Technical Report

Kupol Project

Chukotka, A.O.

Russian Federation

By

Tom Garagan, P.Geo

Hugh MacKinnon, P.Geo

Vancouver, Canada

November 2003

Bema Gold Corporation

43-101 Technical Report

Kupol Project

CERTIFICATE of AUTHOR

Tom Garagan, P.Geo, Vice President Exploration

Bema Gold Corporation

Suite 3100, Three Bentall Centre, 595 Burrard St., PO Box 49143

Vancouver, British Columbia, Canada

Telephone: (604)681-8371

Fax: (604) 681-1242

Email: tgaragan@bemagold.com

1. I, Tom Garagan, P.Geo, do hereby certify that I am Vice President of Exploration for Bema Gold Corporation, Suite 3100, Three Bentall Centre, 595 Burrard St., PO Box 49143 Vancouver, British Columbia, Canada.

2. I graduated with a Bachelor of Science (Honours) degree in Geological Sciences from the University of Ottawa in 1980.

3. I am a member of the Association of Professional Geoscientists and Engineers of British Columbia, Association of Professional Engineers, Geologists and Geophysicists of Alberta and a Fellow of the Geological Association of Canada.

4. I have worked as a geologist for a total of 23 years since my graduation from university. I have been involved in gold exploration and mining in Canada, USA, Russia, South Africa, Ethiopia, Ghana, Chile, Argentina, Venezuela and Mexico.

5. I have read the definition of “qualified person” set out in National Instrument 43-101 (“NI 43-101”) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101.

6. I am responsible for supervising the writing of the technical report titled Bema Gold Corporation’s Kupol Project dated November 28, 2003 (the “Technical Report”) relating to the Kupol Property. I visited the property twice in 2001 and for a total of 25 days during the course of active exploration in 2003.

7. I have not had prior involvement with the property that is the subject of the Technical Report.

8. I am not aware of any material fact or material change with respect to the subject matter of the Technical Report that is not reflected in the Technical Report, the omission to disclose which makes the Technical Report misleading.

9. I am not independent of the issuer. Per section 5.3.2 of National Instrument 43-101 an independent qualified person was not required for the writing Technical Report on the Kupol Property.

Bema Gold Corporation

43-101 Technical Report

Kupol Project

10. I have read National Instrument 43-101 and Form 43-101Fl, and the Technical Report has been prepared in compliance with that instrument and form.

11. I consent to the filing of the Technical Report with any stock exchange and other regulatory authority and any publication by them for regulatory purposes, including electronic publication in the public company files on their websites accessible by the public, of the Technical Report.

Dated this 28th Day of November 2003.

Bema Gold Corporation

43-101 Technical Report

Kupol Project

CERTIFICATE of AUTHOR

Hugh MacKinnon, P.Geo, Project Geologist

Bema Gold Corporation

Suite 3100, Three Bentall Centre, 595 Burrard St., PO Box 49143

Vancouver, British Columbia, Canada

Telephone: (604) 681-8371

Fax: (604) 681-1242

Email: hmackinnon@bemagold.com

1. I, Hugh MacKinnon, P.Geo, do hereby certify that I am a Project Geologist with Bema Gold Corporation, Suite 3100, Three Bentall Centre, 595 Burrard St., PO Box 49143 Vancouver, British Columbia, Canada.

2. I graduated with a Bachelor of Science (Honours) degree in Geology, from Carleton University in Ottawa in 1986.

3. I am a member of the Association of Professional Geoscientists and Engineers of British Columbia

4. I have practiced my profession for a total of seventeen years since my graduation from university and have been involved in the exploration for gold, silver, copper, lead, zinc, tin, platinum/palladium in Canada, Russia, Peru, Kyrgyzstan and Ghana.

5. I have read the definition of “qualified person” set out in National Instrument 43-101 (“NI 43-101”) and certify that by reason of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “qualified person” for the purposes of NI 43-101.

6. I was responsible for the compilation and writing of the Technical Report on the Kupol Property dated November 28, 2003. I was at the Kupol site from April to October of 2003.

7. I have not had any prior involvement with the Kupol Property.

8. I am not aware of any material fact or material change with respect to the subject matter of the Technical Report that is not reflected in the Technical Report, the omission to disclose which makes the Technical Report misleading.

9. I am not independent of the issuer. Per section 5.3.2 of National Instrument 43-101 an independent qualified person was not required for the writing Technical Report on the Kupol Property.

Bema Gold Corporation

43-101 Technical Report

Kupol Project

10. I have read National Instrument 43-101 and Form 43-101F1, and the Technical Report has been prepared in compliance with that instrument and form.

11. I consent to the filing ofthe Technical Report with any stock exchange and other regulatory authority and any publication by them for regulatory purposes, including electronic publication in the public company files on their websites accessible by the public, of the Technical Report.

Dated this 28th Day of November 2003.

Hugh F. MacKinnon, P.Geo

Bema Gold Corporation

43-101 Technical Report

Kupol Project

CONSENTof QUALIFIEDPERSON

TO:British Columbia Securities Commission and Toronto Stock Exchange

I,Tom Garagan do hereby consent to the filing of the Technical Report titled Kupol Property and dated November 28,2003 (the "Technical Report") with the securities regulatory authorities referred to above.

Dated this 28th Day of November, 2003.

Bema Gold Corporation

43-101 Technical Report

Kupol Project

CONSENT of QUALIFIED PERSON

TO:British Columbia Securities Commission and Toronto Stock Exchange

I,Hugh MacKinnon do hereby consent to the filing of the Technical Report titled Kupol Property and dated November 28,2003 (the "Technical Report") with the securities regulatory authorities referred to above.

Dated this 28th Day of November, 2003.

Hugh MacKinnon

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | TOC-i |

Table of Contents

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | TOC-ii |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | TOC-iii |

List of Figures:

|

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | TOC-iv |

List of Tables:

List of Appendices:

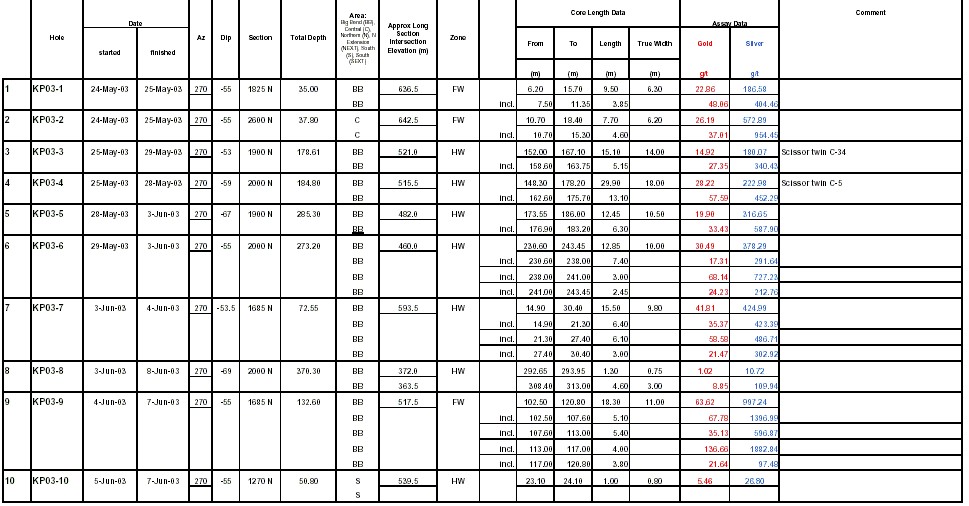

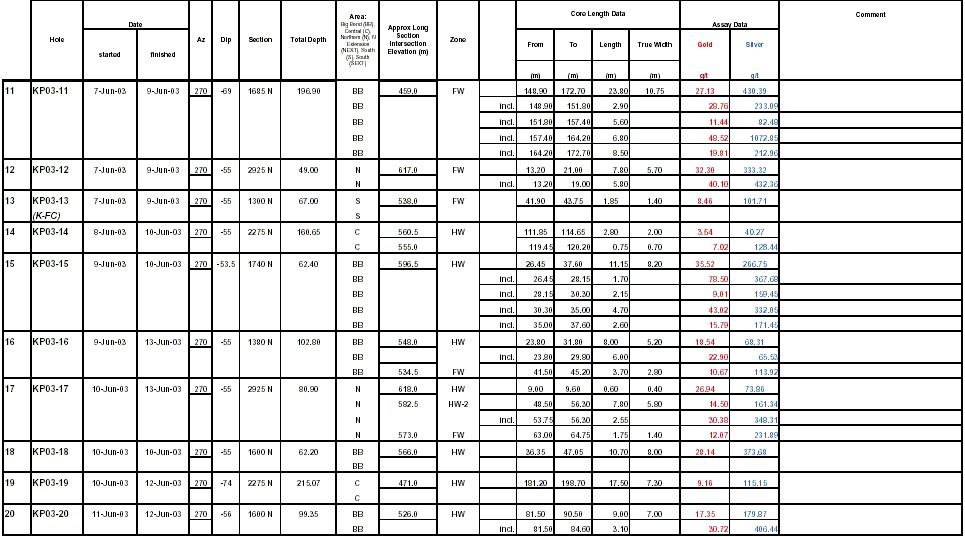

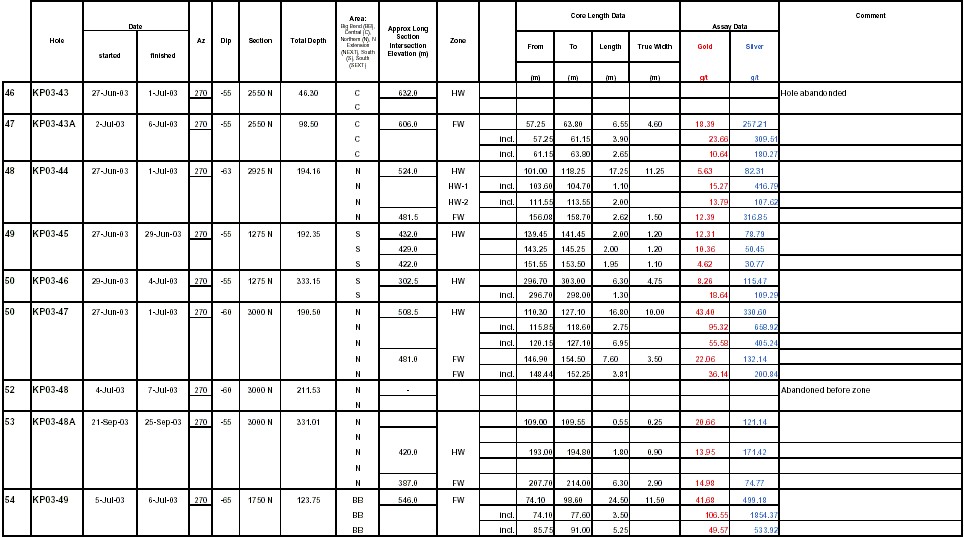

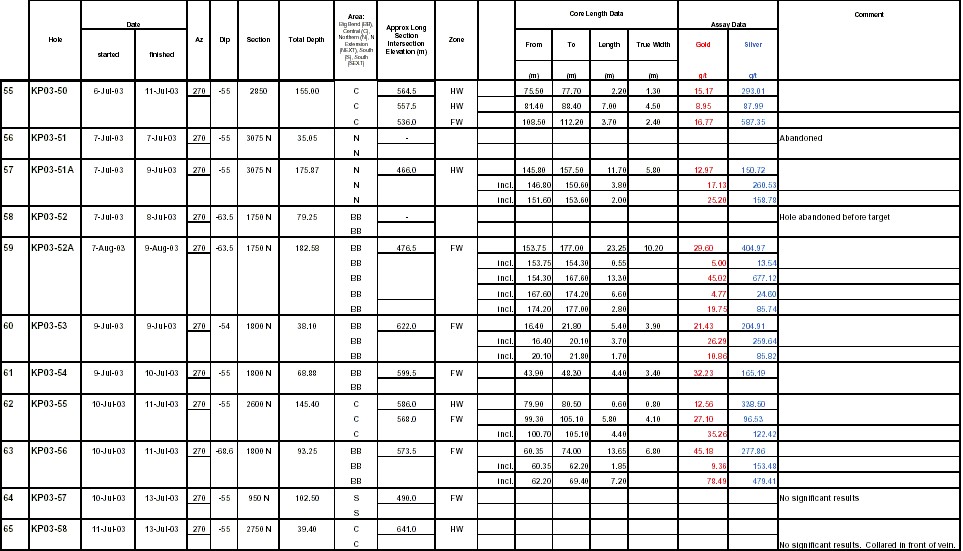

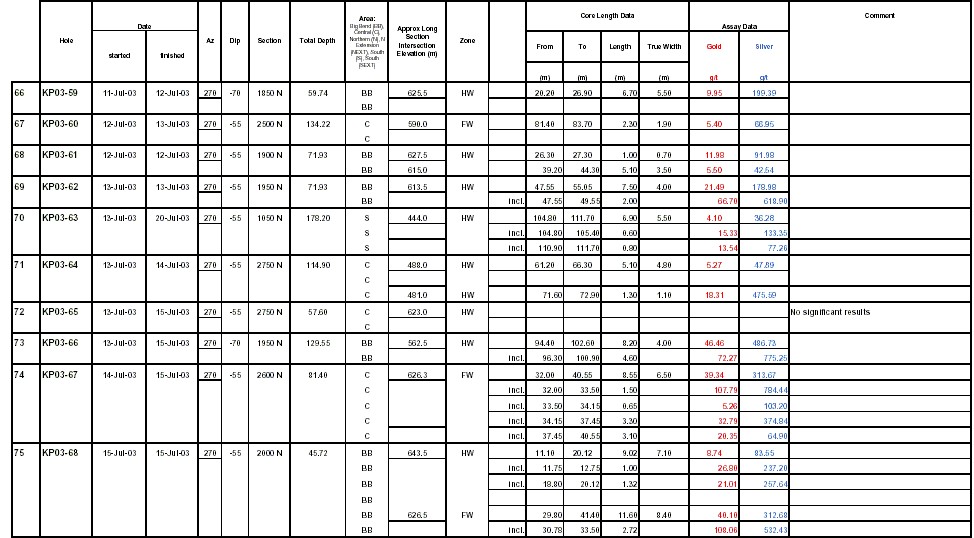

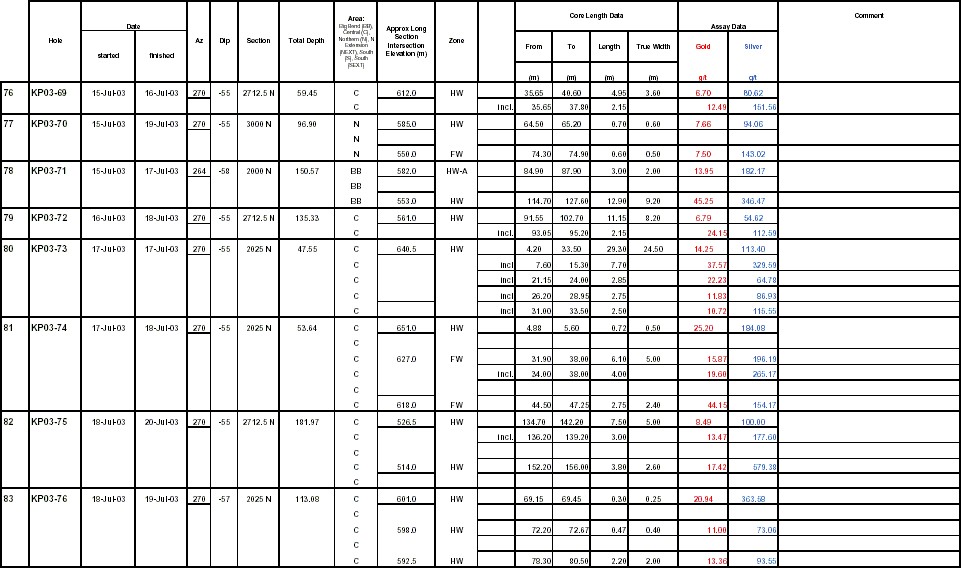

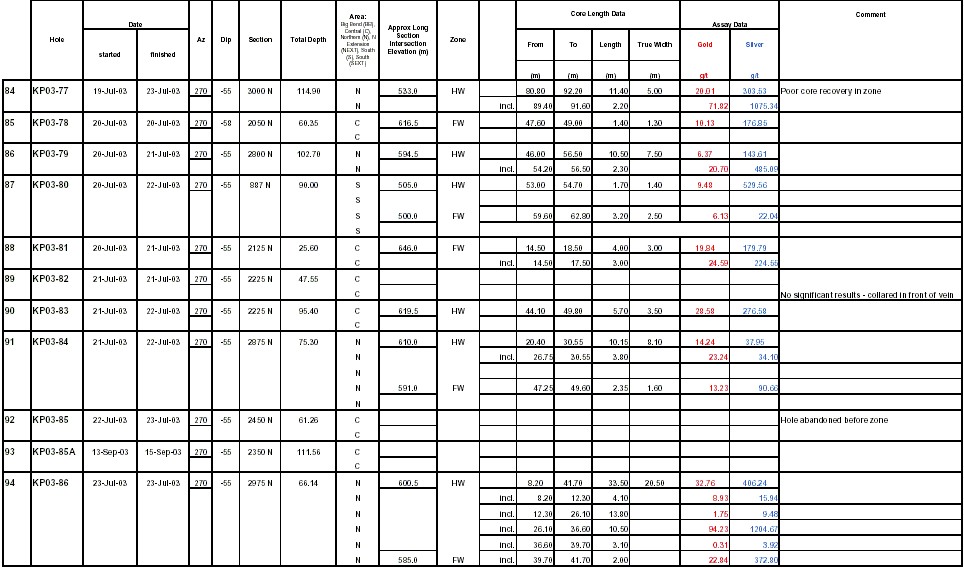

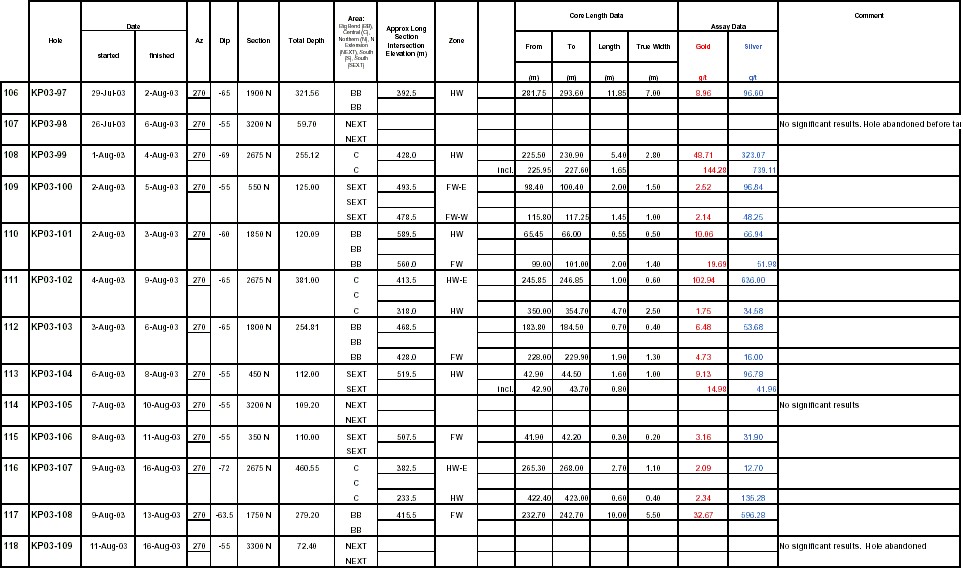

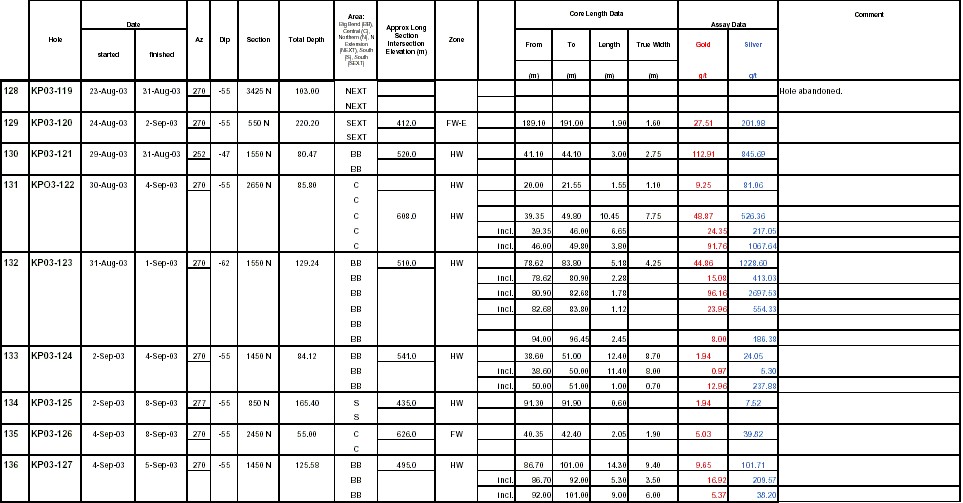

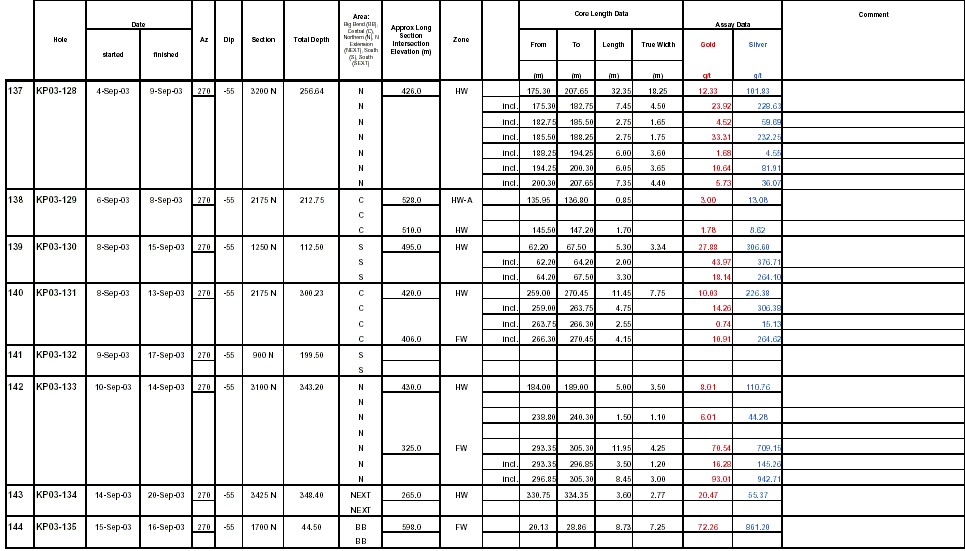

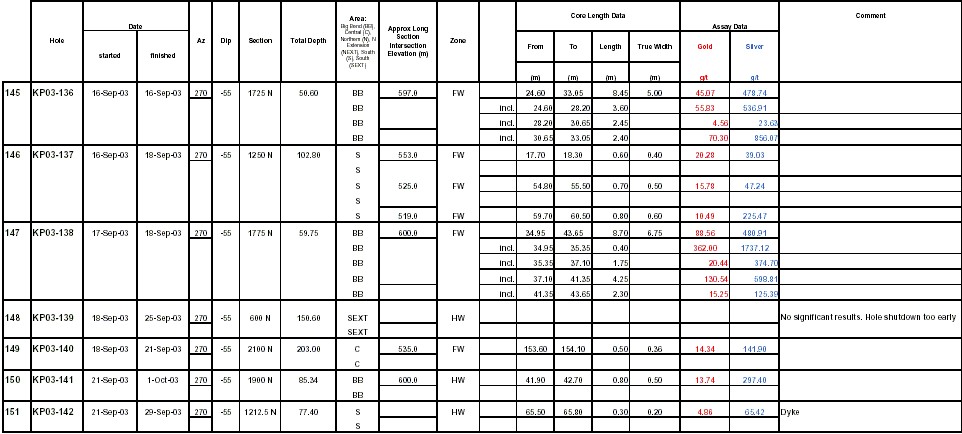

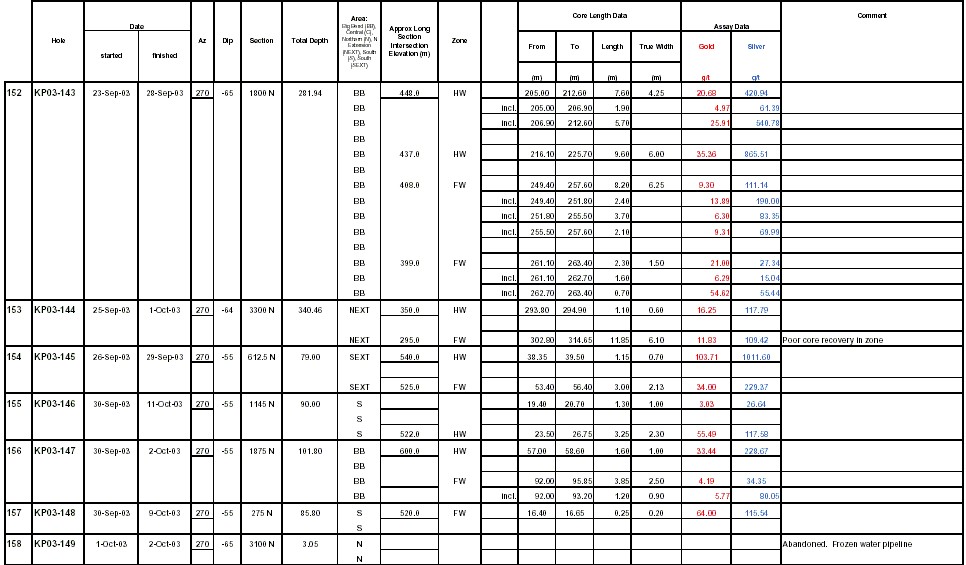

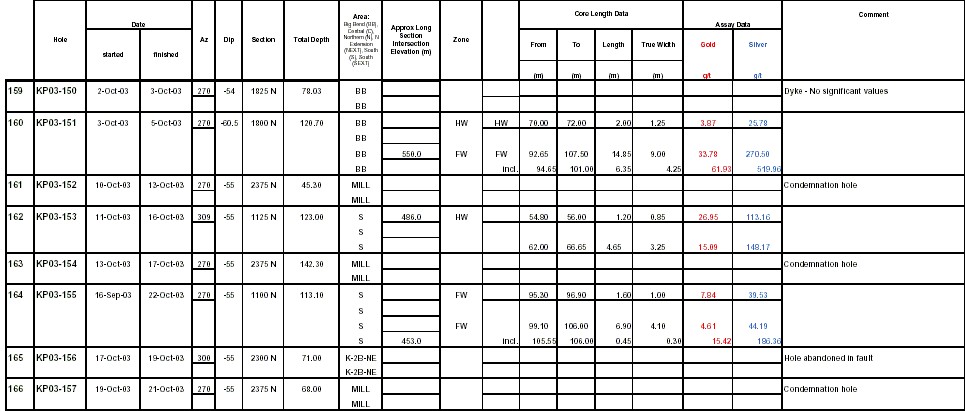

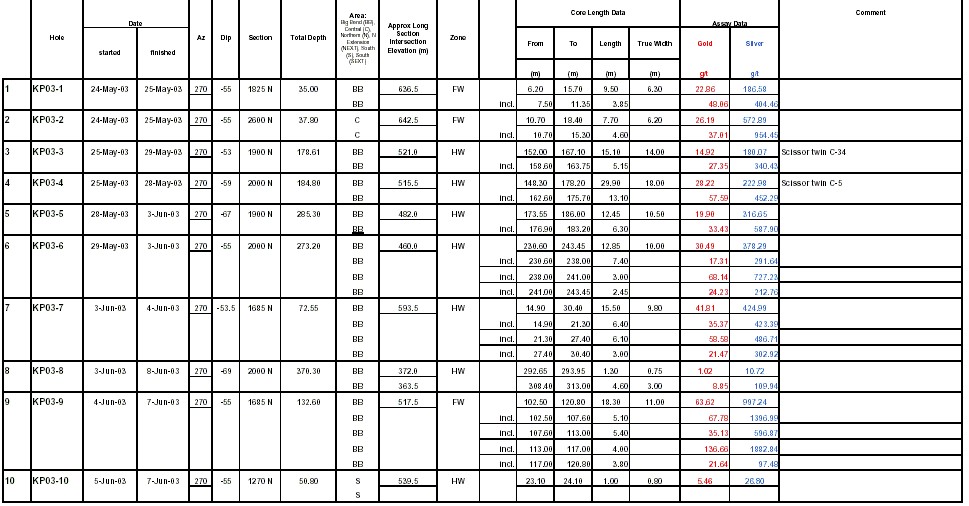

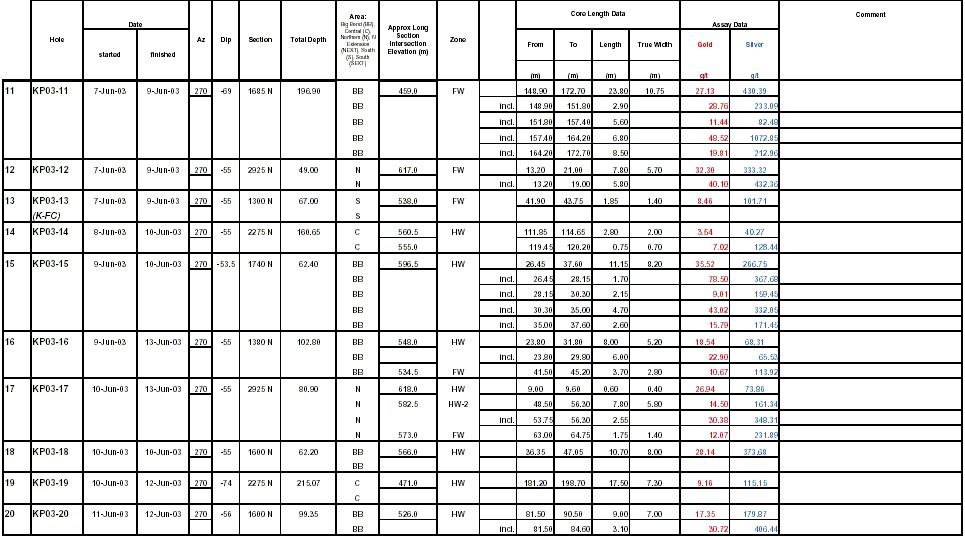

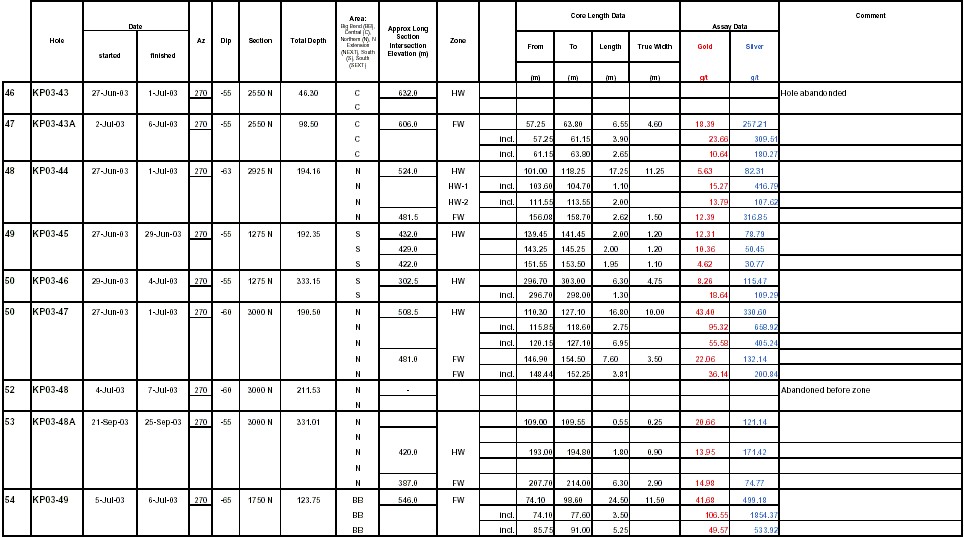

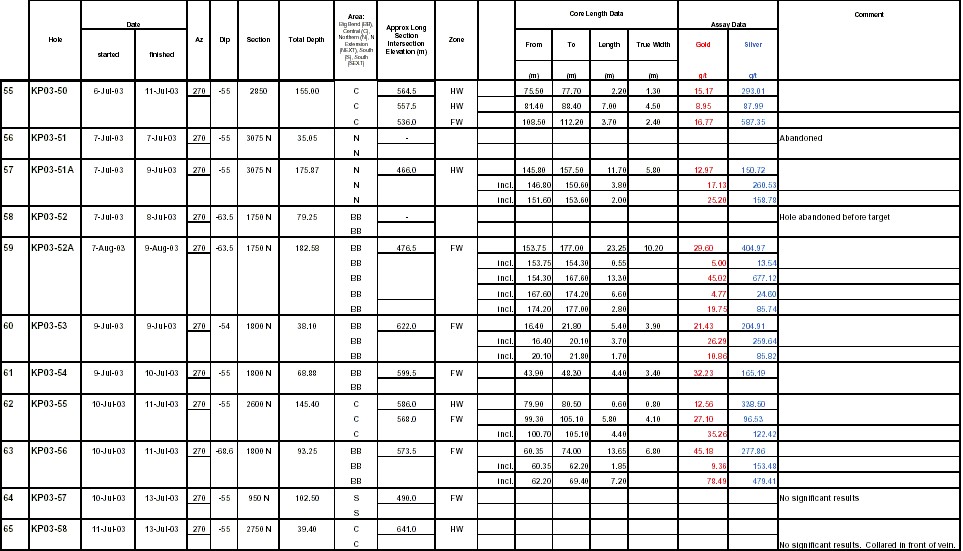

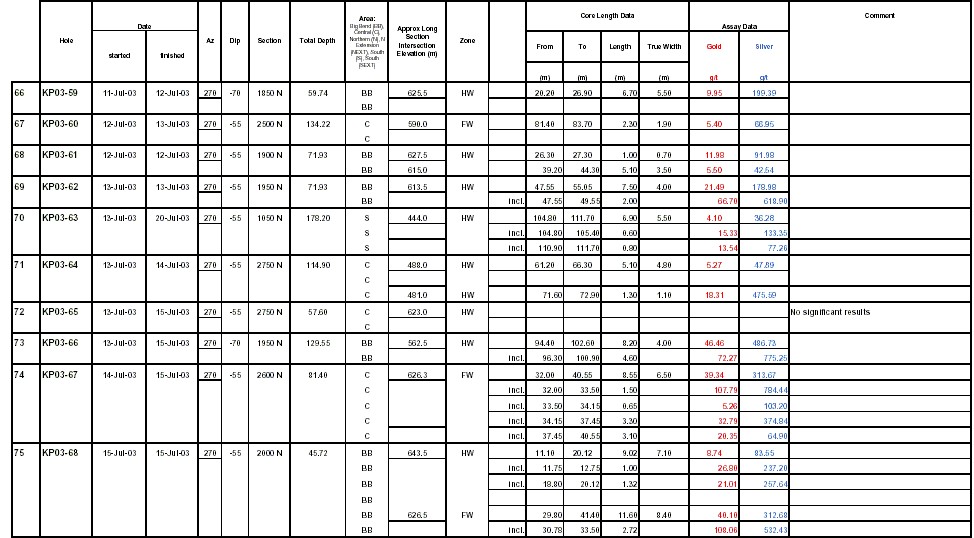

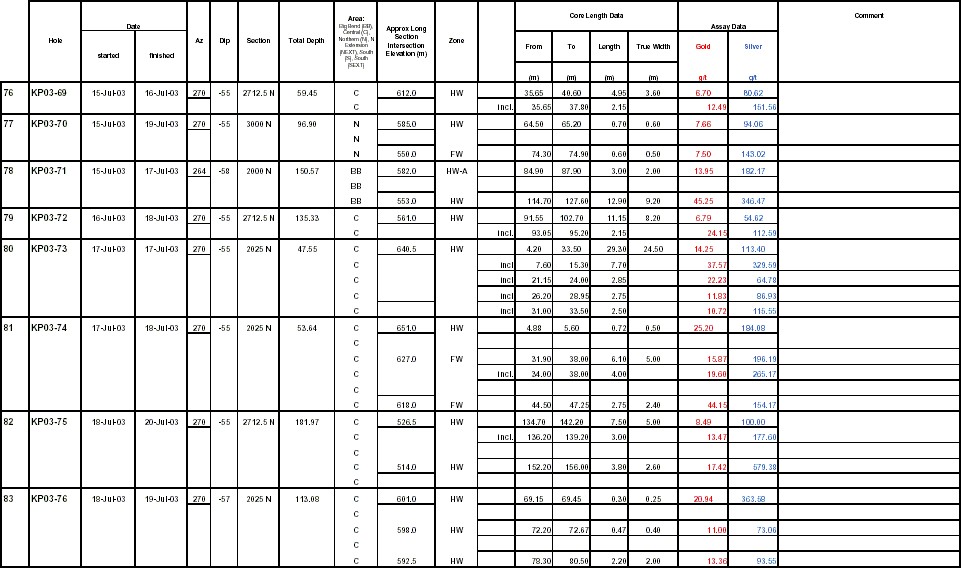

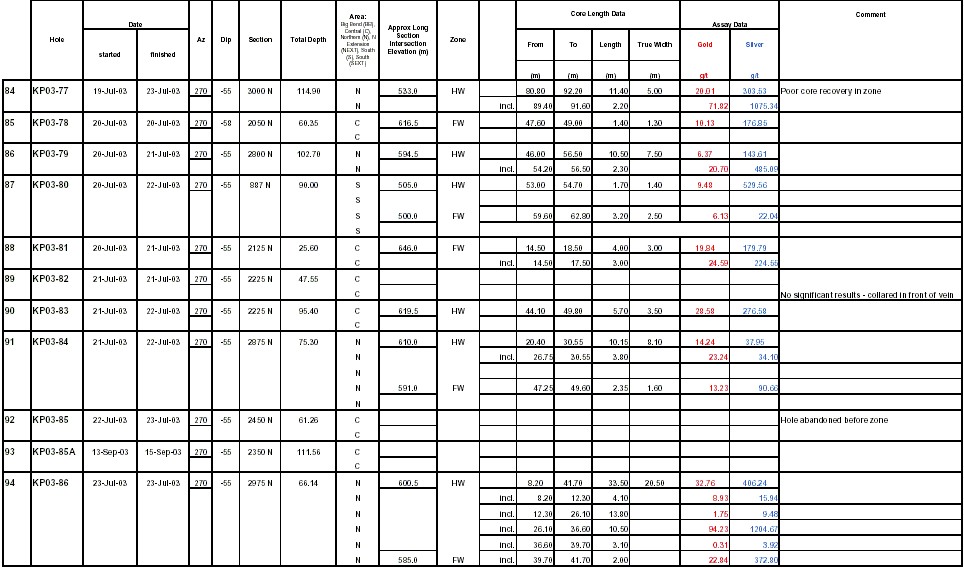

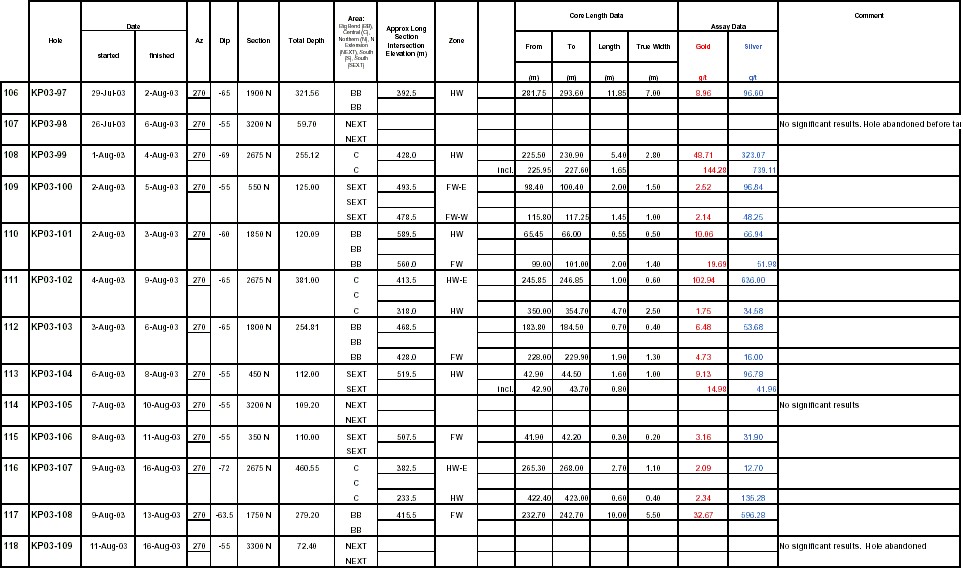

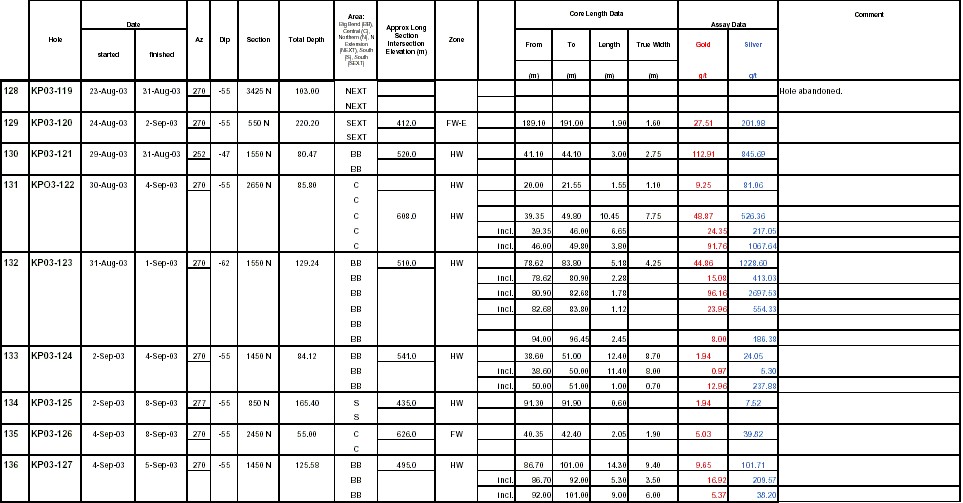

Appendix 1:

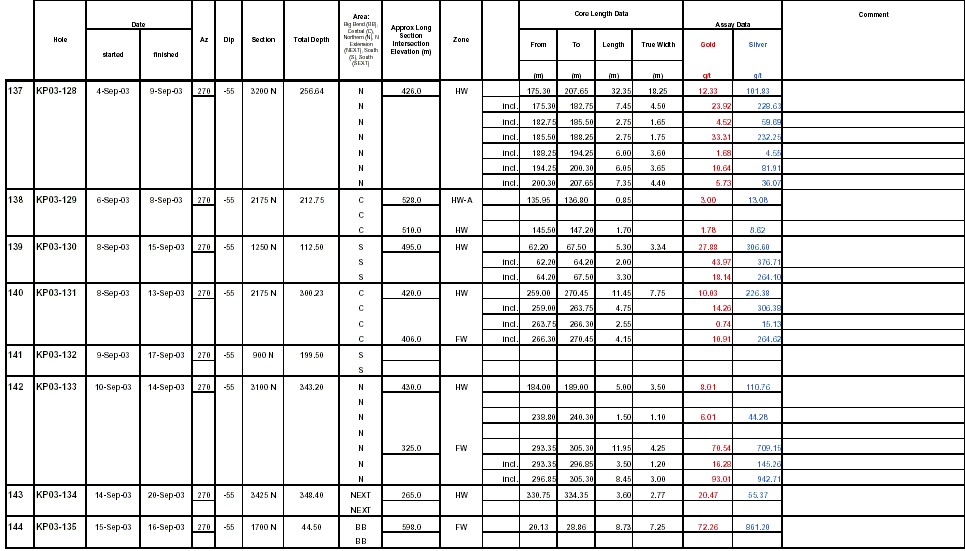

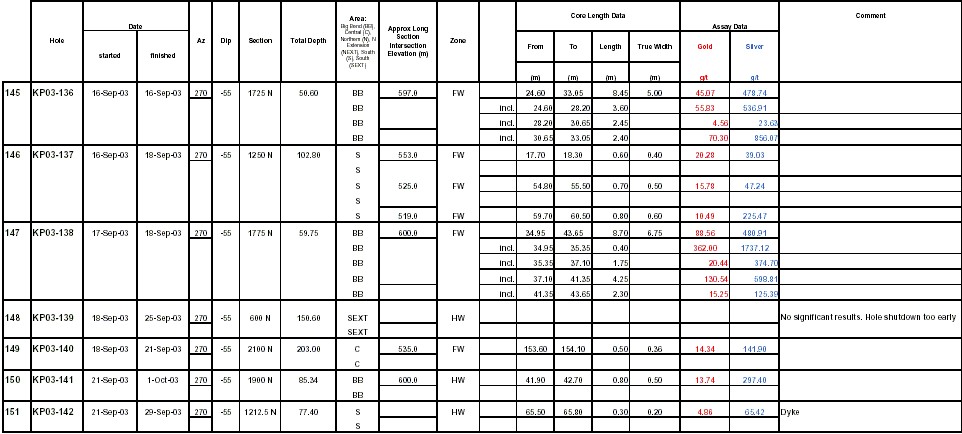

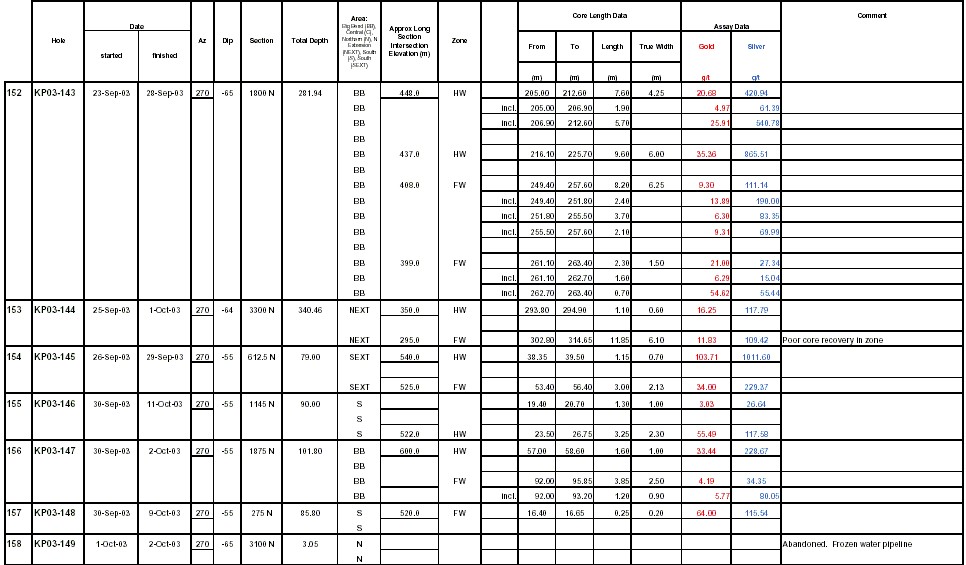

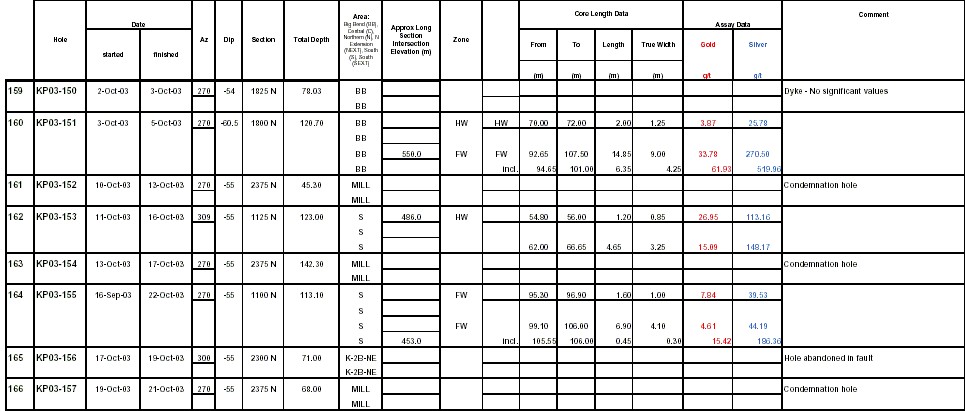

Summary of 2003 Kupol drilling results

Appendix 2:

Summary of 2003 drill hole co-ordinates

Appendix 3:

Summary of 2003 trench co-ordinates

Appendix 4:

A Review of the Quality Control Results and Procedures, Kupol Gold Project Chukotka, Russia, July 2003. Smee and Associates Consulting Ltd.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 1 - p.1 |

1.0 Summary

At the request of the British Columbia Securities Commission a Technical Report on Bema Gold Corporation’s Kupol Project was prepared by Bema Gold Corporation. Tom Garagan, P.Geo, Vice President of Exploration for Bema Gold served as the Qualified Person responsible for the preparation of the Technical Report in accordance with National Instrument 43-101, Standards of Disclosure for Mineral Projects, and in compliance with Form 43-101F1, “Technical Report”.

The Kupol Property is located 220 kilometres from the town of Bilibino in the Chukotka Autonomous Okrug of the Far East Region of the Russian Federation. The Kupol Property is comprised of a 1766.73 hectare license area. Bema Gold Corporation is earning a 75% interest in the property from the Government of Chukotka, A.O., through a combination of cash payments and work commitments. With the payment of $8.5 million dollars (US) in December 2002 and greater than $5 million (US) expended on exploration in 2003, Bema has already earned a 20% interest in the property.

The Kupol Property is situated in the Cretaceous Okhotsk-Chukotka volcanogenic belt, with the project area underlain by a bimodal sequence of shallow dipping andesite and basaltic-andesite flows and pyroclastic units, rhyolite dykes and flow dome complexes. Mineralization is hosted in a north-south trending dilatant splay off of a large regional fault structure of similar orientation. The Kupol deposit consists of one or more polyphase quartz-adularia quartz veins of an epithermal low sulphidation character that are sporadically cut by rhyolite dykes. Gold and silver mineralization is associated with sulphosalt rich bands and pods within brecciated colloform banded veins. At the time of acquisition the deposit had been defined by trenching over 3 kilometres and drilled over 450 metres strike length to a maximum depth of 140 metres. Mapping, geophysical and soil geochemical surveying and trenching indicates the Kupol structure continues to the north and south boundaries of the property.

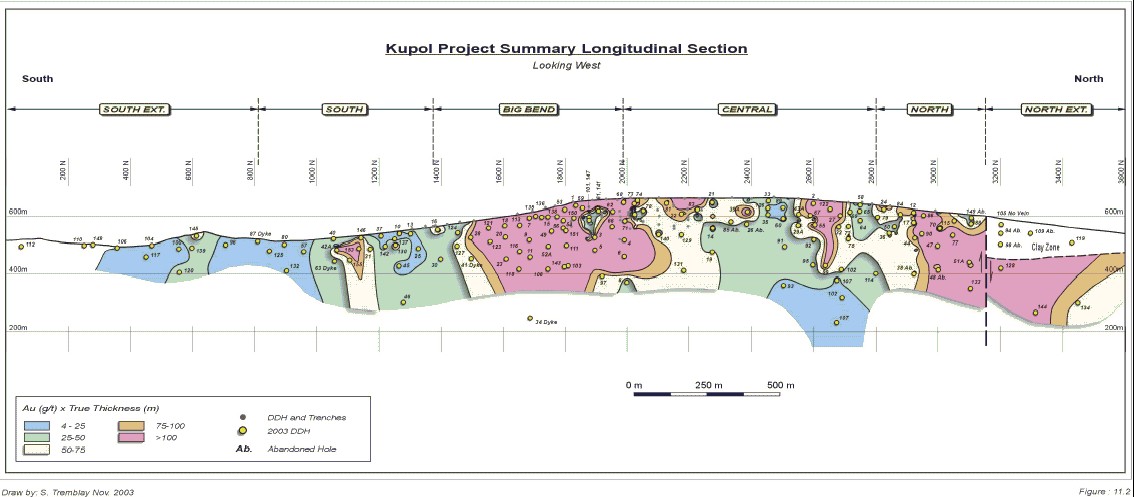

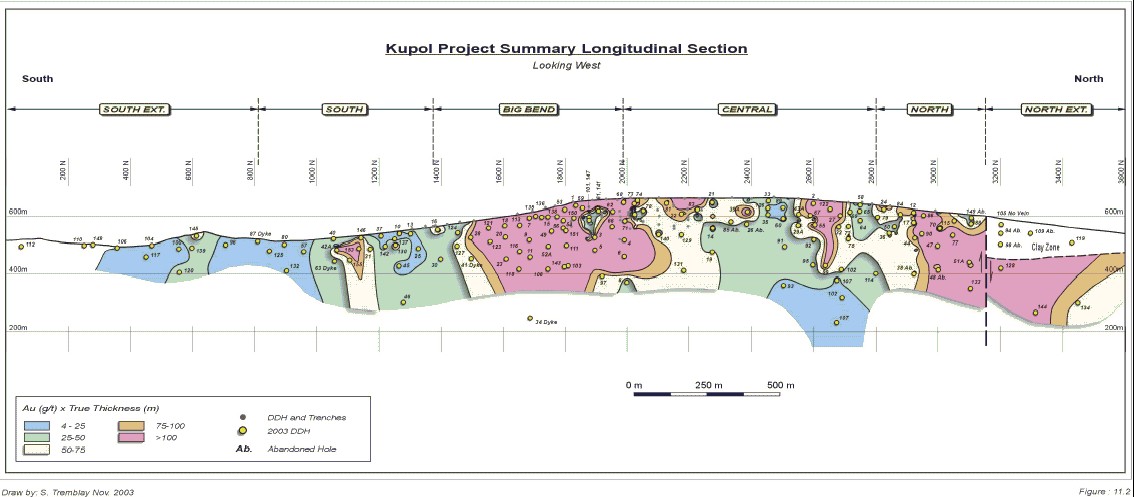

In 2003, 166 drill holes (including re-drills) totaling 22,256 metres were drilled and 15 trenches excavated, of which only 5 were completed. Drilling covered 3.375 kilometres of strike length of the mineralized system to a maximum depth of 420 metres below surface. On the basis of drilling and trenching, the deposit has been divided into six contiguous sectors or zones: South Extension, South, Big Bend, Central, Northern and North Extension. High grade shoots (>25 g/t Au over > 1.5 metres true width) have been defined in all sectors with the largest shoots defined to date in the Big Bend, Central and Northern zones. The main vein is divided into footwall and hanging wall segments depending on its positions relative to the central rhyolite dyke. To the north and in the southern areas, in particular, there is more than one mineralized vein present.

The Big Bend zone is located at a flexure in the Kupol structure. Within this zone there is good continuity of mineralization within and between drill sections over a strike length

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 1 - p.2 |

of 650 metres and to a depth of 250 metres below surface. The zone grade averages 30 g/t Au and >300 g/t Ag over true widths ranging from 1.0 to 18.0 metres.

The main vein in the Central zone is partially disrupted by dykes and faults running parallel to the vein stucture. Vein geometries and textures are more analogous to the upper levels of an epithermal system, with distinct high grade lenses developed of which the shoot centered on section 2600 N is the largest. This shoot strikes at least 100 metres and continues to depths of greater than 225 metres below surface. Intersections of up to 7.7 metres true width of 48.87 g/t Au with 526 g/t Ag were encountered in this shoot.

Drilling in the Northern portion of the deposit indicates that the North and North Extension zone represent one continuous high grade zone striking for greater than 600 metres. The North Extension veining is covered by a clay alteration cap up to 150 metres thick and it is inferred that there is a normal fault separating this zone from the Northern zone. Drilling conditions in these zones were more difficult with poorer recoveries in several of the vein intersections. The deepest hole in the area, at 275 metres below surface, returned 4.25 metres true width grading 70.54 g/t Au and 709.15 g/t Ag.

Limited drilling in the South and South Extension indicates that the veins are narrower, shoots not as well developed, and portions of the veins cut off by rhyolite dykes and flows.

All zones are open at depth and along strike.

The 2003 program incorporated a systematic quality control (QC) and quality assurance (QA) program consisting of the regular insertion of reference standards, field blanks, field duplicates and the use of external check laboratories to confirm the results. Ten to fifteen percent of analyses over the summer were QA/QC samples. The QA/QC program was audited early and mid summer by Smee and Associates Consulting, and found to meet or exceed the requirements of National Instrument 43-101.

Excellent drill results have confirmed expectations for the deposit and a Pre-feasibility study is now underway with a completion scheduled for April 2004. A 55,000 metre infill, exploration and geotechnical drill program is scheduled for 200

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 2 – p.1 |

2.0 Introduction and Terms of Reference

Bema Gold Corporation was requested by the British Columbia Securities Commission to prepare a Technical Report on the Kupol Project to justify a statement by the company in a news release that the project has multimillion ounce potential. Per section 5.3.2 of National Instrument 43-101, Bema Gold Corporation as a mining company, with production of 117,583 ounces of gold in 2002, it was not necessary for Bema to commission an independent Qualified Person to write the Technical Report on the Kupol Project.

Tom Garagan, P.Geo, Vice President of Exploration for Bema Gold Corporation, served as the Qualified Person, as defined under NI 43-101, responsible for the preparation of the Technical Report as defined in National Instrument 43-101, Standards of Disclosure for Mineral Projects, and in compliance with Form 43-101F1, “Technical Report”. Tom Garagan was directly involved in the supervision of the Kupol Project through numerous visits to site over the course of the 2003 field season, and oversaw the review of the geological data. Qualified Person support was provided by Hugh MacKinnon, P.Geo, a Qualified Person as defined under NI 43-101. Hugh MacKinnon is an employee of Bema Gold Corporation with the position of Project Geologist, and was responsible for drill supervision, sampling, data management and quality control for the Kupol Project.

It is the intent of the Technical Report to summarize the results and findings of the 2003 exploration program, and outline the quality control and quality assurance programs put in place to ensure the accuracy of the results reported. The report also summarizes the scope of additional work conducted in 2003 toward a Pre-feasibility study to be completed in April 2004.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 3 – p.1 |

3.0 Disclaimer

No disclaimer statement is necessary for the preparation of this report.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 4 – p.1 |

4.0 Property Description and Location

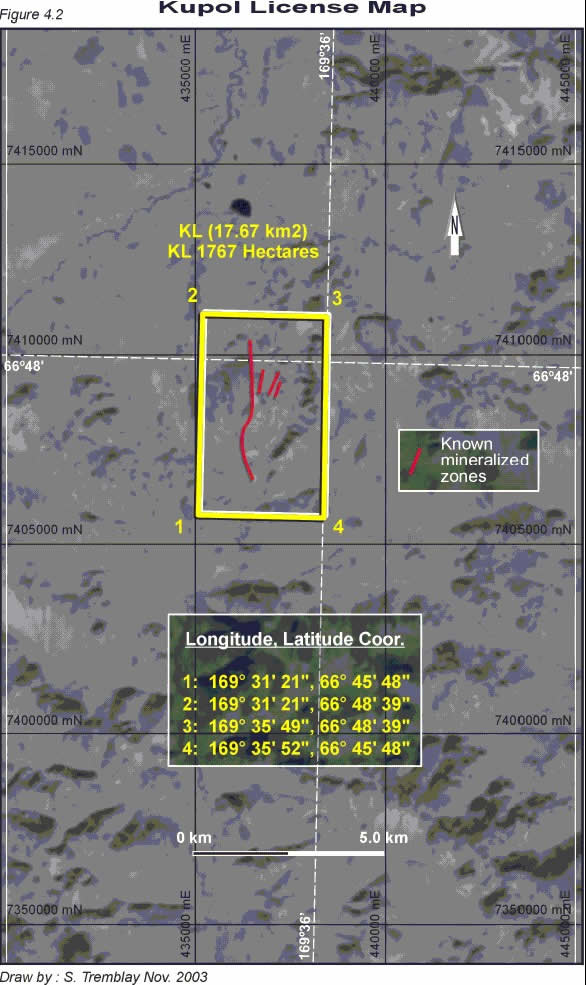

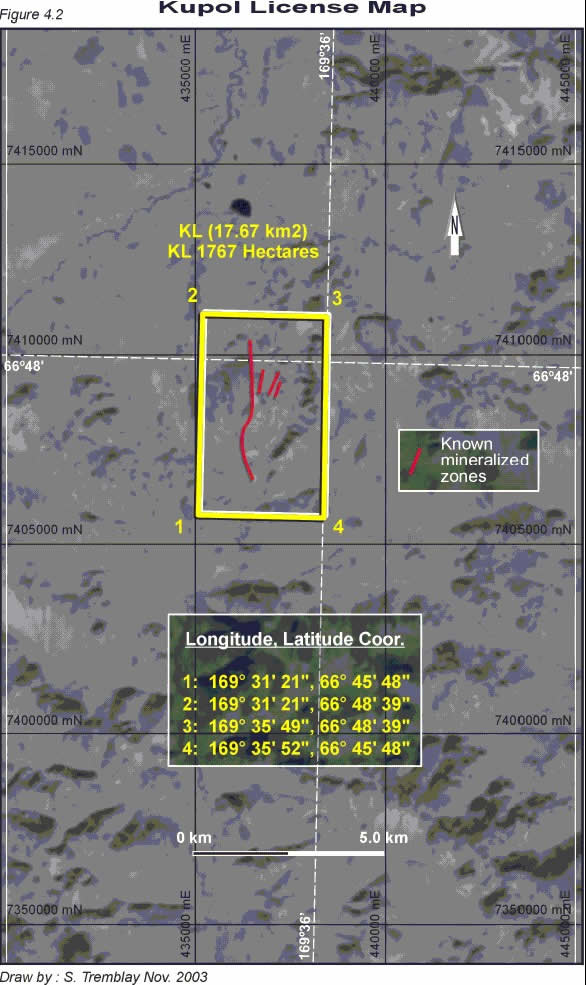

Bema Gold Corporation’s Kupol Project is centered on 66 47’00” North 169 33’00” East in the Chukotka Autonomous Okrug in the Far Eastern Region of the Russia Federation (figure 4.1) The property is situated near the border of the Bilibinsky - Anadyrsky districts and comprised of a 3.3 km by 5.3 km (1766.73 hectare) north-south oriented license area (figure 4.2) .

4.1 Title and Ownership

Bema has the right to earn up to a 75% interest from the license holder, the Government of Chukotka. Bema has already acquired an initial 20% interest by making a payment of $8 million (in December 2002) and by expending a minimum of $5 million on exploration on the Kupol Property since the initial payment was made. Bema will earn a further 10% with a payment of $12.5 million in December 2003. An additional 10% is earned through a payment of $10 million within 24 months of the initial payment and the expenditure of $5 million on exploration during 2004. Bema can then earn the final 35% upon completion of a bankable feasibility study and a payment of $5.00 per ounce of gold for 75% of the ounces identified in the proven and probable reserves contained in the feasibility study. Upon commencement of mine construction, Bema will pay a further $5.00 per ounce of gold for 75% of the ounces identified in the proven and probable reserves contained in the feasibility study. A finder’s fee, staged in the amount of $1.35 million, is to be paid to an arm’s length third party.

The Kupol license is registered as is registered as AНД 11305 БЗ with the Federal Fund of Geological Information, Ministry of Natural Resources, Russian Federation. The license boundaries have not been legally surveyed. The license provides for the right to explore and mine gold and silver for a term of 25 years (March 16, 2024).

4.2 Permitting and Environmental

The 2003 exploration program was fully permitted in accordance with Russian requirements. Environmental baseline permitting was initiated in 2003. Permitting is underway for the exploration and development programs proposed for 2004.

The steel frame for a proposed mill site is present 3 kilometres north of the north boundary of the Kupol project.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 4 – p.2 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 4 – p.3 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 5 – p.1 |

5.0 Accessibility, Climate, Local Resources, Infrastructure and Physiography

During the winter months the property is accessible from the town of Bilibino (population 7,000), via 298 km of roads comprised of 37 km of paved road, followed by 130 km of Government maintained winter road, to the village of the Ilirney (population 500), and 140 km of rudimentary winter road up the Anui River valley. During spring thaw, and for most of the summer, the property is only accessible via helicopter (a 1.25 hour flight from Keperveem or Bilibino). Alternate access is via a 3 hour (480 km) helicopter flight from Anadyr. Russian 'Vezhehoot' tank vehicles can access the property from mid summer to fall along the existing 'road' networks. A gravel airstrip capable of handling IL76 aircraft (during winter) is present at Keperveem (40 kilometres from Bilibino), and Anadyr is serviced by an 'all weather' paved airstrip. Anadyr (population 10,000), the Chukotka A.O. capital, is the closest major centre however the majority of supplies and logistical support come out of the City of Magadan (population 112,000) 1,220 km to the south. Both of these locales, as well as Bilibino and Pevek (300 km north), are mining centres and thus sources for skilled labour.

The property is situated on a height of land adjacent to the divide between the Arctic Ocean and Bering Sea drainages. The Straichnaya River drains north to the Anui River and the Kaiemveem-Sredniy-Kaiemraveem River drains into the Mechkereva River to the south. Topography is moderate with the Kaiemveem River canyon bisecting the eastern portion of the property. Elevations range from 755 metres in the northwest to 450 metres in the southeast portion of the property.

The camp consists of a new 64 person geological exploration tent camp, a containerized laboratory and a collection of Russian balekees ('trailers'). The camp is being expanded to 224 person capacity for next year with the new camp already in transit from Alaska.

The property is located approximately 40 kilometres north of the tree line and covered by tundra, rock outcrop and felsenmeer. Situated as it is above the Arctic Circle, and in the barren lands, the climatic zone is continental high arctic with temperatures to –55°C during the winter months and up to 25°C during the summer months. Because of the relatively high elevation, the higher portions of the property are exposed to winds of up to 160 km per hour. Due to the persistent winds the snow cover over most of the property is generally low, with significant accumulations only as cornices and in lee-slopes. Winter conditions can be expected from early June to mid September, however snowfall can occur any month of the year. Long daylight hours provide for longer operational hours during summer and the reverse in winter. Vegetation is limited to lichen, grass and arctic shrubs and flowers.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 5 – p.2 |

Power is available from the Bilibino nuclear power plant, however the plant is dated and the cost of installing and maintaining a 220 to 300 kilometer power line would likely be prohibitive.

Preliminary sites have been selected (by AMEC) for the tailings containment area, waste rock placement, air-strip, camp site and processing plant sites. Applications for additional land allotments are underway.

Baseline test water wells have been drilled at five locations in the Kaiemveem River valley. Additional testing for potable and plant water will occur next year.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 6 – p.1 |

6.0 History

Quartz veins were originally located in the Kupol area in the late 1960’s, during a Soviet government 1:200,000 regional mapping program. The main deposit was discovered by the Bilibino based Anyusk Geological Expedition in 1995, through follow up of anomalies identified with a 1:200,000 stream sediment geochemical sampling program, conducted the same year. Mapping, prospecting, magnetic and resistivity, lithogeochemical and soil surveys, all at 1:2000 scale, were conducted over the property in 1996 and 1997 (Anyusk, 2000). Four trenches and two drill holes were completed in 1998 followed by an additional 22 drill holes and 31 trenches up to the end of 2001. In 2000 and 2001, a 400 metre length of the vein system was stripped, exposed and channel sampled in detail.

Two metallurgical samples (145 kg and 1.7 tonnes) were collected in 2001 and preliminary petrographic and metallurgical testing conducted by the IRGIREDMET laboratory in Irkutsk (Panchenko and Kogan, 2000). Preliminary results indicated recoveries of 97.45% for Au and 90.7% for Ag based on a 24 hour cyanide leach of a gravity concentrate.

The previous work by the Russians has defined a Russian C1+C2 Reserve of 780,000 tonnes containing 835,000 ounces gold and 9,350,000 ounces silver at an average grade of 33.3 g/t gold and 372.8 g/t silver. This 'reserve' has not been prepared in accordance with 43-101 standards and only covers 450 m strike length, to a maximum depth of 140 metres, within the Central portion of the deposit.

The majority of the license area has been topographically surveyed at 2 metre contour intervals.

In 1999 a Russian Mining artel Metall acquired the rights to the deposit. Using the Anyusk Expedition as contractors geological evaluation work on the deposit was conducted (as indicated above) and the frame for a mill was partially erected to the north of the deposit. Metall did not pay for the work completed, nor did they file the work reports for the license and as a result their license was revoked in 2002.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 7 – p.1 |

7.0 Geological Setting

7.1 Regional Geology

The Kupol deposit is located in the 3000-km long Cretaceous Okhotsk-Chukotka volcanogenic belt (OCVB) (figure 7.1) . The OCVB is interpreted to be an Andean type tectonic setting with a subducting ocean plate being thrusted beneath a continental plate. The Kupol property is situated on the western margins of what the Russians refer to as the Mechkerevskaya volcano-tectonic depression, an apparent 20-25 kilometre wide bimodal nested volcanic complex. Mineralization is associated with a north-south trending splay off of a regional fault structure (Kupol Structure) of similar orientation. The Kupol stucture is interpreted to be a dilatant fault zone associated with major northwest arc-normal compressional dextral strike slip structures; prominent of which is the Anui River fault 25 kilometres to the north of Kupol.

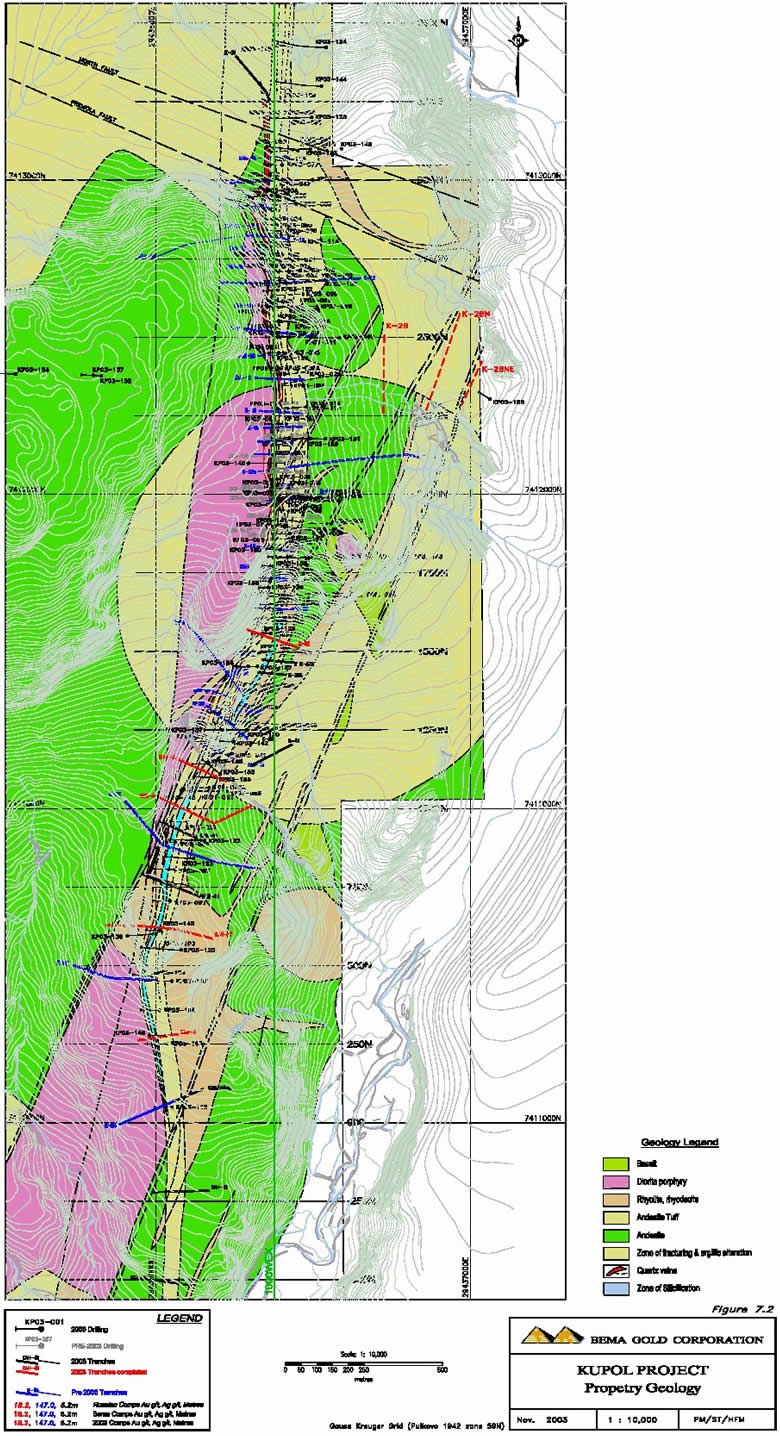

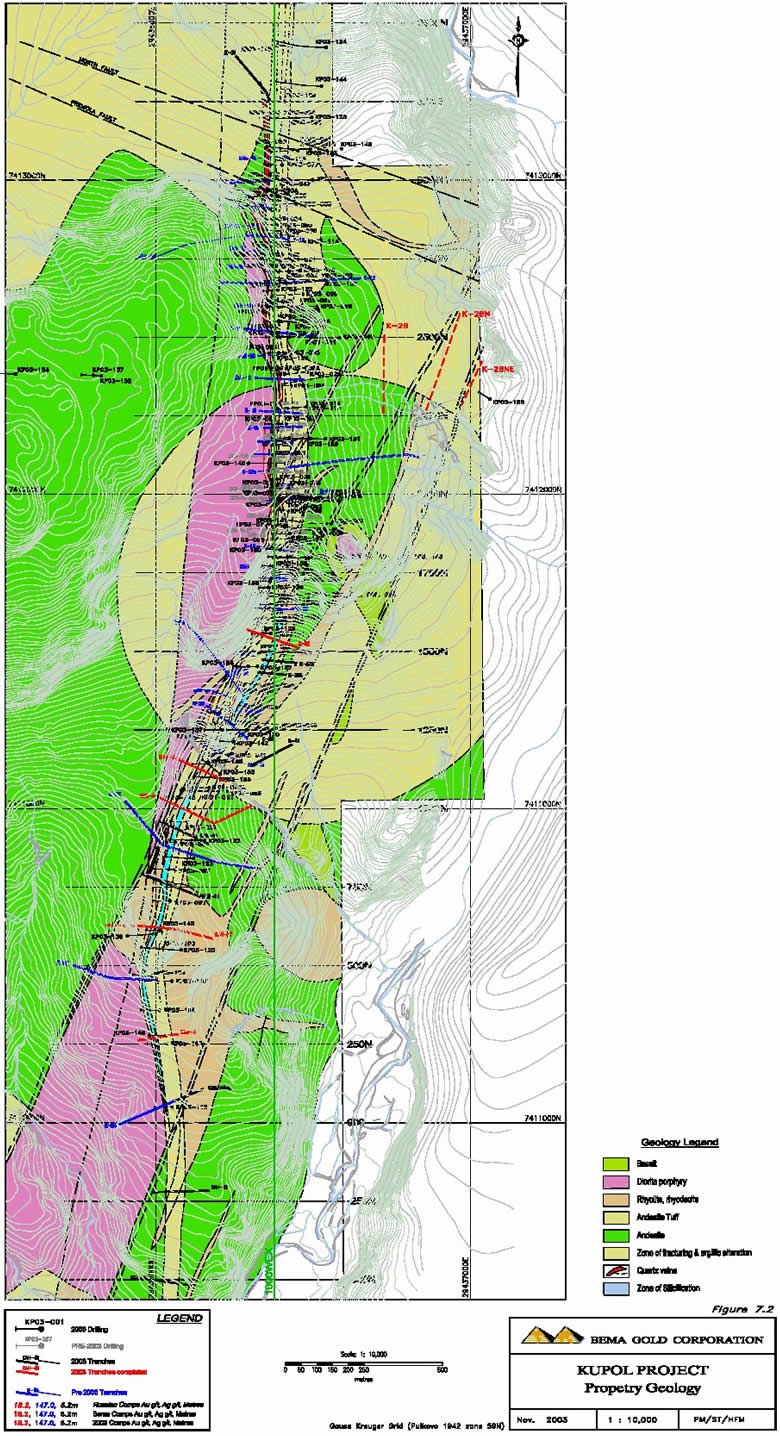

7.2 Property Geology

The property is underlain by a bimodal suite of andesite fragmentals, feldpar-hornblende porphyritic andesite and basaltic-andesite flows with minor basalts that dip eastward at approximately 20° (figure 7.2) . The andesitic volcanics have been intruded by massive to weakly banded rhyolite dykes, rhyolite and dacitic flow dome complexes and dykes of basaltic composition. There are likely two or more generations of felsic volcanism in the area. Late intrusions of andesitic and basaltic compositions cut the earlier units and form prominent features in the area, in particular the porphyritic andesite Kupol Dome structure – from which the property derives its name.

One distinct cross fault, the Premola Fault, cuts the northern part of the property. The faults strikes at approximately 300Az and offsets the veins and stratigraphy 25 to 35 metres in a dextral normal orientation. On the basis of the change in alteration assemblage and vein location, textures and mineralogy a second normal fault is inferred north of this location.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 7 – p.2 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 7 – p.3 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 8 – p.1 |

8.0 Deposit Type

On the basis of geological setting, vein textures, mineralogy and alteration assemblages, the Kupol deposit can be classified as a low sulphidation epithermal fissure vein type deposit in accordance with the classification of Hedenquist, Arribas and Gonzalez-Urien (2000). Another name for the same deposit style is quartz-adularia-sericite type, after the epithermal vein classification of Sillitoe (1993). The epithermal nature of the Kupol deposit is confirmed by Russian fluid inclusion studies that show (Vartanyan et al., 2001), homogenization temperatures for vein samples that range from 160° - 260°C.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 9– p.1 |

9.0 Mineralization

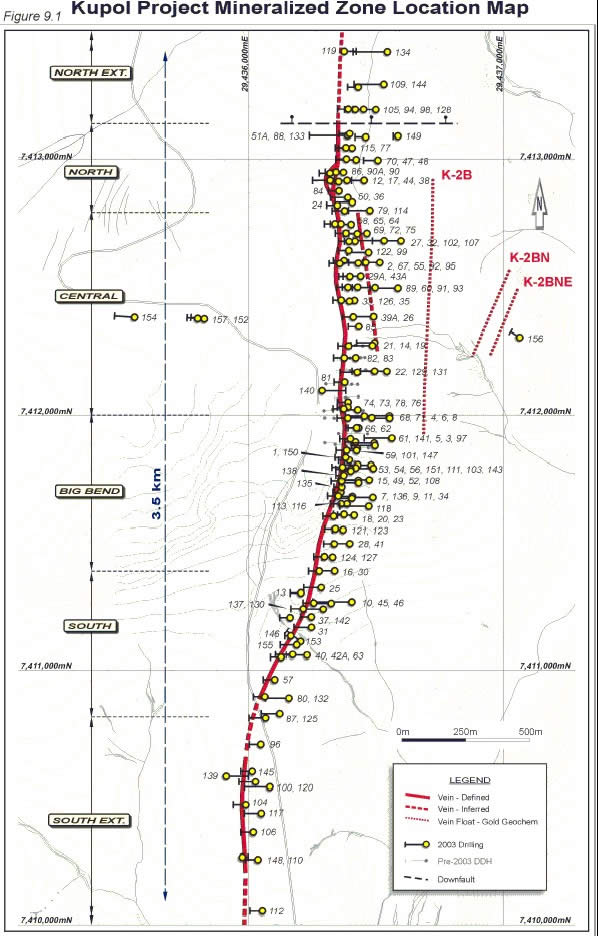

The Kupol deposit is comprised of quartz-adularia veins and quartz-adularia vein breccias hosted within the large north-south trending Kupol fault structure, that has been exposed through prospecting, mapping, geochemical sampling, geophysical surveying, trenching and drilling over a strike length of 5.3 kilometres. The main vein and sheeted-stringer vein zones associated with the vein structure has a maximum width of 55 metres and dips steeply (75-90°) to the east. The main vein has true widths of up to 18 metres and consists of a complex vein and vein breccia zone, that is commonly divided into footwall (FW) and hangingwall (HW) zones by a central rhyolite dyke. Within portions of the main structural corridor zone two or more veins occur in large sigmoid loop structures, in anastomosing vein structures and in bifurcating splays. The vein system has a weak sinusoidal character with flexures and jogs in the structure, producing wider zones of mineralization.

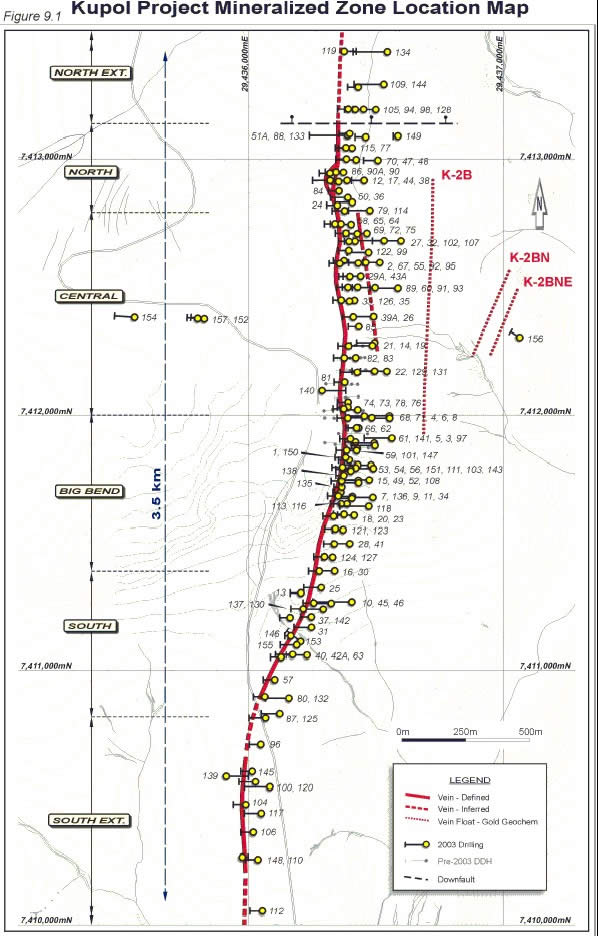

The Kupol vein has been divided into six contiguous zones based on structural breaks and similarity in vein character and mineralization within each of these zones (figure 9.1) . From south to north: 1) South Extension, 2) South, 3) Big Bend, 4) Central, 5) North and 6) North Extension. The vein system is continuous between these zones and has been traced through prospecting, mapping and drilling for 3.3 kilometres. Drilling has defined the vein system to a depth of greater than 425 metres below surface, and 'ore' grades (>8 g/t Au over > 1 metre) have been encountered at greater than 270 metres below surface.

The quartz veins are of an epithermal low sulphidation (quartz-sercite-adularia) type and display classic high level epithermal textures: drusy quartz, banded crustiform, vuggy quartz, cockscomb, banded colloform, cockade, bladed and comb textured. Most of the veins have been brecciated and re-healed. Locally the veins are chalcedonic and contain zoned amethyst veining. Throughout the mineralized system seven predominate vein textures have been identified:

| 1) | massive to sucrosic, vuggy, fine to medium grained |

| 2) | colloform banded vein |

| 3) | sulphide or rock flour cemented breccia vein |

| 4) | quartz healed brecciated quartz vein |

| 5) | wall rock breccia |

| 6) | yellow siliceous breccia |

| 7) | stockwork |

On the basis of mineral composition and sulphide occurrence seven ore types have been distinguished:

| 1) | Pyritic-hematitic, colloform |

| 2) | Brecciated, vuggy, colloform to crustiform sulphosalt rich |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 9– p.2 |

| 3) | Jarosite-sericite rich siliceous breccia |

| 4) | Chloritic+sulphidic quartz-adularia breccias |

| 5) | Pyritic chalcedonic quartz-adularia+colloform banding |

| 6) | Sulphide rich breccias |

| 7) | Chalcedonic-crustiform finely banded |

The best gold and silver mineralization occurs in brecciated colloform banded quartz-adularia veins and where later sulfosalt rich silica flooding cuts across earlier brecciated colloform banded or chalcedonic to fine grained crustiform quartz. Ore minerals comprise; native gold, electrum, acanthite, naumannite, sulphosalts (in general order of abundance; stephanite, perceite, freibergite, pyrargyrite, polybasite, miargyrite and proustite), pyrite, marcasite, galena, chalcopyrite, arsenopyrite, tennantite-tetrahedrite and stibnite (Vartanyan et al., 2001).

Fracture controlled oxidation within the vein system extends to a maximum depth of 300 metres below surface but the bulk of the oxidation is of a transitional type within 40 to 75 metres of surface. Oxidation state varies along strike, but is predominantly in the form of fracture controlled jarosite and limonite in the Big Bend, Central and northern zones of the deposit with hematite to the south.

Native gold, electrum and acanthite can be seen in sulphosalt rich bands, sulphosalt rich fragments, free in quartz, and in sulphosalt rims around breccia fragments.

Russian petrographic studies have identified three stages of gold and sulphosalt mineralization (Vartanyan et al. 2001):

| Stage 1 | 240° - 260° | gold, perceite, chalcopyrite |

| Stage 2 | 200° - 220° | gold, freibergite, stephanite, pyrargyrite |

| Stage 3 | 160° - 180° | gold, pyrargyrite |

Sheeted high-level, epithermal textured quartz vein mineralization (10-20% veining) extends 1 - 5m (and up to 20m) into the structural hangingwall and footwall of the Kupol vein system. Grade within the sheeted vein sets is highly variable.

All significant veins are hosted within andesite and andesite-basalt flows and fragmental units. Aphanitic, flow banded to weakly porphyritic rhyolite dykes and rhyolitic flows and flow breccia complexes occur parallel to sub parallel to the veins and cross-cut the veins.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 9– p.3 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 10 – p.1 |

10.0 2003 Exploration

Exploration in 2003 was biased toward the diamond drilling program discussed in section 11.0. Additional exploration included:

| 1) | Trenching: 2.5 kilometres in 15 trenches |

| 2) | Detailed magnetic surveying: 18.15 line kilometres at 25 m x 5 m spacing. |

| 3) | Reconnaisance mapping, prospecting and sampling in areas of proposed mine infrastructure. |

| 4) | Prospecting and general 1:4,000 scale mapping of selected areas of the property. |

This work is summarized below.

10.1 Trenching

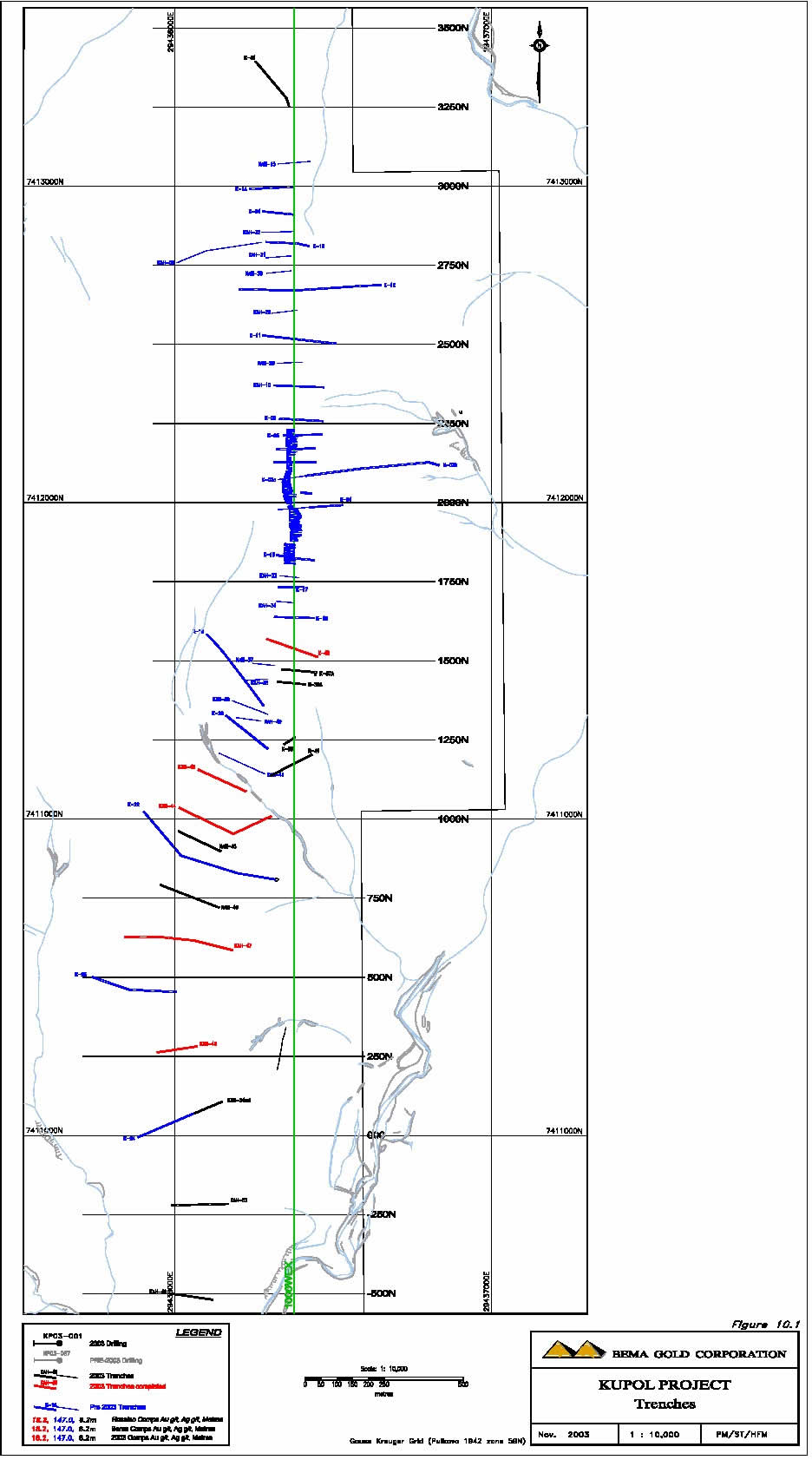

Due to permafrost conditions, excessive water and the poor state of the bulldozer equipment, only 5 of the 15 trenches started this year were partially mapped and sampled. The remaining trenches were mapped in a cursory fashion in an attempt to obtain some information from them prior to the closure of the trenching season. Trenches were placed along the Kupol structure as infill and stepout trenches to help define the grade and width of the vein(s), and define and locate the alteration zone associated with the structure. New trenches are shown on figure 10.1 and results presented below (Table 10.1):

Table 10.1: Summary of 2003 trenching results

| | Section | Zone | Metres | Au g/t | Ag g/t |

| | | | | | |

| K-42 | 1570N | HW | 3.2 | 71.04 | 756.57 |

| | | | | | |

| K-43 | 1150N | | 12.5 | 3.08 | 38.61 |

| | | FW | 2.3 | 9.71 | 71.02 |

| | | | | | |

| K-44 | 1025N | FW | 1.0 | 3.58 | 71.43 |

| | | | | | |

| K-47 | 625N | HW | 3.4 | 34.44 | 775.49 |

| | | | | | |

| K-48 | 200N | FW | 1.0 | 47.86 | 154.78 |

| | | HW | 3.0 | 4.51 | 21.18 |

| | | HW | 5.0 | 3.0 | 152.96 |

Selected trenches were re-sampled to confirm grades previously reported and to check the Kupol laboratory analyses. Results from these trenches are reported below (Table 10.2):

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 10 – p.2 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 10 – p.3 |

Table 10.2: Summary of 2003 trenching re-sampling results

| | Metres | Au (g/t) | Ag (g/t) |

| K-20 | FW | 3.0 | 6.69 | 110.46 |

| K-34 | HW | 10.50 | 93.15 | 462.88 |

| K-16 | FW | 10.0 | 71.57 | 938.06 |

| K-16A | FW | 6.0 | 103.51 | 787.61 |

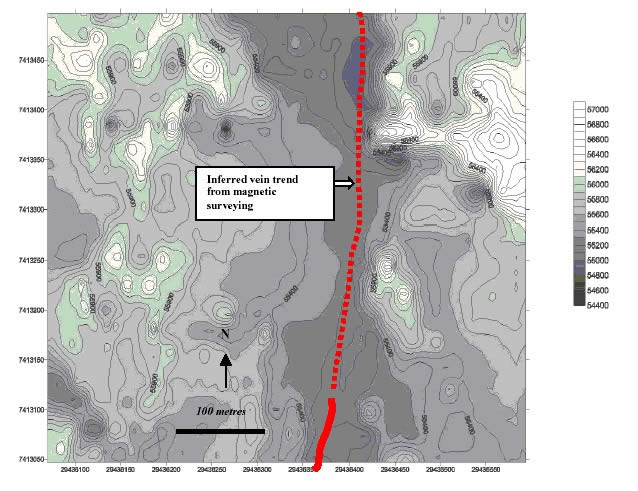

10.2 Magnetic Surveying

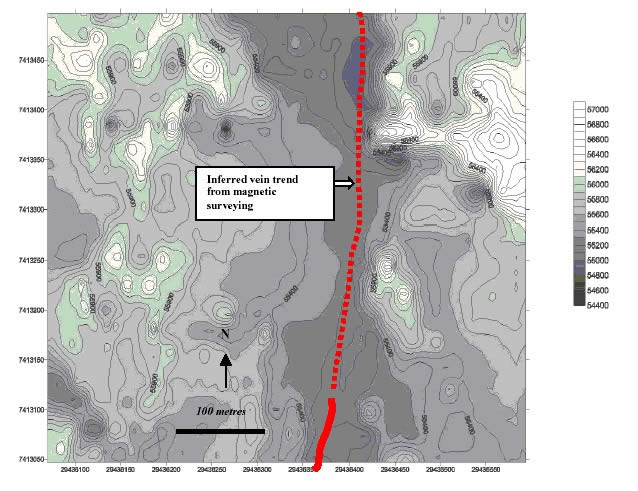

There is a high contrast between unaltered andesites and the mineralized zones, due to the strong alteration and related magnetite destruction. In order to better define the alteration, and coincidentally the vein system, a detailed survey was completed in the northern and southern portions of the property. To the north (figure 10.2), the surveying provided good definition of the main alteration trend and was used for spotting drill holes. In an effort to define alteration trends associated with geochemical anomalies, the southern survey examined the area east of the main Kupol structural corridor. The southern survey (figure 10.3) was not as successful in defining a distinct trend, due to the larger areas of alteration and lower contrast between the altered rhyolites dykes, domes and flows. No distinct anomalies coincident with the geochemical anomalies were located east of the main veins.

Magnetic surveying was performed using a Geometrics Proton G858 magnetometer. A diurnal correction was applied to the data by looping back to a reference point after the completion of each line followed by a computerized leveling correction applied at the end of each day’s surveying. A secular correction was applied to the data by correcting back to the magnetic baseline. The data was plotted using Surfer software.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 10 – p.4 |

Figure 10.2: Kupol Project - Northern Grid Magnetic Survey:

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 10 – p.5 |

Figure 10.3:Kupol Project - Southern Grid Magnetic Survey:

10.3 Mapping and Prospecting

Several smaller high-grade (>10 g/t Au) veins were identified through drilling and mapping in 2003 (figure 9.1) . These veins and float trains occur outside of, but parallel to, sub parallel to the main vein structure. Selected results from these veins are tabulated below (Table 10.3):

Table 10.3: Selected 2003 prospecting sample results

| Zone K-2B: | | | |

| Sample # | Type | Au g/t | Ag g/t |

| P1101 | float | 41.16 | 320.6 |

| P1102 | float | 23.54 | 90.10 |

| P1105 | float | 93.30 | 949.80 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 10 – p.6 |

| P1202 | float | 85.88 | 563.08 |

| P1203 | float | 18.34 | 40.8 |

| | | | |

| Zone K-2B-N: | | | |

| Sample # | Type | Au g/t | Ag g/t |

| P1106 | float | 205.90 | 1812.9 |

| P1109 | float | 17.16 | 119.80 |

| P1110 | float | 13.16 | 366.90 |

| | | | |

| Zone K-2B-NE | | | |

| Sample # | Type | Au g/t | Ag g/t |

| P1114 | grab | 12.0 | 101.04 |

| P1109 | grab | 13.74 | 176.22 |

| P1110 | grab | 15.86 | 156.98 |

| | | | |

| Kupol South | | | |

| Sample # | Type | Au g/t | Ag g/t |

| P1191 | float | 6.78 | 3.24 |

| P1192 | float | 3.24 | 87.16 |

As indicated earlier the Kupol stucture is a long-lived large regional dilational fault structure. On the basis of stratigraphy the Kupol structure appears to a normal fault with west side up. The magnitude of the displacement is not known at this time. Russian mapping suggests the central portion of the deposit is hosted within a circular basin fill caldera subsidence complex. Mapping and drilling has defined several faults in the northern portion of the deposit. The west to northwest trending faults have apparent dextral – normal vectors with up to 40 metres lateral and 125 metres vertical displacement. The north trending fault, located 100 metres east of the main structure, has a normal displacement of 30-40 metres.

Argillitic alteration extends 40 – 50 metres into the structural hangingwall, with the extent of alteration largely dependent on the porosity of the various host units. The clay alteration is often accompanied by pervasive and fracture filling calcium carbonate+disseminated pyrite. The pyroclastic units are generally more strongly altered than the flow units. Determination of clay speciation is underway. To the north the clay alteration is particularly intense with 109 metres of strong to very strong clay alteration encountered in hole KP03-119. This area of clay alteration is interpreted to be the top of the Kupol hydrothermal system. Drilling below this clay alteration, in holes KP03-128, 134 and 144, confirmed the existence of 'ore' grade epithermal vein mineralization. The clay-jarosite alteration zone continues into the Kaiemveem River to the south, as indicated by the broad zone of intense, pyritic clay alteration along the river banks and exposed in trenches K-49, K-52 and K-24. Clay type varies by location with kaolinite dominant to the north and at shallower levels, and illite-montmorillonite more prevalent

|

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 10 – p.7 |

in the Big Bend hanging wall.

Within 150 metres of the Kupol structure, particularly in the hangingwall of the vein, the rocks are weak to moderately propylitically altered (chlorite-calcite+pyrite+epidote).

Alteration adjacent to the veins consists of silica, adularia and pervasive sericite-illite(?) in the hangingwall and footwall volcanic units. In selected areas, the silicification extends up to 40 metres from the vein (eg. Trench K-42). Near surface the silicification-adularization - sericitization is commonly accompanied by a strong late supergene (?) sulphate rich jarositic (yellow) colour anomaly. The rhyolite dykes are commonly weak to moderately clay altered. At depth within the Central and northern Big Bend areas of the deposit there is a broad chloritic alteration zone. Within this zone chlorite+ pyrite replaces original sulphosalt bands and sulphidic breccias, and the fine colloform and crustiform quartz bands have been partially re-crystallized suggesting that this alteration represents a prograde thermal overprint associated with the intrusion of the late Kupol dome or similar plug.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.1 |

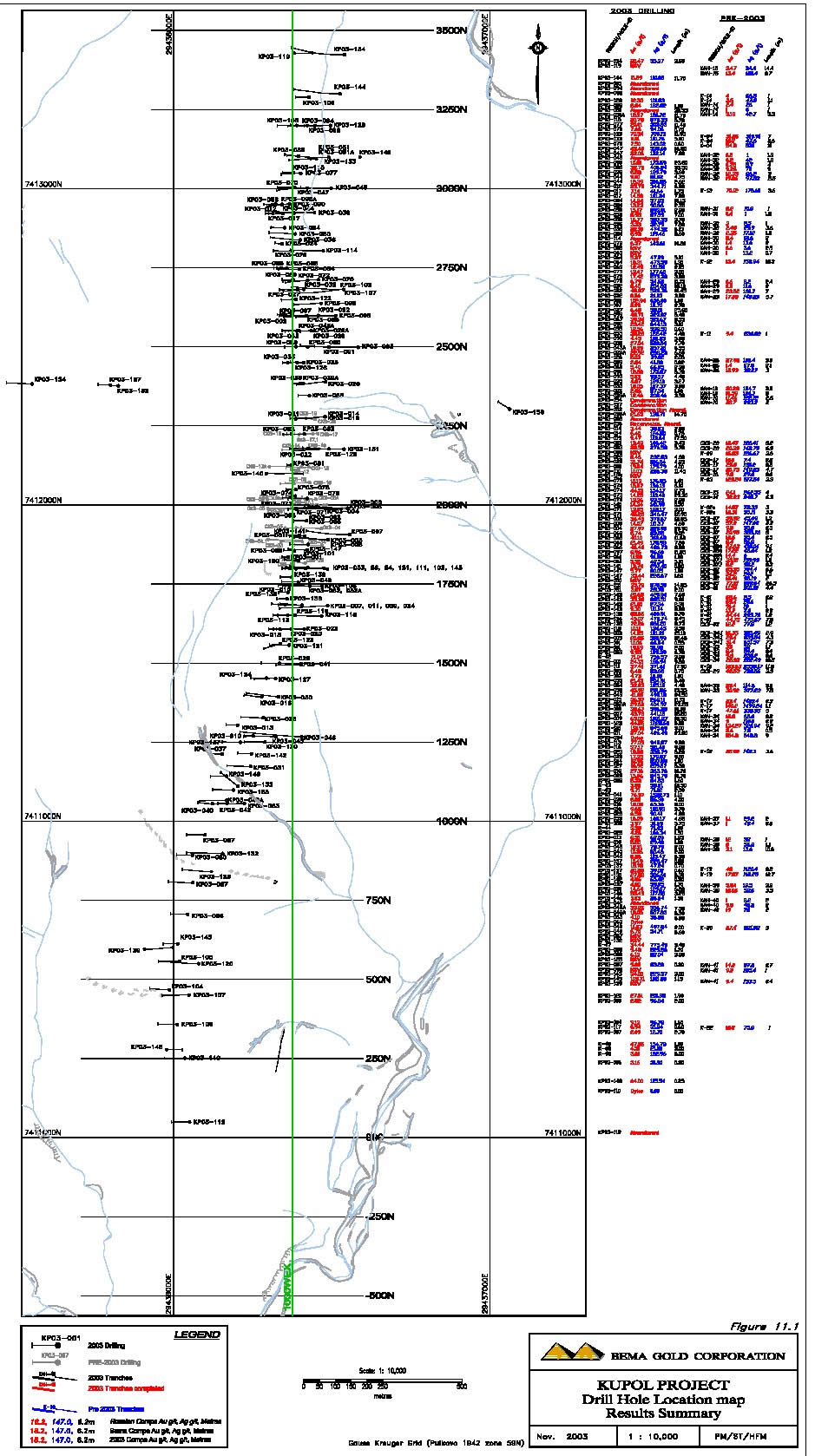

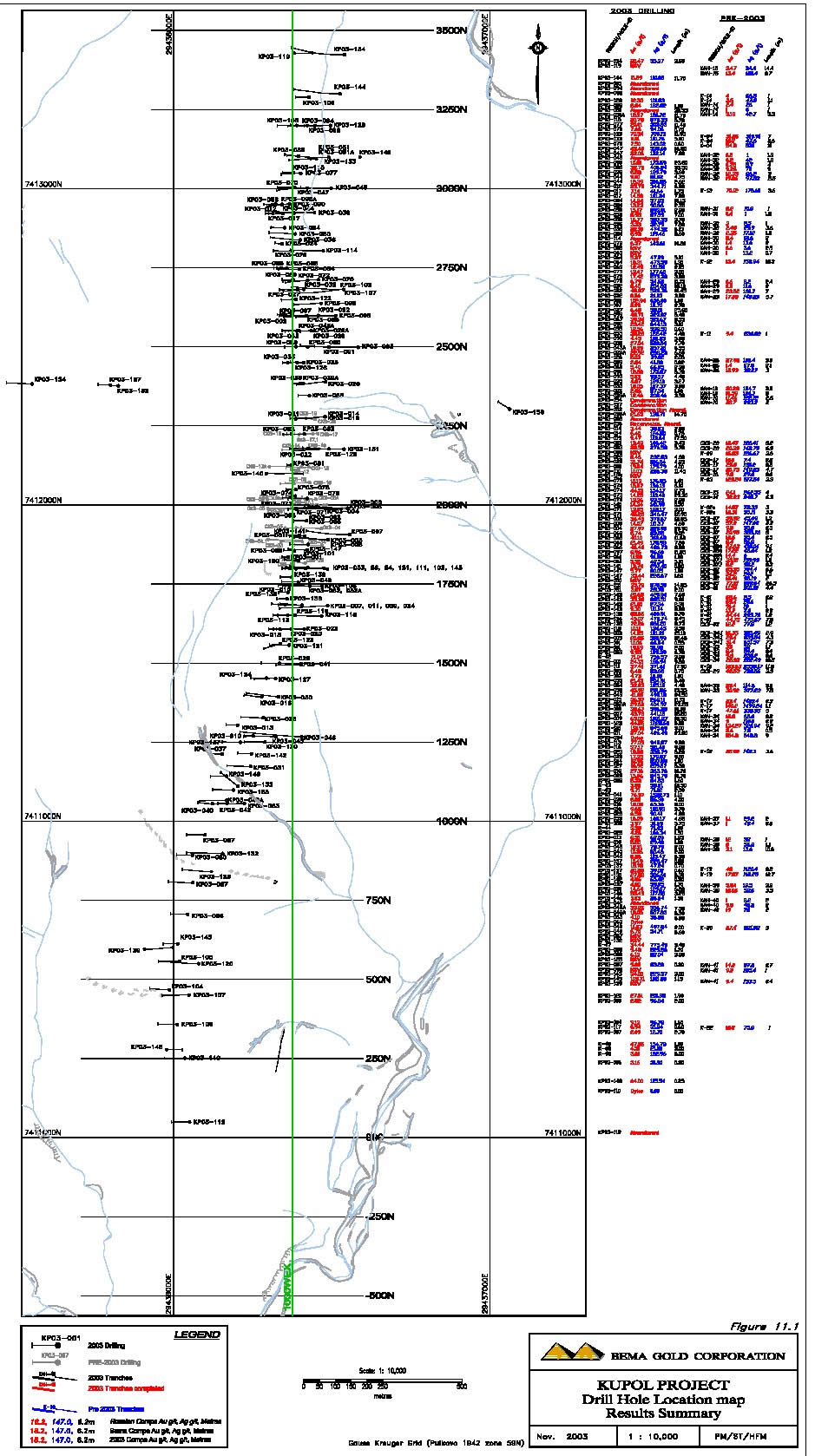

11.0 Drilling

In 2003 22,256 metres of diamond drilling in 166 holes was completed utilizing two Longyear 38 drills, drilling HQ and NQ sized core, and two Russian CKB-4 drills, drilling NQ sized core. All collars were surveyed by conventionaland total station survey instruments and 'all' holes down-hole surveyed utilizing aReflex EZ shot survey instrument. Holes are tied in to a local and regional survey network, in a local Russian grid system and Guass-Kruger (Pulkov 42) geodetic system. Russian theodolitic surveyed locations were audited using Alaskan legal surveyors (Design Alaska out of Fairbanks, AK) and total station instrument. Drill hole locations are shown on figure 11.1.

The drilling program was overseen by Tom Garagan, P.Geo, Vice President Exploration, Bema Gold Corporation, and directly supervised by three registered Canadian Professional Geologists (Project Manager -Hugh MacKinnon, P.Geo, Drill Geologist -Peter Fischl, P.Geo, Drill Geologist -Linda Lewis, P.Geo) and a fourth geologist (Senior Geologist - Vernon Shein) with greater than twenty years exploration, mining and drill experience. All these geologists were responsible for monitoring the drilling, core movement, core logging and core handling during the program. Detailed core logging was performed by university trained professional Russian geologists. Geological data collection included identification of lithologies, vein types, textures, sulphide type and abundance, alteration type and intensity, structure, magnetism, colour and grain sizes. Geotechnical measurements included recoveries and RQD for all core and specific gravity on representative lithologies. Selected holes were logged in geotechnical detail. Logs are written in hand then entered into an EXCEL database and converted to a ACCESS database. The database is controlled, verified and audited by Vivian Park, P.Geo and Jim Smith, P.Geo. Verification was done through a series of checks of data entry against original logs and assay certificates. Vein intervals in the first forty 2003 drill holes were re-logged to ensure conformity of early logging with later logging.

Sample intervals are based on lithology and range from a minimum of 25 cm (HQ) to maximum of 1.0 metres. A minimum of 1.0 and 3.0 metres is sampled in to the footwall and hanging wall of the vein structures.All sample intervals were photographed prior to cutting and characteristic mineralization, vein and ore types photographed in detail.

Core recoveries vary with location with recoveries in the zones ranging from 35% to 100% with an average of about 85%. Drilling muds and polymers are used extensively to enhance recoveries. Holes with poor zone recoveries were re-drilled (KP03-48A and 90A), with the exception of holes KP03-77 and 144 which will have to be re-drilled in 2004.

Drill results are summarized in Appendix 1 and presented on a summary longsection (figure 11.2) . Drill hole locations are tabulated in Appendix 2.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.2 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.3 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.4 |

As stated in section 9.0, the deposit is divided into six contiguous zones (Map 9.1) . A summary of results from each of these zones is presented below.

11.1 South Extension Zone

The South Extension zone extends from the Kaiemveem River at 8+50 S to 8+00 N and has been tested by 11 holes from 0+50 N to 8+00N. Significant drill results from this zone (Appendix 1) include: holes KP03-120 which intersected 1.90 metres of 27.51 g/t Au and 201.98 g/t Ag; hole KP03-145 which intersected 1.15 metres of 103.71 g/t Au and 1011.08 g/t Ag and 3.00 m 34.00 g/t Au and 229.37 g/t Ag; and hole KP03-104 which intersected 1.80 metres grading 9.13 g/t Au and 96.78 g/t Ag. Drilling and mapping indicates that there are three or more veins in this area with variable widths and grades. Rhyolite flows and dykes partially disrupt vein zones. The zones appear to be narrower, partially lensoidal, and not as continuous as those to the north. Drilling to date has been limited within this area, however, it has indicated the potential to develop ore shoots. Tighter spaced drilling will be required to define the geometry of the ores shoots. Vein float and strong alteration along strike to the south and intersections such as that of hole KP03-120 (figure 11.3) indicates the zone is still open to the south and at depth.

11.2 South Zone

The South zone is contiguous with the South Extension and Big Bend zones and comprises 575 metre of strike length of the deposit within which there is a separation of up to 75 metres between the hangingwall and footwall veins. The hangingwall vein is wider than the footwall vein and in general contains higher grades. Twenty one holes tested this zone this year. Better intersections within this zone include: hole KP03-42A with 7.60 metres (6.5 metres true width) of 33.26 g/t Au and 356.74 g/t Ag in the hanging wall and 5.30 metres (4.6 metres true width) grading 18.05 g/t Au and 507.53 g/t Ag in the footwall; hole KP03-130 with 5.30 metres (true 5.30 metres) averaging 27.88 g/t Au and 306.60 g/t Ag in the hangingwall; and hole KP03-31 with 6.8 metres (true width) of 14.64 g/t Au and 129.07 g/t Ag in the hanging wall. The zone is bisected by rhyolite dykes and rhyolite flows that locally disrupt the zone (figure 11.4) . Continuity of the mineralization is good in the hanging wall vein, and needs better definition in the footwall vein. Up to 55 metres (true width 45 metres) of veining and sheeted veining was intersected in this zone of which only shorter intervals carried significant high grades. Drilling covering this zone is still widely spaced so infill drilling is required to define the higher-grade ore shoots. The zone is open at depth.

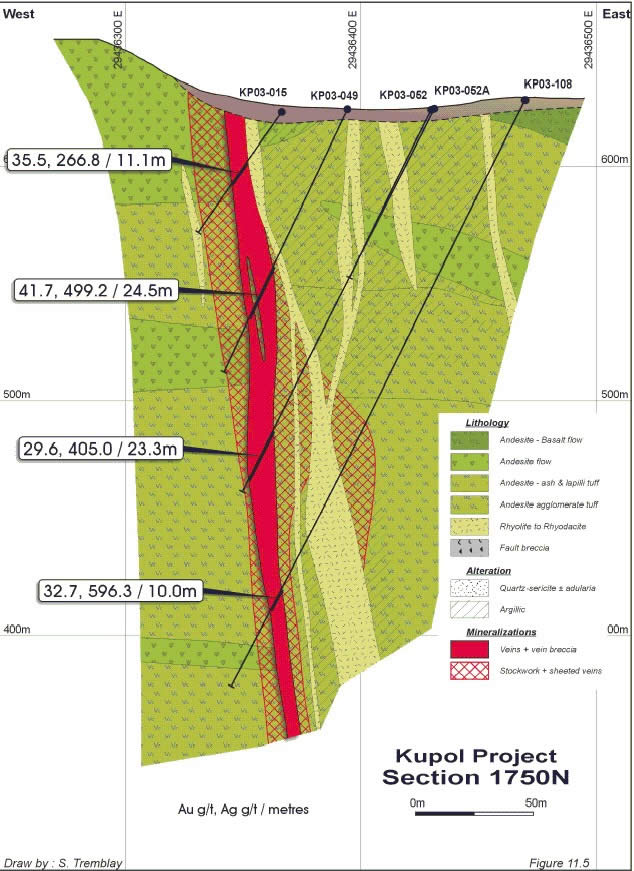

11.3 Big Bend Zone

The Big Bend zone vein strikes continuously for 650 metres and is contiguous with the South and Central zones and occurs at a flexure or kink in the vein system with the gradual change in strike of the structure from 000 to 020 Az toward the southern zone.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.5 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.6 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.7 |

The zone has been at drilled at 50 to 100 metre centres to a maximum depth of 280 metres below surface with selected areas drilled at 25 metre centres, including a geostatistical cross centered on 1800 N at the 600 metre level. True widths vary from 1.0 metres to 18.0 metres with a drill intersected true width average of 6.46 metres for the footwall vein and 6.26 metres for the hangingwall vein. Arithmetic average grades for the intersections are 29.58 g/t Au with 348.59g/t Ag for the footwall and 27.05 g/t Au with 309.65 g/t Ag for the hanging wall.

Two holes, KP03-03 and KP03-04 scissor twinned the Russian hole CKB-34 and CKB-5 respectively. Results are compared below (table 11.1):

Table 11.1: Comparison of scissor twin hole results

| KP-03-03 | CKB-34A | |

| Au g/t | Ag g/t | Intersection

Length

m | True

Width

(TW)

m | Au x TW | Au g/t | Ag g/t | Intersection

Length

m | True

Width

(TW)

m | Au x TW | % Difference

Au x m |

| 14.73 | 180.44 | 15.1 | 14.0 | 206.22 | 16 | 340.1 | 29.2 | 14.0 | 224 | -8.6 |

| KP-03-04 | CKB-05 | |

| Au g/t | Ag g/t | Intersection

Length

m | True

Width

(TW)

m | Au x TW | Au g/t | Ag g/t | Intersection

Length

m | True

Width

(TW)

m | Au x TW | % Difference

Au x m |

| 27.97 | 220.9 | 29.9 | 18 | 503.46 | 51.6 | 530.9 | 41.3 | 27.5 | 1419 | -181.8 |

Both confirmation test holes encountered lower grades over similar true widths. Hole CKB-05 drilled down dip of a high-grade zone in the hanging wall of the vein, while hole KP03-04 encountered high grades in the footwall of the same zone. Further drilling within this area suggests that the grades are somewhat more variable in this small section of the deposit. Due to bad ground conditions no downhole surveying was performed on the pre 2003 Russian holes and other than the internal lab control, no QA/QC program was run to verify the assays reported. As a result the Russian holes will not be used in any of the resource /reserve studies and these holes will be re-drilled as required.

Forty-eight holes tested the Big Bend zone this year. Better intersections from the Big Bend zone include: 18.30 metres (11.0 metres true) grading 65.05 g/t Au and 1021.27 g/t Ag in hole KP03-09, 24.50 metres (11.50 metres true width) grading 43.40 g/t Au and 499.18 g/t Ag in hole KP03-49: 29.90 metres (18 metres true width) grading 27.97 g/t Au and 27.97 g/t Ag in hole KP03-04; and 9.80 metres (6.20 metres true) grading 77.05 g/t Au and 949.87 g/t Ag in hole KP03-113 and 8.70 metres (6.75 metres true) grading 88.56 g/t Au and 480.91 g/t Ag in hole KP03-138. Native gold and coarse grained sulphosalts are very common in the Big Bend zone. Grades reported for the zone intersections reflect continuous high grade mineralization within the veins. The continuity of mineralization within the vein is evident in the examples of drill hole intersections from separate drill sections tabulated below (table 11.2):

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.8 |

Table 11.2: Big Bend Zone – Examples of grade continuity within the vein

| Hole KP03-09 | Hole KP03-111 |

| From | To | Metres | Au g/t | Ag g/t | From | To | Metres | Au g/t | Ag g/t |

| 102.50 | 103.50 | 1.00 | 82.34 | 1313.16 | 116.00 | 116.50 | 0.50 | 15.96 | 252.56 |

| 103.50 | 104.40 | 0.90 | 43.82 | 615.86 | 116.50 | 117.10 | 0.60 | 13.94 | 202.60 |

| 104.40 | 105.00 | 0.60 | 52.52 | 903.14 | 117.10 | 117.80 | 0.70 | 14.36 | 223.76 |

| 105.00 | 106.00 | 1.00 | 34.74 | 727.56 | 117.80 | 118.40 | 0.60 | 32.20 | 272.18 |

| 106.00 | 107.00 | 1.00 | 92.64 | 2083.16 | 118.40 | 119.00 | 0.60 | 72.14 | 235.80 |

| 107.00 | 107.60 | 0.60 | 108.36 | 3174.38 | 119.00 | 119.80 | 0.80 | 50.96 | 145.10 |

| 107.60 | 108.10 | 0.50 | 7.10 | 170.82 | 119.80 | 120.70 | 0.90 | 13.56 | 150.90 |

| 108.10 | 109.00 | 0.90 | 19.48 | 275.56 | 120.70 | 121.30 | 0.60 | 23.48 | 251.64 |

| 109.00 | 110.00 | 1.00 | 67.60 | 1471.86 | 121.30 | 122.30 | 1.00 | 36.64 | 387.78 |

| 110.00 | 111.00 | 1.00 | 13.48 | 385.54 | 122.30 | 123.30 | 1.00 | 43.62 | 577.36 |

| 111.00 | 112.00 | 1.00 | 50.64 | 645.46 | 123.30 | 124.20 | 0.90 | 25.34 | 182.12 |

| 112.00 | 113.00 | 1.00 | 36.90 | 386.82 | 124.20 | 125.20 | 1.00 | 14.68 | 319.48 |

| 113.00 | 114.00 | 1.00 | 217.06 | 3025.78 | 125.20 | 125.70 | 0.50 | 3.02 | 55.24 |

| 114.00 | 115.00 | 1.00 | 120.04 | 1918.68 | 125.70 | 126.50 | 0.80 | 3.26 | 70.44 |

| 115.00 | 116.00 | 1.00 | 158.36 | 1955.90 | 126.50 | 127.50 | 1.00 | 83.62 | 1820.20 |

| 116.00 | 117.00 | 1.00 | 51.20 | 631.00 | 127.50 | 128.10 | 0.60 | 8.82 | 188.58 |

| 117.00 | 117.40 | 0.40 | 14.10 | 90.18 | 128.10 | 128.70 | 0.60 | 1.26 | 24.10 |

| 117.40 | 118.40 | 1.00 | 23.24 | 152.90 | 128.70 | 129.40 | 0.70 | 48.00 | 1381.26 |

| 118.40 | 119.40 | 1.00 | 21.46 | 108.72 | 129.40 | 130.10 | 0.70 | 32.82 | 167.72 |

| 119.40 | 120.40 | 1.00 | 14.78 | 48.40 | 130.10 | 130.80 | 0.70 | 83.06 | 308.32 |

| 120.40 | 120.80 | 0.40 | 42.82 | 60.80 | 130.80 | 131.70 | 0.90 | 143.46 | 379.34 |

| | 131.70 | 132.70 | 1.00 | 27.50 | 276.76 |

| 132.70 | 133.30 | 0.60 | 46.14 | 220.86 |

| 133.30 | 133.90 | 0.60 | 5.00 | 14.32 |

Quartz veining, mineralization and consequently grades in each drill section and between sections within the zone are continuous, as indicated in the representative section shown in figure 11.3.

Over the central and southern portions of the Big Bend there is a single large polyphase breccia vein with associated sheeted veining. This vein is divided into footwall and hangingwall segments by a 3 to 20 metre wide rhyolite dyke that bisects the zone. Toward the Central zone there are two main veins. Over the strike of the Big Bend both vein(s) are open at depth, and as indicated by hole KP03-143, are not thinning at depth. Toward the Central zone there is a partial decrease in grade continuity as a function of the vein starting to bifurcate and feather toward the upper levels of the epithermal system. However, vein segments, either footwall or hanging wall within this area, still carry significant grades.

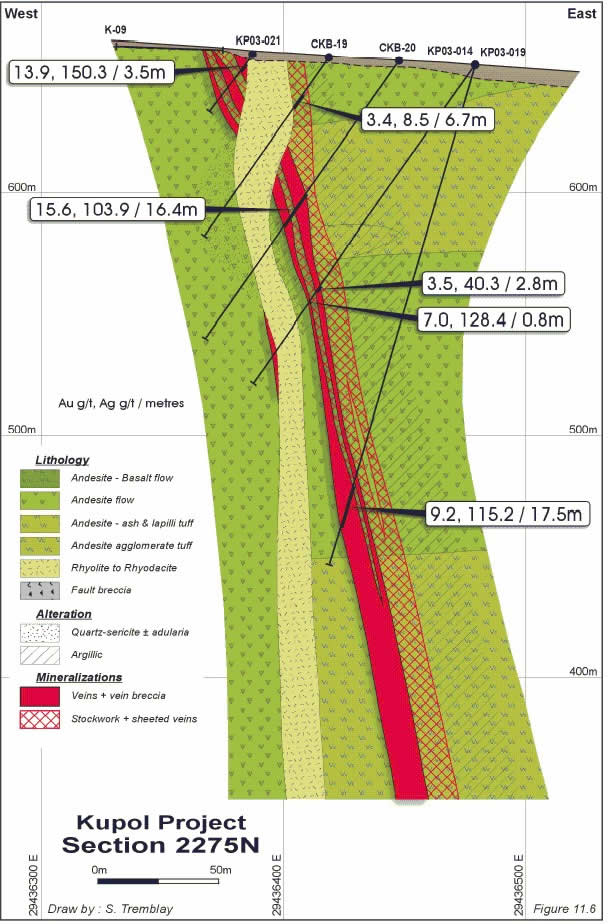

11.4 Central Zone

The Central zone covers an 800 metre strike of the Kupol vein structure contiguous with the Big Bend and North zones. Drill spacing on the upper levels of the zone range from 100 metres to 25 metres but hole spacing in the deeper levels (>100 metres depth) is

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.9 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.10 |

greater than 100 metre. Forty-three holes tested the zone to a maximum depth of 430 metres below surface and it remains open at depth. As with the Big Bend zone the main rhyolite dyke segments the Central zone. The Central zone has distinct high-grade shoots, principal of which is the one centered on 2600 N. The geometry of the main shoots has not been well defined.

Better results from the Central zone include: 7.70 metres (6.20 metres true width) grading 27.04 g/t Au and 580.54 g/t Ag in hole KP03-02; 8.55 metres (6.50 metres true width) grading 39.34 g/t Au and 313.67 g/t Ag in hole KP03-67; 29.30 metres (24.50 metres true width) grading 14.25 g/t Au and 113.40 g/t Ag in hole KP03-73 and 10.45 metre (7.75 metres true width) grading 48.87 g/t Au and 526.36 g/t Ag in hole KP03-122. Shoot development in this zone appears to be in part a function of swings and dilational 'blow outs' in the vein structure, potentially related to junctions with northeast and/or northwest trending structures. At these 'blow outs' large vein and sheeted veins systems are present, including those intersected in the following holes: holes KP03-73, adjacent to the Big Bend, with 24.50 metres true width grading 14.25 g/t Au and 113.40 g/t Ag; hole KP03-32, with 45 metres of veining intersected within which there is 10.50 metres true width graded 8.40 g/t Au with 204.53 g/t Ag; and hole KP03-27 with 15.20 metres true width grading 6.48 g/t Au with 58.01 g/t Ag. Sulphosalt concentrations are generally lower in this zone and there is a higher percentage of lower grade crustiform, chalcedonic veining present. On the basis of the drilling in 2003 the continuity of mineralization within the higher grade zone extends to greater than 250 metres below surface. Outside of the high-grade zones the zone is mineralized over the length of the sector with the exception of limited areas where dyke or fault interaction pinches out the zone. Local pinching and or stockwork development is believed to reflect a reduction in constraining pressure as a function of proximity to surface and interaction with the meteoric water table.

At the northern end of this zone the rhyolite dyke splays to the nrorthwest off of the zone and thus does not limit the northern section of the vein.

A typical section from the Central zone is shown in figure 11.6.

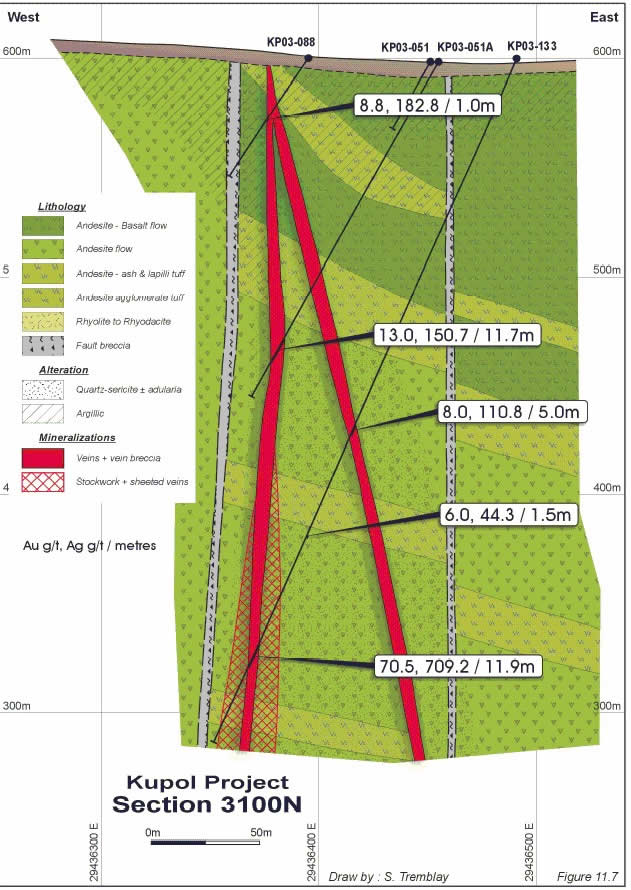

11.5 North Zone

TheNorth zone has a strike length of 350 metres and is contiguous with the Central and North extension zones. Twenty widely spaced drill holes have tested this area resulting in the discovery of a large high-grade zone that encompasses most of this zone. The high-grade zone is open at depth with the deepest intersection, hole KP03-133, returning 70.54 g/t Au and 709.15 g/t Ag over 11.95 metres (4.25 metres true width) at a depth of 275 metres below surface (figure 11.7) Textures and mineralogy of the vein intersection in this hole suggests the hole intersected the upper levels of the bonanza zone of the epithermal vein system. Additional high grade results from this zone include hole KP03-

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.11 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.12 |

86 which returned 33.50 metres (20.5 metres true width) grading 32.76 g/t Au and 406.24 g/tAg and hole KP03-47 with 16.80 metres (10.0 metres true width) of 43.40 g/t Au and 330.60 g/t Ag. Two veins are present in the zone with high-grade values encountered in both veins.

Difficult drilling conditions were encountered in the North zone with five holes abandoned, of which two were re-drilled (KP03-48A and KP03-51A). Poor core recoveries were encountered in several holes resulting in the washing away of the sulphosalt mineralization in more intensely brecciated intervals. Hole KP03-90 was re-drilled as hole KP03-90A, with a subsequent near doubling of gold grade to 19.22 g/t Au and 262.18 g/t Ag over 26.70 metres as a function of near 100% core recoveries.

11.5 North Extension Zone

The North Extension zone is comprised of a deep, high-grade vein zone underneath a 100 to 150 metre thick cap of intense kaolinite altered volcanics. Eight holes have tested the zone of which only three (KP03-128, 134 and 144) were drilled deep enough to intersect veining under the clay alteration. The best result came from hole KP03-128, which intersecting 32.35 meters (18.25 metres true width) grading 12.33 g/t Au and 101.83 g/t Ag (Figure 11.8) . On the basis of alteration zonation, vein textures, mineralogy and mineralization the North Extension is believed to be the down dropped extension of the North zone. The zone is open to the north and at depth.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.13 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 11– p.14 |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 12 – p.1 |

12.0 Sampling Method and Approach

Drill core was delivered from the drills in covered wooden or waxed cardboard boxes and 'Quick' logged by Canadian geologists. Following the quick logging each hole was geotechnically logged then logged in detail by the Russian geologists. Sampling intervals were determined and marked up and tagged by the Russian geologists with intervals based on geology (lithology, mineralogy, texture and structure). Sampling across contacts was only done if the vein width was less than the minimum sample width. Core was oriented to ensure an even split of the veins was taken, ie: no sample bias. Prior to being split the sample intervals were checked by the Canadian geologists. Minimum sample length was 0.25 m (HQ size core, 0.30 m NQ size core) and maximum sample length 1.0 metres. Mineralized zones were bracketed by a minimum of one to three metres of sampling into the footwall and hanging wall. All vein zones and alteration types of interest were sampled in the holes. Continuous sampling was carried across each major zone. Samples containing visible gold or abundant sulphosalt mineralization were marked with a white sample bag at the start of the sample interval so sampling technicians would employ contamination minimization protocols during cutting and laboratory preparation. Field duplicate samples were marked with flagging tape, and core cut into 1/3 sections for an even field duplicate split.

After completion of logging, the core to be sampled was delivered to the splitting shack and each box of core photographed prior to core splitting. Core was 2/3 split using a diamond saw with the remaining third returned to the core box as a record. The core saw core jig was calibrated to ensure an even 2/3 split was taken of the core for both HQ and NQ sized samples. The saw blade was cleaned on a regular basis using a dressing stone and cleaned after each visible gold or well mineralized sample was cut. Fresh water was used at all times to ensure no re-circulation contamination was present. For samples of strongly broken core care was taken to ensure a 2/3 split of the sample was taken. This usually involved the use of a metal divider and a spoon. Samples were bagged, field blank and reference standards inserted into the sample stream, by the geologists, and the samples assembled into batch size (20 sample) shipments for delivered to the laboratory two to three times per day. Well mineralized or visible gold bearing samples were indicated on the submission form to ensure contamination reduction protocols were followed by the laboratory.

Core samples for all mineralized intersections are stored in racks in a locked core storage tent. The remaining (unmineralized) core is stored in racks in locked containers.

The trench sampling followed the same sampling protocols as the core sampling. Samples were collected using a chisel and hammer to cut an even channel across each zone. Care was taken to collect equal volumes of rock were across each channel to ensure there was no sampling bias based on rock softness or fracture density. Sample intervals were marked with metal tags and the start and end points surveyed.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 12 – p.2 |

Core recovery was recorded for all core runs. Within the zone, core recovery averaged greater than 85%, however, in several cases core recoveries over short intervals were low. Hole KP03-90 was re-drilled as hole KP03-90A to improve core recoveries in the zone in this area. Hole KP03-90 will be excluded from any resource calculations as a result. Holes KP03-77 and KP03-144 had lower than ideal core recoveries within the zone with intervals in hole KP03-144 particularly low (<40%). Due to low drill hole density in these areas these holes, will be included in resource studies this year, however they will be re-drilled and excluded from any Feasibility study.

No studies have been done in regards to any effects of near surface oxidation, however, as the oxidation is transitional type and there is good correlation between surface trenching and undercut drill hole values, there is no surface enrichment evident.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.1 |

13.0 Sample Preparation, Analyses and Security

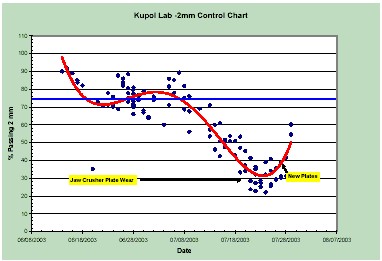

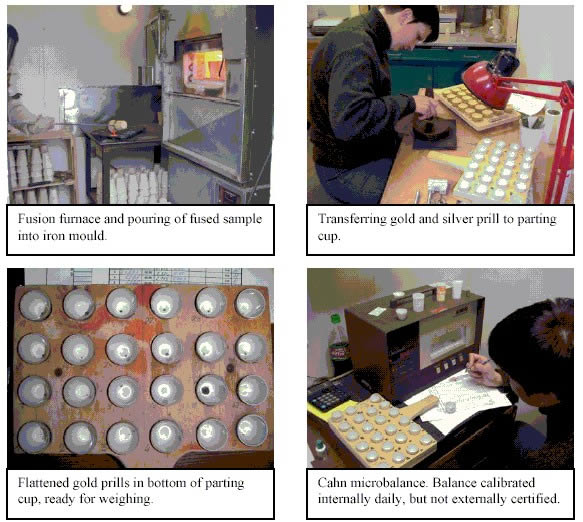

Due to the remote location of the Kupol Project and experience in regards to difficulties with shipments of samples within and exporting from Russia, a containerized field laboratory was set up at Kupol. The laboratory was set up and run as an independent 'arms length' laboratory. No Bema or contractor personnel were allowed in the laboratory or laboratory area unless accompanied by a Laboratory manager. Laboratory management was overseen by qualified North American laboratory managers (Ron Mobley and Jim Weatherby) who supervised Russian certified assayers. The laboratory was operated as an Anyusk Geological Expedition field laboratory under the Anyusk Expedition’s Russian certification. Laboratory procedures and QA/QC protocols were set up by Ron Mobley and Jim Weatherby, and audited by an internationally recognized independent consultant, Dr. Barry Smee, P.Geo., of Smee and Associates Consulting. Barry Smee’s report on the laboratory audit is appended.

Samples were received at the laboratory as follows: each shipment was checked to ensure accuracy of paperwork, samples were logged into the laboratory system and the laboratory signed off on delivery of each submission. Shipments were then placed in a secure container to await processing.

All samples were first dried in a locked, heated container, either within the sample bag or on a steel tray then transferred to the prep lab. Each sample was first crushed in a jaw crusher to 95% passing minus 10 mesh (<2 mm) then divided by Jones Riffle splitter into two 1 kg samples. The first sample is a geological coarse reject duplicate and was kept in a locked container until the geology staff retrieved it. The second sample went to the LM2 bowl and puck pulverizer where it was pulverized until 90% passed minus 150 mesh. The 1 kg pulverized sample was then split into four 250 g samples and placed in a sample envelopes. One pulp sample went for fire assay, one kept as a lab reject, and two retained as geology duplicates. All pulp duplicates are stored in locked containers.

One in twenty samples was screened from both crusher and pulverizer splits to ensure compliance with specifications. All equipment was air washed between samples and a silica blank sample was run as a cleaning medium every 20 samples, and after visible gold bearing or well mineralized samples.

A 50 g split was taken of the 250 g pulp sample and this was analyzed for gold and silver by using standard fire assay technique with a gravimetric finish. The detection limit for gold was 0.2 g/t and for silver 1 g/t.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.2 |

13.1 Quality Control and Quality Assurance Program

A strict protocol for sample quality control and quality assurance was followed throughout the full program and Barry Smee audited this program. The QA/QC program involved the regular insertion of field blanks and standard reference material into the sample stream, the collection of field duplicate samples and external checks using a pulp duplicate. Appended (Appendix 3) to this report is Barry Smee’s report of his initial audits of the QA/QC program. He will be preparing a final report on the Kupol Project QA/QC program in December 2003.

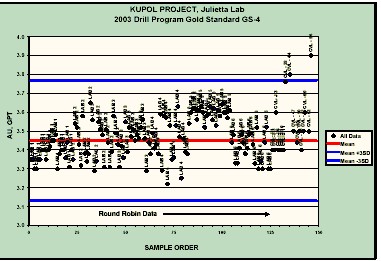

Due to equipment start up problems with the Kupol laboratory, the initial set of samples from the project were run at Bema Gold’s Julietta Mine laboratory. The Russian assayers responsible for assaying at the Kupol laboratory were sent to Julietta to ensure the same protocols were followed for sample prep and analyses as in their lab at Kupol. All samples shipped to Julietta were eventually run at the Kupol laboratory so the project data set represents results from a single laboratory, with Julietta and Assayers Canada, of North Vancouver, British Columbia, Canada, as external check laboratories. All laboratory submissions included a full set of QC samples.

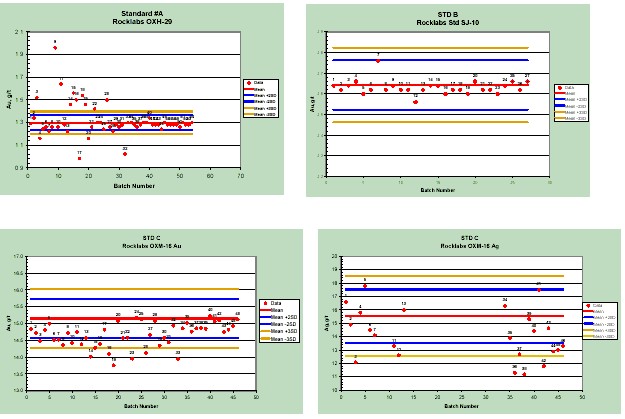

13.1.1 Standard Reference Material

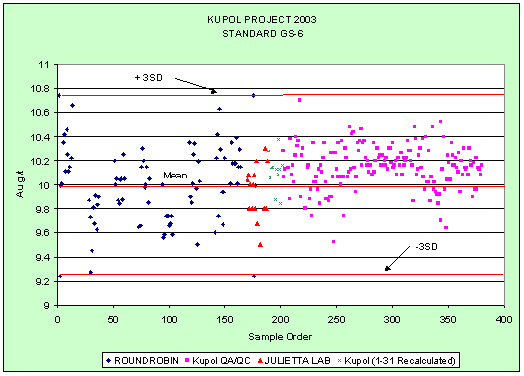

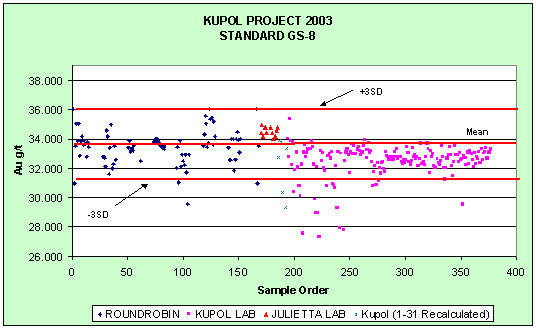

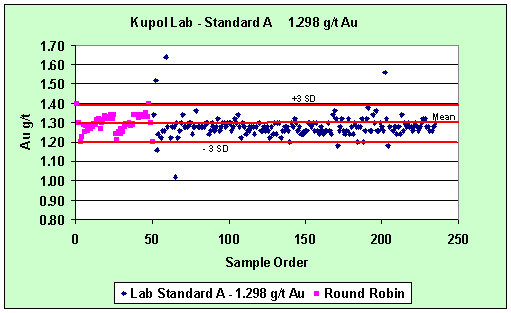

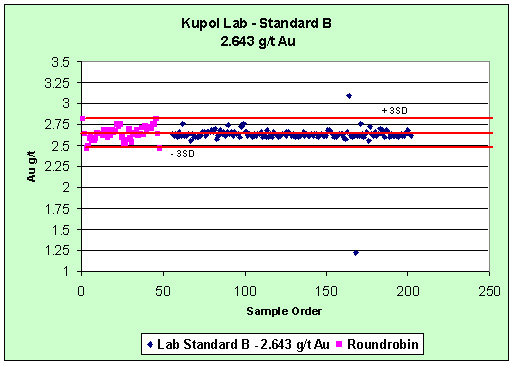

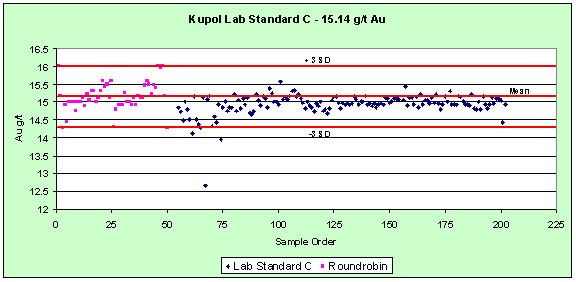

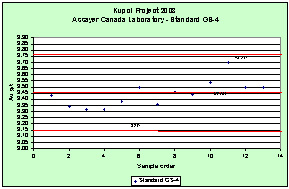

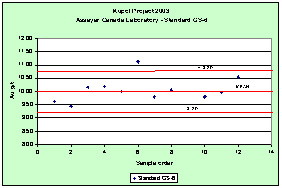

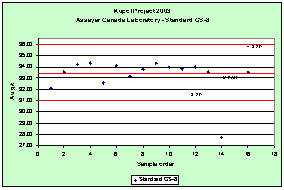

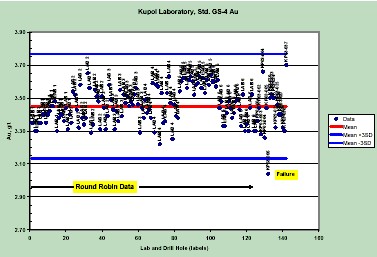

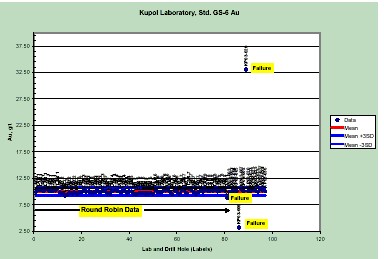

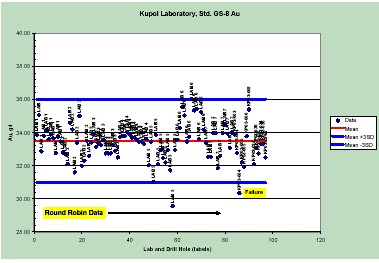

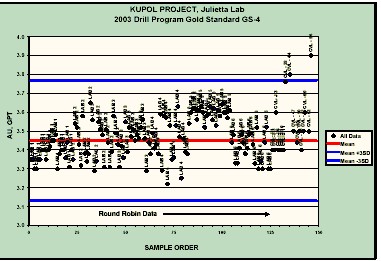

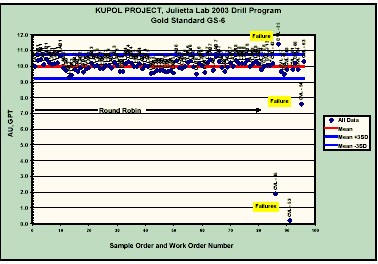

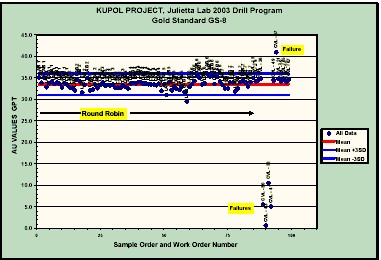

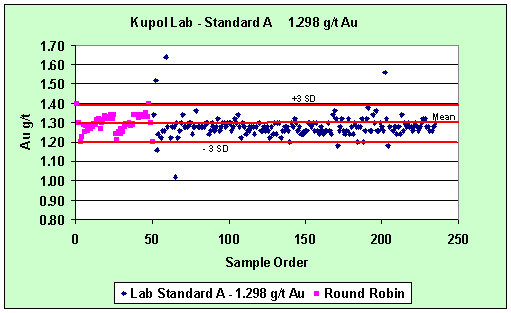

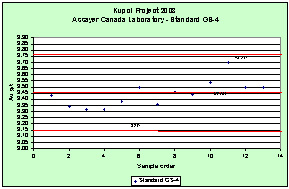

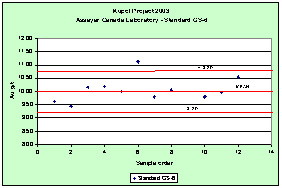

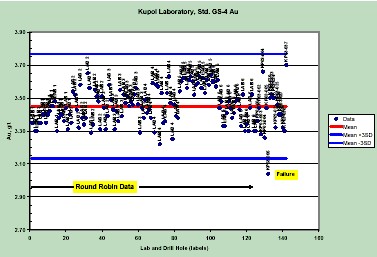

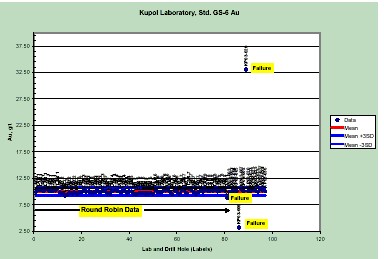

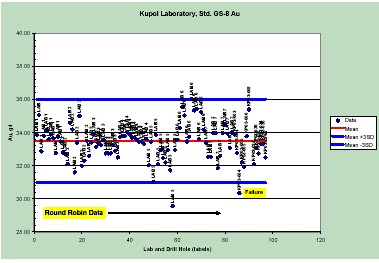

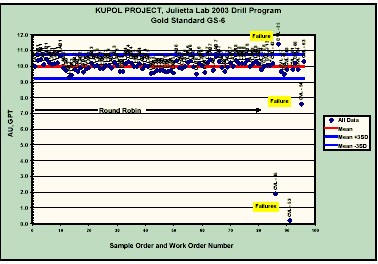

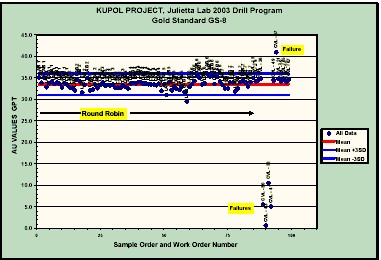

In order to monitor the accuracy of the laboratories three gold reference standards were purchased from CDN Resource Laboratories of Delta, B.C. and inserted in the ratio of 1:20 into the sample stream. Standards were selected to cover a range of grades and came in individually kraft paper wrapped 60 or 75 g packets. These standards are:

| Standard Name | Accepted Mean g/t Au | Standard Deviation, Au g/t |

| GS-4 (STD 1) | 3.45 | +/- 0.105 |

| GS-6 (STD 2) | 9.99 | +/- 0.25 |

| GS-8 (STD 3) | 33.50 | +/- 0.85 |

Each of these standards is a certified standard with an accepted mean as obtained through a round robin assay program. Standard failure limit was set at plus or minus three standard deviations (SD) and any batch with a failed standard was automatically rerun.

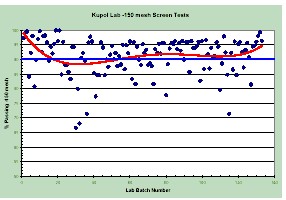

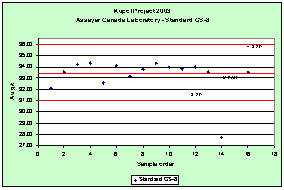

Results for the reference standards are presented in figures 13.1 to 13.3. As indicated by the charts the laboratory the usual start up problems then proceeded to provide accurate analyses once the procedures and protocols had been well established within the laboratory. In early summer, some batches had to be re-run up to three times before they were passed as acceptable for inclusion in the database. Standard GS-8 assays within a tight cluster below the mean, GS-6 is scattered about the mean with a slight bias on the high side of the mean and GS-4 assays generally on the lower side of the mean. Therefore, the Kupol laboratory biases low for samples in the 30 g/t range, a bit high for

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.3 |

samples in the 10 g/t range and low for samples in the 3.5 g/t range. Julietta assay results tend to be a bit higher for the same Kupol sample and the reference standards suggests the laboratory assays high for the GS-4 and GS-8 standards and performs well for the GS-6 standard.

Sample batches which contained a reference standard failure were automatically re-run unless there was a sample number mix up. Sample results were not posted into the database unless a batch passed the QA/QC. In some cases, this required a batch to be rerun several times before a reference standard passed, indicating the batch accuracy was okay.

Figures 13.4 to 13.6 present the charts for the Kupol Laboratory internal QA/QC standards. Results presented indicate the laboratory performed within acceptable limits.

Figure 13.1:

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.4 |

Figure 13.2:

Figure 13.3:

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.5 |

Figure 13.4:

Figure 13.5:

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.6 |

Figure 13.6:

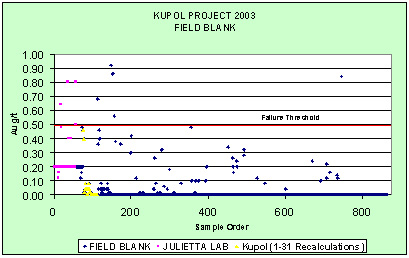

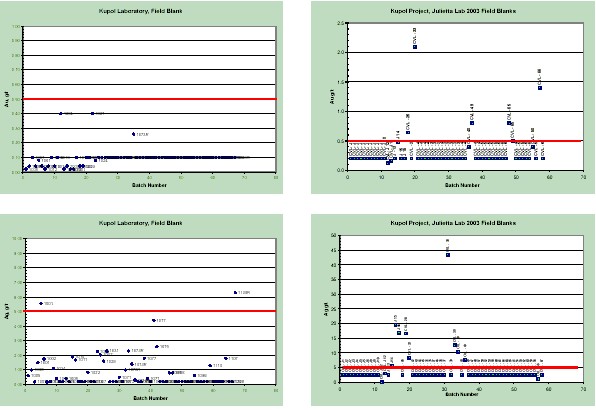

13.1.2 Blank Sample Assays

To check for contamination and sample ordering mix-ups in the laboratory, a coarse field blank was used. Rhyolitic flow material from the north end of the property was selected as a field blank, as it contained no gold and has a bulk composition and character somewhat similar to the mineralized zones. Field blanks were inserted every 20 samples and after well mineralized samples or samples containing visible gold. Failure threshold was set at 0.5 g/t Au (2.5 times x detection limit).

Figure 13.7:

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.7 |

Figure 13.7 shows the blank results for the Kupol and Julietta laboratories. There is very little contamination associated with the preparation work in the Kupol laboratory. The majority of samples above the threshold at both Kupol and Julietta followed very high grade samples and thus did not require a re-run of a batch. The laboratories were informed of the instances of contamination and the lab manager adjusted procedures where appropriate.

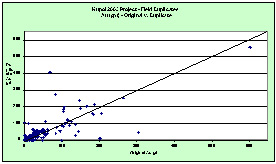

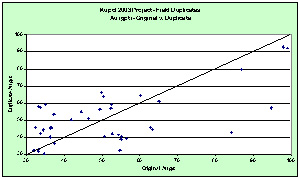

13.1.3 Duplicate Assays

Field duplicates were collected as a 1/3 split of the drill core in order to check on the precision of the laboratory. They were taken every 20 samples and more frequently within well mineralized zones, to ensure there was an adequate statistical data set within the zones. Visible gold bearing samples were usually duplicated, as a check on variability of the gold distribution.

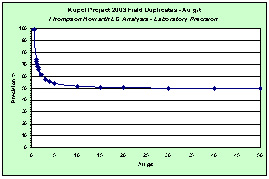

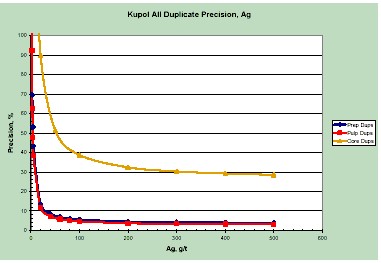

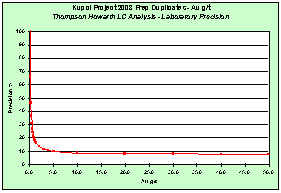

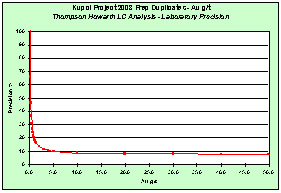

Results for the field duplicates are presented first as a scatter plots (Figures 13.8 to 13.10) then in the form of a Thompson- Howarth LC plot (Thompson and Howarth, 1978) (Figure 13.11) . Field duplicate scatter plots are presented in three ranges, 0-650 g/t Au, 0-30 g/t Au and 30 to 100 g/t Au.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.8 |

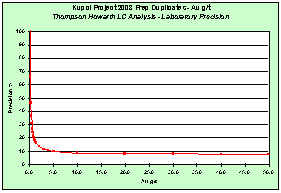

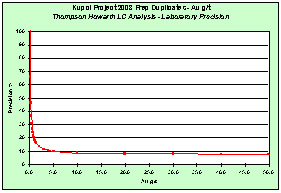

Prep and pulp duplicate samples were collected by the laboratory within each batch of 20 samples with the prep duplicates a split taken of the sample after crushing and the pulp duplicate a 50 g sample from the same 250 g laboratory split as that for the original assay. Thompson-Howarth plots of the prep and pulp duplicates are presented in figures 13.12 and 13.13.

| Figure 13.12: TH plot - Prep Duplicate | Figure 13.13: TH plot - Pulp Duplicate |

|  |

Scatter plots of the field duplicate samples show a wide scatter about the 1:1 reference line. This wide scatter of results is confirmed by the Thompson-Howarth plot of the same data set, and indicates there is poor precision of the field duplicate results.

Plots of the prep and pulp duplicate are very similar and show very good precision once the samples have been homogenized. The reason for the magnitude of difference between the field, pulp and prep duplicates is uncertain. The good correlation of the pulp and prep duplicates indicates there is no problem with the analyses and the internal laboratory splitting. Poor precision in the field duplicates indicates there may be a problem in sampling methodology or inherent variability in the mineralization. There was no significant change in the results from early in the season (low sample population) to late in the season (large sample population). Auditing of the sampling methodology indicates there are neither inherent biases nor errors in sampling technique so the distribution of mineralization within the samples is believed to be responsible for the lower reproducibility of the field duplicates. Since there is an abundance of visible gold in the deposit there appears to be a nugget effect with respect to gold distribution. As the vein system is for the most part a polyphase breccia it is this brecciation and multiple re-healing events which may account for the irregular gold distribution and thus grade variability. Petrographic studies are underway to help determine the gold distribution within the veins.

|

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.9 |

13.1.4 External Check Samples: Assayers Canada and Julietta Laboratories

Assayers Canada of North Vancouver, British Columbia, Canada was used as the main external check laboratory. Bema Gold’s Julietta Mine Laboratory was used as a check laboratory for the intial startup of the Kupol laboratory due to the short turn around time for sample results. All principal intersections for the first sixty-nine holes were assayed in full at either the Julietta or Assayers Canada laboratories. Assays for the remaining holes were checked with a routine ten percent of samples sent for external checks and portions of key intersections sent for verification.

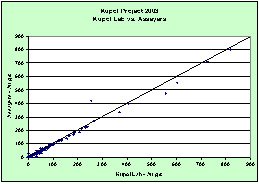

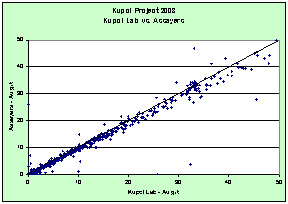

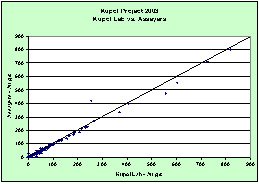

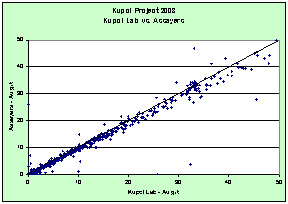

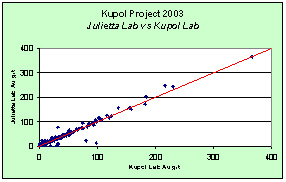

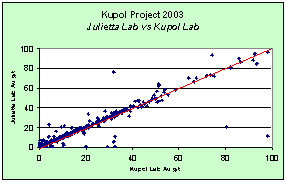

As shown in figures 13.14 to 13.16 there is a good correlation between Kupol and Assayers laboratory with the Assayer laboratory assaying slightly lower than the Kupol laboratory. Reference standards submitted to Assayers indicate that Assayers analyses are within acceptable limits, with results a bit high for higher grade samples. The latter contrast with the Kupol lab results for the same standards.

| Figure 13.14: External Check (0-950 g/t) | Figure 13.15: External Check (0-200 g/t) |

|  |

| |

| Figure 13.16: External Check (0-50 g/t) |

|

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.10 |

| Figure 13.17: Assayers Canada - STD GS-4 | Figure 13.18: Assayers Canada - STD GS-6 |

|  |

| |

| Figure 13.19: Assayers Canada - STDGS-8 |

|

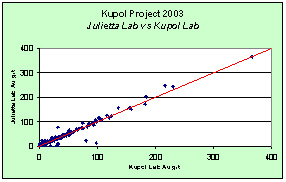

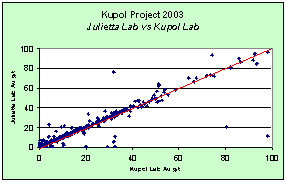

Figures 13.20 and 13.21 show the results of the comparison of the Julietta and Kupol laboratories. There is a good correlation of the Kupol and Julietta laboratories with the Julietta laboratory assaying slightly higher than the Kupol laboratory.

| Figure 13.20: Juletta vs Kupol (0-400 g/t Au) | Figure 13.21: Juletta vs Kupol (0-100 g/t Au) |

|  |

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 13 – p.11 |

13.2 Security

During the core logging and sampling process no unauthorized personnel were allowed in the core storage, logging or cutting facilities. Core for sampling was delivered direct to the core cutting tent or to a secure storage container before cutting. Lids were kept on boxes during transfer. After cutting the samples were assembly into batch shipments within the core cutting tent where they were stored in sealed rice bags pending delivery to the laboratory (30 metres away) several times a day. At the laboratory, each sample submission was checked for accuracy then the laboratory signed off on the receipt of the shipment and took custody of the samples. No Bema staff was allowed access to the samples after this point. Prior to processing, the samples were stored in a locked container.

External check sample shipments were assembled by the laboratory staff in accordance with a submission list prepared by the Bema geologists. Samples for each submisson were placed and sealed intoSecur-Pak secure sample bags with the laboratory signing off on the each submission. TheSecur-Pak bags were placed and sealed in either a box or rice bag for shipping. The secured bags were shipped to Canada along with a chain of custody document and check list. Assayers Canada received these secure bags and reviewed and signed off on the custody document upon receipt. Bema was not notified by Assayers of any tampered (unsealed)Secur-Pak bags arriving at the Assayers laboratory.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 14 – p.1 |

14.0 Data Verification

The assay intervals and lithology databases entries were 100% checked against original logs by systematic multiple checks of hard copies of data. Similar checks are being conducted of the recoveries, RQD, specific gravity, and all other database entries. Additional checks of the data integrity are being carried out via the GEMCOM modeling software.

Ten percent of the assay values were checked against the original hard copy assay certificates and no significant errors were found.

Verification was supervised and for the most part conducted by Vivian Park, P.Geo and Jim Smith, P.Geo, and overseen by the authors. It is the authors’ opinion that the assay and lithology database to be used in the resource calculation has been adequately verified.

| | Bema Gold Corporation

43-101 Technical Report

Kupol Project | Section 15 – p.1 |

15.0 Mineral Processing and Metallurgical Testing

The following Metallurgical work was conducted in 2003:

| 1) | Preliminary metallurgical test work conducted on composites from the first sixteen drill holes. Test work was performed at the Julietta laboratory. |

| | |

| 2) | Metallurgical test composite samples were collected of representative vein types across the deposit area from surface and drill core composites. In total 957 kg of core composite, in 93 composite samples, and 335 kg of surface samples, in 3 samples, were collected for testing and study. |

| | |

| 3) | 510 kg total weight of SAG mill, grindability (McPherson Test), test samples were collected from five holes (KP03-121, KP03-123, KP03-124, KP03-90A). |