Alderon Iron Ore Corp. NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

DATE AND SIGNATURE PAGE

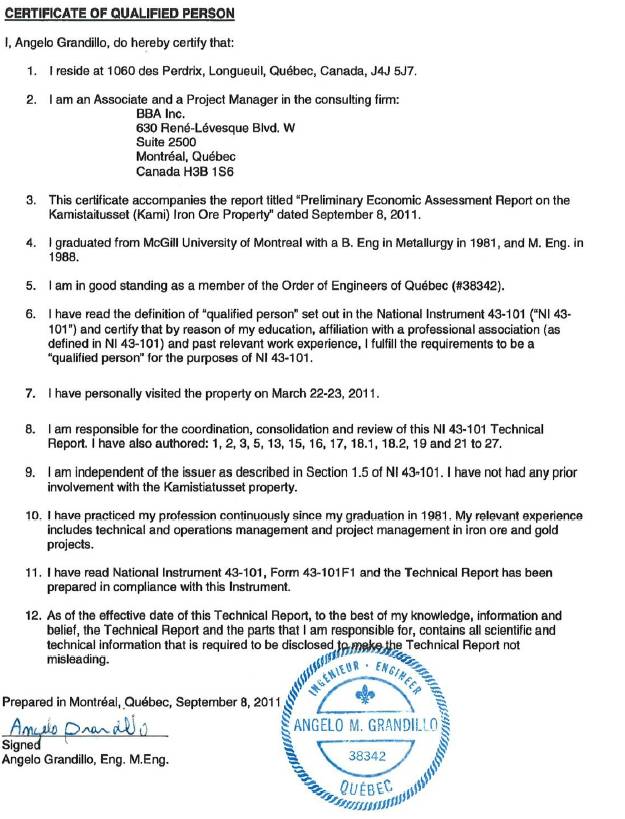

This report is effective as of the 8th day of September, 2011.

‘Angelo Grandillo’ | | September 8, 2011 |

Angelo Grandillo | | Date |

Eng, M.Eng., BBA Inc. | | |

| | |

‘James K. Powell’ | | September 8, 2011 |

James K. Powell | | Date |

P.Eng., M.Eng., Stantec | | |

| | |

‘Michael Kociumbas’ | | September 8, 2011 |

Michael Kociumbas | | Date |

B.Sc., P. Geo, Watts, Griffis and McQuat Limited | | |

| | |

‘Richard W. Risto’ | | September 8, 2011 |

Richard W. Risto | | Date |

M.Sc., P. Geo, Watts, Griffis and McQuat Limited | | |

September 2011

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

TABLE OF CONTENTS

LIST OF ABBREVIATIONS | XV |

UNITS OF MEASURE | XVIII |

1. | SUMMARY | 1-1 |

1.1 | Introduction | 1-1 |

1.2 | Geology and Mineralization | 1-2 |

1.3 | Exploration and Drilling | 1-3 |

1.4 | Mineral Processing and Metallurgical Testwork | 1-4 |

1.5 | Mineral Resource Estimates | 1-7 |

1.6 | Mining Methods | 1-9 |

1.7 | Recovery Methods and Processing Plant Design | 1-11 |

1.8 | Project Infrastructure | 1-11 |

1.9 | Market Studies and Contracts | 1-12 |

1.10 | Environment | 1-12 |

1.11 | Capital Costs | 1-13 |

1.12 | Operating Costs | 1-14 |

1.13 | Economic Analysis | 1-15 |

1.14 | Project Schedule | 1-16 |

1.15 | Conclusions | 1-16 |

2. | INTRODUCTION | 2-1 |

2.1 | Scope of Study | 2-1 |

2.2 | Sources of Information | 2-1 |

2.3 | Terms of Reference | 2-2 |

2.4 | Site Visit | 2-3 |

3. | RELIANCE ON OTHER EXPERTS | 3-1 |

4. | PROPERTY DESCRIPTION AND LOCATION | 4-1 |

4.1 | Property Location | 4-1 |

4.2 | Property Description and Ownership | 4-1 |

4.3 | Property Agreements | 4-6 |

4.4 | Permitting | 4-8 |

5. | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 5-1 |

| | | |

September 2011

i

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

5.1 | Access | 5-1 |

5.2 | Climate | 5-1 |

5.3 | Local Resources and Infrastructure | 5-1 |

5.4 | Physiography | 5-2 |

6. | HISTORY | 6-1 |

7. | GEOLOGICAL SETTING AND MINERALIZATION | 7-1 |

7.1 | Regional Geology | 7-1 |

7.2 | Property Geology | 7-5 |

7.2.1 | General | 7-5 |

7.2.2 | East of Mills Lake | 7-7 |

7.3 | Mineralization and Structure | 7-9 |

7.3.1 | Wabush Basin — Rose Deposits | 7-9 |

7.3.2 | Mills Lake Basin — Mills Lake and Mark Lake Deposits | 7-17 |

7.3.3 | Mineralization by Rock Type and Specific Gravity | 7-20 |

8. | DEPOSIT TYPE | 8-1 |

9. | EXPLORATION | 9-1 |

9.1 | General | 9-1 |

9.2 | Altius Exploration Programs 2006 — 2009 | 9-1 |

9.3 | Alderon’s Summer 2010 Exploration Program | 9-3 |

10. | DRILLING | 10-1 |

10.1 | Historic Drilling | 10-1 |

10.2 | Altius 2008 Drilling Program | 10-1 |

10.2.1 | General | 10-1 |

10.2.2 | 2008 Drillhole Collars and Downhole Surveying | 10-2 |

10.3 | Alderon 2010 Drilling Program | 10-3 |

10.3.1 | General | 10-3 |

10.3.2 | 2010 Drillhole Collars and Downhole Attitude Surveying | 10-7 |

10.3.3 | Geophysical Downhole Surveying | 10-9 |

10.4 | WGM Comments on 2008 and 2010 Drilling | 10-10 |

11. | SAMPLE PREPARATION, ANALYSIS AND SECURITY | 11-1 |

11.1 | Alderon 2010 Drill Core Handling and Logging | 11-1 |

11.2 | Sample Security | 11-2 |

11.3 | Alderon 2010 Sampling Method & Approach | 11-2 |

| | | |

September 2011

ii

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

11.4 | WGM’s Comments on 2008 and 2010 Drilling | 11-4 |

11.5 | 2008 Sample Preparation and Assaying | 11-6 |

11.5.1 | 2008 Quality Assurance and Quality Control | 11-6 |

11.6 | 2010 Sample Preparation | 11-8 |

11.7 | 2010 Sample Assaying | 11-8 |

11.7.1 | General | 11-8 |

11.7.2 | 2010 Quality Assurance and Quality Control | 11-10 |

11.8 | WGM Comments on 2008 and 2010 Sampling and Assaying | 11-30 |

12. | DATA VERIFICATION | 12-1 |

13. | MINERAL PROCESSING AND METALLURGICAL TESTING | 13-1 |

13.1 | Historical Testwork | 13-1 |

13.1.1 | Grindability Tests | 13-3 |

13.1.2 | Gravity and Magnetic Separation Tests | 13-4 |

13.2 | PEA Study Metallurgical Testwork | 13-5 |

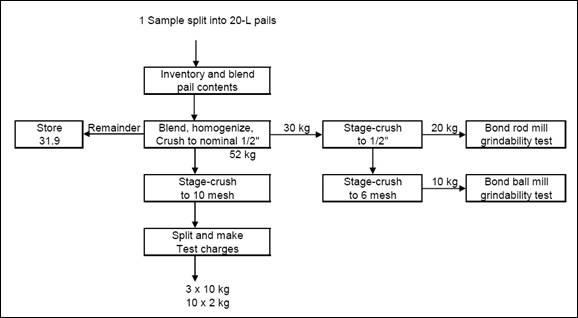

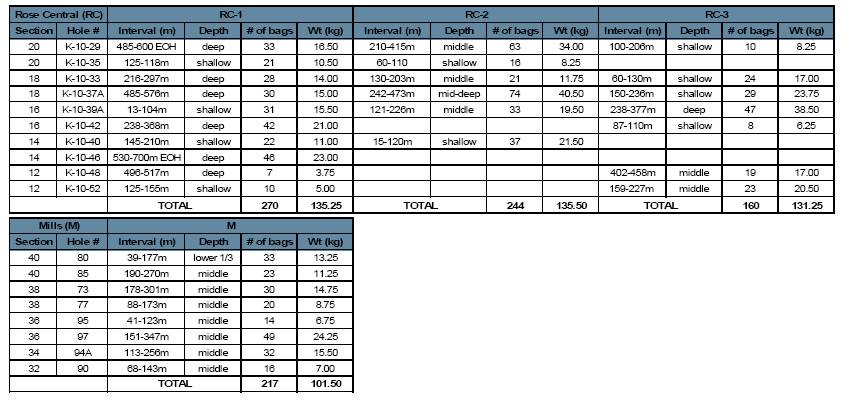

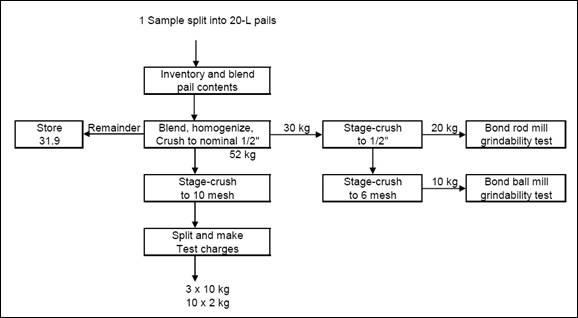

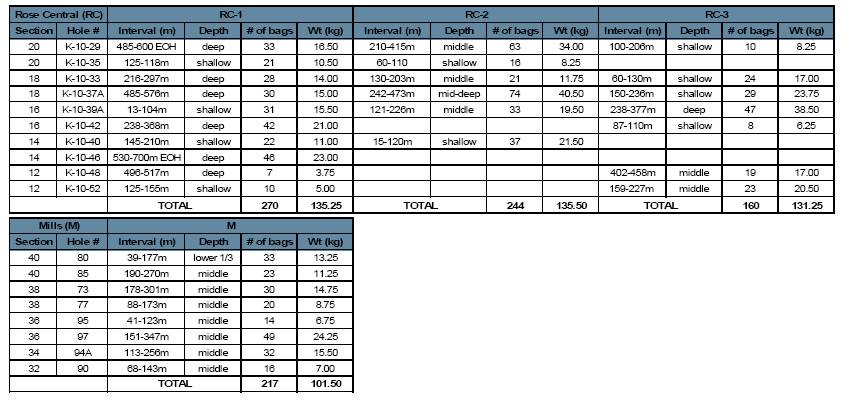

13.2.1 | Sample Selection and Preparation | 13-8 |

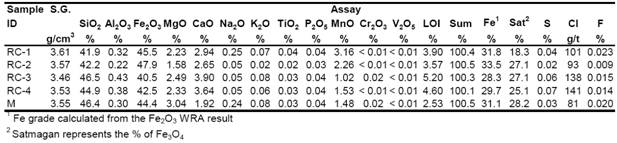

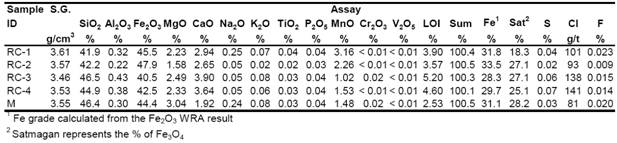

13.2.2 | Head Assays | 13-12 |

13.2.3 | Heavy Liquid Separation and Davis Tube Test Results | 13-13 |

13.2.4 | Mineralogical Analysis (QEMSCAN) | 13-16 |

13.2.5 | Conclusions from the Mineralogical Testwork Results | 13-21 |

13.2.6 | Wilfley Table Testwork | 13-22 |

13.2.7 | Ore Grindability | 13-25 |

13.3 | Process Flowsheet Development | 13-28 |

13.3.1 | Proposed Process Flowsheet | 13-29 |

13.3.2 | Mass Balance Derived from WT Test Results | 13-31 |

13.4 | Recommended Testwork for Feasibility Study | 13-35 |

14. | MINERAL RESOURCE ESTIMATE | 14-1 |

14.1 | WGM Mineral Resource Estimate Statement | 14-1 |

14.2 | General Mineral Resource Estimation Procedures | 14-4 |

14.3 | Database | 14-5 |

14.3.1 | Drillhole Data | 14-5 |

14.3.2 | Data Validation | 14-6 |

14.3.3 | Database Management | 14-6 |

14.4 | Geological Modeling Procedures | 14-7 |

| | | |

September 2011

iii

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

14.4.1 | Cross Section Definition | 14-7 |

14.4.2 | Geological Interpretation and 3-D Wireframe Creation | 14-7 |

14.4.3 | Topographic Surface Creation | 14-17 |

14.5 | Statistical Analysis, Compositing, Capping and Specific Gravity | 14-17 |

14.5.1 | Back-Coding of Rock Code Field | 14-17 |

14.5.2 | Statistical Analysis and Compositing | 14-17 |

14.5.3 | Grade Capping | 14-20 |

14.5.4 | Density / Specific Gravity | 14-20 |

14.6 | Block Model Parameters, Grade Interpolation and Categorization of Mineral Resources | 14-20 |

14.6.1 | General | 14-21 |

14.6.2 | Block Model Setup / Parameters | 14-21 |

14.6.3 | Grade Interpolation | 14-22 |

14.6.4 | Mineral Resource Categorization | 14-24 |

15. | MINERAL RESERVE ESTIMATE | 15-1 |

16. | MINING METHOD | 16-1 |

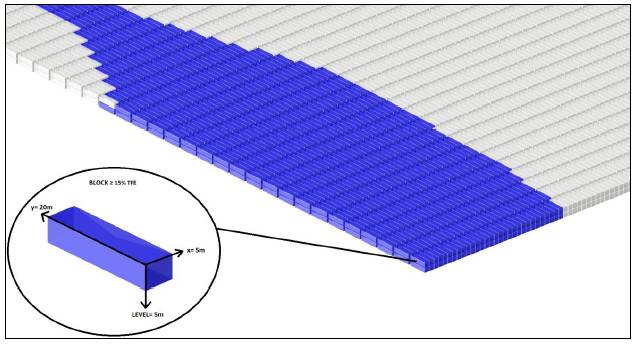

16.1 | Resource Block Model | 16-1 |

16.1.1 | Model Coordinate System | 16-2 |

16.1.2 | Model Densities | 16-3 |

16.2 | Pit Optimization | 16-3 |

16.2.1 | Pit Optimization Parameters | 16-4 |

16.2.2 | Cut-Off Grade Calculation | 16-5 |

16.2.3 | Pit Optimization Results | 16-5 |

16.3 | Engineered Pit Design | 16-8 |

16.3.1 | Pit Slope Design Criteria | 16-8 |

16.3.2 | Engineered Pit Design Results | 16-9 |

16.4 | In-Pit Resource Estimate | 16-16 |

16.5 | Development of the Mine Plan and Mining Operations | 16-18 |

16.5.1 | Waste and Waste Dumps | 16-20 |

16.5.2 | Mine Operations and Mining Equipment Requirements and Selection | 16-21 |

16.6 | Drilling and Blasting | 16-24 |

16.7 | Fuel and Electricity | 16-25 |

16.8 | Manpower Requirements | 16-25 |

| | | |

September 2011

iv

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

17. | RECOVERY METHODS | 17-1 |

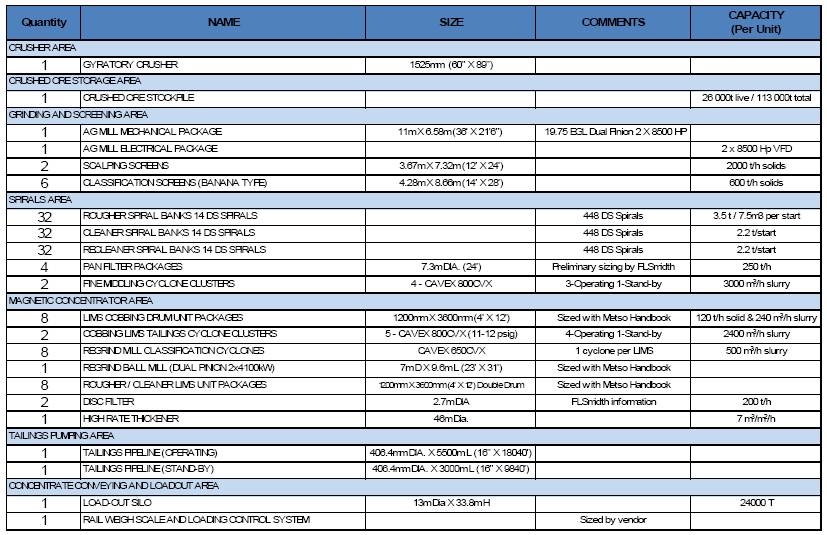

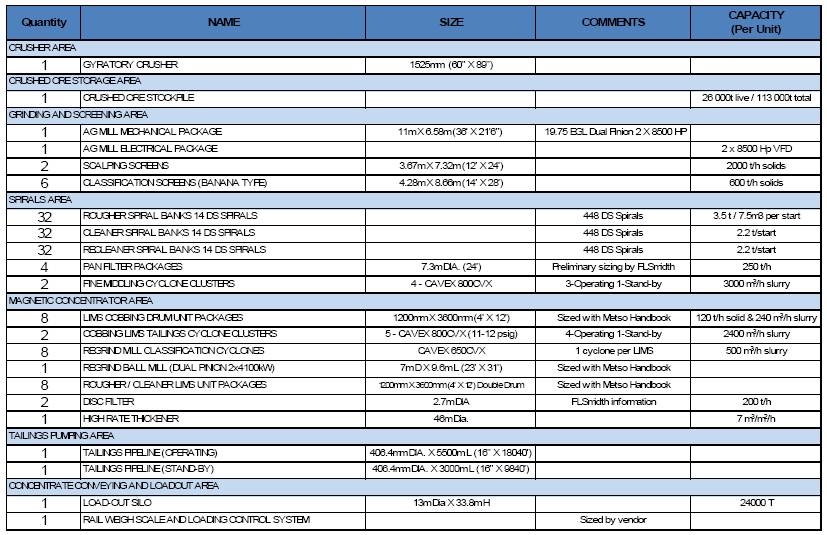

17.1 | Process Design Basis | 17-1 |

17.2 | Process Flowsheet and Mass and Water Balance | 17-3 |

17.3 | General Process Description and Plant Design | 17-8 |

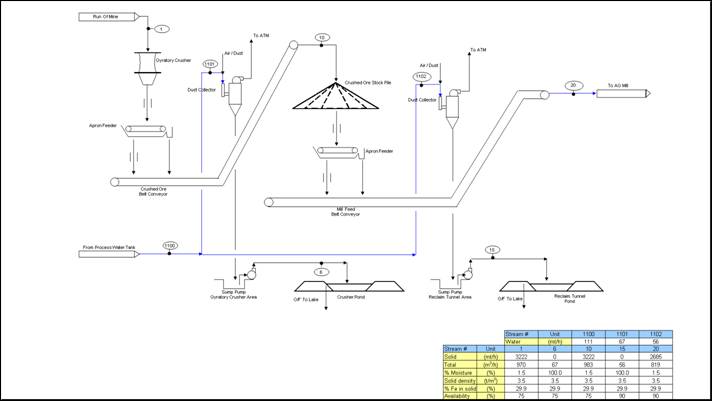

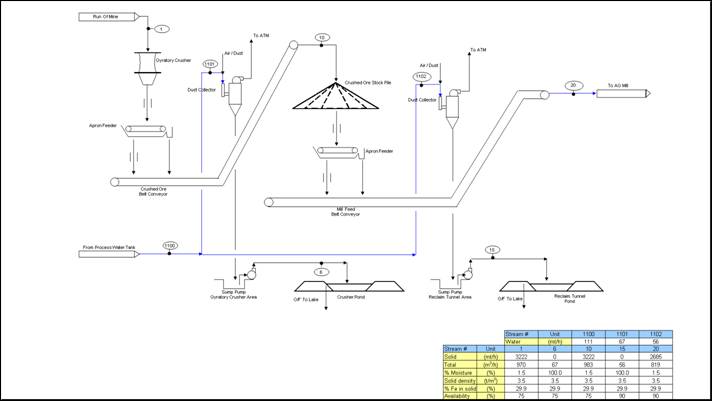

17.4 | Ore Crushing, Conveying and Storage | 17-9 |

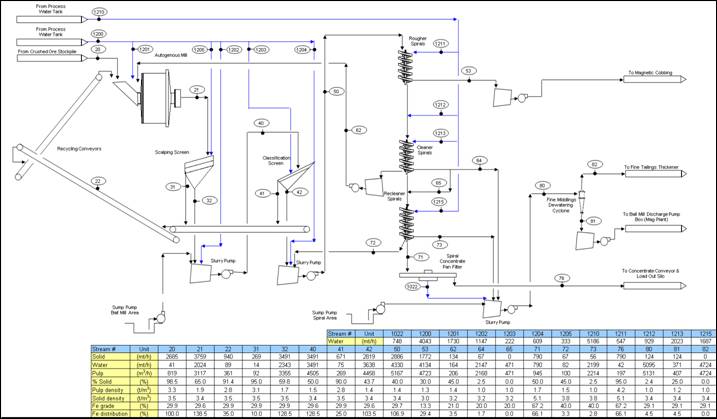

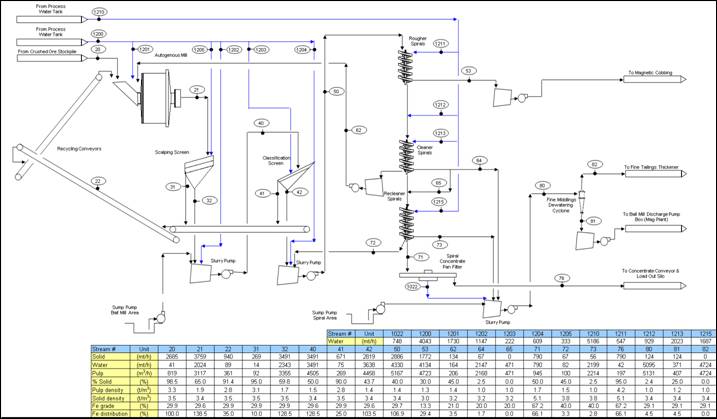

17.5 | Grinding and Screening | 17-10 |

17.5.1 | Primary Grinding Mill Sizing | 17-11 |

17.6 | Gravity Spiral Circuit | 17-12 |

17.7 | Magnetic Concentration Plant | 17-14 |

17.8 | Consolidated Concentrate and Tailings Production | 17-16 |

17.9 | Concentrate Conveying and Load-Out | 17-17 |

17.10 | Tailings Dewatering and Pumping to Tailings Pond | 17-18 |

17.11 | General Concentrator Plant Services | 17-19 |

17.11.1 | Compressed Air | 17-19 |

17.11.2 | Freshwater | 17-19 |

17.11.3 | Process Water | 17-20 |

17.11.4 | Fire Protection | 17-20 |

17.11.5 | Steam | 17-20 |

17.12 | Process Design Criteria | 17-21 |

17.13 | Major Process Equipment List | 17-29 |

18. | PROJECT INFRASTRUCTURE | 18-1 |

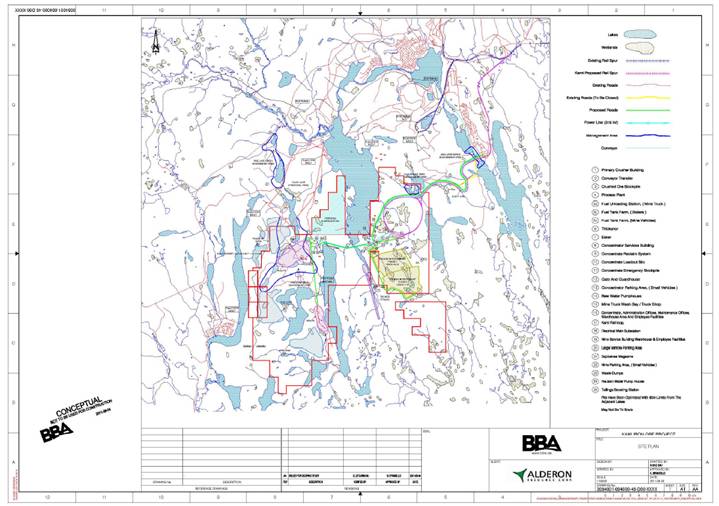

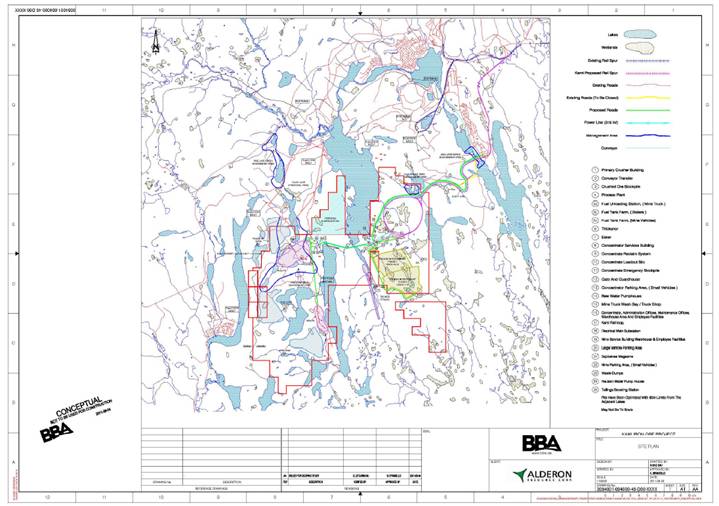

18.1 | General Kami Site Plot Plan | 18-1 |

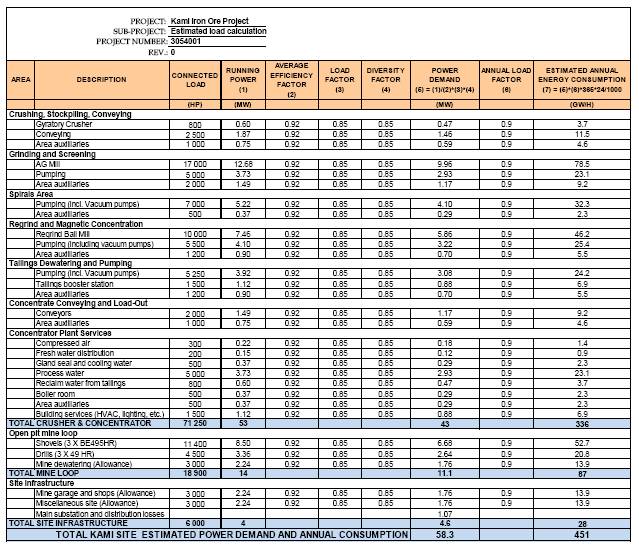

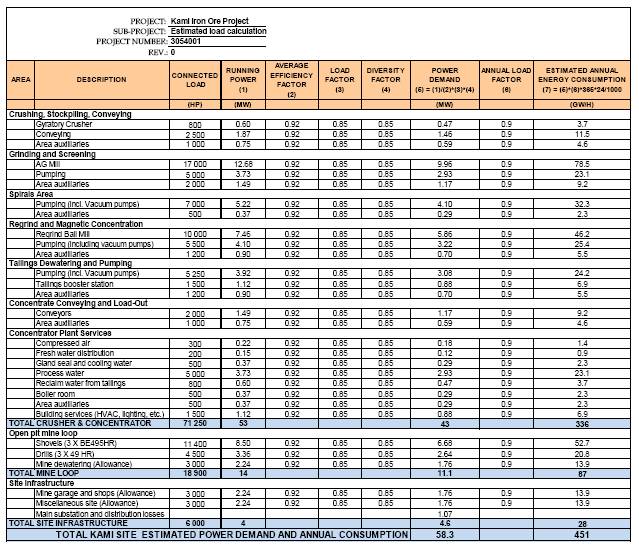

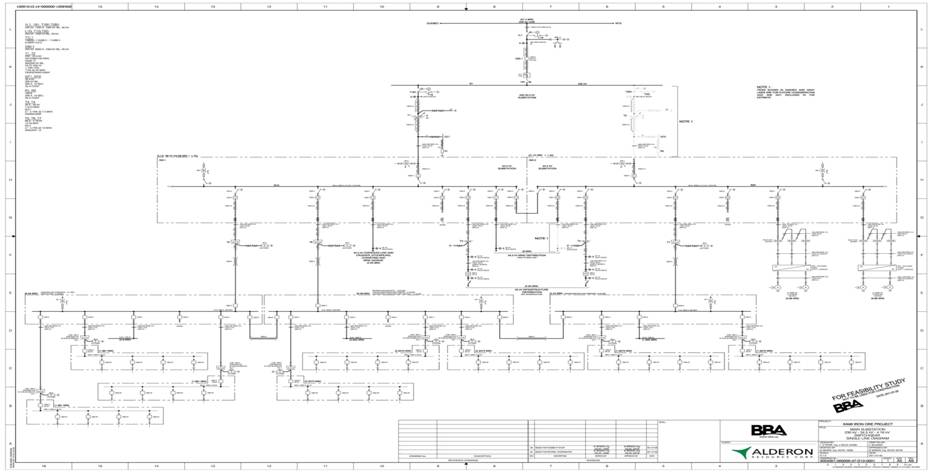

18.2 | Electricity | 18-9 |

18.2.1 | Analysis of Electrical Power Supply Options to the Kami Site | 18-12 |

18.3 | Railway Transportation Options Study | 18-17 |

18.4 | Port Facility | 18-20 |

18.4.1 | Proposed Option Design and Equipment | 18-24 |

19. | MARKET STUDIES AND CONTRACTS | 19-1 |

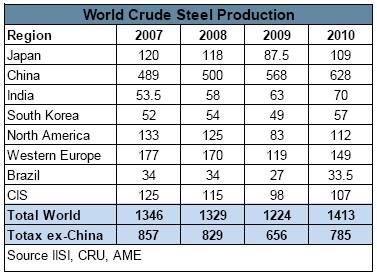

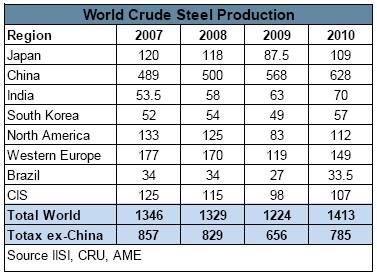

19.1 | Overview of the Iron Ore Market | 19-2 |

19.2 | Iron Ore Products and Consumption Trends | 19-3 |

19.3 | Iron Ore Pricing System | 19-5 |

19.4 | Iron Ore Price Forecast | 19-7 |

19.5 | Freight | 19-8 |

| | | |

September 2011

v

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

19.6 | Iron Ore Quality | 19-8 |

19.7 | Prospects for Alderon Concentrate | 19-9 |

19.8 | Conclusions | 19-10 |

20. | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT | 20-1 |

20.1 | Environmental Setting | 20-1 |

20.1.1 | Kami Mine Site | 20-1 |

20.1.2 | Pointe Noire Port Facility Site | 20-2 |

20.2 | Jurisdiction, Applicable Laws and Regulations | 20-3 |

20.2.1 | Newfoundland and Labrador Environmental Assessment Process | 20-3 |

20.2.2 | Quebec Environmental Assessment Process | 20-4 |

20.2.3 | The Federal Environmental Assessment Process | 20-5 |

20.2.4 | Law List Triggers for CEAA | 20-6 |

20.2.5 | Major Projects Management Office | 20-7 |

20.3 | Environmental Studies | 20-8 |

20.4 | Environmental Permitting | 20-9 |

20.5 | Tailings Management | 20-12 |

20.5.1 | Tailings Management Facility (TMF) Design Considerations | 20-12 |

20.5.2 | TMF Design Basis | 20-14 |

20.6 | Waste Rock Management | 20-18 |

20.6.1 | Conceptual Design of Waste Rock Dump | 20-19 |

20.7 | Site Geotechnical | 20-21 |

20.8 | Baseline Hydrogeology | 20-25 |

20.9 | Hydrologic Study | 20-27 |

20.9.1 | Hydrology | 20-29 |

20.9.2 | Water Supply and Returns | 20-32 |

20.10 | Rehabilitation and Closure Planning | 20-34 |

20.10.1 | Rehabilitation Planning | 20-34 |

20.10.2 | Objectives and Scope of the Rehabilitation and Closure Plan | 20-36 |

20.10.3 | Proposed Approach to Rehabilitation and Closure | 20-39 |

20.10.4 | Progressive Rehabilitation | 20-41 |

20.10.5 | Closure Rehabilitation | 20-42 |

20.10.6 | Post Closure Monitoring and Treatment | 20-45 |

20.11 | Community Relations | 20-45 |

| | | |

September 2011

vi

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

21. | CAPITAL AND OPERATING COSTS | 21-1 |

21.1 | Basis of Estimate and Assumptions | 21-2 |

21.1.1 | Type and Class of Estimate | 21-3 |

21.1.2 | Dates, Currency and Exchange Rates | 21-3 |

21.1.3 | Labour Rates and Labour Productivity Factors | 21-3 |

21.1.4 | General Direct Capital Costs | 21-4 |

21.1.5 | Indirect Costs | 21-6 |

21.1.6 | Contingency | 21-7 |

21.1.7 | Exclusions | 21-7 |

22. | ECONOMIC ANALYSIS | 22-1 |

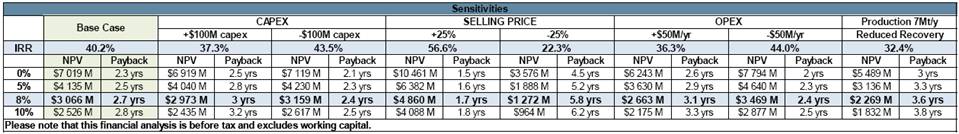

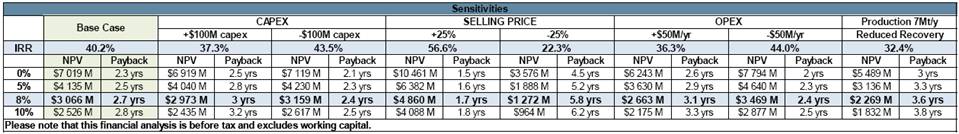

22.1 | Sensitivity Analysis | 22-4 |

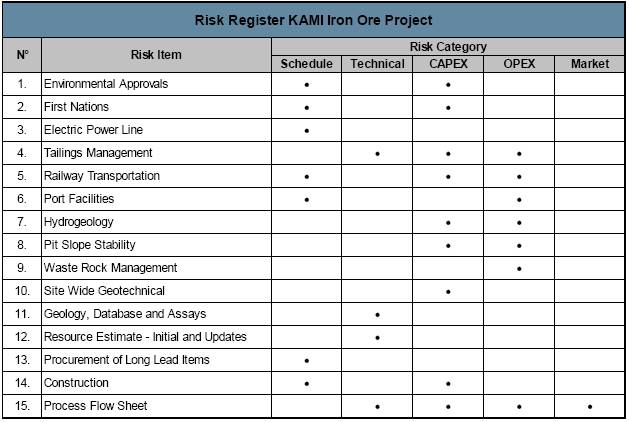

22.2 | Risk Management | 22-6 |

22.2.1 | Scope | 22-6 |

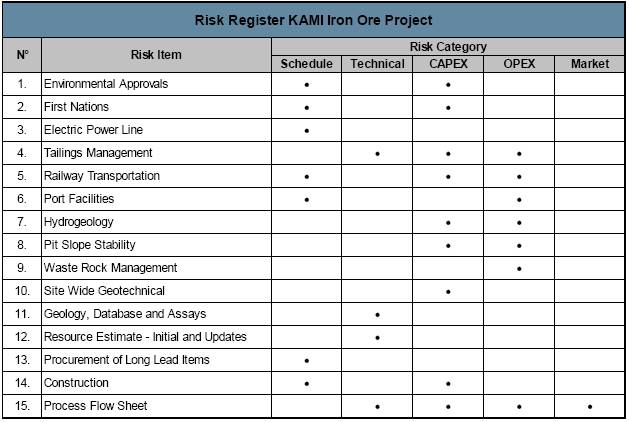

22.2.2 | Risk Assessment Methodology | 22-7 |

23. | ADJACENT PROPERTIES | 23-1 |

24. | OTHER RELEVANT DATA AND INFORMATION | 24-1 |

24.1 | Project Implementation and Execution Plan | 24-1 |

25. | INTERPRETATION AND CONCLUSION | 25-1 |

25.1 | Mineral Resources | 25-1 |

25.2 | Metallurgy and Ore Processing | 25-4 |

25.3 | Environmental Permitting | 25-5 |

25.4 | Conclusions | 25-5 |

26. | RECOMMENDATIONS | 26-1 |

27. | REFERENCES | 27-1 |

| | | |

September 2011

vii

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

LIST OF TABLES |

|

Table 1.1: Categorized Mineral Resource Estimate for Kami Iron Ore Project (COG 20% TFe) | 1-7 |

Table 1.2: Total Estimated Initial Capital Costs (M$) | 1-14 |

Table 1.3: Total Estimated Average Operating Cost ($/t concentrate) | 1-14 |

Table 1.4: Financial Analysis Results | 1-15 |

Table 3.1: Technical Report Section List of Responsibility | 3-2 |

Table 4.1: Kamistiatusset Property in Labrador | 4-2 |

Table 4.2: Kamistiatusset Property in Québec | 4-2 |

Table 4.3: Minimum Cost of Work to be Carried Out on a Québec Claim North of 52° Latitude | 4-6 |

Table 7.1: Regional Stratigraphic Column, Western Labrador Trough | 7-4 |

Table 7.2: Rock/Unit Coding For Kami Property Drill Core Logging | 7-8 |

Table 7.3: Central Rose Deposit — Average Composition of Rock Units from 2008 AND 2010 Drill Core Sample Assays | 7-21 |

Table 7.4: Mills Lake Deposit - Average Composition of Rock Units from 2008 AND 2010 Drill Core Sample Assays | 7-22 |

Table 7.5: North Rose Zone - Average Composition of Rock Units from 2008 and 2010 Drill Core Sample Assays | 7-23 |

Table 7.6: Central Rose Deposit - Averages for Davis Tube Test Results by Rock Type | 7-28 |

Table 7.7: Mills Lake Deposit - Averages for Davis Tube Test Results by Rock Type | 7-28 |

Table 8.1: Deposit Model For Lake Superior-Type Iron Formation After Eckstrand (1984) | 8-2 |

Table 10.1: Drilling Summary — Altius 2008 Program | 10-2 |

Table 10.2: 2010 Drilling Summary by Deposit or Zone | 10-4 |

Table 10.3: Drilling Summary — Alderon 2010 Program | 10-6 |

Table 11.1: Sampling and Analysis Summary, Altius 2008 Drill Program | 11-6 |

Table 11.2: Certified Standard Reference Materials Used for the In-Field QA/QC Program Altius 2008 and Alderon 2010 | 11-7 |

Table 11.3: Sampling and Analysis Summary, Alderon 2010 Drill Program | 11-10 |

Table 11.4: Summary for 2008 and 2010 In-Field Certified Reference Standards | 11-17 |

Table 11.5: Selected Analytical Results for DT Tests Performed on Standard FER-4 | 11-18 |

September 2011

viii

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Table 11.6: Selected Analytical Results for Davis Tube Tests Performed on Eight Duplicate Core Samples | 11-19 |

Table 11.7: Performance of SGS Lakefield Certified Reference Standards %TFE — 2008 and 2010 Programs | 11-25 |

Table 11.8: Performance of SGS Lakefield Certified Reference Standards %FeO — 2008 AND 2010 Programs | 11-25 |

Table 12.1: Summary of WGM Independent Second Half Core Sampling | 12-3 |

Table 12.2: Comparison of Analytical Results - WGM Independent Sample Assays versus 2008 and 2010 Original Sample Assays | 12-4 |

Table 13.1: QEMSCAN Results in Altius SGS Report | 13-3 |

Table 13.2: Summary Description of Composite Sample Selection and Preparation | 13-10 |

Table 13.3: Sample Head Assays | 13-13 |

Table 13.4: HLS and DT Results Summary Table | 13-15 |

Table 13.5: Combined HLS Floats Davis Tube Concentrate Summary | 13-16 |

Table 13.6: Modals Composition within Samples | 13-17 |

Table 13.7: Wilfley Table & Davis Tube Test Result Summary | 13-23 |

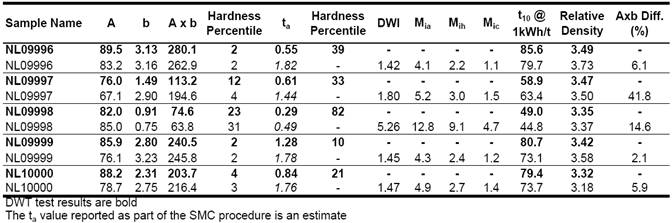

Table 13.8: Grindability Test Result Summary | 13-26 |

Table 13.9: JK Tech SMC Test Result Summary | 13-26 |

Table 13.10: Mia Values and the Resulting Wa Values | 13-27 |

Table 13.11: Preliminary Kami Concentrate Analysis | 13-35 |

Table 13.12: Feasibility Testwork Program | 13-36 |

Table 14.1: Categorized Mineral Resource Estimate for Kami Iron Ore Project (Cutoff of 20% TFe) | 14-2 |

Table 14.2: Basic Statistics of 3 m Composites | 14-18 |

Table 14.3: Categorized Mineral Resources by %TFe_H Cutoff Kami Iron Ore Project | 14-28 |

Table 16.1: Block Model Items | 16-1 |

Table 16.2: Pit Optimization Parameters | 16-4 |

Table 16.3: Rose Central Pit Optimization Results | 16-7 |

Table 16.4: Mills Pit Optimization Results | 16-7 |

Table 16.5: Pit Design Parameters | 16-8 |

Table 16.6: Rose Central In-Pit Resource Estimate | 16-17 |

Table 16.7: Mills In-Pit Resource Estimate | 16-17 |

September 2011

ix

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Table 16.8: Tonnages of Material Moved over the LOM for Production of 8.0 Mt/y of Concentrate | 16-19 |

Table 16.9: Mining Equipment List | 16-23 |

Table 16.10: Mining Equipment List | 16-25 |

Table 16.11: Mining Equipment Estimated Fuel Consumption | 16-26 |

Table 16.12: Mining Equipment Estimated Electricity Consumption | 16-26 |

Table 16.13 Mine Area Hourly Personnel | 16-27 |

Table 16.14 Mine Area Salaried Personnel and Total Headcount | 16-28 |

Table 17.1: Concentrate Production Target and Nominal and Design Production Rates | 17-2 |

Table 17.2: Power Requirement Envelope for the Various Operating Conditions | 17-11 |

Table 17.3: Gravity Circuit Summary | 17-13 |

Table 17.4: Design Basis Showing Consolidated Concentrate and Tailings Production | 17-17 |

Table 17.5: Kami Steam Requirement Estimate | 17-21 |

Table 18.1: Kami Power Load Calculation | 18-10 |

Table 18.2: Comparison of Capital Cost of Options | 18-15 |

Table 19.1: Iron Ore Products Seaborne Trade Trend | 19-4 |

Table 19.2: Iron Ore Products Seaborne Trade Trend | 19-5 |

Table 19.3: Brazilian Fines Price Forecast | 19-10 |

Table 20.1: Potential Permits, Approvals, and Authorizations (Preliminary) - Newfoundland and Labrador | 20-9 |

Table 20.2: Potential Permits, Approval and Authorizations (Preliminary) - Quebec | 20-10 |

Table 20.3: Potential Permits, Approval and Authorizations (Preliminary) - Canada | 20-11 |

Table 20.4: Estimated Waste Rock Quantities | 20-18 |

Table 20.5: Waste Rock Dump Design Parameters | 20-20 |

Table 20.6: Estimated Waste Rock Dump Capacities | 20-20 |

Table 20.7: Details of Available Weather and Flow Station Near the Kami Project | 20-28 |

Table 20.8: Sub-Watershed Details — Kami Project | 20-28 |

Table 20.9: Summary of Climate Normals for Wabush Lake Airport | 20-29 |

Table 20.10: IDF Rainfall Amounts for Wabush Lake Airport | 20-30 |

Table 20.11: Water Budget Calculations for the Kami Mine Project | 20-31 |

Table 20.12: Summary of Flow Proration Results for the Kami Mine Project | 20-31 |

Table 21.1: Total Estimated Initial Capital Costs (M$) | 21-1 |

Table 21.2: Total Estimated Average Operating Cost ($/t concentrate) | 21-2 |

September 2011

x

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

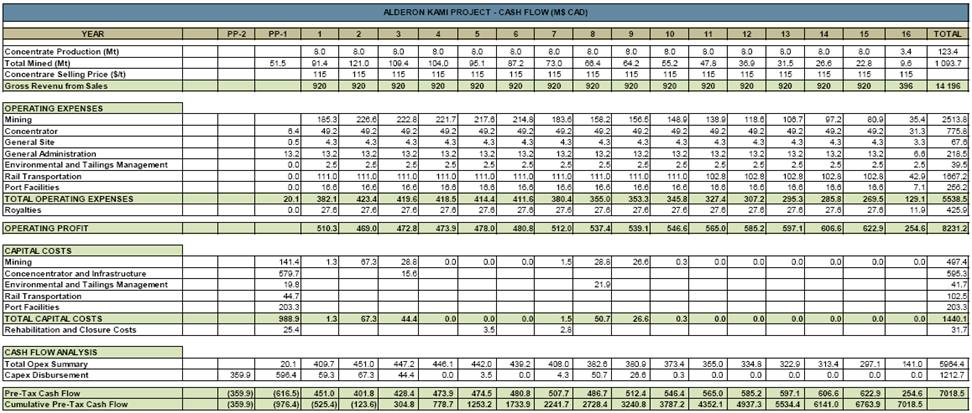

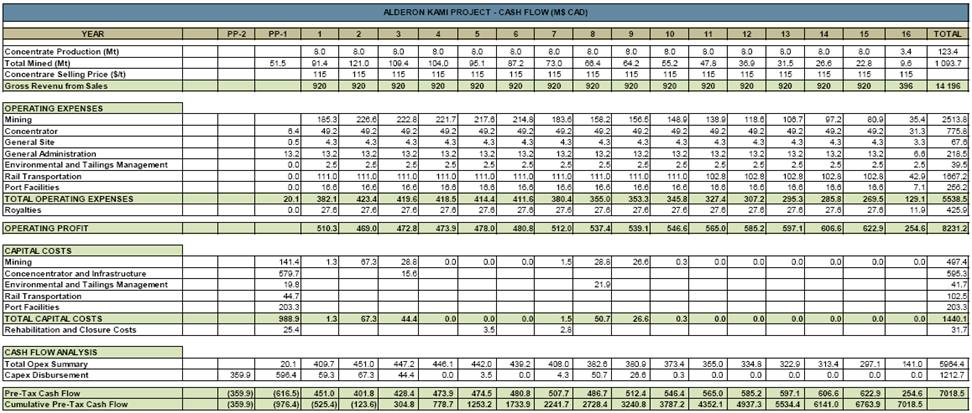

Table 22.1: Kami Project Table of Undiscounted Cash Flow | 22-2 |

Table 22.2: Financial Analysis Results | 22-3 |

Table 22.3: Sensitivity Analysis Table | 22-5 |

Table 22.4: Classification of Occurrence and Manageability | 22-7 |

Table 22.5: Risk Register | 22-8 |

Table 25.1: Categorized Mineral Resource Estimate for Kami Iron Ore Project | |

(Cutoff of 20% TFe) | 25-1 |

Table 25.2: Rose Central In-Pit Resource Estimate | 25-3 |

Table 25.3: Mills In-Pit Resource Estimate | 25-3 |

Table 26.1: Next Study Phase Cost Estimate | 26-2 |

| |

LIST OF FIGURES |

| |

Figure 4.1: Land Status Map | 4-3 |

Figure 7.1: Regional Geology | 7-3 |

Figure 7.2: Property Geology | 7-6 |

Figure 7.3: Ground Magnetic Survey with 2008 and 2010 Drillhole Locations | 7-13 |

Figure 7.4: Rose Lake Area - Cross Section 20E | 7-14 |

Figure 7.5: Rose Lake Area - Cross Section 16E | 7-15 |

Figure 7.6: Mills Lake Area - Cross Section 36+00S | 7-19 |

Figure 7.7: Comparison of %magFe Determined from Satmagan vs. Determined by Davis Tube | 7-25 |

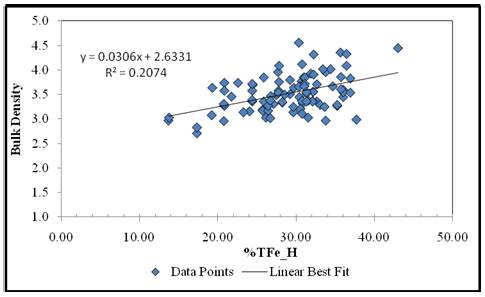

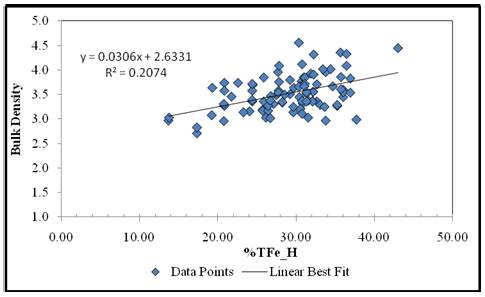

Figure 7.8: Bulk Density for 0.1 m Samples Intervals vs. %TFe on Routine Samples | 7-29 |

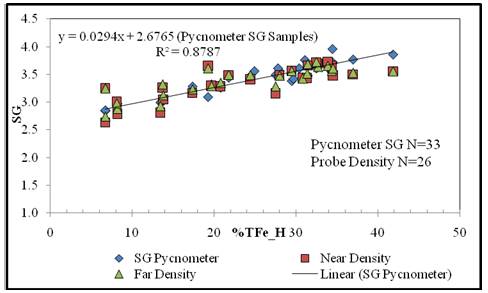

Figure 7.9: SG by Gas Comparison Pycnometer on Pulps vs. %TFe on Routine Assay Samples | 7-30 |

Figure 7.10: SG by Pycnometer on Pulps vs. %TFe for WGM’s Independent Samples | 7-31 |

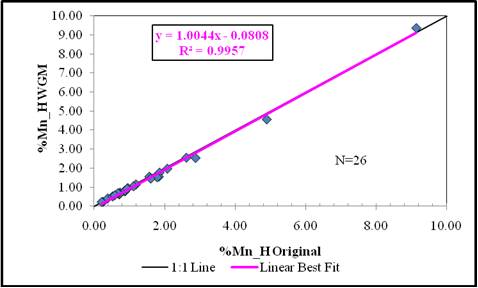

Figure 11.1: Results for Duplicate ¼ Split Drill Core Samples - %TFe_H — 2008 and 2010 Programs | 11-12 |

Figure 11.2: Results for Duplicate ¼ Split Drill Core Samples — %Fe3O4Satmagan_H — 2008 and 2010 Programs | 11-13 |

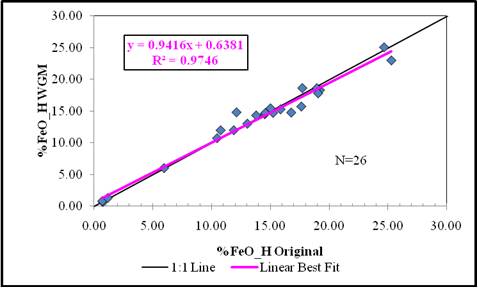

Figure 11.3: Results for Duplicate ¼ Split Drill Core Samples - %FeO_H — 2008 and 2010 Programs | 11-13 |

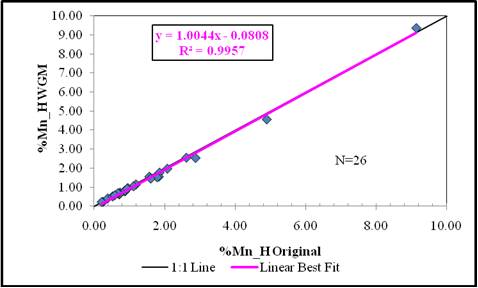

Figure 11.4: Results for Duplicate ¼ Split Drill Core Samples - %Mn_H — 2008 and 2010 Programs | 11-14 |

September 2011

xi

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

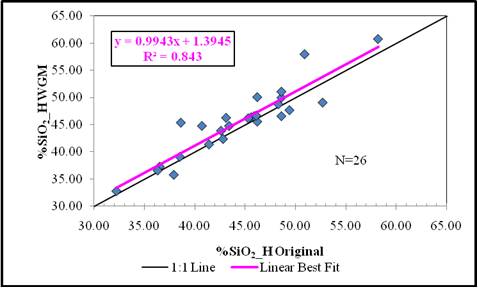

Figure 11.5: Results for Duplicate ¼ Split Drill Core Samples - %SiO2_H — 2008 and 2010 Programs | 11-14 |

Figure 11.6: Results for In-Field Standards for %TFe — 2008 and 2010 Programs | 11-15 |

Figure 11.7: Results for In-Field Standards for %SiO2_H — 2008 and 2010 Programs | 11-15 |

Figure 11.8: Results for In-Field Standards for %Mn_H — 2008 and 2010 Programs | 11-16 |

Figure 11.9: Results for In-Field Standards for %FeO_H — 2010 Program | 11-16 |

Figure 11.10: Results for In-Field Standards for %magFe_H — 2010 Program | 11-17 |

Figure 11.11: %TFe_H for Preparation Duplicates 2008 and 2010 Results | 11-20 |

Figure 11.12: %magFeSat_H for Preparation Duplicates 2008 and 2010 Results | 11-20 |

Figure 11.13: %FeO_H for Preparation Duplicates 2008 and 2010 Results | 11-21 |

Figure 11.14: %magFeSat_H for Analytical Duplicates 2008 and 2010 Results | 11-21 |

Figure 11.15: Performance of SGS Lakefield Certified Reference Standards - %TFe_H 2010 Program | 11-23 |

Figure 11.16: Performance of SGS Lakefield Certified Reference Standards - %FeO_H 2010 Program | 11-24 |

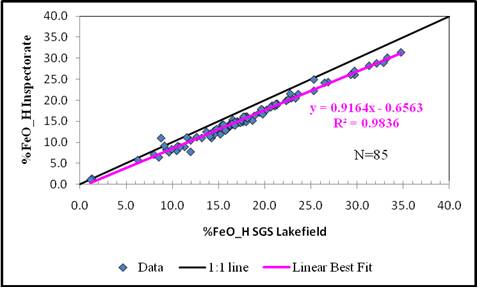

Figure 11.17: %TFe_H at Inspectorate. vs. SGS Lakefield | 11-27 |

Figure 11.18: %FeO_H by HF-H2SO4 Digestion at Inspectorate. vs. SGS Lakefield | 11-27 |

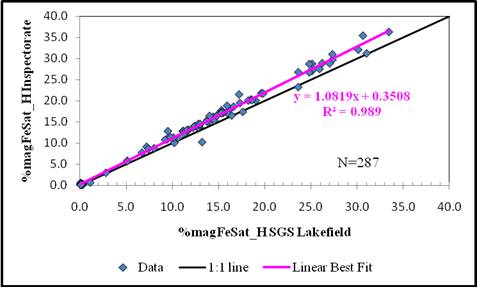

Figure 11.19: %magFeSat at Inspectorate vs. SGS Lakefield | 11-28 |

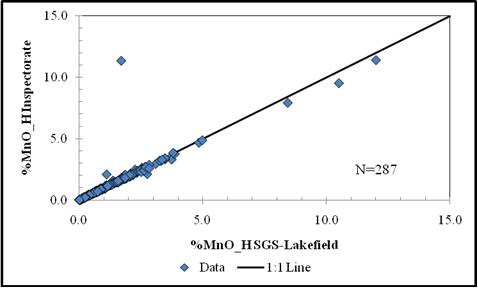

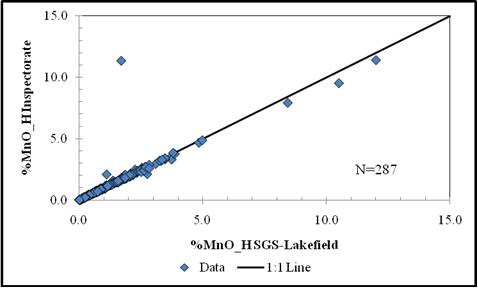

Figure 11.20: %MnO_H at Inspectorate. vs. SGS Lakefield | 11-28 |

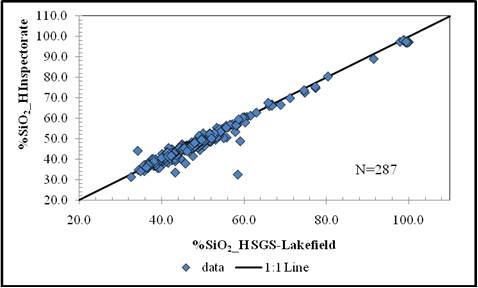

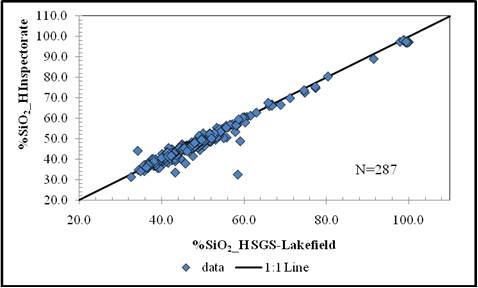

Figure 11.21: %SiO2_H at Inspectorate vs. SGS Lakefield | 11-29 |

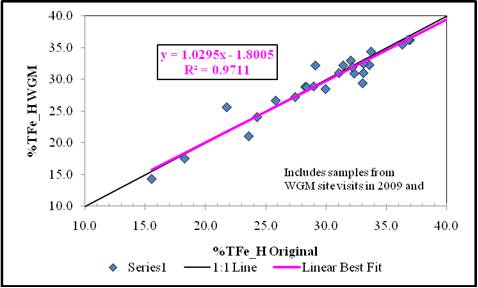

Figure 12.1: %TFe_H for WGM Independent Sample vs. Alderon or Altius Original Sample | 12-6 |

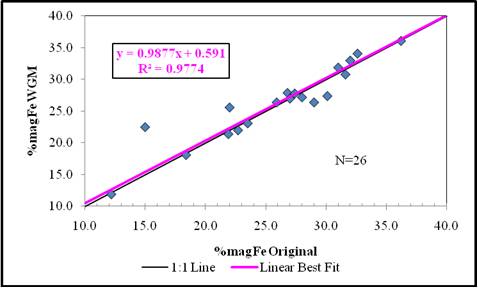

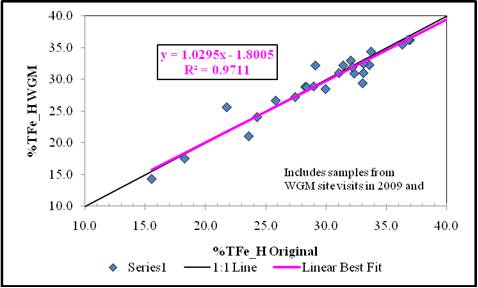

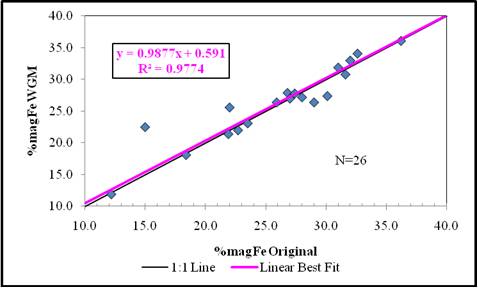

Figure 12.2: %magFe_H (Satmagan) for WGM Independent Sample vs. Alderon or Altius Original Sample Figure | 12-6 |

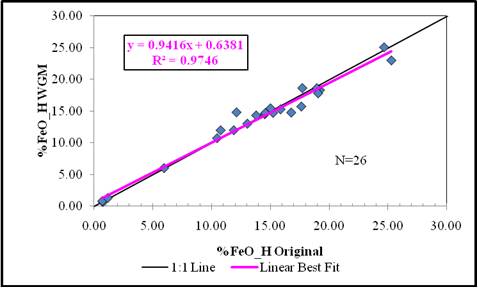

Figure 12.3: %FeO_H for WGM Independent Sample vs. Alderon or Altius Original Sample | 12-7 |

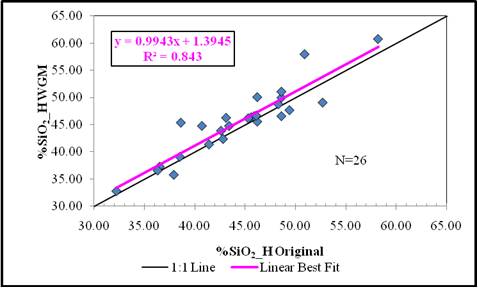

Figure 12.4: %SiO2_H for WGM Independent Sample vs. Alderon or Altius Original Sample | 12-7 |

Figure 12.5: %Mn_H for WGM Independent Sample vs. Alderon or Altius Original Sample | 12-8 |

Figure 13.1: Altius Testwork Sample Preparation Flowsheet | 13-2 |

Figure 13.2: Bags Sampling Flow Diagram at SGS | 13-11 |

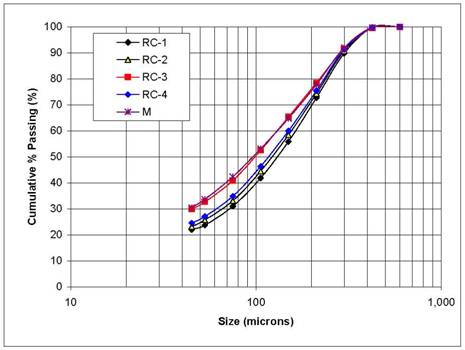

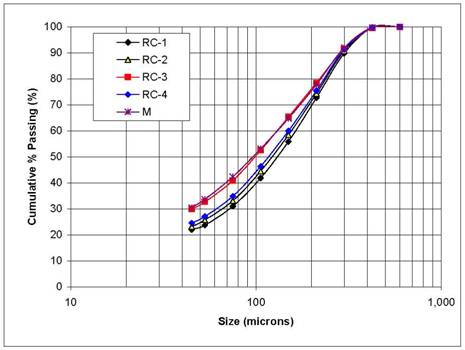

Figure 13.3: Particle Size Distribution of Ground Metallurgical Samples | 13-12 |

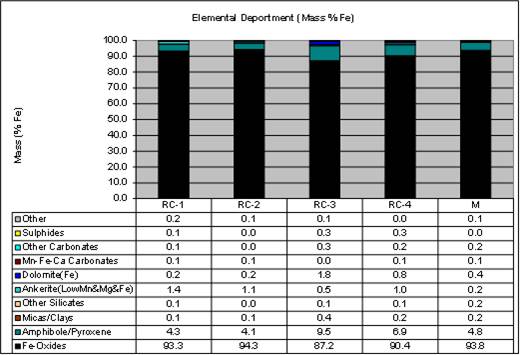

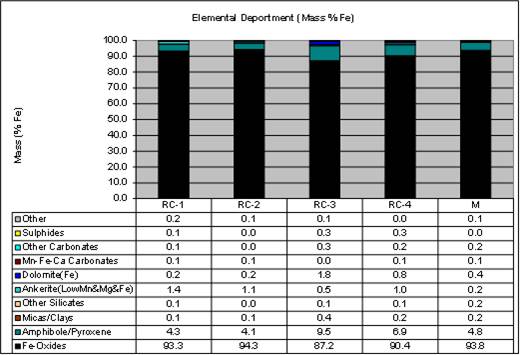

Figure 13.4: Iron Deportment within Samples | 13-18 |

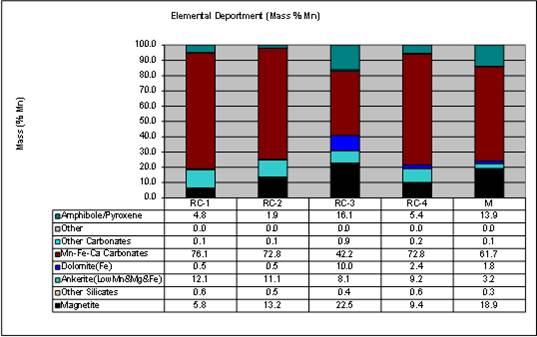

Figure 13.5: Mn Deportment within Samples | 13-19 |

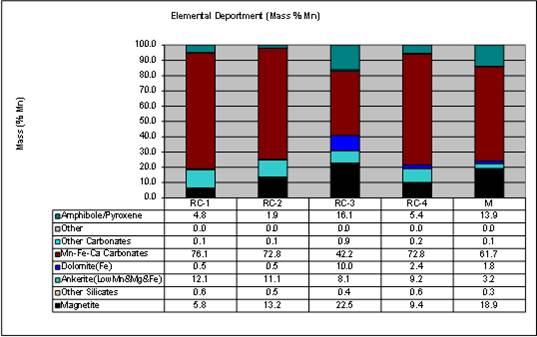

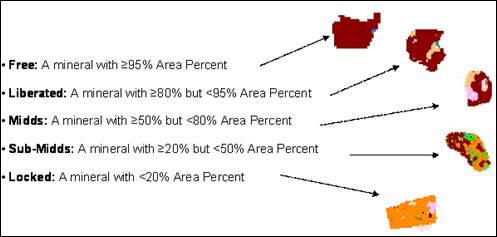

Figure 13.6: Mineral Liberation Size Definition | 13-19 |

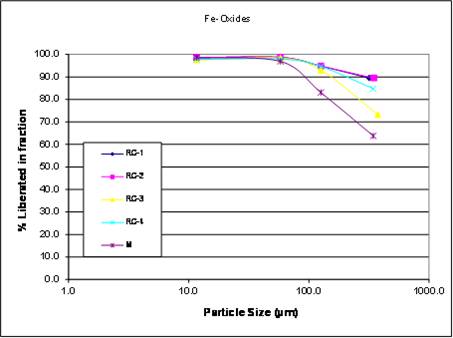

Figure 13.7: Fe-oxide Liberation Curves | 13-20 |

September 2011

xii

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Figure 13.8: Simplified Process Block Diagram | 13-30 |

Figure 13.9: Hypothetical Spiral Feed PSD Used In Mass Balance Development | 13-31 |

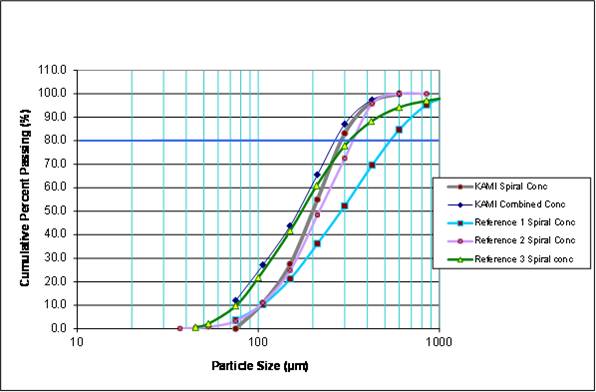

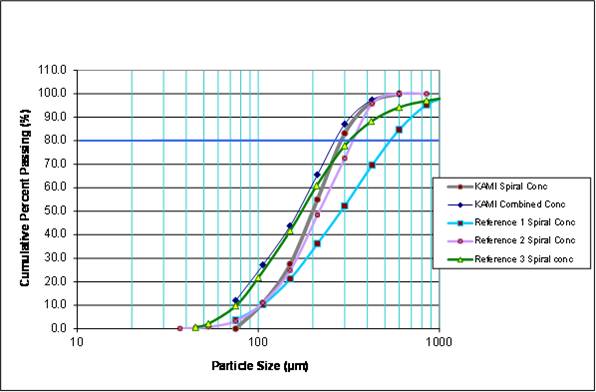

Figure 13.10: Kami PSD Combining Spiral Concentrate and Mag-Plant Concentrate (regrind P50 = 75 microns) Compared to Reference Projects | 13-34 |

Figure 13.11: Feasibility Process Development Test Block Diagram | 13-38 |

Figure 13.12: Feasibility Process Validation Test Block Diagram | 13-39 |

Figure 14.1: Mills Lake 3-D Geological Model | 14-10 |

Figure 14.2: Rose Central 3-D Geological Model — View 1 | 14-11 |

Figure 14.3: Rose Central 3-D Geological Model — View 2 | 14-12 |

Figure 14.4: Rose Central Cross Section 20+00E Showing %TFe Block Grade Model | 14-13 |

Figure 14.5: Rose Central Cross Section 20+00E Showing Mineral Resource Categorization | 14-14 |

Figure 14.6: Mills Lake Cross Section 36+00S Showing %TFe Block Grade Model | 14-15 |

Figure 14.7: Mills Lake Cross Section 36+00S Showing Mineral Resource Categorization | 14-16 |

Figure 14.8: Normal Histogram, %TFe_H — Mills Lake 3 m Magnetite Composites | 14-19 |

Figure 14.9: Normal Histogram, %TFe_H — Rose Central 3 m Magnetite Composites | 14-19 |

Figure 14.10: Rose Central Level Plan 450 m - %TFe Block Grade Model | 14-26 |

Figure 16.1: Block Model Coordinate System | 16-3 |

Figure 16.2: Rose Central Pit Optimization Plan View | 16-6 |

Figure 16.3: Mills Pit Optimization Plan View | 16-6 |

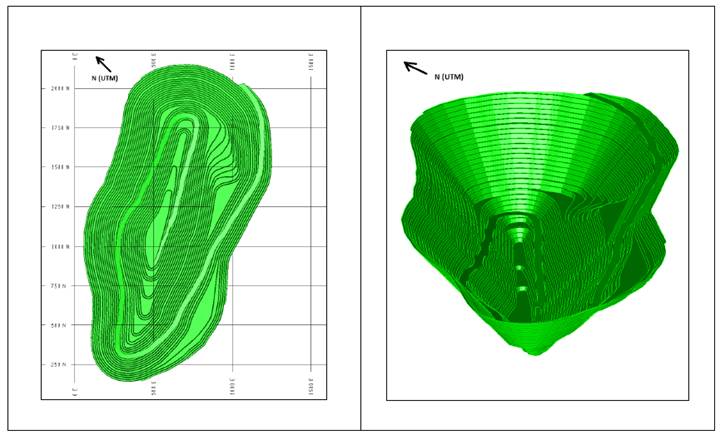

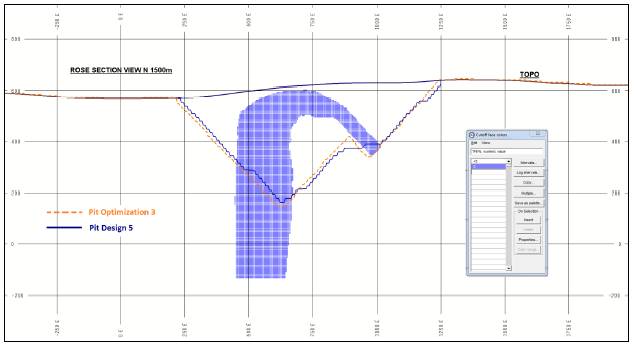

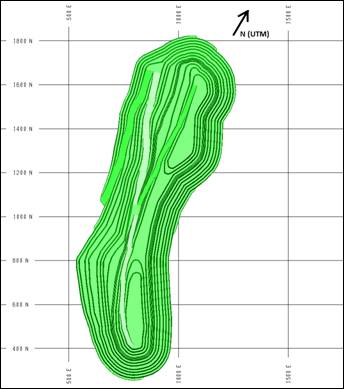

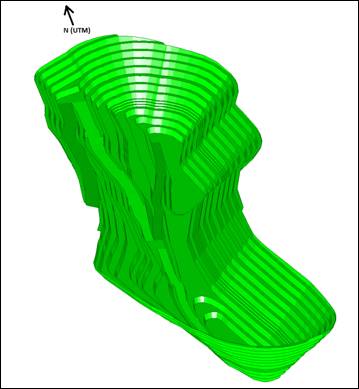

Figure 16.4: Rose Central Engineered Pit Design, Plan View and 3-D View | 16-10 |

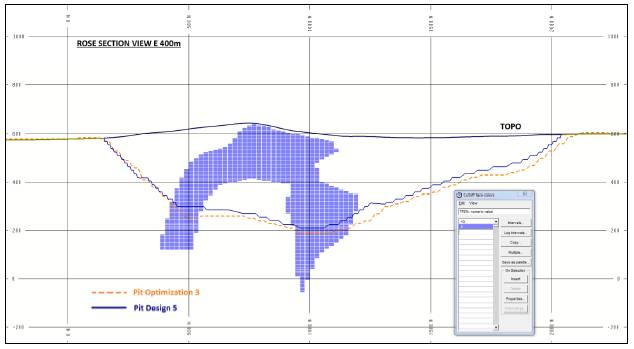

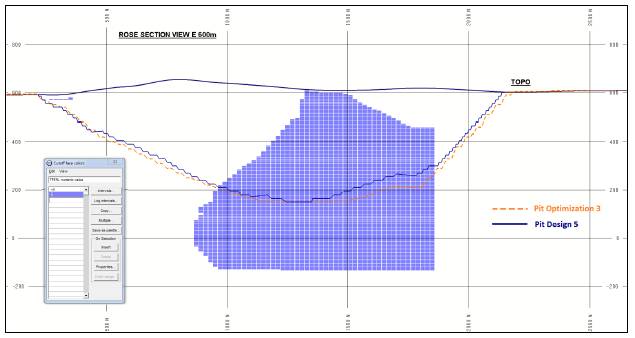

Figure 16.5: Rose Central Pit Section View E 400 m | 16-11 |

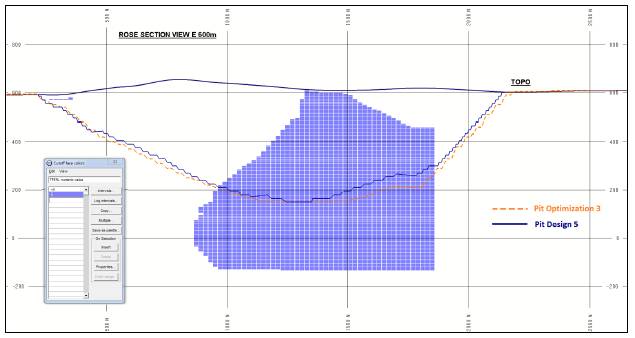

Figure 16.6: Rose Central Pit Section View E 600 m | 16-11 |

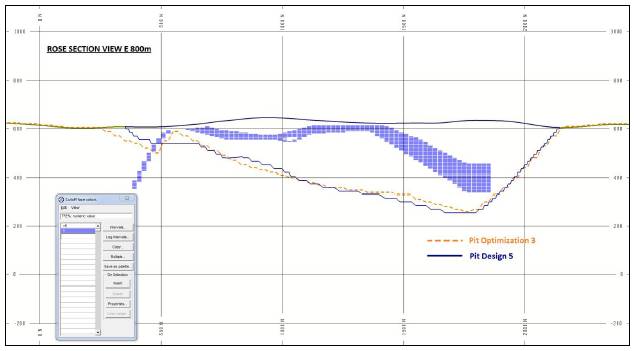

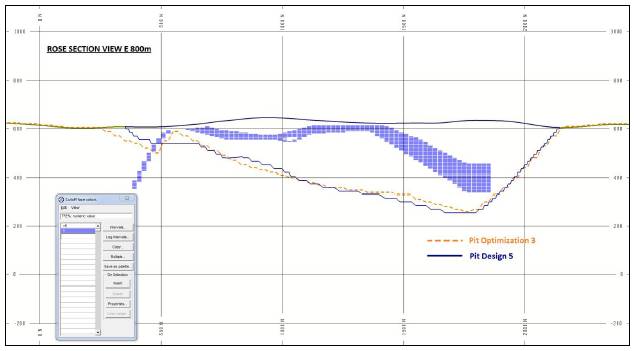

Figure 16.7: Rose Central Pit Section View E 800 m | 16-12 |

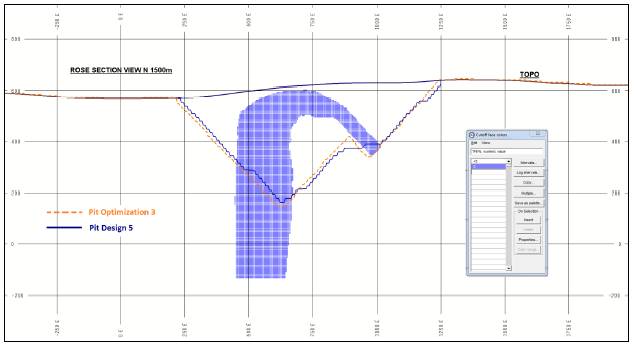

Figure 16.8: Rose Central Pit Section View N 1500 m | 16-12 |

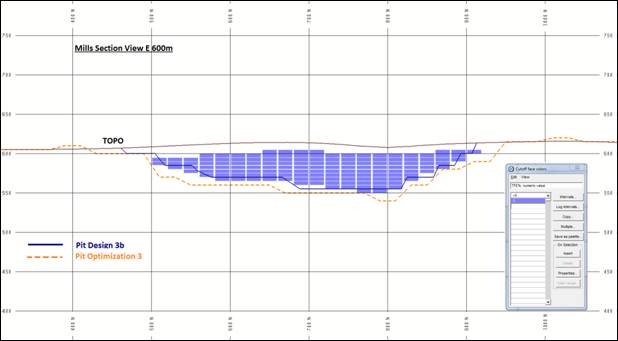

Figure 16.9: Mills Engineered Pit Design, Plan View and 3-D View | 16-13 |

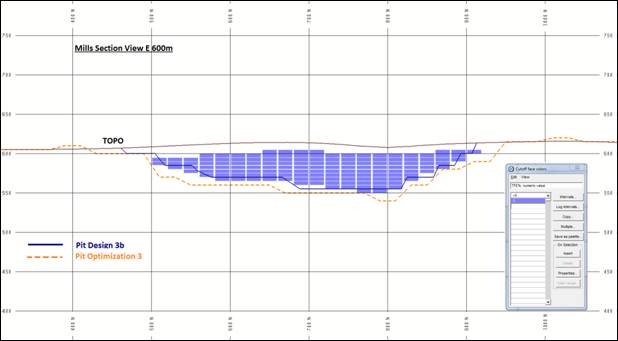

Figure 16.10: Mills Pit Section View E 600 m | 16-14 |

Figure 16.11: Mills Pit Section View E 800 m | 16-14 |

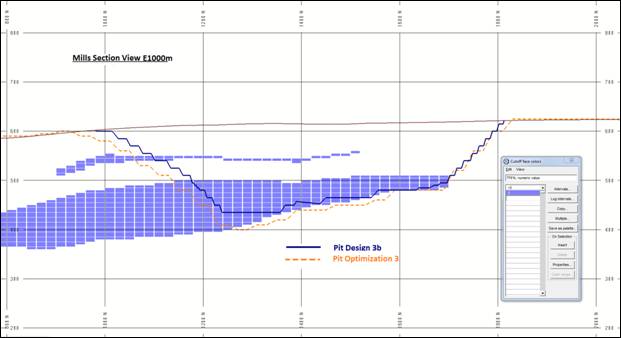

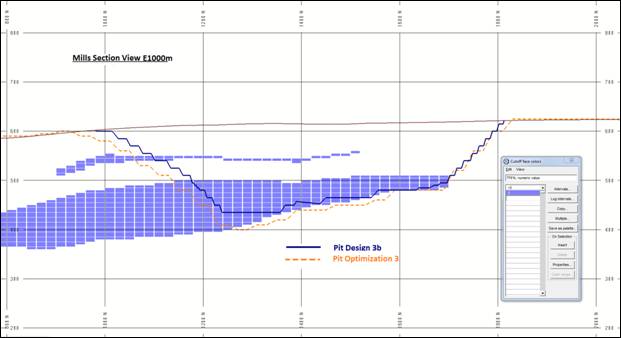

Figure 16.12: Mills Pit Section View E 1000 m | 16-15 |

Figure 16.13: Mills Pit Section View N 1500 m | 16-15 |

Figure 16.14: Annual Mine Truck Fleet Requirements | 16-24 |

Figure 17.1: Process Flow Diagram Crushing and Crushed Ore Storage | 17-4 |

Figure 17.2: Process Flow Diagram Grinding, Screening and Gravity Concentration | 17-5 |

September 2011

xiii

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Figure 17.3: Process Flow Diagram Regrind and Magnetic Separation Plant | 17-6 |

Figure 17.4: Process Flow Diagram General Process Water Balance | 17-7 |

Figure 18.1: Site Plan Kami Iron Ore Project | 18-3 |

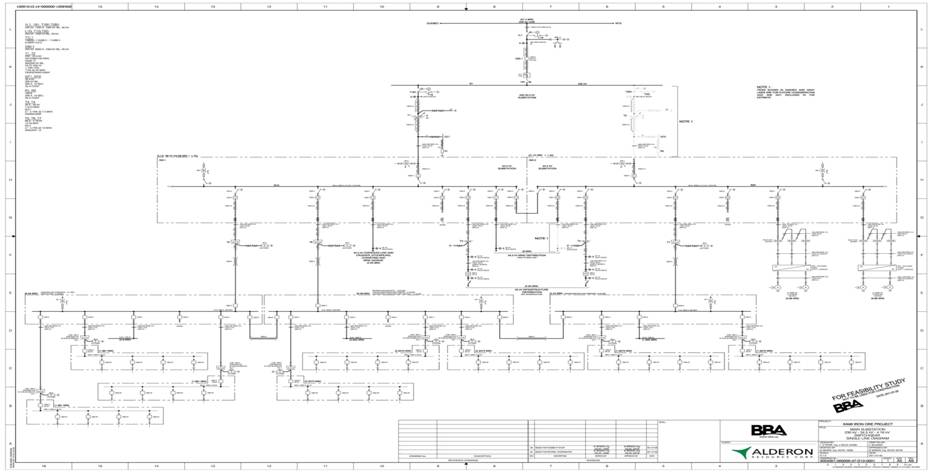

Figure 18.2: Kami Site Wide Electrical Single Line Diagram and Major Electrical Equipment List | 18-11 |

Figure 18.3: Port Site Plan Showing Land Blocks Considered for the Alderon Port Facility | 18-21 |

Figure 18.4: Port Site Plan Showing Option 2 Proposed General Arrangement | 18-23 |

Figure 20.1: Layout and Location of TMF | 20-17 |

Figure 20.2: Flow Hydrograph for Selected Sub-Watersheds | 20-32 |

Figure 22.1: Sensitivity Analysis Graph | 22-5 |

Figure 24.1: Preliminary Construction Manpower Curve | 24-2 |

Figure 24.2: Simplified Project Execution Schedule | 24-3 |

September 2011

xiv

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

LIST OF ABBREVIATIONS

Two Dimensional | | 2D |

Three Dimensional | | 3D |

Aluminum Conductor- Steel Reinforced | | ACSR |

Autogenous | | AG |

Alderon Resource Corporation, Alderon Iron Ore Corp. | | Alderon |

Altius Minerals Corporation | | Altius |

ArcelorMittal Mines of Canada | | AMMC |

Association of Professional Engineers and Geoscientists of British Columbia | | APEGBC |

All-Terrain Vehicle | | ATV |

Bureau d’Audiences Publiques sur l’Environnement | | BAPE |

Breton, Banville and Associates | | BBA |

Bell Geospace Inc. | | BGI |

Basic Oxygen Furnace | | BOF |

Bond Work Index | | BWI |

Capital Expenditure | | CAPEX |

Canadian Council of Ministers of the Environment | | CCME |

Canadian Environmental Assessment Act | | CEAA |

Chemin de Fer Arnaud | | CFA |

Churchill Falls Labrador Corporation | | CFLco |

Cost and Freight China | | CFR-China |

Converting Magnetic Susceptibility | | CGS |

Council of the Canadian Institute of Mining Metallurgy and Petroleum | | CIM |

Cliffs Natural Resources Inc. | | Cliffs |

Cut-Off Grade | | COG |

Crusher work index | | CWI |

Diamond Drillhole | | DDH |

Digital Elevation Model | | DEM |

Fisheries and Oceans Canada | | DFO |

DGI Geosciences Inc. | | DGI |

Differential Global Positioning System | | DGPS |

Diameter | | dia |

Department of Natural Resources | | DNR |

Direct Reduced Iron | | DRI |

Double Start | | DS |

Davis Tube | | DT, DTT |

Department of Transportation and Works | | DTW |

Environmental Assessment | | EA |

Electric Arc Furnace | | EAF |

Environmental Effects Monitoring | | EEM |

Environmental Impact Assessment | | EIA |

Environmental Impact Statement | | EIS |

September 2011

xv

Alderon Iron Ore Corp. NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Ecological Land Classifications | | ELC |

Engineering, Procurement, and Construction Management | | EPCM |

Environmental Preview Report | | EPR |

Evapotranspiration | | ET |

Federal Authority | | FA |

Freight on Board | | FOB |

Feasibility Study | | FS |

General and Administration | | G&A |

General Arrangement | | GA |

Gravity Gradient Instruments | | GGI |

Geographic Information System | | GIS |

Global Positioning System | | GPS |

Government Service Centre | | GSC |

Harmful Alteration, Disruption or Destruction | | HADD |

Hematite | | Hem |

Heavy Liquid Separation | | HLS |

Hematite Iron | | hmFe |

Hydro Québec | | HQ |

Inverse Distance | | ID |

Intensity-Duration-Frequency | | IDF |

Iron Formation | | IF |

Iron Ore Company of Canada | | IOCC |

Internal Rate of Return | | IRR |

Kamistiatusset | | Kami |

Length | | L |

Lerchs-Grossman | | LG |

Low Intensity Magnetic Separation | | LIMS |

Labrador Mining and Exploration Co. Ltd | | LM&E |

Loss on Ignition | | LOI |

Life of Mine | | LOM |

Magnetite | | Mag |

Magnetite Iron | | magFe |

Department of Sustainable Development, Environment and Parks | | MDDEP |

Work Index of Coarse Particle | | Mia |

Work Index of the Fine Particle | | Mib |

Memorandum of Understanding | | MOU |

Major Project Management Office | | MPMO |

Ministère des Ressources Naturelles et de la Faune | | MRNF |

Major Resource Project | | MRP |

Newfoundland and Labrador | | NL |

Newfoundland and Labrador Department of Natural Resources | | NLDNR |

Nearest Neighbour | | NN |

Net Present Value | | NPV |

September 2011

xvi

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Natural Resources Canada | | NRCAN |

Overburden | | OB |

Ordre des Géologues du Québec | | OGQ |

Oxide Iron Formation | | OIF |

Opinions of Probable Costs | | OPC |

Operating Expenditure | | OPEX |

Other Track Material | | OTM |

Optical Televiewer | | OTV |

Project Control Files | | PCF |

Prospectors and Developers Association of Canada | | PDAC |

Preliminary Economic Assessment | | PEA |

Professional Engineers and Geoscientists of Newfoundland and Labrador | | PEGNL |

Process Flowsheet | | PFS |

Particle Size Distribution | | PSD |

Quality Assurance | | QA |

Quality Control | | QC |

Québec Cartier Mining | | QCM |

Quantitative Evaluation of Minerals by Scanning Electron Microscopy | | QEMSCAN |

Quebec, North Shore & Labrador | | QNSL |

Qualified Person | | QP |

Run-of-Mine | | ROM |

Rock Quality Designation | | RQD |

Rod Work Index | | RWI |

Semi Autogenous | | SAG |

Satmagan | | Sat |

Silicate-Carbonate Iron Formation | | SCIF |

Specific Gravity | | SG |

Sales, General, and Administrative Expenses | | SG&A |

SGS Minerals Services | | SGS |

Silicate Iron Formation | | SIF |

Single Line Diagram | | SLD |

SAG Mill Comminution | | SMC |

Spontaneous Potential | | SP |

SAG Power Index | | SPI |

Singlepoint Resistivity | | SPR |

Scoping Study | | SS |

Stassinu Stantec Limited Partnership | | Stantec |

Total Iron Content | | TFe |

Triangulated Irregular Network | | TIN |

Tailings Management Facility | | TMF |

Total Suspended Solids | | TSS |

Toronto Stock Exchange | | TSX |

TSX Venture Exchange | | TSX.V |

September 2011

xvii

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Power Required to Grind the Ore with an AG Mill | | Wa |

Power Required to Grind the Ore from 750 µm (22M) to the Final Product Size | | Wb |

Watts, Griffis and McOuat | | WGM |

Waste Management Plan | | WMP |

Whole Rock | | WR |

Total Operating Grinding Energy | | WT |

Wilfley Table | | WT |

Wabush Terminal Station | | WTS |

X-Ray Diffraction | | XRD |

X-Ray Fluorescence | | XRF |

| | |

UNITS OF MEASURE |

| | |

Foot | | ‘,ft |

Inches | | ”,in |

Dollar | | $ |

Dollar per tonne | | $/t |

Degree | | ° |

Micron | | µm |

Ampere | | A |

Centimeter | | cm |

Canadian Dollars | | CND |

Feet per minute | | fpm |

Gram | | g |

Gram per cubic centimeter | | g/cc, g/cm3 |

Gallons per minute | | GPM |

Giga watt hour | | GWh |

Hectare | | ha |

Horsepower | | hp |

Kilogram | | kg |

Kilometer | | km |

Square kilometer | | km² |

Kilotonne | | kt |

Kilovolt | | kV |

Kilowatt | | kW |

Kilowatt-hours per tonne | | kWh/t |

Pounds per hour | | lb/h |

Meter | | m |

Million | | M |

Million tonnes per year | | M t/y |

Cubic meter per hour | | m3/h |

Meters Above Sea Level | | masl |

Mile | | mi |

September 2011

xviii

Alderon Iron Ore Corp. NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Millimeter | | mm |

Million tonnes | | Mt |

Metric tonnes per hour | | mt/h |

Mega Volt Ampere | | MVA |

Mega Watt | | MW |

Standard cubic feet per minute | | scfm |

Tonnes | | t |

tonnes per hour | | t/h |

tonnes per cubic meter | | t/m3 |

tonnes per year | | t/y |

metric tons | | tonnes or t |

short tons | | tons |

September 2011

xix

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

1. SUMMARY

1.1 Introduction

Alderon Iron Ore Corp. (“Alderon”) acquired a 100% interest in the Kamistiatusset Iron Ore Property (the “Property” or “Kami”) on December 6, 2010 from Altius Minerals Corporation (“Altius”). The purchase is subject to a 3% gross sales royalty. The Property is located approximately 10 km from the Town of Wabush and is approximately 6 km south from the Wabush Mines mining lease owned by Cliffs Natural Resources Inc. The Property straddles the Québec-Labrador provincial border, but the majority of it is in Labrador and no mining activities are planned on the Property within Quebec. The Property in Labrador comprises three map-staked licenses (305 claims) covering 7,625 hectares. The Property in Québec consists of five map-staked licenses covering a nominal area of 125 hectares.

Altius initiated exploration of the Property in 2006 and completed geological mapping, geophysical surveys and in 2008, a diamond drilling program comprising 25 drillholes aggregating 6,129.5 m. In 2010, Alderon acquired further claims, performed an airborne gravity survey and initiated a drilling program in the Rose Central and Mills Lake areas aimed at acquiring sufficient data to allow for the estimation of Mineral Resources. This program comprised 82 drillholes aggregating 25,749 m.

Watts, Griffis and McOuat Limited (WGM) produced an NI 43-101 compliant Technical Report, dated May 20, 2011, presenting a Mineral Resource estimate based on the aforementioned drill program for the Rose Central and the Mills deposits. Alderon filed the Report on SEDAR (www.sedar.com).

Alderon retained the services of BBA Inc. to lead and prepare a Preliminary Economic Assessment (PEA) for the potential development of the Kami Property. Alderon also retained the services of Stassinu Stantec Limited Partnership (“Stantec”) to cover railway transportation, port facilities, environmental studies and site characterization studies.

This Report, prepared at the request of Mr. Brian Penney, COO of Alderon, presents the results of the PEA Study.

September 2011

1-1

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

1.2 Geology and Mineralization

The Property is situated in the highly metamorphosed and deformed metasedimentary sequence of the Grenville Province, Gagnon Terrane of the Labrador Trough (“Trough”). The Trough is comprised of a sequence of Proterozoic sedimentary rocks, including iron formation, volcanic rocks and mafic intrusions. Trough rocks in the Grenville Province are highly metamorphosed and complexly folded. Iron deposits in the Gagnon Terrane, Grenville part of the Trough, include those on the Property and Lac Jeannine, Fire Lake, Mont-Wright, Mont-Reed, and Bloom Lake in the Manicouagan-Fermont area and the Luce, Humphrey and Scully deposits in the Wabush-Labrador City area. The high-grade metamorphism of the Grenville Province is responsible for recrystallization of both iron oxides and silica in primary iron formation, producing coarse-grained sugary quartz, magnetite, and specular hematite schist or gneiss (meta-taconites) that are of improved quality for concentration and processing. The Property is underlain by folded sequences of the Ferriman Group (previously Knob Lake Group) or Gagnon Group containing Wabush/Sokoman Formation iron formation and underlying and overlying units. The stratigraphic sequence varies in different parts of the Property.

The iron formation on the Property is of the Lake Superior-type. Lake Superior-type iron formation consists of banded sedimentary rocks composed principally of bands of iron oxides, magnetite and hematite within quartz (chert)-rich rock with variable amounts of silicate, carbonate and sulphide lithofacies. Such iron formations have been the principal sources of iron throughout the world (Gross, 1996). Mineralization of economic interest on the Property is oxide facies iron formation.

The oxide iron formation consists mainly of semi-massive bands, or layers, and disseminations of magnetite and/or specular hematite (specularite) in recrystallized chert and interlayered with bands (beds) of chert with minor carbonate and iron silicates. Where iron silicates exceed iron oxides, mineralization is Silicate Iron Formation (“SIF”), or where carbonate is also prevalent, mineralization is Silicate-Carbonate Iron Formation (“SCIF”). SIF and variants consist mainly of amphiboles and chert, often associated with carbonate and contains magnetite or specularite in minor amounts. Grunerite is a prominent member of the silicate iron assemblage on the Property. The OIF assemblage on the Property is mostly magnetite-rich but includes hematite-rich units as well as lean oxide iron formation and SIF and SCIF variants. Some sub-members

September 2011

1-2

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

contain increased amounts of hematite (specularite) associated with manganese silicates and carbonates.

In the Mills Lake area, the iron formation consist of a gently east dipping tabular main zone with several parallel ancillary zones. The iron formation in the Rose and Mart Lakes area consists of a series of corrugated gently plunging, northeast-southwest oriented sub-parallel upright to slightly overturned anticlines and synclines. Thickness of oxide and silicate/carbonate iron formation varies widely but is indicated to be up to about 300 m on fold limbs in the Rose Central deposit.

1.3 Exploration and Drilling

All recent exploration and drilling on the Property were completed either by Altius or Alderon. Altius commenced reconnaissance mapping and rock sampling during the summer of 2006 and was completed during the 2007 field season. In 2007, their exploration program also included a high-resolution helicopter airborne magnetic survey and line cutting. The results of the 2007 program were positive and the airborne magnetic survey effectively highlighted the extent of the iron formation. Following the 2007 program, Altius acquired additional property.

The 2008 exploration program conducted by Altius consisted of rock sampling, line cutting, a ground gravity and magnetic survey, a high-resolution satellite imagery survey, an integrated 3-D geological and geophysical inversion model and 6,129 m of diamond drilling in 27 holes (including two abandoned holes which were re-drilled). The drilling program was designed to test three known iron ore occurrences that were targeted through geological mapping and geophysics, namely, Mills Lake, Mart Lake and Rose Lake. Drilling confirmed the presence of iron oxide-rich iron formation and was successful in extending the occurrences along strike and at depth.

Alderon commenced their 2010 drill program on the Property on June 1st. It was focused on the Rose Central and Mills Lake deposits; however, a few drillholes were targeted on the North Rose and South West Rose Zones. An airborne gravity and magnetic survey covering all of the Property in Newfoundland and Labrador was also completed by Bell Geospace Inc.

September 2011

1-3

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

The drill program on the Rose Central deposit comprised 51 drillholes aggregating 18,928 m. Drilling was completed along grid lines 200 m apart, filling in between and extending Altius’ 2008 drilling pattern. Distance between holes varied. The holes covered an approximate northeast-southwest strike length of 1.5 km and tested mineralization to a depth of approximately 500 m. Four drillholes were drilled to test the North Rose Zone and several Central Rose drillholes also tested the North Rose Zone at depth to allow for a preliminary assessment. Ten holes aggregating 1,441 m were targeted on the South-West Rose Zone. On the Mills Lake deposit, 16 holes were drilled aggregating 4,121 m over a North-South strike length of 1.2 km on cross sections 200 m apart. The gently dipping iron formation was tested to a depth of approximately 300 m.

1.4 Mineral Processing and Metallurgical Testwork

BBA developed a metallurgical test plan for this PEA Study based on indications from previous testwork performed by Altius as well as on the general mineralogical and geological characteristics of the Rose Central and Mills deposits. SGS Minerals Services (“SGS”) were retained to perform the testwork. The objective of the testwork was to evaluate the ore’s amenability to be processed by gravity separation and/or by magnetic separation in order to produce a commercially acceptable, quality product that would allow for the economical development of the Kami Iron Ore Project. An important part of the testwork consisted of evaluating the iron liberation granulometry with the objective of achieving a concentrate particle size distribution as coarse as possible (while maintaining an acceptable iron recovery and grade), in order to provide a wider range of applications and wider marketing flexibility. The testwork results were used in defining a conceptual Process Flowsheet to be used as the design basis for this Study. A recommended testwork program for subsequent testwork required for the next study phase of this Project was also developed.

Samples were prepared from drill cores from the Rose Central and Mills deposits. Recognizing that Rose Central comprises three distinct mineralogical zones, a composite sample was prepared for each zone. A composite sample of the three aforementioned zones was also prepared. One composite sample was also prepared for Mills. Each composite sample was tested at three particle size fractions; a coarse fraction (-425/+212 microns), an intermediate

September 2011

1-4

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

fraction (-212/+75 microns) and a fine fraction (-75/+45 microns). The testwork performed during this Study consisted of a combination of the following tests:

· Complete chemical assay of the head samples;

· Complete assays and distributions of each size fraction;

· Heavy Liquid Separation (HLS) on each size fraction;

· Davis Tube (DT) magnetic separation on each size fraction;

· Quantitative Evaluation of Minerals by Scanning Electron Microscopy (QEMSCAN) test for each size fraction to evaluate elemental deportment, oxide liberation and association of various constituents;

· Optical Microscopy;

· Microprobe analysis;

· Wilfley Table (WT) tests on selected samples and size fractions; and

· Grindability tests.

The general conclusions drawn from the testwork were as follows:

· In all mineralization zones, the main gangue minerals consist of quartz, carbonates and silicates;

· In Rose Central, manganese is present predominantly in carbonates in the hematite-rich mineralization zone and in silicates in the magnetite-rich zones with manganese also being chemically bonded to the magnetite;

· In Rose Central, the magnetite-rich zone contains unrecoverable iron (in carbonates and silicates) in the order of 13%, compared to about 6% in the zones containing more hematite;

· In Rose Central, iron-oxide liberation (>90% liberated) size for the hematite-rich zone is about 300 µm and in the order of 150 µm for the magnetite-rich zone;

· In Mills, iron-oxide liberation is indicated to be less than 100 µm. Considering the fine liberation size for Mills, it was decided that Process Flowsheet development for this PEA

September 2011

1-5

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Study would be done for the Rose Central deposit. Further testwork was therefore focused only on Rose Central;

· Wilfley Table (WT) results for the samples tested from Rose Central indicate an acceptable metallurgical performance;

· Ore grindability results raised the following concerns which will be explored in more detail in the next study phase;

· One of the five samples tested, exhibited an unusually high Drop-Weight Test result which is not typical of ores in the region. This result was considered an outlier and was discarded for this Study;

· After discarding the aforementioned outlier, the ore operating Work Index is between 3.7 kWh/t and 4.0 kWh/t;

· The Drop-Weight Test results revealed some evidence of bimodality in the relative density distribution. The consequence of this could be an accumulation of a dense component in the primary mill circulating, leading to possible power problems which could result in a loss of throughput.

Based on the testwork results obtained, it was concluded that a conventional flowsheet consisting of crushing, autogenous grinding and screening, gravity separation using spirals and cobbing of spiral tails, followed by regrinding and magnetic separation, provides a sound design basis for this PEA Study. The testwork results indicate the following metallurgical performance:

· Combining the concentrates from the spiral circuit (78% of the total concentrate) and from the magnetic circuit (22% of the total concentrate), a concentrate averaging 65.5% Fe, 4.5% SiO2 and 0.75% Mn can be produced with iron recovery in the order of 82.8% and weight recovery in the order of 37.8%;

· The Particle Size Distribution of the final concentrate is indicated to be acceptable for the sinter fines market; however, further testing is required to validate this.

September 2011

1-6

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

1.5 Mineral Resource Estimates

WGM developed a Mineral Resource estimate for the Kami Iron Ore Project mineralized areas that have sufficient data to allow for continuity of geology and grades. WGM modeled the Rose Central and Mills Lake deposits. The Rose North Zone or other mineralized areas have not been included since confirmation/infill drilling is required before a Mineral Resource estimate can be completed on these areas. This work is planned as part of the 2011 drilling program.

The classification of Mineral Resources for this Study conforms to the definitions provided in NI 43-101 (revised on June 30th, 2011) and the guidelines adopted by the Council of the Canadian Institute of Mining Metallurgy and Petroleum (“CIM”) Standards. A summary of the Mineral Resources estimate is provided in Table 1.1.

Table 1.1: Categorized Mineral Resource Estimate for Kami Iron Ore Project (COG 20% TFe)

Category | | Zone | | Mt | | TFe% | | Mag

Fe% | | Hm

Fe% | | Mn% | | SiO2% | |

Indicated | | Total Rose Central Zone | | 376.1 | | 29.8 | | 18.6 | | 8.3 | | 1.56 | | 44.9 | |

| | Total Mills Lake Zone | | 114.1 | | 30.5 | | 22.1 | | 5.7 | | 1.02 | | 45.6 | |

| | | | | | | | | | | | | | | |

Inferred | | Total Rose Central Zone | | 46.0 | | 29.8 | | 19.2 | | 8.0 | | 1.61 | | 44.9 | |

| | Total Inferred Mills Lake Zone | | 71.9 | | 30.7 | | 22.2 | | 6.0 | | 1.05 | | 45.4 | |

The data used to generate the Mineral Resource estimate was supplied to WGM by Alderon. The Gemcom drillhole database consisted of 107 diamond drillholes; including “duplicated” hole numbers designated with an “A” nomenclature, meaning the hole was re-drilled in whole or in part, due to lost core/bad recovery. A total of 68 drillholes totaling 24,079 m were used for the current Mineral Resource estimate; 48 holes at Rose Central and 20 holes at Mills Lake. These holes were dispersed along the iron mineralization - approximately 1,600 m of strike length and 700 m of width on Rose Central and 1,400 m by 800 m on Mills Lake. The database tables as originally supplied to WGM contained some errors and these were corrected and confirmed by the Client before proceeding with the Mineral Resource estimate. In general, WGM found the database to be in good order, but it was still a work in progress. After the errors that WGM identified were corrected, there were no additional database issues that would have a material impact on the Mineral Resource estimate, so WGM proceeded to use the most up to date database supplied by Alderon.

September 2011

1-7

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

For this Mineral Resource estimate, the holes were drilled on section lines which were spaced 200 m apart for both deposits in the main area of mineralization. Drillholes on cross sections were variably spaced and with variable dips (and directions) leading to mineralized intersections anywhere from less than 50 m to more than 250 m apart on adjacent holes. Most cross sections contained at least three holes and some had as many as ten holes passing through the mineralized zone due to the variable drilling pattern, however, in both deposits, the closest spaced drilling was near the surface (in the first 150 to 200 m). The deeper mineralization, i.e., below 200 m vertical depth, has been tested by fewer holes and both zones are open at depth. WGM’s zone interpretations of the mineralization were digitized into Gemcom and each polyline was “snapped’ to drillhole intervals allowing for the creation of a true 3-D wireframe. Mineralized boundaries were digitized from drillhole to drillhole which showed continuity of strike, dip and grade, generally from 100 m to 200 m in extent, and up to a maximum of about 300 m on the ends of the zones and at depth where there was no/little drillhole information, but only if the interpretation was supported by drillhole information on adjacent cross sections.

The extensions of the mineralization on the ends and at depth took into account the fact that the drilling pattern was irregular and that a proper grid was not complete; hence many drillholes did not penetrate the entire stratigraphy/zone. The 3-D model for Rose Central was continued at depth as long as there was drillhole information, however, this extension was taken into consideration when classifying the Mineral Resources and these areas were given a lower confidence category. Even though the wireframe continued to a maximum depth of -135 m (approximately 750 m vertically below surface and extending 100 m past the deepest drilling), at this time, no Mineral Resources were defined/considered below 150 m elevation.

The Mineral Resource estimate was completed using a block modeling method, and for the purpose of this Study, the grades have been interpolated using an Inverse Distance estimation technique with a set of equal length (3 m) composites generated from the raw drillhole intervals. A 3 m composite length was chosen to ensure that more than one composite would be used for grade interpolation for each block in the model and 3 m is also close to the average length of the raw assay intervals. The grades were well constrained within the wireframes and the results of the interpolation approximated the average grade of the all the composites used for the estimate.

September 2011

1-8

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

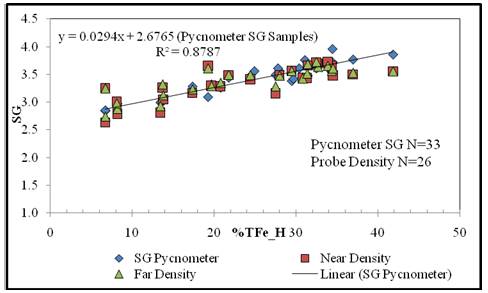

WGM created a variable density model to estimate tonnage. Most of the iron formation consists of a mix of magnetite and hematite, but there are sections that contain very little hematite and are mostly magnetite, and vice versa. The SG results returned by pycnometer measurements correlate strongly with %total iron on samples, and the DGI probe determined density averaged over the same sample intervals similarly and correlate strongly with %TFe. Using WGM’s variable density model, a 30% total iron gives a SG of approximately 3.56.

The details of the geology and geometry of the Rose Central mineralized body is quite complex and more drilling is required to get a better understanding of the depth potential, dip and internal detail of the hematite-rich and waste units. However, the gross overall mineralization controls appear to be fairly well understood with the current amount of drilling completed to date. Both deposits have undergone various degrees of folding, but at this stage of exploration, the search ellipse size and orientations for the grade interpolation were kept simple. Based on the current geological knowledge; the ellipses sizes were kept the same for both deposits, but the orientation and dips changed based on the geological interpretation. For future Mineral Resource estimates and after more drilling information is available, WGM envisions, that due to folding causing orientation/strike complexity and change, different domains will most likely be defined to better control grade distribution along the limbs and to reflect changes in dip/attitude. Alternately, a technique known as unfolding may be applied during the statistical analysis and the grade interpolation.

1.6 Mining Methods

For studies at the Pre-Feasibility and Feasibility levels, CIM guidelines require that only material categorized as Measured or Indicated be classified as a reserve. Considering that this present Study is a Preliminary Economic Assessment, these guidelines require that all material classified as Measured, Indicated, or Inferred be reported as a Mineral Resource.

The block models for Rose Central and Mills were provided to BBA by WGM. The block models were imported into the MineSight software into two respective Project Control Folders (PCF) (i.e. one for Rose Central and one for Mills), as provided, without modifying any of the information given. The model was checked to ensure the validity, and to ensure that the transfer from the WGM files was successful.

September 2011

1-9

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Pit optimization was carried out using the true pit optimizer algorithm Lerchs-Grossman 3-D (“LG 3-D”) in MineSight. The LG 3-D algorithm is based on the graph theory and calculates the net value of each block in the model, i.e. profit minus loss. With all mining costs, processing costs, processing recoveries, weighted recovery values and overall pit slope, the pit optimizer searches for the pit shell with the highest undiscounted cash flow. For this Study, all blocks with rock classifications of Measured, Indicated and Inferred will be included in the economic calculations and in the pit optimization process.

The break-even cut-off grade (COG) is used to classify the material within the pit limits as ore or waste. The milling cut-off grade used for the Kami Project was strategically taken at 15% total iron. This cut-off grade is slightly higher than the break-even cut-off grade. This is done in order to maximize the NPV for this Project.

The detailed mine design is carried out using the LG 3-D optimized pit shell as a base. In order to estimate in-pit resources, operational factors that are required for a mine are added during the engineered pit design phase. These features include a haulage ramp, safety berms, bench face angles, inter-ramp angles, and bench height. Pit slope parameters as well as waste rock dump design parameters were provided by Stantec.

The mining resources were calculated for both the Rose Central engineered pit design and the Mills engineered pit design at an in-pit cut-off grade of 15% total iron. The total mining resources (Indicated + Inferred) calculated in this Study for the Rose Central pit indicate a total of 335.13 Mt, with an average grade of 29.88 % total iron. The total waste contained in the Rose Central pit is 758.62 Mt, which includes 46.77 Mt of overburden. This results in a stripping ratio of 2.26. The mining resources calculated for the Mills pit indicate a total of 89.52 Mt, with an average grade of 30.66 % total iron. The total waste contained in the Mills pit is 92.70 Mt, which includes 14.87 Mt overburden. This results in a stripping ratio of 1.04.

As part of this Study, a preliminary mine plan was developed in order to develop Capital and Operating Cost Estimates for the Project.

September 2011

1-10

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

1.7 Recovery Methods and Processing Plant Design

The metallurgical testwork for the Rose Central deposit performed during this Study allowed for the development of the process mass balance. BBA’s experience on other similar projects allowed for the development of a preliminary water balance. This was used to develop a preliminary process plant design. Considering a target concentrate production of 8.0 Mt/y, the crushing and grinding areas are required to process 21.2 Mt/y of ore. This generates 13.2 Mt/y of tailings for disposal. Based on the Resource Estimate for Rose Central, the mine life will be approximately 15.3 years. These annual tonnages allow for the development of hourly rates in each area of the plant, therefore, major equipment was sized. A process design criteria and major equipment list has been developed and is used for the processing plant Capital Cost Estimate. Power, fuel, consumables and manpower requirements were also estimated for deriving the processing Operating Cost Estimate.

1.8 Project Infrastructure

As part of this Study, a preliminary site plan was developed for the Kami site. Major site infrastructure consists of the following:

· Rose Central and Mills open pits and associated waste rock dumps;

· Mine infrastructure including employee facilities, mine garage and wash station, warehouse and shops;

· The main processing facilities consisting of the following:

· Crusher area and crushed ore conveyors;

· Crushed ore stockpile, reclaim and conveyors;

· Processing plant including maintenance and service area and employee facilities; and

· Thickener.

· Concentrate conveyors, train loadout and emergency concentrate stockpile,

· Tailings pipeline,

· Tailings Management Facility (TMF) and recycled water pumphouse;

· Kami rail loop and rail spur connecting to the QNSL railway;

· Fuel unloading and tank farm;

September 2011

1-11

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

· Access road and on site roadwork;

· Long Lake raw water pumphouse;

· Power transmission line connecting to utility and main electrical substation; and

· Secondary facilities such as fire protection, communication tower, sewage treatment, etc.

Other infrastructure includes Port of Sept-Îles railway loop and spur, car dumper, stacker/reclaimer, concentrate storage and conveyors to common ship loading facility operated by the Port Authority.

1.9 Market Studies and Contracts

BBA understands that Alderon is actively promoting the Project and has engaged in discussions with several potential Clients interested in the concentrate which will be produced at the Kami facility. Alderon has also been in discussions with service Suppliers such as QNSL and Cliffs for rail transportation and with the Port of Sept-Îles for loading concentrate into ships. As of the effective date of this Report, Alderon has not entered into any material commercial agreements with any potential Client or Service Supplier.

Alderon has retained the services of Mr. Jan van Veelen, an independent consultant, to perform a market study. The objective of the study was to determine product marketability and sales strategy with an analysis of target markets and potential end-users for the Kami concentrate. The market study provided an overview of the iron ore seaborne market including historic market trends as well as analysts’ forecasts of demand and pricing for iron ore products. Based on the quality of product expected from the Kami operation, and considering the forecasted growth in sinter fines for Asia and more specifically for China, it was concluded that Alderon should pursue opportunities with potential clients in China.

1.10 Environment

The overall Project is subject to the Environmental Assessment Process of the Province of Newfoundland and Labrador, the Province of Québec as well as the Federal Assessment Process. The requirements for each of these processes are well understood. The environmental

September 2011

1-12

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

studies required have been defined and planned. Permit requirements are also well defined and planned. A schedule for Environmental Permitting for the Project has been developed.

A tailings management strategy has been defined and a preliminary design for the Tailings Management Facility (TMF) has been developed. The TMF will be constructed and operated in phases thus allowing for progressive rehabilitation. An appropriate area has been determined and located on the site plan. Dewatered tailings will be pumped from the concentrator to the TMF. Water will be collected within a polishing pond and returned to the processing plant thus minimizing fresh water consumption. It is anticipated that the tailings supernatant will be inert, with negligible metal and chemical levels.

Waste rock from the mining operation will be permanently stored within two waste rock dumps, one to the North-West and one to the South-West of Rose Central pit. The areas identified do not contain any significant mineralization and make use of the natural topography. Preliminary design parameters have been developed to define the waste rock dump profile that is deemed to be “designed for closure”.

1.11 Capital Costs

Capital costs for the Project were estimated and classified as initial capital costs and sustaining capital. The total initial capital cost for the Project, including mining pre-stripping costs, Indirect Costs and contingency was estimated to be in the order of $989M. This Capital Cost Estimate is expressed in constant August 2011 Canadian Dollars, with an exchange rate at par with the US dollar. Initial capital cost excludes the following items which have been treated separately, as indicated:

· Leased equipment (mining equipment and railcars) estimated value at $259.2M which is included in operating costs;

· The portion of rehabilitation and closure costs required to be disbursed prior to production startup estimated by Stantec to be in the order of $25.5M;

September 2011

1-13

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

· Sustaining capital (capital expenses incurred in Year 1 of production to the end-of-mine-life) estimated at $198.5M.

Initial capital costs are summarized in Table 1.2.

Table 1.2: Total Estimated Initial Capital Costs (M$)

1.12 Operating Costs

Operating Costs have been estimated and are summarized in Table 1.3 in CAD$ per tonne of concentrate produced. Operating costs were estimated based on the average over the life of the mine. Operating costs include the estimated cost of leased equipment over the life of the lease.

Table 1.3: Total Estimated Average Operating Cost ($/t concentrate)

The total estimated operating costs are in the order of $44.87/t of concentrate produced. Royalties are not included in the Operating Cost Estimate presented but are treated separately in the Project economic analysis.

September 2011

1-14

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

1.13 Economic Analysis

The economic evaluation of the Kami Iron Ore Project was performed using the discounted cash flow model. The Capital and Operating Cost Estimates based on the mine plan developed in this Study to produce 8.0 Mt of concentrate annually were used as input to the model. The following parameters and assumptions were made for the Base Case financial analysis:

· A production life of 15.3 years for the Rose Central deposit from Year 1 to Year 16;

· A constant commodity price of $115/t (CAD$) of concentrate of grading at 65.5% Fe;

· All of the concentrate is sold in the same year of production;

· No escalation or inflation factor has been taken into account (constant 2011 $);

· Financial analysis excludes working capital;

· The financial analysis is carried out on a pre-tax basis;

· US Dollar at par with Canadian Dollar.

The NPV calculation was done at discount rates of 0%, 5%, 8% and 10%. The Base Case NPV was assumed at a discount rate of 8%. Table 1.4 presents the results of the financial analysis.

Table 1.4: Financial Analysis Results

| | Base Case | |

| | 40.2% | |

IRR | | NPV | | Payback | |

0% | | $ | 7 019 M | | 2.3 yrs | |

5% | | $ | 4 135 M | | 2.5 yrs | |

8% | | $ | 3 066 M | | 2.7 yrs | |

10% | | $ | 2 526 M | | 2.8 yrs | |

As can be seen, the Project is forecasted to provide an IRR of 40.2% (before tax). At the Base Case discount rate of 8%, NPV is $3,066M. Payback occurs after 2.7 years. A sensitivity analysis was also performed to show the Project sensitivity to a +/- $100M variation in capital cost, a +/- $50M per year variation in operating costs, a +/- 25% variation in commodity price and the effect of a reduced concentrate production rate considering a lower than expected Fe recovery rate. Commodity selling price showed the biggest impact on project economics.

September 2011

1-15

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

A Preliminary Economic Assessment is preliminary in nature and includes Inferred Mineral Resources that are considered too speculative geologically to have economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the Preliminary Economic Assessment will be realized.

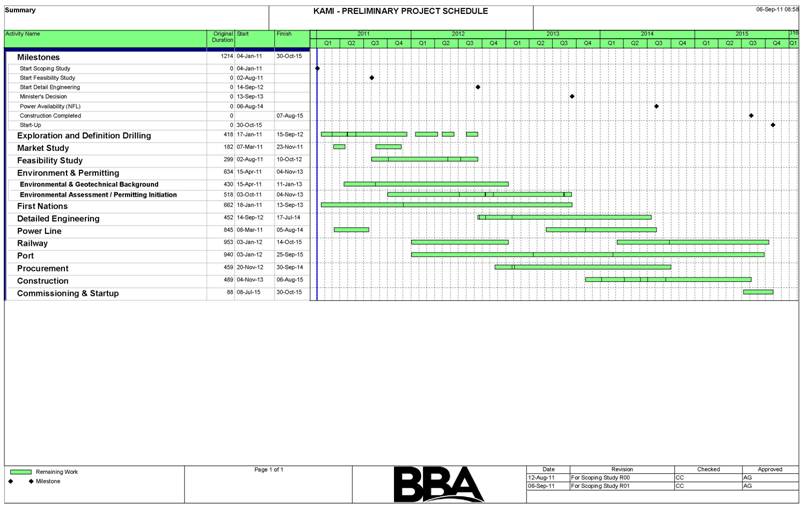

1.14 Project Schedule

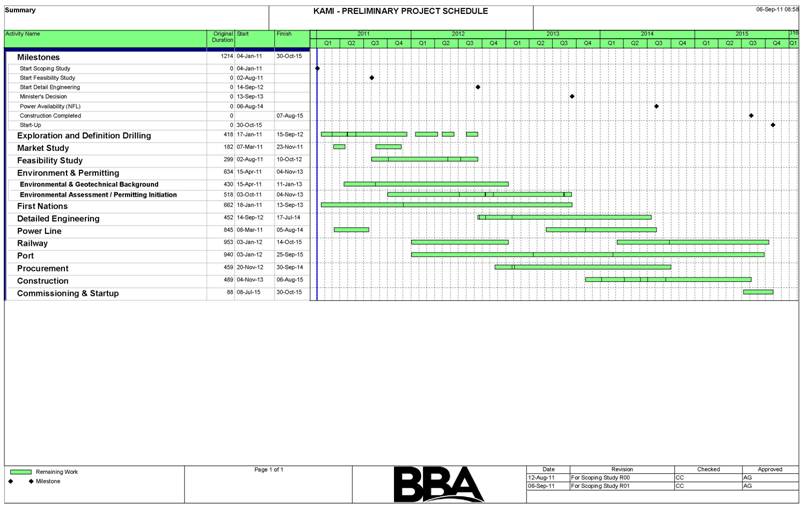

A preliminary project execution schedule was developed. Based on BBA’s understanding of the Environmental Assessment and Permitting process, construction can begin once the required permits are obtained. Construction is expected to begin in early November 2013. Assuming a typical construction schedule lasting about 21 months, the end of construction is estimated to occur in early August 2015. Plant startup is expected for end of October 2015.

1.15 Conclusions

Based on the work accomplished and the results obtained in this PEA Study, it is BBA’s opinion that the Project is sufficiently robust to warrant proceeding with a Feasibility Study.

September 2011

1-16

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

2. INTRODUCTION

2.1 Scope of Study

The following Technical Report (the Report) presents the results of the Preliminary Economic Assessment (PEA) for the development of the Kamistiatusset (Kami) Iron Ore Property, in Western Labrador. In December 2010, Alderon Iron Ore Corporation commissioned the engineering consulting group BBA Inc. to perform this Study. This Report was prepared at the request of Mr. Brian Penney, COO of Alderon. Alderon is a Canadian publicly traded company listed on the TSX Venture Exchange (TSX.V) under the symbol ADV, with its head office situated at:

1240–1140 West Pender Street

Vancouver, BC

Canada, V6E 4G1

Tel: (604) 681-8030

This Technical Report titled “Preliminary Economic Assessment for the Development of the Kamistiatusset (Kami) Iron Ore Deposit” was prepared by a Qualified Person following the guidelines of the “Canadian Securities Administrators” National Instrument 43-101 (effective June 30, 2011), and in conformity with the guidelines of the Canadian Mining, Metallurgy and Petroleum (CIM) Standard on Mineral Resources and Reserves.

This Report is considered effective as of September 8, 2011.

2.2 Sources of Information

This Report is based in part on, internal company technical reports, maps, published government reports, company letters and memoranda, and public information, as listed in Section 27 “References” of this Report. Sections from reports authored by other consultants may have been directly quoted or summarized in this Report, and are so indicated where appropriate.

September 2011

2-1

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

It should be noted that the authors have relied upon selected portions or excerpts from material contained in the following NI 43-101 compliant Technical Report. This Report is publicly available on SEDAR (www.sedar.com):

“Technical Report and Mineral Resource Estimate on the Kamistiatusset Property”, Newfoundland and Labrador for Alderon Iron Ore Corp. NI 43-101 Technical Report prepared by Watts, Griffis and McOuat Limited (WGM), consulting geologists and engineers, dated May 20, 2011 (Risto, Kociumbas and MacFarlane).

This Preliminary Economic Assessment has been completed using the previously mentioned Technical Report as well as available information contained in, but not limited to the following reports and documents:

· Report of baseline mineralogical, metallurgical and grindability characteristics of the ore from the Rose Central deposit conducted by SGS Minerals Services on behalf of Altius Minerals Corporation;

· Block model provided by WGM;

· SGS Minerals Services testwork results;

· A conceptual process flowsheet developed by BBA based on similar operations;

· Internal and commercially available databases and cost models;

· Canadian Milling Practice, Special Vol. 49, CIM;

· Various reports produced by Stantec concerning rail and port facilities studies, environmental considerations for permitting, site hydrology, hydrogeology and geotechnical, tailings management and site closure plan.

2.3 Terms of Reference

Unless otherwise stated:

· All units of measurement in the Report are in the metric system,

· All costs, revenues and values are expressed in terms of Canadian (CDN) Dollars,

· All metal prices are expressed in terms of US dollars,

· A foreign exchange rate of $1.00US = $1.00CDN was used.

September 2011

2-2

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

For reported historical resource estimates, a conversion factor of 0.907 has been used in this Report to convert short tons (tons) to metric tons (tonnes or t).

Grid coordinates for the block model are given in the UTM NAD 27 (Zone 19N) and latitude / longitude system; maps are either in UTM coordinates or latitude / longitude system.

2.4 Site Visit

A site visit was conducted on March 22 and 23, 2011 by BBA, Stantec and Alderon representatives. BBA was represented by Mr. Angelo Grandillo. The purpose of the visit was to provide all key project team members with an overview of the Kami Property and to review project development milestones and planning. Alderon geologists were available to discuss general geological conditions and to provide a tour of the core storage facility with a presentation of select bedrock core material. BBA performed a visual examination of selected drill cores used to compose the composite samples for metallurgical testwork. To provide an overview of the Property terrain, the team members completed a helicopter fly-over.

September 2011

2-3

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

3. RELIANCE ON OTHER EXPERTS

BBA prepared this report using reports and documents as noted in Section 27 “References” of this report. Neither BBA nor WGM have verified the legal titles to the property nor any underlying agreement(s) that may exist concerning the licenses or other agreement(s) between third parties, but has relied on Alderon to have conducted the proper legal due diligence. Any statements and opinions expressed in this document are given in good faith and in the belief that such statements and opinions are not false and misleading at the date of this Report.

It should be understood that the mineral resources presented in this study are estimates of the size and grade of the deposits, based on a certain number of drillholes and samples and on assumptions and parameters currently available. The level of confidence in the estimates depends upon a number of uncertainties. These uncertainties include, but are not limited to, future changes in metal prices and/or production costs, differences in size, grade and recovery rates from those expected, and changes in project parameters. In addition, there is no assurance that the project implementation will be realized.

BBA had the responsibility for assuring that this Technical Report meets the guidelines and standards stipulated. Certain sections of this Report however, were contributed by WGM, Stantec or other Alderon consultants. Table 3.1 outlines responsibility for the various sections of the Report.

September 2011

3-1

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Table 3.1: Technical Report Section List of Responsibility

Section

Number | | Section Title | | Responsibility | | Comments and Exceptions |

1 | | SUMMARY | | BBA | | |

2 | | INTRODUCTION | | BBA | | |

3 | | RELIANCE ON OTHER EXPERTS | | BBA | | |

4 | | PROPERTY DESCRIPTION AND LOCATION | | WGM | | |

5 | | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | | BBA | | |

6 | | HISTORY | | WGM | | |

7 | | GEOLOGICAL SETTING AND MINERALIZATION | | WGM | | |

8 | | DEPOSIT TYPE | | WGM | | |

9 | | EXPLORATION | | WGM | | |

10 | | DRILLING | | WGM | | |

11 | | SAMPLE PREPARATION, ASSAYING AND SECURITY | | WGM | | |

12 | | DATA VERIFICATION | | WGM | | |

13 | | MINERAL PROCESSING AND METALLURGICAL TESTING | | BBA | | |

14 | | MINERAL RESOURCE ESTIMATE | | WGM | | |

15 | | MINERAL RESERVE ESTIMATE | | BBA | | |

16 | | MINING METHODS | | BBA | | Pit slope and waste rock pile design based on geotechnical assessment by Stantec |

17 | | RECOVERY METHODS | | BBA | | |

18 | | PROJECT INFRASTRUCTURE | | BBA/Stantec | | Site infrastructure by BBA, railway and port facilities by Stantec |

19 | | MARKET STUDIES AND CONTRACTS | | BBA | | Source: Alderon independent consultant not considered a QP |

20 | | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT | | Stantec | | Community relations by Alderon |

21 | | CAPITAL AND OPERATING COSTS | | BBA | | Stantec provided CAPEX and OPEX for railway, port, environmental, tailings management and site closure plan |

22 | | ECONOMIC ANALYSIS | | BBA | | |

| | | | | | | | |

September 2011

3-2

Alderon Iron Ore Corp.

NI 43-101 Technical Report – PEA of the Kami Iron Ore Project | |

|

Section

Number | | Section Title | | Responsibility | | Comments and Exceptions |

23 | | ADJACENT PROPERTIES | | BBA | | |

24 | | OTHER RELEVANT DATA AND INFORMATION | | BBA | | |

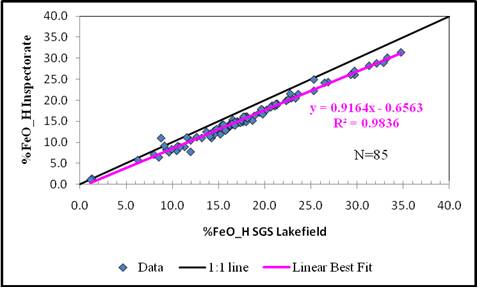

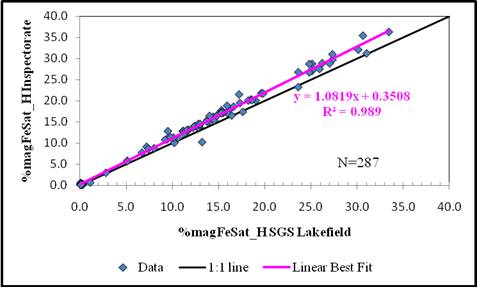

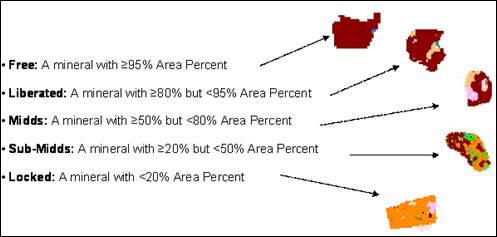

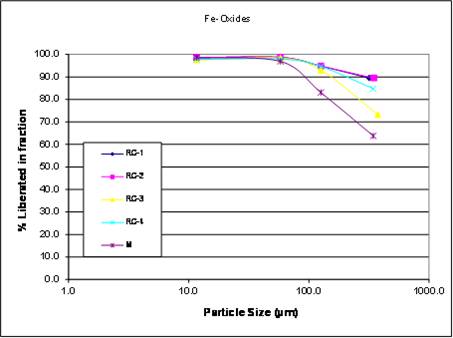

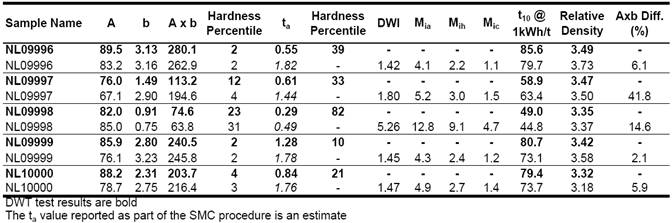

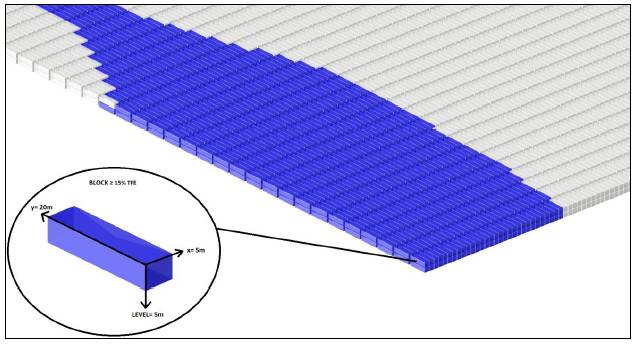

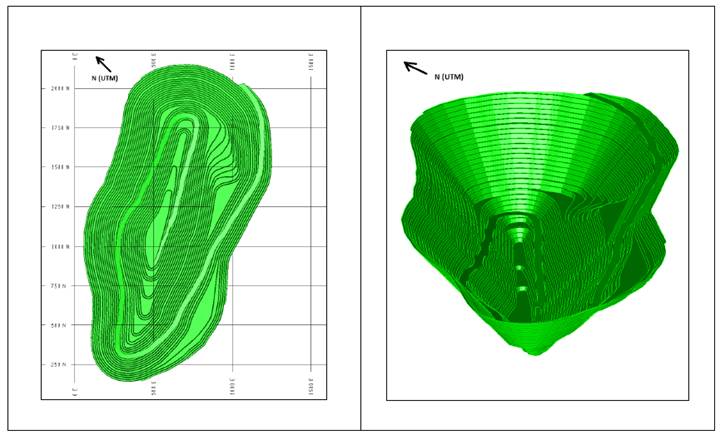

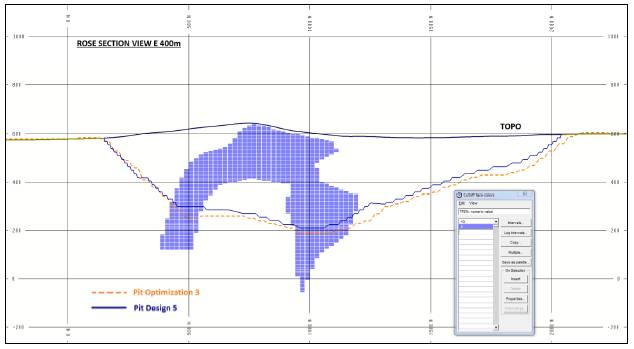

25 | | INTERPRETATION AND CONCLUSIONS | | BBA | | |