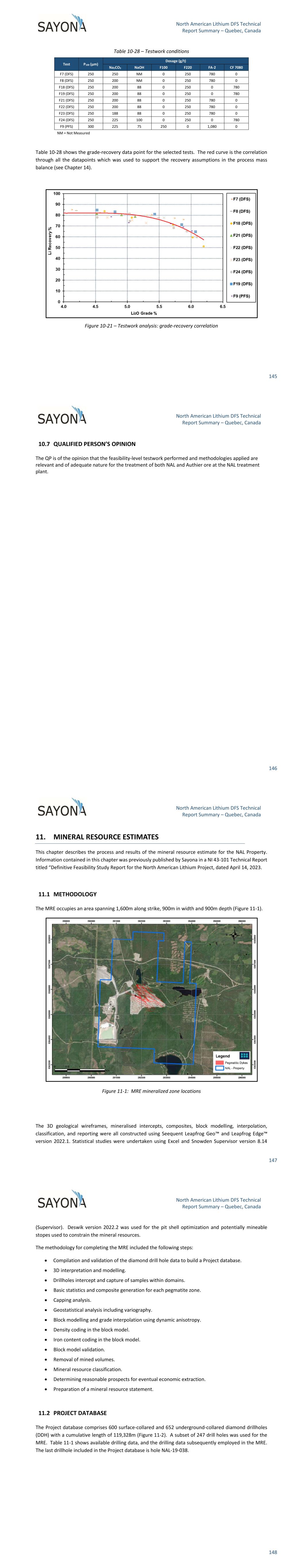

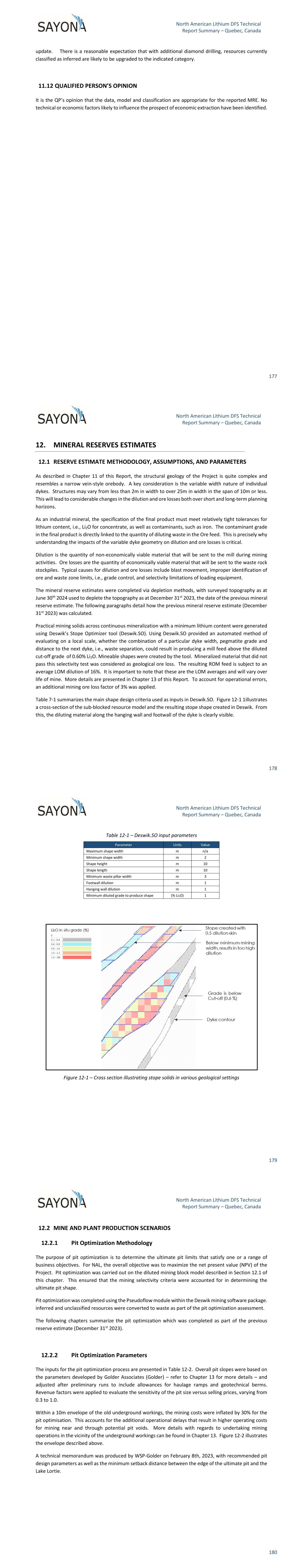

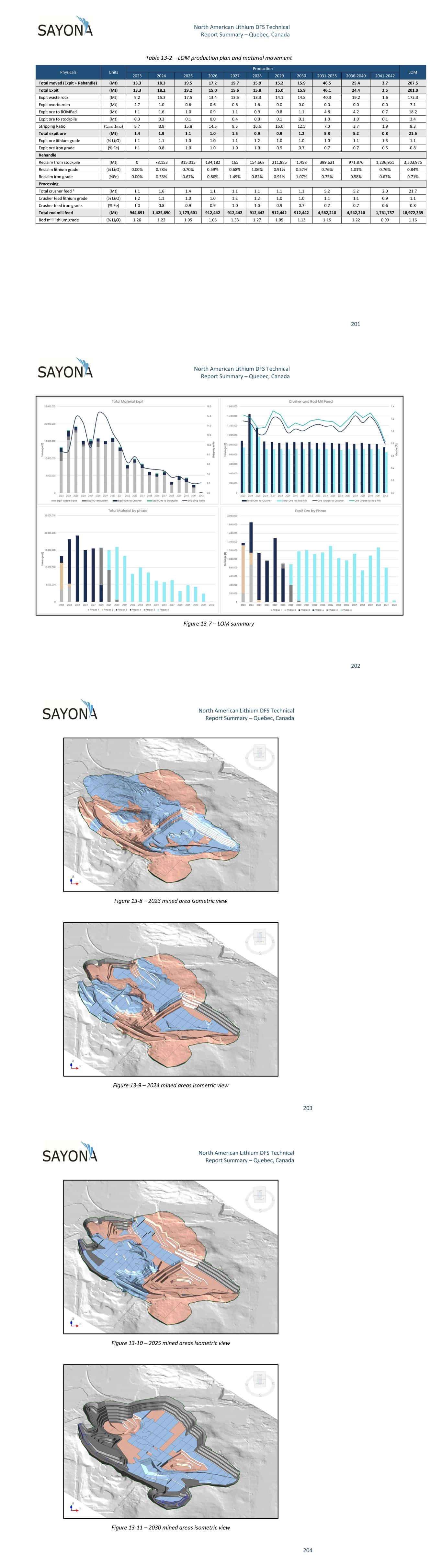

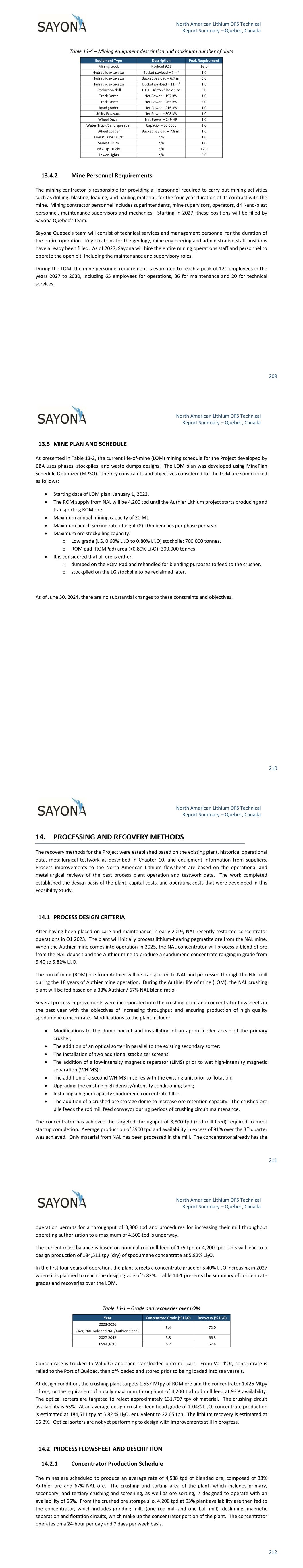

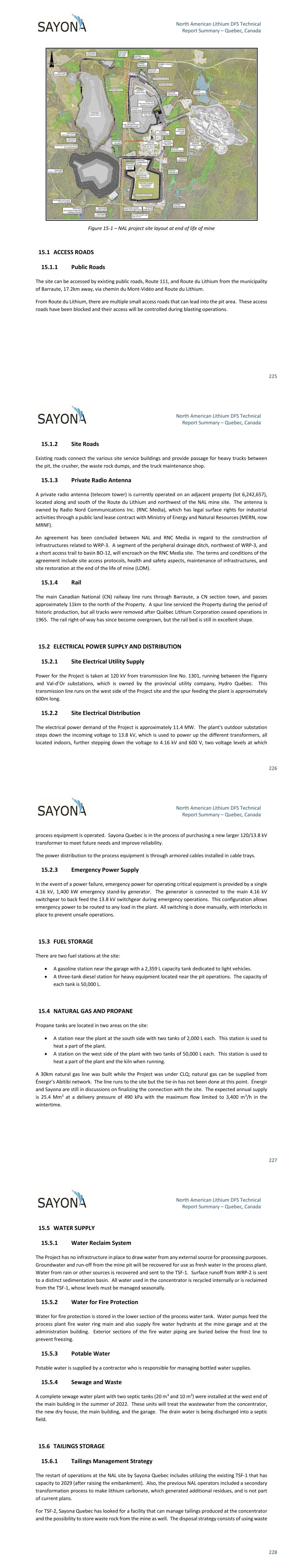

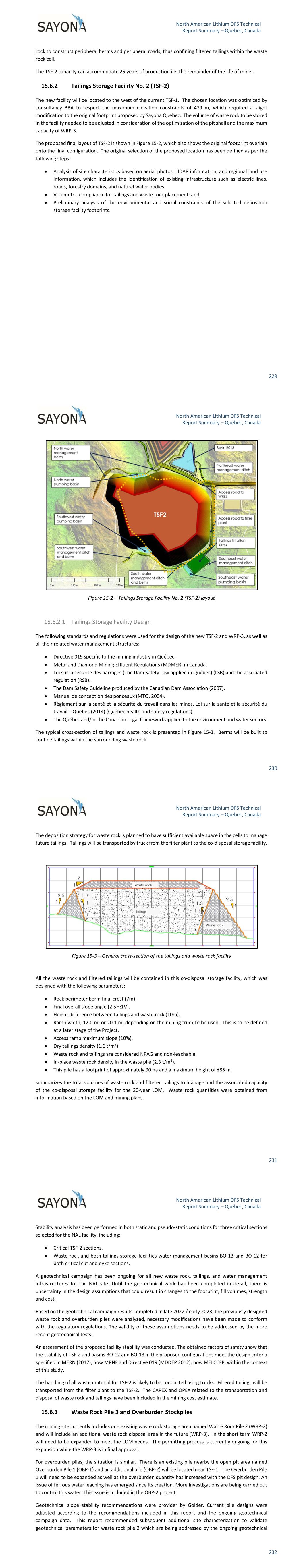

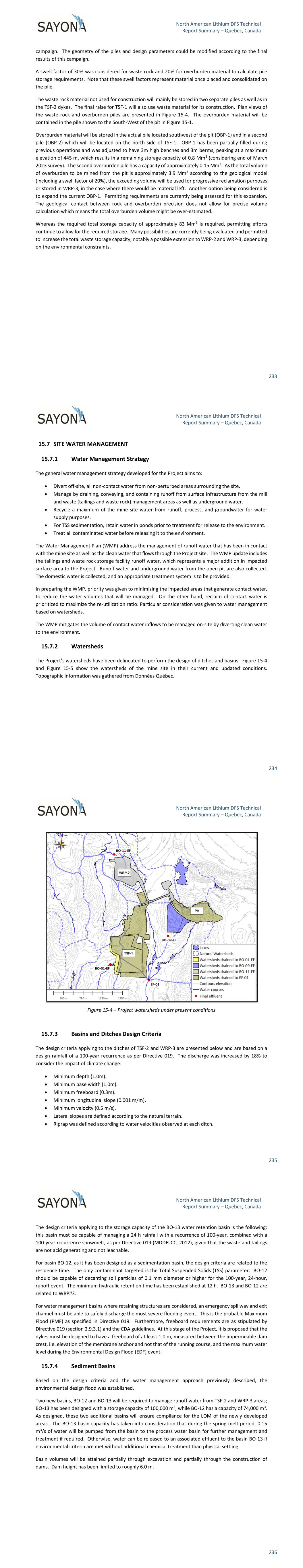

North American Lithium DFS Technical Report Summary – Quebec, Canada 5 6. GEOLOGICAL SETTING, MINERALISATION, AND DEPOSIT ............................................................ 76 6.1 Regional Geology .................................................................................................................. 76 6.2 Local Geology ........................................................................................................................ 76 6.3 Property Geology .................................................................................................................. 80 6.3.1 Volcanics ....................................................................................................................... 81 6.3.2 Granodiorite .................................................................................................................. 82 6.3.3 Pegmatite Dykes ........................................................................................................... 82 6.3.4 Mineralization ............................................................................................................... 84 6.4 Deposit Types ........................................................................................................................ 86 6.4.1 Rare-Element Pegmatites of the Superior Province ..................................................... 86 6.4.2 La Corne Pluton Rare-Element Pegmatites ................................................................... 87 7. EXPLORATION ............................................................................................................................... 89 7.1 Exploration Drilling ................................................................................................................ 89 7.1.1 Historical ....................................................................................................................... 90 7.1.2 Canada Lithium Corp. (2009 – 2011) ............................................................................ 91 7.1.3 North American Lithium Corp. (2016 – 2019) ............................................................... 91 7.1.4 Sayona (2022 – 2024) .................................................................................................... 92 7.2 Drilling Procedures ................................................................................................................ 93 7.2.1 Collar Surveys ................................................................................................................ 93 7.2.2 Downhole Surveys ......................................................................................................... 93 7.3 Core Logging Procedures ...................................................................................................... 94 8. SAMPLE PREPARATION, ANALYSES AND SECURITY ..................................................................... 98 8.1 Sample Preparation Methods ............................................................................................... 98 8.2 Analytical Laboratory Procedures ....................................................................................... 100 8.3 QA/QC (Analytical) Procedures ........................................................................................... 100 8.4 Qualified Person’s Opinion ................................................................................................. 101 9. Data verification ......................................................................................................................... 102 9.1 Project Database Validation ................................................................................................ 102 9.1.1 Drillhole Locations ....................................................................................................... 102 9.1.2 Downhole Surveys ....................................................................................................... 102 9.1.3 Assay Certificates ........................................................................................................ 102 9.2 Site Visit............................................................................................................................... 104 9.2.1 Drilling and Sampling Procedure Validation ............................................................... 106 North American Lithium DFS Technical Report Summary – Quebec, Canada 6 9.2.2 Log and Core Box Validation ....................................................................................... 107 9.2.3 Validation of Sample Preparation, Analytical, QA/QC and Security Procedures ........ 107 9.3 Qualified Person’s Opinion ................................................................................................. 107 10. MINERAL PROCESSING AND METALLURGICAL TESTING ......................................................... 108 10.1 Introduction ........................................................................................................................ 108 10.2 North American Lithium – Historical Process Plant Operations ......................................... 108 10.2.1 Québec Lithium Concentrator Operations 2013-2014 ............................................... 108 10.2.2 North American Lithium – Operations 2017-2019 ..................................................... 109 10.3 Metallurgical Laboratory TestWork Program ..................................................................... 111 10.3.1 North American Lithium Testwork Review ................................................................. 111 10.3.2 Optical Ore Sorting Test Program – 2011 ................................................................... 112 10.3.3 Historical Plant Operating Data – 2014 ....................................................................... 114 10.4 NAL 2016 Re-start Metallurgical Testing ............................................................................ 115 10.5 Authier Metallurgical Testwork Review .............................................................................. 117 10.5.1 Historical Authier Testwork ........................................................................................ 117 10.5.2 Feasibility-level Authier Testwork (2018) ................................................................... 119 10.6 Blended Ore (NAL and Authier) Testwork review ............................................................... 128 10.6.1 Preliminary Testwork (2019) ....................................................................................... 128 10.7 Qualified Person’s Opinion ................................................................................................. 146 11. MINERAL RESOURCE ESTIMATES ............................................................................................ 147 11.1 Methodology ....................................................................................................................... 147 11.2 Project Database ................................................................................................................. 148 11.3 Geological Interpretation and Domaining .......................................................................... 150 11.4 Exploratory Data Analysis ................................................................................................... 152 11.4.1 Raw Assays .................................................................................................................. 152 11.4.2 Compositing ................................................................................................................ 154 11.4.3 Grade Capping ............................................................................................................. 156 11.5 Density Estimation .............................................................................................................. 157 11.6 Geostatistics and Grade Estimation .................................................................................... 158 11.6.1 Variography ................................................................................................................. 158 11.6.2 Block Model ................................................................................................................ 161 11.6.3 Grade Interpolation .................................................................................................... 162 11.6.4 Block Model Validation ............................................................................................... 167 North American Lithium DFS Technical Report Summary – Quebec, Canada 7 11.7 Mineral Resource Classification .......................................................................................... 171 11.8 RPEEE Consideration and Cut-off Grade ............................................................................. 172 11.9 Mineral Resource Statement .............................................................................................. 174 11.10 Iron Content in the MRE ................................................................................................. 175 11.11 Uncertainty ..................................................................................................................... 176 11.12 Qualified Person’s Opinion ............................................................................................. 177 12. Mineral Reserves Estimates .................................................................................................... 178 12.1 Reserve Estimate Methodology, Assumptions, and Parameters........................................ 178 12.2 Mine and Plant Production Scenarios ................................................................................. 180 12.2.1 Pit Optimization Methodology .................................................................................... 180 12.2.2 Pit Optimization Parameters ....................................................................................... 180 12.2.3 Analysis of Pit Optimization Results ............................................................................ 182 12.2.4 Mine Design and Production ....................................................................................... 186 12.2.5 Plant Production ......................................................................................................... 192 12.3 Mineral Reserve Estimate ................................................................................................... 193 12.4 Permitting & Environmental Constraints ............................................................................ 195 12.5 Assumptions and Reserve Estimate Risks ........................................................................... 195 13. Mining Methods ...................................................................................................................... 196 13.1 Mine Design ........................................................................................................................ 196 13.1.1 Pit Phasing Strategy .................................................................................................... 196 13.1.2 LOM Production Plan .................................................................................................. 200 13.2 Geotechnical and Hydrological Considerations .................................................................. 206 13.3 Mine Operating Strategy ..................................................................................................... 207 13.4 Mining Fleet and Manning .................................................................................................. 208 13.4.1 Mine Equipment and Operations ................................................................................ 208 13.4.2 Mine Personnel Requirements ................................................................................... 209 13.5 Mine Plan and Schedule ...................................................................................................... 210 14. Processing and Recovery Methods ......................................................................................... 211 14.1 Process Design Criteria ....................................................................................................... 211 14.2 Process Flowsheet and Description .................................................................................... 212 14.2.1 Concentrator Production Schedule ............................................................................. 212 14.2.2 Concentrator Operating Design Parameters .............................................................. 213 14.2.3 Concentrator Facilities Description ............................................................................. 214 North American Lithium DFS Technical Report Summary – Quebec, Canada 8 14.2.4 Concentrator Consumables ........................................................................................ 217 14.2.5 Concentrator Process Water ....................................................................................... 219 14.2.6 Concentrator Personnel .............................................................................................. 219 14.2.7 Utilities ........................................................................................................................ 221 14.3 Products and Recoveries ..................................................................................................... 222 14.4 Recommendations .............................................................................................................. 222 15. Infrastructure .......................................................................................................................... 224 15.1 Access Roads ....................................................................................................................... 225 15.1.1 Public Roads ................................................................................................................ 225 15.1.2 Site Roads .................................................................................................................... 226 15.1.3 Private Radio Antenna ................................................................................................ 226 15.1.4 Rail ............................................................................................................................... 226 15.2 Electrical Power Supply and Distribution ............................................................................ 226 15.2.1 Site Electrical Utility Supply ........................................................................................ 226 15.2.2 Site Electrical Distribution ........................................................................................... 226 15.2.3 Emergency Power Supply ............................................................................................ 227 15.3 Fuel Storage ........................................................................................................................ 227 15.4 Natural Gas And Propane.................................................................................................... 227 15.5 Water Supply ....................................................................................................................... 228 15.5.1 Water Reclaim System ................................................................................................ 228 15.5.2 Water for Fire Protection ............................................................................................ 228 15.5.3 Potable Water ............................................................................................................. 228 15.5.4 Sewage and Waste ...................................................................................................... 228 15.6 Tailings Storage ................................................................................................................... 228 15.6.1 Tailings Management Strategy ................................................................................... 228 15.6.2 Tailings Storage Facility No. 2 (TSF-2) ......................................................................... 229 15.6.3 Waste Rock Pile 3 and Overburden Stockpiles ........................................................... 232 15.7 Site Water Management ..................................................................................................... 234 15.7.1 Water Management Strategy ..................................................................................... 234 15.7.2 Watersheds ................................................................................................................. 234 15.7.3 Basins and Ditches Design Criteria .............................................................................. 235 15.7.4 Sediment Basins .......................................................................................................... 236 15.7.5 Pumping System .......................................................................................................... 237

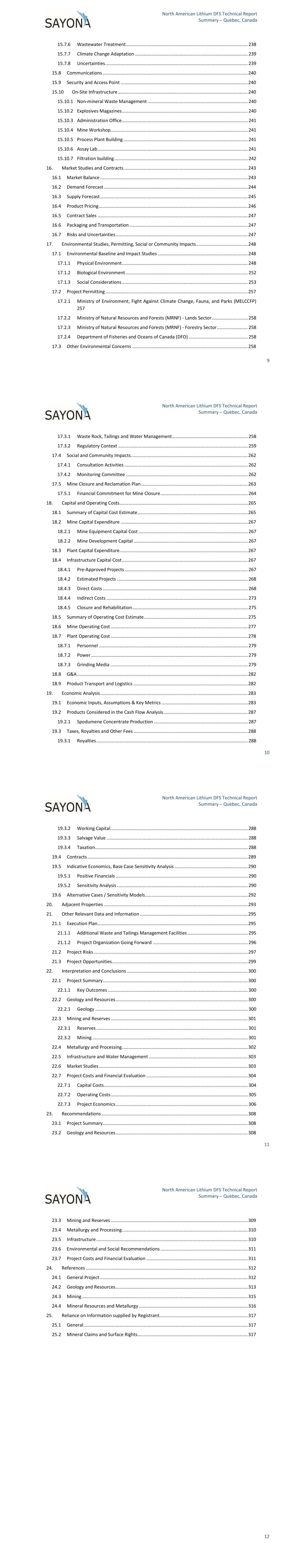

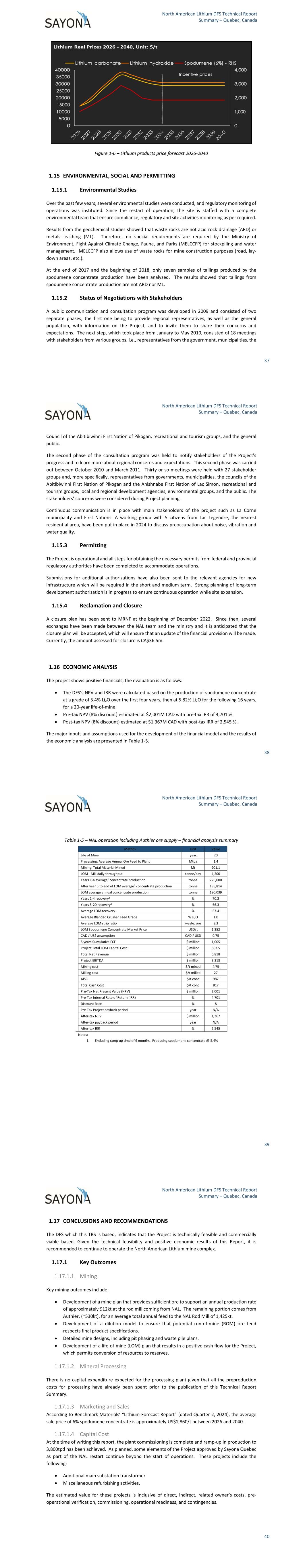

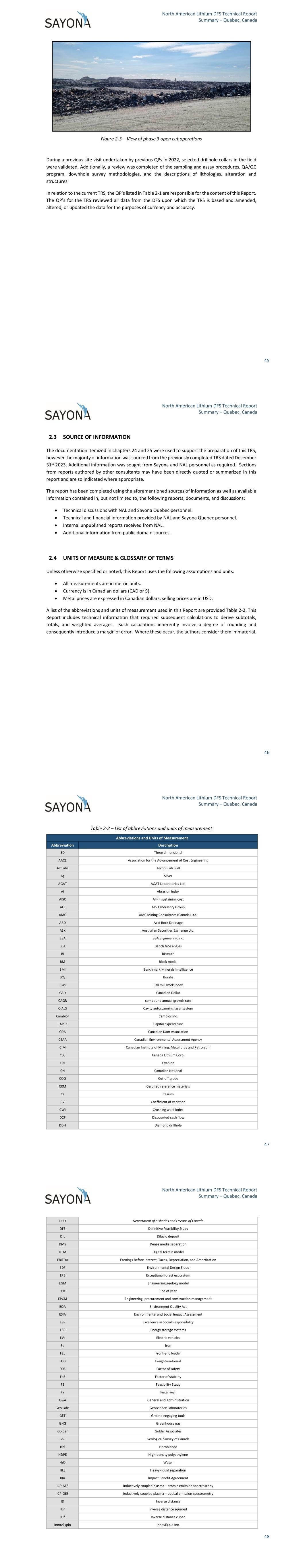

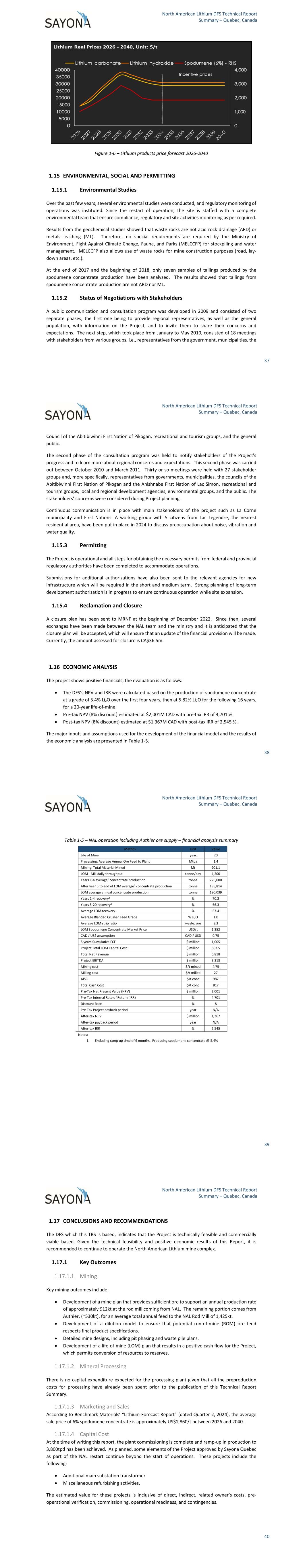

North American Lithium DFS Technical Report Summary – Quebec, Canada 9 15.7.6 Wastewater Treatment ............................................................................................... 238 15.7.7 Climate Change Adaptation ........................................................................................ 239 15.7.8 Uncertainties ............................................................................................................... 239 15.8 Communications ................................................................................................................. 240 15.9 Security and Access Point ................................................................................................... 240 15.10 On-Site Infrastructure ..................................................................................................... 240 15.10.1 Non-mineral Waste Management .............................................................................. 240 15.10.2 Explosives Magazines .................................................................................................. 240 15.10.3 Administration Office .................................................................................................. 241 15.10.4 Mine Workshop........................................................................................................... 241 15.10.5 Process Plant Building ................................................................................................. 241 15.10.6 Assay Lab ..................................................................................................................... 241 15.10.7 Filtration building ........................................................................................................ 242 16. Market Studies and Contracts................................................................................................. 243 16.1 Market Balance ................................................................................................................... 243 16.2 Demand Forecast ................................................................................................................ 244 16.3 Supply Forecast ................................................................................................................... 245 16.4 Product Pricing .................................................................................................................... 246 16.5 Contract Sales ..................................................................................................................... 247 16.6 Packaging and Transportation ............................................................................................ 247 16.7 Risks and Uncertainties ....................................................................................................... 247 17. Environmental Studies, Permitting, Social or Community Impacts ........................................ 248 17.1 Environmental Baseline and Impact Studies ...................................................................... 248 17.1.1 Physical Environment .................................................................................................. 248 17.1.2 Biological Environment ............................................................................................... 252 17.1.3 Social Considerations .................................................................................................. 253 17.2 Project Permitting ............................................................................................................... 257 17.2.1 Ministry of Environment, Fight Against Climate Change, Fauna, and Parks (MELCCFP) 257 17.2.2 Ministry of Natural Resources and Forests (MRNF) - Lands Sector ............................ 258 17.2.3 Ministry of Natural Resources and Forests (MRNF) - Forestry Sector ........................ 258 17.2.4 Department of Fisheries and Oceans of Canada (DFO) .............................................. 258 17.3 Other Environmental Concerns .......................................................................................... 258 North American Lithium DFS Technical Report Summary – Quebec, Canada 10 17.3.1 Waste Rock, Tailings and Water Management ........................................................... 258 17.3.2 Regulatory Context ..................................................................................................... 259 17.4 Social and Community Impacts ........................................................................................... 262 17.4.1 Consultation Activities ................................................................................................ 262 17.4.2 Monitoring Committee ............................................................................................... 262 17.5 Mine Closure and Reclamation Plan ................................................................................... 263 17.5.1 Financial Commitment for Mine Closure .................................................................... 264 18. Capital and Operating Costs .................................................................................................... 265 18.1 Summary of Capital Cost Estimate ...................................................................................... 265 18.2 Mine Capital Expenditure ................................................................................................... 267 18.2.1 Mine Equipment Capital Cost ..................................................................................... 267 18.2.2 Mine Development Capital ......................................................................................... 267 18.3 Plant Capital Expenditure.................................................................................................... 267 18.4 Infrastructure Capital Cost .................................................................................................. 267 18.4.1 Pre-Approved Projects ................................................................................................ 267 18.4.2 Estimated Projects ...................................................................................................... 268 18.4.3 Direct Costs ................................................................................................................. 268 18.4.4 Indirect Costs .............................................................................................................. 273 18.4.5 Closure and Rehabilitation .......................................................................................... 275 18.5 Summary of Operating Cost Estimate ................................................................................. 275 18.6 Mine Operating Cost ........................................................................................................... 277 18.7 Plant Operating Cost ........................................................................................................... 278 18.7.1 Personnel .................................................................................................................... 279 18.7.2 Power .......................................................................................................................... 279 18.7.3 Grinding Media ........................................................................................................... 279 18.8 G&A ..................................................................................................................................... 282 18.9 Product Transport and Logistics ......................................................................................... 282 19. Economic Analysis ................................................................................................................... 283 19.1 Economic Inputs, Assumptions & Key Metrics ................................................................... 283 19.2 Products Considered in the Cash Flow Analysis .................................................................. 287 19.2.1 Spodumene Concentrate Production ......................................................................... 287 19.3 Taxes, Royalties and Other Fees ......................................................................................... 288 19.3.1 Royalties ...................................................................................................................... 288 North American Lithium DFS Technical Report Summary – Quebec, Canada 11 19.3.2 Working Capital ........................................................................................................... 288 19.3.3 Salvage Value .............................................................................................................. 288 19.3.4 Taxation ....................................................................................................................... 288 19.4 Contracts ............................................................................................................................. 289 19.5 Indicative Economics, Base Case Sensitivity Analysis ......................................................... 290 19.5.1 Positive Financials ....................................................................................................... 290 19.5.2 Sensitivity Analysis ...................................................................................................... 290 19.6 Alternative Cases / Sensitivity Models ................................................................................ 292 20. Adjacent Properties ................................................................................................................ 293 21. Other Relevant Data and Information .................................................................................... 295 21.1 Execution Plan ..................................................................................................................... 295 21.1.1 Additional Waste and Tailings Management Facilities ............................................... 295 21.1.2 Project Organization Going Forward .......................................................................... 296 21.2 Project Risks ........................................................................................................................ 297 21.3 Project Opportunities.......................................................................................................... 299 22. Interpretation and Conclusions .............................................................................................. 300 22.1 Project Summary ................................................................................................................. 300 22.1.1 Key Outcomes ............................................................................................................. 300 22.2 Geology and Resources ....................................................................................................... 300 22.2.1 Geology ....................................................................................................................... 300 22.3 Mining and Reserves ........................................................................................................... 301 22.3.1 Reserves ...................................................................................................................... 301 22.3.2 Mining ......................................................................................................................... 301 22.4 Metallurgy and Processing .................................................................................................. 302 22.5 Infrastructure and Water Management ............................................................................. 303 22.6 Market Studies .................................................................................................................... 303 22.7 Project Costs and Financial Evaluation ............................................................................... 304 22.7.1 Capital Costs ................................................................................................................ 304 22.7.2 Operating Costs ........................................................................................................... 305 22.7.3 Project Economics ....................................................................................................... 306 23. Recommendations .................................................................................................................. 308 23.1 Project Summary ................................................................................................................. 308 23.2 Geology and Resources ....................................................................................................... 308 North American Lithium DFS Technical Report Summary – Quebec, Canada 12 23.3 Mining and Reserves ........................................................................................................... 309 23.4 Metallurgy and Processing .................................................................................................. 310 23.5 Infrastructure ...................................................................................................................... 310 23.6 Environmental and Social Recommendations .................................................................... 311 23.7 Project Costs and Financial Evaluation ............................................................................... 311 24. References .............................................................................................................................. 312 24.1 General Project ................................................................................................................... 312 24.2 Geology and Resources ....................................................................................................... 313 24.3 Mining ................................................................................................................................. 315 24.4 Mineral Resources and Metallurgy ..................................................................................... 316 25. Reliance on Information supplied by Registrant ..................................................................... 317 25.1 General ................................................................................................................................ 317 25.2 Mineral Claims and Surface Rights...................................................................................... 317

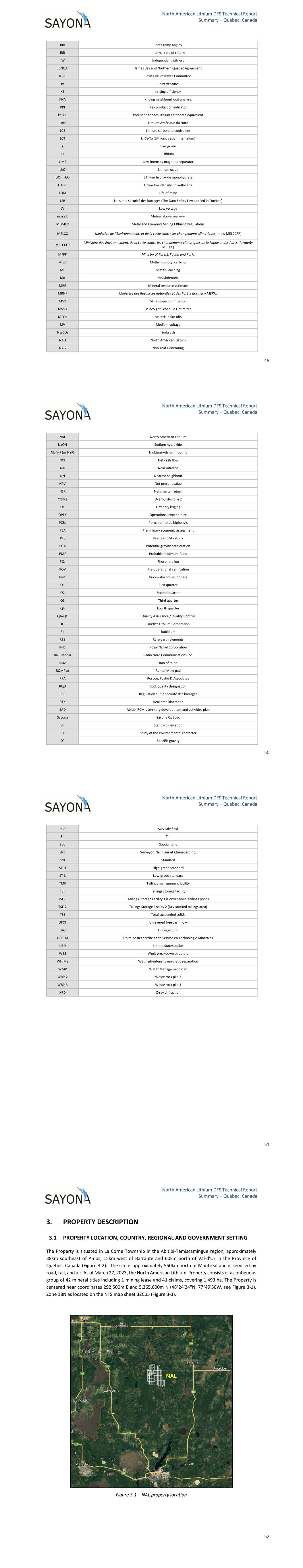

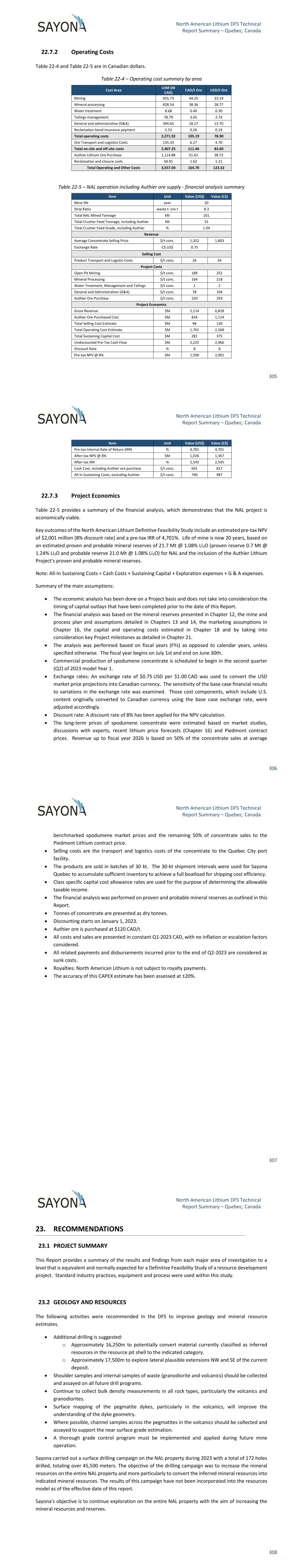

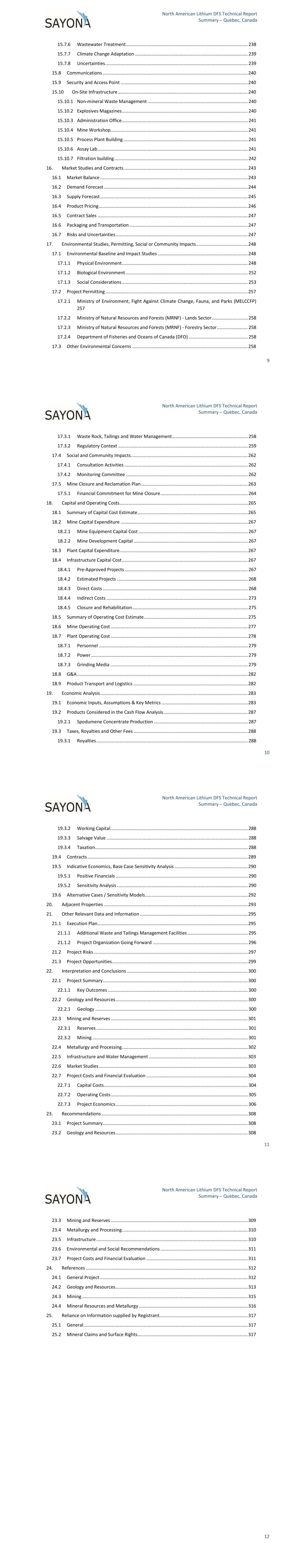

North American Lithium DFS Technical Report Summary – Quebec, Canada 13 LIST OF TABLES Table 1-1 – Mining title list and details ................................................................................................. 25 Table 1-2 – NAL mineral reserve statement at effective date of June 30, 2024 based on USD $1,352/t Li₂O. ....................................................................................................................................................... 28 Table 1-3 – NAL Mineral resource estimate, exclusive of mineral reserves as at June 30, 2024 ......... 29 Table 1-4 – Capital costs summary by major area ................................................................................ 35 Table 1-5 – NAL operation including Authier ore supply – financial analysis summary ....................... 39 Table 2-1 – Chapter contributions ........................................................................................................ 43 Table 2-2 – List of abbreviations and units of measurement ............................................................... 47 Table 3-1 – Mining titles list and details ............................................................................................... 56 Table 3-2 – NAL public land leases ........................................................................................................ 60 Table 5-1 – Summary of ownership and historic activities ................................................................... 69 Table 5-2 – Mine production statistics ................................................................................................. 73 Table 6-3: Local geologic units (in order of oldest to youngest) .......................................................... 77 Table 6-4: Pegmatite types in property ................................................................................................ 82 Table 6-5: Mineralogical zoning of PEG1 type pegmatites (as intersected in core from top to bottom) .............................................................................................................................................................. 83 Table 7-1: Summary of Canada Lithium Corp. drillholes ...................................................................... 91 Table 7-2: Summary of North American Lithium Corp holes ................................................................ 91 Table 7-3: Summary of Sayona drill holes completed in 2023 and 2024 ............................................. 93 Table 7-4: Summary of Canadian Lithium Corp. core logging procedures ........................................... 94 Table 7-5: Summary of North American Lithium Corp. core logging procedures ................................ 95 Table 7-6: Summary of Sayona core logging procedures ..................................................................... 97 Table 8-1: Summary of Canada Lithium Corp. sample preparation methods ...................................... 98 Table 8-2: Summary of North American Lithium Corp. sample preparation methods ........................ 99 Table 8-3: Summary of Sayona sample preparation methods ........................................................... 100 Table 9-1: Percentage of certificates received by drilling programs .................................................. 104 Table 9-2: Geological intervals inspected during site visit .................................................................. 107 Table 10-1 – Example mineralogy of NAL host rock types .................................................................. 112 Table 10-2 – Example assays of NAL host rock types ......................................................................... 112 Table 10-3 – Recent Authier metallurgical testing programs ............................................................. 118 North American Lithium DFS Technical Report Summary – Quebec, Canada 14 Table 10-4 – Chemical compositions of the pilot plant feed samples ................................................ 120 Table 10-5 – Semi-quantitative XRD results (Rietveld analysis) ......................................................... 120 Table 10-6 – Summary of grindability results ..................................................................................... 121 Table 10-7 – Reagent dosages for selected batch tests...................................................................... 123 Table 10-8 – Reagent dosages for the locked-cycle batch tests ......................................................... 125 Table 10-9 – Reagent dosages for selected pilot plant tests .............................................................. 126 Table 10-10 – Assays of ore samples tested ....................................................................................... 129 Table 10-11 – Overview of feed samples tested ................................................................................. 130 Table 10-12 – Final spodumene concentrate grade (3-stages of cleaning) ........................................ 131 Table 10-13 – Assays of the pegmatite and host rock samples .......................................................... 131 Table 10-14 – Mineralogy of the pegmatite and host rock samples .................................................. 133 Table 10-15 – Blended ore assays ....................................................................................................... 133 Table 10-16 – Reagent dosages for optimized tests ........................................................................... 134 Table 10-17 – Final spodumene concentrate assays .......................................................................... 134 Table 10-18 – Composite sample assays of the pegmatite and host rock samples ........................... 136 Table 10-19 – Mineralogy of the pegmatite and host rock samples .................................................. 137 Table 10-20 – Blended feed assays ..................................................................................................... 138 Table 10-21 – Variability sample description ...................................................................................... 139 Table 10-22 – NAL Variability sample assays: pegmatite and host rock ............................................. 139 Table 10-23 – NAL Variability sample mineralogy: pegmatite and host rock ..................................... 140 Table 10-24 – NAL blended variability sample assays ........................................................................ 140 Table 10-25 – Final spodumene concentrate assays .......................................................................... 142 Table 10-26 – Variability test conditions ............................................................................................ 143 Table 10-27 – Final spodumene concentrate assays .......................................................................... 144 Table 10-28 – Testwork conditions ..................................................................................................... 145 Table 11-1: Drilling data used in the geological model and current MRE .......................................... 149 Table 11-2: Raw data statistics – Li2O ............................................................................................... 152 Table 11-3: Composite data statistics used for estimation – Li2O..................................................... 155 Table 11-4: Specific gravity values employed for the MRE ................................................................ 158 Table 11-5: Search ellipsoids .............................................................................................................. 161 Table 11-6: Variogram parameters used for each pegmatite dyke .................................................... 161 North American Lithium DFS Technical Report Summary – Quebec, Canada 15 Table 11-7: Block model parameters used in Leapfrog Edge™ .......................................................... 162 Table 11-8: Summary of the suggested parameters from the KNA analysis ..................................... 162 Table 11-9: Summary of parameters used for Li2O grade interpolation............................................ 163 Table 11-10: Comparison of global grades for estimation method by mineralized zones ................ 170 Table 11-11: Reasonable extraction factors ...................................................................................... 173 Table 11-12: NAL mineral resource estimate, exclusive of mineral reserves – June 30, 2024 ........... 174 Table 11-13: Iron content used for MRE ............................................................................................. 176 Table 12-1 – Deswik.SO input parameters ......................................................................................... 179 Table 12-2 – Open pit optimization parameters ................................................................................. 181 Table 12-3 – Pit optimization results (red line is maximum NPV pit, yellow line is RF=1.0 pit) ......... 184 Table 12-4 – Discounted cash flows .................................................................................................... 185 Table 12-5 – Ultimate pit design parameters ..................................................................................... 189 Table 12-6 – Haul road design criteria ................................................................................................ 190 Table 12-7 – COG calculation parameters .......................................................................................... 193 Table 12-8 – NAL mineral reserve statement at effective date of June 30, 2024 based on USD $1,352/t Li₂O. ..................................................................................................................................................... 194 Table 12-9 – Environmental and permitting constraints affecting mineral reserves ......................... 195 Table 13-1 – Material quantities by phase1 ........................................................................................ 197 Table 13-2 – LOM production plan and material movement ............................................................. 201 Table 13-3 – Typical blast patterns ..................................................................................................... 207 Table 13-4 – Mining equipment description and maximum number of units .................................... 209 Table 14-1 – Grade and recoveries over LOM .................................................................................... 212 Table 14-2 – General process design criteria – concentrator ............................................................. 213 Table 14-3 – Concentrator reagents ................................................................................................... 218 Table 14-4 – Grinding media ............................................................................................................... 218 Table 14-5 – Concentrator salaried manpower .................................................................................. 220 Table 14-6 – Concentrator hourly manpower .................................................................................... 221 Table 14-7 – Grade and recoveries over LOM .................................................................................... 222 Table 15-1 – Typical dimensions of pumping basins .......................................................................... 237 Table 15-2 – OURANOS projections for temperature and precipitation ............................................ 239 Table 17-1 – Provincial and federal acts and regulations ................................................................... 260 North American Lithium DFS Technical Report Summary – Quebec, Canada 16 Table 18-1 – Capital cost estimate contributors ................................................................................. 265 Table 18-2 – Capital costs summary by major area ($M CAD) ........................................................... 265 Table 18-3 – Capital costs over LOM ($M CAD) .................................................................................. 266 Table 18-4 – Design growth ................................................................................................................ 271 Table 18-5 – Labor rate summary (Phase 2) ....................................................................................... 272 Table 18-6 – Labor productivity factors (Phase 2) .............................................................................. 273 Table 18-7 – NAL operating costs per year ($M CAD) ........................................................................ 276 Table 18-8 – General rate assumptions .............................................................................................. 277 Table 18-9 – Mine operating costs ..................................................................................................... 277 Table 18-10 – Concentrator operating costs ...................................................................................... 278 Table 18-11 – Average LOM media wear and consumption rates ..................................................... 280 Table 18-12 – Tailings operating costs ................................................................................................ 281 Table 19-1 – NAL operation including Authier ore supply – financial analysis summary ................... 285 Table 19-2 – NAL operation including Authier ore supply – cashflow over LOM ............................... 286 Table 21-1 – Internal project risks ...................................................................................................... 297 Table 21-2 – Project opportunities ..................................................................................................... 299 Table 22-1 – Major plant upgrades ..................................................................................................... 302 Table 22-2 – Projected metallurgical recoveries ................................................................................ 303 Table 22-3 – NAL CAPEX Summary ..................................................................................................... 304 Table 22-4 – Operating cost summary by area ................................................................................... 305 Table 22-5 – NAL operation including Authier ore supply - financial analysis summary .................... 305

North American Lithium DFS Technical Report Summary – Quebec, Canada 17 TABLE OF FIGURES Figure 1-1 – NAL property location ....................................................................................................... 23 Figure 1-2 – Map showing NAL mineral titles ....................................................................................... 24 Figure 1-3 – Multiple exposure of pegmatite dykes in the pit (face looking west) .............................. 27 Figure 1-4 – NAL ultimate pit design – plan view. ................................................................................ 31 Figure 1-5 – NAL project site layout at end of life of mine ................................................................... 34 Figure 1-6 – Lithium products price forecast 2026-2040 ...................................................................... 37 Figure 2-1 – View of the phase 1 open cut operations ......................................................................... 44 Figure 2-2 – View of phase 2 open cut operations ............................................................................... 44 Figure 2-3 – View of phase 3 open cut operations ............................................................................... 45 Figure 3-1 – NAL property location ....................................................................................................... 52 Figure 3-2 – NAL regional property location ......................................................................................... 53 Figure 3-3 – Property overview map .................................................................................................... 54 Figure 3-4 –NAL mineral titles............................................................................................................... 57 Figure 4-1 – Location of the NAL property ........................................................................................... 61 Figure 4-2 – General arrangement of existing and planned infrastructure at the mine site ............... 63 Figure 4-3 – View looking northwesterly across the plant and mine site............................................. 64 Figure 4-4 – View looking southeasterly showing the plant facilities in the foreground of the tailings impoundment area ............................................................................................................................... 65 Figure 4-5 – Val D’or weather normals (Source: climat.meteo.gc.ca) .................................................. 66 Figure 5-1 – Québec Lithium project open pit mine operations at peak in 2014 ................................. 74 Figure 6-1: Local geology of NAL property .......................................................................................... 78 Figure 6-2: Stratigraphy of NAL property .............................................................................................. 79 Figure 6-3 – History of La Motte and La Corne plutons ........................................................................ 79 Figure 6-4 – Geology of NAL property, centered on the currently interpreted mineralized system ... 80 Figure 6-5 – Geological cross-section of mineralized system, looking northwest ................................ 81 Figure 6-6 – Coarse-grained pegmatite dyke in hole NAL-16-16 .......................................................... 83 Figure 6-7 – Spodumene megacrystals perpendicular to PEG2 contact zone in hole QL-S09-026 ...... 83 Figure 6-8 – Preferential orientation of spodumene crystals in hole NAL-16-024 ............................... 84 Figure 6-9 – Multiple exposure of pegmatite dykes in the pit (face looking west) .............................. 85 North American Lithium DFS Technical Report Summary – Quebec, Canada 18 Figure 6-10 – Coarse- to fine-grained spodumene mineralization in hole NAL-16-024 ....................... 85 Figure 6-11 – Pegmatite dyke zoning and alteration in hole NAL-16-036 ............................................ 86 Figure 6-12 – Chemical evolution of lithium-rich pegmatites over distance (London, 2008) .............. 88 Figure 7-1 Property map showing location of drill holes incorporated within the MRE ...................... 90 Figure 7-2 Infill and extension drilling program (late 2016) ................................................................. 92 Figure 7-3: Core logging facilities at RNC exploration office in Amos (35km from site) ...................... 96 Figure 7-4: Core storage sheds and facilities at the NAL’s mine site ................................................... 96 Figure 9-1 – View of the open pit visited during the site tour ............................................................ 105 Figure 9-2 – Core storage facility at the Project site ........................................................................... 105 Figure 9-3 – Core review at the core storage facility .......................................................................... 106 Figure 10-1 – Monthly spodumene concentrate production ............................................................. 110 Figure 10-2 – Concentrate grade and lithium recovery (monthly averages) ...................................... 110 Figure 10-3 – Ore sorting test program material (pegmatite upper left, granodiorite upper right, basalt lower) .................................................................................................................................................. 113 Figure 10-4 – Example images of sorted products ............................................................................. 114 Figure 10-5 – Magnetic and non-magnetic fractions from test conducted at 8,000 gauss ................ 114 Figure 10-6 – Iron rejection and Li loss to magnetic concentrate for pegmatite with 10% granodiorite (left) and 10% basalt (right) ................................................................................................................ 116 Figure 10-7 – Optimized flotation test results .................................................................................... 116 Figure 10-8 – Drillhole locations for the various metallurgical testing samples ................................. 119 Figure 10-9 – Optimized batch flowsheet ........................................................................................... 122 Figure 10-10 – Batch test grade-recovery curves ............................................................................... 124 Figure 10-11 – Locked-cycle flowsheet (Composite 1) ....................................................................... 125 Figure 10-12 – Pilot plant flowsheet (PP-06) ...................................................................................... 127 Figure 10-13 – Grade – recovery curves ............................................................................................. 129 Figure 10-14 – Fe2O3 vs. Li2O in the concentrate ................................................................................ 130 Figure 10-15 – Grade – recovery curves ............................................................................................. 134 Figure 10-16 – Comparison of WHIMS performance with basalt vs. granodiorite host rock ............. 135 Figure 10-17 – Composite samples – Effect of grind size ................................................................... 141 Figure 10-18 – Effect of collector (FA-2) dosage on flotation performance ....................................... 142 Figure 10-19 – Example of the impact of dilution on flotation performance ..................................... 143 Figure 10-20 – Example of the impact of dilution on flotation performance ..................................... 144 North American Lithium DFS Technical Report Summary – Quebec, Canada 19 Figure 10-21 – Testwork analysis: grade-recovery correlation........................................................... 145 Figure 11-1: MRE mineralized zone locations .................................................................................... 147 Figure 11-2 – 3D view looking north showing pegmatite dykes and drillhole locations .................... 149 Figure 11-3 – 3D Interpretation of pegmatite domains...................................................................... 150 Figure 11-4 – Lithology model for volcanics, granodiorite and gabbro .............................................. 151 Figure 11-5 – Historical mining voids adjusted to fit pegmatite domains, shown with semi-transparent pegmatite domains ............................................................................................................................. 151 Figure 11-6 – Distribution of the length before (left) and after (right) compositing .......................... 154 Figure 11-7 – Capping analysis for Dyke A; capping at 2.3% Li2O ...................................................... 157 Figure 11-8 – Variography study in edge (example from one zone) .................................................. 159 Figure 11-9 – Variography study in Supervisor (example from one zone) ......................................... 160 Figure 11-10 – Cross-section looking west ......................................................................................... 168 Figure 11-11 – Swath plot for mineralized pegmatite dyke A - direction Y ........................................ 169 Figure 11-12 – Classification distribution on a longitudinal section looking northwest .................... 172 Figure 12-1 – Cross section illustrating stope solids in various geological settings ............................ 179 Figure 12-2 – Cross-section view – 10m envelope surrounding underground workings for pit optimization ........................................................................................................................................ 182 Figure 12-3 – Pit optimization results ................................................................................................. 186 Figure 12-4 – Single-lane in-pit haul ramp design .............................................................................. 191 Figure 12-5 – Dual-lane in-pit haul ramp design ................................................................................. 191 Figure 12-6 – Ultimate pit – plan view ................................................................................................ 192 Figure 13-1 – Isometric view of Phase 1 ............................................................................................. 197 Figure 13-2 – Isometric view of Phase 2 ............................................................................................. 198 Figure 13-3 – Isometric view of Phase 3 ............................................................................................. 198 Figure 13-4 – Isometric view of Phase 4 ............................................................................................. 199 Figure 13-5 – Isometric view of Phase 5 ............................................................................................. 199 Figure 13-6 – Isometric view of Phase 6 ............................................................................................. 200 Figure 13-7 – LOM summary ............................................................................................................... 202 Figure 13-8 – 2023 mined area isometric view ................................................................................... 203 Figure 13-9 – 2024 mined areas isometric view ................................................................................. 203 Figure 13-10 – 2025 mined areas isometric view ............................................................................... 204 Figure 13-11 – 2030 mined areas isometric view ............................................................................... 204 North American Lithium DFS Technical Report Summary – Quebec, Canada 20 Figure 13-12 – 2035 mined areas isometric view ............................................................................... 205 Figure 13-13 – 2040 mined areas isometric view ............................................................................... 205 Figure 13-14 – Ultimate Pit isometric view ......................................................................................... 206 Figure 13-15 – Section view of mining method .................................................................................. 208 Figure 14-1 – Simplified process flowsheet – concentrator ............................................................... 214 Figure 15-1 – NAL project site layout at end of life of mine ............................................................... 225 Figure 15-2 – Tailings Storage Facility No. 2 (TSF-2) layout ................................................................ 230 Figure 15-3 – General cross-section of the tailings and waste rock facility........................................ 231 Figure 15-4 – Project watersheds under present conditions .............................................................. 235 Figure 15-5 – Project watersheds in updated conditions ................................................................... 237 Figure 15-6 – Flow Diagram at NAL site – current operating conditions ............................................ 238 Figure 16-1 – Lithium market balance forecast 2026 - 2040 .............................................................. 244 Figure 16-2 – Lithium products price forecast 2026-2040 .................................................................. 247 Figure 17-1 – Location of lakes around NAL operations ..................................................................... 250 Figure 17-2 – Provincial and regional routes around NAL operations ................................................ 255 Figure 18-1 – Concentrator operating costs ....................................................................................... 279 Figure 18-2 – Tailings operating cost breakdown ............................................................................... 282 Figure 19-1 – Production of spodumene concentrate of the LOM..................................................... 287 Figure 19-2 – NAL open pit production profile and Authier ore supply ............................................. 287 Figure 19-3 – Average annual spodumene price sensitivities ............................................................ 291 Figure 19-4 – DFS sensitivity analysis on NPV @ 8% .......................................................................... 291 Figure 20-1 – Local metallic deposits and showings ........................................................................... 293 Figure 20-2 – Claim map of adjacent properties (Supplied by Sayona, March 27, 2023). ................. 294

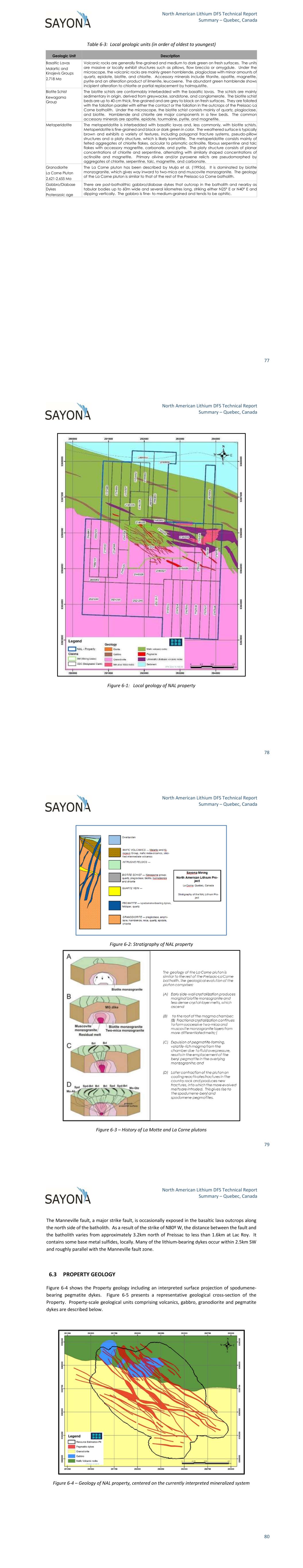

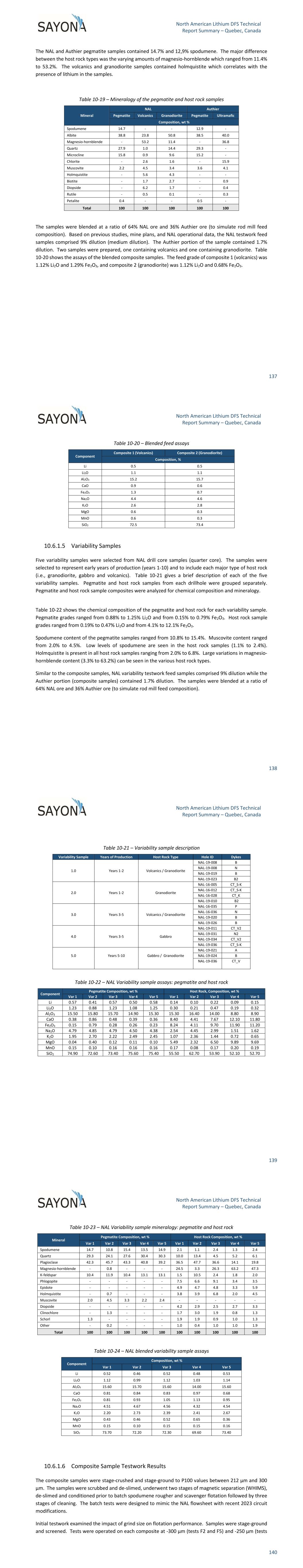

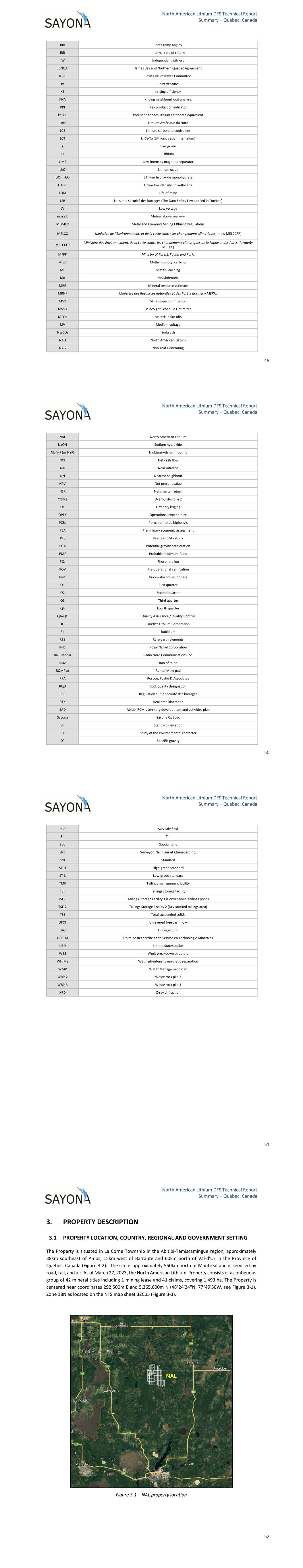

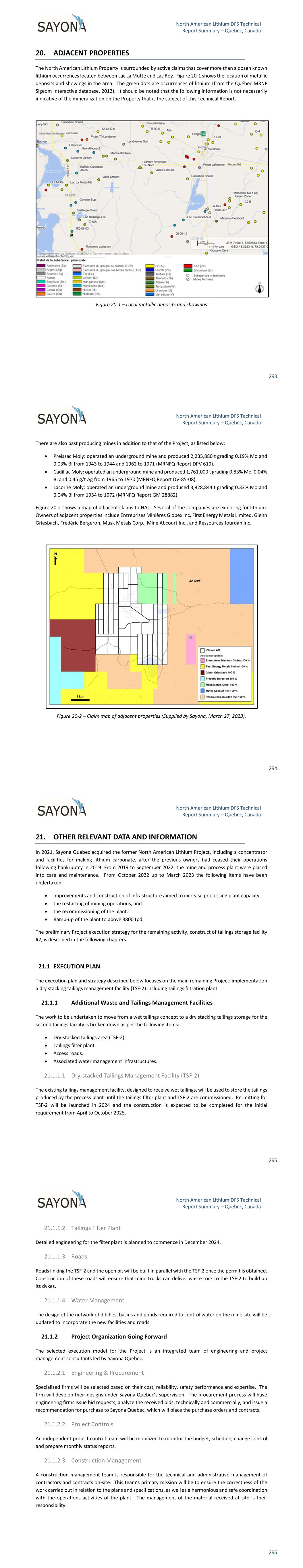

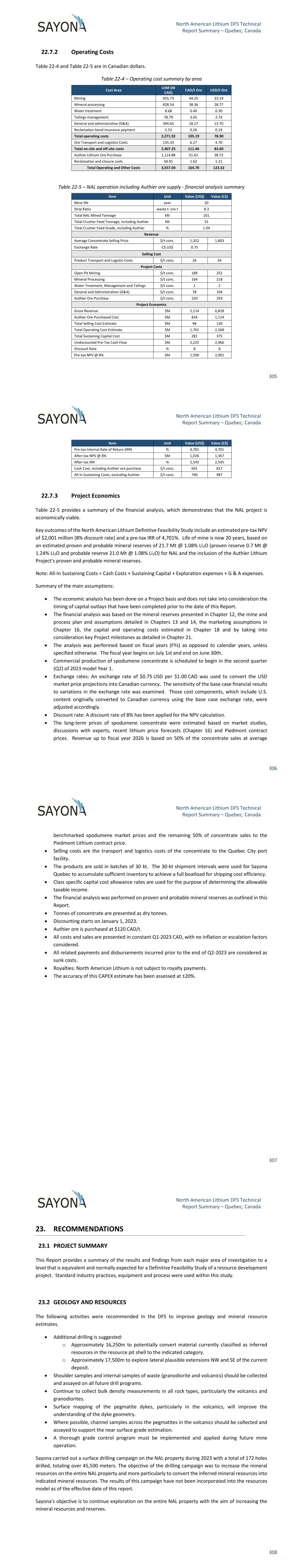

North American Lithium DFS Technical Report Summary – Quebec, Canada 21 1. EXECUTIVE SUMMARY 1.1 INTRODUCTION This S-K 1300 compliant Technical Report Summary was prepared at the request of Sayona, based on an existing S-K 1300 compliant Technical Report Summary, which has been previously published and filed by Piedmont Lithium Inc (“Piedmont”) with an effective date of December 31, 2023. The North American Lithium (“NAL”) property is wholly owned and operated by Sayona Quebec Inc., with Sayona owning 75% and Piedmont 25% of Sayona Quebec in a Joint Venture agreement. The purpose of this TRS was to present the mineral resources estimate and mineral reserves estimate as at June 30th 2024, based on the previously completed Definitive Feasibility Study (DFS). The DFS was based on developing NAL over a 20-year production period, using conventional open-pit truck and shovel methods and concentration of the ore in the NAL concentrator facility that was re-started in March 2023 with substantial upgrades to produce a spodumene concentrate (5.40% to 5.82% Li2O). The project is being mined through surface mining methods by the sole proprietor, Sayona Quebec. The DFS includes the concentration of the Authier site ore material. The Authier run-of-mine (ROM) ore will be transported to the NAL site, blended with the NAL ore material, and fed to the crusher. Sayona Quebec Inc. serves as the registrant of this S-K §229.1300 compliant Technical Report Summary. The statement is based on information provided by Sayona Quebec and reviewed by various professionals and Qualified Persons. Qualified professionals who contributed to the drafting of this report meet the definition of Qualified Persons (QPs), consistent with the requirements of the SEC. The information in this Report related to mineral resources and Mineral reserves is based on, and fairly represents, information compiled by the QPs as of the effective date of the report. The NAL property is considered material to Sayona Quebec Inc. This report has an effective date of June 30th, 2024. 1.2 FORWARD LOOKING NOTICE Sections of the report contain estimates, projections and conclusions that are forward-looking information within the meaning of applicable securities laws. Forward-looking statements are based upon the responsible QP’s opinion at the time that they are made but, in most cases, involve significant risk and uncertainty. Although the responsible QP has attempted to identify factors that could cause actual events or results to differ materially from those described in this report, there may be other factors that cause events or results to not be as anticipated, estimated, or projected. None of the QPs undertake any obligation to update any forward-looking information. There can be no assurance that North American Lithium DFS Technical Report Summary – Quebec, Canada 22 forward-looking information in any section of the report will prove to be accurate in such statements or information. Accordingly, readers should not place undue reliance on forward-looking information. This report also includes methodologies behind the derivation of mineral resources and ore reserves, as defined under the United States Securities and Exchange Commission (SEC), through the consideration of geological, mining, and environmental factors. Proven and probable Mineral reserves, derived from measured and indicated resources respectively, both of which are assessed in this report, ultimately contribute to revenues and profits in a hypothetical business plan which aligns with Sayona Quebec’s mining plan of the subject property as of June 30th 2024, the effective date of this report. Certain information set forth in this report contains “forward-looking information”, including production of reserves, associated productivity rates, operating costs, capital costs, sales prices, and other assumptions. These statements are not guarantees of future performance and undue reliance should not be placed on them. The assumptions used to develop the forward-looking information and the risks that could cause the actual results to differ materially are detailed in the body of this report. IMPORTANT NOTICE This document is not for filing or distribution in Canada. 1.3 BACKGROUND Sayona Quebec Inc. a joint venture between Sayona Mining Limited (ASX code: SYA; OTCQB: SYAXF) (75%) and Piedmont Lithium Inc. (Nasdaq: PLL, ASX: PLL) (25%) acquired the North American Lithium Inc. mine and concentrator in La Corne, Québec, in August 2021. The operation, which was placed on care and maintenance in 2019, and has restarted since Fall 2022, includes an open pit hard rock mine, exploiting lithium-bearing pegmatite dykes, with mineral processing and lithium carbonate production facilities. This report (the Report) has been prepared at the request of Sayona, the registrant, to present the Definitive Feasibility study outcomes for the North American Lithium Project . The Project’s property (the “Property”) has seen historic production from an underground mine (1950s-1960s) with production of spodumene concentrate and lithium chemicals. More recently the mine and concentrator operated under Québec Lithium (2013-2014) and North American Lithium (2017-2019). Since acquisition August 26, 2021, Sayona Quebec has undertaken considerable work in an effort to resume open-pit mining and restart concentrator operations, which occurred respectively in Fall 2022 and Q1-2023. North American Lithium DFS Technical Report Summary – Quebec, Canada 23 1.4 PROPERTY DESCRIPTION AND OWNERSHIP The Property is situated in La Corne Township in the Abitibi-Témiscamingue region, approximately 38km southeast of Amos, 15km west of Barraute and 60km north of Val-d’Or in the Province of Québec, Canada (Figure 1-1). The site is approximately 550km north of Montréal and is serviced by road, rail, and air. As of March 27, 2023, the North American Lithium Property consists of a contiguous group of 42 mineral titles including 1 mining lease and 41 claims, covering 1,493 ha. The Property is centered near coordinates 292,500m E and 5,365,600m N (48°24'24"N, 77°49'50W), Zone 18N as located on the NTS map sheet 32C05. Figure 1-1 – NAL property location The author has not verified the legal titles to the Property or any underlying agreement(s) that may exist concerning the licenses or other agreement(s) between third parties. North American Lithium DFS Technical Report Summary – Quebec, Canada 24 A Canadian National (CN) railway line runs through Barraute, a CN section town, and passes approximately 11km to the north of the Property, but there is no spur line running to the site. There are no royalties applicable to any mineral substances extracted from the lands subject to the aforementioned mining titles. The author did not verify the legality or terms of any underlying agreement(s) that may exist concerning the Project ownership, permits, offtake agreements, license agreements, royalties, or other agreement(s) between NAL / Sayona Québec and any third parties. Table 1-1 and Figure 1-2 present the mining titles of interest. Figure 1-2 – Map showing NAL mineral titles