Exhibit 99.4

Safety at Massey Energy

Drexel Short

Senior Vice President, Group Operations September 27, 2005

NFDL – Non Fatal Days Lost

Standard set by Mine Safety and Health Administration for all the coal industry to measure their safety performance.

Criteria: # LTA’s x 200,000

Manhours

200,000 is representative of 100 workers, working 2,000 hours each per year

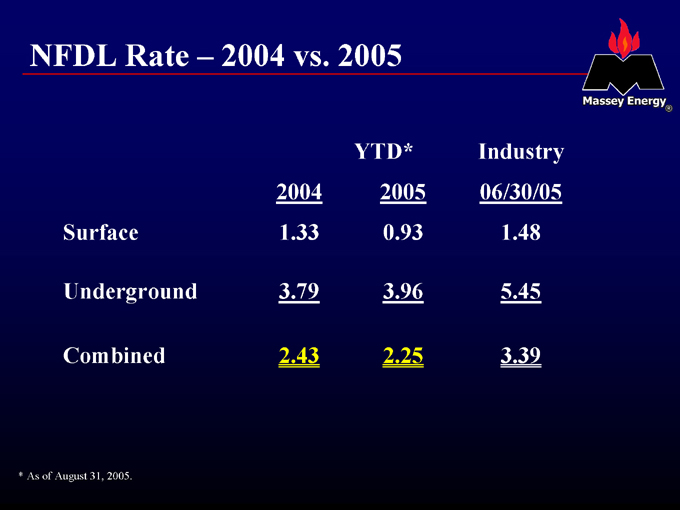

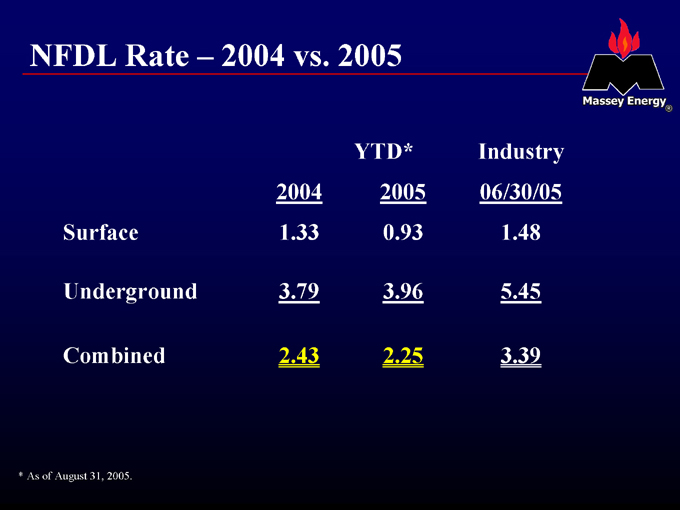

NFDL Rate – 2004 vs. 2005

2004 YTD* 2005 Industry 06/30/05

Surface 1.33 0.93 1.48

Underground 3.79 3.96 5.45

Combined 2.43 2.25 3.39

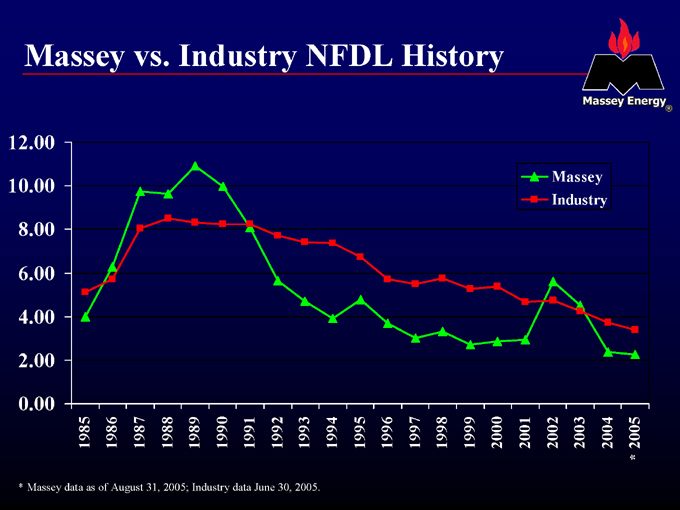

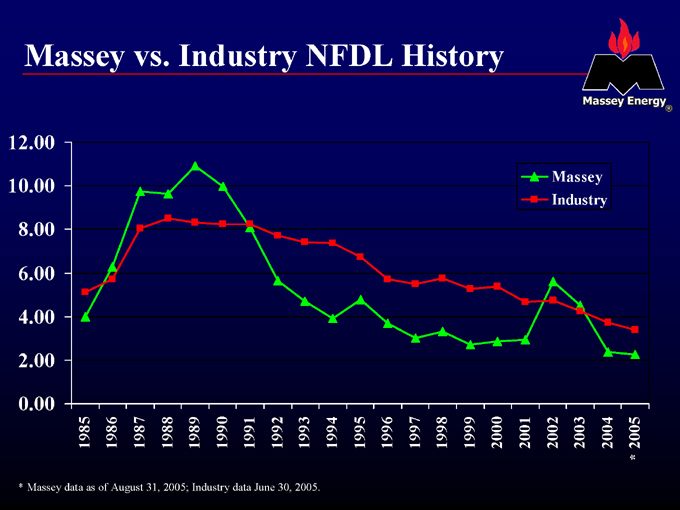

Massey vs. Industry NFDL History Massey Industry

12.00

10.00

8.00

6.00

4.00

2.00

0.00

1985

1986

1987

1988

1989

1990

1991

1992

1993

1994

1995

1996

1997

1998

1999

2000

2001

2002

2003

2004

Massey Industry

* | | Massey data as of August 31, 2005; Industry data June 30, 2005. |

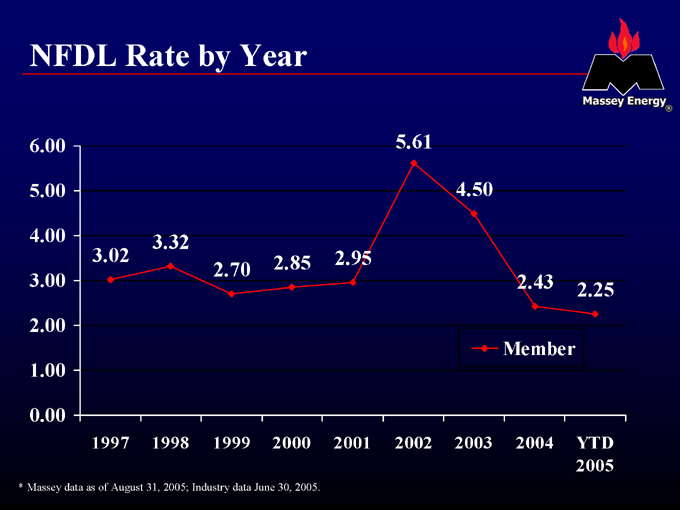

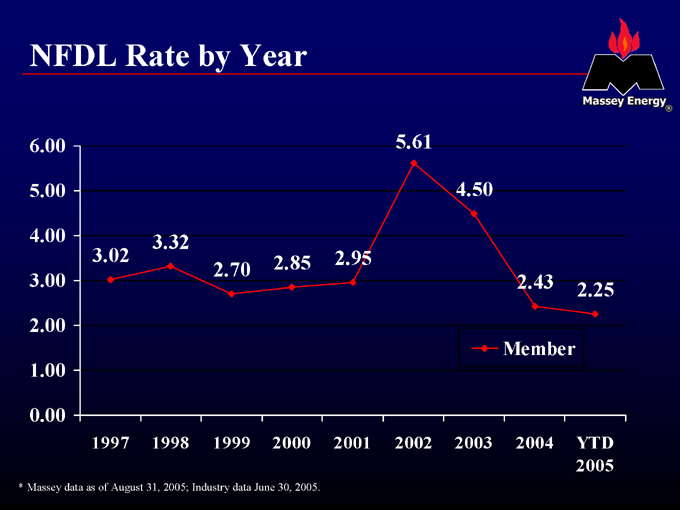

NFDL Rate by Year

6.00

5.00

4.00

3.00

2.00

1.00

0.00

1997 1998 1999 2000 2001 2002 2003 2004 YTD

2005

3.02

3.32

2.70

2.85

2.95

5.61

4.50

2.43

2.25

Member

* | | Massey data as of August 31, 2005; Industry data June 30, 2005. |

Major Programs in Massey

These programs are designed to complement our S-1 Safety Program

Massey Energy’s S-1 Program

Implementation Date – 1992

Comprehensive program consisting of the collective wisdom of Massey Energy’s management and Members

The program sets pragmatic processes & procedures to enhance safety

The program goes above and beyond State & Federal requirements

Improvement in equipment safety is a cornerstone of the program

Massey Energy’s S-1 Program

The program’s continual development is achieved by the following process:

Safety Staff (Safety Development Group – SDG) meet each month for operational safety review

Accidents & Near Miss Incidents at all operations for previous month are analyzed for process and/or procedure improvement as well as equipment improvement

Proposed “improvements” are discussed with frontline Members before final approval by upper management

Upon being approved as an S-1 Policy, the improvement is required to be implemented throughout Massey

Other Programs

Other programs in Massey Energy which aids in achieving performance above industry standards:

Company Wide Standard Orientation Program

New Member Mentor Program

Strain & Sprain Clinic

Training & Development

Equipment Safety Enhancements

Raymond Awards Program

Detailed Preventive Maintenance Program

30/60/90 Day New Member Review

Massey Energy’s Orientation Program

This program is an in depth outline of specific items to be discussed with Members new to Massey.

Massey Energy’s Mentor Program

This program is implemented with our new coal miners and experienced Members, new to Massey. It is designed to educate Members in our programs, policies and work procedures.

Massey Energy’s Strain & Sprain Clinic

In 2003 62% of all injuries were strain & sprain type injuries, which were mostly attributed to handling materials and slip & trip type accidents.

Massey Energy’s Strain & Sprain Clinic

This resulted in development of two Strain & Sprain (S&S) Clinics for Members to attend.

Since the S&S Clinics began we have conducted 97 classes and 1300 Members have attended.

Massey Energy’s S&S ratio is currently 48% of all injuries.

Massey Energy’s Training & Member Development

Below is a list of different types of training conducted with our Members.

Supervisor’s Training at MSHA

Massey Initial Training for Contractors

EMT/MET Training

Foreman Certification

Electrician Certification

Shot Firer Certification

Belt Examiner Certification

TP Hall Management Training

Sprain & Sprain Training

Massey Energy’s Training & Member Development

Respirable Dust Certification

Accident Prevention Training

Paratek Air Bag Training

Cable Thumper Training

Manufacturer Equipment Repair Training

Supervisor Responsibility Training

Fall Protection Training

Larger Tire Training

MSHA Conference Preparation Training

Rigging Training

Coal Truck Driver Academy

Coal Truck Brake Inspection Training

Massey Energy’s Safety Enhancements

Massey Energy is very proud of the many safety enhancements we have developed for our Members and equipment. The following are just a few of the several enhancements that we use which exceed what the law requires:

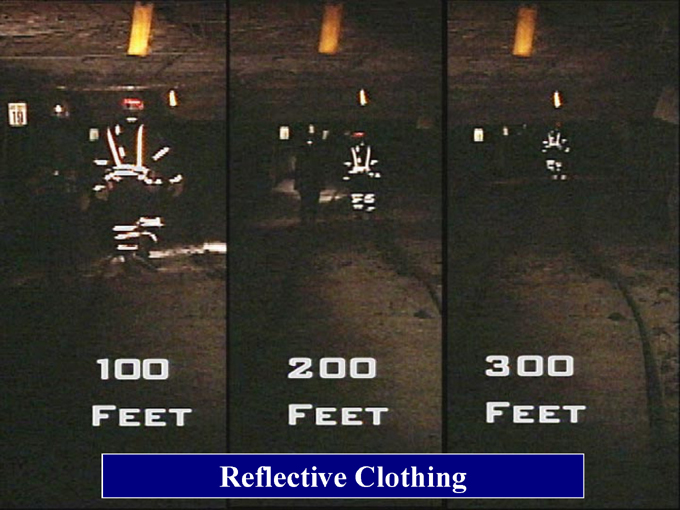

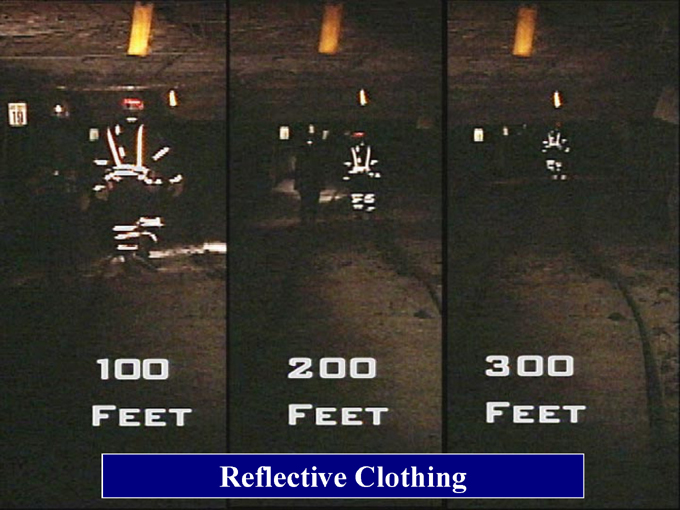

Reflective Clothing

Roofbolter ATRS

Deflector Pads

Massey Energy Continuous Miner

Enhancements

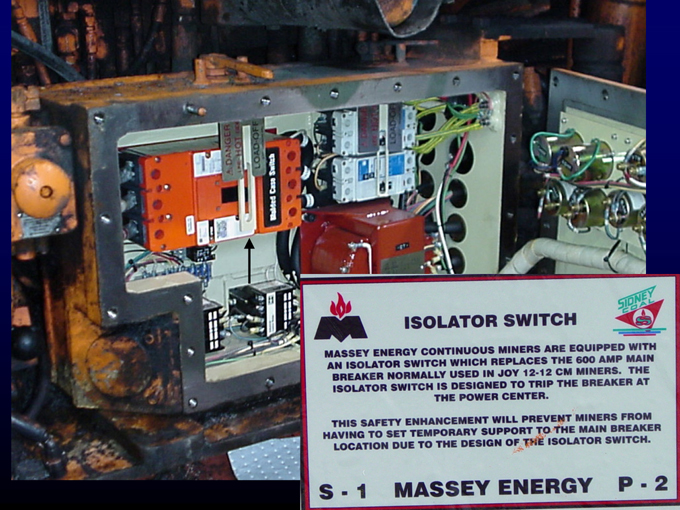

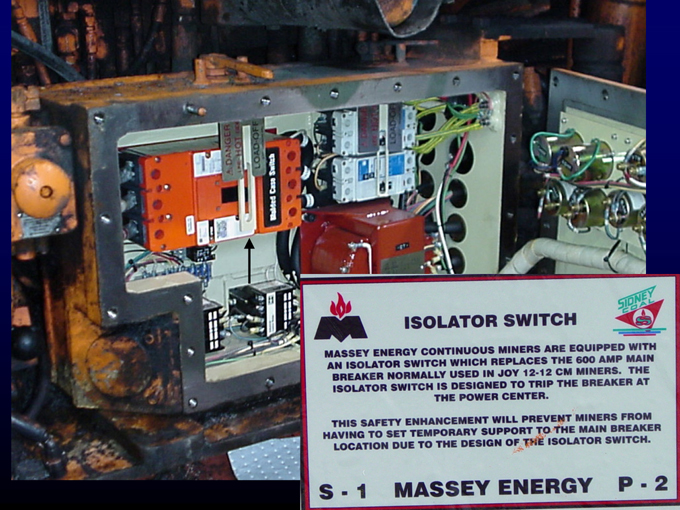

ISOLATOR SWITCH

MASSEY ENERGY CONTINOUS MINERS ARE EQUIPPED WITH AN ISOLATOR SWITCH WHICH REPLACES THE 600 AMP MAIN BREAKER NORMALLY USED IN JOY 12-12 CM MINERS. THE ISOLATOR SWITCH IS DESIGNED TO TRIP THE BREAKER AT THE POWER CENTER.

THIS SAFETY ENHANCEMENT WILL PREVENT MINERS FROM HAVING TO SET TEMPORARY SUPPORT TO THE MAIN BREAKER LOCATION DUE TO THE DESIGN OF THE ISOLATOR SWITCH.

S— 1 MASSEY ENERGY P—2

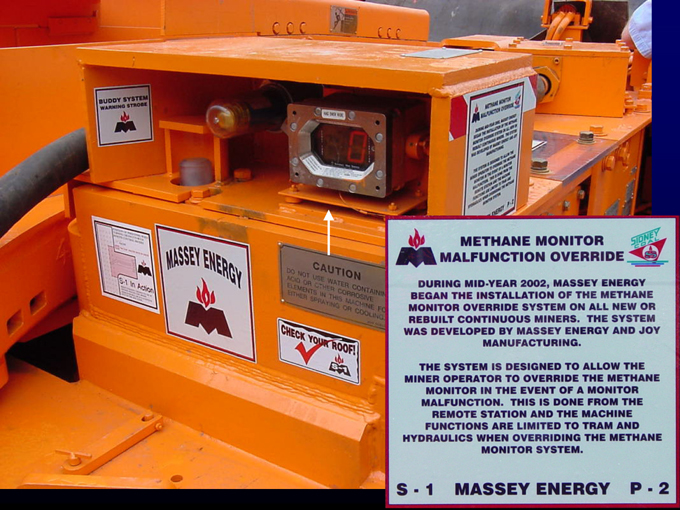

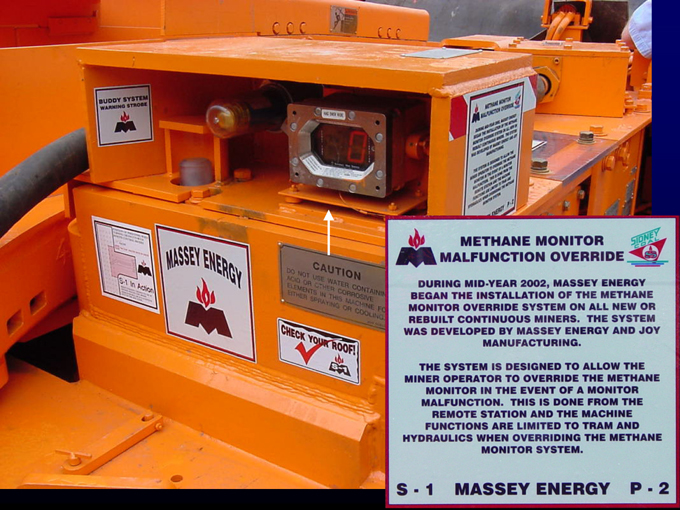

METHANE MONITOR MALFUNCTION OVERRIDE

DURING MID-YEAR 2002, MASSEY ENERGY BEGAN THE INSTALLATION OF THE METHANE MONITOR OVERRIDE SYSTEM ON ALL NEW OR REBUILT CONTINOUS MINERS. THE SYSTEM WAS DEVELOPED BY MASSEY ENERGY AND JOY MANUFACTURING.

THE SYSTEM IS DESIGNED TO ALLOW THE MINER OPERATOR TO OVERRIDE THE METHANE MONITOR IN THE EVENT OF A MONITOR MALFUNCTION. THIS IS DONE FROM THE REMOTE STATION AND THE MACHINE FUNCTIONS ARE LIMITED TO TRAM AND HYDRAULICS WHEN OVERRIDING THE METHANE MONITOR SYSTEM.

S – 1 MASSEY ENERGY P—2

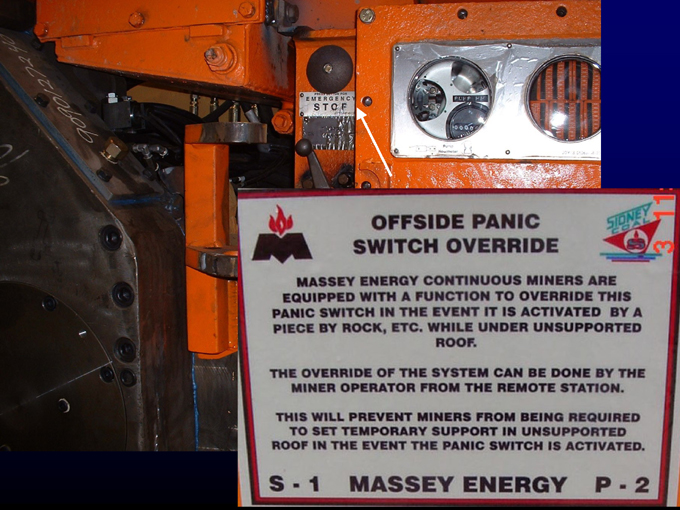

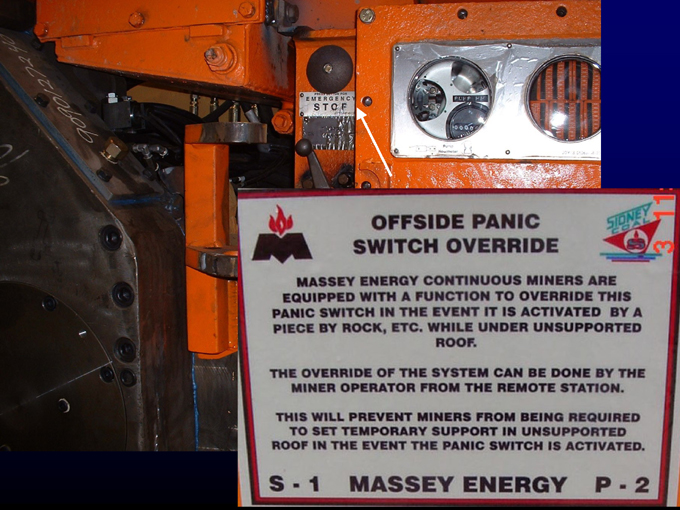

OFFSIDE PANIC SWITCH OVERRIDE

MASSEY ENERGY CONTINUOUS MINERS ARE EQUIPPED WITH A FUNCTION TO OVERRIDE THIS PANIC SWITCH IN THE EVENT IT IS ACTIVATED BY A PIECE BY ROCK, ETC. WHILE UNDER UNSUPPORTED ROOF.

THE OVERRIDE OF THE SYSTEM CAN BE DONE BY THE MINER OPERATOR FROM THE REMOTE STATION.

THIS WILL PREVENT MINERS FROM BEING REQUIRED TO SET TEMPORARY SUPPORT IN UNSUPPORTED ROOF IN THE EVENT THE PANIC SWITCH IS ACTIVATED.

S – 1 MASSEY ENERGY P—2

TRAM BREAKER AUTOMATIC RESET

SINCE JANUARY 2003, ALL MASSEY ENERGY CONTINUOUS MINERS, NEW OR REBUILT, ARE EQUIPPED WITH AN AUTOMATIC TRAM BREAKER RESET OPERATED HYDRAULICALLY FROM THE OPERATOR’S REMOTE STATION.

THE SYSTEM WAS DEVELOPED AND DESIGNED BY MASSEY ENERGY AND JOY MANUFACTURING TO PREVENT MINERS FORM HAVING TO SET TEMPORARY SUPPORT TO GET TO THE TRAM BREAKER RESET LOCATION. THIS SYSTEM PERMITS THE OPERATOR TO HYDRAULICALLY RESET THE TRAM BREAKER FROM THE LOCATION OF THE REMOTE CONTROL.

S – 1 MASSEY ENERGY P—2

NAUTILUS PROXIMITY DETECTION SYSTEM

THIS MACHINE IS EQUIPPED WITH THE NAUTILUS PROXIMITY – BUDDY SYSTEM. THE BUDDY SYSTEM WAS DEVELOPED TO PREVENT CONTINUOUS MINER OPERATORS FORM BEING CRUSHED BETWEEN THE CONTINUOUS MINER AND A COAL RIB. THE SYSTEM WAS DEVELOPED FOR UNDERGROUND COAL MINING BY NAUTILUS INTERNATIONAL IN CONJUNCTION WITH MASSEY ENERGY, MSHA AND JOY MANUFACTURING.

IN THE EVENT THE MINER OPERATOR PLACES HIMSELF WITHIN THE CALIBRATED DISTANCE OF THE MACHINE, A WARNING STROBE WILL FIRST ACTIVATE, AND IF THE MACHINE IS TRAMMED THREE ADDITIONAL FEET TOWARDS THE OPERATOR, THE MACHINE WILL SHUT DOWN.

S – 1 MASSEY ENERGY P—2

Proximity Testing at Sidney

Proximity Testing at Spirit Mine 3/21/05

Access to Stairways on all Trucks

Operator’s View of Monitors

Front Camera Mount

Rear Camera Mount

Sub Kit on Door of Dozer

SCSR’s for Submarine Kit

Sub Kit Bars and Glass

Rear Cab Protector

O & K Cab Modifications

Nascar Netting and Canopies on Mantrips

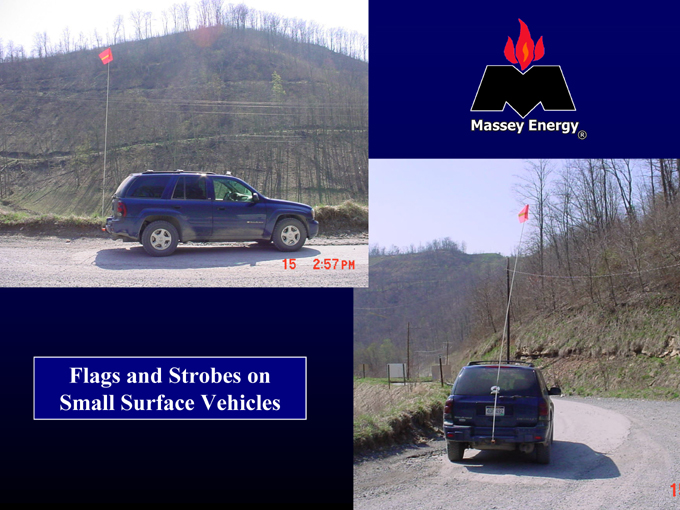

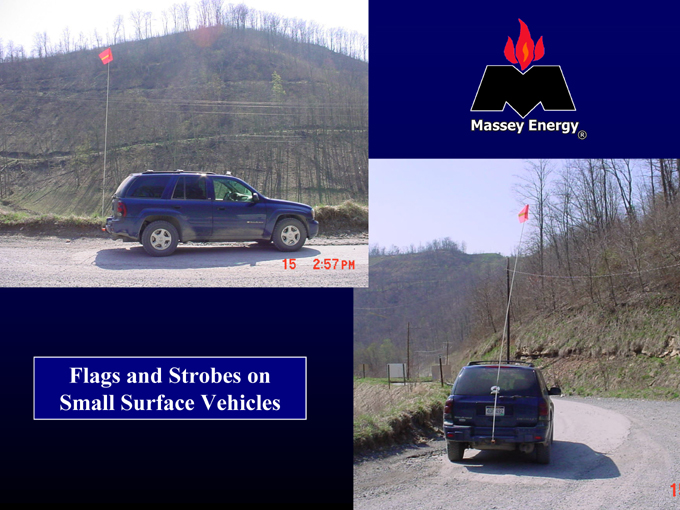

Flags and Strobes on Small Surface Vehicles

The Raymond Safety Program

Annual Raymond A. Bradbury Competition

Monthly/Quarterly/Annual Awards Program

The Raymond A. Bradbury Competition

Companywide Competition

Annual Recognition Banquet

The Raymond Awards Program

The program is an incentive based program designed to promote safety awareness and performance. The program includes incentives based on individual, team and operation site safety performance. Absences is also a disqualifying factor on an individual basis. Each month Members are awarded points based on a three (3) tiered system. The Member then may exchange the points with the awards listed in an elaborate catalog which is provided to the Members and family annually.

The Raymond Awards Program

The Raymond Awards Program

Quarterly and annual prizes are also awarded to Members who have not experienced a lost time injury or disqualifying absence.

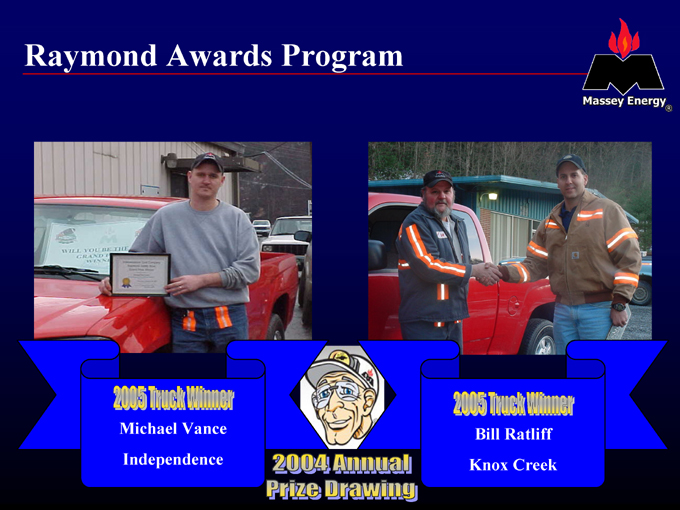

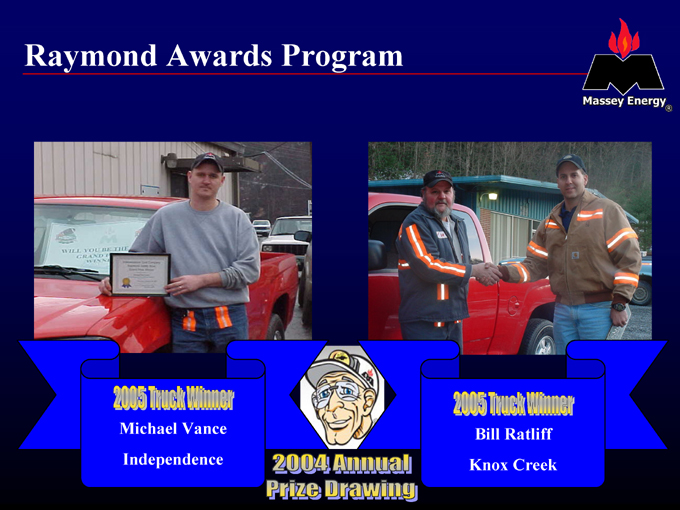

Raymond Awards Program

2005 Truck Winner

Michael Vance

Independence

2005 Truck Winner

Bill Ratliff

Knox

Creek

2004 Annual Prize Drawing

Raymond Awards Program

1st Place

Allen Prater

$3,000 Big Sandy Superstore Shopping Spree

2nd Place

Perry Wallace

$2,000 Big Sandy Superstore Shopping Spree

2005 1st Quarter Prize Drawing

Summary

Industry leader in safety

Established safety culture, with complimentary new innovations (Raymond Program), operator protection, Strain/Sprain Clinic, etc.

Extensive training for new members

Statistical driven emphasis

Doing the Right Thing. with Energy