Exhibit 10.1

FOIA CONFIDENTIAL TREATMENT REQUESTED

PORTIONS OF THE EXHIBITS HERETO MARKED BY *** HAVE BEEN

OMITTED PURSUANT TO A REQUEST FOR CONFIDENTIAL TREATMENT

FILED SEPARATELY WITH THE SECURITIES AND EXCHANGE COMMISSION

ENGINEERING, PROCUREMENT AND CONSTRUCTION AGREEMENT

BETWEEN MIRANT MID-ATLANTIC, LLC & MIRANT CHALK POINT LLC

(EACH INDIVIDUALLY AN “OWNER” AND COLLECTIVELY THE

“OWNERS”) AND MIRANT MID-ATLANTIC, LLC AS AGENT FOR THE

OWNERS

AND

STONE & WEBSTER, INC. (“CONTRACTOR”)

FOR

ENGINEERING, PROCUREMENT & CONSTRUCTION SERVICES

RELATING TO

AIR QUALITY CONTROL SYSTEMS

AT

MORGANTOWN GENERATING STATION,

DICKERSON GENERATING STATION AND

CHALK POINT GENERATING STATION

TABLE OF CONTENTS

| PAGE | ||||||||||

| 1. | DEFINITIONS | 1 | ||||||||

| 2. | OWNER ENTITIES | 11 | ||||||||

| 2.1 | Mirant Mid-Atlantic, LLC | 11 | ||||||||

| 2.2 | Mirant Chalk Point, LLC | 11 | ||||||||

| 2.3 | Owner’s Agent | 12 | ||||||||

| 2.4 | Obligations | 12 | ||||||||

| 3. | EFFECTIVE DATE | 12 | ||||||||

| 4. | TERM | 12 | ||||||||

| 5. | OWNER SCOPE | 12 | ||||||||

| 5.1 | Owner Scope | 12 | ||||||||

| 5.2 | Gypsum Dewatering Plant | 13 | ||||||||

| 5.3 | Schedule for Owner Scope | 13 | ||||||||

| 5.4 | Non-Interference and Safety | 15 | ||||||||

| 6. | PROJECT SCOPE | 15 | ||||||||

| 6.1 | Work To Be Performed | 15 | ||||||||

| 6.1.1 | LNTP for FGD Systems | 15 | ||||||||

| 6.1.2 | INTP for FGD Systems | 15 | ||||||||

| 6.1.3 | NTP for FGD Systems | 15 | ||||||||

| 6.1.4 | LNTP for SCR System | 16 | ||||||||

| 6.1.5 | INTP for SCR System | 16 | ||||||||

| 6.1.6 | Transition of SCR from Contractor to Owner | 16 | ||||||||

| 6.1.7 | Application of Terms and Conditions | 16 | ||||||||

| 6.2 | Engineering/Design Services | 17 | ||||||||

| 6.2.1 | Technical Specifications | 17 | ||||||||

| 6.2.2 | Design Standards | 17 | ||||||||

| 6.2.3 | Design Documentation | 17 | ||||||||

| 6.2.3.1 | Schematic Design Documents | 17 | ||||||||

| 6.2.3.2 | Permitting Documents | 18 | ||||||||

| �� | 6.2.3.3 | Design Development Documents | 18 | |||||||

| 6.2.3.4 | Approved Drawings | 19 | ||||||||

| 6.2.3.5 | Rough Site Grading, Demolition and Relocation | 20 | ||||||||

| 6.2.3.6 | Interfaces and connections for the Gypsum Dewatering Plant | 22 | ||||||||

| 6.2.3.7 | Contractor’s Obligations under Section 6.2.3.6 | 22 | ||||||||

| 6.3 | Procurement Services | 23 | ||||||||

| 6.3.1 | Procurement of Systems Equipment and Construction Equipment | 23 | ||||||||

i

| 6.3.1.1 | Title to Systems Equipment | 23 | ||||||||

| 6.3.1.2 | Risk of Loss | 23 | ||||||||

| 6.3.1.3 | Storage | 23 | ||||||||

| 6.3.2 | Procurement of Chemicals, Start-Up Spares and Consumables | 24 | ||||||||

| 6.3.3 | Inspection and Testing of Materials and Systems Equipment | 24 | ||||||||

| 6.4 | Transportation Charges | 24 | ||||||||

| 6.5 | Construction-Related Work | 24 | ||||||||

| 6.5.1 | Clearance of the Site (by Owner) | 24 | ||||||||

| 6.5.2 | Labor and Personnel | 25 | ||||||||

| 6.5.3 | Construction Utilities Interface | 25 | ||||||||

| 6.5.4 | Testing | 25 | ||||||||

| 6.5.5 | As-Built Drawings | 25 | ||||||||

| 6.5.6 | Operation and Maintenance Manuals | 25 | ||||||||

| 6.5.7 | Turnover Package | 26 | ||||||||

| 6.5.8 | Clean Up and Waste Removal | 26 | ||||||||

| 6.5.9 | Hazardous Substances | 26 | ||||||||

| 6.5.10 | Quality Assurance/Quality Control | 27 | ||||||||

| 6.6 | General | 28 | ||||||||

| 6.7 | Non-Interference | 28 | ||||||||

| 6.8 | Safety | 29 | ||||||||

| 6.8.1 | Contractor Responsibility | 29 | ||||||||

| 6.8.2 | Fitness For Duty, Drug, Alcohol Abuse And Safety Policy For Access To Owner Facilities | 29 | ||||||||

| 6.8.3 | Access To Owner Facilities | 30 | ||||||||

| 6.8.4 | Prohibited Activities | 30 | ||||||||

| 6.8.5 | Suspected Violation Of Policy | 30 | ||||||||

| 6.8.6 | Refusal To Comply | 31 | ||||||||

| 6.8.7 | Protection | 31 | ||||||||

| 6.8.8 | OSHA Compliance | 32 | ||||||||

| 6.8.9 | Material Safety Data Sheets | 32 | ||||||||

| 6.8.10 | Dust and Fume Control | 32 | ||||||||

| 6.8.11 | Water Pollution | 32 | ||||||||

| 6.8.12 | Operating Environment | 32 | ||||||||

| 6.8.12.1 | Generating Sites | 32 | ||||||||

| 6.8.12.2 | Electrical System | 33 | ||||||||

| 6.9 | Operating Utilities Interface | 33 | ||||||||

| 6.10 | Owner’s Right to Inspect, Stop and Re-Perform Work | 33 | ||||||||

| 6.10.1 | Owner’s Right to Attend Contractor Inspections | 33 | ||||||||

| 6.10.2 | Inspection and Re-Performance | 33 | ||||||||

| 7. | PERFORMANCE GUARANTEES | 33 | ||||||||

| 7.1 | Input Guarantees for FGD Systems | 33 | ||||||||

| 7.1.1 | Guaranteed Consumption Levels | 33 | ||||||||

| 7.1.2 | Consumption Within Engineering Design Margins | 34 | ||||||||

| 7.1.3 | Consumption Outside Engineering Design Margins | 34 | ||||||||

ii

| 7.1.4 | Liquidated Damages for Input Guarantees for FGD Systems | 34 | ||||||||||

| 7.1.4.1 | Power Consumption | 34 | ||||||||||

| 7.1.4.2 | Make-Up Water Consumption | 34 | ||||||||||

| 7.1.4.3 | Limestone Consumption | 34 | ||||||||||

| 7.2 | Output Guarantees for FGD Systems | 34 | ||||||||||

| 7.2.1 | List of Output Guarantees | 34 | ||||||||||

| 7.2.2 | Correction by Contractor | 35 | ||||||||||

| 7.2.3 | Mercury Removal | 35 | ||||||||||

| 7.3 | Operational Guarantees for FGD Systems | 36 | ||||||||||

| 7.3.1 | List of Operational Guarantees | 36 | ||||||||||

| 7.3.1.1 | Minimum Turndown Capability | 36 | ||||||||||

| 7.3.1.2 | Maximum Entrained Moisture Carryover | 36 | ||||||||||

| 7.3.1.3 | Fan Characteristics | 36 | ||||||||||

| 7.3.1.4 | Pressure Drop | 36 | ||||||||||

| 7.3.2 | Correction by Contractor | 36 | ||||||||||

| 7.4 | Blank | 36 | ||||||||||

| 7.5 | Blank | 36 | ||||||||||

| 7.6 | Blank | 36 | ||||||||||

| 7.7 | Performance Testing | 36 | ||||||||||

| 7.7.1 | Performance Testing | 36 | ||||||||||

| 7.8 | Concurrent Obligations | 37 | ||||||||||

| 8. | PROJECT SCHEDULE; SCHEDULE GUARANTEES | 37 | ||||||||||

| 8.1 | Project Schedule | 37 | ||||||||||

| 8.1.1 | Guaranteed Provisional Acceptance Date | 38 | ||||||||||

| 8.1.2 | Conditions for Outages | 38 | ||||||||||

| 8.1.3 | Outage Start and End Dates | 38 | ||||||||||

| 8.1.4 | Blank | 38 | ||||||||||

| 8.1.5 | Concurrent Outages | 38 | ||||||||||

| 8.1.6 | Immovable Milestones | 39 | ||||||||||

| 8.2 | Schedule Guarantee | 39 | ||||||||||

| 8.2.1 | Work Progress and Completion | 39 | ||||||||||

| 8.2.1.1 | General | 39 | ||||||||||

| 8.2.1.2 | Maximum Outage Period | 39 | ||||||||||

| 8.2.1.2.1 | Amounts Reasonable | 40 | ||||||||||

| 8.2.1.2.2 | Bonus for Early Completion | 41 | ||||||||||

| 8.2.1.2.3 | Payment of Excessive Outage Payments | 41 | ||||||||||

| 8.2.2 | Guaranteed Provisional Acceptance Date | 41 | ||||||||||

| 8.2.3 | Late Provisional Acceptance Payments | 41 | ||||||||||

| 8.2.3.1 | Before 23:59 on December 31, 2009 for the FGD Systems | 41 | ||||||||||

| 8.2.3.2 | After 23:59 on December 31, 2009 for FGD Systems | 42 | ||||||||||

| 8.2.3.3 | Blank | 42 | ||||||||||

iii

| 8.2.3.4 | Reduced Late Provisional Acceptance Payments Period | 42 | ||||||||||

| 8.2.3.5 | Amounts Reasonable | 43 | ||||||||||

| 8.2.3.6 | Payment of Late Provisional Acceptance Payments | 43 | ||||||||||

| 8.2.4 | Guaranteed Substantial Completion Date | 44 | ||||||||||

| 8.2.4.1 | Late Substantial Completion Payments | 44 | ||||||||||

| 8.2.4.2 | Amounts Reasonable and Exclusive Remedy for Delay | 44 | ||||||||||

| 8.2.4.3 | Payment of Late Substantial Completion Payments | 44 | ||||||||||

| 8.2.5 | Guaranteed Final Completion Date | 45 | ||||||||||

| 8.2.6 | Late Final Completion Payments | 45 | ||||||||||

| 8.2.6.1 | Amounts Reasonable and Exclusive Remedy for Delay | 45 | ||||||||||

| 8.2.6.2 | Payment of Late Final Completion Payments | 45 | ||||||||||

| 8.2.7 | Full Program Completion | 46 | ||||||||||

| 8.2.8 | Reduction of Liquidated Damages Based on Delayed Permitting | 46 | ||||||||||

| 8.3 | Schedules | 47 | ||||||||||

| 8.3.1 | Schedule Software | 47 | ||||||||||

| 8.3.2 | Activity Coding | 47 | ||||||||||

| 8.3.3 | Level 3 Detail | 47 | ||||||||||

| 8.3.4 | Schedule Updates | 47 | ||||||||||

| 8.4 | Work Operations | 47 | ||||||||||

| 8.5 | Recovery Schedule | 48 | ||||||||||

| 8.6 | Critical Schedule Situation | 48 | ||||||||||

| 8.7 | Contractor Responsible for Schedule | 48 | ||||||||||

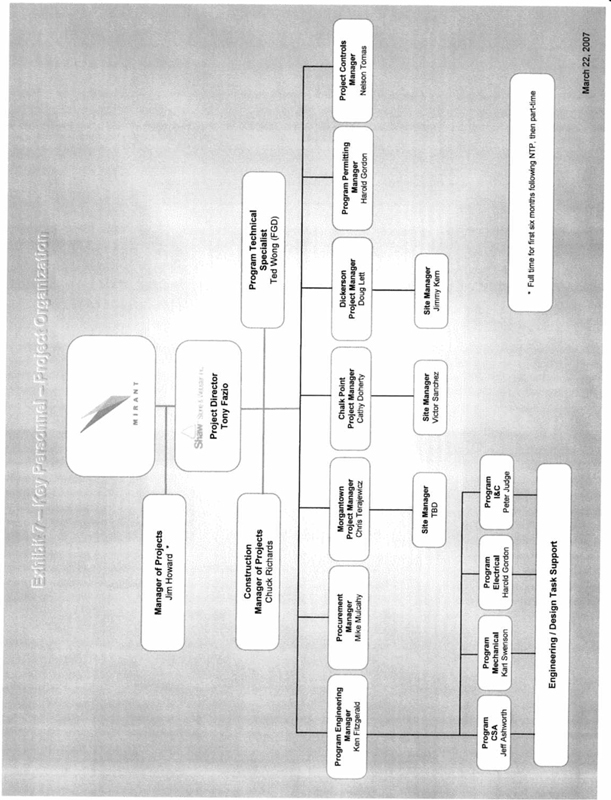

| 9. | KEY PERSONNEL REQUIREMENTS | 48 | ||||||||||

| 9.1 | Personnel Resources | 48 | ||||||||||

| 9.1.1 | Key Personnel | 48 | ||||||||||

| 9.1.2 | Departure of Key Personnel | 49 | ||||||||||

| 9.1.3 | Assignment of Key Personnel | 49 | ||||||||||

| 9.1.4 | Replacement of Key Personnel | 49 | ||||||||||

| 9.1.5 | Key Personnel of Subcontractors | 50 | ||||||||||

| 9.2 | Contractor Personnel Transition Plan | 50 | ||||||||||

| 9.2.1 | Notice of Departure of Key Personnel | 50 | ||||||||||

| 9.2.2 | Mutual Agreement | 50 | ||||||||||

| 9.3 | Independent Contractor: Employees | 51 | ||||||||||

| 9.4 | Applicable Time Period | 51 | ||||||||||

| 10. | TARGET COST | 51 | ||||||||||

| 10.1 | Facility Target Cost | 51 | ||||||||||

| 10.2 | Calculation of Contractor’s Actual Cost | 51 | ||||||||||

| 10.2.1 | Categories of Costs | 51 | ||||||||||

| 10.2.2 | Actual Home Office Labor Costs | 52 | ||||||||||

iv

| 10.2.3 | Actual Field Non-Manual Labor Costs | 52 | ||||||||||

| 10.2.4 | Actual Self-Performed Field Manual Services Cost | 52 | ||||||||||

| 10.2.5 | Actual Third Party Expenses | 53 | ||||||||||

| 10.2.6 | Selling, General and Administrative Expenses | 53 | ||||||||||

| 10.2.7 | Separate Accounts | 54 | ||||||||||

| 10.3 | Cap on Contractor’s Total Engineering Hours | 54 | ||||||||||

| 11. | PRICE | 54 | ||||||||||

| 11.1 | EPC Total Compensation | 54 | ||||||||||

| 11.2 | Project Compensation | 54 | ||||||||||

| 11.3 | Guarantee Costs | 54 | ||||||||||

| 11.3.1 | Classification of Guarantee Costs | 54 | ||||||||||

| 11.3.2 | Treatment of Guarantee Costs | 55 | ||||||||||

| 11.4 | Incentives | 56 | ||||||||||

| 11.4.1 | Blank | 56 | ||||||||||

| 11.4.2 | Performance Incentives | 56 | ||||||||||

| 11.4.2.1 | Early Completion of Work During Planned Outages | 56 | ||||||||||

| 11.4.2.2 | Safety, Schedule and Quality Incentive | 56 | ||||||||||

| 11.5 | Allocable Costs | 58 | ||||||||||

| 11.5.1 | Sections Addressing Allocable Costs | 58 | ||||||||||

| 11.5.2 | Treatment of Allocable Costs | 58 | ||||||||||

| 11.6 | Underrun Bonus | 58 | ||||||||||

| 12. | PAYMENT TERMS | 59 | ||||||||||

| 12.1 | Payments Generally | 59 | ||||||||||

| 12.1.1 | Owner Shall Pay Contractor EPC Total Compensation | 59 | ||||||||||

| 12.1.2 | Milestone-based, Guarantee and Final Payments | 59 | ||||||||||

| 12.1.3 | NTP Milestone Payment | 59 | ||||||||||

| 12.2 | Milestone Progress Payments | 59 | ||||||||||

| 12.2.1 | Approved Final Milestone Payment Schedule | 59 | ||||||||||

| 12.2.2 | Milestone Progress Payments | 59 | ||||||||||

| 12.2.3 | Partial Payment Requests | 60 | ||||||||||

| 12.2.4 | Valid Payment Requests | 61 | ||||||||||

| 12.2.5 | Documentary Evidence of Achieving Milestone | 61 | ||||||||||

| 12.2.6 | Owner Review | 61 | ||||||||||

| 12.2.7 | Payment of Milestone Payment shall not constitute approval or acceptance of Work by Owner | 61 | ||||||||||

| 12.3 | Quarterly Reconciliation | 61 | ||||||||||

| 12.3.1 | Timing of Quarterly Reconciliation | 61 | ||||||||||

| 12.3.2 | Scheduled Milestone | 61 | ||||||||||

| 12.3.3 | Incomplete Milestone | 62 | ||||||||||

| 12.3.4 | Quarterly Reconciliation Ratio | 62 | ||||||||||

| 12.3.5 | Quarterly Actual Cost and Disputed Costs | 62 | ||||||||||

| 12.3.6 | Reconcilable Cost | 62 | ||||||||||

| 12.3.7 | Quarterly Milestone Payment Cost | 62 | ||||||||||

| 12.3.8 | Quarterly Benchmark Cost | 62 | ||||||||||

v

| 12.3.9 | Performance of Reconciliation | 63 | ||||||||||

| 12.3.9.1 | Excess Payment | 63 | ||||||||||

| 12.3.9.2 | Payable Cost | 63 | ||||||||||

| 12.3.10 | Reconcilable Cost greater than Quarterly Benchmark Cost | 63 | ||||||||||

| 12.3.10.1 | Supplemental Contingency Draw Request | 63 | ||||||||||

| 12.3.10.2 | Difference between Quarterly Milestone Payment Cost and Quarterly Benchmark Cost | 63 | ||||||||||

| 12.3.11 | Carryover Cost | 64 | ||||||||||

| 12.3.12 | NTP Milestone Payment added to Quarterly Actual Cost in 13th month | 64 | ||||||||||

12.4 | Blank | 64 | ||||||||||

12.5 | Late Payment Interest | 64 | ||||||||||

12.6 | Contingency | 64 | ||||||||||

| 12.6.1 | Quarterly Contingency Allowance Limit | 64 | ||||||||||

| 12.6.2 | Contingency Draw Request | 64 | ||||||||||

| 12.6.3 | Contingency Draw Notification | 65 | ||||||||||

| 12.6.4 | Owner Approval of Contingency Draw Request | 65 | ||||||||||

12.7 | Purpose of Quarterly Reconciliation Process | 65 | ||||||||||

12.8 | Retention | 65 | ||||||||||

12.9 | Effect of Change Order on Approved Final Milestone Payment Schedule | 66 | ||||||||||

12.10 | Conditions of Payments; Withholdings, Set-Offs | 66 | ||||||||||

| 12.10.1 | Material Breach | 66 | ||||||||||

| 12.10.2 | Required Submittals | 66 | ||||||||||

| 12.10.2.1 | Progress Reports | 66 | ||||||||||

| 12.10.2.2 | Partial Lien Waivers | 66 | ||||||||||

| 12.10.2.3 | Full Lien Release | 66 | ||||||||||

| 12.10.2.4 | Form of Waivers and Releases | 67 | ||||||||||

| 12.10.2.5 | Lien Bonds | 67 | ||||||||||

| 12.10.3 | Withholding to Protect Owner from Loss | 67 | ||||||||||

| 12.10.3.1 | Owner may withhold or retain any Milestone Progress Payment, payment or part | 67 | ||||||||||

| 12.10.3.1.1 | Contractor Event of Default | 67 | ||||||||||

| 12.10.3.1.2 | Lien or Charge Not Discharged | 67 | ||||||||||

| 12.10.3.1.3 | Work Performed by Owner | 68 | ||||||||||

| 12.10.3.2 | Lien Bonds | 68 | ||||||||||

| 12.10.3.3 | Payment after Removal of Cause | 68 | ||||||||||

| 12.10.4 | Set Off | 68 | ||||||||||

12.11 | Final Payment for Target Work at Each Facility | 68 | ||||||||||

| 12.11.1 | Open Book Basis Showing Actual Costs | 68 | ||||||||||

| 12.11.2 | Target Final Payment | 69 | ||||||||||

| 12.11.3 | Target Final Payment Documentation | 69 | ||||||||||

| 12.11.3.1 | Final lien waiver | 69 | ||||||||||

| 12.11.3.2 | As-Built Drawings | 69 | ||||||||||

| 12.11.3.3 | Operating manuals | 69 | ||||||||||

vi

| 12.11.3.4 | Warranty documents | 69 | ||||||||||

| 12.11.3.5 | Back-charges and/or claims satisfied | 69 | ||||||||||

| 12.11.3.6 | Quality and reliability requirements | 69 | ||||||||||

| 12.11.3.7 | Nonconformance items | 69 | ||||||||||

| 12.11.3.8 | Spare parts list | 69 | ||||||||||

| 12.11.3.9 | Mill certifications | 69 | ||||||||||

12.12 | Liens After Final Payment | 69 | ||||||||||

12.13 | Payment of Guarantee Costs | 70 | ||||||||||

| 12.13.1 | Separate Accounting | 70 | ||||||||||

| 12.13.2 | Prior to Target Final Payment | 70 | ||||||||||

| 12.13.3 | After Target Final Payment | 70 | ||||||||||

| 13. | PRICING METHOD | 70 | ||||||||||

13.1 | Blank | 70 | ||||||||||

13.2 | Target Price Method | 70 | ||||||||||

| 14. | WARRANTIES | 71 | ||||||||||

14.1 | Parts and Labor Warranties | 71 | ||||||||||

| 14.1.1 | Warranties | 71 | ||||||||||

| 14.1.2 | Parts and Labor Warranty Period | 72 | ||||||||||

| 14.1.3 | Conditions and Limitations of Warranty | 72 | ||||||||||

| 14.1.4 | Repair of Defects | 72 | ||||||||||

| 14.1.5 | Parts and Labor Warranty Period Extension | 73 | ||||||||||

| 14.1.5.1 | Extension for Corrected Work | 73 | ||||||||||

| 14.1.5.2 | Extension for Total Shutdown | 73 | ||||||||||

14.2 | Blank | 73 | ||||||||||

14.3 | Aggregation of Warranties and Specific Time Limitation | 73 | ||||||||||

14.4 | No Other Warranties/Obligations | 74 | ||||||||||

| 15. | STANDARDS OF PERFORMANCE | 74 | ||||||||||

| 16. | MECHANICAL COMPLETION | 74 | ||||||||||

16.1 | Mechanical Completion | 74 | ||||||||||

16.2 | Notice and Achievement of Mechanical Completion for Each System | 75 | ||||||||||

| 17. | PROVISIONAL ACCEPTANCE/SUBSTANTIAL COMPLETION | 75 | ||||||||||

17.1 | Criteria for Provisional Acceptance of FGD System | 75 | ||||||||||

| 17.2 | Criteria for Substantial Completion of FGD System | 76 | ||||||||||

| 17.3 | Notice and Report of Provisional Acceptance for Each System | 76 | ||||||||||

| 17.4 | Achievement of Provisional Acceptance of the Work | 76 | ||||||||||

| 17.5 | Creation of Punch-List | 77 | ||||||||||

| 17.6 | Notice and Report of Substantial Completion for Each System | 77 | ||||||||||

| 17.7 | Achievement of Substantial Completion of the Work | 77 | ||||||||||

| 17.8 | Transfer of Possession and Control of the Systems to Owner | 78 | ||||||||||

vii

| 18. | FINAL COMPLETION | 78 | ||||||||||

18.1 | Requirements | 78 | ||||||||||

| 18.2 | Notice and Report of Final Completion | 79 | ||||||||||

| 18.3 | Achievement of Final Completion | 79 | ||||||||||

| 19. | CHANGE ORDERS | 79 | ||||||||||

19.1 | Changes | 79 | ||||||||||

| 19.2 | Procedure for Changes | 79 | ||||||||||

| 19.2.1 | Changes Initiated by Contractor | 79 | ||||||||||

| 19.2.2 | Changes Initiated by Owner | 80 | ||||||||||

| 19.2.3 | Change in Cost Element and Fee Element | 80 | ||||||||||

| 19.3 | Change Order Due to Force Majeure Event | 80 | ||||||||||

| 19.4 | Change Order Due to Suspension of Work by Owner | 81 | ||||||||||

| 19.5 | Change Order Due to Differing Site Conditions | 81 | ||||||||||

| 19.6 | Change Order Due to Pre-Existing Hazardous Substances | 81 | ||||||||||

| 19.7 | Change Order Due to Actions of Owner | 81 | ||||||||||

| 19.8 | Blank | 82 | ||||||||||

| 19.9 | Change Order Due to Changes in Applicable Law | 82 | ||||||||||

| 19.10 | Change Order Due to Escalation in Actual Self-Performed Field Manual Services Cost | 82 | ||||||||||

| 19.11 | Change Order Due to Escalation in Home Office Labor Costs and Actual Field Non-Manual Labor Costs | 83 | ||||||||||

| 19.12 | Change Order Due to Escalation of Commodities | 83 | ||||||||||

| 19.13 | Changes Involving Schedule Extensions | 83 | ||||||||||

| 19.14 | Changes to the Contract Price | 83 | ||||||||||

| 19.15 | Continued Performance Pending Resolution of Disputes | 84 | ||||||||||

| 19.16 | Owner’s Right to Offset Changes | 85 | ||||||||||

| 19.17 | Other Work on Site | 85 | ||||||||||

| 20. | FORCE MAJEURE | 85 | ||||||||||

20.1 | Force Majeure | 85 | ||||||||||

| 20.2 | Burden of Proof | 86 | ||||||||||

| 20.3 | Obligations Excused | 86 | ||||||||||

| 20.4 | Costs | 86 | ||||||||||

| 21. | AGGREGATE LIABILITY | 86 | ||||||||||

21.1 | Aggregate Liability | 86 | ||||||||||

| 21.2 | Sub-limits of Liability | 86 | ||||||||||

| 21.2.1 | Liquidated Damages and Warranty Work | 87 | ||||||||||

| 21.2.2 | Systems Equipment Subcontractors | 87 | ||||||||||

| 21.2.3 | Other Subcontractors | 87 | ||||||||||

| 21.2.4 | Facility Limits | 88 | ||||||||||

| 21.3 | Pursuit of Subcontractor Warranties | 88 | ||||||||||

| 21.4 | Consequential Damages | 88 | ||||||||||

| 21.5 | Consequential Damages for Subcontractors | 88 | ||||||||||

| 21.6 | Indemnity for Lessor Claims | 89 | ||||||||||

viii

| 22. | SECURITY | 89 | ||||||||||

| 22.1 | Contractor’s Parent Company Guarantee | 89 | ||||||||||

| 22.2 | Contractor’s Letter of Credit | 89 | ||||||||||

| 22.3 | Performance Bond and Payment Bond | 90 | ||||||||||

| 22.4 | Owner Security | 90 | ||||||||||

| 23. | SUSPENSION AND TERMINATION | 91 | ||||||||||

| 23.1 | Right to Stop Work for Cause | 91 | ||||||||||

| 23.2 | Right to Suspend Work for Convenience | 92 | ||||||||||

| 23.3 | Suspension by Contractor | 92 | ||||||||||

| 23.4 | Termination by Owner for Convenience | 92 | ||||||||||

| 23.4.1 | Right to Terminate | 92 | ||||||||||

| 23.4.2 | Termination Payment | 92 | ||||||||||

| 23.4.3 | Withholding/Conditions Precedent | 93 | ||||||||||

| 23.4.4 | Return of Security | 93 | ||||||||||

| 23.5 | Termination by Owner for Cause | 93 | ||||||||||

| 23.5.1 | Insolvency | 94 | ||||||||||

| 23.5.2 | Delay After Provisional Acceptance | 94 | ||||||||||

| 23.5.3 | Key Personnel | 94 | ||||||||||

| 23.5.4 | Material Breach | 94 | ||||||||||

| 23.6 | Actions Upon Termination | 94 | ||||||||||

| 23.7 | Survival | 94 | ||||||||||

| 24. | ASSIGNMENT | 94 | ||||||||||

| 25. | INSURANCE | 95 | ||||||||||

| 25.1 | Contractor’s Insurance | 95 | ||||||||||

| 25.1.1 | Casualty Insurance | 95 | ||||||||||

| 25.1.1.1 | Commercial General Liability Insurance | 95 | ||||||||||

| 25.1.1.2 | Business Automobile Liability Insurance | 96 | ||||||||||

| 25.1.2 | Workers’ Compensation and Employer’s Liability Insurance | 96 | ||||||||||

| 25.1.3 | Contractor’s Property | 96 | ||||||||||

| 25.1.4 | Transit Insurance | 96 | ||||||||||

| 25.1.5 | Other Insurance | 97 | ||||||||||

| 25.1.5.1 | International Insurance | 97 | ||||||||||

| 25.1.5.2 | Differences in Condition Policy | 97 | ||||||||||

| 25.1.6 | General Insurance Conditions | 97 | ||||||||||

| 25.1.7 | Other Duties, Representations, and Obligations | 97 | ||||||||||

| 25.1.7.1 | Certificates of Insurance | 97 | ||||||||||

| 25.1.7.2 | Violation of Insurance Terms | 98 | ||||||||||

| 25.1.7.3 | Failure to Maintain Insurance | 98 | ||||||||||

| 25.1.7.4 | No Waiver of Liability | 98 | ||||||||||

| 25.1.7.5 | Additional Insurance | 98 | ||||||||||

| 25.1.7.6 | Premium Audit | 98 | ||||||||||

| 25.1.8 | Subcontractor’s Insurance | 98 | ||||||||||

ix

| 25.1.8.1 | Levels of Coverage | 98 | ||||||||||

| 25.1.8.2 | Waiver of Rights | 99 | ||||||||||

| 25.2. | Owner’s Insurance | 99 | ||||||||||

| 25.2.1 | Builder’s All Risk | 99 | ||||||||||

| 25.2.2 | Exclusion from Builder’s Risk | 99 | ||||||||||

| 25.2.3 | Contractor Compliance | 99 | ||||||||||

| 26. | TIME | 99 | ||||||||||

| 27. | TAXES | 100 | ||||||||||

| 27.1 | Taxes | 100 | ||||||||||

| 27.2 | Sales Taxes | 100 | ||||||||||

| 27.3 | Property Taxes | 100 | ||||||||||

| 28. | INDEMNIFICATION | 100 | ||||||||||

| 28.1 | Property Damage | 100 | ||||||||||

| 28.2 | Limitation on Property Damage Indemnification | 101 | ||||||||||

| 28.3 | Royalties and License Fees | 101 | ||||||||||

| 28.4 | Operation of Systems | 101 | ||||||||||

| 28.5 | No Liens or Encumbrances | 101 | ||||||||||

| 28.6 | Contractor’s Indemnities for Personal Injury or Property Damage | 101 | ||||||||||

| 28.7 | Other Contractor’s Indemnities | 102 | ||||||||||

| 28.8 | No Limitation to Workers’ Benefits | 102 | ||||||||||

| 29. | GOVERNING LAW | 102 | ||||||||||

| 30. | PERMITTING | 102 | ||||||||||

| 30.1 | Responsibility for Permitting | 102 | ||||||||||

| 30.1.1 | Owner’s Permits Required for Construction | 103 | ||||||||||

| 30.1.2 | Permission to Begin Installation of Pilings | 103 | ||||||||||

| 30.2 | Other Permits | 103 | ||||||||||

| 31. | SITE CONDITIONS | 103 | ||||||||||

| 31.1 | Geotechnical Study | 103 | ||||||||||

| 31.2 | Special Site Characteristics | 103 | ||||||||||

| 31.3 | Contractor’s Knowledge of Conditions | 103 | ||||||||||

| 31.4 | Sub-Surface Site Conditions | 104 | ||||||||||

| 32. | SUBCONTRACTORS | 104 | ||||||||||

| 32.1 | Approved Subcontractors | 104 | ||||||||||

| 32.2 | Subcontractor and Vendor Identification | 104 | ||||||||||

| 32.3 | Substitute Contractors | 104 | ||||||||||

| 32.4 | Purchase Orders and Subcontracts | 104 | ||||||||||

| 32.5 | Subcontractor Warranties | 105 | ||||||||||

| 32.6 | Subcontractor Insurance | 105 | ||||||||||

| 32.7 | No Privity with Subcontractors | 105 | ||||||||||

| 32.8 | Assignment of Subcontracts to Owner | 106 | ||||||||||

x

| 32.9 | Directed Payments | 106 | ||||||||||

| 32.10 | Neglect to Pay | 106 | ||||||||||

| 33. | DISPUTE RESOLUTION | 106 | ||||||||||

| 33.1 | Applicability of Resolution Procedures | 106 | ||||||||||

| 33.2 | Management Discussions | 106 | ||||||||||

| 33.3 | Mediation | 107 | ||||||||||

| 33.4 | Arbitration | 107 | ||||||||||

| 33.5 | Dispute Review Board | 108 | ||||||||||

| 33.6 | Obligations Continue | 108 | ||||||||||

| 33.7 | Injunctive Relief | 109 | ||||||||||

| 33.8 | Survival | 109 | ||||||||||

| 34. | MISCELLANEOUS | 109 | ||||||||||

| 34.1 | Audit and Maintenance of Records | 109 | ||||||||||

| 34.2 | Rights to Work Product | 109 | ||||||||||

| 34.2.1 | Deliverables | 109 | ||||||||||

| 34.2.2 | License | 109 | ||||||||||

| 34.2.3 | Reuse | 109 | ||||||||||

| 34.3 | Compliance with Laws | 110 | ||||||||||

| 34.3.1 | Familiarity with Laws | 110 | ||||||||||

| 34.3.2 | No Fees or Commissions | 110 | ||||||||||

| 34.4 | Authorized Representatives | 110 | ||||||||||

| 34.5 | Confidentiality | 110 | ||||||||||

| 34.5.1 | Confidential Information | 110 | ||||||||||

| 34.5.2 | Nondisclosure | 111 | ||||||||||

| 34.5.3 | Compelled Disclosure | 111 | ||||||||||

| 34.5.4 | Use Restrictions | 111 | ||||||||||

| 34.6 | Owner Caused Project End Suspension and Other Owner Caused Event | 111 | ||||||||||

| 34.7 | Notices | 112 | ||||||||||

| 34.8 | Relationship of the Parties | 113 | ||||||||||

| 34.9 | Amendments | 114 | ||||||||||

| 34.10 | No Third Party Beneficiaries | 114 | ||||||||||

| 34.11 | Priority Among Contract Documents | 114 | ||||||||||

| 34.12 | Severability | 114 | ||||||||||

| 34.13 | Remedies | 114 | ||||||||||

| 34.14 | Nonwaiver | 114 | ||||||||||

| 34.15 | Interpretation | 114 | ||||||||||

| 34.16 | Entire Agreement | 115 | ||||||||||

| 34.17 | Representations and Warranties of Contractor | 115 | ||||||||||

| 34.17.1 | Due Organization of Contractor | 115 | ||||||||||

| 34.17.2 | Due Authorization of Contractor, Binding Obligation | 116 | ||||||||||

| 34.17.3 | Non-Contravention | 116 | ||||||||||

| 34.17.4 | Regulatory Approvals | 116 | ||||||||||

| 34.18 | Representation and Warranties of Owner | 116 | ||||||||||

| 34.18.1 | Due Organization of Owner | 116 | ||||||||||

xi

| 34.18.2 | Due Authorization of Owner; Binding Obligation | 116 | ||||||||||

| 34.18.3 | Non-Contravention | 116 | ||||||||||

| 34.19 | Further Assurances | 117 | ||||||||||

| 34.20 | �� | No Implied Waiver | 117 | |||||||||

| 34.21 | Exhibits and Schedules | 117 | ||||||||||

xii

TABLE OF EXHIBITS

EXHIBIT | TITLE | |

| 1 | FGD Technical Specification | |

| 2 | FGD Division of Responsibility | |

| 3 | Intentionally Omitted | |

| 4 | Permitting Division of Responsibility | |

| 5 | Intentionally Omitted | |

| 6 | Performance Guarantees and Test Methods | |

| 7 | Key Personnel | |

| 8 | Cost Submitted with Proposal | |

| 8 A | Detailed Cost Summary | |

| 8 B | Details of Cost | |

| 8 C | Contractor’s Technical and Commercial Clarification/Exceptions | |

| 8 D | Rate Sheet | |

| 8 E | Intentionally Omitted | |

| 8 F | Escalation of Commodities | |

| 9 | Progress Milestone Payments | |

| 10 | Applicable Codes and Standards | |

| 11 | Letter of Credit | |

| 12 | Payment Bond and Performance Bond | |

| 13 | Agency Letter | |

| 14 | Intentionally Omitted | |

| 15 | Draft Project Schedule | |

| 16 | Forms for Lien Waivers and Releases | |

| 17 | Dispute Resolution Board Procedure | |

ENGINEERING, PROCUREMENT AND CONSTRUCTION AGREEMENT

THIS ENGINEERING, PROCUREMENT AND CONSTRUCTION AGREEMENT is made this 30th day of July, 2007, by and betweenMIRANT MID-ATLANTIC, LLC , a Delaware limited liability company, andMIRANT CHALK POINT, LLC , a Delaware limited liability company (each individually an“Owner” , or collectively,“Owners” as further described in Sections 2.1 and 2.2),MIRANT MID-ATLANTIC, LLC as agent for the Owners, andSTONE & WEBSTER, INC. , a Louisiana corporation (“Contractor” ).

NOW, THEREFORE, for and in consideration of the mutual covenants set forth in this Agreement, the Parties agree as follows:

1. DEFINITIONS

1.1 “Actual Cost” is the sum of all actual costs for performing the Work as described in Section 10.2.

1.2 “Actual Field Non-Manual Labor Costs” has the meaning set forth in Section 10.2.3.

1.3 “Actual Home Office Labor Costs” has the meaning set forth in Section 10.2.2.

1.4 “Actual Self-Performed Field Manual Services Costs” has the meaning set forth in Section 10.2.4.

1.5 “Actual Third Party Expenses” has meaning set forth in Section 10.2.5.

1.6 “Agreement” means this Engineering, Procurement and Construction Agreement, consisting of Articles 1 through 34, and Exhibits 1, 2, 4, 6 through 13, 15 through 17.

1.7 “Alliance Agreement” means the agreement between Owner and Contractor dated July 11, 2006 pursuant to which preliminary Work has been performed as authorized by Owner through the issuance of LNTP and INTP.

1.8 “Allocable Costs” has the meaning set forth in Section 11.5.1.

1.9 “Applicable Laws” means all laws, statutes, ordinances, rules, regulations, judgments, interpretations, policies and orders of any court, arbitrator or governmental agency or authority having or asserting jurisdiction over the Facility, the Site, the Systems or the performance of the Work, as may be in effect from time to time.

1

1.10 “Applicable Permits” means all valid waivers, franchises, variances, permits, authorizations, licenses or orders of or from any governmental body, agency, authority, court or other body having jurisdiction over the Facility, the Site, the Systems or the performance of Work that are required, necessary or desirable to be obtained or maintained in connection with the Project.

1.11 “Approved Final Milestone Payment Schedule” has the meaning set forth in Section 12.2.1.

1.12 Blank

1.13 “Approved Project Schedule” has the meaning set forth in Section 8.1.

1.14 “Approved Subcontractor List” has the meaning set forth in Section 10.2.5.

1.15 “As-Built Drawings” means drawings which are revised to show all modifications and revisions made by the Contractor (including all Subcontractors to the Contractor) up to Final Completion, for all key drawings which are necessary for the Owner’s continued operation, maintenance, and regulatory compliance for the Project. The final list of As-Built Drawings is listed in Exhibit 1.

1.16 “Authorized Representative” has the meaning set forth in Section 34.4.

1.17 “Baseline Commodity Index Price” for an individual Commodity means the PPI Index Price for that Commodity as provided in Exhibit 8F.

1.18 “Business Day” means a calendar day other than Saturday, Sunday or a national holiday. As used in Section 17.5, “Business Day” also excludes a holiday recognized and followed in the State of Maryland.

1.19 “Chalk Point” means the power station known as “Chalk Point Plant” located at 25199 Chalk Point, Aquasco, MD 20608 consisting of Units E1 and E2.

1.20 “Change” means (i) any addition to, deletion from, suspension of or other modification to the quality, function, intent, quantity, method or entity performing the Work, including without limitation any such addition, deletion, suspension or other modification that requires a change in the Contract Price or the Approved Project Schedule, or (ii) any extension of the Approved Project Schedule or increase in the Contract Price.

1.21 “Change in Applicable Law” has the meaning set forth in Section 19.9.

1.22 “Change Order” has the meaning set forth in Section 19.1.

2

1.23 “Change Order Notice” has the meaning set forth in Section 19.2.1.

1.24 “Change Order Request” has the meaning set forth in Section 19.2.2.

1.25 “Confidential Information” has the meaning set forth in Section 34.5.

1.26 “Construction Equipment” means the equipment, materials, tools and supplies which are to be provided by Contractor and used in the performance of the Work, but which are not incorporated into or become a part of the Systems.

1.27 “Commodities” has the meaning set forth in Exhibit 8F.

1.28 The“Contingency” is an amount equal to ten percent (10%) of the Target Cost at issuance of NTP for that Facility. References to “50% Contingency” mean an amount that equals one-half of the Contingency amount.

1.29 “Contract Documents” means this Agreement and the Drawings, as either of these may be supplemented or amended.

1.30 “Contract Price” has the meaning set forth in Section 13.2.

1.31 “Contractor” has the meaning set forth in the preamble of this Agreement.

1.32 “Contractor Event of Default” has the meaning set forth in Section 23.5.

1.33 “Contractor’s Additional Direct Costs or Savings” has the meaning set forth in Section 19.14.3.

1.34 “Critical Schedule Situation” has the meaning set forth in Section 8.6.

1.35 “Dedicated” has the meaning set forth in Section 9.1.1.

1.36 “Deliverables” has the meaning set forth in Section 34.2.1.

1.37 “Design Development Documents” has the meaning set forth in Section 6.2.3.3.

1.38 “Dickerson” means the power station known as “Dickerson Plant” located at 21200 Martinsburg Road, Dickerson, MD 20842 consisting of Units D1, D2 and D3.

1.39 “Direct Cause” or“Directly Cause(d)” means a cause that naturally brings about a delay or Direct Cost without intervention of any new and independent cause, and without which the delay would not have occurred or the Direct Cost would not have been incurred.

3

1.40 “Direct Cost” means an actual cost necessarily incurred by Contractor in performing the Work, that is substantiated by written invoices, payment applications, time sheets, or other reasonable documentation, that is paid for Actual Third Party Expenses, Actual Field Non-Manual Labor, Actual Self-Performed Field Manual Services, or engineering services by Contractor’s employees, or for costs of repair or replacement of Construction Equipment or Systems Equipment and that is not reimbursed by proceeds of insurance.

1.41 “Disclosing Party” has the meaning set forth in Section 34.5.1.

1.42 “Disputes” has the meaning set forth in Article 33.

1.43 “Drawings” has the meaning set forth in Section 6.2.3.4.

1.44 “DRB” is the Dispute Review Board referred to in Section 33.5.

1.45 “Effective Date” has the meaning set forth in Article 3.

1.46 “Engineering Design Margins” has the meaning set forth in Section 7.1.1.

1.47 The“EPC Total Compensation” is the total compensation to be paid by the Owner to the Contractor for proper performance of all of the Work and shall be calculated pursuant to Article 11.

1.48 “Equivalent Availability Guarantee” has the meaning set forth in Section 1.2 of Exhibit 6.

1.49 “Escalation Report” has the meaning set forth in Section 19.10.

1.50 “Excessive Outage Payments” has the meaning set forth in Section 8.2.1.2.

1.51 “Extended Warranty Equipment” is the booster fans, absorber vessel (materials, internals and internal piping), spray nozzles, agitator, ball mill and recycle pumps.

1.52 “Facilities” means the Morgantown, Chalk Point and Dickerson power stations.

1.53 “Facility” means either Chalk Point, Dickerson or Morgantown, as the context requires.

4

1.54 “Fee” means the Target Fee.

1.55 “Fee Element” has the meaning set forth in Section 19.2.3.2.

1.56 “FGD System” means the total equipment, materials, tools and supplies supplied by Contractor for each fully operable flue gas desulfurization unit as described in Exhibit 1, including the associated balance of plant (“BOP” ) required to meet the Input Guarantees, Output Guarantees and Operational Guarantees applicable to an FGD System under Article 7.

1.57 “FGD Subcontractor” means the Subcontractor supplying the FGD System.

1.58 “Final Completion” has the meaning set forth in Section 18.1.

1.59 “Financing Parties” means any and all lenders providing the construction, interim or long-term financing for the Project, their successors and assigns, and any trustee or agent acting on their behalf.

1.60 “Force Majeure” has the meaning set forth in Section 20.1.

1.61 “Geotechnical Study” has the meaning set forth in Section 31.1.

1.62 “Guarantee Costs” has the meaning set forth in Section 11.3.

1.63 “Guaranteed Final Completion Date” has the meaning set forth in Section 8.2.5 and shall be the date set forth in the Approved Project Schedule.

1.64 “Guaranteed Provisional Acceptance Date” has the meaning set forth in Section 8.2.2 and shall be the date set forth in the Approved Project Schedule.

1.65 “Guaranteed Substantial Completion Date” has the meaning set forth in Section 8.2.4 and shall be the date set forth in the Approved Project Schedule.

1.66 “Gypsum Dewatering Plant” has the meaning set forth in Section 5.1.5.

1.67 “Hazardous Substance” means any and all chemicals, constituents, contaminants, pollutants, materials, and wastes and any other carcinogenic, corrosive, ignitable, radioactive, reactive, toxic or otherwise hazardous substances or mixtures (whether solids, liquids, or gases), or any similar substances now or at any time before Final Completion subject to regulation, control, remediation or otherwise addressed under Applicable Laws, including but not limited to those Applicable Laws relating to the discharge, emission, spill, release, or threatened release into the environment or relating to the disposal, distribution, manufacture, processing, storage, transport, treatment or other use of such substances.

5

1.68 “Incremental Payment Amount” has the meaning set forth in Section 12.2.1.

1.69 “Incremental Percentage” means the Incremental Percentage identified for a Milestone in the Approved Percentage Milestone Payment Schedule as set forth in Exhibit 9.

1.70 An“Initial Performance Test” is the first occurrence of Performance Test PA, the first occurrence of Performance Test 1, or the first 180 days of Performance Test 2, all as referred to in Exhibit 6.

1.71 “Input Guarantee” has the meaning set forth in Section 7.1.

1.72 “INTP” means the Intermediate Notice to Proceed for FGD System set forth in Section 6.1.2.

1.73 “INTP for SCR” means the intermediate notice to proceed for the SCR system as set forth in Section 6.1.5.

1.74 “INTP Security” means the letter of credit posted by Contractor in a form and by an issuing bank acceptable to Owner, in the amount equal to the sum of the purchase orders issued by Owner at LNTP and INTP.

1.75 “Key Personnel” has the meaning set forth in Section 9.1.1.

1.76 “Late Final Completion Payments” has the meaning set forth in Section 8.2.6.

1.77 “Late Provisional Acceptance Payments” has the meaning set forth in Section 8.2.3.

1.78 “Letter of Credit” shall have the meaning as set forth in Section 22.2 and 22.4.

1.79 “LNTP” means the Limited Notice to Proceed for the FGD Systems as set forth in Section 6.1.1.

1.80 “LNTP for SCR” means the limited notice to proceed for the SCR System as set forth in Section 6.1.4.

1.81 “LNTP Security” means the letter of credit posted by Contractor in a form and by an issuing bank acceptable to Owner, in the amount equal to the purchase order issued by Owner for the Work to be performed during the LNTP phase.

6

1.82 “Lost Time Incident Rate” means the number of lost time incidents divided by manhours worked multiplied by two hundred thousand (200,000).

1.83 “Mechanical Completion” has the meaning set forth in Section 16.1.

1.84 “Milestone” means a portion of the Work identified in the Approved Final Milestone Payment Schedule, and for which a related Incremental Payment Amount has been established.

1.85 “Milestone Progress Payment” has the meaning set forth in Section12.2.2.

1.86 “Morgantown” means the power station known as “Morgantown Plant” located at 12620 Crain Highway, Newburg, MD 20664 consisting of Units F1 and F2.

1.87 “Notice of Final Completion” has the meaning set forth in Section 18.2.

1.88 “Notice of Mechanical Completion” has the meaning set forth in Section 16.2.

1.89 “Notice of Project Completion” has the meaning set forth in Section 8.2.7.

1.90 “Notice of Provisional Acceptance” has the meaning set forth in Section 17.3.

1.91 “Notice of Substantial Completion” has the meaning set forth in Section 17.6.

1.92 “NTP” means the notice to proceed for the FGD Systems set forth in Section 6.1.3.

1.93 “Open Book” means that Contractor will maintain and make all of its books, records, schedules, logs and electronic communications and data related to the Work available to Owner to substantiate and document the design, pricing, progress and sequencing of the Work and costs and other expenses incurred or expected to be incurred in connection with performing the Work.

1.94 “Operational Guarantees” has the meaning set forth in Section 7.3.1.

1.95 “Output Guarantees” has the meaning set forth in Section 7.2.1.

1.96 “Owner” has the meaning set forth in Sections 2.1 and 2.2 of this Agreement.

7

1.97 “Owner Agent” has the meaning set forth in Sections 2.1 and 2.3 of this Agreement.

1.98 “Owner Scope” has the meaning set forth in Section 5.1.

1.99 “Owner Security” has the meaning set forth in Section 22.4.

1.100 “Owner’s Separate Contractors” means contractors hired by Owner to perform work in connection with a Facility, not including Contractor.

1.101 “Parties” means Owner and Contractor.

1.102 “Parts and Labor Warranties” has the meaning set forth in Section 14.1.1.2.

1.103 “Parts and Labor Warranty Period” has the meaning set forth in Section 14.1.2.

1.104 “Performance Guarantees” has the meaning set forth in Article 7.

1.105 “Performance Incentives” has the meaning set forth in Section 11.4.2.

1.106 “Performance Test PA” means the Performance Test for Provisional Acceptance referred to in Section One of Exhibit 6.

1.107 “Performance Test 1” means the Performance Test 1 referred to in Section One of Exhibit 6.

1.108 “Performance Test 2” means the Equivalent Availability Test referred to in Section One of Exhibit 6.

1.109 “Performance Tests” has the meaning set forth in Section 7.7.1.

1.110 “PPI Index Price” means the unit price for a Commodity as reported in the applicable publication of the United States Bureau of Labor Statistics, effective as of the date that the firm price is established for purchase of the Commodity by Contractor.

1.111 “Progress Report” means a progress report containing the following information: (i) description of Contractor’s and all Subcontractors’ activities and progress on the Work completed to the date of such report, including but not limited to a comparison of such progress with the Approved Project Schedule, (ii) an identification and evaluation of any problems or deficiencies in the Work, (iii) the status of all deliveries of Systems Equipment, and (iv) a forecast of the Work to complete.

8

1.112 “Project” means the complete design, engineering, procurement, permitting, construction, installation, initial performance tests, commissioning, start-up and completion of the Systems for the Facilities by Contractor on a turn-key basis in accordance with the Contract Documents, excluding only the Owner Scope.

1.113 “Project Compensation” is the amount calculated pursuant to Section 13.2.2.

1.114 “Provisional Acceptance” has the meaning set forth in Section 17.1.

1.115 “Prudent Electrical Practices” means the use of, and adherence to, equipment, practices and methods of applicable United States of America industry codes, standards and regulations, required, necessary or desirable to protect the Systems, the Facility and Owner’s employees, agents, and customers from electrical malfunctions, as embodied in the National Electric Code.

1.116 “Prudent Utility Practices” means the practices, methods, materials, supplies and equipment that are commonly used in the United States of America electric power production industry to design, construct and operate power plants and related equipment (including equipment such as the Facility and the Systems) or any practices, methods and acts, which in the exercise of reasonable judgment in light of the facts known at the time, could have been expected to be used to accomplish the desired result to the specified standards and at the lowest reasonable cost consistent with good business practices, reliability, safety and expedition.

1.117 “Punch-List” has the meaning set forth in Section 17.5.

1.118 “Qualified Person” has the meaning set forth in Section 9.1.4.

1.119 “Receiving Party” has the meaning set forth in Section 34.5.1.

1.120 “Total Recordable Incident Rate” means the number of recordable injuries divided by manhours multiplied by two hundred thousand (200,000).

1.121 “Scheduled Outage Period” means, with respect to each Unit, the time period as set forth in the Approved Project Schedule, during which such Unit will be taken out of operation by Owner for the purpose of allowing Contractor to install the System for such Unit.

1.122 “Schematic Design Documents” has the meaning set forth in Section 6.2.3.1.

1.123 “Separate Contractor” means a person or entity having a separate contract with the Owner to perform all or part of the Owner Scope.

9

1.124 “Site” means a site upon which a Facility is located and upon which the Systems will be constructed.

1.125 “Spill” shall mean any discharge, overflow, spill or release of any kind or nature that constitutes, either by way of adherence, conformance or compliance with Applicable Law or any of either Contractor’s or Owner’s environmental, health and safety policies or programs, a reportable event or requires specialized or significant containment, treatment, action or remediation.

1.126 “Subcontractor” means each and every vendor, supplier, manufacturer, materialman, contractor, subcontractor or sub-subcontractor of any tier other than Contractor, performing any part of the Work, providing any of the Systems Equipment and Construction Equipment, or providing other services or supplies in connection with the Work directly or indirectly for or to Contractor.

1.127 “Substantial Completion” has the meaning set forth in Section 17.2.

1.128 “System” means an FGD System.

1.129 “Systems Equipment” means the equipment, materials, tools and supplies which are to be provided by Contractor as part of the Work, pursuant to Section 6.3.1 and are to be incorporated into and become a part of the Systems owned by Owner.

1.130 The“Target Cost” for each Facility has the meaning set forth in Section 10.1.

1.131 The“Target Fee” is an amount that is five percent (5%) of the Target Cost.

1.132 The“Target Final Payment” has the meaning set forth in Section 12.11.2.

1.133 The“Target Price” is an amount equal to the sum of the Target Cost plus 50% of the Contingency.

1.134 “Taxes” means all sales, use, gross receipts, income and withholding taxes and other similar taxes and contributions imposed by any taxing authority upon the sale, purchase or use of the Systems Equipment or the Construction Equipment, or upon services or labor provided as part of the Work, including, without limitation, taxes on or measured by Contractor’s receipts hereunder and taxes on or measured by wages earned by employees of Contractor or any Subcontractor, subject to application of Article 27.

1.135 “Technical Specifications” means the requirements and specifications set forth in Exhibits 1, 2, 4 and 6.

1.136 “Termination Payment” has the meaning set forth in Section 23.4.2.

10

1.137 “Time” has the meaning set forth in Article 26.

1.138 “ Underrun Bonus ”has the meaning set forth in Section 11.6.

1.139 “Unit D1” means the electricity generating unit comprising part of Dickerson, as more specifically described in Exhibit 1.

1.140 “Unit D2” means the electricity generating unit comprising part of Dickerson, as more specifically described in Exhibit 1.

1.141 “Unit D3” means the electricity generating unit comprising part of Dickerson, as more specifically described in Exhibit 1.

1.142 “Unit E1” means the electricity generating unit comprising part of Chalk Point, as more specifically described in Exhibit 1.

1.143 “Unit E2” means the electricity generating unit comprising part of Chalk Point, as more specifically described in Exhibit 1.

1.144 “Unit F1” means the electricity generating unit comprising part of Morgantown, as more specifically described in Exhibit 1.

1.145 “Unit F2” means the electricity generating unit comprising part of Morgantown, as more specifically described in Exhibit 1.

1.146 “Units” means all units at the specified Facility;“Unit” means a single Unit at a Facility.

1.147 “Warranty Bond” has the meaning set forth in Section 22.3.

1.148 “Work” has the meaning set forth in Section 6.1 of this Agreement.

2. OWNER ENTITIES

2.1 Mirant Mid-Atlantic, LLC . Mirant Mid-Atlantic, LLC leases the Morgantown Generating Station located in Newberg, Maryland (Unit F1 and Unit F2) and the Dickerson Generating Station located in Dickerson, Maryland (Unit D1, Unit D2 and Unit D3). Mirant Mid-Atlantic, LLC is an “Owner” for purposes of the Morgantown and Dickerson Facilities, and is an authorized agent (“Owner Agent”) of itself and Mirant Chalk Point, LLC for the purposes set forth herein.

2.2 Mirant Chalk Point, LLC . Mirant Chalk Point, LLC owns Units E1 and E2 of the Chalk Point Station located in Aquasco, Maryland. Mirant Chalk Point, LLC is an “Owner” for purposes of the Chalk Point Facility.

11

2.3 Owner’s Agent . Mirant Mid-Atlantic, LLC, as an Owner Agent, is authorized to act as Owners’ agent in connection with this Agreement with authority to bind such Owners and to delegate such authority as set forth in this Agreement.

2.4 Obligations . Obligations of an Owner set forth in this Agreement shall be deemed to be the obligations of an Owner of the Facility with respect to the applicable obligation. Obligations owed by Contractor to an Owner under this Agreement shall be deemed owed to the Owner of the Facility(ies) applicable to such obligation. Owner obligations that are independent of a particular Facility shall be owed jointly and severally by both Owners as a single obligation, and Contractor’s obligations owed independent of a particular Facility shall be owed to both Owners as a single obligation by Contractor.

3. EFFECTIVE DATE

The effective date of this Agreement is 30th day of July, 2007 (the“Effective Date” ).

4. TERM

This Agreement will commence on the Effective Date and will expire following the fulfillment of all obligations of the Parties hereunder, unless terminated earlier pursuant to the terms of this Agreement.

5. OWNER SCOPE

5.1 Owner Scope . Owner, in addition to its other obligations under the Agreement, will engage Separate Contractors to perform the following (the “ Owner Scope ”):

5.1.1 Rough Site Grading in accordance with the bidding information prepared by Contractor pursuant to Section 6.2.3.5.1;

5.1.2 Underground Relocation in accordance with the bidding information prepared by Contractor pursuant to Section 6.2.3.5.2;

5.1.3 Site Demolition in accordance with the bidding information prepared by Contractor pursuant to Section 6.2.3.5.3; and

5.1.4 Railroad Improvements in accordance with the general arrangement drawings included in the Drawings approved by Owner pursuant to Section 6.2.3.4, as such general arrangement drawings may be modified from time to time by mutual agreement of the Parties in writing; and

5.1.5 Gypsum handling and dewatering systems (“ Gypsum Dewatering Plant ”) in accordance with Section 5.2.

12

5.2 Gypsum Dewatering Plant . Owner will provide to Contractor, for Contractor’s use in performing its services under Section 6.2.3.6, the foundation loads, general arrangement drawings, and interconnection information for the Gypsum Dewatering Plant for each of the Facilities. Owner will engage a Separate Contractor to engineer, procure and construct a Gypsum Dewatering Plant for each of the Facilities.

5.3 Schedule for Owner Scope . The Owner Scope shall be performed in accordance with Sections 5.3.1 through 5.3.5 below. Owner’s obligations under this Section 5.3 shall be conditioned on timely completion of the related obligations of Contractor. Failure of Owner to timely perform its obligations under this Section 5.3 shall constitute an omission of Owner for the purposes of Section 19.7.

5.3.1 Owner will perform the Rough Site Grading in accordance with Exhibit 15, as same may be modified by mutual agreement of the Parties.

5.3.2 Owner will perform the Underground Relocation in accordance with Exhibit 15, as same may be modified by mutual agreement of the Parties, and from time to time as may be requested by Contractor and agreed by Owner.

5.3.3 Owner will perform the Site Demolition in accordance with Exhibit 15, as same may be modified by mutual agreement of the Parties, and from time to time as may be requested by Contractor and agreed by Owner.

5.3.4 Owner will perform the Railroad Improvements in accordance with Exhibit 15, as same may be modified by mutual agreement of the Parties.

5.3.5 With respect to the Gypsum Dewatering Plants:

5.3.5.1 Owner will provide the certified foundation loads for Morgantown to Contractor on or before August 30, 2007

5.3.5.2 Owner will provide the certified foundation loads for Chalk Point to Contractor on or before August 30, 2007.

5.3.5.3 Owner will provide the certified foundation loads for Dickerson to Contractor on or before August 30, 2007

5.3.5.4 Owner will provide “issued for construction” general arrangement drawings for Morgantown to Contractor on or before August 30, 2007.

5.3.5.5 Owner will provide “issued for construction” general arrangement drawings for Chalk Point to Contractor on or before August 30, 2007.

13

5.3.5.6 Owner will provide “issued for construction” general arrangement drawings for Dickerson to Contractor on or before August 30, 2007.

5.3.5.7 Owner will provide utility interface information for Morgantown to Contractor in accordance with Exhibit 15, as same may be modified by mutual agreement of the Parties,

5.3.5.8 Owner will provide utility interface information for Chalk Point to Contractor in accordance with Exhibit 15, as same may be modified by mutual agreement of the Parties,

5.3.5.9 Owner will provide utility interface information for Dickerson to Contractor in accordance with Exhibit 15, as same may be modified by mutual agreement of the Parties.

5.3.5.10 The “Ready for Tie-In” milestone in the construction schedule of the Separate Contractor for the Gypsum Dewatering Plant at Morgantown will be substantially completed on or before the later of 15 months from substantial completion of piles for the Gypsum Dewatering Plant at Morgantown by Contractor.

5.3.5.11 The “Ready for Tie-In” milestone in the construction schedule of the Separate Contractor for the Gypsum Dewatering Plant at Chalk Point will be substantially completed on or before the later of 15 months from substantial completion of piles for the Gypsum Dewatering Plant at Chalk Point by Contractor.

5.3.5.12 The “Ready for Tie-In” milestone in the construction schedule of the Separate Contractor for the Gypsum Dewatering Plant at Dickerson will be substantially completed on or before the later of 15 months from substantial completion of piles for the Gypsum Dewatering Plant at Dickerson by Contractor.

5.3.5.13 The “Ready for Slurry” milestone in the construction schedule of the Separate Contractor for the Gypsum Dewatering Plant at Morgantown will be substantially completed on of before the later of 45 days satisfactory completion of tie in by Contractor and the last day of the final tie-in outage for the first System at Morgantown.

5.3.5.14 The “Ready for Slurry” milestone in the construction schedule of the Separate Contractor for the Gypsum Dewatering Plant at Chalk Point will be substantially completed on of before the later of 45 days satisfactory completion of tie in by Contractor and the last day of the final tie-in outage for the System at Chalk Point.

14

5.3.5.15 The “Ready for Slurry” milestone in the construction schedule of the Separate Contractor for the Gypsum Dewatering Plant at Dickerson will be substantially completed on of before the later of 45 days satisfactory completion of tie in by Contractor and the last day of the final tie-in outage for the System at Dickerson.

5.4 Non-Interference and Safety . In performing Owner Scope, the Separate Contractors will be subject to the requirements applicable to Contractor under Sections 6.7 and 6.8.

6. PROJECT SCOPE

6.1 Work To Be Performed . Excluding the Owner Scope, Contractor will perform or cause to be performed in accordance with the Contract Documents all work, services and management required for the complete design, engineering, procurement, manufacturing, furnishing, delivery (FOB at Facility), unloading, placement and maintenance in storage as required, removal from storage, permitting, construction, installation, commissioning, check-out, tuning, testing, start-up and completion and placement of air quality control systems that are ready for continuous operation on a turn-key basis (collectively, the“Work” ), such systems consisting of the following:

Two FGD Systems on:

Morgantown- (Units F1 and F2)

One FGD System on each of:

Chalk Point- (Units E1 and E2)

Dickerson- (Units D1, D2, and D3)

The Work with respect to each of the above is further detailed in Exhibits 1, 2, 4, 8C and 15, and includes but is not limited to Sections 6.2 through 6.10 below. For the avoidance of doubt, the Work does not include the Owner Scope.

6.1.1 LNTP for FGD Systems . Pursuant to the Alliance Agreement, Owner has issued a Limited Notice to Proceed (LNTP) and Contractor has posted the LNTP Security.

6.1.2 INTP for FGD Systems . Pursuant to the Alliance Agreement, Owner has issued an Intermediate Notice to Proceed (INTP) and Contractor has posted the INTP Security.

6.1.3 NTP for FGD Systems . Contractor shall continue performance of the Work on the INTP until the Owner’s issuance of an NTP. Prior to issuance of the NTP, Owner and Contractor have agreed on a Target Cost for the Work

15

included in each Facility. Owner shall issue a Notice to Proceed (“NTP” ) to continue the Work upon execution of this Agreement. Contractor shall commence Work on the NTP on the next Business Day after receipt of the NTP. Upon issuance of the NTP, Owner shall post the Owner Security in accordance with Section 22.4 and Contractor shall maintain the Letter of Credit pursuant to Section 22.2.3 and shall post the performance bond and payment bond pursuant to Section 22.3.

6.1.4 LNTP for SCR System . Pursuant to the Alliance Agreement, Owner has issued a Limited Notice to Proceed for the SCR system at Chalk Point, and Contractor commenced work on the LNTP for SCR on the next Business Day after receipt of the LNTP for SCR.

6.1.5 INTP for SCR System . Pursuant to the Alliance Agreement, Owner has issued an Intermediate Notice to Proceed to Contractor for an SCR system at Chalk Point. Contractor commenced Work on the INTP for SCR and has developed certain design documents and has initiated certain procurement activities in connection with that SCR system.

6.1.6 Transition of SCR from Contractor to Owner . Contractor shall tender to Owner, at Owner’s request, all documents relating to the Chalk Point SCR system, including all preliminary and other design documents, CAD files, books, records, drawings, specifications, electronically stored information and other information or data relating to that SCR system. Within ten (10) days after execution of this Agreement Contractor shall obtain and tender appropriate written consents of all subcontractors and vendors, and complete the assignment to Owner of all contracts or agreements relating to the SCR system, including all contracts for procurement of materials or equipment to be used in the construction of that system. Contractor shall also submit to Owner waivers of lien, if any, received from subcontractors and vendors for the SCR System, and a certificate of Contractor verifying payment to date for all materials, equipment, or services provided by subcontractors or vendors. Along with the documents required under this Section 6.1.6, Contractor shall submit to Owner a request for payment of all amounts due and owing to Contractor for work performed by Contractor in connection with the SCR system. Such request for payment shall include documentation of all Actual Costs incurred by Contractor in performing work necessary for the SCR system, and a calculation of the Fee owed to Contractor for such work. Such Fee shall be calculated at the rate of five percent (5%) of Actual Costs. Upon receiving such request, Owner will make payment within 30 days.

6.1.7 Application of Terms and Conditions . The terms and conditions of this Agreement apply to any Work performed by Contractor following Owner’s issuance of the LNTP. Owner reserves the right to modify the scope of the Work (other than deletion of all of the Work associated with a single Facility, except in connection with termination of all the Work for the entire Project) at any time pursuant to this Agreement.

16

6.2 Engineering/Design Services . As part of the Work, Contractor will perform the following engineering and design services, and Owner shall have the right to review all drawings, specifications and other documents and electronic records relating to such services:

6.2.1 Technical Specifications . Exhibits 1, 2 and 4 set forth the basic design concept, intent, objectives and requirements of Owner for the Project. Contractor represents and warrants that it has thoroughly familiarized itself with the Technical Specifications contained in Exhibits 1, 2 and 4, and agrees that it has and will provide all engineering and design services, excluding only the Owner Scope, necessary to produce fully completed Systems that meet or exceed the requirements set forth in the Technical Specifications. All engineering work requiring certification under the laws of the State of Maryland will be certified by professional engineers licensed and properly qualified to perform such engineering services in the State of Maryland. Contractor shall follow the State of Maryland requirements in identifying the Contractor’s drawings, calculations and specifications that must be sealed and signed by a professional engineer licensed in the State of Maryland.

6.2.2 Design Standards . In addition to causing each System to meet or exceed the requirements set forth in the Technical Specifications under the design conditions set forth in Exhibits 1, 2, 4 and 6. Contractor will cause each System, and all design documentation prepared pursuant to Section 6.2.3, to be engineered and designed in a manner which is consistent and in conformance with Prudent Electrical Practices and Prudent Utility Practices, including, without limitation, all applicable codes and standards (including without limitation all applicable engineering, environmental, construction, safety, and electrical generation codes and standards) and in conformance with all other Applicable Laws and Applicable Permits, all as in effect as of the date of Substantial Completion, subject to changes pursuant to Section 19.9. A list of the applicable codes and standards has been agreed upon by the Parties and included as Exhibit 10 to the EPC Agreement.

6.2.3 Design Documentation .

6.2.3.1 Schematic Design Documents . Based upon the Technical Specifications, Contractor will prepare, for written approval by Owner, schematic design documents for the Project consisting of drawings, system descriptions, process flow diagrams, general arrangement drawings, models and other documents illustrating the scale and relationship of the components of each System (collectively, the“Schematic Design Documents” ). The Parties have agreed that the list of the Schematic Design Documents to be reviewed and approved by Owner consists of General Arrangement drawings, P&IDs, Electrical One-line diagrams, and equipment Specifications. Contractor shall provide to

17

Owner each listed Schematic Design Document as it is prepared by Contractor. Owner shall notify Contractor as to whether it approves or disapproves (and, if it disapproves, the reasons therefore) each of the listed Schematic Design Documents within ten (10) Business Days of its receipt of the same. Owner will review the Schematic Design Documents for compliance and will mark and stamp them to indicate whether changes and/or corrections are required. Contractor shall address all material comments and questions appropriately including, when appropriate, incorporating the comments, corrections and/or changes on the original drawing or document and resubmitting the drawing or document. Should Owner fail to provide notification to Contractor within the aforesaid ten (10) day period after its receipt of Schematic Design Documents, then the Schematic Design Documents for which notification is not provided shall be deemed to have been returned as acceptable for procurement, fabrication or construction. One paper print or copy of each submitted design document will be marked with the Owner’s review stamp, comment, and corrections and/or changes and returned to Contractor with a transmittal letter. On resubmitted drawings, Contractor shall clearly mark the section of the drawing which has been revised with a revision number, cloud around the appropriate item or a similar written designation. Owner’s approval or disapproval, or refusal to review any design documents, including but not limited to the “Schematic Design Documents” shall not impose on Owner any responsibility for the design and shall not be deemed a waiver and will not relieve Contractor of Contractor’s obligations for turnkey design, procurement and construction of the Work in accordance with the Contract Documents.

6.2.3.2 Permitting Documents . Contractor shall produce and provide to Owner, pursuant to the schedule and list of Deliverables to be agreed upon by the Parties after issuance of the LNTP, all Deliverables required for permitting under Applicable Law and Applicable Permits. Should Contractor fail to provide any such Deliverable by the scheduled date, then for each such late Deliverable, Contractor shall be assessed liquidated damages in the amount of Five Thousand Dollars ($5,000) per day for each day after the scheduled date of delivery until such Deliverable is provided to Owner. Such liquidated damages shall accrue and be treated as Guarantee Costs pursuant to Section 11.3.

6.2.3.3 Design Development Documents . Based upon the Technical Specifications and the approved Schematic Design Documents, Contractor will prepare, for written approval by Owner, both basic and detailed design development documents for the Project consisting of drawings, models, specifications, plans and other documents necessary to fix and describe the size and character of each System with respect to the civil engineering, structural, instrumentation, control, mechanical, electrical, fire protection, acoustical and life safety systems to be

18

incorporated therein (collectively, the“Design Development Documents” ). The Parties have agreed that the list of the Design Development Documents to be reviewed and approved by Owner consists of General Arrangement drawings, P&IDs, Electrical One-line diagrams, and equipment Specifications. Contractor shall provide to Owner each listed Design Development Document as it is prepared by Contractor. Owner shall notify Contractor as to whether it approves or disapproves (and, if it disapproves, the reasons therefore) each of the listed Design Development Documents within ten (10) Business Days of its receipt of the same. Owner will review the design documents for compliance and will mark and stamp them to indicate whether changes and/or corrections are required. Contractor shall address all material comments and questions appropriately including, when appropriate, incorporating the comments, corrections and/or changes on the original drawing or document and resubmitting the drawing or document. Should Owner fail to provide notification to Contractor within the aforesaid ten (10) day period after its receipt of Design Development Documents, then the Design Development Documents for which notification is not provided shall be deemed to have been returned as acceptable for procurement, fabrication or construction. On resubmitted drawings, Contractor shall clearly mark the section of the drawing which has been revised with a revision number, cloud around the appropriate item, or a similar written designation. After expiration of Owner’s ten (10) day review period, Contractor may proceed with the Work during the review process. Owner’s approval or disapproval, or refusal to review any design documents, including but not limited to the “Design Development Documents” shall not impose on Owner any responsibility for design, and shall not be deemed a waiver and will not relieve Contractor of Contractor’s obligations for turnkey design, procurement and construction of the Work in accordance with the Contract Documents.

6.2.3.4 Approved Drawings . After issuance of an INTP, and based upon the Technical Specifications, the approved Design Development Documents, and any further adjustments in the scope of the Project authorized in writing by Owner, Contractor will proceed to prepare, for written approval by Owner, a list of the drawing type as well as drafts of the key drawings setting forth the requirements for the complete construction of each System (as approved by Owner, the“Drawings” ). The Parties have agreed that the list of the Drawings to be reviewed and approved by Owner consists of General Arrangement drawings, P&IDs, Electrical One-line diagrams, and equipment Specifications. Contractor shall provide to Owner each listed Drawing as it is prepared by Contractor. Following Owner’s written approval of the listed Drawings, Contractor will proceed with the procurement, construction, installation, start-up and completion of the Systems based upon the Technical Specifications and the Drawings. Owner shall notify

19

Contractor as to whether it approves or disapproves (and, if it disapproves, the reasons therefore) each of the Drawings within ten (10) Business Days of its receipt of the same. Owner will review the Drawings for compliance and will mark and stamp them to indicate whether changes and/or corrections are required. Contractor shall address all material comments and questions appropriately including, when appropriate, incorporating the comments, corrections and/or changes on the original drawing or document and resubmitting the drawing or document. Should Owner fail to provide notification to Contractor within the aforesaid ten (10) day period after its receipt of Drawings, then the Drawings for which notification is not provided shall be deemed to have been returned as acceptable for procurement, fabrication or construction. Owner’s approval or disapproval of any design documents, including but not limited to the “Drawings” shall not impose on Owner any responsibility for design and shall not be deemed a waiver, and will not relieve Contractor of Contractor’s obligations for turnkey design, procurement and construction of the Work in accordance with the Contract Documents. Performance of any work, fabrication of materials or procurement of fabricated material, requiring the review of drawings, data, etc., prior to obtaining final review of drawings, data, etc., is at Contractor’s risk.

6.2.3.5 Rough Site Grading, Demolition and Relocation: As part of the Work, Contractor shall perform the following engineering and design services in connection with the Owner Scope:

6.2.3.5.1 Contractor has provided to Owner preliminary bidding information that includes Contractor’s requirements for rough site grading work (“Rough Site Grading”). The bidding information shall include, as necessary to satisfy Contractor’s requirements, engineering, drawings, and specifications. The bidding information shall be suitable for soliciting bids from rough site grading contractors for performance of the Rough Site Grading by such contractors in accordance with Contractor’s requirements. The design for the Rough Site Grading shall account for, be prepared in accordance with, and be coordinated with, the Approved Project Schedule, the approved Drawings, the existing Site conditions and any other planned or reasonably anticipated activities in the vicinity of Rough Site Grading. The drawings and specifications included in the bidding information shall provide detail, such as relevant geotechnical information, locations of existing structures and utilities, and beginning and final coordinates and elevations, so as to facilitate efficient and effective prosecution of the Rough Site Grading.

6.2.3.5.2 Contractor has provided to Owner bidding information that includes Contractor’s requirements for

20

requirements for underground relocation work (“Underground Relocation“). The bidding information consists of drawings indicating existing locations of underground utilities and proposed relocation routing. Existing underground utilities locations are based on Ground Penetrating Radar (GPR) surveys and as built drawings obtained from Owner, and will have to be field verified by Owner or Owner’s underground relocation contractors. The proposed relocation routing for the utilities is based on existing General Arrangement drawings. Field rerouting will be verified by the Underground Relocation contractors. For other unanticipated interferences encountered during the re-routing implementation, the Owner or the Owner’s underground relocation contractor will follow the same process. The bidding information is suitable for soliciting bids from underground relocation contractors for performance of the Underground Relocation by such contractors in accordance with Contractor’s requirements as outlined above. The plan for the Underground Relocation shall account for, be prepared in accordance with, and be coordinated with, the Approved Project Schedule, the approved Drawings, the existing Site conditions and any other planned or reasonably anticipated activities in the vicinity of Underground Relocation. The drawings included in the bidding information provide, in as much detail as can be reasonably determined by GPR surveys and other information on as-built drawings provided to Contractor by Owner, such as location, size, nature, and other defining characteristics of the identified underground utilities and other items required to be relocated, approximate coordinates and approximate elevations for those items (elevation and plan), relevant geotechnical information, locations of existing structures and obstructions, so as to facilitate prosecution of the Underground Relocation and to avoid subsequent relocation of the same utilities or other items. Before any relocated utilities or other items are covered up or buried, Contractor shall be afforded an opportunity, at its option, to inspect the utilities or other items to confirm that they have been relocated. Owner and Contractor shall follow the same process for any subsequent Underground Relocation required by Contractor during performance of the Work.

6.2.3.5.3 Contractor will prepare and deliver to Owner a package describing the demolition work at each Site necessary for proper construction and completion of the Project (“Site Demolition ”). Contractor shall provide to Owner bidding information that includes Contractor’s requirements for Site Demolition. The bidding information shall include, as necessary to satisfy Contractor’s requirements, engineering and drawings. Design and implementation of rerouting for utilities and services in

21