Washington, D.C. 20549

INTEGRATED DEVICE TECHNOLOGY, INC.

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See definition of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

The aggregate market value of the voting and non-voting common equity held by non-affiliates was approximately $939 million, computed by reference to the last sales price of $6.60 as reported by The NASDAQ Stock Market LLC, as of the last business day of the registrant’s most recently completed second fiscal quarter, September 25, 2009. Shares of common stock held by each executive officer and director and by each person who owns 5% or more of the outstanding common stock have been excluded in that such persons may be deemed affiliates. This determination of affiliate status is not necessarily a conclusive determination for other purposes.

The number of outstanding shares of the registrant's Common Stock, $.001 par value, as of April 25, 2010 was approximately 162,424,487.

Items 10, 11, 12, 13, and 14 of Part III incorporate information by reference from the registrant’s Proxy Statement for the 2010 Annual Meeting of Stockholders.

We have made statements in this Annual Report on Form 10-K in Item 1-“Business”, Item 1A-“Risk Factors”, Item 3-“Legal Proceedings”, Item 7-“Management’s Discussion and Analysis of Financial Condition and Results of Operation” and in other sections of this Annual Report on Form 10-K that are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended and Section 21E of the Securities Exchange Act of 1934, as amended. These statements relate to future events and the future results of Integrated Device Technology, Inc. and are based on current expectations, estimates, forecasts and projections about the industry in which we operate and the beliefs and assumptions of our management. In addition, in this Annual Report on Form 10-K, the words ‘expects,’ ‘anticipates,’ ‘targets,’ ‘goals,’ ‘projects,’ ‘intends,’ ‘plans,’ ‘believes,’ ‘seeks,’ ‘estimates,’ and variations of such words and similar expressions, as they relate to us, our business and our management, are intended to identify such forward-looking statements. Forward-looking statements should not be read as a guarantee of future performance or results, and will not necessarily be accurate indications of the times at, or by, which such performance or results will be achieved. Forward-looking statements are based on information available at the time those statements are made and/or management’s good faith belief as of that time with respect to future events, and are subject to risks and uncertainties that could cause actual performance or results to differ materially from those expressed in or s uggested by the forward-looking statements. Factors that might cause or contribute to such differences include, but are not limited to, those discussed in this Report under the section entitled “Risk Factors” under Part I, Item 1A and elsewhere in this Report, and in other reports we file with the Securities and Exchange Commission (SEC), including our most recent reports on Form 10-Q.

Forward-looking statements speak only as of the date the statements are made. You should not put undue reliance on any forward-looking statements. We assume no obligation to update forward-looking statements to reflect actual results, changes in assumptions or changes in other factors affecting forward-looking information, except to the extent required by applicable securities laws. If we do update one or more forward-looking statements, no inference should be drawn that we will make additional updates with respect to those or other forward-looking statements.

We design, develop, manufacture and market a broad range of low-power, high-performance mixed signal semiconductor solutions for the advanced communications, computing and consumer industries. Our communications products target markets including the enterprise, data center and wireless markets. Our computing products are designed specifically for desktop, notebook, sub-notebook, storage and server applications while our consumer products are optimized primarily for gaming consoles, set-top boxes, digital TV and smart phones.

With best-in-class talent, technology and an innovative product-development philosophy targeted at digital media, IDT enables the industry to synchronize, transport, process and deliver digital media. We do this by developing deep systems-level knowledge and applying our fundamental semiconductor heritage to create essential solutions to the compelling technology challenges faced by our customers.

We market our products on a worldwide basis primarily to original equipment manufacturers (OEMs) through a variety of channels, including a direct sales force, distributors, electronic manufacturing suppliers (EMSs) and independent sales representatives.

We seek to differentiate our products from our competitors’ products through the following capabilities:

IDT was incorporated in California in 1980 and reincorporated in Delaware in 1987. The terms "the Company," "IDT," "our," "us" and "we" refer to Integrated Device Technology, Inc. and its consolidated subsidiaries.

We provide a broad portfolio of essential semiconductor solutions, including integrated circuits (ICs) that enable digital media to be synchronized, transported, processed and delivered in current and next-generation communications, computing and consumer applications. We serve equipment vendors by applying our advanced hardware, integrated software and heritage technologies to create flexible, highly integrated products that enhance the functionality and processing of digital media.

In the first quarter of fiscal 2010, as part of a refinement of our business strategy, we transferred multi-port products from the Communications segment into the Computing and Consumer segment. This change in segment reporting had no impact on our consolidated balance sheets, statements of operations, statements of cash flows or statements of stockholders’ equity for any periods. The segment information for the years ended March 29, 2009 and March 30, 2008 has been adjusted retrospectively to conform to the current period presentation.

In fiscal 2010, the Communications and Computing and Consumer segments accounted for approximately 46% and 54%, respectively, of our total revenues of $535.9 million. In fiscal 2009, these segments accounted for approximately 44% and 56%, respectively, of our total revenues of $663.2 million. During fiscal 2008, these segments accounted for approximately 45% and 55%, respectively, of our total revenues of $781.5 million.

We offer custom designed products, ASSPs and general purpose industry-standard products.

This segment includes clock generation and distribution products, high-performance server memory interfaces, PCI Express switching solutions, multi-port products, PC audio and video products.

We are a leading provider of timing solutions, offering a complete portfolio of products for clock generation, distribution, recovery and jitter attenuation to serve numerous computing, consumer and communications applications.

In June 2009, we acquired Tundra Semiconductor Corporation for approximately $104.3 million in cash and assumed options to purchase up to 0.8 million shares of IDT common stock with a fair value of $0.7 million for a total consideration of approximately $105.0 million. We expect that the Tundra technologies, combined with our mixed signal product portfolio and channel capabilities, will further reinforce our leadership in interconnect and switching solutions for the communication, computing and consumer segments.

In June 2009, we purchased certain sensor technology and related assets from Leadis Technology, Inc. along with members of its engineering team for a total consideration of $6.3 million in cash to complement our core competencies enabling the multimedia triumvirate of sight (video), sound (audio) and touch (sense). Leadis' patented single-ITO (Indium Tin Oxide) touch technology enables the integration of highly differentiated, value-added, ASSPs incorporating timing, audio, power management and touch, thereby providing an entry into new growth markets.

In January 2010, we acquired Mobius Microsystems, a leader in precision all-silicon quartz crystal oscillator replacement technology. The transaction was an all-cash agreement to purchase the outstanding shares of Mobius. The acquisition of Mobius Microsystems, a leading innovator in patented all-silicon oscillator technology, reinforces our commitment to our clock / timing segments and will enable us to develop high-accuracy, crystal oscillator replacements, thereby doubling our silicon timing SAM over the next several years.

On November 30, 2009, we completed the sale of certain assets and transferred certain liabilities related to our military business to Spectrum Control, Inc ("Spectrum Control") for approximately $12.8 million. As a result, in the third quarter of fiscal 2010, we recorded a loss of $4.3 million related to this divestiture. All employees in our military business were transferred to Spectrum Control as a result of the transaction. In addition, we signed a sublease agreement with Spectrum Control, which will expire in May 2010. Prior to divestiture, the military business was part of a larger cash-flow generating product group and did not, on its own, represent a separate operation of the Company. Therefore, discontinued operations reporting did not apply. See Note 3 of the Notes to Consolidated Financial Statements for further deta ils.

On December 4, 2009, we completed the sale of certain assets and transferred certain liabilities related to Tundra's Silicon Logic engineering business to Open Silicon, Inc (“OSI’) for $1 in cash. We recorded a loss of $0.2 million in fiscal 2010 related to this divestiture. In connection with the divestiture, we entered into a design service agreement with OSI, whereby they agreed to provide and we agreed to purchase design services from OSI through the end of calendar year 2010. The total commitment under this design service agreement was $0.8 million. We also signed a sublease agreement with OSI, which will expire in June 2012.

On July 17, 2009, we completed the sale of certain assets related to our network search engine business (the "NWD Assets") to NetLogic Microsystems, Inc ("Netlogic"). Upon closing of the transaction, NetLogic paid us $100 million in cash consideration, which included inventory valued at approximately $10 million, subject to adjustment. On September 27, 2009, the inventory we sold to Netlogic was valued at $8.2 million. Subsequently, in the third quarter of fiscal 2010, we reimbursed Netlogic the excess cash for the inventory in the amount of $1.8 million. Our NWD Assets were part of the Communications reportable segment. In the second quarter of fiscal 2010, we recorded a gain of $82.7 million related to the divestiture. See Note 3 – “Divestitures” in part II, Item 8 for further information.

One family of distributors, Maxtek and its affiliates, represented approximately 21% of our total revenues in both fiscal 2010 and 2009, respectively. Another distributor, Avnet, represented approximately 11% and 10% of our total revenues in fiscal 2010 and 2009, respectively. No single direct or consignment customer represented 10% or more of our total revenues in fiscal 2010, 2009, or 2008.

During fiscal 2010, sales within the Americas, Europe, APAC, and Japan represented approximately 17%, 8%, 65% and 10%, respectively, of our total revenues. Additional details regarding revenues are included in the Consolidated Financial Statements and Notes to Consolidated Financial Statements in Item 8 of this Annual Report.

We market our products on a worldwide basis, primarily to OEMs, who in turn, incorporate our products into the customers’ products marketed under their brands. We work closely with our OEM customers to design and integrate current and next generation products to meet the requirements of end users. Many of our end-customer OEMs have outsourced their manufacturing to a concentrated group of global EMSs and original design manufacturers (ODMs), who then buy product directly from us or through our distributors on behalf of the OEM. These EMSs and ODMs have achieved greater autonomy in design win, product qualification and product purchasing decisions, especially for commodity products. No direct OEM customer accounted for 10% or more of our total revenues in fiscal 2010, 2009 or 2008. However, when sales throu gh all channels are considered, we estimate that end-customer sales to Cisco represented approximately 12% and 15% of our revenues in fiscal 2009 and 2008, respectively. No customer accounted for 10% or more of our total revenues in fiscal 2010.

Certain of our subsidiaries derive revenue from contracts and subcontracts with agencies of, or prime contractors to, the U.S. government, including U.S. military agencies. Although former employees of Integrated Circuit Systems, Inc. (ICS) who work for us have experience contracting with agencies of the U.S. government, historically we have not contracted with agencies of the U.S. government. As a company engaged, in part, in supplying defense-related equipment to U.S. government agencies, we are subject to certain business risks that are particular to companies that contract with U.S. government agencies. These risks include the ability of the U.S. government or related contractors to unilaterally:

In addition, because we have defense industry contracts with respect to products that are sold both within and outside of the United States, we are subject to the following additional risks in connection with government contracts:

The revenue from, and activity with, contracts and subcontracts with agencies of, or prime contractors to, the U.S. government, has declined subsequent to the disposition of our military business to Spectrum Control, Inc.

In fiscal 2010, we assembled or packaged products at several different subcontractors in the APAC region. Utilizing several different subcontractors located in different countries enables us to negotiate lower prices and limits the risk associated with production concentration in one country or company. The criteria used to select assembly subcontractors include, but are not limited to cost, quality, delivery, and subcontractor financial stability.

We performed the vast majority of test operations at two company-owned test facilities located in Malaysia and Singapore. A relatively small amount of test operations are also performed at third party subcontractors in the APAC region. On February 1, 2010, we announced a plan to discontinue manufacturing operations in our Singapore facility and consolidate with our manufacturing operations in Malaysia.

Our backlog (which we define as all confirmed, unshipped direct orders) as of March 28, 2010 was $73.3 million compared to $37.7 million as of March 29, 2009. We offer custom designed products, as well as Industry-Standard Products and ASSPS. Sales are made primarily pursuant to standard purchase orders, which are frequently revised by customers as their requirements change. We have also entered into master purchase agreements, which do not require minimum purchase quantities, with many of our OEM and EMS customers. We schedule product deliveries upon receipt of purchase orders under the related customer agreements. Generally, these purchase orders and customer agreements, especially those for standard products, also allow customers to change the quantities, reschedule delivery dates and cancel purchase orders without significant penalties. In general, orders, especially for industry standard products, are often made with very short lead times and may be canceled, rescheduled, re-priced or otherwise revised prior to shipment. In addition, certain distributor orders are subject to price adjustments both before and after shipment. For all these reasons, we do not believe that our order backlog is a reliable indicator of future revenues.

Our research and development efforts emphasize the development and design of proprietary, differentiated high performance, low-power analog and mixed-signal semiconductor products. We believe that a sustained level of investment in research and development is necessary to maintain our competitive position. We operate research and development centers in San Jose and

Sunnyvale, California; Tempe, Arizona; Atlanta, Georgia; Austin, Texas; Warren, New Jersey; Worcester and Boston, Massachusetts; Ann Arbor, Michigan, Toronto and Ottawa, Canada; Shanghai, China and Singapore. Research and development expenses, as a percentage of revenues, were approximately 29%, 24% and 21% in fiscal 2010, 2009 and 2008, respectively.

Our product development activities are focused on the design of integrated circuits that provide differentiated features and enhanced performance primarily for communications, computing and consumer applications.

The semiconductor industry is characterized by rapid technological advances, cyclical market patterns, erosion of product sale prices and evolving industry standards. Many of our competitors have substantially greater technical, marketing, manufacturing or financial resources than we do. In addition, several foreign competitors receive financial assistance from their governments, which could give them a competitive advantage. We compete in different product areas to varying degrees on the basis of technical innovation and product performance, as well as product quality, availability and price.

Our competitive strategy is to use our applications expertise to develop a deep understanding of customers' systems and to use our unique combination of analog and digital technologies to develop complete product portfolios that solve our customers’ whole problem. We differentiate our products through innovative configurations, proprietary features, high performance, and breadth of offerings. Our ability to compete successfully and to expand our business will depend on a number of factors, including but not limited to:

We compete with product offerings from numerous companies, including LSI, Conexant Systems, Cypress Semiconductor, Exar, Freescale Semiconductor, Infineon Technologies, Integrated Silicon Solutions, Intel, Maxim Integrated Products, NEC, Parade Technologies, Pericom Semiconductor, Philips Electronics, PLX Technology, Realtek Semiconductor, Samsung Electronics, STMicroelectronics, Texas Instruments, Toshiba, Analog Devices, Inphi, Silicon Laboratories, Montage, Diablo and Zarlink Semiconductor.

We rely primarily on our patents, trade secrets, contractual provisions, licenses, copyrights, trademarks, and other proprietary rights mechanisms to protect our intellectual property. We believe that our intellectual property is a key corporate asset, and we continue to invest in intellectual property protection. We also intend to continue our efforts to increase the breadth of our patent portfolio. There can be no assurance that any patents issued to us will not be challenged, invalidated or circumvented, that the rights granted there under will provide competitive advantages to us or that our efforts to protect our intellectual property rights will be successful.

In recent years, there has been a growing trend of companies resorting to litigation to protect their semiconductor technology from unauthorized use by others. We are, and have been involved in patent litigation, which has adversely impacted our operating results. Although we have obtained patent licenses from certain semiconductor manufacturers, we do not have licenses from a number of semiconductor manufacturers with broad patent portfolios. While we are not knowingly infringing on any of their patents, these semiconductor manufacturers may resort to litigation or other means in an effort to find infringements and force us to obtain licenses to their patents. Our success will depend in part on our ability to obtain necessary intellectual property rights and protect our intellectual property rights. While we have filed patent applications, we cannot be certain that these applications will issue into patents or that we will be able to obtain the patent coverage and other intellectual property rights necessary to protect our technology. Further, we cannot be certain that once granted, the intellectual property rights covered by such patents will not be challenged by other parties.

We are committed to protecting the environment and the health and safety of our employees, customers and the public. We endeavor to adhere to the most stringent standards across all of our facilities, to encourage pollution prevention and to strive towards continual improvement. As an integral part of our total quality management system, we strive to exceed compliance with regulatory standards in order to achieve a standard of excellence in environmental, health and safety management practices.

Our manufacturing facilities are subject to numerous environmental laws and regulations, particularly with respect to the storage, handling, use, discharge and disposal of certain chemicals, gases and other substances used or produced in the semiconductor manufacturing process. Compliance with these laws and regulations has not had a material impact on our capital expenditures, earnings, financial condition or competitive position. Although we believe that we are fully compliant with all applicable environmental laws and regulations there can be no assurance that current or future environmental laws and regulations will not impose costly requirements upon us. Any failure by us to comply with applicable environmental laws and regulations could result in fines, suspension of production, alteration of fabrica tion processes and legal liability.

As of March 28, 2010, we had approximately 2,004 employees worldwide, with approximately 1,014 employees located in the United States. Our future success depends in part on our ability to attract and retain qualified personnel, particularly engineers, who are often in great demand. We have implemented policies enabling our employees to share in our success, including stock option, restricted stock unit, stock purchase and incentive bonus plans. We have never had a work stoppage related to labor issues. None of our employees are currently represented by a collective bargaining agreement, and we consider our relationship with our employees to be good.

We electronically file our annual reports on Form 10-K, quarterly reports on Form 10-Q and current reports on Form 8-K pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as amended with the SEC. The public may read or copy any materials we file with the SEC at the SEC’s Public Reference Room at 100 F Street, NE, Washington, DC 20549. The public may obtain information on the operation of the Public Reference Room by calling the SEC at 1-800-SEC-0330. The SEC maintains an Internet site that contains reports, proxy and information statements, and other information regarding issuers that file electronically with the SEC. The address of that site is http://www.sec.gov. You may obtain a free copy of our annual reports on Form 10-K, quarterly reports on Form 10-Q and current reports on Form 8-K and amendments to those reports with the SEC on our website on the World Wide Web at http://www.IDT.com, by contacting the Investor Relations Department at our corporate offices by calling (408) 284-8200 or by sending an e-mail message to ir@IDT.com.

Investing in our common stock involves a high degree of risk. You should carefully consider the risks and uncertainties described below and all information contained in this report before you decide to purchase our common stock. If any of the possible adverse events described below actually occurs, we may be unable to conduct our business as currently planned and our financial condition and operating results could be harmed. In addition, the trading price of our common stock could decline due to the occurrence of any of these risks, and you may lose all or part of your investment. The risks described below are not the only risks facing us. Additional risks not currently known to us or that we currently believe are immaterial may also impair our business operations, results, and financial condition.

Our operating results can fluctuate dramatically. Our operating results have fluctuated in the past and are likely to vary in the future. For example, we recorded net income of $40.0 million in fiscal 2010, a net loss of $1,045.2 million in fiscal 2009 and net income of $34.2 million in fiscal 2008. Fluctuations in operating results can result from a wide variety of factors, including:

| · | Global market and economic conditions, including those related to the credit markets, may adversely affect our business and results of operations; |

| · | The cyclicality of the semiconductor industry; |

| · | The availability of industry-wide wafer processing capacity; |

| · | The availability of industry-wide and package-specific assembly subcontract capacity and related raw materials; |

| · | Changes in the demand for and mix of products sold and in the markets we and our customers serve; |

| · | Competitive pricing pressures; |

| · | The success and timing of new product and process technology announcements and introductions from us or our competitors; |

| · | Potential loss of market share among a concentrated group of customers; |

| · | Difficulty in attracting and retaining key personnel; |

| · | Difficulty in predicting customer product requirements; |

| · | Production difficulties and interruptions caused by our complex manufacturing and logistics operations; |

| · | Difficulty in managing fixed costs of our manufacturing capability in the face of changes in demand; |

| · | Reduced control over our manufacturing and product delivery as a result of our increasing reliance on subcontractors, foundry and other manufacturing services; |

| · | Costs and other issues relating to future acquisitions; |

| · | Availability and costs of raw materials from a limited number of suppliers; |

| · | Political and economic conditions in various geographic areas; |

| · | Costs associated with other events, such as intellectual property disputes or other litigation; and |

| · | Legislative, tax, accounting, or regulatory changes or changes in their interpretation. |

Global Market and Economic Conditions, including those related to the credit markets, may adversely affect our business and results of operations.

Adverse changes in global financial markets and rapidly deteriorating business conditions in the world’s developed economies in late 2008 and the first half of calendar year 2009 resulted in a significant global economic recession. Concerns about the impact of high energy costs, geopolitical issues, the availability and cost of credit, the U.S. mortgage market, a declining real estate market in the U.S. and added concerns fueled by federal government interventions in the U.S. financial and credit markets contributed to instability in both U.S. and international capital and credit markets, reduced corporate profits and capital spending, weakened demand and diminished expectations for the U.S. and global economy. These conditions, and the resulting low business and consumer confidence and high unemployment have c ontributed to substantial volatility in global capital markets and uncertain demand for our products throughout fiscal 2010. It is difficult for our customers, our vendors and us to accurately forecast and plan future business activities in this economic environment.

As a result of these market and business conditions, the cost and availability of capital and credit have been and may continue to be adversely affected by illiquid credit markets and wider credit spreads. If these market conditions continue, they may limit our ability, and the ability of our customers, to timely borrow and access the capital and credit markets to meet liquidity needs, resulting in an adverse effect on our financial condition and results of operations. Poor credit market conditions and the

contraction of global economic activity may have an adverse effect on the financial condition of our customers or suppliers. Should one or more of our major customers become financially constrained, or insolvent, our revenues and results of operations may be adversely affected.

The economic slowdown resulted in reduced customer spending for semiconductors and weakened demand for our products which had a negative impact on our revenue, gross profit, results of operations and cash flows during fiscal 2010. Although business conditions improved during the second half of fiscal 2010, credit markets continue to be volatile and continued improvement in global economic activity is uncertain. Should the nascent global economic recovery falter, customer demand for our products may decline which is likely to have a negative impact on our revenue, gross profit, results of operations and cash flows. Reduced customer spending and weakened demand may drive the semiconductor industry to reduce product pricing, which would also have a negative impact on revenue, gross profit and results of opera tions. In addition, the semiconductor industry has traditionally been highly cyclical and has often experienced significant downturns in connection with, or in anticipation of, deterioration in general economic conditions and we cannot accurately predict how severe and prolonged any downturn might be.

The cyclicality of the semiconductor industry exacerbates the volatility of our operating results.

The semiconductor industry is highly cyclical. The semiconductor industry has experienced significant downturns, often in connection with product cycles of both semiconductor companies and their customers, but also related to declines in general economic conditions. These downturns have been characterized by volatile customer demand, high inventory levels and accelerated erosion of average selling prices. Any future downturns could significantly impact our business from one period to the next relative to demand and resulting selling price declines. In addition, the semiconductor industry has experienced periods of increased demand, during which we may experience internal and external manufacturing constraints. We may experience substantial changes in future operating results due to the cyclical nature of the semiconductor industry.

Demand for our products depends primarily on demand in the communications, enterprise computing, personal computer (PC), and consumer markets which can be significantly impacted by concerns over macroeconomic issues.

Our product portfolio consists predominantly of semiconductor solutions for the communications, computing, and consumer markets. Our strategy and resources will be directed at the development, production and marketing of products for these markets. The markets for our products will depend on continued and growing demand for communications equipment, servers, PCs and consumer electronics. These end-user markets may experience changes in demand that could adversely affect our business and could be greater in periods of economic uncertainty and contraction. To the extent demand for our products or markets for our products do not grow, our business could be adversely affected.

We build most of our products based on estimated demand forecasts.

Demand for our products can change rapidly and without advance notice. Demand can also be affected by changes in our customers’ levels of inventory and differences in the timing and pattern of orders from their end customers. A large percentage of our revenue in the Asia Pacific region is recognized upon shipment to our distributors. Consequently, we have less visibility over both inventory levels at our distributors and end customer demand for our products. Further, the distributors have assumed more risk associated with changes in end demand for our products. Accordingly, significant changes in end demand in the semiconductor business in general, or for our products in particular, may be difficult for us to detect or otherwise measure, which could cause us to incorrectly forecast end-mar ket demand for our products. If we are not able to accurately forecast end demand for our products, we may be left with large amounts of unsold products, may not be able to fill all actual orders, and may not be able to efficiently utilize our existing manufacturing capacity or make optimal investment and other business decisions. As a result, we may end up with excess and obsolete inventory or we may be unable to meet customer short-term demands, either of which could have an adverse impact on our operating results.

We are reliant upon subcontractors and third-party foundries.

Beginning in fiscal 2008, we do not perform assembly services in-house and are now totally dependent on subcontractors for assembly operations. We are also dependent on third-party outside foundries for the manufacture of a portion of our silicon wafers. Our increased reliance on subcontractors and third-party foundries for our current products increases certain risks because we will have less control over manufacturing quality and delivery schedules, maintenance of sufficient capacity to

meet our orders and generally, maintaining the manufacturing processes we require. We expect our use of subcontractors and third-party foundries to continue to increase. Due to production lead times and potential capacity constraints, any failure on our part to adequately forecast the mix of product demand and resulting foundry and subcontractor requirements could adversely affect our operating results. In addition, we cannot be certain that these foundries and subcontractors will continue to manufacture, assemble, package and test products for us on acceptable economic and quality terms, or at all, and it may be difficult for us to find alternatives in a timely and cost-effective manner if they do not do so.

We are dependent on a limited number of suppliers.

Our manufacturing operations depend upon obtaining adequate raw materials on a timely basis. The number of suppliers of certain raw materials, such as silicon wafers, ultra-pure metals and certain chemicals and gases needed for our products, is very limited. In addition, certain packages for our products require long lead times and are available from only a few suppliers. From time to time, suppliers have extended lead times or limited supply to us due to capacity constraints. Our results of operations would be materially and adversely affected if we were unable to obtain adequate supplies of raw materials in a timely manner or if there were significant increases in the costs of raw materials, or if foundry or assembly subcontractor capacity was not available, or was only available at uncompetitive prices.

We have made and may continue to make acquisitions and divestitures which could divert management’s attention, cause ownership dilution to our stockholders, be difficult to integrate and/or adversely affect our financial results.

Acquisitions and divestitures are commonplace in the semiconductor industry and we have and may continue to acquire or divest businesses or technologies. Integrating newly acquired businesses or technologies could put a strain on our resources, could be costly and time consuming, and might not be successful. Acquisitions or divestitures could divert our management’s attention from other business concerns. In addition, we might lose key employees while integrating new organizations. Acquisitions and divestitures could also result in customer dissatisfaction, performance problems with an acquired company or technology, dilutive or potentially dilutive issuances of equity securities, the incurrence of debt, the assumption or incurrence of contingent liabilities, or other unanticipated events or circumstances, any of which could harm ou r business. Consequently, we might not be successful in integrating any acquired businesses, products or technologies, and might not achieve anticipated revenues and cost benefits.

Intellectual property claims against and /or on behalf of the Company could adversely affect our business and operations.

The semiconductor industry is characterized by vigorous protection and pursuit of intellectual property rights, which has resulted in significant and often protracted and expensive litigation. We have been involved with patent litigation and asserted intellectual property claims in the past, both as a plaintiff and a defendant, which adversely affected our operating results. Although we have obtained patent licenses from certain semiconductor manufacturers, we do not have licenses from a number of semiconductor manufacturers that have broad patent portfolios. Claims alleging infringement of intellectual property rights have been asserted against us in the past and could be asserted against us in the future. These claims could result in our having to discontinue the use of certain processes; license certain technologies; cease the manufact ure, use and sale of infringing products; incur significant litigation costs and damages; and develop non-infringing technology. We might not be able to obtain such licenses on acceptable terms or to develop non-infringing technology. Further, the failure to renew or renegotiate existing licenses on favorable terms, or the inability to obtain a key license, could materially and adversely affect our business. Future litigation, either as a plaintiff or a defendant, could adversely affect our operating results, as a result of increased expenses, the cost of settled claims, and/or payment of damages.

Our results are dependent on the success of new products.

The markets we serve are characterized by competition, rapid technological change, evolving standards, short product life cycles and continuous erosion of average selling prices. Consequently, our future success will be highly dependent upon our ability to continually develop new products using the latest and most cost-effective technologies, introduce our products in commercial quantities to the marketplace ahead of the competition and have our products selected for inclusion in leading system manufacturers’ products. In addition, the development of new products will continue to require significant R&D expenditures. If we are unable to successfully develop, produce and market new products in a timely manner, have our products available in commercial quantities ahead of competitive products or have our products s elected for inclusion in products of systems manufacturers and sell them at gross margins comparable to or better than our current products, our future

results of operations could be adversely impacted. In addition, our future revenue growth is also partially dependent on our ability to penetrate new markets in which we have limited experience and where competitors are already entrenched. Even if we are able to develop, produce and successfully market new products in a timely manner, such new products may not achieve market acceptance.

We are dependent on a concentrated group of customers for a significant part of our revenues.

A large portion of our revenues depends on sales to a limited number of customers. If these relationships were to diminish, or if these customers were to develop their own solutions or adopt a competitor’s solution instead of buying our products, our results could be adversely affected. For example, any diminished relationship with one or more of our key customers could adversely affect our results.

Many of our end-customer OEMs have outsourced their manufacturing to a concentrated group of global EMSs and original design manufacturers (“ODMs”) who then buy product directly from us or from our distributors on behalf of the OEM. These EMSs and ODMs have achieved greater autonomy in the design win, product qualification and product purchasing decisions, especially for commodity products. Competition for the business of these EMSs and ODMs is intense and there is no assurance we can remain competitive and retain our existing market share with these customers. If these companies were to allocate a higher share of commodity or second-source business to our competitors instead of buying our products, our results would be adversely affected. Furthermore, as EMSs and ODMs have represented a growing percentage of o ur overall business, our concentration of credit and other business risks with these customers has increased. Competition among global EMSs and ODMs is intense as they operate on extremely thin margins. If any one or more of these global EMSs or ODMs were to file for bankruptcy or otherwise experience significantly adverse financial conditions, our business would be adversely impacted as well.

Finally, we utilize a relatively small number of global and regional distributors around the world, who buy product directly from us on behalf of their customers. For example, one family of distributors, Maxtek and its affiliates, represented approximately 21% of our total revenues for fiscal 2010 and represented approximately 23% of our gross accounts receivable as of March 28, 2010. If our business relationships were to diminish or any of these global distributors were to file for bankruptcy or otherwise experience significantly adverse financial conditions, our business could be adversely impacted. Because we continue to be dependent upon continued revenue from a small group of OEM end customers, global and regional distributors, any material delay, cancellation or reduction of orders from or loss of these or othe r major customers could cause our sales to decline significantly, and we may not be able to reduce the accompanying expenses at the same rate.

The costs associated with the legal proceedings in which we are involved can be substantial, specific costs are unpredictable and not completely within our control, and unexpected increases in litigation costs could adversely affect our operating results.

We are currently involved in legal proceedings, as described below in Part I, Item 3 "Legal Proceedings." The costs associated with legal proceedings are typically high, relatively unpredictable and are not completely within our control. While we do our best to forecast and control such costs, the costs may be materially more than expected, which could adversely affect our operating results. Moreover, we may become involved in unexpected litigation with additional companies at any time, which would increase our aggregate litigation costs and could adversely affect our operating results. We are not able to predict the outcome of any of our legal actions and an adverse decision in any of our legal actions could significantly harm our business and financial performance.

We are dependent on key personnel.

Our performance is substantially dependent on the performance of our executive officers and key employees. The loss of the services of any of our executive officers, technical personnel or other key employees could adversely affect our business. In addition, our future success depends on our ability to successfully compete with other technology firms in attracting and retaining specialized technical and management personnel. If we are unable to identify, hire and retain highly qualified technical and managerial personnel, our business could be harmed.

Our product manufacturing operations are complex and subject to interruption.

From time to time, we have experienced production difficulties, including lower manufacturing yields or products that do not meet our or our customers' specifications, which has resulted in delivery delays, quality problems and lost revenue opportunities. While delivery delays have been infrequent and generally short in duration, we could experience manufacturing problems, capacity constraints and/or product delivery delays in the future as a result of, among other things, the complexity of our manufacturing processes, changes to our process technologies (including die size reduction efforts), transfer to other facilities including the transfer of our internal wafer fabrication capability to third party wafer foundries and difficulties in ramping production in both our facilities and at third-party foundries and subcontractors and install ing new equipment at our facilities. In addition, any significant quality problems could damage our reputation with our customers and could take focus away from the development of new and enhanced products. These could have a significant negative impact on our financial results.

Substantially all of our revenues are derived from products manufactured at facilities which are exposed to the risk of natural disasters. If we are unable to use our facilities or those of our subcontractors and third party foundries as a result of a natural disaster or otherwise, our operations would be materially adversely affected. While we maintain certain levels of insurance against selected risks of business interruption, not all risks can be insured at a reasonable cost. For example, we do not insure our facilities for earthquake damage due to the costs involved. Even if we have purchased insurance, the adverse impact on our business, including both costs and lost revenue opportunities, could greatly exceed the amounts, if any, that we might recover from our insurers.

We are dependent upon electric power and water provided by public utilities where we operate our manufacturing facilities. We maintain limited backup generating capability, but the amount of electric power that we can generate on our own is insufficient to fully operate these facilities, and prolonged power interruptions and restrictions on our access to water could have a significant adverse impact on our business.

Our results of operations could vary as a result of the methods, estimates and judgments we use in applying our accounting policies.

The methods, estimates and judgments we use in applying our accounting policies have a significant impact on our results of operations (see “Significant Accounting Policies” in Part II, Item 8 of this Form 10-K). Such methods, estimates and judgments are, by their nature, subject to substantial risks, uncertainties and assumptions, and factors may arise over time that leads us to change our methods, estimates and judgments. Changes in those methods, estimates and judgments could significantly affect our results of operations. In particular, the calculation of stock-based compensation expense under the authoritative guidance requires us to use valuation methodologies that were not developed for use in valuing employee stock options and make a number of assumptions, estimates and conclusions regarding matters such as expected forfeitures, expected volatility of our share price and the exercise behavior of our employees. Changes in these variables could impact our stock-based compensation expense and have a significant impact on our gross margins, research and development and selling, general and administrative expenses.

Our financial results may be adversely impacted by higher than expected tax rates or exposure to additional tax liabilities.

As a global company, our effective tax rate is highly dependent upon the geographic composition of worldwide earnings and tax regulations governing each region. We are subject to income taxes in the United States and various foreign jurisdictions, and significant judgment is required to determine worldwide tax liabilities. Our effective tax rate could be adversely affected by changes in the mix of earnings between countries with differing statutory tax rates, in the valuation of deferred tax assets, in tax laws or by material audit assessments, which could affect our profitability. In particular, the carrying value of deferred tax assets, which are predominantly in the United States, is dependent upon our ability to generate future taxable income in the United States. In addition, the amount of income taxes we pay is subject to ongoing au dits in various jurisdictions, and a material assessment by a governing tax authority such as the United States Internal Revenue Service could affect our profitability.

Our reported financial results may be adversely affected by new accounting pronouncements or changes in existing accounting standards and practices.

We prepare our financial statements in conformity with accounting principles generally accepted in the United States. These accounting principles are subject to interpretation by the Financial Accounting Standards Board (FASB), the Securities and Exchange Commission (SEC) and various organizations formed to interpret and create appropriate accounting standards and practices. New accounting pronouncements and varying interpretations of accounting standards and practices have occurred

and may occur in the future. New accounting pronouncements or a change in the interpretation of existing accounting standards or practices may have a significant effect on our reported financial results and may even affect our reporting of transactions completed before the change is announced or effective.

We are exposed to potential impairment charges on certain assets.

Over the past several years, we have made several acquisitions. As a result of these acquisitions, we had over $1 billion of goodwill and over $204 million of intangible assets on our balance sheet at the beginning of fiscal 2009. As a result of our interim impairment analysis in the third quarter of 2009 and annual impairment analysis in the fourth quarter of fiscal 2009, we recorded a goodwill impairment charge of $946.3 million and an acquisition-related intangible asset impairment charge of $79.4 million in fiscal 2009. In determining fair value, we consider various factors including our market capitalization, forecasted revenue and costs, risk-adjusted discount rates, future economic and market conditions, determination of appropriate market comparables and expected periods over which our assets will be utilized and other variables.

If our assumptions regarding forecasted cash flow, revenue and margin growth rates of certain long-lived asset groups and reporting units are not achieved, it is reasonably possible that an impairment review may be triggered for the remaining balance of goodwill and long-lived assets prior to the next annual review in the fourth quarter of fiscal 2011, which could result in material charges that could impact our operating results and financial position. In addition, from time to time, we have made investments in other companies, both public and private. If the companies that we invest in are unable to execute their plans and succeed in their respective markets, we may not benefit from such investments, and we could potentially lose the amounts we invest. In addition, we evaluate our investment portfolio on a regular basis to determine if impairments have occurred. Impairment charges could have a material impact on our results of operations in any period.

Tax benefits we receive may be terminated or reduced in the future, which would increase our costs.

As a result of our international manufacturing operations, a significant portion of our worldwide profits are in jurisdictions outside the United States, including Bermuda, Singapore and Malaysia which offer significant reductions in tax rates. These lower tax rates allow us to record a relatively low tax expense on a worldwide basis. Under current Bermuda law, we are not subject to tax on our income and capital gains. If U.S. corporate income tax laws were to change regarding deferral of manufacturing profits or other issues impacting our operating structure, this would have a significant impact to our financial results. President Obama’s Administration recently announced new U.S. tax legislative proposals that, if enacted, may adversely impact our effective tax rate and overall tax payin g position in the U.S.

In addition, the Economic Development Board of Singapore granted Pioneer Status to our wholly-owned subsidiary in Singapore in 1997. Initially, this tax exemption was to expire after ten years, but the Economic Development Board in January 2008 agreed to extend the term to twelve years. As a result, a significant portion of the income we earn in Singapore during this period will be exempt from the Singapore income tax. We were required to meet several requirements as to investment, headcount and activities in Singapore to retain this status. If it is retroactively determined that we did not meet these requirements, or for other reasons beyond our control, our financial results could be negatively impacted. Also, in Malaysia, we have been granted a tax holiday related to certain profits. If we are unable to renew this tax holida y when it expires, we will be required to start paying income tax at the statutory tax rate on our operations, which will adversely impact our effective tax rate.

International operations add increased volatility to our operating results.

A substantial percentage of our total revenues are derived from international sales, as summarized below:

(percentage of total revenues) | | Fiscal 2010 | | | Fiscal 2009 | | | Fiscal 2008 | |

| Americas | | | 17 | % | | | 20 | % | | | 28 | % |

| Asia Pacific | | | 65 | % | | | 63 | % | | | 56 | % |

| Japan | | | 10 | % | | | 9 | % | | | 9 | % |

| Europe | | | 8 | % | | | 8 | % | | | 7 | % |

| Total | | | 100 | % | | | 100 | % | | | 100 | % |

In addition, our facilities in Malaysia and Singapore, our design centers in Canada and China, and our foreign sales offices incur payroll, facility and other expenses in local currencies. Accordingly, movements in foreign currency exchange rates can impact our revenues and costs of goods sold, as well as both pricing and demand for our products.

Our offshore sites and export sales are also subject to risks associated with foreign operations, including:

| · | Political instability and acts of war or terrorism, which could disrupt our manufacturing and logistical activities; |

| · | Regulations regarding use of local employees and suppliers; |

| · | Currency controls and fluctuations, devaluation of foreign currencies, hard currency shortages and exchange rate fluctuations; |

| · | Changes in local economic conditions; |

| · | Governmental regulation of taxation of our earnings and those of our personnel; and |

| · | Changes in tax laws, import and export controls, tariffs and freight rates. |

Contract pricing for raw materials and equipment used in the fabrication and assembly processes, as well as for foundry and subcontract assembly services, may also be impacted by currency controls, exchange rate fluctuations and currency devaluations. We sometimes hedge currency risk for currencies that are highly liquid and freely quoted, but may not enter into hedge contracts for currencies with limited trading volume.

In addition, as much of our revenues are generated outside the United States, a significant portion of our cash and investment portfolio accumulates offshore. At March 28, 2010, we had cash, cash equivalents and investments of approximately $249.8 million invested overseas in accounts belonging to various IDT foreign operating entities. While these amounts are primarily invested in U.S. dollars, a portion is held in foreign currencies, and all offshore balances are exposed to local political, banking, currency control and other risks. In addition, these amounts may be subject to tax and other transfer restrictions.

If the recent credit market conditions worsen, it could have a material adverse impact on our investment portfolio.

Although we manage our investment portfolio by purchasing only highly rated securities and diversifying our investments across various sectors, investment types, and underlying issuers, recent volatility in the short-term financial markets has been unprecedented. We have a nominal amount of securities in asset backed commercial paper and hold no auction rated or mortgage backed securities. However it is uncertain as to the full extent of the current credit and liquidity crisis and with possible further deterioration, particularly within one or several of the large financial institutions, the value of our investments could be negatively impacted.

We rely upon certain critical information systems for the operation of our business.

We maintain and rely upon certain critical information systems for the effective operation of our business. These information systems include telecommunications, the Internet, our corporate intranet, various computer hardware and software applications, network communications, and e-mail. These information systems are subject to attacks, failures, and access denials from a number of potential sources including viruses, destructive or inadequate code, power failures, and physical damage to computers, communication lines and networking equipment. To the extent that these information systems are under our control, we have implemented security procedures, such as virus protection software and emergency recovery processes, to address the outlined risks. While we believe that our information systems are appropriately controlled and that we have processes in place to adequately manage these risks, security procedures for information systems cannot be guaranteed to be failsafe and our inability to use or access these information systems at critical points in time could unfavorably impact the timely and efficient operation of our business.

We are subject to a variety of environmental and other regulations related to hazardous materials used in our manufacturing processes.

Any failure by us to adequately control the use or discharge of hazardous materials under present or future regulations could subject us to substantial costs or liabilities or cause our manufacturing operations to be suspended.

We have limited experience with government contracting, which entails differentiated business risks.

We derive some revenue from contracts and subcontracts with agencies of, or prime contractors to, the U.S. government, including U.S. military agencies. As a company engaged, in part, in supplying defense-related equipment to U.S. government agencies, we are subject to certain business risks that are particular to companies that contract with U.S. government agencies. These risks include the ability of the U.S. government or related contractors to unilaterally:

| · | Terminate contracts at its convenience; |

| · | Terminate, modify or reduce the value of existing contracts, if budgetary constraints or needs change; |

| · | Cancel multi-year contracts and related orders, if funds become unavailable; |

| · | Adjust contract costs and fees on the basis of audits performed by U.S. government agencies; |

| · | Control and potentially prohibit the export of our products; |

| · | Require that the company continue to supply products despite the expiration of a contract under certain circumstances; |

| · | Require that the company fill certain types of rated orders for the U.S. government prior to filling any orders for other customers; and |

| · | Suspend us from receiving new contracts pending resolution of any alleged violations of procurement laws or regulations. |

In addition, because we have defense industry contracts with respect to products that are sold both within and outside of the United States, we are subject to the following additional risks in connection with government contracts:

| · | The need to bid on programs prior to completing the necessary design, which may result in unforeseen technological difficulties, delays and/or cost overruns; |

| · | The difficulty in forecasting long-term costs and schedules and the potential obsolescence of products related to long-term fixed price contracts; and |

| · | The need to transfer and obtain security clearances and export licenses, as appropriate. |

Our common stock has experienced substantial price volatility.

Volatility in the price of our common stock may occur in the future, particularly as a result of the current economic downturn and quarter-to-quarter variations in our actual or anticipated financial results, or the financial results of other semiconductor companies or our customers. Stock price volatility may also result from product announcements by us or our competitors, or from changes in perceptions about the various types of products we manufacture and sell. In addition, our stock price may fluctuate due to price and volume fluctuations in the stock market, especially in the technology sector, and as a result of other considerations or events described in this section.

We depend on the ability of our personnel, raw materials, equipment and products to move reasonably unimpeded around the world.

Any political, military, world health or other issue which hinders the worldwide movement of our personnel, raw materials, equipment or products or restricts the import or export of materials could lead to significant business disruptions. Furthermore, any strike, economic failure, or other material disruption on the part of major airlines or other transportation companies could also adversely affect our ability to conduct business. If such disruptions result in cancellations of customer orders or contribute to a general decrease in economic activity or corporate spending on information technology, or directly impact our marketing, manufacturing, financial and logistics functions, our results of operations and financial condition could be materially and adversely affected.

ITEM 1B. UNRESOLVED STAFF COMMENTS

None.

We own and operate a wafer fabrication facility in Hillsboro, Oregon (approximately 245,000 square feet) and own and operate a test facility in Malaysia (approximately 145,000 square feet). As of March 28, 2010, we operated a test facility in Singapore

(approximately 37,000 square feet), which we discontinued in April 2010. See Note 11 – “Restructuring” in Part II, Item 8 for further discussion. Our Malaysian facility is subject to ground leases and our Singapore facility is subject to a leased space arrangement. For more information on our production facilities, please refer to Item 1, "Manufacturing," in this Report 10-K.

Our corporate headquarters, and various administrative, engineering and support functions are located in San Jose, California. We own and occupy approximately 263,000 square feet of space at our San Jose headquarters. We also lease various facilities throughout the world for research and development and sales and marketing functions, including design centers in the United States, Canada and China.

We believe that the facilities that we currently own or lease are suitable and adequate for our needs for the immediate future.

ITEM 3. LEGAL PROCEEDINGS

On October 24, 2006, we were served with a civil antitrust complaint filed by Reclaim Center, Inc., et. al. as plaintiffs in the U.S. District Court for the Northern District of California against the Company and 37 other entities on behalf of a purported class of indirect purchasers of Static Random Access Memory (SRAM) products. The Complaint alleges that we and other defendants conspired to raise the prices of SRAM, in violation of Section 1 of the Sherman Act, the California Cartwright Act, and several other states’ antitrust, unfair competition, and consumer protection statutes. Shortly thereafter, a number of other plaintiffs filed similar complaints on behalf of direct and indirect purchasers of SRAM products. Given the similarity of the complaints, the Judicial Panel on Multidistrict Litigation transferred the case s to a single judge in the Northern District of California and consolidated the cases for pretrial proceedings in February 2007. The consolidated cases are captioned In re Static Random Access Memory (SRAM) Antitrust Litigation. In August 2007, direct purchasers of SRAM products and indirect purchasers of SRAM products filed separate Consolidated Amended Complaints. We were not named as a defendant in either complaint. Pursuant to tolling agreements with the indirect and direct purchaser plaintiffs, the statute of limitations was tolled until January 10, 2009 as to potential claims against us. The tolling agreements have now expired and the statute of limitations is running on potential claims against us. Discovery has closed in both cases. We intend to vigorously defend ourselves against these claims.

In April 2008, LSI Corporation and its wholly owned subsidiary Agere Systems Inc. (collectively “LSI”) instituted an action in the United States International Trade Commission (ITC or “Commission”), naming us and several other respondents. The ITC action sought an exclusion order under section 337 of the Tariff Act to prevent importation into the U.S. of semiconductor integrated circuit devices and products made by methods alleged to infringe an LSI patent relating to tungsten metallization in semiconductor manufacturing. LSI also filed a companion case in the U.S. District Court for the Eastern District of Texas seeking an injunction and damages of an unspecified amount relating to such alleged infringement. Some of the defendants in the action have since settled the claims against them. The action in t he U.S. District Court is currently stayed pending the outcome of the ITC action. On September 21, 2009, the Administrative Law Judge (“ALJ”) for the ITC action issued an Initial Determination finding that the patent claims asserted by LSI were invalid in light of the prior art. Based on the finding of invalidity, the Court held that no violation of section 337 has occurred with respect to the asserted claims. On October 5, 2009, LSI filed a Petition to Review by the full Commission, and respondents filed a Common Contingent Petition for Review on common matters in the case. We separately filed a Contingent Petition for Review on Company-specific matters in the case. On November 23, 2009, the Commission issued a Notice of determination to review in-part the ALJ’s Initial Determination. The Commission further instructed the ALJ to consider on remand the merit of responden ts' arguments with respect to invalidity of one asserted claim for obviousness. On January 14, 2010, the ALJ issued a Remand Determination that respondents had not demonstrated by clear and convincing evidence that the claim at issue on remand was invalid due to obviousness. The Commission also extended the target date for completion of the investigation to March 22, 2010. Subsequently, briefing responsive to the Remand was filed by both parties. On March 22, 2010, the Commission issued its Notice of Decision indicating that it had found that the patent claims asserted by LSI were invalid and that there had been no violation of section 337 by us, and thereupon terminated its investigation.

In December 2009, Ring Technology Enterprises of Texas, LLC (“Ring”) filed a complaint in the Eastern District of Texas against 30 defendants alleging infringement of a Ring patent related to memory access technology. Ring filed another, separate complaint in the Eastern District of Texas in March of 2010 claiming infringement of the same patent by 43 additional defendants. We were not named as a defendant in either complaint, however, a number of the defendants are purchasers of our Advanced Memory Buffer (“AMB”) products, which may be relevant to the claims made against defendants in the complaints by Ring. Certain of these defendants have requested that we indemnify and provide a defense under the terms of purchase for

our AMB products. Based on a good-faith review of the claims by Ring, we have initially agreed to provide a defense for some of these defendants. We have reserved the right to withdraw our defense if, during the course of litigation it is determined that we have no liability for indemnification based on the claims made by Ring.

.

PART II

ITEM 5. MARKET FOR REGISTRANT'S COMMON EQUITY, RELATED STOCKHOLDER MATTERS AND ISSUER PURCHASES ON EQUITY SECURITIES

Price Range of Common Stock

Our Common Stock is traded on the NASDAQ Global Select Market under the symbol IDTI. The following table shows the high and low closing sales prices for our Common Stock as reported by the NASDAQ Global Select Market for the fiscal periods indicated:

| | | High | | | Low | |

| Fiscal 2010 | | | | | | |

| First Quarter | | $ | 6.62 | | | $ | 4.54 | |

| Second Quarter | | | 7.29 | | | | 5.80 | |

| Third Quarter | | | 6.81 | | | | 5.66 | |

| Fourth Quarter | | | 6.78 | | | | 5.36 | |

| | | | | | | | | |

| Fiscal 2009 | | | | | | | | |

| First Quarter | | $ | 12.51 | | | $ | 8.93 | |

| Second Quarter | | | 11.34 | | | | 8.26 | |

| Third Quarter | | | 7.82 | | | | 4.33 | |

| Fourth Quarter | | | 6.25 | | | | 4.12 | |

Stockholders

As of April 30, 2010, there were approximately 754 record holders of our Common Stock. A substantial majority of our shares are held by brokers and other institutions on behalf of individual stockholders.

Dividends

We have never paid cash dividends on our Common Stock. We currently plan to retain any future earnings for use in our business and do not currently anticipate paying cash dividends in the foreseeable future.

Issuer Purchases of Equity Securities

The following table sets forth information with respect to repurchases of our common stock during the fourth quarter of fiscal 2010:

| Period | | Total Number of Shares Purchased | | | Average Price Paid Per Share | | | Total Number of Shares Purchased as Part of Publicly Announced Plans or Programs | | | Approximate Dollar Value of Shares that May Yet Be Purchased Under the Plans or Programs | |

| December 28, 2009 – January 24, 2010 | | | 237,200 | | | $ | 6.48 | | | | 237,200 | | | $ | 73,010,468 | |

| January 25, 2010 – February 21, 2010 | | | 1,321,600 | | | $ | 5.68 | | | | 1,321,600 | | | $ | 65,476,001 | |

| February 22, 2010 – March 28, 2010 | | | 2,047,900 | | | $ | 5.82 | | | | 2,047,900 | | | $ | 53,524,736 | |

| Total | | | 3,606,700 | | | $ | 5.81 | | | | 3,606,700 | | | | | |

On January 18, 2007, our Board of Directors initiated a $200 million share repurchase program. During fiscal 2008, our Board of Directors approved a $200 million expansion of the share repurchase program to a total of $400 million. In fiscal 2008, we repurchased approximately 28.9 million shares at an average price of $11.60 per share for a total purchase price of $334.8 million. On April 30, 2008, our Board of Directors approved an additional $100 million expansion of the share repurchase program to a total of $500 million. In fiscal 2009, we repurchased approximately 8.4 million shares at an average price of $7.46 per share for a total purchase price of $62.3 million. In fiscal 2010, we repurchased approximately 4.2 million shares at an average price of $5.83 per share for a total purchase price of $24.3 millio n. As of March 28, 2010, approximately $53.5 million was available for future purchase under the share repurchase program. Share repurchases were recorded as treasury stock and resulted in a reduction of stockholders’ equity.

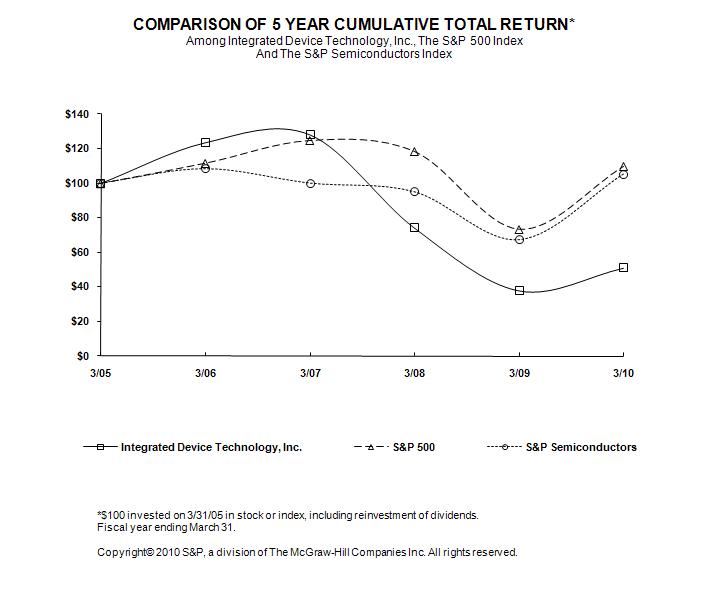

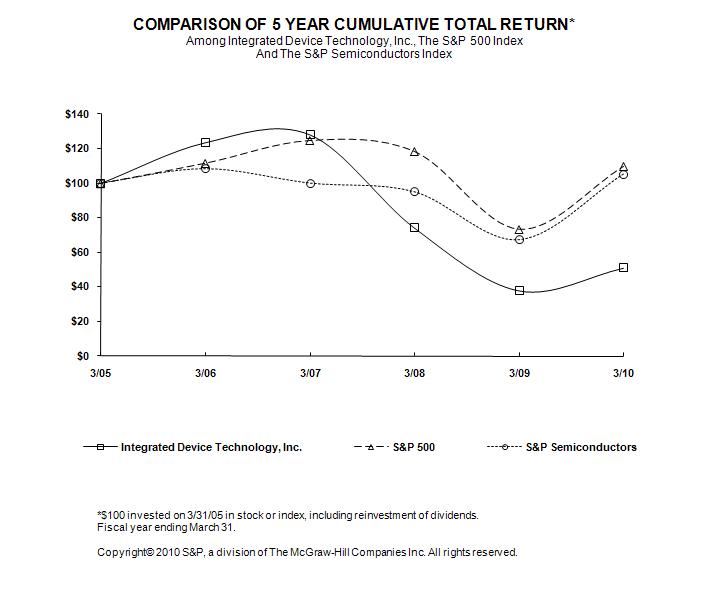

Stock Performance Graph

Set forth below is a line graph comparing the percentage change in the cumulative total stockholder return on our common stock against the cumulative total return of the S&P 500 Index and the S&P Electronics (Semiconductors) Index for a period of five fiscal years. Our fiscal year ends on a different day each year because our year ends at midnight on the Sunday nearest to March 31 of each calendar year. However, for convenience, the amounts shown below are based on a March 31 fiscal year end. “Total return,” for the purpose of this graph, assumes reinvestment of all dividends.

The performance of our stock price shown in the following graph is not necessarily indicative of future stock price performance.

| Cumulative Total Return | |

| | | 2005 | | | 2006 | | | 2007 | | | 2008 | | | 2009 | | | 2010 | |

| Integrated Device Technology, Inc. | | $ | 100.00 | | | $ | 123.52 | | | $ | 128.18 | | | $ | 74.23 | | | $ | 37.82 | | | $ | 50.96 | |

| S&P 500 | | $ | 100.00 | | | $ | 111.73 | | | $ | 124.95 | | | $ | 118.60 | | | $ | 73.43 | | | $ | 109.97 | |

| S&P Semiconductor index | | $ | 100.00 | | | $ | 108.31 | | | $ | 99.99 | | | $ | 94.97 | | | $ | 67.27 | | | $ | 105.27 | |

ITEM 6. SELECTED FINANCIAL DATA

The data set forth below are qualified in their entirety by reference to, and should be read in conjunction with, "Management's Discussion and Analysis of Financial Condition and Results of Operations" and the Consolidated Financial Statements and related notes thereto included in this Annual Report on Form 10-K.

Statements of Operations Data

| | | Fiscal Year Ended | |

(in thousands, except per share data) | | March 28, 2010 | | | March 29, 2009 | | | March 30, 2008 | | | April 1, 2007 | | | April 2, 2006 | |

| Revenues | | $ | 535,906 | | | $ | 663,245 | | | $ | 781,467 | | | $ | 803,596 | | | $ | 527,778 | |

| Research and development expenses | | | 157,486 | | | | 161,192 | | | | 165,599 | | | | 166,433 | | | | 127,591 | |

| Selling, general and administrative | | | 107,037 | | | | 125,810 | | | | 161,708 | | | | 191,211 | | | | 142,518 | |

| Goodwill and intangible assets impairment | | | -- | | | | 1,025,685 | | | | -- | | | | -- | | | | -- | |

| Operating income (loss) | | | (39,616 | ) | | | (1,043,835 | ) | | | 12,025 | | | | (17,496 | ) | | | (94,842 | ) |

| Net Income (loss) | | $ | 40,019 | | | $ | (1,045,167 | ) | | $ | 34,179 | | | $ | (7,578 | ) | | $ | (81,708 | ) |

| Basic net income (loss) per share | | | 0.24 | | | | (6.22 | ) | | | 0.18 | | | | (0.04 | ) | | | (0.52 | ) |

| Diluted net income (loss) per share | | | 0.24 | | | | (6.22 | ) | | | 0.18 | | | | (0.04 | ) | | | (0.52 | ) |

| Shares used in computing net income (loss) per share: | | | | | | | | | | | | | | | | | | | | |

| Basic | | | 165,408 | | | | 168,114 | | | | 187,213 | | | | 198,106 | | | | 157,345 | |

| Diluted | | | 165,961 | | | | 168,114 | | | | 189,260 | | | | 198,106 | | | | 157,345 | |

Balance Sheets and Other Data

(in thousands, except employee data) | | March 28, 2010 | | | March 29, 2009 | | | March 30, 2008 | | | April 1, 2007 | | | April 2, 2006 | |

| Cash, cash equivalents and investments (1) | | $ | 343,189 | | | $ | 296,073 | | | $ | 239,191 | | | $ | 359,933 | | | $ | 295,973 | |

| Total assets | | | 750,945 | | | | 678,367 | | | | 1,783,253 | | | | 2,041,732 | | | | 2,037,691 | |

| Other long-term obligations | | | 21,833 | | | | 14,314 | | | | 18,364 | | | | 16,001 | | | | 15,581 | |

| Stockholders' equity | | $ | 599,740 | | | $ | 557,068 | | | $ | 1,620,822 | | | $ | 1,839,090 | | | $ | 1,858,199 | |

| Number of employees | | | 2,004 | | | | 2,112 | | | | 2,353 | | | | 2,400 | | | | 2,700 | |

(1) Cash, cash equivalents and investments exclude equity investments not classified as available for sale.

ITEM 7. MANAGEMENT'S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS

The following discussion and analysis should be read in conjunction with “Item 6. Selected Financial Data” and “Item 8. Financial Statements and Supplementary Data”, included elsewhere in this Annual Report on Form 10-K.

The information in this Annual Report contains forward looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. Any statements contained herein that are not statements of historical facts may be deemed to be forward-looking. Forward-looking statements are based upon current expectations that involve a number of risks and uncertainties. These risks and uncertainties include, but are not limited to: operating results; new product introductions and sales; competitive conditions; capital expenditures and resources; manufacturing capacity utilization; customer demand and inventory levels; intellectual property issues; and the risk factors set forth in the section “Risk Factors” in Part I, Item 1A, of this Annual Report on Form 10-K. As a result of these risks and uncertainties, actual results and timing of events could differ significantly from those anticipated in the forward-looking statements. We undertake no obligation to publicly release any revisions to the forward-looking statements for future events or new information after the date of this Annual Report on Form 10-K.

Critical Accounting Policies

Our consolidated financial statements have been prepared in accordance with accounting principles generally accepted in the U.S. The preparation of such statements requires us to make estimates and assumptions that affect the reported amounts of revenues and expenses during the reporting period and the reported amounts of assets and liabilities as of the date of the financial statements. Our estimates and assumptions are based on historical experience and other factors that we consider to be appropriate in the circumstances. However, actual future results may vary from our estimates and assumptions.

We believe that the following accounting policies are "critical", as defined by the SEC, in that they are both highly important to the portrayal of our financial condition and results, and they require difficult management judgments, estimates and assumptions about matters that are inherently uncertain.

Revenue Recognition. Our revenue results from semiconductors sold through three channels: direct sales to original equipment manufacturers (OEMs) and electronic manufacturing service providers (EMSs), consignment sales to OEMs and EMSs, and sales through distributors. We recognize revenue when persuasive evidence of an arrangement exists, delivery has occurred or services have been rendered, the price is fixed or determinable and our ability to collect is reasonably assured. For direct sales, we recognize revenue in accordance with the applicable shipping terms. Revenue related to the sale of consignment inventory is not recognized until the product is pulled from inventory stock by the customer.