Coronado Global Resources Inc.

Statement of Coal Resources and Reserves for

the

Logan County Complex in Accordance with

the JORC Code and United States SEC Regulation

S-K 1300 as

Central Appalachian Coal Basin

West Virginia, USA

M

ARSHALL

M

ILLER

&

A

SSOCIATES

,

I

NC

.

26

Table 11

-1:

General Reserve & Resource Criteria

Item

Parameters

Technical Notes & Exceptions*

•

General Reserve Criteria

Reserve Classification

Reserve and Resource

Coal resources as reported are inclusive of coal reserves.

Reliability Categories

Reserve (Proven and Probable)

Resource (Measured, Indicated & Inferred)

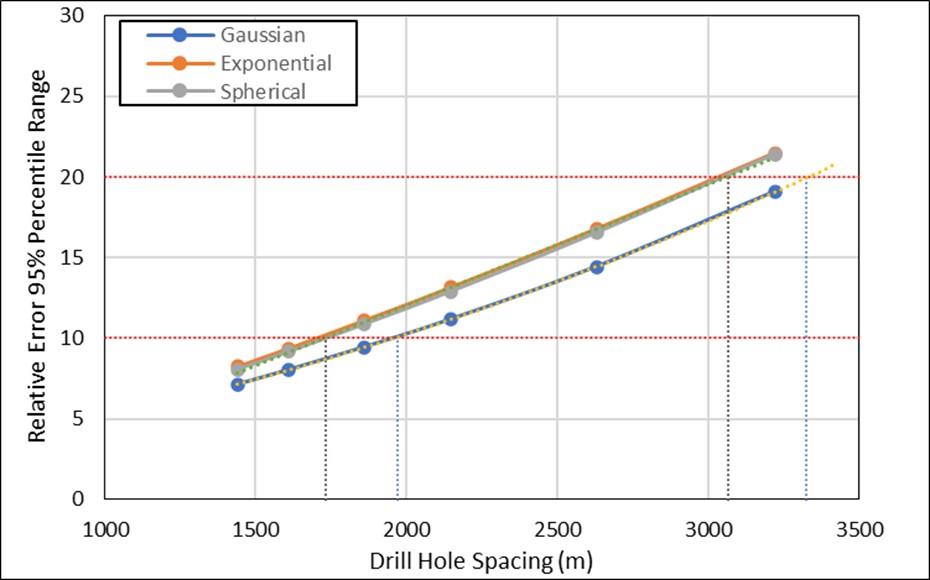

To better reflect

geological conditions of the coal deposits,

distance between points of observation is standard USGS

(in meters), respectively, for measured

and indicated and

inferred.

Effective Date of Resource Estimate

December 31, 2021

Coal resources were updated for depletion and non-material

resource additions based on information from Coronado.

Effective date for coal resources is as of December

31,

2021.

Effective Date of Reserve Estimate

December 31, 2021

Coal reserves were updated for depletion and non-material

reserve additions based on information from Coronado.

Effective date for coal reserves is as of December

31, 2021.

Seam Density

Variable, dependent upon seam characteristics

(based on available drill hole quality).

In the

absence of laboratory data, estimated by (1)

assuming specific gravity of 1.30 for coal and 2.25 to

2.5 for rock parting, or (2) 1280 kg/m

3

to 1324 kg/m

3

for a "clean" seam)

•

Underground-Mineable Criteria

Map Thickness

Total seam thickness

Minimum Seam Thickness

0.76 meters (thermal coal); 0.68 meters

Minimum Mining Thickness

1.4 to 1.8 meters

Minimum Total Coal

Thickness

0.76 meters (thermal coal); 0.68 meters

Minimum In-Seam Wash Recovery

50 percent; 40 percent where coal is belted directly

to preparation plant

Wash Recovery Applied to Coal

Reserves

Based on average yield for drill holes within reserve

area, or in the absence of laboratory washability

data, based on estimated visual recovery using

specific gravities noted above and 95 percent yield

on "clean" coal

•

Underground-Mineable Criteria

Out-of-Seam Dilution Thickness for

Run-of-Mine Tonnes

Applied to Coal

Reserves

0.05 meters minimum

2243 kg/m³ density used for dilution tonnage estimate

Mine Barrier

60.96-meter distance from abandoned mines and

sealed or pillared areas; 100-foot distance from

planned highwall miner panels

Minimum Reserve Tonnage

226,796 recoverable tonnes for individual area

(logical mining unit)

Minimum Overburden Depth

30.48 meters

Minimum Interval to Rider Coal

Considered on a case-by-case basis, depending on

interval lithology, etc.

<1.5 meters are resource

Minimum Interval to Overlying or

Underlying Reserves

Considered on a case-by-case basis, depending on

interval lithology, extent and

type of extraction, etc.

Minimum Interval to Overlying or

Underlying Mined Areas

Considered on a case-by-case basis, depending on

interval lithology, extent and

type of extraction, etc.

Adjustments Applied to Coal Reserves

6 percent moisture increase; 5 percent preparation

plant inefficiency

Surface Mineable Criteria

Topographic Map Source

Reserves estimated based on aerial topography,

where available, and best available aerial

topography for other areas.

Pre-law highwalls also

based on aerial topography, where

available

Map Thickness

Total mineable seam

thickness (excluding removal

partings)

Mine Recovery Applied to Coal

Reserves

90 percent; 25 percent for previously underground