Exhibit 96.3

Bulawayo Mining Company Limited

Redwing Mine

S-K 1300 Technical Report Summary

January 2025

Redwing Mine

S-K 1300 Technical Report Summary

Bulawayo Mining Company Limited

WSP

Level 3, 51-55 Bolton St

Newcastle NSW 2300

PO Box 1162

Newcastle NSW 2300

Tel: +61 2 4929 8300

Fax: +61 2 4929 8382

wsp.com

| Rev | Date | Details |

| D | 29/01/2025 | Final report |

| | Name | Date | Signature |

| Prepared by: | Aaron Radonich Allan Blair | 29/01/2025 | /s/ Aaron Radonich /s/ Allan Blair |

| Reviewed by: | Jerry DeWolfe | 09/01/2025 | /s/ Jerry DeWolfe |

| 1 | Executive summary | 1 |

| 1.1 | Property description and ownership | 1 |

| 1.2 | Geology and mineralisation | 1 |

| 1.3 | Exploration | 1 |

| 1.4 | Mineral Resources estimates | 2 |

| 1.5 | Mineral Reserves estimates | 3 |

| 1.6 | Capital and operating costs | 3 |

| 1.7 | Permitting requirements | 3 |

| 1.8 | QPs’ conclusions and recommendations | 3 |

| 1.8.1 | Mineral Resources | 3 |

| 1.8.2 | Mineral Reserves | 5 |

| | | |

| 2 | Introduction | 7 |

| 2.1 | Registrant information | 7 |

| 2.2 | Terms of reference and purpose | 8 |

| 2.3 | Sources of information | 11 |

| 2.4 | Personal inspection | 11 |

| 2.5 | Previously filed Technical Report Summaries | 11 |

| 2.6 | WSP declaration | 11 |

| | | |

| 3 | Property description | 12 |

| 3.1 | Property location | 12 |

| 3.2 | Title and mineral rights | 12 |

| 3.3 | Encumbrances | 13 |

| 3.4 | Risks to access, title, or right to perform work | 13 |

| 3.5 | Agreements and royalties | 14 |

| | | |

| 4 | Accessibility, climate, local resources, infrastructure, and physiography | 15 |

| 4.1 | Topography, elevation, and vegetation | 15 |

| 4.2 | Access | 15 |

| 4.3 | Proximity to population centres | 15 |

| 4.4 | Climate | 15 |

| 4.5 | Local resources and existing infrastructure | 16 |

| 4.5.1 | Power supply | 16 |

| CONTENTS (Continued) | |

| | |

| 4.5.2 | Water supply | 16 |

| 4.5.3 | Personnel | 16 |

| 4.5.4 | Suppliers | 16 |

| | | |

| 5 | History | 17 |

| 5.1 | Exploration and ownership history | 17 |

| 5.2 | Production history | 18 |

| 5.3 | Production reconciliation | 19 |

| 5.4 | Aggregate fiscal year production | 19 |

| 5.5 | Exploration and development by previous owners or operators | 19 |

| 5.6 | Liabilities | 20 |

| | | |

| 6 | Geological setting, mineralisation, and deposit | 21 |

| 6.1 | Regional geology | 21 |

| 6.1.1 | Mozambique Greenstone Belt | 21 |

| 6.1.2 | Granitoids | 21 |

| 6.2 | Structural setting | 22 |

| 6.3 | Local and property geology | 22 |

| 6.3.1 | Felsite | 22 |

| 6.3.2 | MSZ | 22 |

| 6.4 | Deposit type and geology | 23 |

| 6.5 | Mineralisation | 23 |

| | | |

| 7 | Exploration | 26 |

| 7.1 | Diamond drilling | 26 |

| 7.2 | QP’s opinion | 31 |

| | | |

| 8 | Sample preparation, analyses, and security | 35 |

| 8.1 | Sampling techniques | 35 |

| 8.1.1 | Core sampling | 35 |

| 8.1.2 | Channel sampling | 35 |

| 8.1.3 | Grab sampling | 35 |

| 8.1.4 | Drive face and stope-bench sampling | 35 |

| 8.1.5 | Sample security | 35 |

| CONTENTS (Continued) | |

| | |

| 8.2 | Dry bulk density determination | 35 |

| 8.3 | Sample preparation, analysis and procedures | 35 |

| 8.4 | Quality Assurance Quality Control | 36 |

| 8.4.1 | Drill core | 36 |

| 8.4.2 | Channel and grab samples | 36 |

| 8.4.3 | Certified Reference Material | 37 |

| 8.4.4 | Blanks | 37 |

| 8.4.5 | Duplicates | 37 |

| 8.5 | QP’s opinion on adequacy | 37 |

| | | |

| 9 | Data verification | 38 |

| 9.1 | Mineral Resources data verification | 38 |

| 9.1.1 | Data verification conducted by RMC Zimbabwe | 38 |

| 9.1.2 | Data verification conducted by WSP | 38 |

| 9.1.3 | Limitations on exploration and Mineral Resources data verification | 38 |

| 9.2 | Mining and Mineral Reserves data verification | 39 |

| 9.3 | Geotechnical data verification | 39 |

| 9.4 | Hydrogeology and hydrology data verification | 40 |

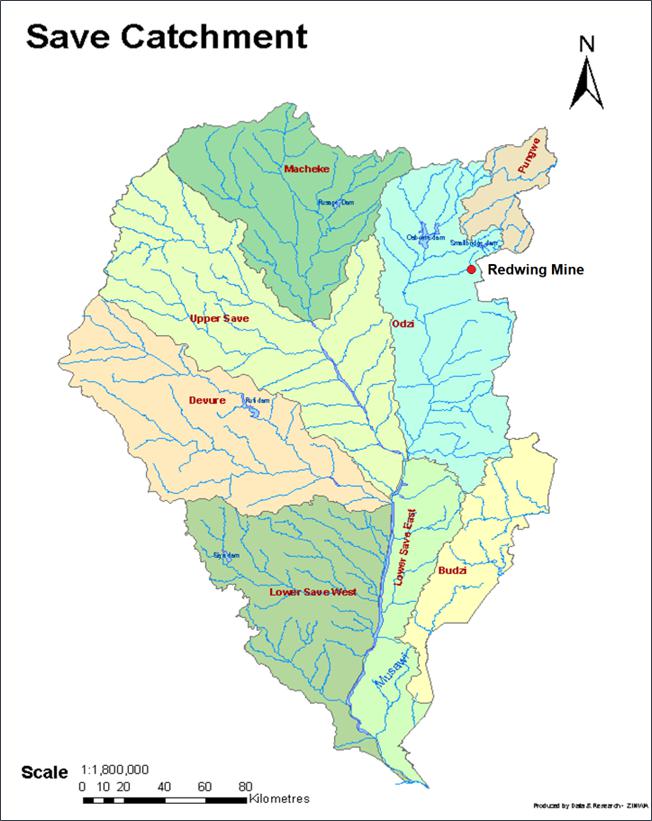

| 9.4.1 | Hydrology | 42 |

| 9.4.2 | Hydrogeology | 42 |

| 9.5 | Processing and recovery methods data verification | 42 |

| | | |

| 10 | Mineral processing and metallurgical testing | 43 |

| 10.1 | Nature and extent of mineral processing and metallurgical testing | 43 |

| 10.1.1 | Mineral processing | 43 |

| 10.1.2 | Process testwork | 44 |

| 10.2 | Metallurgical sampling representativity | 44 |

| 10.3 | Details of analytical or testing laboratories | 45 |

| 10.4 | Recovery Estimates | 45 |

| 10.5 | QP’s opinion on adequacy of the data collected | 45 |

| | | |

| 11 | Mineral Resource estimates | 46 |

| 11.1 | Key assumptions, parameters, and methods | 46 |

| 11.1.1 | Care and maintenance | 46 |

| 11.1.2 | Resource database | 46 |

| CONTENTS (Continued) | |

| | | |

| 11.1.3 | Geological interpretation | 46 |

| 11.1.4 | Data preparation | 46 |

| 11.1.5 | Exploratory data analysis | 46 |

| 11.1.6 | Dry bulk density | 47 |

| 11.1.7 | Block models | 47 |

| 11.1.8 | Grade interpolation parameters | 48 |

| 11.1.9 | Grade estimation | 48 |

| 11.1.10 | Model validation | 48 |

| 11.2 | Mineral Resources classification | 49 |

| 11.2.1 | Measured Mineral Resources | 49 |

| 11.2.2 | Indicated Mineral Resources | 50 |

| 11.2.3 | Inferred Mineral Resources | 51 |

| 11.3 | Cut-off grade, price, and justification | 51 |

| 11.3.1 | Tonnage-grade factors | 52 |

| 11.4 | Mineral Resources statement | 53 |

| 11.5 | Uncertainty in the estimates of Inferred, Indicated, and Measured Mineral Resources | 54 |

| 11.6 | QP’s opinion on factors likely to influence the prospect of economic extraction | 55 |

| 12 | Mineral Reserves estimates | 56 |

| 13 | Mining methods | 57 |

| 13.1 | Introduction | 57 |

| 13.2 | Parameters relative to the design and schedule | 57 |

| 13.2.1 | Geotechnical | 57 |

| 13.2.2 | Hydrogeological | 58 |

| 13.3 | Production parameters | 58 |

| 13.3.1 | Production rates | 58 |

| 13.3.2 | Expected mine life | 58 |

| 13.3.3 | Mining model | 59 |

| 13.3.4 | Mining dilution and recovery factors | 59 |

| 13.4 | Mining fleet, machinery, and personnel requirements | 60 |

| 13.5 | Scheduling results | 60 |

| 13.6 | Mining unit dimensions | 61 |

| 13.7 | Mine layout | 61 |

CONTENTS (Continued)

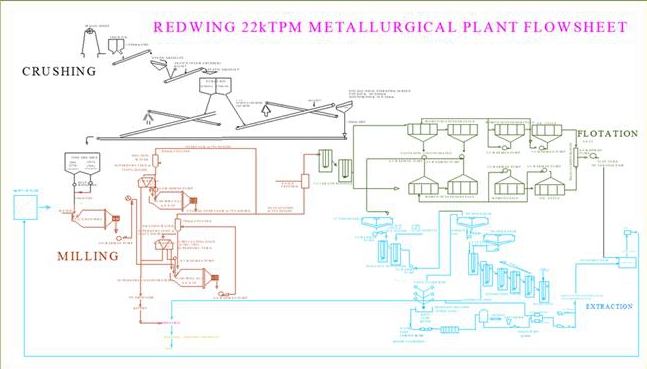

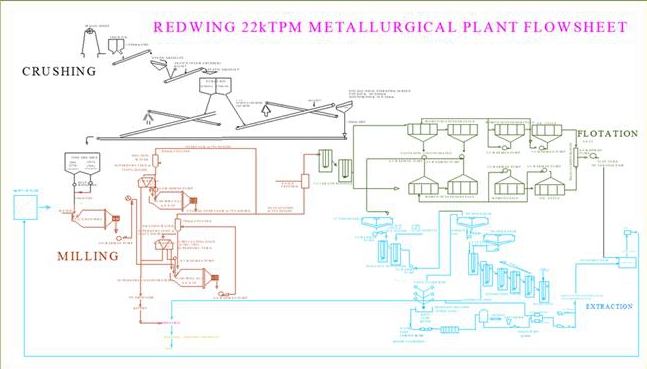

| 14 | Processing and recovery methods | 63 |

| 14.1 | Processing methodologies and flowsheets | 63 |

| 14.2 | Processing plant throughput and characteristics | 63 |

| 14.3 | Primary and secondary crushing | 64 |

| 14.3.1 | Primary crushing | 64 |

| 14.3.2 | Secondary crushing | 64 |

| 14.4 | Downhill conveying | 64 |

| 14.5 | Product sampling | 64 |

| 14.6 | Product stockyard | 64 |

| 14.7 | Offshore tertiary crushing and screening | 64 |

| 14.8 | Energy and water process materials requirements | 64 |

| 14.8.1 | Mine power supply | 64 |

| 14.8.2 | Mine water management system | 65 |

| 14.9 | QP’s opinion | 65 |

| 15 | Infrastructure | 66 |

| 15.1 | Rail access | 66 |

| 15.2 | Port access | 66 |

| 15.3 | Roads | 66 |

| 15.4 | Camp | 66 |

| 15.5 | Tailings | 66 |

| 15.6 | Potable water and wastewater | 66 |

| 15.7 | Accommodation and offices | 67 |

| 15.8 | Non process infrastructure | 67 |

| 15.9 | Information and communications technology (ICT) systems | 67 |

| 15.10 | Other support facilities and utilities | 67 |

| 16 | Market studies | 68 |

| 16.1 | Nature and material terms of agency relationships | 68 |

| 16.2 | Results of relevant market studies | 68 |

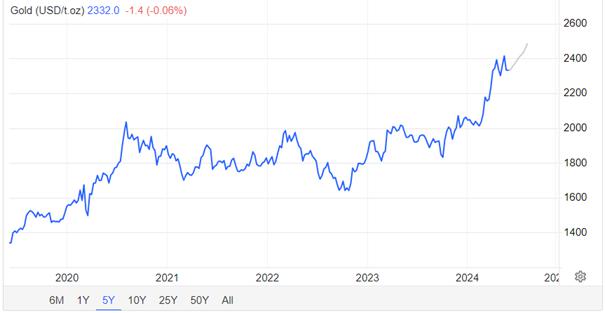

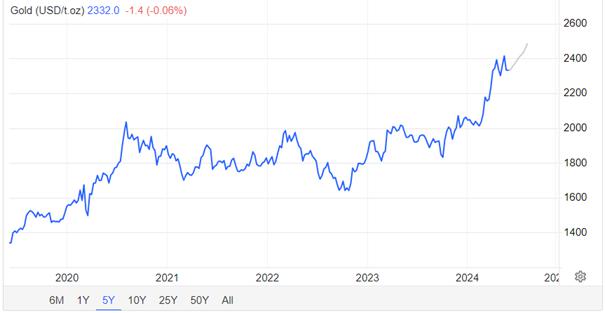

| 16.3 | Commodity price projections | 68 |

CONTENTS (Continued)

| 16.4 | Mining and processing | 70 |

| 16.5 | Product transport and handling | 70 |

| 16.6 | Hedging arrangements | 70 |

| 16.7 | Forward sales contracts | 70 |

| 16.8 | Contracts with affiliated parties | 70 |

| 17 | Environmental studies, permitting, and plans, negotiations, or agreements with local individuals or groups | 71 |

| 17.1 | Introduction | 71 |

| 17.2 | Project context | 71 |

| 17.3 | Project permitting | 71 |

| 17.4 | Environmental and social impact assessment | 72 |

| 17.4.1 | Biodiversity and natural resources | 72 |

| 17.4.2 | Managing impacts on water | 72 |

| 17.4.3 | Acid and metalliferous drainage (AMD) | 72 |

| 17.4.4 | Erosion and protection of soils | 72 |

| 17.4.5 | Noise and vibration | 72 |

| 17.4.6 | Air quality | 72 |

| 17.4.7 | Local climate impacts | 72 |

| 17.4.8 | Greenhouse gas emissions | 72 |

| 17.4.9 | Resources use and non-mineral waste | 72 |

| 17.5 | Project standards | 73 |

| 17.6 | Stakeholder engagement | 73 |

| 17.6.1 | Stakeholder engagement plan | 73 |

| 17.6.2 | Consultation | 73 |

| 17.7 | Cultural, economic, and social conditions | 73 |

| 17.7.1 | Cultural heritage | 73 |

| 17.7.2 | Local landscape | 73 |

| 17.7.3 | Contributing to the national and local economy | 73 |

| 17.7.4 | Establishing a social management framework | 73 |

| 17.7.5 | Impacts on land use and access | 73 |

| 17.7.6 | Protecting community health and safety | 74 |

| 17.7.7 | Protecting the workforce | 74 |

| 17.7.8 | Commitment to local procurement and hiring | 74 |

| 17.8 | Mine closure | 74 |

| 17.8.1 | Plan | 74 |

| 17.8.2 | Cost | 74 |

| 17.9 | Translating the ESIA into environmental and social management | 75 |

CONTENTS (Continued)

| 17.10 | QP’s opinion | 75 |

| 18 | Capital and operating costs | 76 |

| 19 | Economic analysis | 77 |

| 20 | Adjacent properties | 78 |

| 21 | Other relevant data and information | 79 |

| 22 | Interpretation and conclusions | 80 |

| 22.1 | Mineral Resources interpretations and conclusions | 80 |

| 22.2 | Mineral Reserves interpretations and conclusions | 80 |

| 23 | Recommendations | 81 |

| 23.1 | Mineral Resources recommendations | 81 |

| 23.2 | Mineral Reserves recommendations | 81 |

| 24 | References | 82 |

| 25 | Reliance on information provided by the Registrant | 83 |

List of tables

| Table 1.1 | RGM underground Measured and Indicated Mineral Resource estimate as of 31 December 2023 | 2 |

| | | |

| Table 1.2 | RGM underground Inferred Mineral Resource estimate as of 31 December 2023 | 2 |

| | | |

| Table 2.1 | List of acronyms and abbreviations used in this TRS | 9 |

| | | |

| Table 2.2 | List of QPs | 11 |

| | | |

| Table 5.1 | Mineral Resource summary comparison end December 2022 to end December 2023 | 19 |

| | | |

| Table 6.1 | Structural deformation events | 22 |

| | | |

| Table 9.1 | Summary of laboratory results (SRKSA (2016)) | 39 |

| | | |

| Table 11.1 | Variography summary (KDM 2018) | 47 |

| | | |

| Table 11.2 | Block dimension schemes for the 30 June 2018 block models (KDM 2018) | 47 |

List of tables continued

| Table 11.3 | Kriging parameters generated from variographic analysis (KDM 2018) | 48 |

| | | |

| Table 11.4 | 31 December 2023 COG estimation parameters | 52 |

| | | |

| Table 11.5 | RGM underground Measured and Indicated Mineral Resource estimate as of 31 December 2023 | 53 |

| | | |

| Table 11.6 | RGM underground Inferred Mineral Resource estimate as of 31 December 2023 | 53 |

| | | |

| Table 13.1 | Block call factors 2012–2018 (RGM Operations Reports) | 59 |

| | | |

| Table 13.2 | Preliminary mining design parameters | 61 |

| | | |

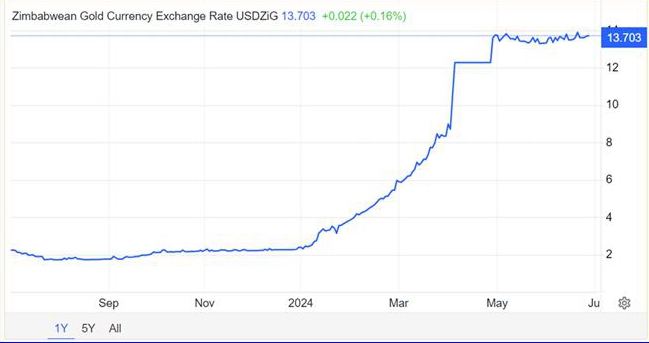

| Table 16.1 | Zimbabwean inflation rate and economic indicators (Trading Economics, 30 May 2024) | 69 |

| | | |

| Table 17.1 | RGM present closure obligation (Enmin 2024) | 74 |

| | | |

| Table 20.1 | Summary of adjacent claims (Virimai 2022) | 78 |

List of figures

| Figure 2.1 | BMC Limited corporate structure | 7 |

| | | |

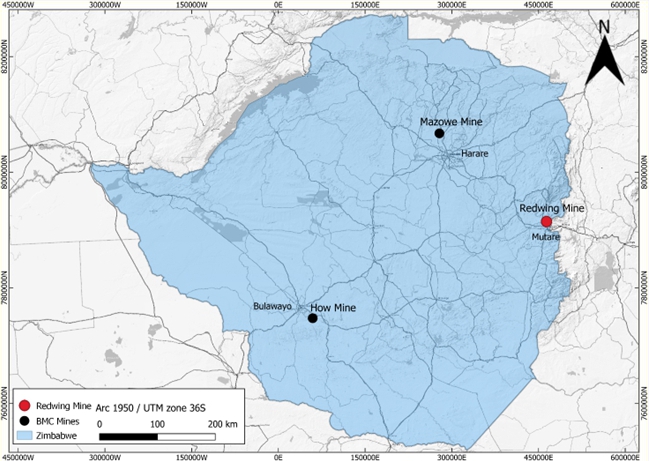

| Figure 3.1 | Property location map | 12 |

| | | |

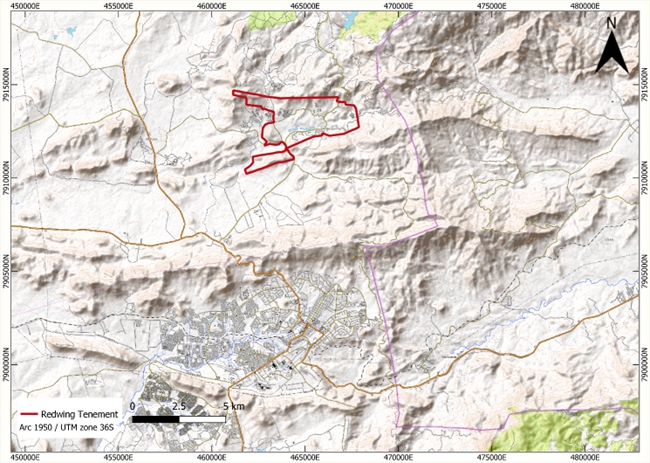

| Figure 3.2 | RGM ML 34 boundary | 13 |

| | | |

| Figure 4.1 | Climate statistics for Penhalonga, Zimbabwe (Meteoblue, 2024) | 16 |

| | | |

| Figure 5.1 | RGM total gold production 1981–2023 | 18 |

| | | |

| Figure 6.1 | Regional geology of Zimbabwe showing locations of greenstone belts (Prendergast 2004) | 21 |

| | | |

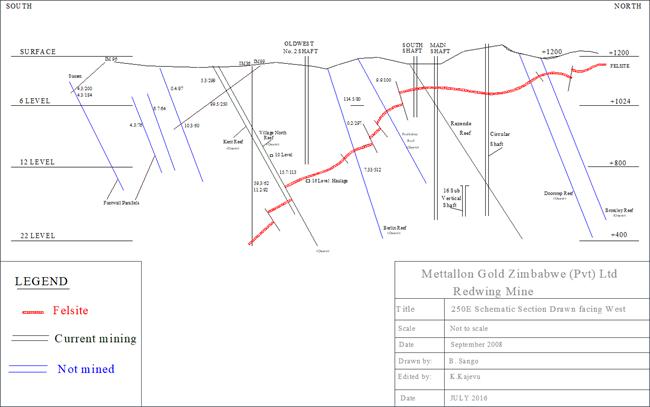

| Figure 6.2 | RGM MSZ schematic section | 23 |

| | | |

| Figure 6.3 | Penhalonga Valley local geology | 24 |

| | | |

| Figure 6.4 | RGM surface geology | 24 |

| | | |

| Figure 6.5 | RGM local stratigraphy | 25 |

| | | |

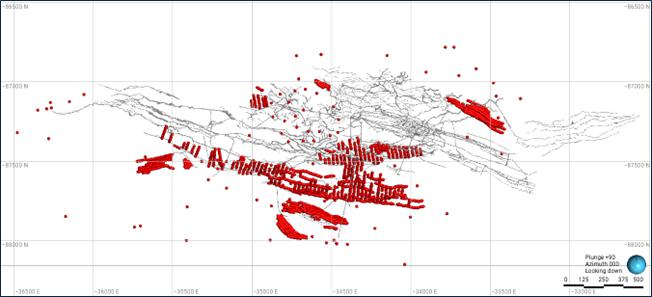

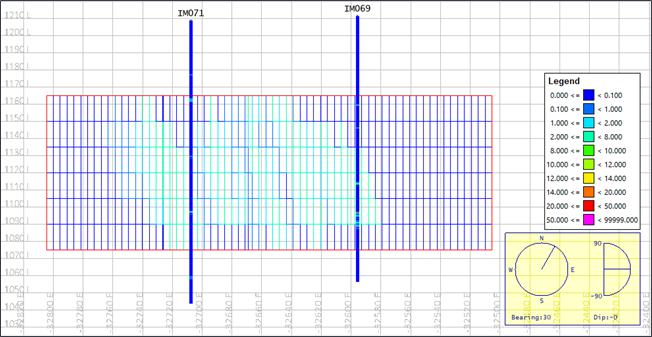

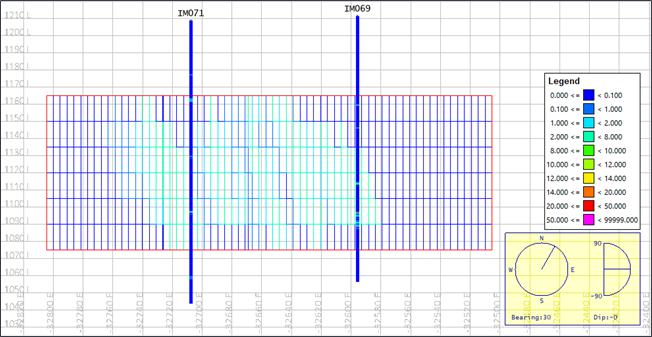

| Figure 7.1 | Plan view of all drill hole collars and existing mine development | 31 |

| | | |

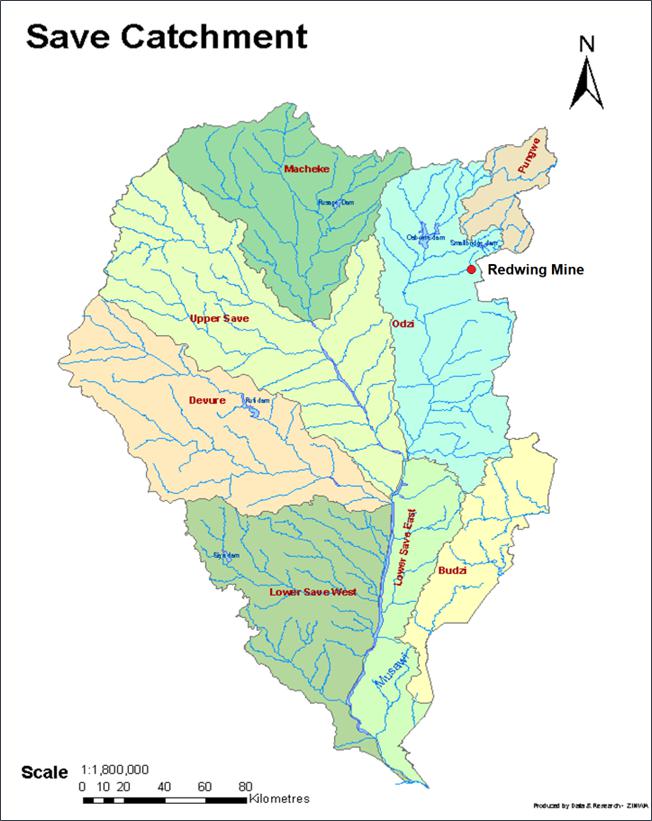

| Figure 9.1 | Catchment boundaries of Zimbabwe (BMC Limited) | 40 |

| | | |

| Figure 9.2 | Sub-catchment boundaries of Save Zimbabwe (BMC Limited) | 41 |

| | | |

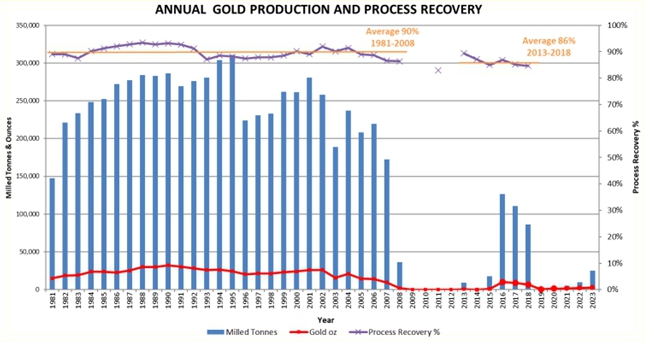

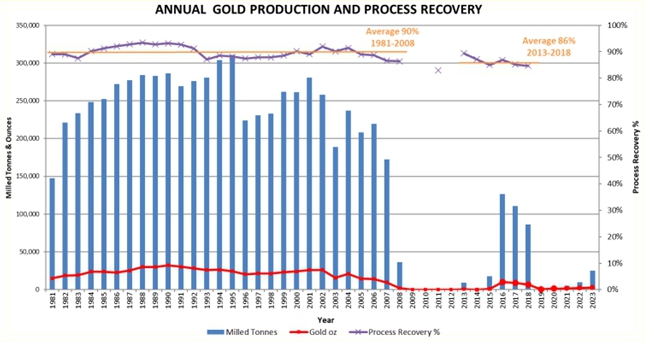

| Figure 10.1 | Process plant production and recovery 1981–2023 | 43 |

| | | |

| Figure 11.1 | 40L 020 Bund block grade and drill hole comparison | 49 |

| | | |

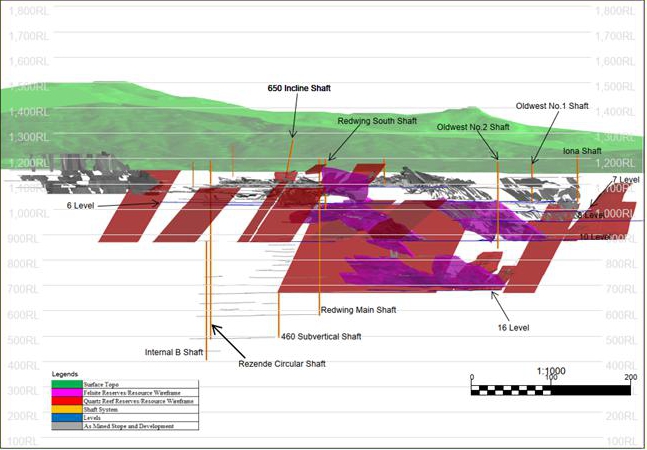

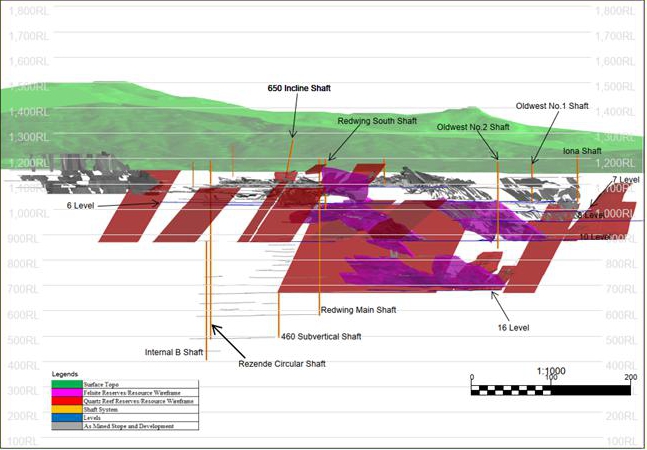

| Figure 13.1 | RGM mine layout looking south | 62 |

| | | |

| Figure 14.1 | RGM processing flowsheet (Virimai, 2018) | 63 |

| | | |

| Figure 16.1 | Historical (blue) gold spot price and forecast (grey) in US$/oz (Trading Economics 30 May 2024) | 68 |

| | | |

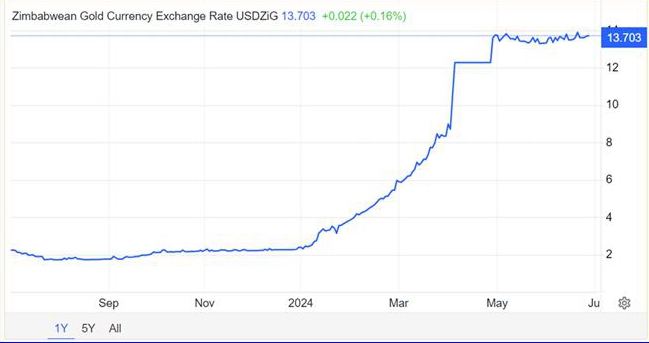

| Figure 16.2 | Zimbabwean gold currency exchange rate ZiG/USD (Trading Economics, 1 July 2024) | 70 |

List of appendices

| Appendix A | Limitations statement | |

| 1.1 | Property description and ownership |

The Redwing Gold Mine (RGM) [or the Property] is located in Penhalonga, some 20 km north-northeast of the City of Mutare (latitude 18°52’S and longitude 32°41’E), Manicaland Province, in the Mutare Mining District of Zimbabwe. The RGM is situated within the ML 34 tenement which has a surface area of 1,254 hectares (ha).

Redwing Mining Company (Private) Limited Zimbabwe (RMC Zimbabwe), a wholly owned subsidiary of KD Mining Company (UK) Limited (KDM UK), which is a wholly owned subsidiary of Bulawayo Mining Company Limited (BMC Limited), currently holds Mining Lease (ML) 34.

The RGM is accessible to major commercial centres via a well-established network of primary asphalt roads and is accessible from the surrounding communities through secondary gravel roads. Penhalonga has a population of approximately 8,000, and Harare has a population of approximately 1.5 million.

Access to the mine site and to the ore is authorised by the applicable mining legislation, and RMC Zimbabwe’s title and mining rights. Mining exploration and exploitation works conducted or to be conducted on site are authorised in accordance with the applicable legislation, and RMC Zimbabwe’s title and mining rights.

| 1.2 | Geology and mineralisation |

The RGM is located within the Mutare Greenstone Belt (MGB), which extends from the Mozambique Belt in the east, into the granites and gneisses of the Zimbabwe Craton in the west. The geology is dominated by an east-west trending series of metavolcanics consisting of olivine cumulates, komatiites, komatiitic basalts and high iron tholeiites. The rocks are extrusive, indicated by the presence of spinifex texture and pillow lavas as well as lenses of intercalated clastic sediments and discontinuous strings of Banded Iron Formation (BIF). The MGB is bounded by the Penhalonga Diorite to the north and south.

The local geology around the RGM includes an intrusive felsite consisting of a tabular micro-granitic body. The felsite lies in the core of the Penhalonga synform and it is the folding of this micro-granitic sheet within the diorite that is believed to be responsible for the localisation of gold mineralisation within Mineralised Shear Zones (MSZ).

Mineralisation within the MSZ (narrow reefs) is distinctly limited to physical deformation that has allowed the migration of hydrothermal fluids resulting in the deposition of quartz, sulphides and gold. While comparatively high gold values are associated with grey quartz and pyrite impregnation, zones of sheared and propylitised diorite commonly form part of contiguous reef structure.

The orebody strikes east-west and dips at a locally variable but shallow angle of approximately 35° to the south. At its widest, the orebody attains a thickness of approximately 7 m. It has been worked on a strike length of more than 2,500 m.

The RGM orebody boundaries are clearly defined, and the mineralisation envelope is defined by assay cut-offs.

Diamond core drilling is the drilling method employed at the RGM, with core sizes typically AXT (35.51 mm core diameter) and BQ (36.50 mm core diameter) for evaluation and exploration drill holes respectively. Diamond drill core is logged and sampled on a 1 m interval, depending on geology. Samples are taken to at least 1 m beyond the geologically defined mineralisation boundary in all drill holes. For underground evaluation and exploration drill holes, full core is sampled, while for surface exploration drill holes, mineralised zones only are split in half using a core splitter, with half the core being sent for assay and the other half kept for future reference.

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 1 |

| Bulawayo Mining Company Limited | |

Diamond drill core and channel samples were used for the purposes of geological modelling and Mineral Resources estimation.

Geotechnical laboratory results are sparse and incomplete.

| 1.4 | Mineral Resources estimates |

This report is prepared as a Technical Report Summary (TRS) for the Property, in accordance with the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601(b)(96).

The disclosure of Mineral Resources under this report is based upon the Qualified Person’s (QP’s) initial assessment. The Mineral Resources estimate has been defined, classified, and reported according to the guiding principles and minimum standards set out in SAMREC (2016). WSP’s view is that there are no material differences between SAMREC (206), and S-K 1300 requirements for the reporting of Mineral Resources.

The relevant Qualified Persons (QPs) are satisfied that there has been sufficient orebody knowledge work completed to support Reasonable Prospects for Economic Extraction (RPEE) at the Property from a Mineral Resources perspective. The initial assessment incorporates the QPs’ qualitative evaluation of relevant technical and economic factors likely to influence the prospect of economic extraction to establish the economic potential of the mining property or project (Section 11.3).

Evaluation data collection includes diamond drilling, channel sampling and sludge drilling.

Given there has been no mining or exploration conducted since the mine was placed on C&M, while the workings have been flooded, in the QP’s opinion the 2018 assumptions for definition of the resource base remain current.

For the purpose of demonstrating the capacity to exploit the resource as required under S-K 1300, the QPs have reviewed a high level cashflow model and are satisfied that the scale of the resource and free cashflow after operating costs will cover the cost of re-establishing access to underground workings, dewatering underground workings, surface infrastructure, and plant refurbishment/replacement. A process recovery of 90% for gold was applied for cashflow modelling consistent with recent historical averages and fixed tail estimates. Further assumptions are provided under Section 11.3 and Table 11-5.

Table 1.1 presents the underground Measured and Indicated Mineral Resources (exclusive of Mineral Reserves) reported as at 31 December 2023 on an in-situ basis.

Table 1.1 RGM underground Measured and Indicated Mineral Resource estimate as of 31 December 2023

| Category | Tonnage (Mt) | Au Grade (g/t) | Au Metal (koz) |

| Underground |

| Measured Resources | 1.45 | 2.92 | 136 |

| Indicated Resources | 8.20 | 3.99 | 1,052 |

| Grand Total | 9.65 | 3.83 | 1,188 |

Notes: Mt = million tonnes; Au Grade g/t = gold grams per tonne; koz = thousand ounces.

Table 1.2 presents the underground Inferred Mineral Resources reported as at 31 December 2023 on an in-situ basis.

Table 1.2 RGM underground Inferred Mineral Resource estimate as of 31 December 2023

| Category | Tonnage (Mt) | Au Grade (g/t) | Au Metal (koz) |

| Underground |

| Inferred Resources | 15.83 | 2.61 | 1,328 |

| Grand Total | 15.83 | 2.61 | 1,328 |

Notes: Mt = million tonnes; Au Grade g/t = gold grams per tonne; koz = thousand ounces.

It should be noted that the underground Mineral Resources estimate for the Property is reported exclusive of Mineral Reserves. The Property does not have a current Mineral Reserve.

It should be noted that the sands (tailings) Mineral Resources estimate for the Property is not included as part of the Mineral Resources for the Property, as the RGM does not currently possess a processing facility capable of processing the sands (tailings) material.

The Mineral Resources presented in this Section are not Mineral Reserves, and do not reflect demonstrated economic viability. The reported Inferred Mineral Resources are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorised as Mineral Reserves. There is no certainty that all or any part of this Mineral Resource will be converted into Mineral Reserve.

All figures are rounded to reflect the relative accuracy of the estimates and totals may not add correctly.

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 2 |

| Bulawayo Mining Company Limited | |

Based on the geological results presented in this TRS, supported by the assumptions made by RMC Zimbabwe (presented in Section 11.3), it is the QP’s opinion that the Mineral Resources have RPEE.

| 1.5 | Mineral Reserves estimates |

Not applicable since this TRS is an Initial Assessment and no Mineral Reserves have been estimated.

| 1.6 | Capital and operating costs |

Not applicable since this TRS is an Initial Assessment and no Mineral Reserves have been estimated.

Any future estimation of Mineral Reserves and potential recommencement of operations will require the support of an additional drilling and resource definition campaign and at least a pre-feasibility to feasibility level of evaluation.

| 1.7 | Permitting requirements |

The ML is inspected on an annual basis by the Government of Zimbabwe. The area covered by the ML was surveyed and declared to be 1,254.2 ha. The ML 34 is inspected annually, and the current certificate is valid till 13 August 2025.

There is also a requirement for renewal of environmental and miscellaneous operating permits as outlined in Section 17.3 before recommencement of active mining operations. All the environmental and miscellaneous licensing is currently expired.

There has been a significant increase in artisanal gold mining activities during the period of business administration to the present day, confined to areas outside the fenced RGM tenement area. The previous business administrator (appointed July 2020, removed by court action September 2022) engaged parties under contract for this purpose, with the main contractors nominated as Betterbrands and Probatek. Poor artisanal mining practices resulted in a significant number of fatalities that posed a risk to permitting and future operation, including 22 fatalities and 8 lost time accidents in 2022, 22 fatalities and 9 lost time accidents in 2023, and 2 fatalities and 1 lost time accident to end April 2024. Following legal action to remove Betterbrands, concluded in January 2024, the control of operations has now reverted back to RMC and contract artisanal miners are in the process of being removed from site. These issues pose a risk to permitting and future operation that will need to be effectively managed.

| 1.8 | QPs’ conclusions and recommendations |

Based on the information presented in this TRS, the QP’s key conclusions are as follows:

| — | The level of understanding in terms of regional geology, local geology and the nature and controls on mineralisation is high and provides a solid foundation for geological modelling, Mineral Resource estimation and mining geology. |

| — | Location of samples for surface and level-infill drilling are un-reliable due to errors with collar location and downhole survey. |

| — | Mineral Resource estimates are currently transitioning from paper-based estimates to digital estimates. |

| — | Mineral Resource estimates were completed on an unconstrained basis. |

| — | Estimates utilised all available samples i.e., channel, sludge, diamond drill core etc. |

| — | Dry bulk density (BD) of 2.7 tonnes per cubic metre (t/m3) assigned for all domains. |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 3 |

| Bulawayo Mining Company Limited | |

| — | Validation of the Mineral Resource estimates has not been reported. Standard industry practice is to conduct both visual and statistical validation of estimates and present the findings of this work in the Mineral Resource report to give the reader an appreciation of the robustness of the estimates. |

| — | Estimation within modelled mineralisation domains (constrained estimate) would likely result in an increase in contained metal. |

| — | Gold price increase have not been reflected in the reporting Au Cut-off Grade (COG). A lower reporting cut-off grade may lead to an increase in contained metal. |

| — | The on-site assay laboratory is well-equipped and maintained and is considered suitable for the work that it is used for. |

| — | The drilling, sampling, assay and Quality Assurance and Quality Control (QAQC) techniques used for both exploration and resource definition are consistent with standard industry practice and are considered appropriate for the purposes of geological modelling and Mineral Resource estimation. More detailed information on core recovery is however required. |

| — | Data and database management requires further work. |

| — | The COG used for Mineral Resource estimation seem reasonable on face value, but the methodology used for determination of these values has not been reported and requires further explanation. |

| — | The method used for high-grade cutting is deemed appropriate and consistent with industry practice. |

| — | Mineral Resource estimates used a combination of paper-based estimation methods and digital estimation |

| — | The Mineral Resources Mineral Reserves (MRMR) technical report developed by RMC Zimbabwe covers a number of areas in sufficient detail, however; a number of areas require more detail to give the reader a more thorough understanding of the work that has been conducted, the results of the work and any inherent risks to the Mineral Resource estimate. |

| — | Mining, processing, and market modifying factors, study assumptions and parameters are used to establish RPEE for the reporting of Mineral Resources. No significant risks exist that could impact the reliability and/or confidence of Mineral Resources estimates. |

Based on the information presented in this TRS, the QP’s key recommendations are as follows:

| — | Data and database management is an area that requires further work. The RGM would benefit from the introduction of a corporate database, with inbuilt validation routines and reporting functionality, to assist with what is a large quantity of geological information. |

| — | Review lithology, structural and mineralisation modelling practices. |

| — | Data analysis is conducted; however, it is recommended that for future Mineral Resource estimates, deposit wide Exploratory Data Analysis (EDA) is undertaken prior to estimation, to ensure data is fit for purpose for geological modelling and Mineral Resource estimation. |

| — | It is recommended that a succinct geological modelling and Mineral Resource estimation process flow is developed and followed for future Mineral Resource estimates. |

| — | It is recommended that Mineral Resource estimation is constrained to modelled mineralisation domain wireframes, using an appropriate Au cut-off grade. |

| — | All paper-based estimation techniques should be converted to computer-based (digital) as soon as possible. |

| — | A comparison between BD values determined from underground grab samples, and drill core should be undertaken to ensure that the mean values used for Mineral Resource estimation are appropriate, and that bias is not being incorporated into the Mineral Resource estimate. |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 4 |

| Bulawayo Mining Company Limited | |

| — | Validation of the Mineral Resource estimates produced, or at least the documentation of validation work undertaken is an area that requires further work. Standard industry practice is to conduct both visual and statistical validation of estimates and present the findings of this work in the Mineral Resource report, to give the reader an appreciation of the robustness of the estimates. |

| — | RPEE have been considered, and the parameters used are considered reasonable. |

| — | Review Mineral Resource classification methodology and block assignment. |

| — | The Mineral Resource report developed covers a number of areas in sufficient detail; however, some areas require more detail to give the reader a more thorough understanding of the work that has been conducted, the results of the work and any inherent risks to the Mineral Resource estimate. |

| — | Mineral Resource reconciliation practices should be reviewed, and a system implemented that provides a measure of Mineral Resource estimate performance. Planned versus actual resource tonnages and grades should be developed and updated each time a Mineral Resource estimate is completed. It is recommended that mined development and production be reconciled monthly, and stope close-out reports be developed for each completed stope. |

| — | A Mineral Resource update, according to industry best practice, should be completed prior to re-establishment of commercial production. |

| — | An underground drilling program, collared from footwall drives, aimed at increasing confidence in the existing resource should be undertaken. |

| — | Subsequent to future MRM updates, a stope optimisation exercise is recommended. Stope optimisation allows for the rapid development of valid stope shapes according to specified criteria. |

Not applicable since this TRS is an Initial Assessment and no Mineral Reserves have been estimated.

For the historical 2018 Mineral Reserve estimate, the QP provides comment as follows:

| — | QP’s view is that the Mineral Reserve estimate represents a low level of conversion of the existing resource base as a function largely of those blocks that are readily accessible and meet the technical and economic constraints, such as pay limits for viable economic extraction. The QP notes that the relatively low inventory might have difficulty supporting both the capital and operating costs without the support from additional sources and that the average grades remaining are considerably higher than recent historical mining and processing performance at 2.7 g/t Au for 2016-2018. |

| — | It should be noted that a Mineral Reserve has not been estimated and reported since June 2018 as the RGM has been on C&M since 1 April 2019. Due to the positive change in gold price between 30 June 2018 (approx. US$1,250/oz) and 31 December 2023 (3-year trailing average US$1,848/oz), it is likely that a Mineral Reserve estimated at end December 2023 would be reported at a lower pay-limit, resulting in an increase in Mineral Reserve tonnages and therefore gold content. |

| — | The process of estimating the mineral reserve for RGM is well developed and relatively straight forward. |

| — | The Mineral Resource estimated for the RGM is significant and deserving of a long-term plan for increased exploitation and production ramp-up. This can be facilitated by improving the Mineral Reserve base estimate for mining. It should include consideration of process plant upgrade or replacement (improved throughput and recovery) and options for modernising the underground operation. Surface mining opportunities should also be examined. |

| — | The current methodology for estimation of Mineral Reserves appear to conform with standard African mining industry approaches but will benefit from clarification and upgrade of the approach. |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 5 |

| Bulawayo Mining Company Limited | |

For the historical 2018 Mineral Reserve estimate, the QP provides comment as follows:

| — | The 2018 Mineral Reserve estimate will require update to reflect significant changes in gold price, operating costs and capital costs to support any future proposal to recommence mining operations. |

| — | The mine could consider amalgamating the separate models to assist with interpretation and processing. |

| — | WSP understands that wireframe surfaces are developed for the purpose of the Mineral Resource estimation and subsequently converted by spreadsheet calculation using modifying factors and pay limits to ascertain final reserve estimates. Industry recommended practice also includes preparation of development and stoping wireframes representing the material planned to be mined, inclusive of allowances for mining method, pillars and minimum mining widths. These wireframe solids can then be used to directly interrogate tonnage and grade from the block model by category and facilitate subsequent automated scheduling and animation using software such as Mine24D™ and Deswik™. RMC Zimbabwe could consider implementing this approach. |

| — | Consideration could also be given to application of pay limits, minimum mining width, BF and APF on a block-by-block basis commensurate with the technical and economic merits of each stoping block. |

| — | The QP recommends reviewing individual stope performance to test and vary the relatively nominal assumptions. This could include modelling of dilution skins and using block model grades. |

| — | Prepare a LOM design to support a detailed mining schedule. Consider using industry leading practice to generate 3D mine designs linked to physical quantity and cost schedules. |

| — | Identify access and requirements and estimate pay limits for each block. Annotate and exclude those blocks that are not accessible or economic. |

| — | Where possible, prioritise high value (Au grade) targets for escalated development and earlier production as this may have a significant impact on project returns. |

| — | Prepare a detailed narrative report to support the annual LOM plan. |

| — | Identify those areas where more mechanised long hole stope mining may be introduced to improve productivity and unit cost. A structured plan is required that explains how the proposed production rates will be achieved. This will require a pre-feasibility to feasibility study level of assessment. |

| — | Employee numbers averaging 872 at peak production appear nominal and will need to be adjusted to reflect the approach and mining method(s) adopted. |

| — | Estimates for development advance at the rate of 15.6 km per annum appear nominal rather than based on a clear and detailed plan. |

| — | Drill metres (jackhammer only) also appear to be nominal and underestimated if based on 1.33 t/m drilled. |

| — | Power outage (10% of hours) issues that plague the mine are assumed to be resolved after two years. A plan needs to be put in place that clearly identifies how this will be achieved. |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 6 |

| Bulawayo Mining Company Limited | |

| 2.1 | Registrant information |

This Technical Report Summary (TRS) is for the Bulawayo Mining Company Limited (BMC Limited) owned Redwing Gold Mine (RGM) [the Property], located in Manicaland Province in eastern Zimbabwe, and was prepared by the Qualified Persons (QPs) for BMC Limited.

BMC Limited is a private company incorporated in the United Kingdom (UK) and is a wholly owned subsidiary of Metallon Corporation Limited (UK) [Metallon]. KD Mining Company (UK) Limited (KDM) is a private company incorporated in the UK and is a wholly owned subsidiary BMC Limited.

Bulawayo Mining Company (Private) Limited Zimbabwe (BMC Zimbabwe), Mazowe Mining Company (Private) Limited Zimbabwe (RMC Zimbabwe), and Redwing Mining Company (Private) Limited Zimbabwe (RMC Zimbabwe) are responsible for the management of mineral assets located in Zimbabwe, the principal activities of which include exploration, development and operation of precious metals mineral assets.

RMC Zimbabwe is directly responsible for the day-to-day management of the mining operations and holds Mining Lease (ML) 34. The area covered by ML 34 has a surface area of 1,254 hectares (ha) [Figure 3.2] (BMC 2023a).

Figure 2.1 presents the corporate structure of BMC Limited.

Figure 2.1 BMC Limited corporate structure

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 7 |

| Bulawayo Mining Company Limited | |

In October 2002, Metallon (herein referred to as BMC Limited) acquired a portfolio of mineral assets from a holding subsidiary of Lonmin plc (Lonmin), known as Independence Mining (Private) Limited.

This portfolio of mineral assets located in Zimbabwe consists of three mining properties located within a significant land package consisting of some 66.02 square kilometres (km2) in area. The mining properties comprise three separate underground gold mines, namely: How, Mazowe, and Redwing. Each mining property is serviced by its own dedicated processing facilities and accompanying infrastructure. BMC Limited considers there to be significant exploration potential at each of the mining properties.

From acquisition of the assets in 2002 until 2006, gold production steadily increased with gold production peaking in 2005 at approximately 156,000 ounces (oz) of gold, making BMC Limited Zimbabwe’s largest gold producer.

Due to political unrest and hyperinflation in 2007, BMC Limited’s mining activities in Zimbabwe ceased and all mines were placed on Care and Maintenance (C&M). In 2009, mining activities recommenced, with many of the mines requiring rehabilitation work.

Operations were suspended at the Mazowe Gold Mine (MGM) on 31 December 2018, and at the RGM on 30 March 2019 due to general economic challenges. Both mines were placed on a Supreme Court ordered Corporate Rescue, with the MGM commencing 20 February 2020, and the RGM commencing 23 July 2020. Both Corporate Rescue proceedings were nullified on 7 October 2021 for the MGM, and 5 September 2022 for the RGM.

During the Corporate Rescue period, Betterbrands Mining Company (Pvt) Ltd (BBM) was engaged as a tributor to mine on Mining Lease (ML) 34 (Virimai 2022). On 8 March 2024, the non-standard tribute agreement with BBM was cancelled, and BBM was evicted from the RGM.

In January 2024, 15 artisanal miners were trapped for a period of three days at the RGM.

Gold production from RGM since 2018 is as follows (RMC Operation Reports):

BMC Limited’s forward strategy is to produce 300,000 oz of gold per annum through expansion across all mines, and through a broader acquisition strategy across Africa.

BMC Limited is pursuing a focused expansion strategy throughout Africa, with the aim of securing prospective green minerals assets in Zimbabwe, and the Democratic Republic of Congo (DRC).

| 2.2 | Terms of reference and purpose |

The purpose of this TRS is to report Mineral Resources, and Mineral Reserves for the Property effective as of 31 December 2023. The TRS utilises:

| — | Australian English spelling. |

| — | Metric units of measure. |

| — | Grades presented in grams per tonne (g/t). |

| — | Co-ordinate system presented in metric units using Cape/Lo29. |

| — | United States Dollars (USD). |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 8 |

| Bulawayo Mining Company Limited | |

Summary Mineral Resources in Table 1.1 and Table 1.2 are presented based on a BMC Limited equity ownership basis (100%). No current Mineral Reserves as at 31 December 2023 have been estimated.

Key acronyms and definitions used in this TRS include those items listed in Table 2.1.

Table 2.1 List of acronyms and abbreviations used in this TRS

| Acronym/abbreviation | Description |

| AAS | Atomic Absorption Spectroscopy |

| amsl | Above mean sea level |

| APF | Assay plan factor |

| ASCII | American Standard Code for Information Interchange |

| Au | Gold |

| BBM | Betterbrands Mining Company (Pvt) Ltd |

| ⁰C | Degrees Celsius |

| BCF | Block Call Factor |

| BD | Bulk Density |

| BIF | Banded Iron Formation |

| BF | Block Factor |

| BMC Limited | Bulawayo Mining Company Limited |

| BSV | Bernheim-Storis-Vesuvius |

| CIP | Carbon in Pulp |

| cm | Centimetres |

| C&M | Care and Maintenance |

| COG | Cut Off Grade |

| CRM | Certified Reference Material |

| CV | Coefficient of Variation |

| DRC | Democratic Republic of Congo |

| EIA | Environmental Impact Assessment |

| EMP | Environmental Management Plan |

| ER | Extraction Ratio |

| g/cm3 | Grams per cubic centimetre |

| g/t | Grams per tonne |

| ha | Hectares |

| ID2 | Inverse squared distance |

| k | Thousand |

| kg | Kilograms |

| KDM | KD Mining Company (UK) Limited |

| km | Kilometres |

| km2 | Square kilometres |

| koz | Thousand ounces |

| kt | Thousand tonnes |

| ktpa | Thousand tonnes per annum |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 9 |

| Bulawayo Mining Company Limited | |

| ktpm | Thousand tonnes per month |

| kV | Kilovolts |

| l/s | Litres per second |

| LDV | Low Density Villages |

| LOM | Life of Mine |

| m3 | Cubic metre |

| Ma | Million years |

| MAR | Mean Annual Run-off |

| MCF | Mine Call Factor |

| MGB | Mutare Greenstone Belt |

| MGM | Mazowe Gold Mine |

| ML | Mining Lease |

| mm | millimetres |

| Moz | Million ounces |

| MRMR | Mineral Resources Mineral Reserves |

| MSZ | Mineralised Shear Zones |

| Mt | Million tonnes (metric) |

| Mtpa | Million tonnes per annum |

| MVA | Megavolt-ampere |

| OK | Ordinary Kriging |

| oz | Ounces |

| QP | Qualified Person |

| RGM | Redwing Gold Mine |

| RMC Zimbabwe | Redwing Mining Company (Private) Limited |

| RPEE | Reasonable Prospects for Economic Extraction |

| RTGS | Real time gross settlement |

| SAMREC | South African Mineral Resource Committee |

| SD | Standard Deviation |

| SRK | SRK consulting (UK) Ltd |

| SRKSA | SRK Consulting (South Africa) (Pty) Ltd |

| t | Tonnes |

| t/m | Tonnes per metre |

| t/m3 | Tonnes per cubic metre |

| TBL | Terminal Benefits Liability |

| TRS | Technical Report Summary |

| TSF | Tailings Storage Facility |

| μm | Micrometre |

| USD | United States Dollar |

| V | Volts |

| WSP | WSP Australia Pty Limited |

| Wt.% | Weight percent |

| ZETDC | Zimbabwe Electricity Transmission and Distribution Company |

| ZiG | Zimbabwe gold currency |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 10 |

| Bulawayo Mining Company Limited | |

| 2.3 | Sources of information |

This TRS relies upon various reports and other material prepared by BMC Limited, and BMC Limited’s staff and consultants as provided to WSP. This data and information have been supplemented with information in the public domain, and through information gathered during a site inspection by WSP in May 2024 (Section 2.4).

While WSP has reviewed the data and other information contained in the reports and other material provided to it and is not aware of any reason to doubt that such data and information is complete and accurate, excluding Golder (2021), WSP was not responsible for the preparation of those reports and other material.

WSP has taken reasonable care to ensure that the information contained in this TRS is in accordance with the facts and information available to it and is unaware of any omission likely to affect its import. In this regard, the attention of any reader of the TRS is specifically directed to Section 24, and Appendix A.

Information in this TRS has been prepared under the supervision of the following QPs:

| — | Aaron Radonich, Fellow of the Australasian Institute of Mining and Metallurgy (FAusIMM, Member Number 221172), Principal Geologist, WSP. Aaron is responsible for RGM Mineral Resources. The date of the last personal inspection was May 2024. |

| — | Allan Blair, Member of the Australasian Institute of Mining and Metallurgy (FAusIMM, Member Number 102240), Principal Mining Engineer, WSP. Allan is responsible for RGM Mineral Reserves. The date of the last personal inspection was May 2024. |

Table 2.2 presents a tabulation of the QPs, their personal inspections, and their areas of responsibility.

| QP | Qualifications/Affiliation | Date of Personal Inspection | Areas of Responsibility |

| Aaron Radonich | Fellow AusIMM, PGCert Geostatistics, BSc (Hons.), BSc | May 2024 | Sections 1.1, 1.2, 1.3, 1.4, 1.7, 1.8.1, 2, 3, 4, 5, 6, 7, 8, 9.1, 11, 20, 21, 22,1, 23.1, 24 and 25. |

| Allan Blair | FAusIMM, MBA, BSc, BAppSc Mining Engineering | May 2024 | Sections 1.5, 1.6, 1.8.2, 5, 9.2, 9.3, 9.4, 9.5, 10, 12, 13, 14, 15, 16, 17, 18, 19, 22.2 and 23.2. |

| 2.5 | Previously filed Technical Report Summaries |

This is the first TRS filed for the Property and therefore does not update a previously filed TRS.

The opinions of QPs in the employ of WSP contained herein and effective 31 December 2023, are based on information collected throughout the course of investigations by the QPs. The information in turn reflects various technical and economic conditions at the time of preparing the TRS. Given the nature of the mining business, these conditions can change significantly over relatively short periods of time. Consequently, actual results may be significantly more or less favourable.

This TRS may include technical information that requires subsequent calculations to derive sub-totals, totals, and weighted averages. Such calculations inherently involve a degree of rounding, and consequently introduce a margin of error. Where these occur, the QPs do not consider them to be material.

Neither WSP, nor the QPs responsible for this TRS, are insiders, associates, or affiliates of BMC Limited or any of its subsidiaries. The results of the technical review by the QPs are not dependent on any prior agreements concerning the conclusions to be reached, nor are there any undisclosed understandings concerning any future business dealings.

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 11 |

| Bulawayo Mining Company Limited | |

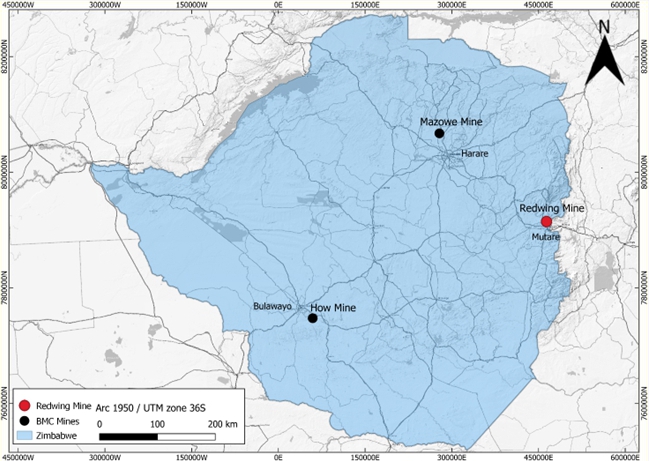

The RGM is located in Penhalonga, some 20 km north-northeast of the City of Mutare (latitude 18°52’S and longitude 32°41’E), Manicaland Province, in the Mutare Mining District of Zimbabwe (Figure 3.1).

The RGM is located approximately 265 km southeast of the capital city of Harare.

Figure 3.1 Property location map

3.2 Title and mineral rights

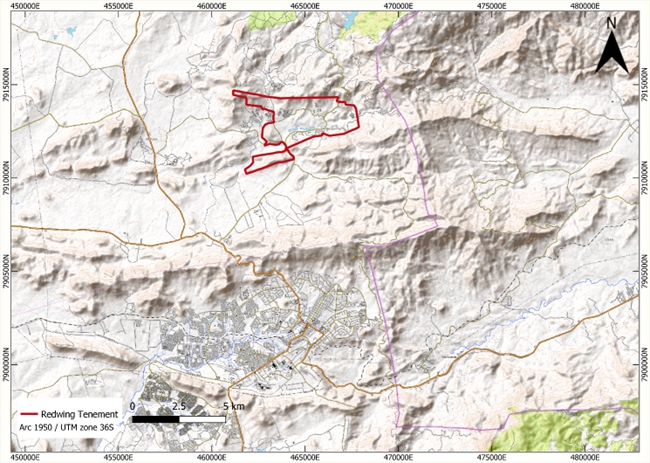

RMC Zimbabwe holds ML 34. The area covered by the ML was surveyed in 2015 as having a surface area of 1,254 hectares (ha). Cases of illegal gold mining activities have been reported in some sections of the ML, including along the Mutare River (KDM 2018).

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 12 |

| Bulawayo Mining Company Limited | |

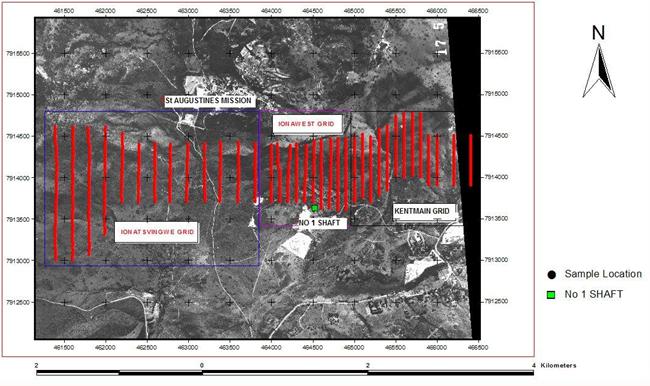

Figure 3.2 presents the ML 34 boundary.

Figure 3.2 RGM ML 34 boundary

While WSP has referred to tenement holdings in this TRS, such reference is for convenience only and may not be complete or accurate. WSP is not expert in tenement management and the reader should not rely on information in this TRS relating to the current ownership and legal standing of the tenements or any encumbrances impacting on those tenements. This TRS assumes that all tenements and tenement applications are in good standing and free of all encumbrances other than those set out in this TRS.

There are no known significant encumbrances to the Property that would impact the current Mineral Resources or Mineral Reserves. Risks to access, title or right to perform work.

| 3.4 | Risks to access, title, or right to perform work |

Access to the mine site and to the ore is authorised by the applicable mining legislation, and RMC Zimbabwe’s title and mining rights (Section 3.2). Mining exploration and exploitation works conducted or to be conducted on site are authorised in accordance with the applicable legislation, and RMC Zimbabwe’s title and mining rights (Section 3.2). Other required permits and authorisations (e.g., environmental, building, etc.) are applied for by RMC Zimbabwe in accordance with the applicable legislation.

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 13 |

| Bulawayo Mining Company Limited | |

| 3.5 | Agreements and royalties |

In 2022, the government of Zimbabwe has promulgated new regulations through Statutory Instrument 189 of 2022 to the effect that mineral royalties are to be paid partly in kind and partly in monetary form. The mineral royalties are collected from minerals specified in terms of section 49(1)(c1) of the Reserve Bank of Zimbabwe Act [Chapter 11:15] deemed to be components of the reserves maintained by the Reserve Bank of Zimbabwe. Minerals include but are not limited to gold, diamonds, platinum group metals, and lithium. These regulations have also caused timeous amendments to the Finance Act and the Reserve Bank of Zimbabwe Act to ensure the cooperation in application of legislation (BMC 2023)

In 2024, the monetary component was revised. Royalties remitted to the Zimbabwe Revenue Authority in respect of gold and those minerals specified are paid based on 50% in kind and 50% in monetary form. With regards the “in kind component”, miners submit actual minerals they would have extracted. The 50% monetary component would be paid as follows:

| — | 37.5% in the Zimbabwe Gold (ZiG) currency. |

| — | 12.5% in foreign currency (RBZ 2024). |

Prior to the promulgation of these regulations, royalties were paid only in monetary form.

A US$21 per kilogram (/kg) realisation fee is also charged for gold lodged with Fidelity Printers and Refiners (BMC 2023).

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 14 |

| Bulawayo Mining Company Limited | |

| 4 | Accessibility, climate, local resources, infrastructure, and physiography |

| 4.1 | Topography, elevation, and vegetation |

The RGM sits at an altitude of approximately 1,200 m above mean sea level (amsl). The RGM is situated close to the Mutare River which flows south-westerly into the Odzi River, and provides a source of potable water, as well as being considered the primary recharge source of the underground water system, which serves as the key water source for the RGM processing facilities (SRK 2012).

The vegetation type in the area shows a strong lithological influence, where Brachsygeia Species (masas and mpfuit) cover the majority of the greenstone belt, while Uapaca Kirkiana (sugar plum) is dominant on the granites. Hyparrhenia is the dominant grass species (SRK 2012).

Climatic conditions in the area ensure a perennial flow of these two major rivers and their associated tributaries (KDM 2018).

The RGM is linked to major commercial centres by a well-established network of primary asphalt roads and is accessible from the surrounding communities through secondary gravel roads (KDM 2018).

Penhalonga has a population of approximately 8,000 and Harare has a population of approximately 1.5 million.

| 4.3 | Proximity to population centres |

The RGM is located in Penhalonga, some 20 km north-northeast of the City of Mutare (latitude 18°52’S and longitude 32°41’E), Manicaland Province, in the Mutare Mining District of Zimbabwe. The RGM is located some 265 km southeast Harare. The mine is linked to major commercial centres by a well-established network of primary asphalt roads and is accessible from the surrounding communities through secondary gravel roads.

Harare is serviced by Robert Gabriel Mugabe (RGM) International Airport, operated by the Airport Company of Zimbabwe (Private) Limited (ACZ), which has the capacity to handle 2.5 million passengers per annum (ACZ 2024). The National Railways of Zimbabwe (NRZ) provides both freight services (NRZ 2024a), and passenger services (NRZ 2024b).

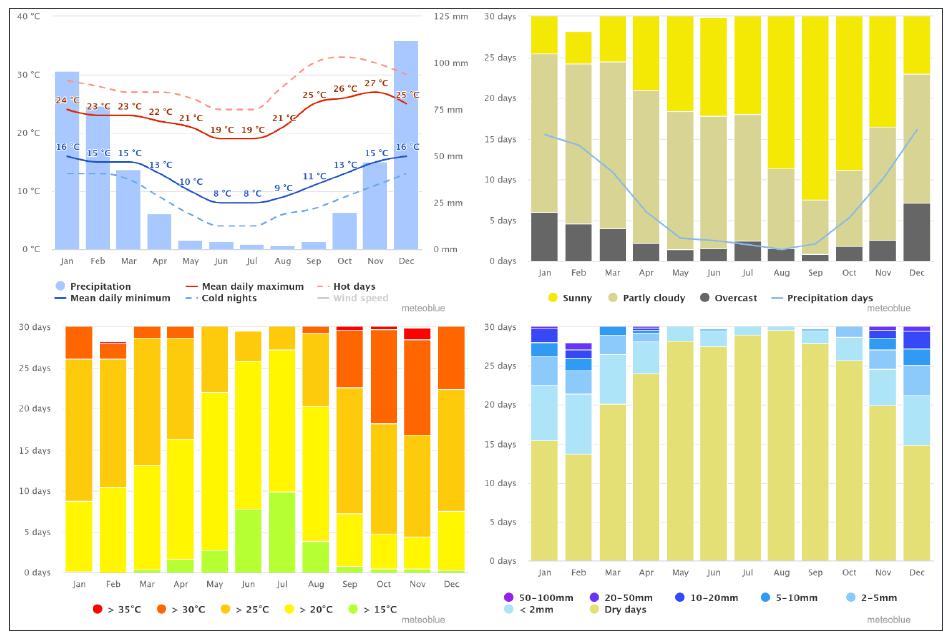

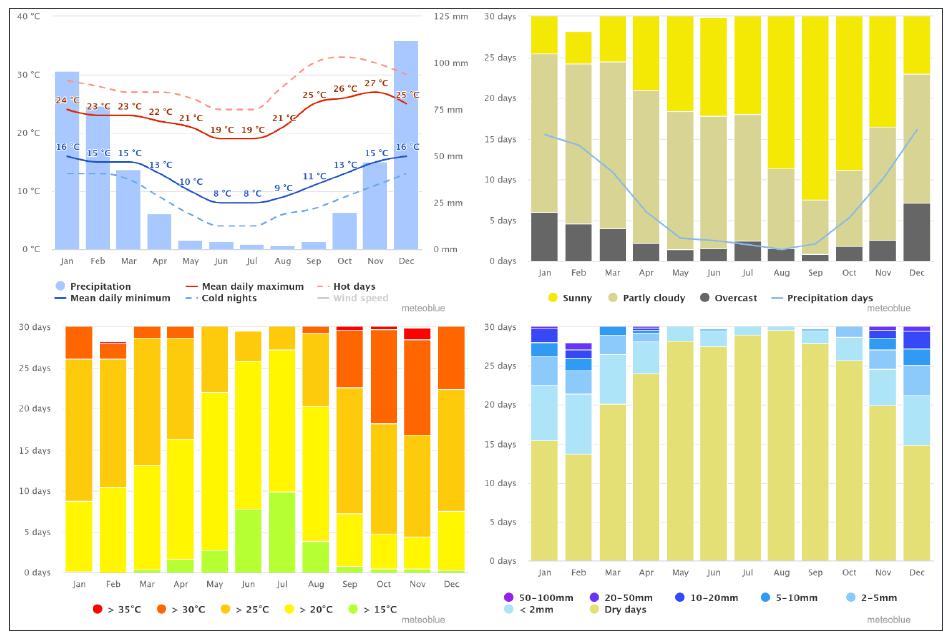

The RGM operates continuously throughout the year, with no interruptions dues to seasonal changes.

The RGM lies in natural farming region I, of Zimbabwe’s Agro-ecological farming regions. The RGM is situated on the high veldt in the eastern highlands of Zimbabwe. Winters are generally cold with mild summers. Rainfall is distinctly higher than the rest of the country which under normal climatic conditions is evenly distributed around the year. Despite its tropical location, the city has a temperate climate. The average annual temperature is 19°C. The coldest month is July (minimum 6°C and maximum 20°C) and the hottest month is October (minimum 16°C and maximum 32°C). The annual rainfall is 818 mm.

Rain falls mostly in the months December to February although heavy showers are possible before and after this period. The wettest month on record was January 1926 which received 580 mm while January 1991 received only 24 mm. Average rainfall received over the past 5 years is 1,000 mm (MGZ 2019).

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 15 |

| Bulawayo Mining Company Limited | |

Figure 4.1 presents climate statistics for Penhalonga, Zimbabwe.

| Figure 4.1 | Climate statistics for Penhalonga, Zimbabwe (Meteoblue, 2024) |

| 4.5 | Local resources and existing infrastructure |

Power is supplied to RGM by a 33 kilovolts (kV) supply from the power utility company, Zimbabwe Electricity Transmission and Distribution Company (ZETDC). The installed capacities of the mine substations are as follows (BMC Limited):

| — | Redwing: | 7.5 Megavolt-ampere (MVA). |

Domestic water is diverted from the Mutare River and is transported by gravity through a concreted trench to a sump, where it is pumped to the RGM water treatment plant. The RGM water treatment plant consists of two 212 cubic metres (m3) tanks (4 and 5) for settling sludge by addition of aluminium sulphate. Water then passes through three 19 m3 sand filter tanks before flowing into the 212 m3 fresh water holding tank (9), where it is chlorinated prior to distribution. Tanks 1, 2, and 3 are used for temporary water treatment during cleaning or maintenance of tanks 4, 5, and 9 (Golder 2021).

A 6-inch take-off line runs to Old West, from which a 4-inch branch feeds the RGM village and other take-offs feed the clinic, workshops, administration offices, compressors and the Low Density Village houses (Golder 2021).

A separate 4-inch line runs to feed the Liverpool High Density Village, before it proceeds as a 3-inch line to feed the Rezende houses. The total volume of water processed is 95 m3/hour (Golder 2021).

General labour force is available within the surrounding communities. For specialised skills, advertisements are advertised in the public press and will usually be sourced from any part of the country.

Consumables and spares are sourced locally with a few exceptional cases where some are imported, especially from South Africa.

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 16 |

| Bulawayo Mining Company Limited | |

| 5.1 | Exploration and ownership history |

Various portions of the present day RGM property are part of the shallow historical workings that exploited the numerous mineralised shear zones (MSZ) located above the water table. In 1889, Baron de Rezende and James Henry Jeffreys pegged the Rezende Mineralised Shear Zone (the Rezende Mine) and began mining operations. In 1909, Rezende Mines Ltd. (Rezende) was formed to operate the mine and other deposits in close vicinity. Operations continued until 1954, when Rezende Mine closed. There was little activity until 1955, when the Rezende Mine was acquired by Independence Gold Mining (Pvt) Ltd. (Independence). Independence was subsequently acquired by Lonrho Zimbabwe (Pvt) Ltd. (Lonrho) in 1980 (KDM 2018).

The Old West Mine was initially pegged in 1899; however, mining did not commence until 1909, before ceasing operations in 1950. The nearby RGM was worked down to the water table between 1904 and 1905, before ceasing operations in 1909. Rezende acquired the claims covering the RGM in 1909, sunk a shaft and resumed mining operations, which again ceased in 1919. In 1968, Mutare Exploration Co. Ltd. (Mutare) acquired both the RGM and Old West properties and initiated a diamond drilling campaign to cover the Felsite ore body. Between 1975 and 1978, Independence acquired the properties prior to a takeover by Lonrho in 1980 (KDM 2018).

An exploration drilling campaign targeting mostly the Felsite mineralisation was conducted in close proximity to the RGM in the early 1980’s. The drilling covered an approximate area of 9 km2 (6 km by 1.5 km), and a total of 22,883 m of drilling was completed. The drill holes were on a widely spaced irregular grid. The area north of the RGM that was also covered by this exploration drilling is a target for future in-fill drilling aimed at increasing resource confidence.

Lonmin plc (Lonrho) relinquished ownership of Independence to Metallon Resources of South Africa in October 2002. Independence then changed the name to Metallon Gold Zimbabwe (Pvt) Ltd in September 2004 (KDM 2018).

In 2008, the RGM was flooded. The causes of flooding were attributed to a shortage of foreign currency, emanating from the 2007/2008 economic meltdown, prolonged power outages and ZESA’s inability to supply adequate power to the region. The situation was worsened by aged pumps that were due for replacement. Consequently, in September 2008, the mine suspended operations as working areas and other critical equipment were submerged. The mine subsequently acquired five submersible pumps in the first quarter of 2010, each pumping an average of 140 cubic metres per hour (m3/hour). Two pumps were installed in the Rezende Shaft, two in the Redwing Main Shaft and one in the Old West Shaft. The pumps were commissioned in March 2010 (KDM 2018).

The RGM resumed operations in September 2009, with re-treatment of tailings (sands) dumps i.e., the Duiker and Concentrate Dumps. This re-treatment ceased on 25 September 2013, mainly due to depressed feed grades that rendered re-processing of sands uneconomic (KDM 2018).

Having pumped water to below 6 Level, the RGM resumed underground mining by instituting development on 4 Level on 21 February 2015. This was in preparation of production of gold from underground, that eventually commenced in November 2015 (KDM 2018).

Following an organisational re-structuring process, which became effective from 1 June 2016, the Redwing Mine now falls under The King’s Daughter Mining Company (Private) Limited (KDM), a wholly owned subsidiary of Metallon (KDM 2018).

Access for men and materials to and from the underground workings is through the South Winze Shaft to 6 Level and rock hoisting to surface is via the Redwing Main Shaft. The Rezende Shaft to the east is used for de-watering while to the west of the RGM, the Old West No. 1 and 2 shafts are not used (KDM 2018).

The RGM was placed on C&M on 1 April 2019.

A Supreme Court ordered Corporate Rescue was implemented on 23 July 2020. During the Corporate Rescue period, BBM was engaged as a tributor to mine on ML 34 (Virimai 2022).

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 17 |

| Bulawayo Mining Company Limited | |

Mine dewatering was maintained until suspended on 23 December 2020, due to power supply disconnections. The water level has since risen to 47.3 m from the Redwing Shaft surface collar (or 71.1 m above 4 Level) and has been stagnant at that level since 19 April 2021. Any recommencement of mining operations will require dewatering to access Mineral Resources and Mineral Reserves.

The Corporate Rescue proceedings were nullified on 5 September 2022.

In January 2024, 15 artisanal miners were trapped for three days at the RGM.

On 8 March 2024 the non-standard tribute agreement with BBM was cancelled, and BBM was evicted from ML 34.

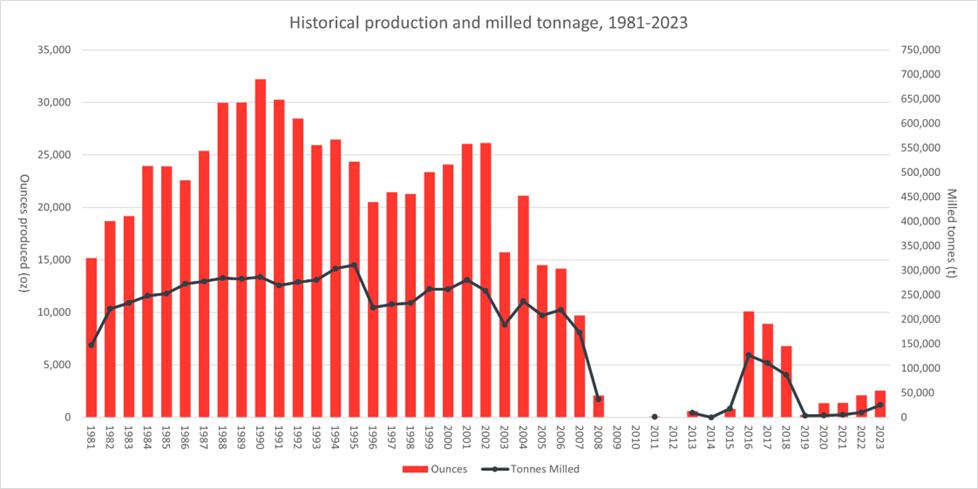

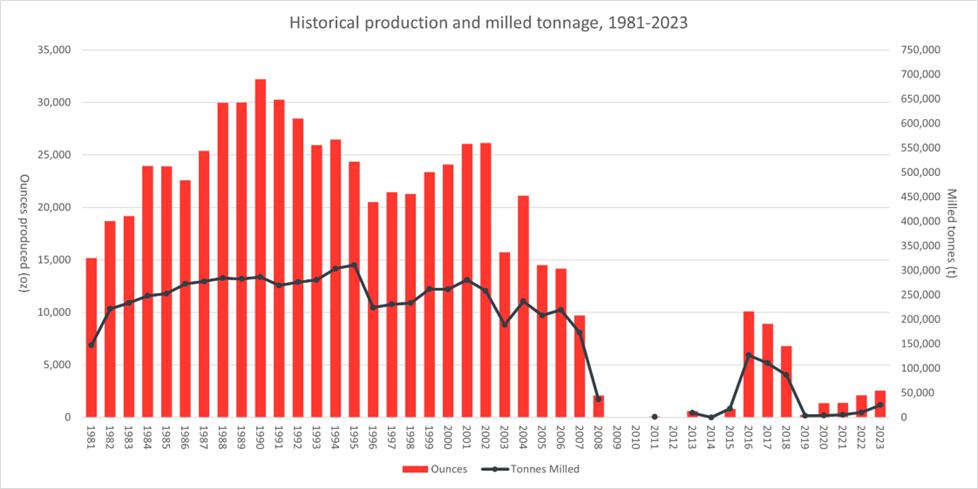

Total gold produced from the RGM between 1981 and 2023 is approximately 0.65 million ounces (Moz). Figure 5.1 presents total gold production from the RGM for the period 1981-2023.

| Figure 5.1 | RGM total gold production 1981–2023 |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 18 |

| Bulawayo Mining Company Limited | |

| 5.3 | Production reconciliation |

The Property’s Mineral Resources as of the end of the last fiscal year 2023 compared to the 2022 fiscal year are compared in Table 5.1. While there has been minor adjustment of COG between 2022 and 2023 there was no change between the Mineral Resources for 2022 and 2023. There has been no statement of Mineral Reserves for 2022 and 2023 and therefore no requirement for comparison.

| Table 5.1 | Mineral Resource summary comparison end December 2022 to end December 2023 |

| Category | 31 December 2022 | 31 December 2023 | Var. (%) |

Tonnes

(kt) | Grade (Au g/t) | Au

(koz) | Tonnes

(kt) | Grade (Au g/t) | Au

(koz) | Au

(koz) |

| Total Mineral Resources |

| Measured Mineral Resources | 1,450 | 2.92 | 136 | 1,450 | 2.92 | 136 | 0% |

| Indicated Mineral Resources | 8,200 | 3.99 | 1,052 | 8,200 | 3.99 | 1,052 | 0% |

| Total M+I Mineral Resources | 9,650 | 3.83 | 1,188 | 9,650 | 3.83 | 1,188 | 0% |

| Inferred Mineral Resources | 15,830 | 2.61 | 1,328 | 15,830 | 2.61 | 1,328 | 0% |

| Total Mineral Resources | 25,480 | 3.07 | 2,515 | 25,480 | 3.07 | 2,515 | 0% |

Notes: Numbers are rounded.

| 5.4 | Aggregate fiscal year production |

Since the mine has been on C&M since April 2019, there has been no material production from Mineral Resources over the past 3 years.

| 5.5 | Exploration and development by previous owners or operators |

Previous exploration and development is discussed in Section 5.1.

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 19 |

| Bulawayo Mining Company Limited | |

Inspection of the Financial Statements for the year ended 31 December 2022 indicates RMC carries substantial liabilities that total US$8.88 M comprising:

| — | Non-Current Liability for an “Environmental rehabilitation provision” for US$3.007 M |

| — | Current Liability for “Trade and other payables” for US$5.873 M. |

Inspection RMC records of current assets and current liabilities as at end February 2024 reveals:

| — | Current Assets comprising “Other Debtors” for US$2.452 M |

| — | Current Liabilities of US$7.214 M comprising “Trade Creditors” US$1.939 M, “Statutory Payments” US$2.211 M and “Other” US$3.064 M. |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 20 |

| Bulawayo Mining Company Limited | |

| 6 | Geological setting, mineralisation, and deposit |

| 6.1.1 | Mozambique Greenstone Belt |

The RGM is located within the Mutare Greenstone Belt (MGB) extends from the Mozambique Belt in the east, into the granites and gneisses of the Zimbabwe Craton in the west. It forms a tapering triangular shape from approximately 20 km in the east to less than 3 km in the west. The grade of metamorphism increases with the degree of structural deformation, from greenschist facies in the east to amphibolite facies in the southwest. The geology is dominated by an east-west trending series of metavolcanics consisting of olivine cumulates, komatiites, komatiitic basalts, and high iron tholeiites. The rocks are extrusive, indicated by the presence of spinifex texture and pillow lavas as well as lenses of intercalated clastic sediments and discontinuous strings of banded iron formations (BIF) (KDM 2018).

The Penhalonga tonalities, syntectonic granodiorites, trondhjemites and tonalities (now gneisses), microgranites (sheets and dykes), potassium-rich granites (ca. 2,600 Ma), dolerite dykes and sills have all intruded the greenstone supracrustals. The Penhalonga tonalities (ca. 2,741 ± 3 Ma) are the oldest intrusions and therefore provide a good estimate of the age of the MGB (KDM 2018).

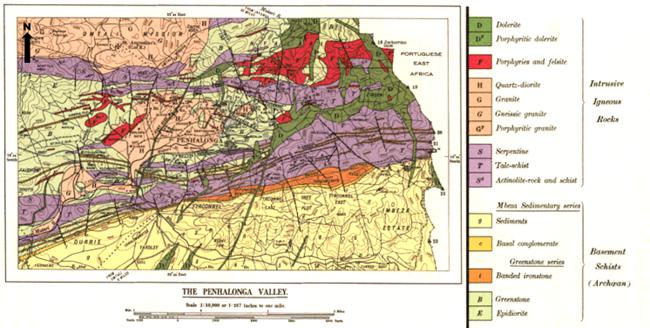

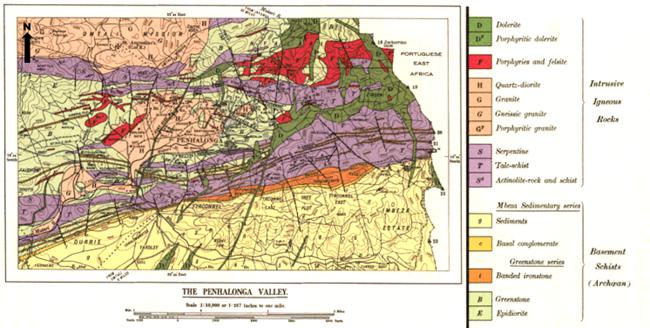

Figure 6.1 presents a simplified regional geology map of Zimbabwe and the locations of major greenstone belts. The MGB can be seen in the middle right.

The MGB is bounded by the Penhalonga Diorite to the north and south.

| Figure 6.1 | Regional geology of Zimbabwe showing locations of greenstone belts (Prendergast 2004) |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 21 |

| Bulawayo Mining Company Limited | |

The MGB has undergone at least four deformation events, as described in Table 6.1 (KDM 2018).

| Table 6.1 | Structural deformation events |

| Deformation Event | Description |

| D1 | SSE-NNW regional compression, resulting in folding of the MGB into a series of at least two east-west striking synclinoria, separated by a tight antiform. Regional shearing and cleavage formation, striking east-west accompanied this folding. |

| D2 | Faulting transecting all rock types characterised by NNE-SSW faults parallel to the Great Dyke and conjugate NW-SE faulting. |

| D3 | ENE-WSW striking faults displacing both the D1 and D2 structures in a sinistral sense. |

| D4 | Locally developed E-W striking fault system, exposed underground at the RGM where Faults displace mineralised structures. |

Known gold deposits occur in all lithologies apart from the younger potassium-rich granites. More than 80% of known mineralisation is hosted by east-west trending structural elements, sub-parallel to the regional strike. These dip on average at 60° to the north or south. The east-west striking deposits show a clear spatial relationship to those structures formed during the D1 deformation event. These deposits are located in subsidiary or second-order structures that commonly splay off or are associated with the regional D1 shears. The Champion Mine is a typical example. Other deposits, including the Rezende dip steeply either to the northeast or southwest and are hosted in D2 structures (NW-striking faults) [KDM 2018].

| 6.3 | Local and property geology |

The Felsite consists of a tabular micro-granitic body, which intruded the Penhalonga diorite. It is a robust orebody, constituting the main mineralisation style at the RGM. It strikes east-west and dips at a locally variable but shallow angle of approximately 35° to the south. At its widest, the orebody attains a thickness of approximately 7 m. It has been worked on a strike length of more than 2,500 m. The Felsite lies in the core of the Penhalonga synform and it is the folding of this micro-granitic sheet within the diorite that is believed to be responsible for the localisation of gold mineralisation (KDM 2018).

Two phases of deformation are recognisable in the Felsite, and these are believed to be responsible for the development of three cleavage plane generations within the orebody. These cleavage plane generations consist of the following (KDM 2018):

| — | Shallow dipping, northeast trending, un-mineralised cleavage planes, which lack quartz infill. |

| — | East-southeast dipping, quartz-filled, mineralised planes with variable inclinations. The shallow dipping (approximately 25°) cleavage planes are mineralised but lack quartz infill. These generally displace the steeply dipping cleavage planes. The steep dipping (+25°) planes are predominantly quartz filled. |

| — | The contact between the diorite and the Felsite is locally sheared and mineralised. This shearing, either from the contact or in most cases from the fold hinges, continues into the diorite as a single dilational quartz filled plane, shallowly dipping, predominantly towards the east-northeast. |

Superimposed on the first folding event of the Felsite, is a second folding event with an axis appearing to plunge steeply towards the north. This has resulted in a fold interference believed to have produced the apparent dome and basin configuration that is evident, particularly on the upper levels of the RGM (KDM 2018).

There are several sub-parallel shears that cut across both the Penhalonga diorite and Felsite. These shears are southeast striking deformation zones, which have a variable but steep dip, ranging between 45° and 75° to the north-northeast. These shears include the Rezende, Village North and Kent reefs. Elongated lineations in the Rezende mineralised shear zone are oriented west-northwest and east-southeast, suggesting both dextral and sinistral senses of movement (KDM 2018).

The MSZ host grey to white, fine-grained quartz veins and veinlets. These are characterised by a distinct crack-seal, banded or ribboned appearance, with anastomosing slivers of altered country rock. Associated sulphide mineralisation includes pyrite, galena, chalcopyrite, accessory arsenopyrite, and occasional native gold. The Rezende mineralised shear zone averages 2.5 m in thickness, with a strike extent of approximately 1,400 m and 800 m up and down-dip. The Village North and Kent MSZ have widely variable thickness, ranging from several cm to more than 6 m in places (KDM 2018).

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 22 |

| Bulawayo Mining Company Limited | |

| 6.4 | Deposit type and geology |

Mineralisation at RGM may be described as a lithological and structurally controlled/shear hosted gold deposit, hosted predominantly within the Felsite and MSZ.

There is strong structural and lithological control on gold mineralisation at the RGM. The sulphide and gold mineralisation in the Felsite orebody is bound within the structurally deformed micro-granitic body, with few transgressive shear or vein extensions into the host diorite. To date, no significant mineralisation has been delineated within the diorite. While no specific metallogenetic studies have been completed, the prevalence of galena in the Felsite orebody reduce with depth. This also appears to be the case with gold (KDM 2018).

Mineralisation within the MSZ (narrow reefs) is distinctly limited to physical deformation that has allowed the migration of hydrothermal fluids resulting in the deposition of quartz, sulphides and gold. While comparatively high gold values are associated with grey quartz and pyrite impregnation, zones of sheared and propylitised diorite commonly form part of contiguous reef structure (KDM 2018).

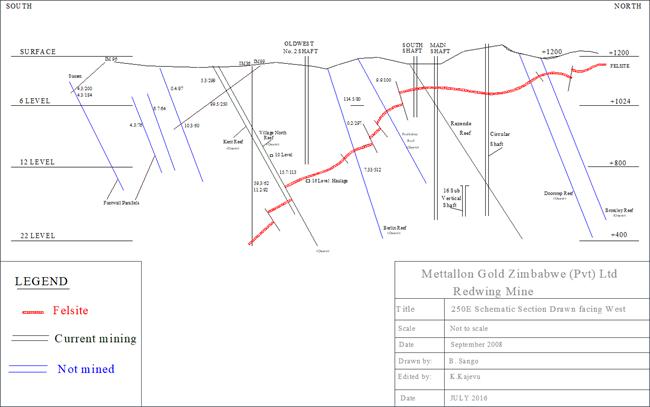

Figure 6.2 presents a schematic section of the RGM MSZ (quartz reefs) in relation to the Felsite orebody.

| Figure 6.2 | RGM MSZ schematic section |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 23 |

| Bulawayo Mining Company Limited | |

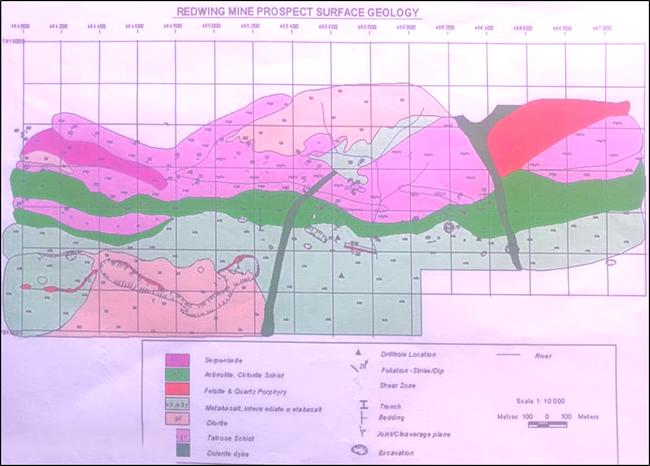

The local geology of the Penhalonga Valley is presented in Figure 6.3.

| Figure 6.3 | Penhalonga Valley local geology |

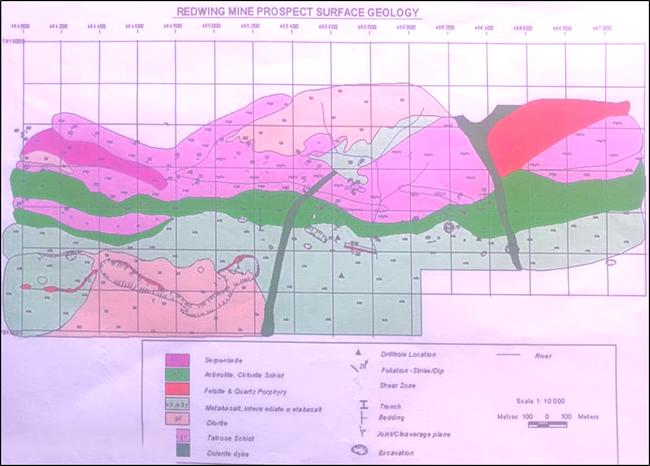

| Figure 6.4 | present the surface geology of the RGM. |

| Figure 6.4 | RGM surface geology |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 24 |

| Bulawayo Mining Company Limited | |

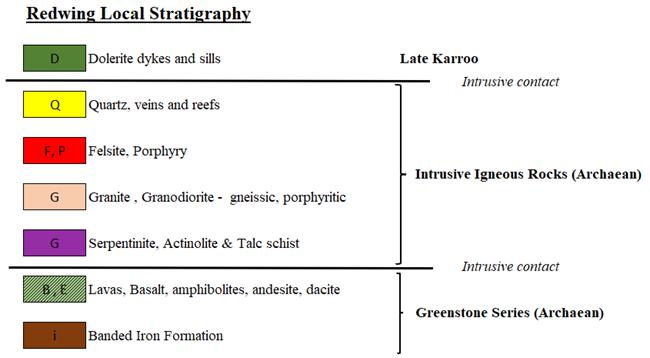

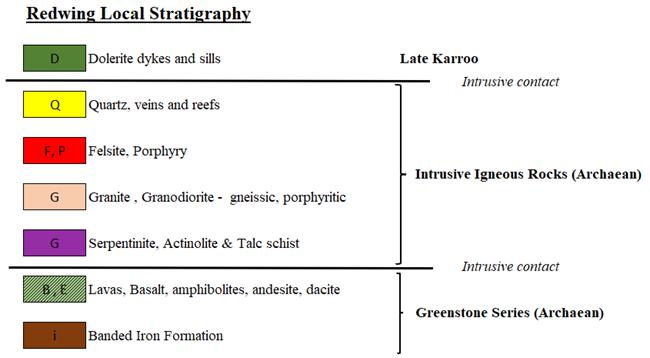

| Figure 6.5 | presents the local stratigraphy of the RGM area. |

| Figure 6.5 | RGM local stratigraphy |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 25 |

| Bulawayo Mining Company Limited | |

Diamond core drilling is the drilling method employed at the RGM. Diamond drill core is logged and sampled on a 1 m interval, depending on geology. Samples are taken to at least 1 m beyond the geologically defined mineralisation boundary in all drill holes (KDM 2018).

Core size drilled at the RGM is typically AXT (35.51 mm core diameter) and BQ (36.50 mm core diameter) for evaluation and exploration drill holes respectively (KDM 2018).

All exploration drill holes are collar and downhole surveyed (KDM 2018).

| 7.1.1 | Historical exploration drilling |

An exploration drilling campaign targeting mostly the felsite orebody was carried out around RGM in the early 1980’s. The drilling covered an approximate area of 9 km2 (6 km x 1.5 km), with a total of 22 883 m drilled. The holes were on a widely spaced irregular grid. A total of 78 vertical drill holes were drilled, 31 of which had tails drilled near the end of hole with 1 drill hole having 2 tails drilled. 22 angled drill holes were drilled at various dips and bearings.

The area north of RGM that was covered by this exploration drilling is a target of in-fill drilling to upgrade the felsite resource from Inferred to Indicated mineral resource category.

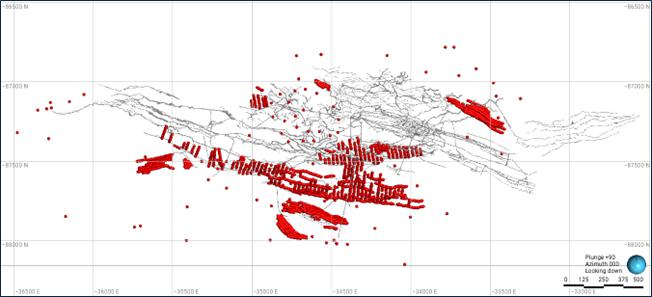

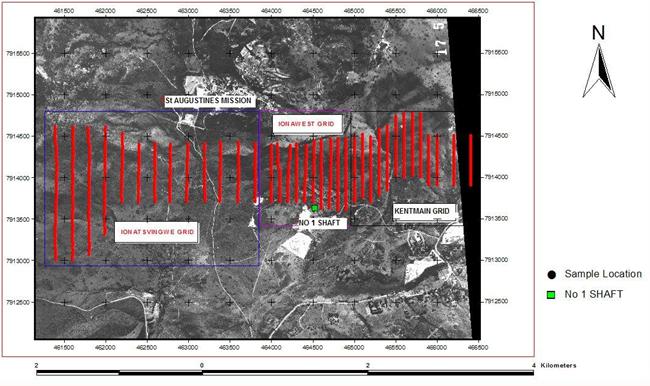

Drill hole identity and collar survey coordinates are contained in Table 7.1. A plan view of all drill hole collars is provided in Figure 7.1.

| Table 7.1 | RGM historical surface drill hole data |

| Drill hole ID | Hole type | X-collar

(mE) | Y-collar

(mN) | Z-collar

(mRL) | Dip

(⁰) | Bearing

(⁰) | Depth

(m) |

| IM001 | Core | -35,016.70 | -87,338.50 | 1,195.80 | -90 | 180 | 160.00 |

| IM002 | Core | -34,814.50 | -87,325.00 | 1,181.20 | -90 | 180 | 136.00 |

| IM002DEF1 | Core | -34,814.50 | -87,325.00 | 1,094.10 | -75 | 0 | 22.40 |

| IM003 | Core | -34,612.50 | -87,372.00 | 1,189.50 | -90 | 180 | 99.40 |

| IM003DEF1 | Core | -34,612.50 | -87,372.00 | 1,122.10 | -75 | 0 | 20.40 |

| IM004 | Core | -34,314.60 | -87,470.10 | 1,181.60 | -90 | 180 | 231.40 |

| IM004DEF1 | Core | -34,314.60 | -87,470.10 | 962.40 | -75 | 0 | 12.20 |

| IM005 | Core | -34,102.20 | -87,530.10 | 1,169.00 | -90 | 180 | 284.00 |

| IM005DEF1 | Core | -34,102.20 | -87,530.10 | 909.20 | -75 | 0 | 22.40 |

| Project No PS213686 | WSP |

| Redwing Mine | January 2025 |

| S-K 1300 Technical Report Summary | Page 26 |

| Bulawayo Mining Company Limited | |

| Drill hole ID | Hole type | X-collar

(mE) | Y-collar

(mN) | Z-collar

(mRL) | Dip

(⁰) | Bearing

(⁰) | Depth

(m) |

| IM006 | Core | -34,428.00 | -87,398.50 | 1,184.30 | -90 | 180 | 246.00 |

| IM007 | Core | -35,275.30 | -87,617.20 | 1,182.10 | -90 | 180 | 394.00 |

| IM007DEF1 | Core | -35,275.30 | -87,617.20 | 811.70 | -75 | 0 | 13.30 |

| IM008 | Core | -31,525.80 | -86,237.00 | 1,414.29 | -60 | 180 | 106.00 |

| IM008A | Core | -31,526.90 | -86,236.60 | 1,414.30 | -90 | 180 | 224.00 |

| IM009 | Core | -34,706.20 | -86,982.70 | 1,232.00 | -90 | 180 | 163.60 |

| IM009DEF1 | Core | -34,706.20 | -86,982.70 | 1,083.30 | -75 | 0 | 14.90 |

| IM010 | Core | -34,565.10 | -86,827.10 | 1,220.30 | -90 | 180 | 53.50 |

| IM011 | Core | -34,675.70 | -87,178.80 | 1,195.50 | -90 | 180 | 99.20 |

| IM011DEF1 | Core | -34,675.70 | -87,178.80 | 1,116.90 | -75 | 0 | 13.70 |

| IM012 | Core | -34,879.70 | -87,133.80 | 1,206.00 | -90 | 180 | 122.50 |

| IM012DEF1 | Core | -34,879.70 | -87,133.80 | 1,125.50 | -75 | 0 | 27.50 |

| IM013 | Core | -34,705.80 | -86,980.20 | 1,232.00 | -45 | 180 | 145.00 |

| IM014 | Core | -34,565.00 | -86,829.00 | 1,220.30 | -45 | 180 | 47.00 |

| IM015 | Core | -34,616.20 | -87,516.30 | 1,183.40 | -90 | 180 | 321.00 |

| IM015DEF1 | Core | -34,616.20 | -87,516.30 | 880.40 | -75 | 0 | 17.20 |

| IM016 | Core | -34,844.10 | -87,532.10 | 1,176.30 | -90 | 180 | 286.00 |