UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended March 31, 2006

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(D) OF THE SECURITIES EXCHANGE ACT OF 1934 FOR THE TRANSITION PERIOD FROM TO |

Commission File No. 0-14225

EXAR CORPORATION

(Exact Name of Registrant as specified in its charter)

| | |

| Delaware | | 94-1741481 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification Number) |

48720 Kato Road, Fremont, CA 94538

(Address of principal executive offices, Zip Code)

Registrant’s telephone number, including area code: (510) 668-7000

SECURITIES REGISTERED PURSUANT TO SECTION 12(b) OF THE ACT: NONE

SECURITIES REGISTERED PURSUANT TO SECTION 12(g) OF THE ACT:

COMMON STOCK

(Title of Class)

Indicate by check mark if the Registrant is a well-known seasoned issuer, as defined in Rule 405 the Securities Act. Yes ¨ No x

Indicate by check mark if the Registrant is not required to file reports pursuant to Section 13 or 15(d) of the Act. Yes ¨ No x

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the Registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See the definition of “accelerated filer and large accelerated filer” in Rule 12b-2 of the Exchange Act.

Large accelerated filer ¨ Accelerated filer x Non-accelerated filer ¨

Indicate by check mark whether the Registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ¨ No x

The aggregate market value of the voting stock held by non-affiliates of the Registrant as of September 30, 2005 was $494,074,109 based on the last sales price reported for such date as reported on The NASDAQ National Market.

The number of shares outstanding of the Registrant’s Common Stock was 35,942,845 as of May 31, 2006, net of treasury shares.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Company’s 2006 Definitive Proxy Statement to be filed not later than 120 days after the close of the 2006 fiscal year are incorporated by reference into Part III, Items 10, 11, 12, 13 and 14 of this Report.

EXAR CORPORATION AND SUBSIDIARIES

INDEX TO

ANNUAL REPORT ON FORM 10-K

FOR FISCAL YEAR ENDED MARCH 31, 2006

2

PART I

FORWARD LOOKING STATEMENTS

This Annual Report on Form 10-K (the “Annual Report”) contains forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended. Forward-looking statements are generally written in the future tense and/or may generally be identified by words such as “will,” “may,” “should,” “could,” “expect,” “suggest,” “believe,” “anticipate,” “intend,” “plan,” or other similar words. Forward-looking statements contained in this Annual Report include, among others, statements made in “Part II, Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations- “Outlook for Fiscal Year 2007” and elsewhere regarding (1) the Company’s market share and competitive position, (2) the Company’s revenue growth, (3) the Company’s belief that its success will continue to depend on its distributors and sales representatives, (4) the Company’s product enhancements (5) the Company’s design wins, (6) the Company’s gross profits, (7) the Company’s research and development efforts and related expenses, (8) the Company’s selling, general and administrative expenses (9) the Company’s belief that its cash and cash equivalents, short-term marketable securities and cash flows from operations will be sufficient to satisfy working capital requirements and capital equipment needs for at least the next 12 months, (10) the effect of interest rates on the Company’s interest income, (11) the Company’s anticipation that it will continue to finance operations with cash flows from operations, existing cash and investment balances, and some combination of long-term and/or lease financing and additional sales of equity securities and (12) the possibility of future acquisitions and investments. Actual results may differ materially from those projected in the forward-looking statements as a result of various factors. Factors that could cause actual results to differ materially from those included herein include, but are not limited to: the information contained under the captions “Part I, Item 1. Business,” “Part I, Item 1A. Risk Factors” and “Part II, Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations.” The Company disclaims any obligation to update information in any forward-looking statement.

Overview

Exar Corporation (“Exar” or the “Company”) designs, develops and markets high-performance, high-bandwidth physical interface and access control solutions that facilitate the aggregation and transport of signals in access, metro and wide area networks over the worldwide communications infrastructure. The Company’s industry-proven analog and digital design expertise, system-level knowledge and standard complementary metal oxide semiconductors (“CMOS”) process technologies provides original equipment manufacturers (“OEMs”) with innovative, highly integrated circuits (“ICs”) addressing standards such as T/E carrier, ATM, SONET/SDH and Multi-Protocol Over SONET (“MPOS”). In addition, the Company has developed a portfolio of clock products that address various system needs for clock generation, distribution, skew adjustment and fail-safe applications. The clock and timing product lines leverage Exar’s phase locked-loop (“PLL”) technology that is used extensively in its existing network and transmission products. The clock and timing products are targeted at wireless base stations, network switches and routers.

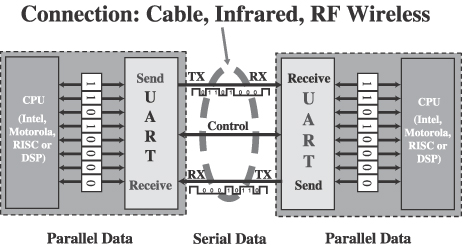

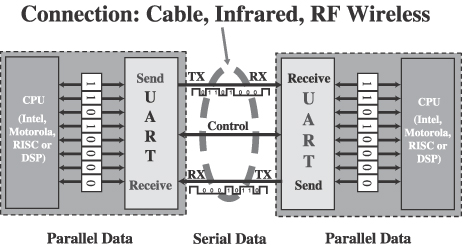

The Company also provides a comprehensive family of serial communications solutions comprised of low voltage, single/multi-channel universal asynchronous receiver transmitters (“UARTs”). UARTs are well suited to increase data transfer efficiency for various industrial, telecommunications and consumer applications.

The Company designs and markets IC products that address select applications for the video and imaging markets. Late in fiscal year 2006, Exar introduced its first SATA/SAS Port-Multiplier product addressing the storage marketplace.

Exar was incorporated in California in 1971 and reincorporated in Delaware in 1991. Exar’s common stock trades on The NASDAQ National Market (“NASDAQ”) under the symbol “EXAR”. See the information in “Part II, Item 8,

3

Financial Statements and Supplementary Data” for information on the Company’s financial position as of March 31, 2006 and 2005 and its results of operations and cash flows for the periods ended March 31, 2006, 2005 and 2004.

Exar believes its broad product offerings provide its customers the following benefits:

| | • | | increased bandwidth through the integration of multiple channels on a single device; |

| | • | | reduced system noise/jitter to improve data integrity; |

| | • | | a single source for a full range of transceivers, mappers and framer solutions and transmission rates; |

| | • | | reduced overall system cost and size through the integration of multiple functions on a single device; |

| | • | | accelerated time-to-market by allowing customers to focus on core competencies and outsource standards-based solutions; and |

| | • | | unique value added features and functions. |

Key elements of the Company’s solution include:

Commitment to Connectivity. Exar remains steadfast in its commitment to connectivity—a strategic principle that drives Exar’s product strategies and serves as a foundation for customer and vendor engagements. Connectivity describes our distinctive approach in creating and providing value to our shareholders, employees, customers and suppliers.

Leading Analog and Mixed-Signal Design Expertise. Exar has approximately thirty-five years of proven technical competency in developing analog and mixed-signal ICs. As a result, the Company has developed deep expertise in these areas and a comprehensive library of design elements. For example, the Company believes that it has particularly strong expertise in the design of high-speed, low-jitter phase-locked loops, which are key elements in its mixed-signal transceiver, jitter attenuator, data aggregation mapper products and clock devices. As a result, Exar can provide its customers with solutions that typically exceed standard specifications and allow them flexibility in designing other system elements.

Comprehensive Solutions to Enhance System Integration. The combination of Exar’s design and system-level expertise allows it to provide a comprehensive solution that encompasses hardware, software and applications support. Exar believes that, by using its solutions, OEMs can efficiently integrate the Company’s devices into their systems, better leverage their development resources and reduce their time-to-market.

Compelling Performance Solutions. The Company uses its systems expertise and its analog, digital and mixed-signal design techniques to architect high-performance products based on standard CMOS process technologies. Exar believes that these CMOS processes are proven, stable, predictable and able to meet its customers’ speed, power and performance requirements at a competitive price point.

The Company’s OEM customers include, among others, Adtran Inc. (“Adtran”), Alcatel, Cisco Systems Inc. (“Cisco”), Digi International, Inc. (“Digi International”), Fujitsu Limited (“Fujitsu”), Hewlett-Packard Company (“Hewlett-Packard”), Huawei Technologies Company, LTD. (“Huawei”), ITT Industries, Inc. (“ITT”), Lucent Technologies, Inc. (“Lucent”), Ericsson/Marconi, Mitsubishi Electronic Corporation of Japan (“Mitsubishi Electronics”), NEC Corporation (“NEC”), Nokia Corporation (“Nokia”), Plantronics, Inc. (“Plantronics”), Siemens A.G. (“Siemens”), and Tellabs, Inc. (“Tellabs”). For the fiscal year ended March 31, 2006, Alcatel represented 10.5% of the Company’s net sales.

Industry Background

Communications

The communications industry, and its underlying technology, has gone through a significant transformation during the last several years. It has been driven by the continuing adoption of broadband, and the increasing

4

consumer demand for more services delivered at ever-faster speeds. This phenomenon has changed the complexion of the market, and the companies that support it. The industry is typified by increasing competition with the convergence of telecommunication and cable/satellite operators expanding to offer telecommunications, Internet and video services. Recently, the telecommunication industry has experienced consolidation as surviving carriers acquire wireline and wireless networks to compete with expanded coverage and services.

The network infrastructure—a highway of interconnections—must transmit varied traffic (voice, data and video) at different speeds over the Internet. To accomplish this, OEMs are designing complex ICs in multi-service equipment leveraging industry standard protocols and high data transmission speeds enabling networks to communicate with each other. In North America, the high-speed data traffic standard is Synchronous Optical Network (“SONET”), and in most of the rest of the world, it is Synchronous Data Hierarchy (“SDH”). Over optical fiber, the SONET/SDH standard ensures network reliability, data integrity and the interoperability of equipment deployed across the network from different manufacturers. Additionally, carriers are ramping up triple play services (voice, data and video) over converged wireless and wireline infrastructure using standards-based Multi-protocol over SONET/SDH solutions and on “greenfield” deployments using native Ethernet based technologies, while making sure that reliable and seamless services are offered across these multiple inter-networking domains. Beyond the wireline infrastructure, wireless services have also evolved during this period with more carriers offering consumers advanced capabilities such as video conferencing and wireless TV services.

The combined effect of all of these changes in the telecommunications market is driving IC manufacturers to increase the bandwidth supported by their devices by providing vertical integration (more functionality) and horizontal integration (more channels). This push to more cost effective devices in turn is increasing the adoption rate of these services in both the established and emerging markets. The Company believes that IC companies with analog and digital design expertise and a deep understanding of system-level applications will have a competitive advantage in this changing market environment.

Storage

The need for reliable and cost effective storage technologies has increased almost exponentially with the increased volume of data transmitted over the Internet. This data now includes critical business and personal information, which in many cases no longer has paper back-up.

This increase in the volume of data is already pushing IC manufacturers to constantly augment the throughput of their devices to data rates of three gigabytes per second and higher. The critical nature of the data is also pressuring IC manufacturers to pay constant attention to the performance of these devices especially at the physical layer.

Data reliability and security is improved by distributing the storage functionality across multiple hosts and drives. This method includes deploying port multipliers that provide access to multiple disk drives by a single host and deploying port selectors that allow multiple hosts to access a single drive. In some cases, both the port multiplier and port selector functionality is implemented in a single system that addresses both the reliability and redundancy requirements of a storage system.

Clock and Timing

During the past several years, clock and timing products have played a more ubiquitous and critical role within digital systems. The appetite of consumers for digital entertainment and instant global connectivity, and the drive for complex data processing require a broad range of timing solutions. This change in system dynamics is fueling the need to support higher speed synchronization and communication between complex microprocessors, memory, application specific integrated circuits (“ASICs”), and other elements on the system board. To effectively facilitate gigabyte rates in communications systems, clock and timing solutions now have to provide very high frequencies combined with stringent jitter performance.

5

Consumer applications such as set top boxes and digital televisions require timing solutions that provide a high level of flexibility in terms of frequencies and programmability. Computing systems also need clocks and buffers that can manage vast arrays of memory within sophisticated workstations and servers. The timing market has to keep pace with these diverse applications that are driving the volumes and sophistication of clock synthesizers and related products.

Serial Communications

The move from parallel to serial interfaces for chip-to-chip or system-to-system interconnects is required to address the needs of the fastest-growing data communications markets. By converting parallel links into serial links, UARTs play a vital role in reducing the large number of wires and traces in legacy designs. In addition to this conversion, a UART offers additional benefits by off loading functions such as interrupt processing and data flow control from the CPU, which results in increased bandwidth.

UARTs are used in a wide range of communications equipment for control and diagnostics functions. UARTs are also used in system management to monitor Quality of Service (“QoS”) information, or to provide redundancy in fault tolerant systems. The Company’s highly integrated single/multi-channel UARTs have been specifically designed for communication systems with high throughput. These include servers, routers, network management equipment, computer telephony, remote access servers, wireless base stations and repeaters.

Multi-channel UARTs are commonly used in industrial applications such as process control and factory automation. Point-of-sale host systems often communicate to multiple remote terminals and self-service pumps at gas/petrol stations. These environments will typically have 8 to 32 (RS-232 or RS-485) ports by using multiple UARTs for communications.

Single and multi-channel UARTs are used in portable consumer applications such as multi-media products, Global Positioning System (“GPS”) and Personal Digital Assistant (“PDA”) devices. Products such as smart phones and PDAs utilize multiple serial interfaces to connect to Bluetooth, compact flash, IrDA, serial docking interface and GPS receivers for wireless or wired interface to global positioning systems. When a Bluetooth or GPS receiver is not integrated in the device, an external module can easily be connected via the UART interface in most applications. The Company’s UARTs are well suited for battery-operated applications that require mobility such as handheld data entry devices, security alarm and point-of-sale terminals.

Strategy

Exar strives to be a leading provider of physical layer high-performance, high-bandwidth IC solutions for use in the worldwide communications infrastructure. The Company also designs, develops and markets IC products that address the needs of the serial communications market. To achieve its business objectives, the Company employs the following strategies:

Focus on Growing Market Share within the Communications Markets. Exar targets communications markets, including T/E carrier, ATM, SONET/SDH and MPOS. The Company has built substantial expertise in the areas of analog and digital design, systems architecture and applications support. Exar believes that the integration of these capabilities enables the Company to develop solutions addressing the high-bandwidth physical layer requirements of communications systems OEMs. The Company’s broad product offerings support differentiated features that the Company believes will enable it to increase its market share. Additionally, the Company seeks to expand its markets by incorporating adjacent functionality into its products.

Leverage Analog and Mixed-Signal Design Expertise to Provide Integrated System-Level Solutions. Utilizing its strong analog and mixed-signal design expertise, the Company integrates mixed-signal physical interface devices with digital access control devices. The Company offers products that integrate transceivers, jitter attenuators and

6

framers/ATM UNIs on a single IC. The Company’s data aggregation devices leverage its T/E carrier and SONET/SDH expertise, mapping multiple T3 data streams into a single SONET/SDH stream. These configurations enable OEMs to use less board space and reduce their overall system cost. In the last two years, the Company has utilized its PLL expertise to introduce new clock products for communications and server applications. Lastly, the Company expanded its mixed-signal expertise to solve signal integrity design challenges in the storage market with the introduction of SATA/SAS port multipliers.

Expand the Company’s Revenue Content Per System. Exar’s analog and mixed-signal design expertise has enabled the Company to build what it believes to be a technological advantage in T/E transceivers and framers and SONET mapping and aggregation. The Company intends to leverage this advantage and its established customer relationships to capture design wins for its physical layer products, thereby increasing the Company’s overall revenue content per system.

Strengthen and Expand Strategic OEM Relationships. Exar’s OEM customers include Alcatel, Cisco, Digi International, Hewlett-Packard, Huawei, Lucent, Marconi/Ericsson, NEC, Nokia and Tellabs. To promote the early adoption of its solutions, the Company actively seeks collaborative relationships with strategic OEMs during product development. The Company believes that OEMs recognize the value of Exar’s early involvement because designing their system products in parallel with the Company’s development can accelerate time-to-market for their end products. In addition, Exar believes that collaborative relationships help the Company to obtain early design wins and to increase the likelihood of market acceptance of its new products.

Leverage Broad Product Portfolio to Accelerate Communications Product Development. Exar believes it has developed a strong presence in the serial communications market, where the Company has leading industry customers and proven technological capabilities. The Company’s design expertise has enabled it to offer a diverse portfolio of both industry standard and proprietary serial communications products. The Company plans to expand this portfolio by developing integrated solutions that extend the reach of its offerings into new input/output applications. In addition, the Company has further expanded its communications portfolio by offering a family of clock devices, which leverage technology common with its existing network and transmission products.

Use Standard CMOS Process Technologies to Provide Compelling Price/Performance Solutions. Exar designs its products to be manufactured using standard CMOS processes. The Company believes that these processes are proven, stable and predictable and benefit from the extensive semiconductor-manufacturing infrastructure devoted to CMOS processes. Therefore, the Company believes that it can achieve a higher level of performance at a lower cost than competitors’ products based on alternative manufacturing technologies. However, in certain specialized cases the Company may use other process technologies to take advantage of their performance characteristics.

Leverage Fabless Semiconductor Model. Exar has long-standing relationships with third-party assembly, test and wafer foundries to manufacture the Company’s ICs. The Company’s fabless approach allows it to avoid substantial capital spending, obtain competitive pricing, minimize the negative effects of industry cycles, reduce time-to-market, reduce technology and product risks, and facilitate the migration of the Company’s products to new CMOS process technologies, which reduces costs and power consumption and optimizes performance. By leveraging the fabless model, Exar can focus on its core competencies of sales and marketing as well as product design, development and support.

Products

Communications

Exar’s products for T/E carrier, ATM, SONET/SDH and MPOS applications include high-speed analog, digital and mixed-signal physical interface and access control ICs. The physical interface IC consists of a transmitter and receiver that, when integrated, is called a transceiver. Transceivers interface with the physical transmission media. Most of these high-speed, mixed-signal ICs convert digital inputs in a parallel format into a

7

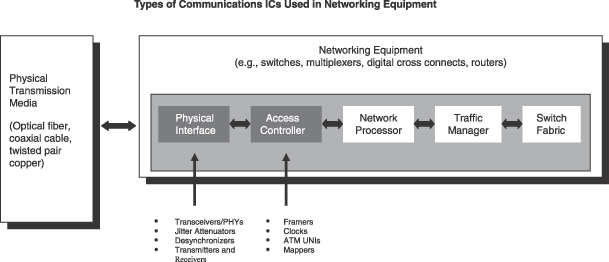

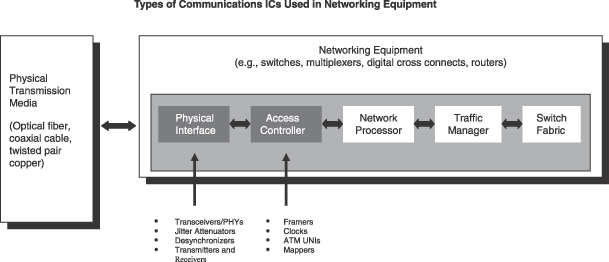

single bit stream that is many times faster than the original signal. Access control circuits are digital circuits that format, or frame, the data, perform error checking, and in some applications, aggregate signals by mapping multiple lower-speed data streams into one single higher-speed stream. The figure below illustrates where the Company’s products are employed within networking equipment.

Exar’s communications products include analog front ends (“AFEs”), transmitters, receivers, transceivers (also known as line interface units or “LIUs” or “PHYs”), jitter attenuators, framers, clocks, ATM UNIs and data aggregation mappers. These products are used in networking equipment such as SONET/SDH Add/Drop Multiplexers (“ADMs”), PBX, central office switches, digital cross connects, multi-service provisioning platforms, routers and Digital Subscriber Loop Access Multiplexes (“DSLAMs”).

T/E

Exar offers a broad range of products in the T1/E1 segment encompassing AFEs, short-haul and long-haul LIUs and LIU/framer combinations that incorporate reconfigurable, relayless, redundancy with integrated termination resistors and jitter attenuators. Used individually or in chip sets, Exar’s T1/E1/J1 devices offer customers key advantages including design flexibility, enhanced system reliability and standards compliance which are critical components of high-density, low-power system boards and line-cards. In addition, Exar’s T1/E1/J1 LIU combination products simplify the design process. Exar’s T1/E1 portfolio includes products with up to 21 channels of AFEs, up to 14 channels LIU/JA and up to 8 channel LIU/framer combinations.

Exar has developed a diversified portfolio of single/multi-channel T3/E3 physical interface solutions with integrated transceivers and jitter attenuators, that achieve high performance levels while reducing board space and overall power in multi-port applications. Extending its jitter attenuation capabilities, Exar incorporates desynchronization in its transceivers and data aggregation mappers to solve complex timing issues associated with mapping/demapping from SONET/SDH (synchronous) to T3/E3 (asynchronous) environments. In addition, the Company has integrated its LIU and framer functions into its multi-channel DS3/E3 LIU/Framer/JA combination device that offer customers additional design flexibility.

The Company also supplies a family of V.35 transceiver products used for data transmission, primarily in networking equipment such as routers and bridges.

SONET/SDH

Exar’s data aggregation mapper solutions leverage the Company’s expertise in T/E carrier with SONET/SDH, enabling the Company to provide unique solutions to the SONET/SDH market place. In addition to

8

integrating SONET PHY capability into its data aggregation mappers, the Company also offers OC-3/12/48 PHYs and plans to complement these devices with additional OC-48 data aggregation solutions. Exar’s access control products include framers and ATM UNIs, in addition to its data aggregation mappers. Complementing Exar’s OC-3 to OC-48 SONET/SDH devices was the addition of a highly integrated and innovative OC-3/STM-1 to OC-192/STM-64 multi-rate framer. This product extends Exar’s SONET/SDH capabilities to cover all data rates starting from OC-3/STM-1 to OC-192/STM-64. In addition, the device enables significant flexibility in line card design coupled with substantial cost and power savings. Exar extended its mixed-signal technology leadership into next generation metro core and transport network markets with the introduction of the first in a family of multi-protocol over SONET/SDH framers. Deployment of these devices is ideal for the growing market shift towards the convergence of triple-play services over SONET/SDH.

Clock and Timing

Whether regulating data transmissions or executing system instructions, clocks perform the critical role of producing precisely timed and repeated pulses that synchronize the overall system or other embedded applications. In fiscal year 2004, Exar introduced a family of five new clock products targeted at high-performance system boards, offering flexibility to board designers by providing them with precision, low jitter, programmable skew, zero delay and fan out buffers. These were followed in fiscal year 2005 by a series of Intelligent Dynamic Clock Switch (“IDCS”) devices. These products offer features including dynamic switch, manual override, on-board redundancy and fail-safe operations plus other features that enable customers to easily develop applications that increase over-all system reliability. In fiscal year 2006, the Company further expanded its clock products by introducing several families of high performance, industry standard Zero Delay Buffers (“ZDB”) for the timing market segment. These ZDB devices are instrumental for effective distribution of clock signals across a printed circuit board’s (“PCBs”) timing topology. They have ubiquitous applications within all key market segments including networking, computation and consumer applications.

Storage

Market demand is driving the need for increased storage capacity for a host of consumer, home media, and industrial applications where cost effective, dense storage is a requirement. There are many approaches to data storage deployment: Storage Area Network (“SAN”), Direct Attached Storage (“DAS”), Network Attached Storage (“NAS”), Redundant Array of Inexpensive Disks (“RAID”) and Just a Bunch of Disks (“JBOD”). Each of these will support unique configurations (number of disk drives) and locations (internal to the system, or connected externally to an enclosure). Connecting to all of these storage environments entails supporting industry-adopted protocols including Serial Advanced Technology Attachment (“SATA”) and Serial Attached SCSI (“SAS”), among others. The SATA I/II specifications were recently standardized as a serial interconnect technology of choice between advanced host controllers and storage drives. Exar’s SATA/SAS port multipliers enable distribution of data across multiple disk drives from a single host. Exar’s port selectors enable multiple hosts to access a single drive. These approaches ensure greater data reliability and security.

Serial Communications

As a leader of UART solutions, Exar offers a broad line of industry-proven product families. Exar’s product portfolio consists of single, dual, quad and octal channel devices with enhanced feature sets, and a broad range of packaging options. These products provide an easy migration path from one product generation to the next. All are highly integrated UARTs that the Company believes are the defacto industry standard for UARTs with First-In First-Out (“FIFO”) used in multi-port applications. In fiscal year 2006, Exar introduced four innovative solutions: a multi-channel 66MHz PCI 3.0 compliant UART family, a small UART (5x5x0.9mm); 1.8 Volt single-channel UART in 24 and 32-pin QFN packages; and a dual-channel 66MHz PCI 3.0 compliant device. Collectively, these innovative products provide immediate competitive advantages to designers. Utilization of Exar’s devices accelerate time-to-market and performance capabilities by reducing development time and addressing the growing need for board space savings, lower power, and increased bandwidth requirements for communications, industrial and consumer applications.

9

During fiscal year 2006, the Company developed an integrated 8-bit UART and RS-232 Transceiver device, the first in a family of innovative Combo devices for introduction in fiscal year 2007. By integrating these two functions into a simple space saving package, the series targets the growing market demand of consumer and battery powered applications including laptops and portable devices; desktop PCs; and industrial peripheral interfaces such as handheld terminals and Point-of-Sale (“POS”) systems, amongst others.

Exar sells its UART products to the remote access, data collection, industrial automation, point-of-sale, handheld/mobile and consumer markets.

Video and Imaging

Exar supplies high-performance analog-to-digital converters, and integrated analog front ends, for products such as copiers and scanners, digital still cameras, and multifunctional peripherals. These ICs incorporate scanning, faxing, copying and printing functions in a single integrated system. The Company uses advanced design techniques and process technologies to integrate low-power converter architectures with surrounding analog functions, thereby reducing system costs.

Sales and Customers

The Company markets its products globally through both direct and indirect channels. In North and South America through 21 independent sales representatives and two independent, non-exclusive primary distributors, as well as the Company’s own direct sales organization. The Company currently has domestic support offices in or near Atlanta, Boston, Chicago, Dallas, Los Angeles and Fremont, California. Additionally, the Company is represented in Europe and the Asia/Pacific region by its wholly-owned foreign subsidiaries and international support offices in Vallauris, France; Kawasaki, Japan; and Shanghai, China. In addition to these Exar offices, 21 independent sales representatives and other independent, non-exclusive distributors represent the Company in Europe and the Asia/Pacific region. The Company’s international sales represented 51.3%, 50.9% and 53.5% of net sales for the fiscal years ended March 31, 2006, 2005 and 2004, respectively.

10

The Company’s OEM customers include, among others, the following:

| | |

| Communications | | Serial and Other Communications |

• Adtran • Alcatel • Cisco • Huawei • Lucent • Marconi/Ericsson • NEC • Nokia • Siemens • Tellabs | | • Cisco • Digi International • Fujitsu • Plantronics • Hewlett-Packard • Huawei • Mitsubishi Electronics |

Alcatel accounted for 10.5% of the Company’s net sales for the fiscal year ended March 31, 2006. For the fiscal years ended March 31, 2005 and 2004, no OEM customer accounted for 10% or more of the Company’s net sales. The Company sells its products to distributors and OEMs throughout the world. For the year ended March 31, 2006, worldwide sales through the Company’s two primary distributors for subsequent resale to OEMs or their subcontract manufacturers accounted for 40.0% of net sales. Future Electronics (“Future”) was and continues to be the Company’s largest primary distributor. Future, on a worldwide basis, represented 24.1%, 20.4% and 20.3% of net sales in fiscal years 2006, 2005 and 2004, respectively. The Company’s second largest primary distributor, Nu Horizons Electronics Corp. (“Nu Horizons”), accounted for 15.9%, 16.4% and 13.4% of net sales in fiscal years 2006, 2005 and 2004, respectively.

Manufacturing

Exar outsources all of its fabrication and assembly, as well as the majority of its testing operations. This fabless manufacturing model allows the Company to focus on its core competencies of sales and marketing as well as product design, development and support.

The majority of the Company’s current products are implemented in standard CMOS. The Company uses CMOS manufacturing processes to take advantage of that technology’s lower power consumption, cost-effectiveness, foundry availability and ever-increasing speed. Chartered Semiconductor Manufacturing Ltd. (“Chartered”) manufactures the majority of the Company’s CMOS semiconductor wafers from which the Company’s products are manufactured. The Company does not have long-term supply agreements with its suppliers. See“Part I, Item 1A Risk Factors.”

Most semiconductor wafers are shipped to the Company’s subcontractors in Asia for wafer test and assembly, where they are cut into individual die and packaged. Independent contractors in Hong Kong, Indonesia and the Philippines perform most of the Company’s assembly work. Following assembly, final test and quality assurance are performed either at the Company’s Fremont, California facility or at its subcontractors’ facilities in Asia.

Research and Development

Exar believes that ongoing innovation and the introduction of new products in its targeted and adjacent markets is essential to sustaining growth. Exar’s research and development is focused on developing high-performance analog, digital and mixed-signal solutions addressing the high-bandwidth requirements of both communications and storage systems OEMs. Exar continues to make significant investments in advanced design tools and high-performance standard cell libraries. By utilizing these tools, the Company pursues the development of design methodologies that are optimized for reducing design-cycle time and increasing the

11

likelihood of first-time successes. In order to support high pin-count devices, the Company continues to develop high-performance packages for its new products in collaboration with packaging suppliers. Exar spent $24.7 million, $22.0 million and $21.8 million on research and development in fiscal years 2006, 2005 and 2004, respectively.

Competition

The semiconductor industry is intensely competitive and is characterized by rapid technological change and a history of price reductions as production efficiencies are achieved in successive generations of products. Although the market for analog and mixed-signal integrated circuits is generally characterized by longer product life cycles and less dramatic price reductions than the market for digital integrated circuits, the Company faces substantial competition in each market in which it participates. Competition in the Company’s markets is based principally on technical innovation, product features, timely introduction of new products, quality and reliability, performance, price, technical support and service. The Company believes that it competes favorably in all of these areas.

Because the IC markets are highly fragmented, the Company generally encounters different competitors in its various target markets. Competitors with respect to the Company’s communications products include Agere Systems, Applied Micro Circuits Corporation, Infineon Technologies North America Corp., Integrated Device Technology, Inc., Mindspeed Technologies, Inc., PMC Sierra, Inc., TranSwitch Corporation and Vitesse Semiconductor Corporation. Competitors in the clock products area include Cypress Semiconductor and Integrated Device Technology, Inc. Competitors in the Company’s serial communications and video and imaging markets include Royal Philips Electronics, Texas Instruments Incorporated and Wolfson Microelectronics LTD.

Backlog

Exar defines backlog to include OEM orders and distributor orders for which a delivery schedule has been specified for product shipment occurring during the succeeding six months. As of March 31, 2006, Exar’s backlog was $14.6 million, compared to $9.6 million as of March 31, 2005.

The Company’s business and, to a large extent, that of the semiconductor industry, has been characterized by short order-to-shipment schedules. Sales are made pursuant to either purchase orders for current delivery of standard items or agreements covering purchases over a period of time, which are frequently subject to revisions and cancellations. Lead times for the release of purchase orders depend on the scheduling practices of the individual customer, and the Company’s rate of bookings varies from month-to-month. In addition, Exar’s domestic distributor agreements generally permit the return of up to 10% of purchases of the preceding quarter for purposes of stock rotation and also provide for credits to distributors in the event that Exar reduces the price of any inventoried product. Since orders constituting the Company’s backlog are subject to changes in delivery schedules or to cancellations at the option of the customer without significant penalty, backlog is not necessarily an indication of future sales. The Company believes that its backlog as of any particular date may not be representative of actual sales for any succeeding six month period.

Intellectual Property Rights

The Company has 113 patents issued and 26 patent applications pending in the United States. The Company has 18 patents issued and 34 patent applications pending in various foreign countries. The Company’s existing patents will expire between 2006 and 2023, or sooner if it chooses not to pay renewal fees. The Company believes that its intellectual property is critical to its current and future success. However, the Company does not believe that it is materially dependent upon any one patent. To protect its intellectual property, the Company also relies on a combination of mask work registrations, trademarks, copyrights, trade secrets, employee and third party nondisclosure agreements and licensing arrangements. The Company may enter into license agreements or other agreements to gain access to externally developed products or technologies.

12

The Company may fail to adequately protect its intellectual property. Others may gain access to the Company’s trade secrets or disclose such trade secrets to third parties. Some or all of the Company’s pending and future patent applications may not result in issued patents that provide it with a competitive advantage. Even if issued, such patents, as well as the Company’s existing patents, may be challenged and later determined to be invalid or unenforceable. In addition, others may develop similar or superior products without access to or without infringing upon the Company’s intellectual property, including intellectual property that is protected by trade secret and patent rights.

The Company cannot be sure that its products or technologies do not infringe patents that may be granted in the future pursuant to pending patent applications or that the Company’s products do not infringe any patents or proprietary rights of third parties. Occasionally, the Company is informed by third parties of alleged patent infringement. In the event that any relevant claims of third-party patents are found to be valid and enforceable, the Company may be required to:

| | • | | stop selling, incorporating or using its products that use the infringed intellectual property; |

| | • | | obtain a license to make, sell or use the relevant technology from the owner of the infringed intellectual property, although, such license may not be available on commercially reasonable terms, if at all; or |

| | • | | redesign the Company’s products so as not to use the infringed intellectual property, which may not be technically or commercially feasible or meet customer requests. |

If the Company were required to take any of the actions described above or defend against any claims from third parties, its business, financial condition and results of operations could be harmed. See“Part I, Item 1A. Risk Factors.”

Employees

As of March 31, 2006, the Company employed 255 full-time employees, with 118 in research and development, 44 in operations, 49 in marketing and sales and 44 in administration. Of the 118 research and development employees, 51 hold advanced degrees. The Company’s ability to attract, motivate and retain qualified personnel is essential to its continued success. See“Part I, Item 1A. Risk Factors”None of the Company’s employees is represented by a collective bargaining agreement, nor has the Company ever experienced a work stoppage due to labor issues. The Company believes its employee relations are good.

Available Information

The Company files electronically with the SEC its Annual Reports on Form 10-K, Quarterly Reports on Form 10-Q, current Reports on Form 8-K, and amendments to those Reports pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934. Those reports and statements (1) may be read and copied at the SEC’s public reference room at 100 F Street, N.E., Washington, DC 20549, (2) are available at the SEC’s internet site (http://www.sec.gov), which contains reports, proxy and information statements and other information regarding issuers that file electronically with the SEC and (3) are available free of charge through our website (www.exar.com) as soon as reasonably practicable after electronic filing with, or furnishing to, the SEC. Information regarding the operation of the SEC’s public reference room may be obtained by calling the SEC at 1-800-SEC-0330. Copies of such documents may be requested by contacting the Company’s Investor Relations Department at (510) 668-7201 or by sending an e-mail through the Investor Relations page on the Company’s website. The Company has adopted a Code of Business Conduct and Ethics for its principal executive officer, principal financial officer, principal accounting officer or controller, or persons performing similar functions. The Company has posted its Code of Business Conduct and Ethics on its website. Any future amendments to this code will also be posted to its website.

13

EXECUTIVE OFFICERS OF THE REGISTRANT

The names of the Company’s executive officers, and their ages as of March 31, 2006, are as follows:

| | | | |

Name | | Age | | Position |

Roubik Gregorian | | 56 | | President, Chief Executive Officer and Director |

Mir Bahram Ghaderi | | 54 | | Vice President and General Manager, Network and Transmission Products Division |

Ronald W. Guire | | 57 | | Executive Vice President, Chief Financial Officer, Assistant Secretary and Director |

Thomas R. Melendrez | | 52 | | General Counsel, Secretary and Vice President Business Development |

Levent Ozcolak | | 44 | | Division Vice President and General Manager, Interface Products |

Stephen W. Michael | | 59 | | Vice President, Operations and Reliability & Quality Assurance |

Roubik Gregorian joined the Company in 1995 as President, Startech Division, when the Company acquired Startech Semiconductor, Inc., where he had served as President. During Dr. Gregorian’s tenure at the Company, he was appointed Chief Technology Officer and Vice President of the Communications Division in 1996 and Chief Technology Officer, Senior Vice President/General Manager, Communications Division, in 1998. Dr. Gregorian was promoted to Executive Vice President/General Manager, Communications Division in 2002 and to Chief Operating Officer in 2003. Dr. Gregorian served as the Company’s acting President and Chief Executive Officer from September 2004 to February 2005, when he was appointed to his current position of President and Chief Executive Officer. Dr. Gregorian has been a director of the Company since March 2005. From 1983 to 1994, Dr. Gregorian served as Vice President of Research and Development and Chief Technology Officer for Sierra Semiconductor where he directed the company’s product strategy and product development activities including the data communications and graphic products which were instrumental in taking the company public in 1991. From 1977 to 1983, Dr. Gregorian was manager of analog and telecommunications products at American Microsystems where he received several awards including one for developing the industry’s first PCM CODEC. Dr. Gregorian has been issued 27 patents, authored two textbooks and 45 technical articles. He received his M.S.E.E. and Ph.D. in Electrical Engineering from the University of California at Los Angeles, as well as a M.Sc. from Tehran University in Electrical Engineering.

Mir Bahram Ghaderi joined the Company in March 1995 as Director of Engineering, Startech Division, when the Company acquired Startech Semiconductor, Inc., where he had served as Vice President of Engineering. He was promoted to Divisional Vice President of Engineering, Communications Division in September 2001, and to his current position as Vice President and General Manager, Network and Transmission Products Division, in April 2003. Prior to joining Startech in 1994, he was Director of Engineering, Modem/Clock Products, at Sierra Semiconductor, Inc. Dr. Ghaderi has 25 years of product development experience in the semiconductor industry and received a M.S.E.E. and Ph.D. in Electrical Engineering from the University of California at Los Angeles, as well as a M.S.E.E. from Tehran University.

Ronald W. Guire is the Executive Vice President, Chief Financial Officer, and Assistant Secretary for Exar. He joined the Company in 1984 as Vice President and Treasurer; in 1985 his title was changed to Vice President, Chief Financial Officer (CFO) and Secretary (until June 2001 when he became Assistant Secretary), and in 1995 Mr. Guire was named Executive Vice President. Mr. Guire has been a director of the Company since 1985. Mr. Guire was a partner in the certified public accounting firm of Graubart & Co. from 1979 until joining the Company. Mr. Guire is a member of the California Society of Certified Public Accountants and a member of Financial Executives International. Mr. Guire holds a B.S. in Accounting from California College of Commerce and has been a certified public accountant since 1977.

Thomas R. Melendrez joined the Company in April 1986 as Corporate Attorney. He was promoted to Director, Legal Affairs in July 1991, and again to Corporate Vice President, Legal Affairs in March 1993. In March 1996, Mr. Melendrez was promoted to Corporate Vice President, General Counsel. In June 2001, Mr. Melendrez was appointed Secretary of the Company. In April 2003, Mr. Melendrez assumed, in addition to

14

his other duties, the responsibilities of Vice President, Business Development. Mr. Melendrez has over 25 years of legal experience in the semiconductor and related industries. He received a B.A. from the University of Notre Dame, a J.D. from the University of San Francisco, and an M.B.A. from Pepperdine University.

Levent Ozcolakjoined the Company in 1985 after completing school as a Design Engineer. He held several engineering management positions prior to his promotion to Director of Engineering, Video and Imaging Division in 1998. Mr. Ozcolak was appointed Director of Marketing, Video and Imaging Division in 1999, and Director of Marketing, Interface Products Division in 2003. He was promoted to General Manager, Interface Products Division in 2004, and to his current position of Division Vice President and General Manager, Interface Products in 2005. Mr. Ozcolak has over 20 years of product development experience in the semiconductor industry and holds a B.S. in Electrical Engineering from the Massachusetts Institute of Technology and an M.S. in Electrical Engineering from the University of California at Los Angeles, as well as an M.B.A. from the University of Phoenix.

Stephen W. Michael joined Exar as Vice President New Market Development in September 1992. In July 1995, he was appointed Vice President Operations, and in May 2001, he was appointed to his current position of Vice President, Operations and Reliability & Quality Assurance. Mr. Michael has thirty years of semiconductor industry experience. Prior to joining Exar, Mr. Michael was Vice President and General Manager, Analog and Custom Products with Catalyst Semiconductor. Prior to joining Catalyst Semiconductor, he served in various senior positions at GE Semiconductor, Intersil, Fairchild and National Semiconductor. He holds a B.S. in Electrical Engineering from the University of California at Davis.

ITEM 1A. RISK FACTORS

We are subject to a number of risks. Some of these risks are endemic to the high-technology industry and are the same or similar to those disclosed in our previous SEC filings, and some new risks may arise in the future. You should carefully consider all of these risks and the other information in this Annual Report before investing in us. The fact that certain risks are endemic to the high-technology industry does not lessen the significance of these risks.

As a result of these risks, our business, financial condition or results of operations could be materially and adversely affected. This could cause the trading price of our common stock to decline, and stockholders might lose some or all of their investment.

IF WE ARE UNABLE TO GENERATE REVENUE ABOVE CURRENT LEVELS FROM THE SALE OF OUR COMMUNICATIONS PRODUCTS, OR OUR REVENUE FROM THESE PRODUCTS DECLINES, OUR BUSINESS, FINANCIAL CONDITION AND RESULTS OF OPERATIONS WILL BE MATERIALLY AND ADVERSELY IMPACTED.

We continue to focus a significant portion of our research and sales resources on the communications market with the expectation that the communications sector will grow over the long term. Given our dependence on the communications market to support revenue growth, we must continue to generate additional sales from this market by successfully marketing the existing product portfolio, introducing new products and securing design wins which are released into production or by gaining market share. If we are unable to generate increased revenue from our communications products or our revenue from these products declines, our business, financial condition, and results of operations will be materially and adversely impacted.

THE UNCERTAINTY IN THE U.S. AND GLOBAL ECONOMIES, AS WELL AS THE COMMUNICATIONS EQUIPMENT MARKET, MAY CONTINUE TO MATERIALLY AND ADVERSELY AFFECT OUR BUSINESS, FINANCIAL CONDITION AND RESULTS OF OPERATIONS.

Periodic declines or fluctuations in corporate profits, lower capital equipment spending, the impact of conflicts throughout the world, terrorist acts, natural disasters, the outbreak of communicable diseases such as the

15

Avian Flu and other geopolitical factors have had, and may continue to have, a negative impact on the U.S. and global economies. Our revenue and profitability have generally followed the modest recovery of the communications equipment industry. This modest recovery has affected carrier capital equipment spending which in turn has affected the demand for our customers’ products, thus affecting our revenues and profitability. Communications service providers and equipment manufacturers continue to experience consolidation in their industries. Although there currently appears to be positive signs for growth, further delay or reduction in anticipated communications equipment spending levels may adversely affect our business, financial condition and results of operations.

We are unable to predict the timing, strength or duration of the communications market recovery or effects of equipment manufacturer consolidation. If the sector does not continue to recover measurably, or declines, our business, financial condition and results of operations may be materially and adversely impacted.

IF WE FAIL TO DEVELOP AND INTRODUCE NEW PRODUCTS IN OUR CORE OR NEW MARKETS THAT MEET EVOLVING MARKET NEEDS, OUR BUSINESS, FINANCIAL CONDITION AND RESULTS OF OPERATIONS COULD BE MATERIALLY AND ADVERSELY IMPACTED.

The markets for our products are characterized by:

| | • | | evolving and competing industry standards; |

| | • | | changing customer requirements; |

| | • | | increasing costs of product development; |

| | • | | long design-to-production cycles; |

| | • | | frequent product introductions and enhancements; |

| | • | | increasing functional integration; |

| | • | | increasing price pressure; |

| | • | | moderate to slow growth; |

| | • | | capital equipment spending levels and/or deployment; and/or |

| | • | | changing competitive landscape (consolidation, financial conditions). |

Our success depends in part on the successful development of new products for our core markets. We must: (i) be able to anticipate customer and market requirements and changes in technology and industry standards; (ii) be able to accurately define and develop, on a timely basis, new products; (iii) be able to gain access to and use technologies in a cost-effective manner; (iv) continue to expand our technical and design expertise; (v) be able to timely introduce and cost-effectively have manufactured new products; (vi) be able to differentiate our products from our competitors’ offerings; and (vii) gain customer acceptance of our products. In addition, we must continue to have our products designed into our customers’ future products and maintain close working relationships with key customers to develop new products that meet their evolving needs. Moreover, we must be able to respond to shifts in market demands, the trend towards increasing functional integration and other changes in a rapid and cost-effective manner. Migration from older products to newer products may result in volatility of earnings during periods of transition of the products.

Products for communications applications are based on continually evolving industry standards and new technologies. Our ability to compete will depend in part on our ability to identify and ensure compliance with these industry standards. The emergence of new standards could render our products incompatible with systems

16

developed by major communications equipment manufacturers. As a result, we could be required to invest significant time, effort and expenses to develop and qualify new products to ensure compliance with industry standards.

The process of developing and supporting new products is complex, expensive and uncertain, and if we fail to accurately predict and understand our customers’ changing needs and emerging technological trends, our business may be harmed. We cannot assure that we will be able to identify new product opportunities successfully, develop and bring to market new products, achieve design wins, ensure when and which design wins actually get released to production, or respond effectively to technological changes or product announcements by our competitors. In addition, we may not be successful in developing or using new technologies or may incorrectly anticipate market demand and develop products that achieve little or no market acceptance. Our pursuit of necessary technological advances may require substantial time and expense and may ultimately prove unsuccessful. Failure in any of these areas may harm our business, financial condition and results of operations.

IF WE ARE UNABLE TO CONVERT A SIGNIFICANT PORTION OF OUR DESIGN WINS INTO ACTUAL REVENUE, OUR BUSINESS, FINANCIAL CONDITION AND RESULTS OF OPERATIONS COULD BE MATERIALLY AND ADVERSELY IMPACTED.

We have secured a significant number of design wins for new and existing products. Such design wins are necessary for revenue growth. However, many of our design wins may never generate revenues if their end-customer projects are unsuccessful in the market place or the end-customer terminates the project, which may occur for a variety of reasons. Additionally, some of our design wins are with privately-held, early-stage companies that may fail to bring their product to market. If design wins do generate revenue, the time lag between the design win and meaningful revenue may be in excess of eighteen months. If we fail to convert a significant portion of our design wins into substantial revenue, our business, financial condition and results of operations could be materially and adversely impacted.

OUR FINANCIAL RESULTS MAY FLUCTUATE SIGNIFICANTLY BECAUSE OF A NUMBER OF FACTORS, MANY OF WHICH ARE BEYOND OUR CONTROL.

Our financial results may fluctuate significantly. Some of the factors that affect our financial results, many of which are difficult or impossible to control or predict, are:

| | • | | our difficulty predicting revenues and ordering the correct mix of products from suppliers due to limited visibility provided by customers and channel partners coupled with a high number of orders placed for products to be shipped in the same quarter; |

| | • | | the reduction, rescheduling, cancellation or timing of orders by our customers and channel partners due to, among others, the following factors; |

| | • | | management of customer, subcontractor and/or channel inventory; |

| | • | | dependency on a single product with a single customer; |

| | • | | volatility of demand for equipment sold by our large customers, which in turn, introduces demand volatility for our products; |

| | • | | temporary disruption in customer demand as customers change or modify their complex subcontract manufacturing supply chain; |

| | • | | the inability of our customers to obtain components from their other suppliers; and |

| | • | | disruption in the sales or distribution channels; |

| | • | | changes in sales and implementation cycles for our products; |

17

| | • | | the ability of our suppliers, customers and communications service providers to obtain financing or to fund capital expenditures; |

| | • | | changes in the mix of products that our customers purchase; |

| | • | | risks associated with entering new markets, such as increased competition, should we decide to do so; |

| | • | | the announcement or introduction of products by our competitors; |

| | • | | loss of market share by our customers; |

| | • | | competitive pressures on selling prices or product availability; |

| | • | | pressures on selling prices overseas due to foreign currency exchange fluctuations; |

| | • | | erosion of average selling prices coupled with the inability to sell newer products with higher average selling prices, resulting in lower overall revenue and margins; |

| | • | | market and/or customer acceptance of our products; |

| | • | | consolidation among our competitors, our customers and/or our customers’ customers; |

| | • | | changes in our customers’ end user concentration or requirements; |

| | • | | loss of one or more major customers; |

| | • | | significant changes in ordering pattern by major customers; |

| | • | | our or our channel partners’ ability to maintain adequate inventory levels; |

| | • | | the availability and cost of materials and services, including foundry, assembly and test capacity, needed by us from our foundries and suppliers; |

| | • | | discontinuance of wafer fabrication or packaging technologies by our suppliers; |

| | • | | if wafer fabrications or packaging and test suppliers discontinue or experience extended disruption of supply, we may incur increased costs to obtain alternative suppliers or investment in inventory to meet continuity of supply obligations to customers; |

| | • | | temporary disruptions in our or our customers’ supply chain due to natural disaster, fire, outbreak of communicable diseases such as the Avian Flu, or labor disputes; |

| | • | | fluctuations in the manufacturing output, yield capabilities, and capacity of our suppliers; |

| | • | | fluctuation in suppliers’ capacity due to reorganization, relocation or shift in business focus; |

| | • | | problems, costs, or delays that we may face in shifting our products to smaller geometry process technologies and in achieving higher levels of design and device integration; |

| | • | | our ability to successfully introduce and transfer into production new products and/or integrate new technologies; |

| | • | | increase in manufacturing costs; |

| | • | | increase in mask tooling costs associated with advanced technologies; |

| | • | | the amount and timing of our investment in research and development; |

| | • | | costs and business disruptions associated with shareholder or regulatory issues; |

| | • | | the timing and amount of employer payroll tax to be paid on our employees’ gains on stock options exercised; |

| | • | | increasing costs and time associated with compliance with accounting rules or other regulatory requirements; |

18

| | • | | changes in accounting or other regulatory rules, such as the future requirement to record expenses for employee stock option grants; |

| | • | | fluctuations in interest rates and/or market values of our marketable securities; |

| | • | | litigation costs associated with the defense of suits brought or complaints made against us; and/or |

| | • | | legislators’ desire or ability to renew favorable tax legislation in a timely manner, which may subject our tax provision to volatility. |

As a consequence, operating results for a particular future period are difficult to predict and prior results are not necessarily indicative of results to be expected in the future. Any of the foregoing factors, or any other factors discussed elsewhere herein, may have a material adverse effect on our business, financial condition and results of operations.

WE HAVE MADE AND MAY IN THE FUTURE MAKE ACQUISITIONS AND SIGNIFICANT STRATEGIC EQUITY INVESTMENTS, WHICH MAY INVOLVE A NUMBER OF RISKS. IF WE ARE UNABLE TO ADDRESS THESE RISKS SUCCESSFULLY, SUCH ACQUISITIONS AND INVESTMENTS COULD HAVE A MATERIALLY ADVERSE IMPACT ON OUR BUSINESS, FINANCIAL CONDITION AND RESULTS OF OPERATIONS.

We have undertaken a number of strategic acquisitions and investments in the past and may do so from time to time in the future. The risks involved with these acquisitions and investments include, among others:

| | • | | the possibility that we may not receive a favorable return on our investment or incur losses from our investment, or the original investment may become impaired; |

| | • | | failure to satisfy the strategic objectives; |

| | • | | our assumption of known or unknown liabilities or other unanticipated events or circumstances; and/or |

| | • | | the diversion of management’s attention from normal daily operations of the business. |

Additional risks involved with acquisitions include, among others:

| | • | | difficulties in integrating the operations, technologies, products and personnel of the acquired company or its assets; |

| | • | | difficulty in supporting acquired products or technologies; |

| | • | | difficulties or delays in the transfer of manufacturing flows and supply chains of products of acquired businesses; |

| | • | | failure to retain key personnel; |

| | • | | unexpected capital equipment outlays and related expenses; |

| | • | | difficulties in entering markets in which we have limited or no direct prior experience and where competitors in such markets may have stronger market positions; |

| | • | | insufficient revenues to offset increased expenses associated with acquisitions; |

| | • | | under-performance problems with an acquired company; |

| | • | | issuance of common stock that would dilute our current stockholders’ percentage ownership; |

| | • | | recording of goodwill and non-amortizable intangible assets that will be subject to periodic impairment testing and potential impairment charges against our future earnings; |

| | • | | incurring amortization expenses related to certain intangible assets; |

| | • | | the opportunity cost associated with committing capital in such investments; |

19

| | • | | incurring large and immediate write-offs; and/or |

| | • | | becoming subject to litigation. |

Risks involved with strategic equity investments include, among others:

| | • | | the possibility of litigation resulting from these types of investments; |

| | • | | the possibility that we may not receive a favorable return on our investments or incur losses from these investments, or the original investment may become impaired; |

| | • | | a change or poorly executed strategic plan; and/or |

| | • | | the opportunity cost associated with committing capital in such investments. |

We cannot assure that we will be able to address these risks successfully without substantial expense, delay or other operational or financial problems. Any delays or other such operations or financial problems could adversely impact our business, financial condition and results of operations.

WE MAY NOT INTEGRATE ACQUIRED TECHNOLOGY SUCCESSFULLY.

We have made and may in the future acquire intellectual property to accelerate our time to market for new products. Acquisitions of intellectual property may involve risks such as successful technical integration into existing products, market acceptance of new products, and achievement of planned return on investment. The potential failure of product introduction utilizing acquired intellectual property could lead to an impairment of capitalized intellectual property acquisition costs.

COMPETITION IN THE MARKETS IN WHICH WE PARTICIPATE, OR MAY PARTICIPATE, MAY MAKE IT MORE DIFFICULT FOR US TO BE SUCCESSFUL.

We compete against an established group of semiconductor companies that focus on similar markets. These competitors include Applied Micro Circuits Corporation, Integrated Device Technology Inc., Mindspeed Technologies Inc., PMC Sierra Inc., Royal Philips Electronics, Texas Instruments Incorporated, TranSwitch Corporation, Vitesse Semiconductor Corporation and Wolfson Microelectronics LTD. Additionally, we are facing competition from other established companies and start-up businesses that seek to enter the markets in which we participate.

We have experienced increased competition at the design stage, where customers evaluate alternative solutions based on a number of factors, including price, performance, product features, technologies, and availability of long-term product supply and/or roadmap guarantee. Additionally, we experience, in some cases, severe pressure on pricing from some of our competitors or cost expectations from customers. Such circumstances may make some of our products unattractive due to price or performance measures. These circumstances may result in us losing design opportunities or may decrease our revenue and margins as a result of the price competition. Also, competitors from new companies in emerging countries with significant lower costs could affect selling price and gross margins.

WE DEPEND ON THIRD-PARTY FOUNDRIES TO MANUFACTURE OUR INTEGRATED CIRCUITS. ANY DISRUPTION IN OR LOSS OF THE FOUNDRIES’ CAPACITY TO MANUFACTURE OUR PRODUCTS SUBJECTS US TO A NUMBER OF RISKS, INCLUDING THE POTENTIAL FOR AN INADEQUATE SUPPLY OF PRODUCTS AND HIGHER MATERIALS COSTS. THESE RISKS MAY LEAD TO DELAYED PRODUCT DELIVERY OR INCREASED COSTS, WHICH COULD MATERIALLY AND ADVERSELY AFFECT OUR BUSINESS, FINANCIAL CONDITION AND RESULTS OF OPERATIONS.

We do not own or operate a semiconductor fabrication facility, or a foundry. Most of our products are based on complementary metal oxide semiconductor, or CMOS, processes. Chartered Semiconductor Manufacturing Ltd., or Chartered, located in Singapore, manufactures the majority of the CMOS wafers from which our

20

products are manufactured. Chartered produces semiconductors for many other companies (many of which have greater requirements than us), and therefore we may not have access on a timely basis to sufficient capacity or certain process technologies. In addition, we are reliant on Chartered’s continued financial health and ability to continue to invest in smaller geometry manufacturing processes and foundries.

Many of our new products are designed to take advantage of smaller geometry manufacturing processes. Due to the complexity and increased cost of migrating to smaller geometries, we may experience problems, which could result in design and production delays of our products. If such delays occur, our products may have delayed market acceptance or customers may select our competitors’ products during the design process.

We do not have long-term wafer supply agreements with Chartered or our other foundries that would guarantee wafer or product quantities, prices, delivery or lead times. Rather, the foundries manufacture our products on a purchase order basis. We provide Chartered and our other foundries with rolling forecasts of our production requirements. However, the ability of our foundries to provide wafers is limited by the foundries’ available capacity. In addition, we cannot be certain that we will continue to do business with Chartered or our other foundries on terms as favorable as our current terms. Significant risks associated with our reliance on third party foundries include:

| | • | | the lack of assured process technology and wafer supply; |

| | • | | financial and operating stability of the foundries; |

| | • | | limited control over delivery schedules; |

| | • | | limited manufacturing capacity of the foundries; |

| | • | | limited control over quality assurance, manufacturing yields and production costs; and/or |

| | • | | potential misappropriation of our intellectual property. |

We could experience a substantial delay or interruption in the shipment of our products or an increase in our costs due to any of the following:

| | • | | a manufacturing disruption experienced by foundries utilized by us or sudden reduction or elimination of any existing source or sources of semiconductor manufacturing materials or processes, which might include the potential closure, change of ownership, change of management or consolidation by one of our foundries; |

| | • | | extended time required to identify, qualify and transfer to alternative manufacturing sources for existing or new products; |

| | • | | failure of our suppliers to obtain the raw materials and equipment; |

| | • | | financial and operating stability of the foundry or any of our suppliers; |

| | • | | acts of terrorism or civil unrest or an unanticipated disruption due to communicable diseases, political instability, natural disasters; and/or |

| | • | | a sudden, sharp increase in demand for semiconductor devices, which could strain the foundries’ manufacturing resources and cause delays in manufacturing and shipment of our products. |

IF OUR FOUNDRIES DISCONTINUE OR LIMIT THE AVAILABILITY OF THE MANUFACTURING PROCESSES NEEDED TO MEET OUR DEMANDS OR ARE UNABLE TO PROVIDE THE TECHNOLOGIES NEEDED TO MANUFACTURE OUR PRODUCTS, WE MAY FACE PRODUCTION DELAYS, WHICH COULD MATERIALLY AND ADVERSELY IMPACT OUR BUSINESS, FINANCIAL CONDITION AND RESULTS OF OPERATIONS.

Our wafer requirements represent a small portion of the total production of the foundries that manufacture our products. As a result, we are subject to the risk that a foundry may cease production of a wafer fabrication

21

process required by us. Additionally, we cannot be certain that our foundries will continue to devote resources to the production of our products or continue to advance the process design technologies on which the manufacturing of our products are based. Each of these events could increase our costs and harm our ability to deliver our products on time, or force us to terminate affected products, thereby materially and adversely affecting our business, financial condition and results of operations.

TO SECURE FOUNDRY CAPACITY, WE MAY BE REQUIRED TO ENTER INTO FINANCIAL AND OTHER ARRANGEMENTS WITH FOUNDRIES, WHICH COULD RESULT IN THE DILUTION OF OUR EARNINGS OR OTHERWISE HARM OUR OPERATING RESULTS.

Allocation of a foundry’s manufacturing capacity may be influenced by a foundry customer’s size, the existence of a long-term agreement with the foundry or other commitments. To address foundry capacity constraints, we and other semiconductor companies that rely on third-party foundries have utilized various arrangements, including equity investments in or loans to foundries in exchange for guaranteed production capacity, joint ventures to own and operate foundries or “take or pay” contracts that commit a company to purchase specified quantities of wafers over extended periods. While we are not currently a party to any of these arrangements, we may decide to enter into these arrangements in the future. We cannot be sure, however, that these arrangements will be available to us on acceptable terms, if at all. Any of these arrangements could require us to commit substantial capital and, accordingly, could require us to reduce our cash holdings, incur additional debt or secure equity financing. This could result in the dilution of our earnings or the ownership of our stockholders or otherwise harm our operating results. Furthermore, there can be no assurance that we will be able to obtain sufficient foundry capacity in the future pursuant to such arrangements.

OUR DEPENDENCE ON THIRD-PARTY SUBCONTRACTORS TO ASSEMBLE AND TEST OUR PRODUCTS SUBJECTS US TO A NUMBER OF RISKS, INCLUDING THE POTENTIAL FOR AN INADEQUATE SUPPLY OF PRODUCTS AND HIGHER MATERIALS COSTS. THESE RISKS MAY LEAD TO DELAYED PRODUCT DELIVERY OR INCREASED COSTS, WHICH COULD MATERIALLY AND ADVERSELY AFFECT OUR BUSINESS, FINANCIAL CONDITION AND RESULTS OF OPERATIONS.

We depend on independent subcontractors in Asia for all of the assembly and the majority of the testing of our products. Our reliance on these subcontractors involves the following risks:

| | • | | our reduced control over manufacturing yields, production schedules and product quality; |

| | • | | the potential closure, change of ownership, change in business conditions or relationships, change of management or consolidation by one or more of our subcontractors; |

| | • | | long term financial stability of our subcontractors and their ability to invest in new capabilities and equipment; |

| | • | | disruption of services due to the outbreak of communicable diseases such as the Avian Flu, acts of terrorism, natural disasters, labor disputes, or civil unrest; |

| | • | | disruption of manufacturing or test services due to relocation of subcontractor manufacturing facilities; |

| | • | | failure of our subcontractors to obtain the raw materials and equipment; |

| | • | | entry into “take-or-pay” agreements; |

| | • | | difficulties in selecting, qualifying and integrating new subcontractors; |

| | • | | reallocation or limited manufacturing capacity of the subcontractors; |

| | • | | a sudden, sharp increase in demand for semiconductor devices, which could strain the subcontractor’s manufacturing resources and cause delays in manufacturing and shipment of our products; |

| | • | | limited warranties from the subcontractors for products assembled and tested for us; |

22

| | • | | the possible unavailability of qualified assembly or test services; |

| | • | | the subcontractors may cease production on a specific package type used to assemble product required by us and the possible inability to obtain an alternate source to supply the package; |

| | • | | potential increases in assembly and test costs; and/or |

| | • | | the third party subcontractors abilities to transition to smaller package types and to new package compositions. |

These risks may lead to shipment delays and supply constraints of our products or increased cost for the finished products, either of which could adversely affect our business, financial condition or results of operations.