Exhibit 15.1

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

TECHNICAL REPORT SUMMARY FOR TITAN PROJECT

Forward-Looking Information

This Technical Report Summary contains forward-looking statements within the meaning of the United States (US) Securities Act of 1933 and the US Securities Exchange Act of 1934, which are intended to be covered by the safe harbor created by such sections. Such forward-looking statements include, without limitation, statements regarding mineral resource estimates, recoveries and grade, future mineralization, future adjustments and sensitivities and other statements that are not historical facts. These statements are not guarantees of future performance and undue reliance should not be placed on them. The assumptions used to develop forward-looking information and the risks that could cause the actual results to differ materially are detailed in the body of this report.

Forward-looking statements address activities, events, or developments that IperionX expects or anticipates will or may occur in the future and are based on current expectations and assumptions. Although IperionX’s management believes that its expectations are based on reasonable assumptions, it can give no assurance that these expectations will prove correct. Such assumptions, include, but are not limited to: (i) there being no significant change to current geotechnical, metallurgical, hydrological and other physical condition assumptions; (ii) permitting being consistent with current expectations (iii) political developments being consistent with its current expectations; (iv) certain exchange rate assumptions being approximately consistent with current levels; (v) certain price assumptions for zircon, rutile, ilmenite, rare earth elements, and staurolite; and (vii) other planning assumptions.

Important factors that could cause actual results to differ materially from those in the forward-looking statements include, among others, risks that estimates of mineral resources are uncertain and the volume and grade of mineralization actually recovered may vary from the estimates presented in this report, risks relating to fluctuations in commodity prices; risks due to the inherently hazardous nature of mining-related activities; risks related to the jurisdiction in which IperionX operates, uncertainties due to health and safety considerations, uncertainties related to environmental considerations, including, without limitation, climate change, uncertainties relating to obtaining approvals and permits, including renewals, from governmental regulatory authorities; and uncertainties related to changes in law; as well as those factors discussed in IperionX’s filings with the US Securities and Exchange Commission, including IperionX’s latest Annual Report on Form 10-K for the period ended June 30, 2024, which is available on EDGAR.

IperionX does not undertake any obligation to release publicly revisions to any “forward-looking statement,” to reflect events or circumstances after the date of this report, or to reflect the occurrence of unanticipated events, except as may be required under applicable securities laws. Investors should not assume that any lack of update to a previously issued “forward-looking statement” constitutes a reaffirmation of that statement. Continued reliance on “forward-looking statements” is at investors’ own risk.

Page 1 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

TECHNICAL REPORT SUMMARY FOR TITAN PROJECT

| 1 | Executive Summary | 5 |

| 1.1 | Introduction | 5 |

| 1.2 | Property Description | 5 |

| 1.3 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 6 |

| 1.4 | History | 6 |

| 1.5 | Geological Setting, Mineralization, and Deposit | 6 |

| 1.6 | Exploration | 7 |

| 1.7 | Sample Preparation, Analyses, and Security | 8 |

| 1.8 | Data Verification | 8 |

| 1.9 | Mineral Processing and Metallurgical Testing | 9 |

| 1.10 | Mineral Resource Estimate | 9 |

| 1.11 | Risks and Opportunities | 12 |

| 1.12 | Recommendations | 12 |

| 2 | Introduction | 14 |

| 2.1 | Introduction | 14 |

| 2.2 | Terms of Reference | 14 |

| 2.3 | Qualified Persons | 15 |

| 2.4 | Qualified Person Site Visits and Laboratory Visits | 15 |

| 2.5 | Report Date | 15 |

| 2.6 | Information Sources and References | 15 |

| 2.7 | Previously Filed Technical Report Summaries | 16 |

| 3 | Property Description | 17 |

| 3.1 | Location | 17 |

| 3.2 | Ownership | 17 |

| 3.3 | Mineral Title | 17 |

| 3.4 | Surface Rights and Water Rights | 19 |

| 3.5 | Royalties | 20 |

| 3.6 | Encumbrances | 20 |

| 3.7 | Environmental Studies | 20 |

| 3.8 | Permitting | 21 |

| 3.9 | Community Relations | 22 |

| 3.10 | Significant Factors and Risks That May Affect Access, Title or Work Programs | 26 |

| 4 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 27 |

| 4.1 | Accessibility | 27 |

| 4.2 | Climate and Length of Operating Season | 27 |

| 4.3 | Local Resources and Infrastructure | 27 |

Page 2 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 4.4 | Topography, Elevation and Vegetation | 27 |

| 5 | History | 28 |

| 6 | Geological Setting, Mineralization, and Deposit | 29 |

| 6.1 | Deposit Model | 29 |

| 6.2 | Regional Geology | 29 |

| 6.3 | Local Geology | 31 |

| 6.4 | Project Geology | 31 |

| 7 | Exploration | 32 |

| 7.1 | Exploration | 32 |

| 7.2 | Drilling | 32 |

| 7.3 | Hydrogeology | 38 |

| 7.4 | Geotechnical Data | 41 |

| 8 | Sample Preparation, Analyses, and Security | 42 |

| 8.1 | Sample Collection and Security | 42 |

| 8.2 | Laboratory Procedures | 42 |

| 8.3 | QAQC Controls | 43 |

| 8.4 | Database | 43 |

| 8.5 | Opinion of Qualified Person | 44 |

| 9 | Data Verification | 45 |

| 9.1 | Data Verification Completed by the Qualified Person | 45 |

| 9.2 | Limitations Placed on Data Verification | 45 |

| 9.3 | Opinion of Qualified Person | 45 |

| 10 | Mineral Processing and Metallurgical Testing | 46 |

| 10.1 | 2021 Metallurgical Test Results | 46 |

| 10.2 | 2023 Metallurgical Test Results | 49 |

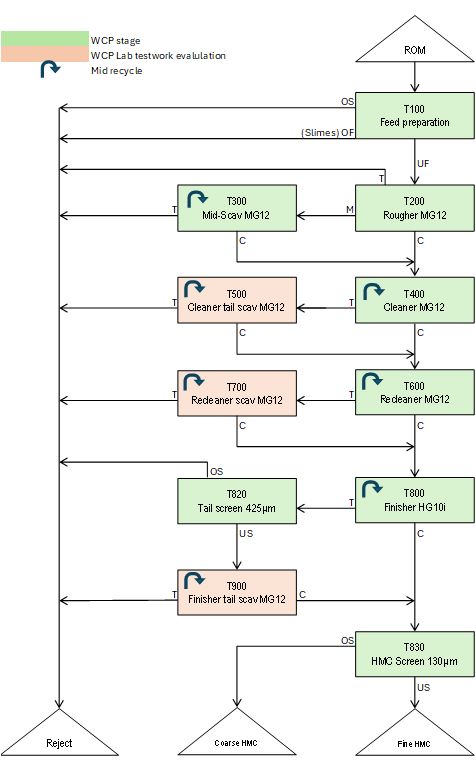

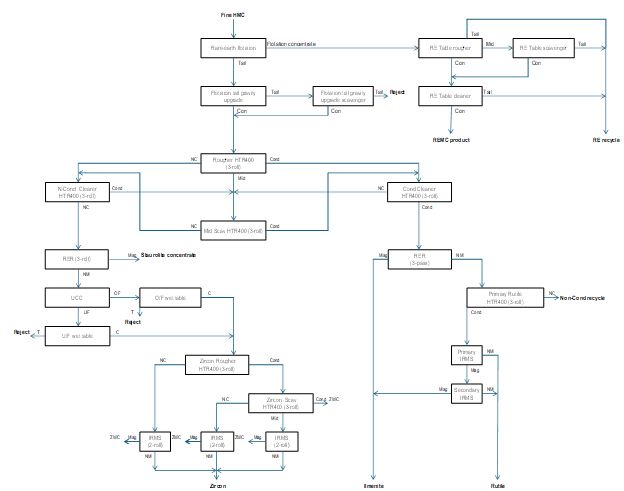

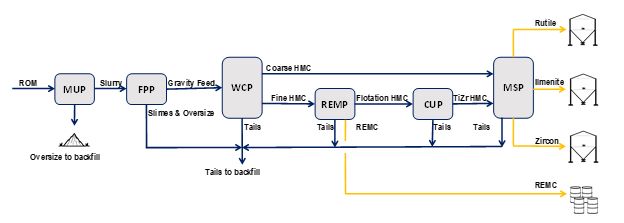

| 10.3 | Flowsheet Development | 53 |

| 10.4 | Metallurgical Recovery Forecasts | 56 |

| 10.5 | Metallurgical Variability | 56 |

| 10.6 | Deleterious Elements | 56 |

| 10.7 | Opinion of Qualified Person | 56 |

| 11 | Mineral Resource Estimate | 57 |

| 11.1 | Introduction | 57 |

| 11.2 | Geological Models | 57 |

| 11.3 | Density Assignment | 57 |

| 11.4 | Grade Capping/Outlier Restrictions | 57 |

| 11.5 | Compositing | 57 |

| 11.6 | Variography | 58 |

| 11.7 | Estimation/Interpolation Methods | 58 |

| 11.8 | Block Model Validation | 58 |

Page 3 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 11.9 | Classification of Mineral Resources | 58 |

| 11.10 | Reasonable Prospects for Economic Extraction | 59 |

| 11.11 | Mineral Resource Statement | 67 |

| 11.12 | Factors That May Affect the Mineral Resource Estimates | 68 |

| 12 | Mineral Reserve Estimate | 69 |

| 13 | Mining Methods | 70 |

| 14 | Processing and Recovery Methods | 71 |

| 15 | Infrastructure | 72 |

| 16 | Market Studies | 73 |

| 17 | Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups | 74 |

| 18 | Capital and Operating Costs | 75 |

| 19 | Economic Analysis | 76 |

| 20 | Adjacent Properties | 77 |

| 21 | Other Relevant Data and Information | 78 |

| 22 | Interpretation and Conclusions | 79 |

| 22.1 | Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements | 79 |

| 22.2 | Geology and Mineralization | 79 |

| 22.3 | Exploration and Drilling | 80 |

| 22.4 | Sampling and Analysis | 80 |

| 22.5 | Data Verification | 81 |

| 22.6 | Metallurgical Testwork | 81 |

| 22.7 | Mineral Resource Estimates | 82 |

| 22.8 | Risks and Opportunities | 82 |

| 22.9 | Conclusions | 83 |

| 23 | Recommendations | 84 |

| 24 | References | 85 |

| 24.1 | Bibliography | 85 |

| 24.2 | Abbreviations, Acronyms and Units of Measure | 85 |

| 24.3 | Glossary of Terms | 86 |

| 25 | Reliance on Information Provided by the Registrant | 89 |

Page 4 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 1 | Executive Summary |

| 1.1 | Introduction |

This report (the Report) on the Titan Project (the Project) was prepared for IperionX Limited (IperionX) by Karst Geo Solutions, LLC (KGS). The Project is located near Camden, Tennessee in the United States.

The Report was prepared to be attached as an exhibit to support mineral property disclosure, including mineral resource estimates, for the Titian Project for the year ending June 30, 2024.

Mineral resources are reported for the Titan deposit using the definitions in Regulation S-K 1300 (S-K1300), under Item 1300.

All units of measurement used in this report use the International System of Units (SI) metric system unless otherwise stated. Mineral resources are reported in metric tonnes.

Currency is expressed in United States dollars (US$) as identified in the text.

The Report uses US English.

| 1.2 | Property Description |

The Titan Project is located near Camden, Tennessee, US, approximately 128 km (80 miles) west of Nashville, Tennessee and approximately 11 km (7 miles) northwest of Camden, Tennessee.

The Project is centered at approximately 36.14734997015158N, -88.20974639890532W. The Project is located on the Mansfield, Manleyville, Vale and Bruceton United States Geological Survey Quadrangles.

The Project is owned by IperionX Critical Minerals, LLC., a wholly owned subsidiary of IperionX Limited.

As of June 30, 2024, the Titan Project resource area comprised approximately 11.0 km2 (2,726 acres) of surface and associated mineral rights in Tennessee, of which approximately 4.9 km2 (1,211) acres are owned by IperionX, approximately 1.0 km2 (242 acres) are subject to long-term lease by IperionX, and approximately 5.2 km2 (1,273 acres) are subject to exclusive option agreements with IperionX. These exclusive option agreements, upon exercise, allow IperionX to the surface property and associated mineral rights. IperionX holds additional mineral tenures that are not considered currently to be part of the Titan Project resource area under this TRS.

IperionX has acquired surface, subsurface and water rights to the properties within the resource area.

Upon exercise, in the case of an option to lease, IperionX will pay an annual minimum royalty, generally $75 per acre, and a mining royalty, generally 5% of net revenues from products sold on all leased properties. All properties owned by IperionX or its subsidiary TN Exploration, LLC. will not incur a royalty.

There are no known encumbrances.

Environmental studies were completed from 2020 to 2022 covering aspects such as: Critical Issue Analysis, United States Army Corps of Engineers Wetland Delineation and Tennessee Department of Environment and Conservation Hydrologic Determination Field Work, Federally and State Threatened and Endangered Habitat Survey, Cultural Resources Background Research and Baseline Groundwater and Surface Water Study.

Tennessee Department of Environment and Conservation (TDEC) granted IperionX the required state Surface Mining Permit (OM-70711-01) and National Pollutant Discharge Elimination System Permit (TN0070711) on 14 August 2023. TN Surface Mining Permit is a five-year permit and will need to be renewed and updated every five years. The first renewal will be required by 14 August 2028.

Page 5 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

TDEC also determined that IperionX’s proposed sand processing operations would constitute an insignificant activity or insignificant emissions unit, as defined in part 1200-03-09-.04(2)(a)3. of the Tennessee Air Pollution Control Regulations.

TDEC has confirmed that all regulatory permit requirements for the Titan Project phase 1 have been met by IperionX.

IperionX has actively engaged with TDEC, Tennessee Valley Authority, TN state government officials, community members, business owners, local government officials, local school systems, universities, technical schools, local and state government groups. IperionX will continue identifying and engaging with new groups and stakeholders.

| 1.3 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

General access to the Project is via a well-developed network of primary and secondary roads. The Project site can be accessed via highway 641 north 41.0 km from Interstate 40 near the town of Camden, TN, Reynoldsburg Rd for 1.6 km, Pleasant Hill Rd for 1.6 km and the Little Benton Rd, a gravel road, for 4.8 km. Little Benton Rd goes through the Project site.

The climate is temperate with warm summers and cold winters including the potential for snow/ice. Annual rainfall for the area is 136.6 cm. It is expected that any future mining activity would be year-round.

The existing infrastructure includes power and gas, with 161 kV transmission lines near the Project area. IperionX intends to implement fully renewable power sourcing options for the Titan Project, including the assessment of existing on-grid solutions currently provided by existing power generators and suppliers in the general Project area. Additional communications will be required with the Tennessee Valley Authority, local power supplier, and gas suppliers.

Water supply could be sourced from nearby surface water bodies or from shallow groundwater sources.

Personnel are assumed to live in surrounding communities. No accommodations camp would be required. Local active sand mining, gravel mining and timber operations could be sources of recruiting experienced operators.

| 1.4 | History |

No previous heavy mineral sand mining has occurred in the region.

The general Project area has been explored for heavy mineral sands since the 1950s as the McNairy Formation was known to contain high concentrations of heavy minerals based on work by federal and state agencies.

DuPont de Nemours, Inc., Kerr-McGee Corporation, RGC Mineral Sands Inc., Iluka Resources Inc, Altair International Inc., and Astron Corporation limited are known to have evaluated the McNairy Formation deposits in the Project area at various times.

| 1.5 | Geological Setting, Mineralization, and Deposit |

An exploration program that uses the “Heavy Mineral Sands in Coastal Environments” model is considered acceptable for exploration purposes in the Project area.

Heavy mineral sands are created through physical and mechanical concentration of detrital minerals liberated through weathering. This weathering portion of this process occurs inland, while the deposition of these minerals ultimately occurs along coastlines through features such as deltas, foreshore, shoreface, barrier islands, dunes and tidal lagoons. IperionX have observed all these features locally, within a deltaic infill environment.

The Project’s location in western Tennessee represents the eastern flank of the Mississippi Embayment, a large, southward-plunging syncline within the Gulf Coastal Plain.

Page 6 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

The McNairy Formation represents a pro-grading deltaic environment during a regressive marine sequence. This is evidenced by the coarsening upward sequence grading from the glauconitic clay-rich Coon Creek Formation to the finer grained lower member of the McNairy Formation to the coarser grained upper member of the McNairy Formation.

The main mineralized zone at the Project is hosted stratigraphically in the lower member of the McNairy Formation, which dips gently to the west in the Project area. The upper zone is also mineralized in some areas. Mineralization in the lower member had been traced at the Report date, for 6.2 km along strike.

The base of mineralization ranges in relative level from 90–110 m above current sea level. Mineralization varies from 6–51 m thick and averages 31 m in thickness. Mineralization primarily occurs in two zones within the McNairy Formation. The main mineralized zones are interrupted by low grade sand. The primary minerals associated with the mineralized horizons are altered ilmenite, zircon, rutile, staurolite, kyanite, monazite and xenotime. The gangue minerals are predominantly quartz and clays. Though extensive basement faulting is present in the region, it does not appear to impact the stratigraphy at the scale of this Project.

| 1.6 | Exploration |

Drilling on the Project area comprises162 drill holes, this includes 16 reverse circulation holes (837 m) and 146 roto-sonic drill holes (7,338 m).

All drilling was completed by IperionX.

There are an additional 11 roto-sonic drill holes completed for the purposes as part of a hydrogeological study by HDR. These holes were drilled on IperionX’s behalf and not used for resource estimation purposes.

The mineral resource database was closed as at 04-August-2021 and included 107 roto-sonic drill holes (4,101 m).

The area covered by the drilling is roughly 6.2 km (north) by 3.6 km (east); the area that hosts the mineral resource estimate is further broken up into several areas based on land holdings (land agreements). These range from 0.5 km (north) by 0.9 km (east) for the smallest area to 5.1 km (north) by 3.6 km (east) for the largest area. Drill hole spacing is generally 150 x 300 m. Some areas had difficult access and drill spacing in those areas is wider spaced, approximately up to 300 x 600 m.

A total of 66 drill holes were excluded from mineral resource estimation. This included 39 roto-sonic exploration holes that the results were received after the database cut-off date, 11 holes that were drilled in association with a hydrogeological study, and 16 reverse circulation drill holes because of the high likelihood of down hole sample contaminations.

Drill companies included Knoxville, TN; Drillwise USA of Holladay, TN; and Betts Drilling of Atlanta, GA.

Drill rigs included a Geoprobe 5140LS roto-sonic drill rig (Geoprobe) a Terrasonic 150c rig (Terrasonic), and a Wallis RC rig. The Geoprobe core barrel was 3 m long, and 10 cm in diameter with a 15-cm diameter outer casing. The Terrasonic core barrel was 3 m long and had a 10-cm diameter core barrel. Drill casing was used periodically when re-entering drill holes that had caved. Select drill holes were re-drilled and re-analyzed as part of data validation.

All drilling for the Project that is used in mineral resource estimation has been roto sonic. This method alternates advancement of a core barrel and a removeable casing (casing is used when needed to maintain sample integrity). The sonic drilling method has been shown to provide representative unconsolidated mineral sands samples across a variety of deposits as it is a direct sampling method of the formation(s). At times water is used to create a head to reduce the expansion of the clay-rich Coon Creek Formation sediments. Expansion of the Coon Creek Formation lithologies by up to 0.9 m length in the core barrel has been observed.

In the field procedures included coring 3 m sections of material at a time with a roto-sonic drill rig. Drill teams set up on the proposed drill site with all holes drilled at a 90-degree angle, which is essentially perpendicular to mineralization. Generally, holes are drilled without the use of water and typically without the use of casing. After each 3 m section was extracted, drill teams recovered the core in equal length plastic sleeves. Geologists then divided the core into two 1.5 m sections that were analyzed for lithologic significance and heavy mineral potential.

Page 7 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

After termination, holes were backfilled, and global positioning system coordinates were taken once the rig was moved from the hole. Field notes were recorded in the database.

At times water was used during drilling to create a head on the formation by lubricating the hole. This assisted in allowing core to be brought to the surface. However, it can inadvertently also create a more homogenized core, which may not reflect the subsurface.

| 1.7 | Sample Preparation, Analyses, and Security |

Roto-sonic drill core samples, typically 3m in length, were collected directly from the plastic sample sleeve at the drill site. Some interpretation was involved as the material could expand or compact as it was recovered from the core barrel into the plastic sleeve. Samples were collected at regular 1.5 m intervals unless geological contacts were encountered. Sample length ranged from 0.3 m to 4.5 m. The samples that were not consistent with the 1.5 m sampling interval accounted for 0.05% of all samples.

The unconsolidated sonic cores were sampled by splitting the core in half lengthwise using a machete, then recovering an even fillet with a trowel along the entire length of the sample interval. The sample volume was about 2 kg and was appropriate for the analytical method(s) being used and ensured adequate sample volume was collected. Samples were collected directly to pre-labeled/pre-tagged sample bags; the remaining sample was further split into a replicate/archival sample. What sample remained after these steps was used to backfill the drill hole.

Sample bags were sealed with a zip tie at the drill site, placed in rice bags, and remained in the custody of the field geologist from time of collection until time of delivery to the Project’s temporary storage location. This was either a secure third-party storage unit or a leased barn. A red security tag was used to secure the top of each rice bag, and these tags were verified by the laboratory to confirm all sample bags were intact when delivered to the laboratory.

Drill samples were sent to the SGS facility in Lakefield, ON, Canada (SGS Lakefield). SGS Lakefield is a qualified third-party laboratory that is independent of IperionX. SGS Lakefield is accredited as an ISO 17025 facility for selected analytical techniques.

Samples were subjected to standard mineral sand industry assay procedures of size fraction analysis, heavy-liquid separation, and chemical analysis.

Accuracy monitoring was addressed by submission of in-house heavy mineral sand standards developed specifically for the Project. There is no commercially available standard reference material for heavy mineral sand. It is an common practice within heavy mineral sands exploration and operations to generate standards that represent a matrix match to the target material being analyzed.

| 1.8 | Data Verification |

KGS conducted several site visits throughout the drilling campaigns and metallurgical testing programs. KGS also visited the Mineral Technologies laboratory SGS Lakefield. The site visits provided visual confirmation of mineralization, drill hole locations, bulk sample collection and logging and sampling procedures. KGS is satisfied with the metallurgical testing procedures as witnessed during the Mineral Technologies laboratory inspection. The laboratory procedures witnessed during the KGS inspection of SGS Lakefield are considered acceptable.

KGS provided training on logging, sampling, material interpretations and density measurements. KGS and IperionX staff had regular database validations to ensure data quality was sufficient.

Page 8 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 1.9 | Mineral Processing and Metallurgical Testing |

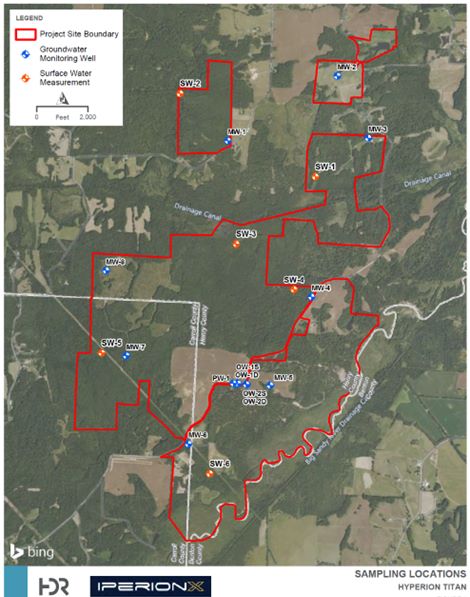

Two test work programs were conducted within mineral resource area, one in 2021 and the second in 2023. All test work was completed on behalf of IperionX.

Test work was completed by, or under the supervision of, Mineral Technologies. The company is a reputable testing organization, with laboratories with significant experience in mineral sands flowsheet development located in Florida, and in Queensland, Australia. The laboratories are ISO 9001, 45001 and 14001 accredited. Mineral Technologies is independent of IperionX. A portion of the test work was completed at IperionX’s Camden mineral demonstration facility, under the supervision of Mineral Technologies personnel. Neither facility is accredited for metallurgical test work procedures; this is routine for metallurgical testing facilities as there is currently nobody that certifies laboratories specifically for metallurgical test work.

Assays were conducted by SGS Lakefield, and Bureau Veritas in Perth, Australia, using X-ray fusion (XRF), laser ablation/inductively-couple plasma mass spectrometry (ICP–MS) and QEMSCAN analytical methods. Bureau Veritas is independent of IperionX and holds ISO 17025 accreditations for selected analytical techniques.

The final products, ilmenite, rutile, zircon, rare earth mineral concentrate, were produced from the 2023 test work. Ilmenite graded 64.9%TiO2, and the rutile graded 91.2% TiO2. The zircon graded 66.8% ZrO2. The rare earth mineral concentrate had a total rare earth oxide (TREO) grade of 59.1%. The product grades generally align with 2021 scoping test work results and were considered to be saleable products.

The test work showed that high-quality ilmenite, rutile, zircon products could be achieved using conventional separation equipment through a typical wet concentrator plant and fine and coarse mineral separation plant flowsheet. A rare earth mineral concentrate product was created at a high monazite recovery using a wet rare earth mineral concentrate circuit.

Circuit simulation models were generated for the wet concentration plant, rare earth mineral plant and mineral separation plant flowsheets to evaluate recycle streams and resultant mass flows. The expected future performance of the processing plant was based on metallurgical test work results and benchmarked against other deposits that have similar characteristics to the Titan deposit. The simulated recoveries for in-size sample (+45 μm material) from ROM to products are:

| • | Rare earth mineral recovery of 82.6%. |

| • | Ilmenite recovery of 79.7%. |

| • | Rutile recovery of 66.9%. |

| • | Zircon recovery of 77.6%. |

The three variability samples used in the 2023 metallurgical test work were composite samples representative of the different types and styles of mineralization within the Titan deposit. The variability bulk samples included coarse- and fine-grained mineralization as well as areas of differing assemblage.

Deleterious elements such as iron, magnesium, uranium, thorium, chromium, and vanadium are present at low levels and can negatively impact the marketability of heavy mineral sands products, especially uranium and thorium for the Project. High levels of these contaminants may reduce product quality, result in regulatory penalties, or require additional processing, which increases costs. Environmental considerations, particularly tailings management and the potential presence of radioactive or toxic elements, can add complexity and expenses due to stricter regulations, water management, and the need for site rehabilitation after mining operations.

| 1.10 | Mineral Resource Estimate |

The resource database contains sonic drill data collected between 2020–2021. Data are from 107 drill holes (4,101 m) and include 2,626 total heavy mineral assay samples (heavy liquid) and 181 total heavy mineral and composite mineralogy (QEMSCAN) determinations.

Page 9 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

Geological interpretations were compiled using Vulcan software. Variography was completed using R and Vulcan software version 2021.3. Vulcan software version 2021.3 was used for grade interpolation.

A parent block size of 100 x 200 x 1.5 m was used. Parent cells were typically centered on the drill holes with a floating cell centered between drill holes along and across strike. No sub-celling was used.

The geological model was based on the geological interpretations of lithology and mineralization from a series of east–west and north–south sections spaced 100 m apart. IperionX interpreted five lithological units. The Upper and Lower McNairy Formation units were the units with the largest volumes; the fine-grained Lower McNairy Formation unit was preferentially mineralized with respect to heavy minerals.

IperionX modeled the soil zone, Upper McNairy Formation waste zones, Upper McNairy Formation mineralized zone, Lower McNairy Formation waste zone, Lower McNairy Formation mineralized zone and the Coon Creek Formation zone. The Lower McNairy Formation zone accounted for most of the mineralized volume at approximately 67%, the remaining 33% percent of mineralized material is captured within the Upper McNairy Formation zone. No grade was attribute to the soil or Coon Creek Formation zones.

KGS compared the plans and sections with logged data from the drill holes and concluded that there was acceptable three-dimensional consistency in the lithology and mineral type models and that the models respected the majority intervals in lithology and mineral type recorded.

Testing for bulk density was performed by taking 5 cm sections of the 10-cm sonic core, drying the samples to calculate the percent moisture and weighing.

The density value was developed from a collection of 200 samples from both the Upper and Lower McNairy Formation sand units.

Bench-scale bulk density measurements were collected that range between 1.38 t/m3 and 1.82 t/m3. A single bulk density of 1.65t/m3 was used for the resource evaluation.

No total heavy mineral top cut was used, nor was it considered necessary for this deposit due to the geology, style, and consistency of the mineralization.

Samples were composited at 3 m intervals, based on an assumption of 6 m bench heights in an open pit mining operation. Composites honored mineralization contacts.

Variograms are run to test spatial continuity within the selected geological domains.

Grade, slimes, and assemblage estimations were completed using inverse distance weighting to the third power (ID3) interpolation, which is appropriate for this style of mineralization.

Drill hole sample data were flagged with domain (zone) codes corresponding to the geological structure of the deposit and the domains imprinted on the model from three-dimensional surfaces generated from geological interpretations.

A primary search dimension of 212 x 425 x 3 m (x, y, z) was used for all assay data. Successive search volume factors of two and four were adopted to interpolate grade in areas of lower data density. A search orientation of 30 east of north was used to emulate the trend of the mineralization. No consistent plunge was apparent in the mineralization.

Visual validation compared the estimated grades in the block model to composite grades and composites along drill hole traces in both section and plan views. The block grades were considered to reasonably reflect the composite grades.

The Titan deposit block models were estimated using nearest neighbor, inverse distance weighting to the second power (ID2), and ID3. The ID3 method was used for public reporting of the mineral resource estimate.

The resource classification was determined based on drill hole density reflecting the geological confidence.

Page 10 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

The mineral resources were constrained within a conceptual pit shell that used the parameters listed in Table 1. An assumed vertical slope was applied to the pit shells. The vertical slopes are attainable due to low depths of mineralization, unconsolidated material and the active reclamation process.

Table 1: Assumptions used in defining prospects of economic extraction

| Parameter | Units | Value | ||||

Commodity price | ||||||

| • | Rutile | US$/t | 1,440 | |||

| • | Ilmenite | US$/t | 280 | |||

| • | Rare earth mineral concentrate | US$/t | 11,630 | |||

| • | Zircon | US$/t | 1,680 | |||

Metallurgical recovery | ||||||

| • | Rutile | % | 66.9 | |||

| • | Ilmenite | % | 79.7 | |||

| • | Rare earth mineral concentrate | % | 82.6 | |||

| • | Zircon | % | 77.6 | |||

Operating costs | ||||||

| • | Mining cost | $/ROM t | 2.66 | |||

| • | Processing cost | $/ROM t | 2.91 | |||

| • | Transport cost | $/ROM t | 0.22 | |||

| • | Reclaim/rehandle | $/ROM t | 2.66 (only used for selective mining comparison) | |||

| • | Incremental in pit management | $/ROM t | 1.00 (only used for selective mining comparison) | |||

| • | General and administrative cost | $/ROM t | 0.71 | |||

Royalty | % | 5 | ||||

Mineral resources are reported using the mineral resource definitions set out in SK1300. The reference point for the estimate is in situ. Mineral resources are current as at June 30, 2024. The third-party firm responsible for the estimate is KGS. The mineral resource estimates are provided in Table 2.

Table 2: Mineral resource estimate and total heavy minerals assemblage

Mineral Resource Estimate | Cut off | Tons | Total Heavy Minerals | Total Heavy Minerals | Zircon | Rutile | Ilmenite | Rare Earth Elements | |

(Total heavy minerals or THM %) | (Mt) | (%) | (Mt) | (%) | (%) | (%) | (%) | ||

| Indicated | 0.4 | 241 | 2.2 | 5.3 | 11.3 | 9.3 | 39.7 | 2.1 | |

| Inferred | 0.4 | 190 | 2.2 | 4.2 | 11.7 | 9.7 | 41.2 | 2.2 |

Notes to accompany mineral resource table:

| 1. | Mineral resources are reported using the definitions set out in Regulation S-K 1300 and are current as at June 30, 2024. Mineral resources are reported in situ. |

| 2. | The third-party firm responsible for the estimate is Karst Geo Solutions LLC. |

| 3. | Mineral resources are reported within a conceptual pit shell that uses the following key assumptions: rutile prices of US$1,440/t; ilmenite prices of US$280/t; rare earth mineral concentrate prices of US$11,630/t; zircon prices of US$1,680/t; metallurgical recoveries: rutile of 66.9%, ilmenite of 79.7%, rare earth mineral concentrate of 82.6%, zircon of 77.6%; mining costs of US$2.66/t run-of-mine; processing costs of US$2.91/t run-of-mine, transport cost of US$0.22/t run-of-mine, general and administrative costs of US$0.71/t run-of-mine, reclaim/rehandle cost of US$2.66/t run-of-mine (only used for selective mining comparison) and incremental in pit management cost of 1.00$/t run-of-mine (only used for selective mining comparison) and royalty of 5%. |

| 4. | Mineral resources are reported above a cut-off grade of 0.4% THM. |

| 5. | Estimates have been rounded. |

Page 11 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

Specific factors that may affect the estimates include:

| • | Changes to forecast commodity and final product price assumptions. |

| • | Changes in local interpretations of mineralization geometry such as the presence of unrecognized mineralization, faults, and continuity of mineralized zones. |

| • | Changes to metallurgical recovery assumptions. |

| • | Changes to assumptions as to deleterious elements. |

| • | Changes to the input assumptions used to derive the conceptual open pit shell that is used to constrain the estimates. |

| • | Changes to the cut-off values applied to the estimates. |

| • | Variations in geotechnical, hydrogeological and mining assumptions |

| • | Changes to environmental, permitting and social license assumptions. |

| 1.11 | Risks and Opportunities |

The Project is subject to certain risks including but not limited to: commodity prices, unanticipated inflation of costs, geological uncertainty, geotechnical and hydrologic studies.

Deleterious elements such as iron, magnesium, uranium, thorium, chromium, and vanadium can negatively impact the marketability of heavy mineral sands products, especially uranium and thorium for the Project. High levels of these contaminants may reduce product quality, result in regulatory penalties, or require additional processing, which increases costs. Environmental considerations, particularly tailings management and the potential presence of radioactive or toxic elements, can add complexity and expenses due to stricter regulations, water management, and the need for site rehabilitation after mining operations.

There is also a risk that the conceptual project infrastructure locations that were assumed in the Initial Assessment would not be able to be constructed where provisionally envisaged, and additional studies would be required.

Opportunities for the Project include:

| • | Upgrade of some or all of the inferred mineral resources to higher-confidence categories, such that such better-confidence material could be used in mineral reserve estimation |

| • | Higher product prices than assumed could present upside opportunities |

| 1.12 | Recommendations |

The recommended work programs from KGS include:

| • | Environmental baseline studies. A budget estimate for this work is approximately US$ 1 million. |

| • | Geotechnical investigations for process plant, mine pit side wall slopes and tailings stabilization; A budget estimate for this work is approximately US$ 0.8 million. |

| • | Hydrogeologic assessment and hydrogeologic model update based on mine plan; A budget estimate for this work is approximately US$ 0.2 million. |

| • | Trade-off studies for plant location and product suites; sediment and erosion control design; mining method and mine design; mineral reserve estimate; material characterization of overburden and tailing materials and tails design; overall site water balance and management plan; A budget estimate for this work is approximately US$ 1 million. |

| • | Process plant design and infrastructure design; risk review; capital cost estimate and operating cost estimate; financial model etc. A budget estimate for this work is approximately US$ 2 million. |

Page 12 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| • | Overall project management and third-party review. A budget estimate for this work is approximately US$ 1 million. |

The estimated total budget for the above work programs is approximately US$6 million.

Page 13 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 2 | Introduction |

| 2.1 | Introduction |

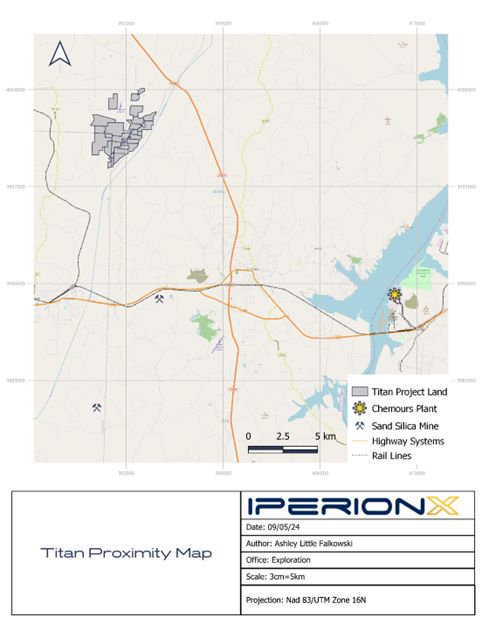

This report (the Report) on the Titan Project (the Project) was prepared for IperionX Limited (IperionX) by Karst Geo Solutions, LLC (KGS). The Project is located near Camden, Tennessee in the United States (U.S.), refer to Figure 1. Mines and plants shown in this figure are held by third parties.

Figure 1: Titan project location

| 2.2 | Terms of Reference |

The Report was prepared to be attached as an exhibit to support mineral property disclosure, including mineral resource estimates, for the Titian Project for the year ending June 30, 2024.

Page 14 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

Mineral resources are reported for the Titan deposit using the definitions in Regulation S-K 1300 (S-K1300), under Item 1300.

All units of measurement used in this report use the International System of Units (SI) metric system unless otherwise stated. Mineral resources are reported in metric tonnes.

Currency is expressed in United States dollars (US$) as identified in the text.

The Report uses US English.

| 2.3 | Qualified Persons |

KGS is using the allowance for a third-party firm consisting of mining expert to date and sign the Report.

KGS had appropriate individual Qualified Persons (QPs) prepare the content that is summarized in this Report.

| 2.4 | Qualified Person Site Visits and Laboratory Visits |

KGS made several inspections of the site from October 2020 to June 2022 to review the drilling methods, sample collection, bulk sample collection, bulk processing and quality assurance and quality control (QAQC) procedures, as shown in Table 3.

Table 3: KGS site and laboratory visits summary

| Visit Start Date | Visit End Date | Location | Scope | ||||

14-Oct-2020 | 16-Oct-2020 | Mansfield, TN | Initial drilling support and procedure development | ||||

24-Feb-2021 | 26-Feb-2021 | Mansfield, TN | Phase 2 drilling support and procedures check | ||||

5-Apr-2021 | 5-Apr-2021 | Starke, FL | Oversight of metallurgical testing process | ||||

19-Apr-2021 | 21-Apr-2021 | Mansfield, TN | Drilling and sampling review, geochemistry and metallurgical review of results, Initial modelling | ||||

15-Jun-2021 | 17-Jun-2021 | Mansfield, TN | Bulk density testing, review of results, resource modelling | ||||

17-Aug-2021 | 20-Aug-2021 | Mansfield, TN | Drilling and sampling review, review of results | ||||

1-Dec-2021 | 5-Dec-2021 | Mansfield, TN | Drilling and sampling review and support | ||||

21-Feb-2022 | 25-Feb-2022 | Mansfield, TN | Drilling and sampling review and support | ||||

2-May-2022 | 6-May-2022 | Mansfield, TN | Drilling and sampling review and support | ||||

26-Jun-2022 | 30-Jun-2022 | Mansfield, TN | Drilling and sampling review and support | ||||

24-Apr-2023 | 25-Apr-2023 | Lakefield, Canada | Oversight of analytical procedures |

KGS visited the Mineral Technologies laboratory in Florida on 5 April 2021 and was satisfied with the laboratory procedures as witnessed during that inspection.

KGS visited SGS Lakefield between 24–25 April 2023 and was satisfied with the laboratory procedures witnessed during that inspection.

| 2.5 | Report Date |

The Report is current as at June 30, 2024.

| 2.6 | Information Sources and References |

The reports and documents listed in Chapter 24 and Chapter 25 of this Report were used to support Report preparation.

Page 15 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

KGS has relied upon information provided by IperionX as identified in Chapter 25.

| 2.7 | Previously Filed Technical Report Summaries |

IperionX has previously filed a technical report summary on the Project: “Technical Report Summary for Titan Project”, “6-K (Current report) EX-99.2” filed on EDGAR on 1 July 2022.

Page 16 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 3 | Property Description |

| 3.1 | Location |

The Titan Project is located near Camden, Tennessee, US, approximately 128 km (80 miles) west of Nashville, Tennessee and approximately 11 km (7 miles) northwest of Camden, Tennessee.

The Project is centered at approximately 36.14734997015158N, -88.20974639890532W. The Project is located on the Mansfield, Manleyville, Vale and Bruceton United States Geological Survey Quadrangles.

| 3.2 | Ownership |

The Project is owned by IperionX Critical Minerals, LLC., a wholly-owned subsidiary of IperionX Limited.

| 3.3 | Mineral Title |

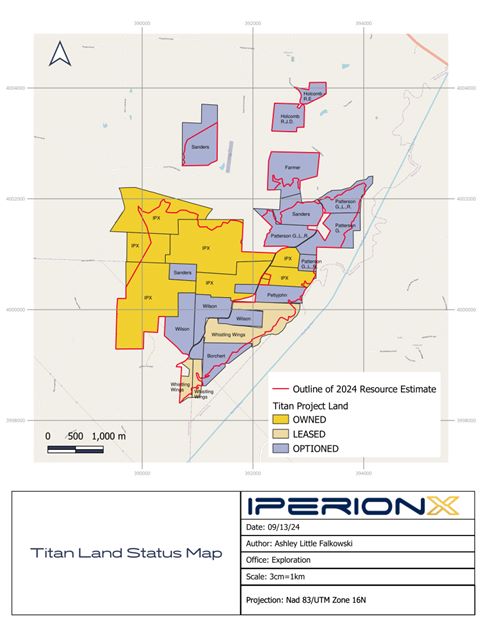

As of June 30, 2024, the Titan Project resource area comprised approximately 11.0 km2 (2,726 acres) of surface and associated mineral rights in Tennessee, of which approximately 4.9 km2 (1,211) acres are owned by IperionX, approximately 1.0 km2 (242 acres) are subject to long-term lease by IperionX, and approximately 5.2 km2 (1,273 acres) are subject to exclusive option agreements with IperionX. These exclusive option agreements, upon exercise, allow IperionX to the surface property and associated mineral rights. IperionX holds additional mineral tenures that are not considered currently to be part of the Titan Project resource area under this TRS.

A Titan land list is provided as Table 4. The claim locations are shown in Figure 2.

Table 4: Titan land list

Land Status | Acreage | Owner | Parcel # | Address | City | Zip code | County | Ownership Interest | Grant Date | Expiry Date |

Leased | 31.3 | Whistling Wings Farm LLC | 009 023 00200 000 | Pleasant Hill Rd | Hollow Rock | 38342 | Carroll | Surface, Mineral, Water | 24-Oct-23 | 24-Oct-43 |

Leased | 27.5 | Whistling Wings Farm LLC | 040 175 01301 000 | W Sandy River | Mansfield | 38236 | Henry | Surface, Mineral, Water | 24-Oct-23 | 24-Oct-43 |

Leased | 183 | Whistling Wings Farm LLC | 040 171 01100 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 24-Oct-23 | 24-Oct-43 |

Optioned | 100 | Borchert Timothy W | 040 171 01300 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-Oct-20 | 30-Oct-25 |

Optioned | 145.9 | Farmer Brent & Jessica Living Trust | 040 168 01100 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 15-Jan-21 | 15-Jan-26 |

Optioned | 34 | Holcomb Richard Eugene | 040 168 00502 000 | 565 Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 15-Jan-21 | 15-Jan-26 |

Optioned | 63.6 | Holcomb Richard Joel Dwight | 040 168 00501 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 15-Jan-21 | 15-Jan-26 |

Optioned | 110 | Patterson Gary N etux Karay L | 040 171 00504 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-May-21 | 3-May-26 |

Optioned | 97 | Patterson Gary N& Patterson Lary D& Medema Rita M | 040 171 00500 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-May-21 | 3-May-26 |

Optioned | 22.3 | Patterson Gary N& Patterson Lary D& Medema Rita M | 040 171 00501 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-May-21 | 3-May-26 |

Optioned | 88.2 | Patterson Gary N& Patterson Lary D& Medema Rita M | 040 168 01700 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-May-21 | 3-May-26 |

Optioned | 84 | Pettyjohn Steven | 040 171 00800 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-Oct-20 | 30-Oct-25 |

Optioned | 36 | Sanders Timm | 009 005 00201 000 | Pleasant Hill Rd Nw | Hollow Rock | 38342 | Carroll | Surface, Mineral, Water | 30-Nov-20 | 30-Nov-25 |

Page 17 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

Land Status | Acreage | Owner | Parcel # | Address | City | Zip code | County | Ownership Interest | Grant Date | Expiry Date |

Optioned | 150 | Sanders Timm | 040 168 01300 000 | Porter Norwood Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-Nov-20 | 30-Nov-25 |

Optioned | 90.3 | Sanders Timothy | 040 168 01801 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-Nov-20 | 30-Nov-25 |

Optioned | 102 | Wilson Finas etux Sarah et al David Wilson et ux | 009 005 00300 000 | Pleasant Hill Rd | Hollow Rock | 38342 | Carroll | Surface, Mineral, Water | 30-Nov-20 | 30-Nov-25 |

Optioned | 104 | Wilson Finas etux Sarah & David etux Cindy | 040 171 01001 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-Nov-20 | 30-Nov-25 |

Optioned | 45.5 | Wilson Finas etux Sarah & Wilson David etux Cindy | 040 171 01000 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 30-Nov-20 | 30-Nov-25 |

Owned | 327.4 | IperionX Critical Minerals LLC | 009 005 00200 000 | Pleasant Hill Rd | Hollow Rock | 38342 | Carroll | Surface, Mineral, Water | 1-Sep-20 | N/A |

Owned | 66.5 | IperionX Critical Minerals LLC | 040 171 00901 000 | 3105 Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 1-Dec-20 | N/A |

Owned | 3.9 | IperionX Critical Minerals LLC | 040 171 00903 000 | 3105 Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 1-Dec-20 | N/A |

Owned | 3.9 | IperionX Critical Minerals LLC | 040 171 00904 000 | 3105 Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 1-Dec-20 | N/A |

Owned | 308 | IperionX Critical Minerals LLC | 040 171 00300 000 | County Line Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 1-Sep-20 | N/A |

Owned | 35.2 | IperionX Critical Minerals LLC | 040 171 00503 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 1-Dec-20 | N/A |

Owned | 100 | IperionX Critical Minerals LLC | 040 171 00200 001 | County Line Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 1-Sep-20 | N/A |

Owned | 229.7 | IperionX Critical Minerals LLC | 040 168 014.03 000 | Bear Creek Rd | Mansfield | 38320 | Henry | Surface, Mineral, Water | 15-May-21 | N/A |

Owned | 137 | IperionX Critical Minerals LLC | 040 171 00900 000 | Little Benton Rd | Mansfield | 38236 | Henry | Surface, Mineral, Water | 10-Feb-21 | N/A |

Page 18 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

Figure 2: Titan land status map

IperionX’s option to lease agreements, upon exercise, allow IperionX to lease the surface property and associated mineral rights from the local landowners, and generally have expiry dates between mid-2026 to late 2027. During the option period, the option to lease agreements provide for annual option payments and bonus payments during periods when drilling is conducted. IperionX’s annual option payments are $75.00 per acre and the drilling bonuses generally average approximately $1.00 per drill foot. IperionX’s obligation to make annual option payments and drilling bonus payments cease if the company exercises the option to lease.

| 3.4 | Surface Rights and Water Rights |

IperionX has acquired surface, subsurface and water rights to the properties within the resource area. Some of the properties have been acquired in fee simple by IperionX, with IperionX now being the sole owner of the surface, subsurface and water rights for such properties. IperionX has entered into long-term ground leases for other properties, with the right to control the surface, subsurface and water rights related to those properties for the term of the respective ground leases. For the rest of the properties, IperionX holds an option to lease such properties conditioned on annual option payments that are current and ongoing. The option agreements grant IperionX the right to evaluate the surface, subsurface and water rights to such optioned properties.

Page 19 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 3.5 | Royalties |

Upon exercise, in the case of an option to lease, IperionX will pay an annual minimum royalty, generally $75 per acre, and a mining royalty, generally 5% of net revenues from products sold on all leased properties. All properties owned by IperionX or its subsidiary (TN Exploration, LLC.) will not incur a royalty.

| 3.6 | Encumbrances |

There are no known encumbrances.

There are no current material violations and fines, as imposed in the mining regulatory context of the Mine Safety and Health Administration (MSHA) in the US that apply to the Titan Project.

| 3.7 | Environmental Studies |

| 3.7.1 | Critical Issues Analysis |

In 2020, HDR Engineering, Inc. (HDR) conducted a desktop review of topographic and aerial photograph base maps for the Project area using publicly available geographic information system (GIS) and interactive web-based mapping applications. HDR used available data for Benton, Carroll and Henry Counties to assess potential environmental conditions.

Following mapping and the initial environmental assessment, HDR completed a regulatory review and permit evaluation of the proposed project as it relates to the following federal, state, and local environmental regulations.

| 3.7.2 | United States Army Corps of Engineers Wetland Delineation and Tennessee Department of Environment and Conservation Hydrologic Determination Field Work |

In 2021, HDR conducted a stream/wetland delineation, threatened and endangered species habitat survey, cultural resources review, and continue to support a groundwater quality and quantity testing program.

HDR conducted field visits in May and June 2021 to document United States Army Corps of Engineers (USACE)-regulated jurisdictional Waters of the US and Tennessee Department of Environment and Conservation (TDEC)-regulated waters of the state within the site.

| 3.7.3 | Federally and State Threatened and Endangered Habitat Survey |

HDR identified federal and state listed species habitat likely to occur on or in the vicinity of the site. HDR requested an Environmental Review through the TDEC Natural Heritage Program (NHP) which provided site-specific data of known state and federal concern plant and animal species, ecologically significant sites, and certain conservation managed lands. HDR conducted a pedestrian survey of the site to verify the presence or absence of potential habitat for federally threatened and endangered species that may occur on the site.

A brief memorandum to IperionX was prepared detailing the results of the federal and state threatened and endangered species habitat survey results. The memorandum was delivered to IperionX on 1 July 2021.

| 3.7.4 | Cultural Resources Background Research |

HDR conducted a National Historic Preservation Act (NHPA) cultural resources background investigation for the approximately 2,432-acre portion of the Titan Project located in Carroll and Henry Counties in April 2021. The purpose of the investigation was to identify known historic (National Register of Historic Places (NRHP)-eligible) properties in the Project Area and surrounding one-mile radius and make recommendations on further NHPA cultural resources work for the Project.

Page 20 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

The research included results from the Tennessee Division of Archaeology (TDOA), the Tennessee Historical Commission (THC), the NRHP GIS database, and the Tennessee Cemetery Database (TNGenWeb). HDR synthesized the research results and issued a report summarizing the findings of the background investigation completed for the Titan Project and associated recommendations that was delivered to IperionX on 30 June 2021.

HDR identified six previously recorded archaeological sites and five cemeteries within one mile of the Project area. None of these sites are located within the Project area.

| 3.7.5 | Baseline Groundwater and Surface Water Study |

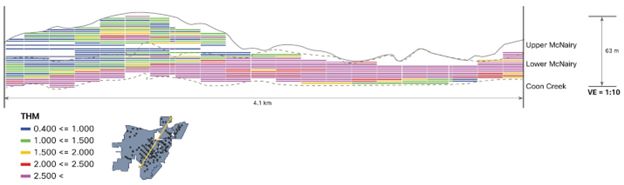

Baseline groundwater and surface water assessment data collection was completed in 2021 by HDR. This included installation of monitoring and aquifer test wells, together with a 72-hr aquifer pumping test conducted in June 2021. HDR completed six bi-monthly groundwater and surface water monitoring tests from June 2021 to April 2022.

| 3.7.6 | Partnership with University of Tennessee’s Institute of Agriculture |

IperionX is partnering with the University of Tennessee Institute of Agriculture (UTIA) to research the implementation of sustainable operating and rehabilitation practices at the Titan Project in West Tennessee. The University of Tennessee is the flagship university in the state of Tennessee, and UTIA is at the forefront of agribusiness research, education and community outreach.

The Titan Project will include programs focused on post mineral extraction practices and carbon sequestration opportunities for generational land-use benefits for local landowners. The initial scope of work will focus upon the elimination of invasive vegetation and subsequent improved ecological revegetation using native warm season grasses, undertaken on IperionX’s owned properties.

IperionX and UTIA with aid from county University of Tennessee (UT) extension offices, has established a seven acre native site at the Titan Project for UTIA’s use for the initial scope of work, with the potential for the site to be used for additional sustainability investigations, including the use of biochars, gypsum and other soil amendments to aid in higher crop yields and the carbon sequestration.

IperionX and UTIA are also in the process of preparing an additional three-acre lot that will be used to grow a mixture of native grass and pollinator plants to assist with the biodiverse efforts of habitat restoration in the area.

| 3.8 | Permitting |

TDEC granted IperionX the required state Surface Mining Permit (OM-70711-01) and National Pollutant Discharge Elimination System Permit (TN0070711) on 14 August 2023. TN Surface Mining Permit is a five-year permit and will need to be renewed and updated every five years. The first renewal will be required by 14 August 2028.

TDEC also determined that IperionX’s proposed sand processing operations would constitute an insignificant activity or insignificant emissions unit, as defined in part 1200-03-09-.04(2)(a)3. of the Tennessee Air Pollution Control Regulations.

TDEC has confirmed that all regulatory permit requirements for the Titan Project phase 1 have been met by IperionX.

| 3.9 | Community Relations |

IperionX has actively engaged with TDEC, Tennessee Valley Authority (TVA), TN state government officials, community members, business owners, local government officials, local school systems, universities, technical schools, local and state government groups. IperionX will continue identifying and engaging with new groups and stakeholders.

Page 21 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

IperionX advised KGS that the company’s vision is to create a legacy of operational excellence by maintaining positive and sustainable industry standards, credible communications, and shared beneficial opportunities, including a focus on local employment. IperionX advised that it plans to continue to operate with a transparent and open-door standard. IperionX has sponsored local recreation teams, provided scholarships and given seminars at local schools and universities.

Table 5 provides a summary of the community relations activities completed at the Report date.

Table 5: Community relations activities list

| Date | Organization | Community Relations Activity | |||

20-Jan-2021 | Benton County officials | First introduction to IperionX | |||

29-Jan-2021 | WRJB radio | Interview | |||

15-Feb-2021 | Benton County Commission | Meeting with County Commission | |||

10-Mar-2021 | Carroll County officials | Meeting with Carroll County officials | |||

11-Mar-2021 | Henry County officials | Meeting with Henry County officials | |||

17-Mar-2021 | Community | IperionX office grand opening | |||

28-Mar-2021 | Veterans Honor Guard | Donation | |||

20-Apr-2021 | Benton County school officials | Meeting with school officials | |||

25-May-2021 | Benton County officials | Meeting with Benton County officials | |||

8-Jun-2021 | West TN Bass Tournament | IperionX information booth/sponsor | |||

1-Jul-2021 | Governors | Meeting with TN government | |||

20-Jul-2021 | PGS | Community Forum hosted by PGS | |||

1-Aug-2021 | TN Achieves Mentor Program | Volunteer | |||

4-Aug-2021 | TN Governors Conference | Attendance at the TN Governors Conference | |||

18-Aug-2021 | Benton County High School Academic Banquet | Attendance | |||

24-Aug-2021 | Benton County Fair | IperionX Information booth/lawnmower race sponsor | |||

1-Sep-2021 | University of Knoxville | Meeting with President Randy Boyd | |||

12-Oct-2021 | University of Knoxville | Meeting with UTK Professors | |||

28-Oct-2021 | First Responders Dinner | Hosted dinner | |||

31-Oct-2021 | IperionX Halloween | IperionX Halloween event | |||

5-Dec-2021 | University of Knoxville | Visited the UTK campus and dinner | |||

10-Dec-2021 | TN Chamber/Manufactures and Industry roundtable | Attended the round table | |||

18-Dec-2021 | Senior Citizens home | Adopt a Senior | |||

20-Dec-2021 | Benton County Christmas parade | IperionX truck in parade | |||

5-Feb-2022 | District Director Sam Neinow at Congressman Mark Green | Sam Neinow brief for Congressman Green | |||

10-Feb-2022 | Congressman Green | Meeting with Congressman Green | |||

5-Feb-2022 | Agricultural Commission Board | IperionX CEO addressed Agricultural Commission Board members | |||

8-Mar-2022 | Carroll County government | Attendance at Carroll County government meeting |

Page 22 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| Date | Organization | Community Relations Activity | |||

14-Mar-2022 | Carroll County Prodigy softball | Donation for softball team | |||

28-Mar-2022 | Benton County teacher inservice | Presentation | |||

6-Apr-2022 | Benton County public Q&A session | Information and update | |||

10-Apr-2022 | Henry County fish fry | IperionX tent demonstration | |||

16-Apr-2022 | Fishing rodeo | Attendance and donation | |||

24-Apr-2022 | Scotts Hill career day | Presentation | |||

10-May-2022 | Carroll County golf tournament | IperionX tent/sponsorship | |||

1-Jun-2022 | Forever Communications | Interview with Henry County radio | |||

6-Jun-2022 | Carroll County schools | Academic sponsorship | |||

12-Jun-2022 | Get Loaded Tea | IperionX promotion and sponsorship | |||

18-Jun-2022 | Senator Hagerty/Benton County Mayor | Meeting with Senator Hagerty/Benton County Mayor | |||

20-Jun-2022 | Benton County STEM camp | STEM camp presentation | |||

22-Jun-2022 | Henry County Carl Perkins Center for Child Abuse | Table sponsorship | |||

26-Jun-2022 | Magic Valley Golf/Buccaneers | Attended and sponsored the Pro Golf tournament | |||

29-Jun-2022 | Benton County Drug Prevention/UT Ag | Children Yoga sponsorship | |||

3-Jul-2022 | Birdsong Resort & Marina | 4th of July attendance/sponsorship | |||

7-Jul-2022 | Tennessee Department of Economic and Community Development | Meeting with several groups | |||

12-Jul-2022 | University of Tennessee at Martin | Campus tour | |||

15-Jul-2022 | UT Martin Director | IperionX information discussion | |||

18-Jul-2022 | Henry County Mike Weatherford show | IperionX interview | |||

20-Jul-2022 | West TN football/cheer | Sponsorship | |||

24-Jul-2022 | County officials | Meeting with several groups | |||

30-Jul-2022 | Benton County Drug Prevention Coalition | Attendance at the Red Sand event | |||

4-Aug-2022 | UT Extension | Donation for new agriculture silos | |||

9-Aug-2022 | District Director Sam Neinow at Congressman Mark Green /Benton County Mayor | Meeting with Sam Neinow/Benton County Mayor | |||

13-Aug-2022 | Henry County Terra Recycling event | Sponsored an electronics recycling drive in Henry County | |||

15-Aug-2022 | Benton County Fair Salute to First Responders | Attendance | |||

22-Aug-2022 | Henry County Fair | Attendance and IperionX booth/demonstration | |||

26-Aug-2022 | Benton County Fair | Attendance and IperionX booth/demonstration | |||

27-Aug-2022 | STEAM Garden | Donated to the new STEAM Garden | |||

4-Sep-2022 | Mckenzie sweet tea festival | IperionX tent demonstration | |||

9-Sep-2022 | Forever Communications | IperionX CEO interview | |||

9-Sep-2022 | Native American Indian Association of Tennessee | Donation | |||

10-Sep-2022 | One Community One Heart | Benton County Volunteer Day event | |||

11-Sep-2022 | 911 Memorial Walk | IperionX Attendance | |||

12-Sep-2022 | Benton County Prevention Coalition | Attended /hosted luncheon |

Page 23 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| Date | Organization | Community Relations Activity | |||

20-Sep-2022 | Camden Masonic Lodge | Donation for food plates | |||

20-Sep-2022 | West TN Veterans bike ride | Donation | |||

21-Sep-2022 | IperionX Media Day at Demo Site | IperionX information update to several groups | |||

15-Oct-2022 | West TN Saddle Club | Sponsorship | |||

16-Oct-2022 | Native American Indian Association of Tennessee | Pow Wow sponsorship | |||

27-Oct-2022 | Carroll County Boo Bash | Halloween Trunk or Treat | |||

29-Oct-2022 | Henry County Spooktacular | Halloween Trunk or Treat | |||

31-Oct-2022 | Benton County IperionX Halloween Bash | Annual office Halloween event | |||

2-Nov-2022 | University of Tennessee at Martin | Geo Sciences Club meeting attendance | |||

8-Nov-2022 | All American Cheer | Purchased coupon book | |||

9-Nov-2022 | Henry County Noon on the square | Attendance | |||

11-Nov-2022 | American Legion Veterans | Volunteer | |||

2-Dec-2022 | Henry County Shop with a Cop | Donation | |||

5-Dec-2022 | Benton County Manufactures Day | Presentation | |||

15-Dec-2022 | Carroll County Toys for Tots | Toy donation | |||

15-Dec-2022 | Benton County Toys for Tots | Toy donation | |||

18-Dec-2022 | Henry County Christmas parade | IperionX truck in parade | |||

18-Dec-2022 | St Vincent DePaul | Donation for flood victims | |||

1-Jan-2023 | TN Acheives Mentor Meeting | Meeting at Bethel University | |||

14-Jan-2023 | Beta Club | 5-kilometer run | |||

25-Jan-2023 | Benton County School Board | Attendance | |||

30-Jan-2023 | Carroll County Career & Technical Ed | Attendance/IperionX discussion | |||

31-Jan-2023 | American Legion Girls State | Scholarship donation | |||

1-Feb-2023 | Big Sandy Q&A | Community Q&A | |||

8-Feb-2023 | Carroll County Chamber Coffee | Attendance/networking | |||

16-Feb-2023 | Carroll County Q&A | Community Q&A | |||

17-Feb-2023 | Henry County Q&A | Community Q&A | |||

18-Feb-2023 | American Legion Veterans | Chili dinner | |||

6-Mar-2023 | Benton County Animal Shelter | Sponsorship of a dog adoption fee | |||

6-Mar-2023 | Benton County Garden Club | IperionX attendance and presentation | |||

9-Mar-2023 | IperionX Children’s Book Launch | Introduction of the children’s book in Henry County | |||

25-Mar-2023 | Henry County Elementary | Book reading/presentation | |||

25-Mar-2023 | Carroll County Elementary | Book reading/presentation | |||

28-Mar-2023 | Benton County Elementary | Book reading/presentation | |||

30-Mar-2023 | Henry County Library | Book presentation/donation | |||

30-Mar-2023 | Carroll County Library | Book presentation/donation | |||

14-Apr-2023 | Scotts Hill High School | Career Day presentation | |||

26-Apr-2023 | Henry County High School | Project Graduation donation | |||

26-Apr-2023 | Benton County High School | Project Graduation donation | |||

26-Apr-2023 | Carroll County High School | Project Graduation donation |

Page 24 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| Date | Organization | Community Relations Activity | |||

28-Apr-2023 | Henry County fish fry | Attendance/networking | |||

15-May-2023 | West TN Boy Scouts | Tour of Boy Scouts of America Camp | |||

30-May-2023 | Native American Indian Association | Scholarship donation | |||

10-Jun-2023 | TN Kids fishing rodeo | Awards sponsorship | |||

11-Jun-2023 | TN Mining Association | Conference sponsorship | |||

28-Jun-2023 | Camden Elementary School | STEM summer camp presentation/donation | |||

9-Jul-2023 | Native American Indian Association of Tennessee | Pow Wow sponsorship | |||

20-Jul-2023 | West TN STEM Scholarship | Scholarship donation | |||

2-Sep-2023 | WRAP Jam | IperionX Tent | |||

6-Sep-2023 | West TN Public Utility | Luncheon attendance/networking | |||

7-Sep-2023 | Camden Elementary School | Outdoor Garden Open House | |||

29-Sep-2023 | Camden Masonic Lodge | Dinner attendance | |||

19-Oct-2023 | Carroll County Career & Technical Ed | Meeting attendance/discussion | |||

19-Oct-2023 | United Way Radio Auction | Guest Auctioneer/donation | |||

20-Oct-2023 | TMA Conference in Gatlinburg | Attendance/sponsorship | |||

21-Oct-2023 | Native American Indian Association of Tennessee | Attendance at the Pow Wow | |||

25-Oct-2023 | Carroll County Career Fair | Attendance IperionX tent booth | |||

28-Oct-2023 | Henry County Trunk or Treat | Handed out candy | |||

29-Oct-2023 | Elementary schools | Delivered Halloween coloring pages/safety checklist | |||

31-Oct-2023 | IperionX Halloween event | Annual office Halloween event | |||

9-Nov-2023 | Darkhorse Veterans Lodge | Volunteer | |||

17-Nov-2023 | Carroll County Veterans Art Exhibit | Volunteer | |||

5-Dec-2023 | Mckenzie Rotary Club | IperionX Presentation | |||

5-Dec-2023 | Mckenzie Industrial Board | Toured Mckenzie Industrial Site Commercial Facility | |||

12-Dec-2023 | Carroll County Toys for Tots | Donation | |||

12-Dec-2023 | Henry County Toys for Tots | Donation | |||

13-Dec-2023 | IperionX holiday cards | 100 cards mailed to key county personnel and all IperionX Landowners | |||

14-Dec-2023 | Benton County Senior Citizen Holiday | Holiday Basket donation to senior citizen | |||

3-Jan-2024 | Senator Marsha Blackburn Meeting | Drop-in meeting held at Second Harvest Food Bank | |||

12-Jan-2024 | Henry County Helping Hands | Donation to Pleasant Hill community | |||

25-Jan-2024 | Northwest Economic Development Food Boxing | Volunteer | |||

14-Feb-2024 | Tennessee Mining Association | Joined TMA on Capitol Hill in Nashville | |||

12-Mar-2024 | TN Achieves Lunch and Tennessee Colleges of Applied Technology | Mentor lunch and TCAT tech school tour | |||

19-Mar-2024 | Forever Communications | Visit in Henry County | |||

19-Mar-2024 | Henry County Real Hope Youth Center | Visit in Henry County | |||

20-Mar-2024 | Carroll County Career Day | IperionX tent/demonstration for career day | |||

26-Mar-2024 | Benton County Volunteer Program | Presentation/IperionX Information |

Page 25 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| Date | Organization | Community Relations Activity | |||

27-Apr-2024 | Henry County fish fry | Attendance/networking | |||

27-Apr-2024 | Darkhorse Veterans Lodge | Donation | |||

28-Apr-2024 | Tennessee Mining Association | Conference sponsorship | |||

2-May-2024 | Scotts Hill Career Day | Presentation/IperionX Information | |||

4-May-2024 | Benton County Drug Prevention Awareness Day | IperionX tent | |||

18-Jun-2024 | TN Health Connect | Overdose prevention training | |||

20-Jun-2024 | 2024 Scholarship Presentation | Scholarship | |||

25-Jun-2024 | Tennessee College of Applied Technology | Groundbreaking ceremony |

| 3.10 | Significant Factors and Risks That May Affect Access, Title or Work Programs |

To the extent known to KGS, there are no other significant factors and risks that may affect access, title, or the right or ability to perform work on the Project that are not discussed in this Report.

Page 26 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 4 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

| 4.1 | Accessibility |

General access to the Project is via a well-developed network of primary and secondary roads. The Project site can be accessed via highway 641 north 41.0 km from Interstate 40 near the town of Camden, TN, Reynoldsburg Rd for 1.6 km, Pleasant Hill Rd for 1.6 km and the Little Benton Rd, a gravel road, for 4.8 km. Little Benton Rd goes through the Project site.

US Interstate I-80 is 35.4 km to the south of the Project. Tennessee overall has approximately 153,000 km of highway, including eight interstate highways, which can provide ready access to a majority of the US consumer markets.

Tennessee is the third-largest rail center in the US. The CSX Transportation Memphis subdivision mainline runs through Camden (~ 4.8 km south of the Titan Project). The KWT Rail line connects to this mainline ~2.4 km east of the Titan Project).

There are more than 1,600 km of navigable waterways in Tennessee, which access all other major waterways in the eastern US. A major barge-loading point is located 24 km from the Titan Project.

There are four commercial airports near Camden, including two international airports at Memphis (approximately 217 km to the southwest) and Nashville (approximately 137 km to the east).

The Project location in relation to key local infrastructure was shown in Figure 1.

| 4.2 | Climate and Length of Operating Season |

The climate is temperate with warm summers and cold winters including the potential for snow/ice. Annual rainfall for the area is 136.6 cm.

Any future mining operation could operate year-round.

| 4.3 | Local Resources and Infrastructure |

The Project area is located near the towns of Camden and Paris, Tennessee.

The existing infrastructure includes power and gas, with 161 kV transmission lines near the Project area. IperionX intends to implement fully-renewable power sourcing options for the Titan Project, including the assessment of existing on-grid solutions currently provided by existing power generators and suppliers in the general Project area. Additional communications will be required with the Tennessee Valley Authority, local power supplier, and gas suppliers.

Water supply could be sourced from nearby surface water bodies or from shallow groundwater sources.

Personnel are assumed to live in surrounding communities. No accommodations camp would be required. Local active sand mining, gravel mining and timber operations could be sources of recruiting experienced operators.

| 4.4 | Topography, Elevation and Vegetation |

The Project area is located in the eastern portion of the United States and contains gently rolling topography with drainages (wetlands) dissecting the Project area.

Surface elevations at the Project range from approximately 175 m above sea level in the upland regions and approximately 100 m at the stream level.

The area exhibits a mix of hardwood forest, conifer forest and agricultural fields.

Page 27 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 5 | History |

No previous heavy mineral sand mining has occurred in the region.

The general Project area has been explored for heavy mineral sands since the 1950s as the McNairy Formation was known to contain high concentrations of heavy minerals based on work by federal and state agencies.

DuPont de Nemours, Inc., Kerr-McGee Corporation, RGC Mineral Sands Inc., Iluka Resources Inc, Altair International Inc., and Astron Corporation limited are known to have evaluated the McNairy Formation-hosted deposits in the Project area at various times.

Page 28 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 6 | Geological Setting, Mineralization, and Deposit |

| 6.1 | Deposit Model |

An exploration program that uses the “Heavy Mineral Sands in Coastal Environments” model is considered acceptable for exploration purposes in the Project area.

Heavy mineral sands are created through physical and mechanical concentration of detrital minerals liberated through weathering. This weathering portion of this process occurs inland, while the deposition of these minerals ultimately occurs along coastlines through features such as deltas, foreshore, shoreface, barrier islands, dunes and tidal lagoons. IperionX have observed all these features locally, within a deltaic infill environment.

| 6.2 | Regional Geology |

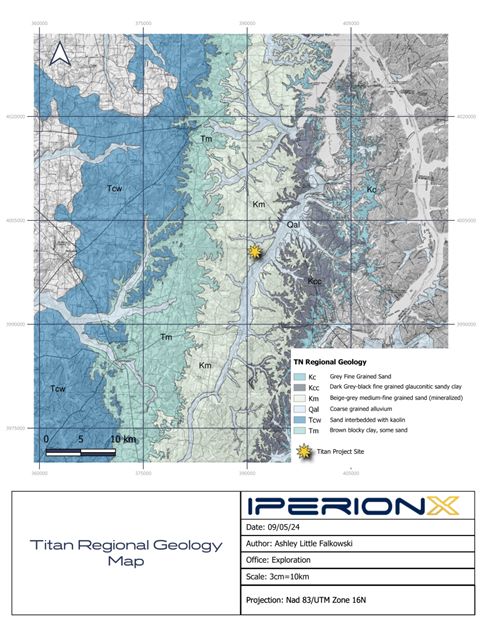

The Project’s location in western Tennessee represents the eastern flank of the Mississippi Embayment, a large, southward-plunging syncline within the Gulf Coastal Plain indicated in Figure 3.

Figure 3: Mississippi Embayment & Cretaceous coastline

Page 29 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

This feature extends from southern Illinois to the north and to Mississippi and Alabama to the south. The embayment is filled with sediments and sedimentary rocks of Cretaceous to Quaternary age. Figure 4 shows regional geology map encompassing Titan Project.

Figure 4: Regional geology map encompassing Titan Project

Page 30 of 89

IPERIONX TITAN PROJECT, TENNESSEE – TECHNICAL REPORT SUMMARY

| 6.3 | Local Geology |

The McNairy Formation represents a pro-grading deltaic environment during a regressive marine sequence. This is evidenced by the coarsening upward sequence grading from the glauconitic clay-rich Coon Creek Formation to the finer grained lower member of the McNairy Formation to the coarser grained upper member of the McNairy Formation. Figure 5 is a simplified stratigraphic column through the McNairy Formation.

Figure 5: Idealized stratigraphic column through the McNairy sand

| 6.4 | Project Geology |

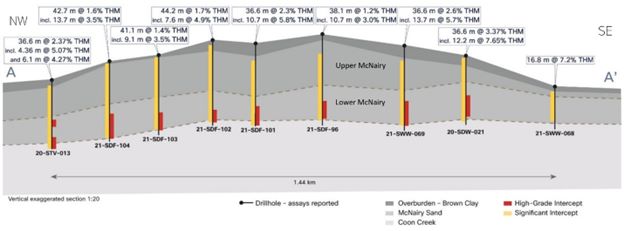

The primary mineralized zone at the Project is hosted stratigraphically in the lower member of the McNairy Formation, which dips gently to the west in the Project area. The upper member is also mineralized in some areas at the Project and is at times separated from the lower zone by a barren coarse sand. Mineralization in both members had been traced at the Report date, for 6.2 km along strike.

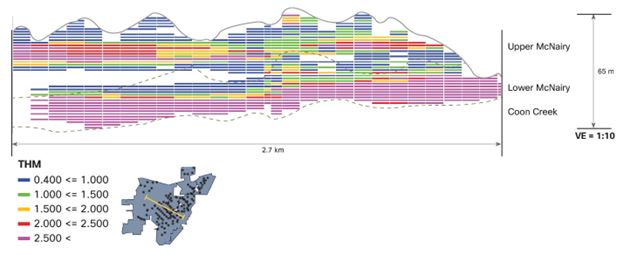

The base of mineralization ranges in relative level from 90–110 m above current sea level. Mineralization varies from 6–51 m thick and averages 31 m in thickness and is generally made up of large thicknesses of stacked laminations of HMs; however, some more massive mineralization is present where individual laminations are not present. The primary minerals associated with the mineralized horizons are altered ilmenite, zircon, rutile, staurolite, kyanite, monazite and xenotime with some variation in the proportion of these minerals between the upper and lower zones. Generally, the finer-grained lower zone contains more higher-value HMs including rutile, zircon, monazite, and xenotime than the upper coarser-grained zone. The gangue minerals are predominantly quartz and clays. Though extensive basement faulting is present in the region, it does not appear to impact the sedimentary stratigraphy at the scale of this project. Figure 6 presents the an example cross section.