TECHNICAL REPORT

ON THE

KAMISTIATUSSET PROPERTY,

NEWFOUNDLAND AND LABRADOR

FOR

0860132 B.C. LTD. AND ALDERON RESOURCE CORP.

prepared by

Richard W. Risto, M.Sc., P.Geo.,

Senior Associate Geologist

David Power-Fardy, M.Sc., P.Geo.,

Senior Geologist

and

G. Ross MacFarlane, P.Eng.,

Senior Associate Metallurgical Engineer

February 12, 2010 Toronto, Canada |

|

TABLE OF CONTENTS

| | Page |

| | |

1. SUMMARY | 1 |

| |

2. INTRODUCTION AND TERMS OF REFERENCE | 10 |

2.1 | GENERAL | 10 |

2.2 | TERMS OF REFERENCE | 10 |

2.3 | SOURCES OF INFORMATION | 12 |

2.4 | UNITS AND CURRENCY | 12 |

| | |

3. RELIANCE ON OTHER EXPERTS | 15 |

| |

4. PROPERTY DESCRIPTION AND LOCATION | 16 |

4.1 | PROPERTY LOCATION | 16 |

4.2 | PROPERTY DESCRIPTION AND OWNERSHIP | 16 |

4.3 | PROPERTY AGREEMENTS | 20 |

4.4 | PERMITTING | 21 |

4.5 | ENVIRONMENTAL ISSUES | 21 |

4.6 | FIRST NATION ISSUES | 22 |

| | |

5. ACCESS, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 23 |

5.1 | ACCESS | 23 |

5.2 | CLIMATE | 23 |

5.3 | PHYSIOGRAPHY | 23 |

5.4 | LOCAL RESOURCES AND INFRASTRUCTURE | 23 |

| | |

6. HISTORY | 24 |

6.1 | GENERAL | 24 |

| | |

7. GEOLOGICAL SETTING | 29 |

7.1 | REGIONAL GEOLOGY | 29 |

7.2 | PROPERTY GEOLOGY | 31 |

| | |

8. DEPOSIT TYPES | 35 |

| |

9. MINERALIZATION | 37 |

| |

10. EXPLORATION | 53 |

ii

TABLE OF CONTENTS

(continued)

| | Page |

| | |

11. DRILLING | 55 |

11.1 | HISTORIC DRILLING | 55 |

11.2 | ALTIUS 2008 DRILLING PROGRAM | 55 |

11.3 | WGM COMMENT ON 2008 DRILLING | 57 |

| | |

12. SAMPLING METHOD AND APPROACH | 58 |

12.1 | GENERAL | 58 |

12.2 | 2006 AND 2007 SURFACE SAMPLING PROGRAMS | 58 |

12.3 | 2008 DRILL CORE HANDLING AND LOGGING | 58 |

12.4 | 2008 SAMPLING APPROACH | 59 |

12.5 | 2008 SAMPLING METHOD | 59 |

12.6 | CORE STORAGE | 60 |

12.7 | WGM COMMENT ON LOGGING AND SAMPLING | 60 |

| | |

13. SAMPLE PREPARATION, ASSAYING AND SECURITY | 61 |

13.1 | 2008 SAMPLE PREPARATION | 61 |

13.2 | 2008 SAMPLE ASSAYING | 61 |

13.3 | QUALITY ASSURANCE AND QUALITY CONTROL | 61 |

13.4 | WGM COMMENT ON ALTIUS’ SAMPLING AND ASSAYING | 68 |

| | |

14. DATA CORROBORATION | 69 |

| |

15. ADJACENT PROPERTIES | 74 |

| |

16. MINERAL PROCESSING AND METALLURGICAL TESTING | 77 |

| |

17. MINERAL RESOURCE AND MINERAL RESERVE ESTIMATES | 83 |

| |

18. OTHER RELEVANT DATA AND INFORMATION | 84 |

| |

19. INTERPRETATION AND CONCLUSIONS | 85 |

| |

20. RECOMMENDATIONS | 87 |

| | |

21. SIGNATURE PAGE | 89 |

| |

CERTIFICATES | 90 |

iii

TABLE OF CONTENTS

(continued)

| Page |

| |

REFERENCES | 96 |

| |

APPENDIX 1: WGM INDEPENDENT SAMPLING RESULTS | 101 |

LIST OF TABLES

1. | Summary of terms and abbreviations for units | 14 |

2. | Kamistiatusset property in Labrador | 16 |

3. | Kamistiatusset property in Québec | 16 |

4. | Minimum cost of work to be carried out on a Québec claim north of 52o latitude | 19 |

5. | Regional stratigraphic column, Western Labrador Trough | 31 |

6. | Rock/unit coding for Kami Property drill core logging | 33 |

7. | Deposit model for Lake Superior Type iron formation | 36 |

8. | Stratigraphy of mineralization at the Scully Mine | 37 |

9. | Stratigraphic column Wabush Lake area | 37 |

10. | Average composition of rock units from Altius 2008 drill core sample assays | 47 |

11. | Drilling summary — Altius 2008 program | 56 |

12. | Sampling and analysis summary, Altius 2008 drill program | 61 |

13. | Certified standard reference materials used for the in-field QA/QC program, Altius 2008 | 62 |

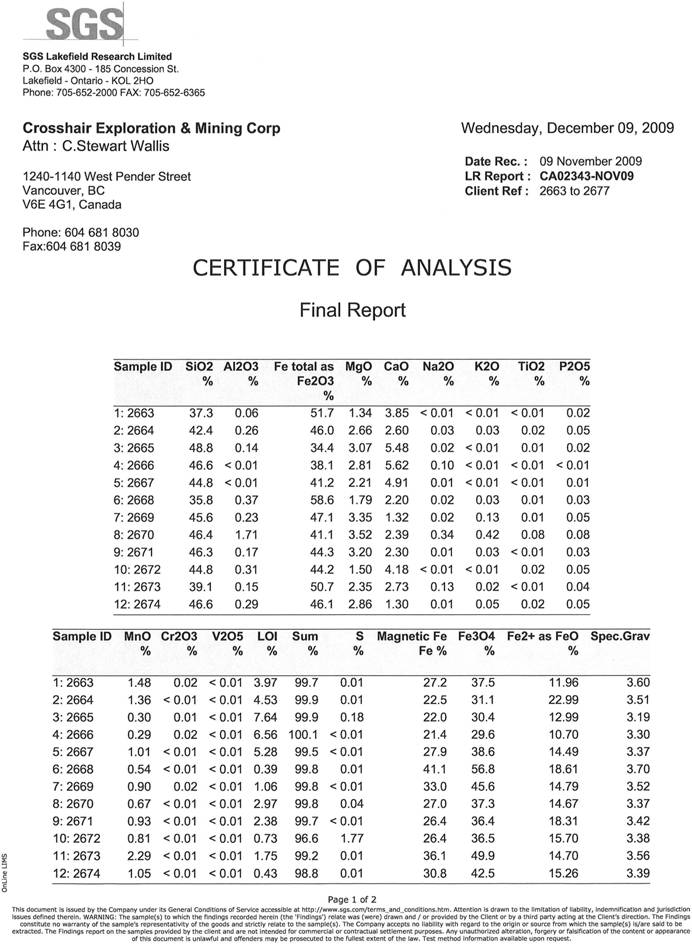

14. | Summary of WGM independent second half core sampling | 70 |

15. | Comparison of analytical results WGM independent quarter core sampling to original Altius results | 71 |

16. | Make-up of metallurgical sample | 77 |

17. | Ore characterization summary | 78 |

18. | Ore characterization details | 78 |

19. | Beneficiation characterization summary | 79 |

20. | Overall metallurgical summary | 81 |

21. | Wabush mines concentrate specifications | 82 |

22. | Proposed exploration program, Phase I Kamistiatusset Property | 88 |

| | |

LIST OF FIGURES |

| | |

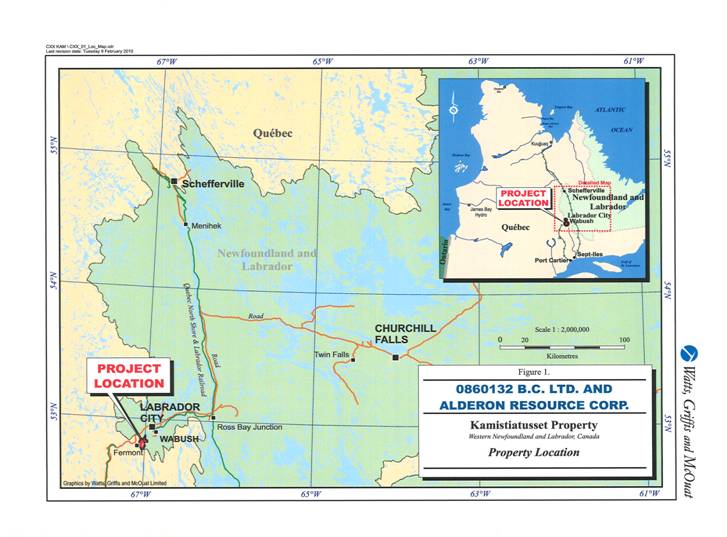

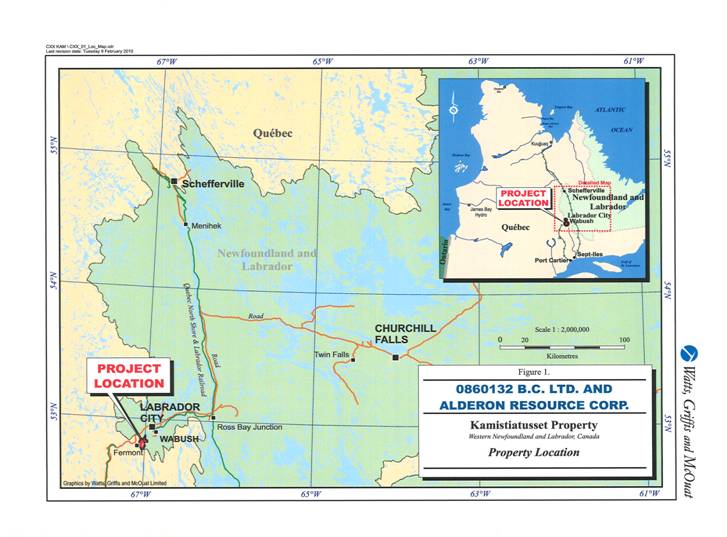

1. | Property location | 11 |

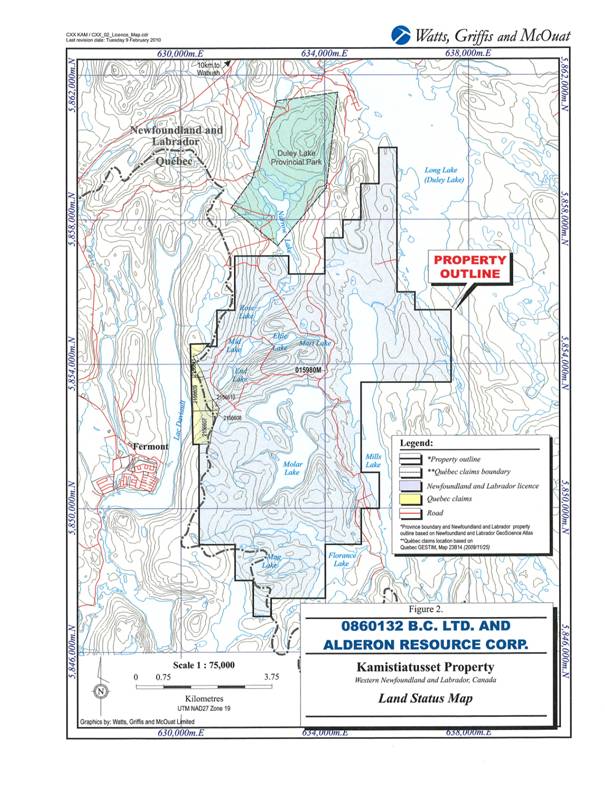

2. | Land Status map | 18 |

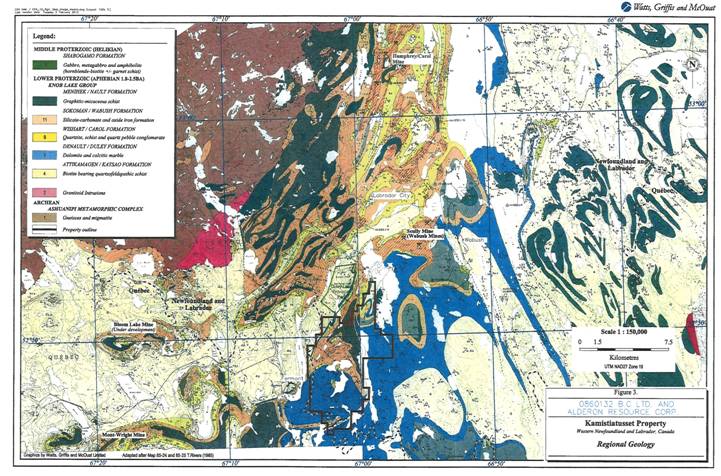

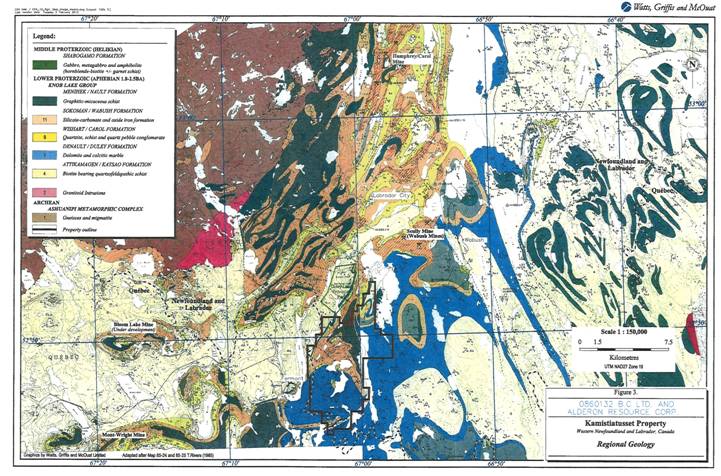

3. | Regional geology | 30 |

4. | Property geology | 32 |

5. | Ground magnetic survey with 2008 drillhole locations | 39 |

iv

TABLE OF CONTENTS

(continued)

| | Page |

| | |

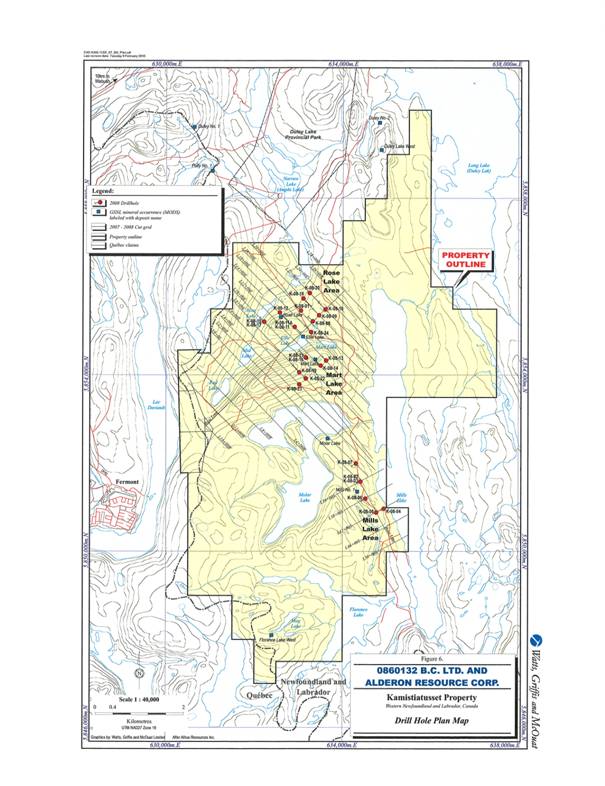

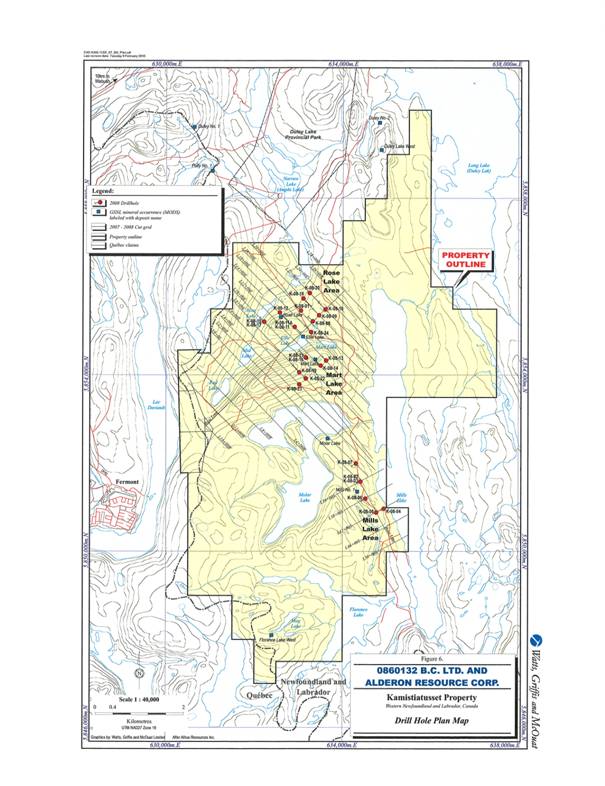

6. | Plan map showing drillholes | 40 |

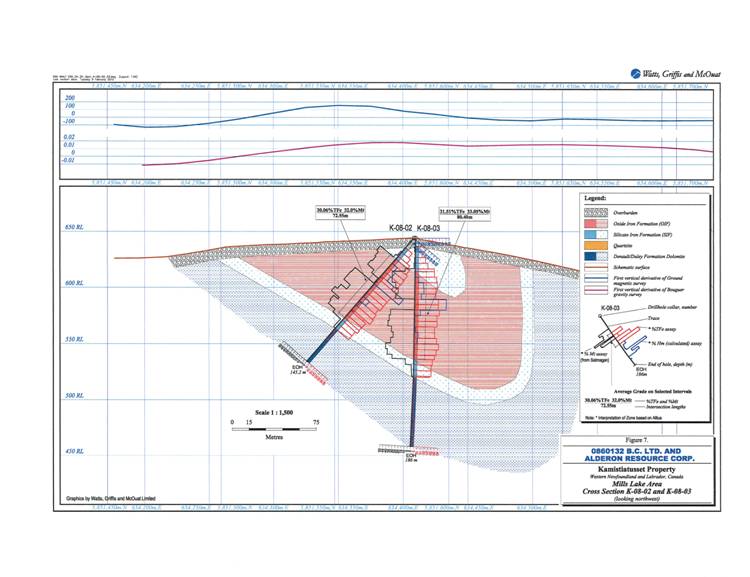

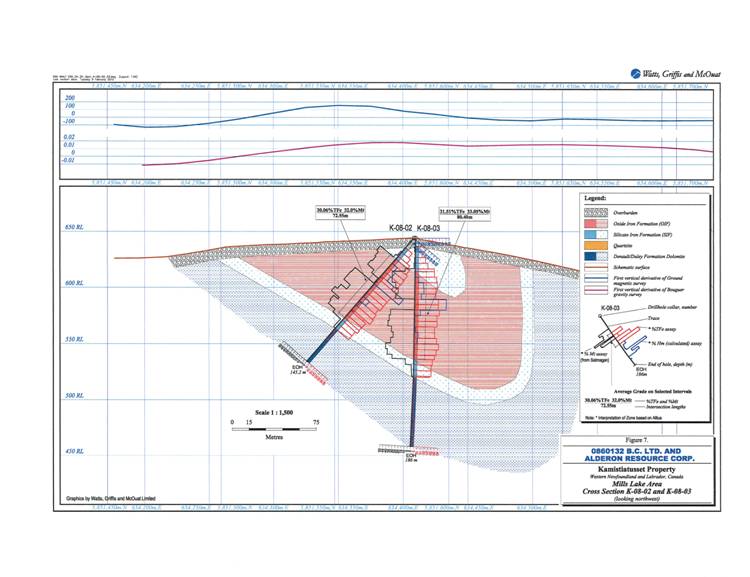

7. | Mills Lake area cross section K-08-02 and K-08-03 | 41 |

8. | Rose Lake area cross section K-08-09 and K-08-18 | 44 |

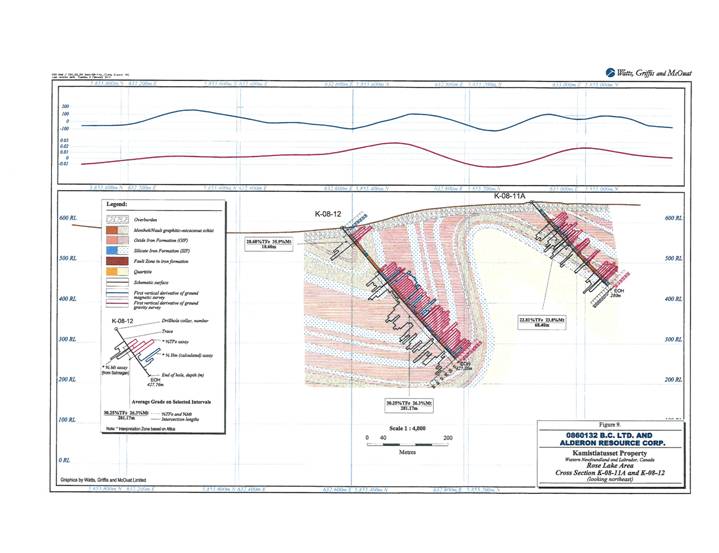

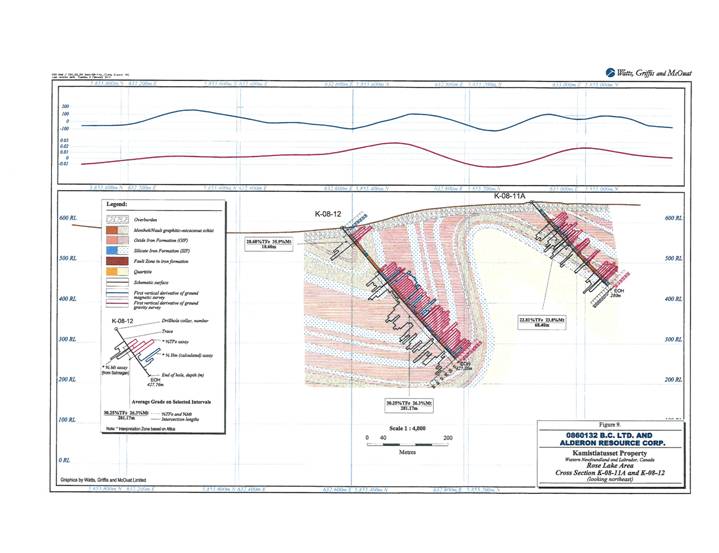

9. | Rose Lake area cross section K-08-11A and K-08-12 | 46 |

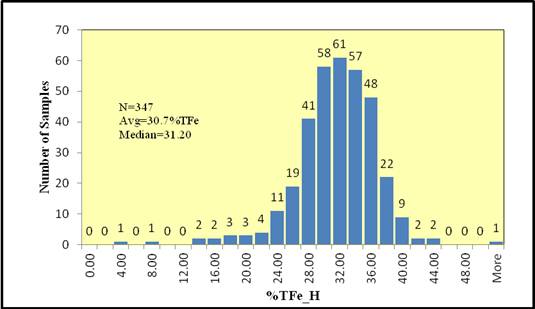

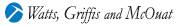

10. | Histogram for %TFe in Altius drill core samples | 48 |

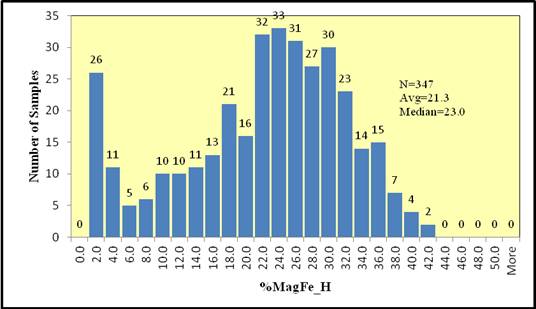

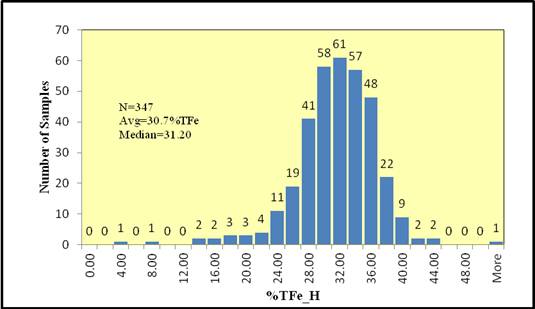

11. | Histogram for %Magnetic Fe in Altius drill core samples | 48 |

12. | Histogram for %Hematite (calculated) in Altius drill core samples | 49 |

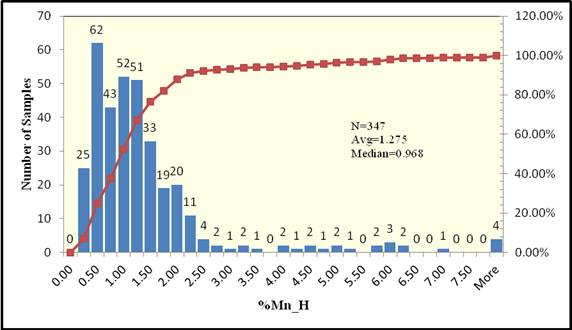

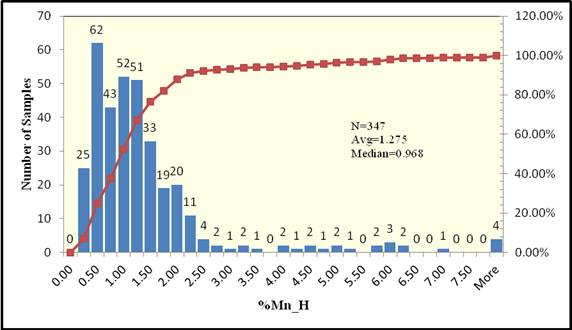

13. | Histogram and cumulative frequency for %Mn in Altius drill core samples | 49 |

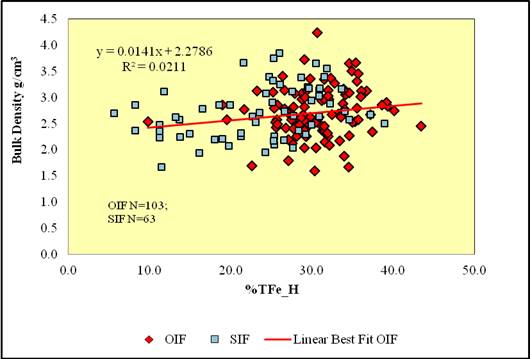

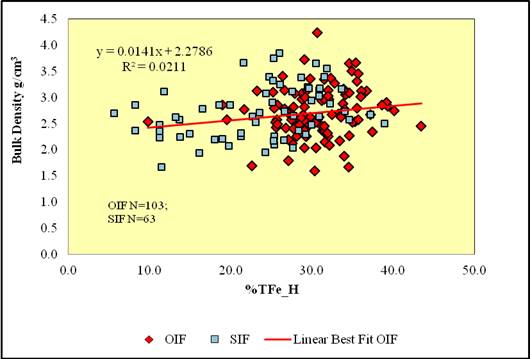

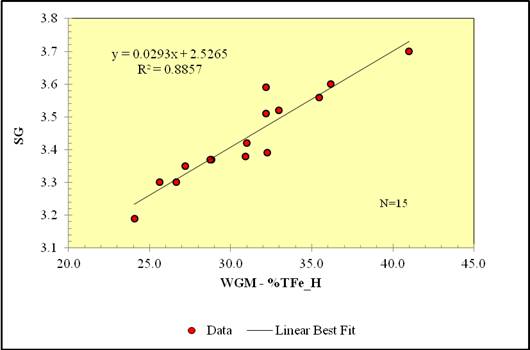

14. | Bulk density determined by Altius in the field vs. %TFe_H assays for routine samples | 52 |

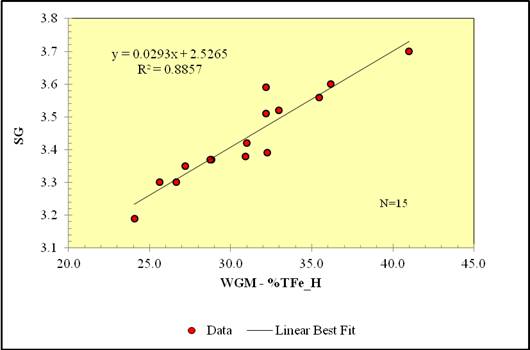

15. | SG vs. %TFe_H for WGM independent samples | 52 |

16. | Results for in-field inserted certified reference materials and blanks | 62 |

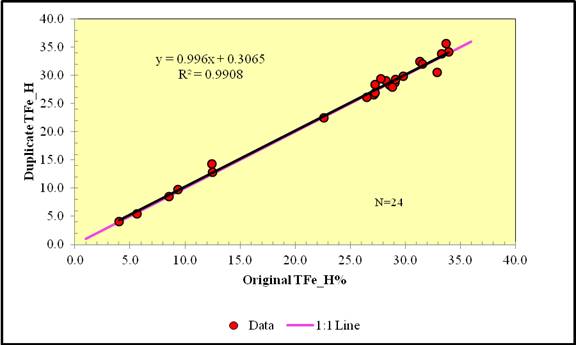

17. | Results for duplicate ¼ split drill core samples - %TFe Head | 63 |

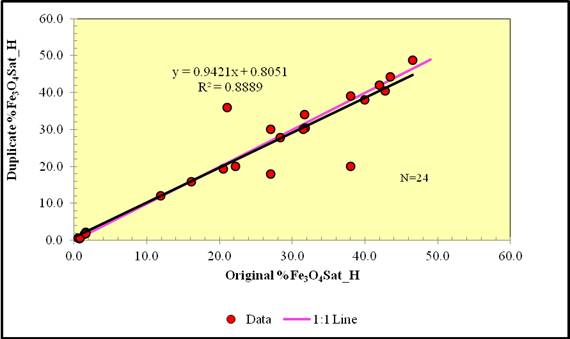

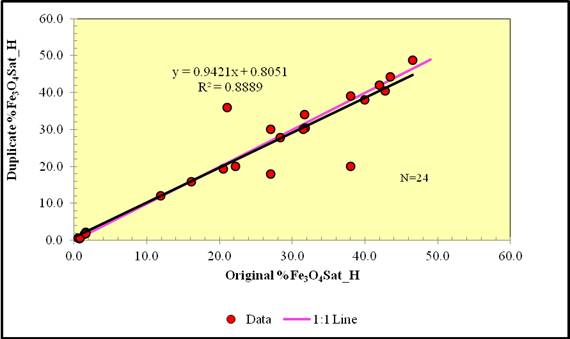

18. | Results for duplicate ¼ split drill core samples - %Fe3O4Sat Head | 63 |

19. | Results for duplicate ¼ split drill core samples - %FeO Head | 64 |

20. | Results for duplicate ¼ split drill core samples - %SiO2 Head | 64 |

21. | Results for duplicate ¼ split drill core samples - %Mn Head | 65 |

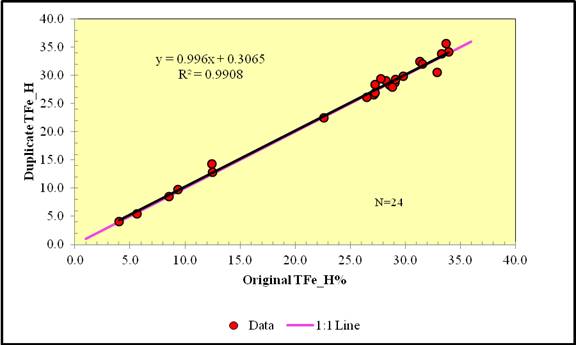

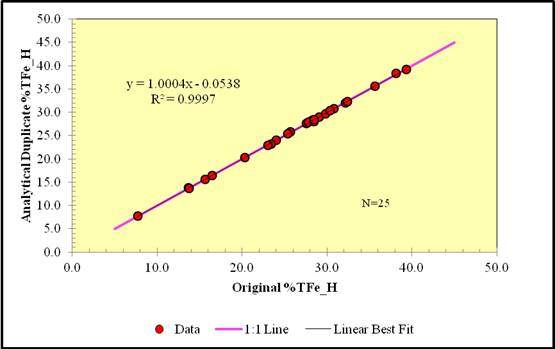

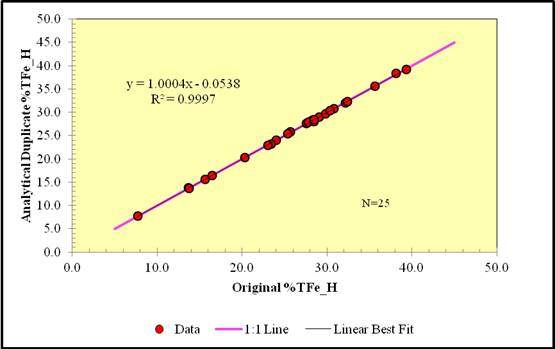

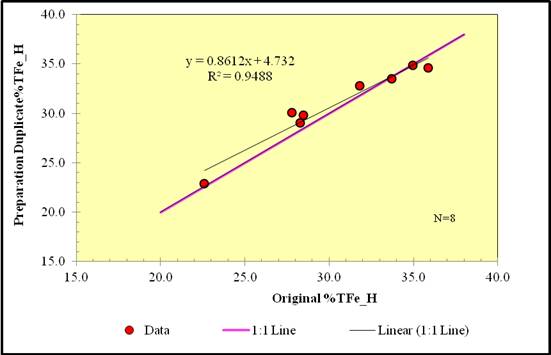

22. | Results for analytical duplicates at SGS-Lakefield for %TFe_H | 66 |

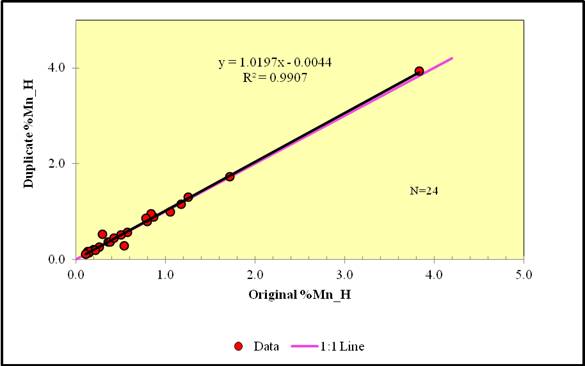

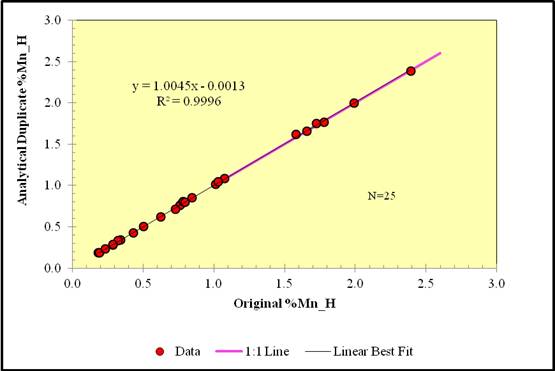

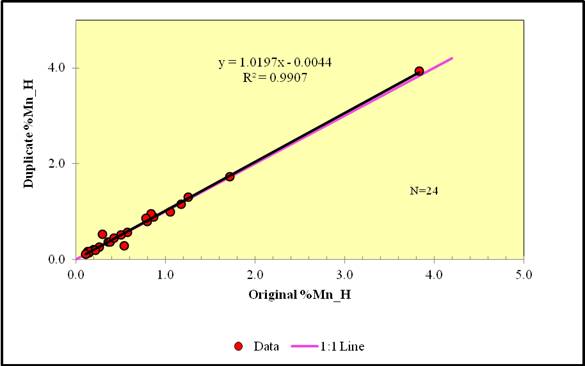

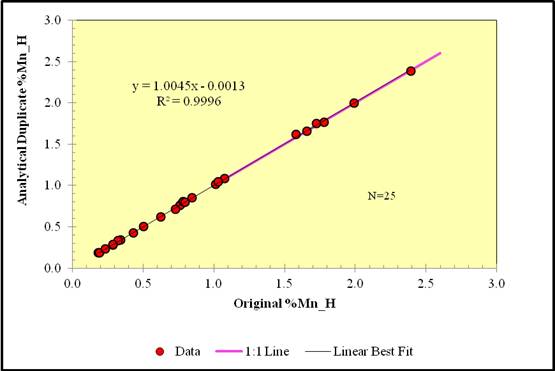

23. | Results for analytical duplicates at SGS-Lakefield for %Mn_H | 66 |

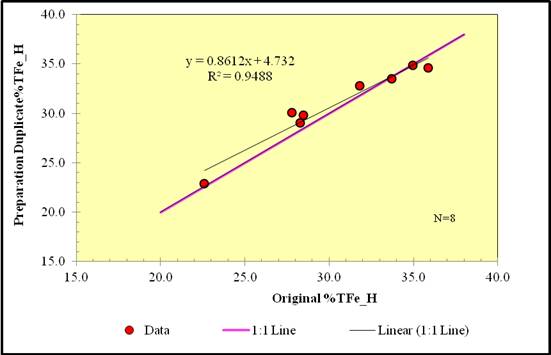

24. | Results for preparation duplicates at SGS-Lakefield for %TFe_H | 67 |

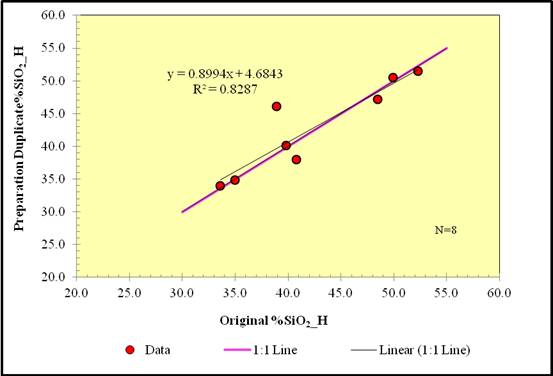

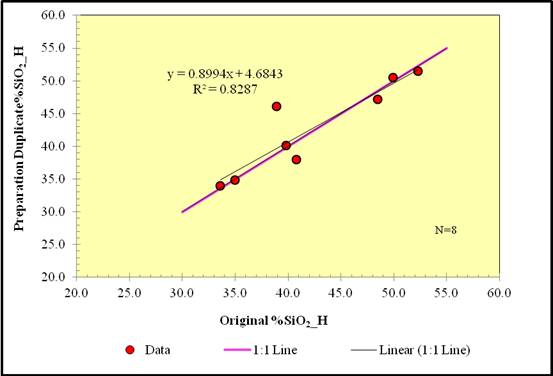

25. | Results for preparation duplicates at SGS-Lakefield for %SiO2_H | 67 |

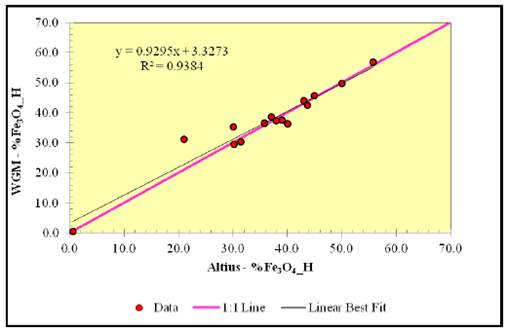

26. | %TFe_H for WGM independent sampling vs. Altius original | 72 |

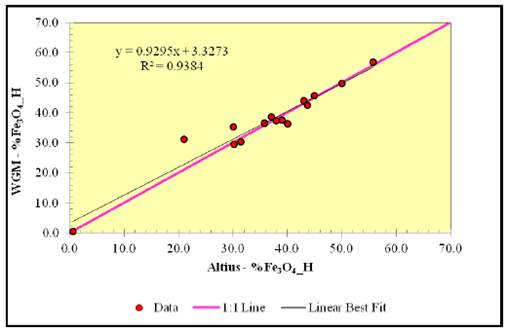

27. | %Fe3O4_H (Satmagan) for WGM independent sampling vs. Altius original | 72 |

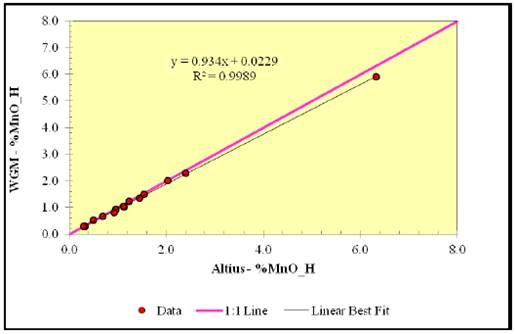

28. | %SiO2_H for WGM independent sampling vs. Altius original | 73 |

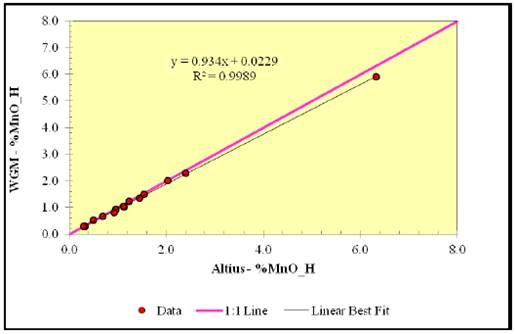

29. | %MnO_H for WGM independent sampling vs. Altius original | 73 |

v

1. SUMMARY

General and Terms of Reference

0860132 B.C. LTD. has recently completed an agreement with Altius Minerals Corporation (“Altius”) to acquire the iron ore Kamistiatusset Project (the “Kami Project”). 0860132 B.C. LTD. has assigned its rights to acquire the property to Alderon Resource Corp. (“Alderon”). In this report BCL refers to both 0860132 B.C. LTD. and Alderon (“BCL”). The Kamistiatusset property (the “Property”) is located approximately 10 km from the town of Wabush, Western Labrador and is approximately 6 km south from the Wabush Mines mining lease. The Property straddles the Québec-Labrador provincial border but the majority of it is in Labrador and is owned 100% by Altius. Altius initiated exploration of the Property in 2006 and has completed field work including prospecting, confirmatory geological mapping, gravity and airborne magnetic surveys and in 2008, a drilling program. Some historical exploration results are available, but these appear to be of limited value.

Watts, Griffis and McOuat Limited (“WGM”) was retained by BCL to complete a review of the Kami Project and document the results in an independent technical report prepared in compliance with Canadian National Instrument 43-101 (“NI 43-101”) standards and guidelines. The preparation of this report was authorized by Mr. Mark J. Morabito, President of 0860132 B.C. Ltd. on September 28, 2009.

Property

The Property in Labrador comprises one map-staked licence, of 191 claim units covering 4,775 hectares issued December 29, 2004. The Property in Québec, with registration date May 29, 2008, consists of five map-staked licenses covering a nominal area of 125.46 ha. Both Properties are currently in good standing. Alderon may acquire a 100% interest in the Property, subject to a 3% net sales royalty payable to Altius, by completing expenditures totalling $1 million on or before November 2, 2010, completing a total of $5 million on or before November 2, 2011 and issuing Altius sufficient shares so that Altius owns 50% of the outstanding shares of Alderon at the time of achieving a seed threshold financing of at least $5 million.

Previous Work

The earliest geological reconnaissance in the southern extension of the Labrador Trough within the Grenville Province was by prospectors in 1914 in search of gold. Several parties visited the area between 1914 and 1933. J.E. Gill, in 1933 first recognized the metamorphosed iron formation in the vicinity of Wabush Lake. In 1937, the first geological map and report was published for the area. A few years later, the Labrador Mining and Exploration Co. Ltd. (“LM&E”) evaluated the iron formation.

1

In 1949, interest in the Carol Lake area by LM&E was renewed and geological mapping was carried out in the Duley Lake - Wabush Lake area by H.E. Neal. Concentrations of magnetite and specularite were found in many places west of Duley Lake and Wabush Lake during the course of Neal’s geological mapping. The material was considered to be of economic significance, as the metallurgical tests indicated that it could be concentrated. In 1951, nearly all of the concession held by LM&E within the Labrador Trough was flown with an airborne magnetometer. This survey showed the known deposits to be more extensive than apparent from surface mapping and suggested further ore zones may be present in drift-covered areas. In 1953, a program of geological mapping in the Mills Lake - Dispute Lake area was conducted by R.A. Crouse of the Iron Ore Company of Canada (“IOCC”). In 1957, an area to the west of Duley Lake was remapped and test drilled by IOCC to determine areas for beneficiating ore. Dip needle surveying served as a guide in determining the locations of iron formation in drift-covered areas. The Mills No.1 Zone was outlined by six drillholes and found to have a maximum length of 3,048 m and a maximum width of 610 m. Mineralization is described s being composed of specularite with varying amounts of magnetite, grading on average 32.1% Fe. IOCC continued mapping and evaluation of the deposits lying west of Wabush Lake through 1959.

In 1972, an extensive helicopter magnetic and electromagnetic survey for LM&E covering the Labrador City area was carried out. In 1979, a ground magnetometer survey was conducted on Block No. 24 (part of the Property). Also in 1979, one diamond drillhole was drilled on the Property and in 1983, LM&E collared a diamond drillhole north of Elfie Lake. The drillhole encountered minor oxide facies metamorphosed iron formation.

In 1981 and 1982, an air photography and topographic mapping program was completed by IOCC to re-photograph the mining areas and the survey was extended to cover all the lease and licence blocks in the Labrador City area. In 2001, IOCC staked a considerable portion of the iron formation in the Labrador City area, with the Kamistiatusset area being the southern extent of the company’s focus. The Kamistiatusset area and the area north of the Property was recommended as a high priority target by SRK Consulting Ltd. as part of the 2001 IOCC work report, however, no work was reported for the area.

Geology and Mineralization

The Property is situated in the highly metamorphosed and deformed metasedimentary sequence Knob Lake Group of the Grenville Province, Gagnon terrane of the Labrador Trough (the “Trough”). The Trough is comprised of a sequence of Proterozoic sedimentary rocks, including iron formation, volcanic rocks and mafic intrusions. Trough rocks in the Grenville Province are highly metamorphosed and complexly folded. Iron deposits in the Gagnon terrane, Grenville part of the Trough, include those on the Property and Lac Jeannine,

2

Fire Lake, Mont-Wright, Mont-Reed, and Bloom Lake in the Manicouagan-Fermont area and the Luce, Humphrey and Scully deposits in the Wabush-Labrador City area. The high-grade metamorphism of the Grenville Province is responsible for recrystallization of both iron oxides and silica in primary iron formation, producing coarse-grained sugary quartz, magnetite, and specular hematite schist or gneiss (meta-taconites) that are of improved quality for concentration and processing.

The Property is underlain by folded sequences of the Knob Lake or Gagnon Group containing Wabush/Sokoman Formation iron formation and underlying and overlying units. The stratigraphic sequence varies in different parts of the Property. Altius’ exploration was focussed on three parts of the Property known as the Mills Lake, Rose Lake and the Mart Lake areas. On some parts of the Property, the Sokoman/Wabush is directly underlain by Denault/Duley Formation dolomite and the Wishart/Carol Formation quartzite is missing. In other places, both the dolomite and quartzite units are present.

The iron formation on the Property is the Lake Superior-type. Lake Superior-type iron formation consists of banded sedimentary rocks composed principally of bands of iron oxides, magnetite and hematite within quartz (chert)-rich rock with variable amounts of silicate, carbonate and sulphide lithofacies. Such iron formations have been the principal sources of iron throughout the world (Gross, 1996). Mineralization of economic interest on the Property is oxide facies iron formation. The oxide iron formation (“OIF”) consists mainly of semi-massive bands, or layers, and disseminations of magnetite and/or specular hematite (specularite) in recrystallized chert and interlayered with bands (beds) of chert with minor carbonate and iron silicates. Silicate iron formation (“SIF”) also is prevalent on the Property. SIF consists mainly of amphiboles and chert, often associated with carbonate and contains magnetite or specularite in minor amounts. The oxide iron formation on the Property is mostly magnetite-rich. Some sub-members contain increased amounts of hematite (specularite).

In The Mills Lake area, the iron formation is interpreted to be situated within a north-northwest trending, upright, gently south plunging syncline. The Rose and Mart Lakes area is characterized as a corrugated series of northeast-southwest oriented sub-parallel upright to gently overturned anticlines and synclines. Thickness of oxide and silicate iron formation varies widely but is indicated to be over 300 m in the hinge parts of folds and thinner on fold limbs.

3

Exploration and Drilling

BCL has completed no exploration or drilling of the Property. All recent exploration and drilling were completed by Altius. Reconnaissance mapping and rock sampling commenced during the summer of 2006 and was completed during the 2007 field season. Altius’ 2007 exploration program also included a high resolution helicopter airborne magnetic survey and linecutting. The results of the 2007 program were positive and the airborne magnetic survey effectively highlighted the extent of the iron formation. Following the 2007 program, Altius acquired additional property.

The Altius 2008 exploration program on the Property consisted of rock sampling for physical properties testing, linecutting, a ground gravity and magnetic survey, a high resolution satellite imagery survey, an integrated 3D geological and geophysical inversion model and 6,129.49 m of diamond drilling in 25 holes. The drilling program was designed to test three known iron ore occurrences that were targeted through geological mapping and geophysics on the Property, namely; Mills Lake, Mart Lake and Rose Lake. Drilling confirmed the presence of iron oxide-rich iron formation at the three iron occurrences and was successful in extending the occurrences along strike and at depth. Drilling was fundamental to help refine the geological and structural models for each area to aid in targeting and in positioning future drillholes.

Altius’ 2008 drilling program consisted of 27 holes totalling 6,129.5 m (two abandoned holes which were re-drilled) testing the three main iron occurrences or areas: Mills Lake (6 drillholes), Rose Lake (13 drillholes) and Mart Lake (7 drillholes). Drilling was carried out between June and October.

Logging, Sampling and Assaying

Core logging included descriptive logging and Rock quality designation (“RQD”), specific gravity, magnetic susceptibility measurements and core photography.

Sample intervals were determined on a geological basis, as selected by the drill geologist during logging, and marked out on the drill core. Core was first aligned and then sampled systematically at 5 m sample intervals where possible, except where lithological contacts are less than 5 m. All rock estimated to contain abundant iron oxide was sampled. In addition, two 3-m samples on either side of all iron formation were taken, where possible, to bracket all iron formation sequences. Three-part sample tickets, with unique sequential numbers, were used to number and label samples for assay. Core was sawn in half using a rock saw at Altius’ core facility by an Altius geotechnician.

4

Samples were shipped to SGS-Lakefield Minerals Services’, Lakefield, Ontario facility for sample preparation and assay. Samples were crushed riffle split and a portion pulverized to 200 mesh.

Altius’ drill core samples were analyzed for whole rock analysis (“WR”), major element oxides including total Fe2O3 by lithium metaborate fusion XRF, FeO was determined by H2SO4/HF acid digest-potassium dichromate titration, and Fe3O4 by Satmagan. A group of 14 samples were also analysed for S. In-field QA/QC included the insertion into the sample stream of Blanks, quarter core Duplicates and two Certified Reference Standards. A total of 676 samples, including in-field QC materials, were sent for assay.

Data Corroboration

WGM Senior Geologist, David Power-Fardy, P.Geo., accompanied by BCL representative, Mr. Stewart Wallis, P.Geo., and Altius representative Ms. Carol Seymour, Geologist, completed a site visit to the project in October, 2009. Drill core was reviewed at Altius’ core storage facility in Wabush on October 6 and again on October 8. Facilitated by helicopter, Mr. Power-Fardy, Mr. Wallis and Ms. Seymour visited the Property on October 7. WGM independently collected 15 samples from 2008 drillholes and these samples were sent to SGS-Lakefield for analysis.

Adjacent Properties

The northern boundary of the Property is located approximately 6 km south of the Scully Mine of Wabush Mines, owned 100% by Arcelor-Mittal Steel’s Canadian subsidiary Dofasco. The Carol operations (Humphry Mine) owned by Rio Tinto Iron Ore subsidiary IOCC located north of Labrador City, is approximately 18 km north of the Property. QCM’s Mont-Wright Iron Mine, also owned by Arcelor-Mittal Steel is located 9 km west of the Property. The Property is also located approximately 10 km southeast of the Bloom Lake Iron Deposit that is undergoing advanced mine development by Consolidated Thompson Iron Mines Ltd. All of these iron mines in the area extract similar iron mineralization as found at the Property, although for each deposit, there are variations in geology and character of mineralization.

Mineral Processing and Metallurgical Testing

One testwork program completed in 2009 at SGS-Lakefield has been conducted on mineralization from the Property. The metallurgical sample was a composite made from routine sample intervals from drillholes K-08-01 and K-08-18. These intervals of magnetite-rich iron formation, with lower specularite, were selected by Altius as reasonably representative of the overall deposit mineralization. The sample was submitted for a detailed ore characterization including head assays, mineralogy, preliminary grindability and

5

beneficiation testwork including low-intensity magnetic separation (“LIMS”) and gravity separation.

The test combining LIMS and Mozley separations on the LIMS tailings achieved the best overall performance, with weight and TFe recoveries of 40.7% and 88.6%, respectively, at final TFe and SiO2 grades of 67.5% and 3.01%, respectively. This result was a slight improvement in weight yield and 5.3% increase in TFe recovery over the Mozley only result on material with a P80 of 200 microns (65 mesh) which would result in considerably less grinding energy and costs. The most optimal flowsheet may be governed by the need to control manganese levels in the concentrate to meet concentrate specifications.

Conclusions and Recommendations

· Mineralization on the Property comprising iron formation of the Sokoman/Wabush Formation is hosted in a series of upright to slightly overturned anticlines and synclines. Typical of the Wabush area oxide iron formation, it is overlain, and underlain respectively by an Upper Iron Formation (“UIF”) sequence and a Lower iron Formation (“LIF”) sequence, consisting mainly of silicate iron formation with carbonate. The UIF is in turn overlain by Menihek Formation argillaceous schist. The LIF is underlain by quartzites and dolomite formations and more argillaceous/mica schist formations; respectively the Wishart/Carol, Duley/Denault and Attikamagen/Katsao Formations;

· Although Altius’ drillhole collars require survey with DGPS, WGM’s check during its site visit on several collars showed that the collar locations are reasonably accurate. All assays from Altius’ drilling were performed at an accredited laboratory and both Altius and SGS-Lakefield inserted QA/QC materials to endure quality assay results. No samples were, however, re-assayed at a secondary laboratory and this should be standard practice. The drill core samples WGM collected during its site visit were collected independent of Altius and/or BCL and were submitted blind to the laboratory. These samples reported assays reasonably similar to those reported by Altius and thus indicate that Altius’s sample results are reliable;

· In the Mills Lake area, one main tight upright synclinal structure is indicated. This structure has an indicated strike length in the order of 4.3 km. The main zone oxide iron formation where it has been drill tested varies in thickness from less than 40 m to 100 m true thickness. More drilling is required to determine variations in thickness along the indicated structure.

The Mart and Rose Lake areas are characterized by a repetitive series of tight upright to slightly overturned parallel synclines and anticlines containing zones or stratigraphic units of iron formation. In the Rose Lake area, structures have indicated strike lengths in the order of 4.5 km. Drillhole intersections indicate the main zones of dominantly oxide iron

6

formation vary in true thickness from 70 m on fold limbs, to over 300 m in fold hinge areas. On some sections, OIF and SIF are interlayered with argillaceous/micaceous metasediments. In the Mart Lake area, iron formation is less well developed than in the Rose Lake area. Zones of oxide iron formation are thinner and SIF is more prevalent than in the Rose Lake or Mills Lake areas. More drilling is required in all areas to determine the extent and thicknesses of iron formation and confirm structural interpretation;

· Oxide iron formation on the Property consists dominantly of magnetite-rich material, but includes material that is dominantly magnetite and with lesser hematite, dominantly hematite with moderate magnetite, and for some discrete intervals, mainly hematite with very little magnetite. Three hundred and forty-seven of Altius’ 2008 drill core samples were oxide iron formation. These samples averaged 30.67% TFe, 44.40% SiO2 and 1.28% Mn, with an overall average magnetite content of 29.5% determined by Satmagan. Overall hematite content is calculated at nearly 11%. Hematite-rich members of the oxide iron formation sequence contain more manganese than magnetite-rich members;

· The limited metallurgical testwork to date indicates that concentrates with iron and silica grades that meet market specifications for manganese cannot be produced, i.e., in the range of 0.08 to 0.2% MnO, but manganese levels will be lower than those for Scully concentrates and pellets. The market limitations of manganese content will be a concern for portions of the deposit to ensure that the concentrate specifications for manganese can be maintained in a commercial operation; and

· The technology being considered by Wabush Mines to reduce the manganese content in concentrates should be investigated and tested as a possible way to achieve better quality concentrates, as well as increase the proportion of the deposit that can be included in the Mineral Resource.

WGM makes the following recommendations:

1. Contacts are required with government to determine implications of Duley Provincial Park to project development and discuss land use issues regarding existing cottages and recreational facilities and other land use issues south of the park within the Property.

2. Environmental studies should be initiated during the next exploration campaign to identify sensitive issues.

3. Drillhole collars should be DGPS surveyed.

4. External check assays by a secondary laboratory should be a routine part of a standard QA/QC protocol. The labs should be requested to include the results for their internal

7

Standards and Blanks on their certificates of Analysis. Project reports should include a analysis of QA/QC data.

5. Sample IDs through various data tables must be kept consistent in syntax.

6. A better approach to sample database structure than used by Altius would be to include the in-field quality control materials in the main assay table and then code them. This would allow for assay certificates to be directly imported into the table without having to partition out in-field quality control samples.

7. Conduct a metallurgical testwork program to further investigate the metallurgical characteristics and probable commercial flowsheet. This should be carried out on a composite sample from the most recent drill campaign. Then in conjunction with the next drilling campaign, a standard metallurgical concentration test should be carried out to metallurgically map the deposit to guide what areas of the mineralization constitute Mineral Resources. Special attention to the manganese distribution and concentrate specifications should be conducted.

8. Investigate and test the potential to reduce the manganese in the final concentration process as researched by Wabush Mines.

BCL has developed a Phase I program with a budget to advance the Kami Property. The proposed Phase I program consists of:

· Additional linecutting to enable further gravity and magnetic surveys on extension of Mills and Rose Lake grids. Linecutting to infill the Mills Lake grid to 200 m line spacing and to extend the Rose Lake grid to the southwest and northeast as far as Duley Lake; and

· Diamond drilling of approximately 20 drillholes aggregating 3,500 m. This is broken down into: a) seven holes totalling 1,000 m to infill the Mills Lake grid to 200 m spacing, b) four exploration drillholes totalling 600 m to test gravity anomalies or coincident magnetic/gravity anomalies north and southwest of Rose Lake along the strike of the iron formation, c) the remainder of the drilling, approximately nine holes totalling 1,900 m, to commence infilling the Rose Lake grid at 200 m spacing to further define the structure of the deposit.

BCL’s Phase I program totals approximately $1,000,000 and a budget outline is provided below.

8

Phase II work will be carried out contingent on results of Phase I. The purpose of Phase II is to obtain a sufficient density of drilling to enable the preparation of a NI 43-101 compliant Mineral Resources estimate and advance the project towards prefeasibility. Phase II includes expenditures for metallurgical testwork, a prefeasibility study and permitting. Phase II totals approximately $5.5 million.

WGM recommends that BCL incorporate WGM’s recommendations 1 to 8 listed above into their Phase 1 program. This will not add substantially to the current proposed budget and will ensure industry standard practices going forward.

BCL Proposed Exploration Program,

Phase I Kamistiatusset Property

Phase I | | Unit | | Unit Cost

(C$) | | Total Cost

(C$) | |

Linecutting (line km) | | 50 | | $ | 1,000 | | $ | 50,000 | |

Geophysics Surveys, Magnetics and gravity (line km) | | 50 | | $ | 1,300 | | $ | 65,000 | |

Diamond drilling (m) | | 3,500 | | $ | 175 | | $ | 612,500 | |

Diamond drilling support, geology, assays (m) | | 3,500 | | $ | 70 | | $ | 245,000 | |

Contingency, approximately | | | | | | $ | 27,500 | |

GRAND TOTAL PHASE I | | | | | | C$ | 1,000,000 | |

9

2. INTRODUCTION AND TERMS OF REFERENCE

2.1 GENERAL

Altius Minerals Corporation (“Altius”) owns a 100% interest in the iron ore Kamistiatusset Project (the “Kami Project”). 0860132 B.C. LTD. has recently completed an agreement with Altius to acquire theProject. 0860132 B.C. LTD. has assigned the option to Alderon Resource Corp. (Alderon). In this report BCL refers to 0860132 B.C. LTD. and Alderon (“BCL”). The Kamistiatusset property (the “Property”) as shown in Figure 1 is located approximately 10 km from the town of Wabush, Western Labrador and is approximately 6 km south from the Wabush Mines mining lease. The Property straddles the Québec-Labrador provincial border but the majority of it is in Labrador. Altius initiated exploration of the Property in 2006 and has completed field work including prospecting, confirmatory geological mapping, gravity and airborne magnetic surveys and in 2008, a drilling program aggregating 6,029.5 m in 27 drillholes. Some historical exploration results are available, but these appear to be of limited value. Much of the description and summary for the results of the surface exploration and drilling programs are contained in Section 9 of this report titled: Mineralization.

2.2 TERMS OF REFERENCE

Watts, Griffis and McOuat Limited (“WGM”) was retained by BCL to complete a review of the Kami Project and document the results in an independent technical report prepared in compliance with Canadian National Instrument (“NI 43-101”) standards and guidelines. WGM understands that the report will be used to satisfy certain TSX Venture exchange listing requirements per Alderon’s application.

This technical report is copyright protected; the copyright is vested in WGM, and this report or any part thereof may not be reproduced in any form or by any means whatsoever without the written permission of Watts, Griffis and McOuat Limited. Furthermore, WGM permits the report to be used as a basis for project financings and for filing on SEDAR. Part or all of the report may be reproduced by BCL in any subsequent reports, with the prior consent of WGM.

The preparation of this report was authorized by Mr. Mark J. Morabito, President of 0860132 B.C. Ltd. on September 28, 2009.

10

Figure 1. Property Location

11

2.3 SOURCES OF INFORMATION

Much of the material used to prepare this report has been provided by Altius. This data included assessment reports completed for Altius, and filed with the Department of Natural Resources Government of Newfoundland and Labrador to document its 2006, 2007 and 2008 exploration programs. These assessment filings often contain reports by several contractors including geophysical contractors. Other sources of historic exploration and generalgeological information include the Ministère des Resources Naturelle et Fauna du Québec (“MNRF”) and the Geological Survey of Canada. WGM reviewed the documents available, corroborated a number of details concerning the Property and deposit geology.

Additional information was sourced from WGM files. WGM had been auditing the Mont-Wright operation for Québec Cartier Mining Company (“QCM”) since 1994 on a biennial basis. WGM managed the exploration and analytical program for QCM on the Bloom Lake Project in 1998-99 and completed an internal Mineral Resource estimate. WGM was also retained by Consolidated Thompson-Lundmark Gold Mines Limited, now Consolidated Thompson Iron Mines Ltd. (“Consolidated Thompson”), to update the Bloom Lake Project report and complete a NI 43-101 compliant Mineral Resource estimate in 2005. These other deposits are in the vicinity of the Property and details of their geology and mineralization are relevant to the Property.

WGM Senior Geologist, Mr. David Power-Fardy, P.Geo., QP visited the Property in October 2009 and reviewed Altius’ program results with Carol Seymour, B.Sc., Project Geologist for Altius and Mr. C. Stewart Wallis, P.Geo., representing BCL. Mr. Power-Fardy also collected independent drill core samples during his site visit. Co-authors of this report, WGM Senior Associate Geologist, Mr. Richard Risto P.Geo., QP and WGM Senior Associate Metallurgical Engineer G. Ross MacFarlane, P.Eng., QP, have not visited the Property.

A complete list of the material reviewed is found in the “References” section of this report.

2.4 UNITS AND CURRENCY

Metric units are used throughout this report unless specified otherwise and all dollar amounts are quoted in Canadian currency (“C$”). Historical data and some government map data are generally in Imperial units. WGM has converted the necessary data for inclusion in this report, although Imperial units are often provided for clearer reference to historical data.

12

Altius’ 2006, 2007 and 2008 surface and drill core samples were analysed by X-Ray Florescence (“XRF”) methods on metaborate discs by SGS Minerals Services (“SGS-Lakefield”) at its Lakefield, Ontario facility. Iron results on SGS-Lakefield certificates of analysis are reported in the form of Fe2O3 and are total iron. Total Iron (“TFe”) refers to the total iron in a sample. TFe is calculated from Fe2O3 by dividing the Fe2O3 wt% value by 1.4295. TFe assays are often completed on both Head and Crude samples of rock and also on the concentrates produced from the rock. %TFe Head or %TFe_H refers to the percent total iron in a Head or Crude sample. %SiO2_H represents silica in the Head or Crude sample.

Altius’ 2008 drill program on the Property, in addition to using chemical assays, also included determining magnetic iron, or the magnetite content of samples using the Satmagan method (Satmagan is an acronym for Saturation Magnetization Analyzer). Satmagan refers to an electromagnetic method to estimate the magnetite content of a sample. These assays are expressed as %Fe3O4 or as %magnetite (“Mt”).

Altius also completed a bench scale metallurgical testwork program on one composite sample from the Property in 2009. This testwork included the preparation of Davis Tube concentrates (“DTCs”) for drillhole samples. The Davis Tube provides an alternative method to Satmagan for estimating the magnetic iron content of a sample. The Davis Tube refers to the equipment and a procedure that produces a mineral concentrate high in magnetic iron by separating that portion of the sample that is magnetic from the portion that is non-magnetic, following sample comminution. Percent Davis Tube Weight Recovery (“%DTWR”) refers to the weight percent of the sample concentrated in the magnetic fraction using the Davis Tube procedure. The result is approximately the same as percent magnetite in the crude sample, but degree of liberation of the magnetite is an issue. Davis Tube concentrates are also assayed for iron and other oxides expressed in weight percent. %Fe_DTC and %SiO2_DTC refer respectively to the iron and silica content in Davis Tube concentrates and a number of other elements are often expressed in this same way. The %magnetic iron in the Crude sample can be estimated by multiplying the %DTWR figure by the %Fe in the Davis Tube concentrate. Total Iron Recovery (“TFe Recovery” or Rec’y) is the %TFe units recovered in the concentrate compared to the TFe in the Crude sample.

Other whole rock analysis results for samples are expressed in weight percent (“Wt%”). Table 1 documents several of the commonly used abbreviations and acronyms in the text of this report.

13

TABLE 1.

SUMMARY OF TERMS AND ABBREVIATIONS FOR UNITS

Abbreviation | | Term |

% or Wt% | | Weight Percent |

Head or Crude or H | | Non-concentrated material |

TFe | | Total Iron |

SFe | | Soluble iron |

Fe | | Iron; SFe and TFe |

DT, DTC or C | | Davis Tube, Davis Tube Concentrate, Concentrate |

%DTWR | | % Davis Tube Weight Recovery |

%Wt Recovery | | General term for weight recovery |

TFe Recovery or Rec’y | | %TFe units recovered compared to TFe units in Head |

14

3. RELIANCE ON OTHER EXPERTS

WGM prepared this study using the resource materials, reports and documents as noted in the text and “References” at the end of this report.

WGM has not independently verified the legal title to the Property. We are relying on public documents and information provided by Altius and BCL for the descriptions of title and status of the Property agreements.

Drill core and surface rock samples collected by Altius were submitted by Altius to SGS-Lakefield which is an accredited laboratory. Although WGM has reviewed the assay results generated by SGS-Lakefield and believes they are accurate, WGM is relying on SGS-Lakefield.

We have also not carried out any independent geological surveys of the Property, but did complete a site visit in October 2009 to view first-hand the Property site, view 2008 drill core, collect samples from the drill core and to review historic exploration and development work. These samples were collected and assayed independently of BCL to validate Altius’ results. We have relied for our geological descriptions and program results solely on the basis of historic reports, notes and communications with BCL and Altius.

15

4. PROPERTY DESCRIPTION AND LOCATION

4.1 PROPERTY LOCATION

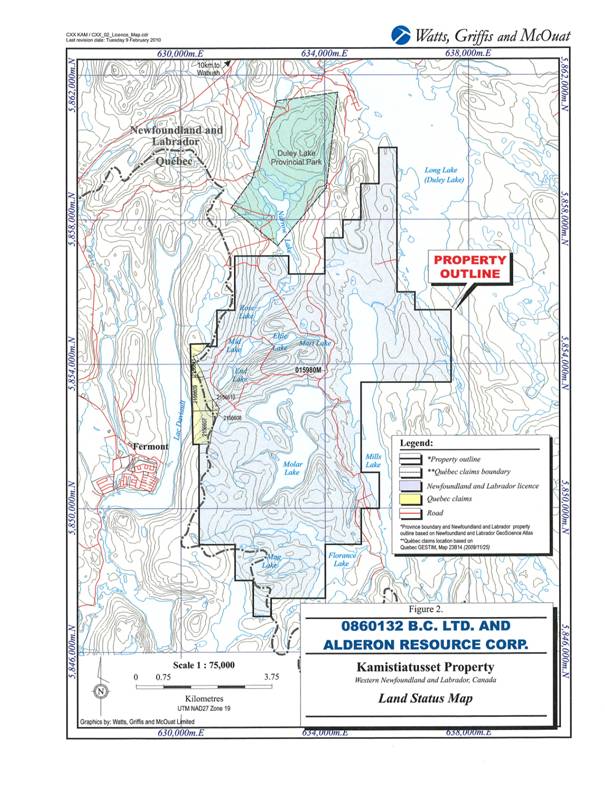

The Property is located in western Labrador and eastern Québec and straddles the interprovincial boundary. It is approximately 10 km southwest from the town of Wabush, Newfoundland and Labrador and immediately adjacent (east) of the town of Fermont in Québec. The Property perimeter is approximately 6 km southwest from the Wabush Mines mining lease. The Property spans an area that extends about 7 km east-west and 13 km north-south in NTS map areas 23B/14 and 15 and centred at approximately 52°49’N latitude and 67°02’W longitude.

4.2 PROPERTY DESCRIPTION AND OWNERSHIP

The Property is mainly located in Labrador but also a group of contiguous licences is held in Québec. The total area of the Property is nominally 4,900 ha but some of the claims in Labrador and Quebec overlap slightly. The Property in Labrador comprises one map-staked licence, 015980M, totalling 191 claim units covering 4,775 hectares issued December 29, 2004. This license, issued in 2009, replaced licenses 014957M, 014962M, 014967M, 014968M and 015037M. Surface rights on the acquired lands are held by the provincial governments but may be subject to First Nations Rights. Table 2 provides details of the current mineral land holdings in Labrador.

TABLE 2.

KAMISTIATUSSET PROPERTY IN LABRADOR

Licence | | Claims | | Area (ha) | | NTS Areas | | Issuance Date | | Renewal Date | | Report Date |

015980M | | 191 | | 4,775 | | 23B14 23B15 | | Dec 29, 2004 | | Dec 29, 2014 | | March 1, 2010 |

The Property in Québec consists of five map-staked licenses covering a nominal area of 125.46 ha. Table 3 provides details of the mineral land holdings in Québec.

TABLE 3.

KAMISTIATUSSET PROPERTY IN QUÉBEC

Licence | | Area

(ha) | | NTS

Areas | | Registration

Date | | Expiry

Date | | Designation

Date | | Work Necessary

for Renewal($) | | Required Fees

for Renewal($) | |

CDC2156611 | | 25.03 | | 23B14 | | May 29, 2008 | | May 28, 2010 | | Mar 27, 2008 | | 120.00 | | 96.00 | |

CDC2156609 | | 45.31 | | 23B14 | | May 29, 2008 | | May 28, 2010 | | Mar 27, 2008 | | 135.00 | | 107.00 | |

CDC2156607 | | 49.4 | | 23B14 | | May 29, 2008 | | May 28, 2010 | | Mar 27, 2008 | | 135.00 | | 107.00 | |

CDC2156610 | | 3.50 | | 23B14 | | May 29, 2008 | | May 28, 2010 | | Mar 27, 2008 | | 48.00 | | 26.00 | |

CDC2156608 | | 4.22 | | 23B14 | | May 29, 2008 | | May 28, 2010 | | Mar 27, 2008 | | 48.00 | | 26.00 | |

Total | | 125.46 | | | | | | | | | | | | | |

16

The Property land holdings are depicted on Figure 2.

The Property has not been legally surveyed, but the claims and licences both in Québec and Labrador were map-staked and are defined by UTM coordinates, so the Property location is accurate.

In Labrador, a mineral exploration licence is issued for a term of five years. However, a mineral exploration licence may be held for a maximum of twenty years provided the required annual assessment work is completed and reported upon and the mineral exploration licence is renewed every five years. The minimum annual assessment work required to be done on a licence are:

$200/claim in the first year

$250/claim in the second year

$300/claim in the third year

$350/claim in the fourth year

$400/claim in the fifth year

$600/claim/year for years six to ten, inclusive

$900/claim/year for years eleven to fifteen, inclusive

$1,200/claim/year for years sixteen to twenty, inclusive.

The renewal fees are:

for Year five $25/claim

for Year ten $50/claim

for Year fifteen $100/claim.

The minimum annual assessment work must be completed on or before the anniversary date. The assessment report must then be submitted within 60 days after the anniversary date.

The Property is now in its 5th year. Total expenditures on the 191 claims to date accepted by the Department of Mines and Energy total $2,423,380.05. Accepted expenditures in 2008 amounted to $1,855,089. Government claim records indicate that to maintain the Property in good standing, through December 29, 2018, a total of $171,900 of acceptable work expenditures are required.

In Québec, the term of a claim is two years from the day the claim is registered, and the claim can be renewed indefinitely providing the holder meets all the conditions set out in the Mining Act, including the obligation to invest a minimum amount required in exploration work

17

Figure 2. Land Status Map

18

determined by regulation. The Act includes provisions to allow any amount disbursed to perform work in excess of the prescribed requirements to be applied to subsequent terms of the claim.

The claim holder may renew title for a two year period by:

· submitting an application for renewal prior to the claim expiry date;

· paying the required fees, which vary according to the surface area of the claim, its location, and the date the application is received. If renewal application is received 60 days prior to the claim expiry date, the regular fees apply; if it is received within 60 days of the claim (prior to expiry date) expiry date, the fees are doubled; and submitting an assessment work report and the work declaration form at least 60 days before the claim expiry date. If the remittance of these documents is made during the 60 days prior to the expiry date, a penalty fee of $100 per claim is applied for the late submission.

BCL’s Québec claims range in size from approximately 3 ha to 50 ha and fees for renewal vary with claim size as listed in Table 3. If renewals are late, then late fees apply. If the required work was not performed or was insufficient to cover the minimums required, then the claim holder may pay a sum equivalent to the minimum cost of work that should have been performed. Assessment work requirements escalate with renewal term and all fees are subject to revision (Table 4). After a claim’s 6th term, which would be at the end of its 12th year of validity, assessment costs are static. None of BCL’s Québec claims have been renewed so all are in their first term. To renew these claims for their second term, exploration work ranging in value from $48 to $135 per claim will be required, depending on the claim concerned because the claim size varies.

TABLE 4.

MINIMUM COST OF WORK TO BE CARRIED OUT

ON A QUÉBEC CLAIM NORTH OF 52° LATITUDE

| | Area of Claim | |

Term | | Less than 25 ha | | 25 to 45 Ha | | Over 45 Ha | |

1 | | 48 | | $ | 120 | | $ | 135 | |

2 | | 160 | | $ | 400 | | $ | 450 | |

3 | | 320 | | $ | 800 | | $ | 900 | |

4 | | 480 | | $ | 1,200 | | $ | 1,350 | |

5 | | 640 | | $ | 1,600 | | $ | 1,800 | |

6 | | 750 | | $ | 1,800 | | $ | 1,800 | |

7 and over | | 1,000 | | $ | 2,500 | | $ | 2,500 | |

19

4.3 PROPERTY AGREEMENTS

According to the agreement of November 2, 2009 (the “Altius Option Agreement”), 0860132 B.C. LTD. acquired an option (the “Option”) to earn a 100% interest in the Property, from Altius, subject to certain royalties. The Option shall be exercisable by 0860132 B.C. LTD. for 24 months following November 2, 2009.

In order to exercise the Option 0860132 B.C. LTD. must:

· Assign the Option to a company (“Pubco”) acceptable to Altius; this condition has been met with the assignment of the Option to Alderon;

· Satisfy the exploration obligations, which include:

· incurring cumulative exploration expenditures of at least $1,000,000 within 12 months from the execution date of the agreement;

· incurring exploration expenditures of at least $5,000,000 or incurring exploration expenditures of $2,500,000 and paying Altius the difference between actual exploration expenditures and $5,000,000 within a period of 24 months from the execution date;

· Arrange for Pubco, before the closing, to conduct one or more equity financings for gross proceeds of at least $5,000,000 – the seed financing threshold;

· Arrange for Pubco, to issue to Altius, shares of Pubco equal to 50% of the issued and outstanding capital of Pubco on a fully diluted basis, calculated at the time the seed financing threshold is obtained; and

· Arrange for Pubco to complete subsequent to the closing date, an equity financing of at least $5,000,000 – the secondary financing.

Altius has the option to repurchase the entire 100% interest in the Property for $2,500,000 if the secondary financing is not completed within 12 months of the closing. Upon Pubco acquiring 100% interest in the Property, it shall grant Altius a 3% gross sales royalty. 0860132 B.C. LTD. also maintains a right of first refusal concerning other property in western Labrador iron ore mining district should Altius wish to sell or dispose of any property.

On December 15, 2009, 0860132 B.C. LTD., Mr. Mark Morabito and Alderon entered into a definitive Share Exchange Agreement (the “Share Exchange Agreement”) whereby Alderon will acquire all of the issued and outstanding shares of 0860132 B.C. LTD. from Mr. Morabito in consideration of issuing 5,000,000 shares of Alderon to Mr. Morabito. Also on December 15, 2009 Alderon, 0860132 B.C. LTD. and Altius entered into an assignment

20

agreement (the “Assignment Agreement”) pursuant to which Alderon assumed the obligations of Pubco under the Altius Option Agreement. The conditions of closing set out in the Share Exchange agreement include, among others, that:

· all necessary consents, approvals and other authorizations of any regulatory authorities, shareholders or third parties;

· Alderon shall have completed an equity financing to raise gross proceeds of not less than $1,500,000 by issuing 10,000,000 subscription receipts at a price of $0.15 per subscription receipt and upon satisfaction of certain conditions, each subscription receipt will automatically convert into one-post-consolidated common share of Alderon, for no additional consideration; (completed) and

· all terms and conditions of the Altius Option Agreement shall have been complied with.

As far as WGM is aware, except for the Alderon Share Exchange Agreement and the Assignment Agreement, 0860132 B.C. LTD. has completed no third party property agreements concerning the Property.

4.4 PERMITTING

No permits have so far been obtained for future exploration programs.

4.5 ENVIRONMENTAL ISSUES

The Property is located immediately to the south of Duley Lake Provincial Park. A part of the watershed on the Property drains into the Park. This may be a sensitive issue for any mine development and WGM urges BCL to discuss the implications with the Government of Newfoundland and Labrador. WGM is also aware that there are a number of cottages on the Property along various rivers and lakes. Any mining operation will impact these buildings and recreational facilities and will also have to be dealt with. Tailings disposal will also be an issue for the Ministry of Fisheries and Oceans, Government of Canada.

Neither BCL nor Altius have conducted any environmental studies to date on the Property. During the next phase of work, flora, fauna and baseline water quality surveys should be initiated.

21

4.6 FIRST NATION ISSUES

Three Aboriginal groups: the Labrador Innu Nation, the Innu Takuaikan Uashat Mak Mani-Utenam of Sept-Îles and the Matimeskush-Lac John of Schefferville have unresolved land claims in the area. WGM is not aware of any First Nation issues concerning the Property but recommends BCL contact and consult these groups.

22

5. ACCESS, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE

AND PHYSIOGRAPHY

5.1 ACCESS

The Property is accessible from Labrador City/Wabush, Newfoundland via 4x4 vehicle roads. All-Terrain Vehicle (“ATV”) trails enable access to the remainder of the Property. Wabush is serviced daily by commercial airline form Sept-Îles, Montreal and Québec City and also by flights from points east.

5.2 CLIMATE

The climate in the region is typical of north-central Québec/Western Labrador. Winters are harsh, lasting about six to seven months, with heavy snow from December through April. Summers are generally cool and wet; however, extended day-light enhances the summer work-day period. Early and late-winter conditions are acceptable for ground geophysical surveys and drilling operations.

5.3 PHYSIOGRAPHY

The Property is characterized by gently rolling hills and valleys that trend northeast-southwest to the north of Molar Lake and trend north-south to the west of Molar Lake reflecting the structure of the underlying geology. Elevations range from 1,950 ft to 2,300 ft.

The Property area drains east or north into Duley Lake. A part of the Property drains north into the Duley Lake Provincial Park before draining into Duley Lake.

In the central Property area, forest fires have helped to expose outcrops; the remainder of the Property has poor outcrop exposure (see Figure 1). The cover predominantly consists of various coniferous and deciduous trees with alder growth over burnt areas.

5.4 LOCAL RESOURCES AND INFRASTRUCTURE

The centre of the Property is within 16 km of the railroad and power lines located in the town of Wabush. Infrastructure near Wabush Mines perhaps provides an alternative closer source of power. A qualified work force is located within the general area due to the operating mines and long history of exploration in this region.

23

6. HISTORY

6.1 GENERAL

A summary of the historical work is presented below. WGM believes the historical descriptions presented are generally accurate but WGM has however not independently verified the data.

The earliest geological reconnaissance in the southern extension of the Labrador Trough within the Grenville Province was by prospectors who went there in 1914 in search of gold. Several parties visited the area between 1914 and 1933, but it was not until 1937 that the first geological map and report was published by Gill et al., 1937 (Rivers, 1980).

The metamorphosed iron formation in the vicinity of Wabush Lake was first recognized by Dr. J.E. Gill in 1933. A few years later, the Labrador Mining and Exploration Co. Ltd. (“LM&E”) evaluated the iron formation, but decided it was too lean for immediate consideration (Gross et al., 1972).

In 1949, interest in the Carol Lake area by LM&E was renewed and geological mapping was carried out in the Duley Lake - Wabush Lake area by H.E. Neal. The work was done on a scale of 1”= 1/2 mi. and covered an area approximately 8 km wide by 40 km long from Mills Lake northward to the middle of Wabush Lake. This work formed part of the systematic mapping and prospecting carried on by LM&E in their concession.

Concentrations of magnetite and specularite were found in many places west of Duley Lake and Wabush Lake during the course of Neal’s geological mapping. Broad exposures of this enrichment, up to 1.2 km long, assayed from 35 to 54% Fe and 17 to 45% SiO2. Ten enriched zones of major dimensions were located and six of these were roughly mapped on a scale of 1” = 200 ft. Seventy-four samples were sent to Burnt Creek for analysis. Two bulk samples, each about 68 kg, were taken for ore dressing tests. One was sent to the Hibbing Research Laboratory, the other to the Bureau of Mines, Ottawa. The material was considered to be of economic significance, as the metallurgical tests indicated that it could be concentrated.

Geological mapping on a scale of 1”= 1/2 mi was carried out by H.E. Neal in the Wabush Lake - Shabogamo Lake area in 1950. Neal (1951) also reported numerous occurrences of pyrolusite and psilomelane (botryoidal goethite being frequently associated with the manganese) within the iron formation and quartzite.

24

Mills No. 1 was one of the iron deposits discovered in 1950 and was sampled and described at that time. A narrow irregular band of pyrolusite was reported to extend for 457 m within a friable magnetite-hematite iron formation located 914 m southwest of the prominent point on the west side of Mills Lake (Neal, 1951).

In 1951, nearly all of the concession held by LM&E within the Labrador Trough was flown with an airborne magnetometer. This survey showed the known deposits to be more extensive than apparent from surface mapping and suggested further ore zones in drift-covered areas (Hird, 1960).

In 1953, a program of geological mapping in the Mills Lake - Dispute Lake area was conducted by R.A. Crouse of the Iron Ore Company of Canada (“IOCC”). Crouse (1954) considered the possibility of beneficiating ores within the iron formation and all high magnetic anomalies and bands of magnetite-specularite iron formation were mapped in considerable detail. Occurrences of friable magnetite-specularite gneiss, containing enough iron oxides to be considered as beneficiating ore, were found in several places west of Duley Lake and northwest of Canning Lake. Representative samples assayed 18.55 to 43.23% Fe and 26.66 to 71.78% SiO2 (Crouse, 1954). Seven zones of this material were located in the area. Three of these (one of which was Mills No. 1 Deposit) were mapped on a scale of 1”=200 ft. On two of these occurrences, dip needle lines were surveyed at 122 m (400 ft) intervals. Forty-two samples were sent to the Burnt Creek Laboratory for analysis. Three samples were sent to Hibbing, Minnesota for magnetic testing (Crouse, 1954). Crouse (1954) reported that at Mills No. 1 the ore was traced for a distance of 488 m along strike, with the minimum width being 107 m.

In 1957, an area of 86.2 km2 to the west of Duley Lake was remapped on a scale of 1”= 1,000 ft and test drilled by IOCC to determine areas for beneficiating ore. Dip needle surveying served as a guide in determining the locations of iron formation in drift-covered areas. According to Hird (1960), 272 holes for a total of 7,985 m (26,200 ft) were drilled during the 1957 program (approximately 66 holes are located on the Property). Mathieson (1957) reported that there were no new deposits found as a result of the drilling, however, definite limits were established for the iron formation found during previous geological mapping. Three zones of “ore” were outlined, which included Mills No. 1, and an area of 19.1 km2 was blocked out as the total area to be retained (Mathieson, 1957). According to Mathieson (1957), the Mills No.1 zone was outlined by six drillholes and found to have a maximum length of 3,048 m (10,000 ft) and a maximum width of 610 m (2,000 ft). Mathieson (1957) describes mineralization to be composed of specularite with varying amounts of magnetite grading on average 32.1% Fe. A search by Altius for the logs and/or

25

core from the 1957 LM&E drilling program has not been successful. From local sources, it is known that all holes drilled in this area were of small diameter and very shallow (~30 m).

Early in 1959, a decision was made by IOCC to proceed with a project designed to open up and produce from the ore bodies lying to the west of Wabush Lake and a major program of construction, development drilling and ore testing was started in the Wabush area (Macdonald, 1960). Geological mapping (1”=1,000 ft) and magnetic profiling were conducted by R. Nincheri of LM&E in the Duley - Mills Lake area that year. Zones of potential beneficiating ores were located to the southwest of Mills Lake (Nincheri, 1959).

In 1972, an extensive airborne electromagnetic survey covered 2,150 km2 of territory, and entailed 2,736 line km of flying in the Labrador City area. The area covered extended from the southern extremity of Kissing Lake to north of Sawbill Lake, and from approximately the Québec-Labrador border on the west to the major drainage system, through Duley, Wabush and Shabogamo Lakes on the east. The survey was done by Sander Geophysics Ltd. (for LM&E) using a helicopter equipped with a NPM-4 magnetometer, a fluxgate magnetometer, a modified Sander EM-3 electromagnetic system employing a single coil receiver, and a VLF unit (Stubbins, 1973).

In 1972 to 1973, an airborne magnetic survey was conducted over the area by Survair Ltd., Geoterrex Ltd., Lockwood Survey Corporation Ltd. for the Geological Survey of Canada (GSC, 1975).

In 1977, geological mapping was initiated by T. Rivers of the Newfoundland Department of Mines and Energy within the Grenville Province covering the Wabush-Labrador City area. This work was part of the program of 1:50,000 scale mapping and reassessment of the mineral potential of the Labrador Trough by the Newfoundland Department of Mines and Energy. Mapping was continued by Rivers in western Labrador in 1978 to 1980. As part of an experimental geochemical exploration program in Labrador by LM&E in 1978, many of the lakes in the Labrador City area were sampled both for lake-bottom sediments and for lake-water (Stubbins, 1978). Lake sediment samples were sent to Barringer Research Ltd., Toronto, Ontario, for a multi-element analysis (Stubbins, 1978). Water samples were tested at Labrador City for acidity before being acidified for shipment. Some samples were also shipped to Barringer analysis and some were analysed in the Sept-Îles laboratory of IOCC. A sample portion was also sent to the Hibbing Minnesota laboratory of Learch Brothers for additional analysis (Stubbins, 1978). On Block No. 24 (part of the Property), only one site was sampled. The sediment assay results indicated the sample to be statistically ‘anomalous’ in phosphorous. None of the water samples were defined as anomalous (Stubbins, 1978). Stubbins (1978) concluded that the samples as a group are widely scattered and it is difficult

26

to draw any firm conclusion from the results. He added that further study might indicate that it is worthwhile to take more samples.

In 1979, a ground magnetometer survey was conducted on Block No. 24 (part of the Property). A total of four lines having a combined length of 3,500 m were surveyed on this block (Price, 1979). The standard interval between successive magnetometer readings was 20 m. Occasionally, over magnetically ‘quiet’ terrain, this interval was increased. Whenever an abrupt change in magnetic intensity was encountered, intermediate stations were surveyed. According to Price (1979), the magnetometer profiles and observations of rare outcrops confirm that oxide facies iron formation occurs on Block No. 24 (in the Mills No. 1 area of the Property). Also in 1979, one diamond drillhole was drilled by LM&E near the north end of Elfie Lake on the Property. The hole (No. 57-1) was drilled vertically to a depth of 28 m (Grant, 1979) and did not encounter the iron oxide facies of interest. In 1983, LM&E collared a 51 m deep (168 ft) diamond drillhole 137 m north of Elfie Lake (DDH No. 57-83-1). The drillhole encountered metamorphosed iron formation from 17 m to a depth of 51 m; of this, only 2 m was oxide facies. Core recovery was very poor (20%) (Avison et al., 1984).

In 1981 and 1982, an air photography and topographic mapping program was completed by IOCC to re-photograph the mining areas as part of its program to convert to the metric system. Two scales of photography (1:10,000 and 1:20,000) were flown and new topographic maps (1:2,000 scale) were made from these photos. The photography was extended to cover all the lease and licence blocks in the Labrador City area (Smith et al. 1981; Kelly and Stubbins, 1983).

A lake sediment and water reconnaissance survey was undertaken by the GSC, in conjunction with the Newfoundland Department of Mines and Energy, over about one-half (134,000 km2) of Labrador during the summers of 1977 and 1978. The survey was designed to provide the exploration industry with data on bedrock composition and to identify metaliferous areas as large scale prospecting targets (McConnell, 1984). Sampling continued in 1982 in south-western Labrador. Waters and sediments from lakes over an area of about 50,000 km2 were sampled at an average density of one sample per 13 km2. Lake sediment samples were analysed for U, Cu, Pb, Zn, Co, Ni, Ag, Mo, Mn, Fe, F, As, Hg and L.O.I. In addition, U, F and pH were determined on the water samples (Davenport and Butler, 1983).

During 1985, field work by C. McLachlan of LM&E was concentrated on the northern part of Block No. 24. A pace and compass grid was established near Molar Lake. Cross lines were put in at 152 m (500 ft) intervals. The grid was used to tie in the sample sites and a systematic radiometric survey was performed. There were four soil samples and six rock samples (one analysed) collected (Simpson et al., 1985). A possible source of dolomite as an

27

additive for the IOCC’s pellet plant was examined near Molar Lake. Simpson concluded from visual examination that the dolomite was high in silica.

In 2001, IOCC staked a considerable portion of the iron formation in the Labrador City area, with the Kamistiatusset area being in the southern extent of the company’s focus. Extensive geophysical testing was conducted over the area using airborne methods. The Kamistiatusset area and the area north of the Property was recommended as a high priority target by SRK Consulting Ltd. as part of the 2001 IOCC work report (GSNL open file LAB1369), however, no work was reported for the area.

In 2004, Altius Resources staked 20 claims comprising licence 10501M, and in the spring of 2006 staked another 38 claims to the north comprising licence 11927M.

28

7. GEOLOGICAL SETTING

7.1 REGIONAL GEOLOGY

The Property is situated in the highly metamorphosed and deformed metasedimentary sequence Knob Lake Group of the Grenville Province, Gagnon terrane of the Labrador Trough (“Trough”), adjacent to and underlain by Archean basement gneiss (Grenville Front), (Figure 3).

The Trough, otherwise known as the Labrador-Québec Fold Belt, extends for more than 1,000 km along the eastern margin of the Superior Craton from Ungava Bay to Lake Pletipi, Québec. The belt is about 100 km wide in its central part and narrows considerably to the north and south.

The Trough is comprised of a sequence of Proterozoic sedimentary rocks, including iron formation, volcanic rocks and mafic intrusions. The southern part of the Trough is crossed by the Grenville Front representing a metamorphic fold-thrust belt in which Archean basement and Early Proterozoic platformal cover were thrust north-westwards across the southern portion of the southern margin of the North American Craton during the 1,000 Ma Grenvillian orogeny (Brown, Rivers, and Callon, 1992). Trough rocks in the Grenville Province are highly metamorphosed and complexly folded. Iron deposits in the Gagnon terrane, Grenville part of the Trough, include those on the Property and Lac Jeannine, Fire Lake, Mont-Wright, Mont-Reed, and Bloom Lake in the Manicouagan-Fermont area and the Luce, Humphrey and Scully deposits in the Wabush-Labrador City area. The high-grade metamorphism of the Grenville Province is responsible for recrystallization of both iron oxides and silica in primary iron formation, producing coarse-grained sugary quartz, magnetite, and specular hematite schist or gneiss (meta-taconites) that are of improved quality for concentration and processing.

North of the Grenville Front, the Trough rocks in the Churchill Province have been only subject to greenschist or sub-greenshist grade metamorphism and the principal iron formation unit is known as the Sokoman Formation. The Sokoman Formation is underlain by the Wishart Formation (quartzite), the Denault Formation (dolomite) and the Attikamagen Formation (shale). In the Grenville part of the Trough, where the Property is located, these same Proterozoic units can be identified, but are more metamorphosed and deformed. In the Grenville portion of the Trough, the Sokoman rocks are known as the Wabush Formation, the Wishart as the Carol Formation (Wabush area) or Wapusakatoo Formation (Gagnon area), the Denault as the Duley Formation and the Attikamagen as the Katsao Formation. In practice,

29

Figure 3. Regional Geology

30

both sets of nomenclature for the rock formations are often used. Altius has used the Menihek, Sokoman, Wishart, Denault, and Attikamagen nomenclature throughout their reports to name rock units on the Property, and WGM, to minimize confusion in this report, has elected to also use these same rock unit names but often gives reference to the other name. The regional stratigraphy is summarized in Table 5.

TABLE 5.

REGIONAL STRATIGRAPHIC COLUMN, WESTERN LABRADOR TROUGH

Description | | |

PROTEROZOIC – Helikian |

Shabogamo Group | | Gabbro, Diabase |

| | |

Intrusive Contact |

|

PROTEROZOIC – Aphebian |

|

| | |

Gagnon Group | | |

Nault Formation (Menihek Formation) | | Graphitic, chloritic and micaceous schist |

Wabush Formation (Sokoman iron formation) | | Quartz, magnetite-specularite-silicate-carbonate iron formation |

Carol Formation (Wishart Formation) | | Quartzite, quartz-muscovite-garnet schist |

Duley Formation (Denault Formation) | | Meta-dolomite and calcite marble |

Katsao Formation (Attikamagen Formation) | | Quartz-biotite-feldspar schist and gneiss |

Unconformity |

| | |

ARCHEAN |

Ashuanipi Complex | | Granitic and Granodioritic gneiss and mafic intrusives |

Note: The names in brackets provide reference to the equivalent units in the Churchill Province part of the Trough.

7.2 PROPERTY GEOLOGY

7.2.1 GENERAL

The most comprehensive mapping of this area was done by T. Rivers as part of his Labrador Trough mapping program of the mid-1980s. Several maps of the area were produced, with the most applicable to this area being Maps 85-25 and 85-24 (1:100,000) covering National Topographic System Sheet 23B/14. Figure 4, Property Geology, is based mainly on River’s work with modifications made by Altius through mapping and interpretation of the high resolution helicopter-borne magnetic survey completed in 2007. Lithological contacts have been further revised during Altius’ 2008 work program using information gathered from diamond drilling.

31

Figure 4. Property Geology

32

The Property is underlain by folded sequences of the Knob Lake Group containing Wabush/Sokoman Formation iron formation. The stratigraphic sequence varies in different parts of the Property. Altius’ exploration was focussed on three parts of the Property known as the Mills Lake, Rose Lake and the Mart Lake areas. On some parts of the Property, the Sokoman/Wabush is directly underlain by Denault/Duley Formation dolomite and the Wishart/Carol Formation quartzite is missing. In other places, both the dolomite and quartzite units are present.

Table 6 presents the lithological codes used by Altius for its drill core logging of 2008 program core.

TABLE 6.

ROCK/UNIT CODING FOR KAMI PROPERTY DRILL CORE LOGGING

Lithology Code | | Description | | Formal Unit Name |

OVB | | Overburden | | |

AMP | | Gabbro /metagabbro / amphibolite schist | | Shabogamo Intrusive Suite |

MSG | | Mica schist with graphite | | Menihek/Nault Formation |

MOIF | | Magnetite-rich oxide iron formation | | Sokoman/Wabush iron Formation |

SOIF | | Specularite-rich oxide iron formation | | Sokoman/Wabush iron Formation |

MSOIF | | Magnetite-specularite-rich oxide iron formation | | Sokoman/Wabush iron Formation |

SMOIF | | Specularite-magnetite-rich oxide iron formation | | Sokoman/Wabush iron Formation |

MGOIF | | Magnetite-rich oxide iron formation with grunerite | | Sokoman/Wabush iron Formation |

SIF | | Silicate iron formation | | Sokoman/Wabush iron Formation |

QRMS | | Quartzite - mica schist | | Wishart/Carol Formation |

QR | | Quartzite | | Wishart/Carol Formation |

Denault | | Calcite marble / dolomitic marble | | Denault/Duley Formation |

BMS | | Biotite - muscovite schist | | Attikamagen/Katsao Formation |

FZ | | Fault zone | | |

SZ | | Shear Zone | | |

Alteration Zone | | Alteration zone | | |

Notes: “M” in lithology codes for oxide iron formation (“OIF”) refers to magnetite; “S” for OIF refers to the presence of specularite. Accordingly MSOIF is nomenclature for Specularite-magnetite oxide iron formation.

Amphibolite dikes and sills cut through all other rock units and are a consideration as they may negatively impact the chemistry of iron concentrates made from mineralization containing these rocks that may be difficult to exclude during mining.

33

7.2.2 STRUCTURE

The structure of the project area is characterized by tight, west verging F1 folds and broad F2 folds, both of which are roughly north to northeast trending, with D1 and D2 thrusts which repeat the stratigraphy. The fold interference of the F1/F2 generations has produced a geometry that is similar to other structures in the district that host economic deposits, specifically, the doubly folded F1/F2 synforms. Significant shear zones were noted in drill core and interpreted on drill cross sections as thrust faults. Moreover, an interpretation of the magnetic survey data highlighted several discontinuities in lithology coinciding with interpreted faults.

34

8. DEPOSIT TYPES

The iron formation on the Property is iron formation of the Lake Superior-type. Lake Superior-type iron formation consists of banded sedimentary rocks composed principally of bands of iron oxides, magnetite and hematite within quartz (chert)-rich rock with variable amounts of silicate, carbonate and sulphide lithofacies. Such iron formations have been the principal sources of iron throughout the world (Gross, 1996). Table 7, after Eckstrand, editor (1984), presents the salient characteristics of the Lake Superior-type iron deposit model.

Lithofacies that are not highly metamorphosed or altered by weathering and are fine grained are referred to as taconite. The KéMag and LabMag deposits owned by New Millennium Capital Corp. located immediately north of Schefferville, Québec are magnetite-rich taconite containing lesser amounts of hematite. The deposits at Schefferville, which were mined by IOCC prior to the mine shutdown in 1982, are supergene residual deposits formed by the leaching of silica and the concentration of iron oxides from what was originally taconite (also called “protore”) resulting in high grade, “Direct Shipping” ores.

Strongly metamorphosed taconites are known as meta-taconite or itabirite (particularly if hematite-rich). The iron deposits in the Grenville part of the Labrador Trough in the vicinity of Wabush and Mont-Wright, operated by IOCC, QCM and Wabush Mines are meta-taconite. The Consolidated Thompson Bloom Lake iron deposit is also a meta-taconite. The iron formation on the Property is similarly Lake Superior-type meta-taconite.

For non-supergene-enriched iron formation to be mined economically, iron content must generally be 25% to 30%, but also the iron oxides must be amenable to concentration (beneficiation) and the concentrates produced must be low in deleterious elements such as silica, aluminium, phosphorus, manganese, sulphur and alkalis. For bulk mining, the silicate and carbonate lithofacies and other rock types interbedded within the iron formation must be sufficiently segregated from the iron oxides. Folding can be important for repeating iron formation and concentrating iron formation beds to create economic concentrations of iron.

35

TABLE 7.

DEPOSIT MODEL FOR LAKE SUPERIOR TYPE IRON FORMATION

AFTER ECKSTRAND (1984)

Commodities | | Fe (Mn) |

Examples:

Canadian - Foreign | | Knob Lake, Wabush Lake and Mont-Wright areas, Que. and Lab. - Mesabi Range, Minnesota; Marquette Range, Michigan; Minas Gerais area, Brazil. |

| | |

Importance | | Canada: the major source of iron.

World: the major source of iron. |

| | |

Typical Grade, Tonnage | | Up to billions of tonnes, at grades ranging from 15 to 45% Fe, averaging 30% Fe. |

| | |

Geological Setting | | Continental shelves and slopes possibly contemporaneous with offshore volcanic ridges. Principal development in middle Precambrian shelf sequences marginal to Archean cratons. |

| | |

Host Rocks or Mineralized Rocks | | Iron formations consist mainly of iron- and silica-rich beds; common varieties are taconite, itabirite, banded hematite quartzite, and jaspilite; composed of oxide, silicate and carbonate facies and may also include sulphide facies. Commonly intercalated with other shelf sediments: black |

| | |

Associated Rocks | | Bedded chert and chert breccia, dolomite, stromatolitic dolomite and chert, black shale, argillite, siltstone, quartzite, conglomerate, redbeds, tuff, lava, volcaniclastic rocks; metamorphic equivalents. |

| | |

Form of Deposit, Distribution of Ore Minerals | | Mineable deposits are sedimentary beds with cumulative thickness typically from 30 to 150 m and strike length of several kilometres. In many deposits, repetition of beds caused by isoclinal folding or thrust faulting has produced widths that are economically mineable. Ore mineral distribution is largely determined by primary sedimentary deposition. Granular and oolitic textures common. |

| | |

Minerals: Principal Ore Minerals - Associated Minerals | | Magnetite, hematite, goethite, pyrolusite, manganite, hollandite.

- Finely laminated chert, quartz, Fe-silicates, Fe-carbonates and Fe-sulphides; primary or. metamorphic derivatives |

| | |

Age, Host Rocks | | Precambrian, predominantly early Proterozoic (2.4 to 1.9 Ga). |

| | |

Age, Ore | | Syngenetic, same age as host rocks. In Canada, major deformation during Hudsonian and, in places, Grenvillian orogenies produced mineable thicknesses of iron formation. |

| | |

Genetic Model | | A preferred model invokes chemical, collodial and possibly biochemical precipitates of iron and silica in euxinic to oxidizing environments, derived from hydrothermal effusive sources related to fracture systems and offshore volcanic activity. Deposition may be distal from effusive centres and hot spring activity. Other models derive silica and iron from deeply weathered land masses, or by leaching from euxinic sediments. Sedimentary reworking of beds is common. The greater development of Lake Superior-type iron formation in early Proterozoic time has been considered by some to be related to increased atmospheric oxygen content, resulting from biological evolution. |

| | |

Ore Controls, Guides to Exploration | | 1. Distribution of iron formation is reasonably well known from aeromagnetic surveys. 2. Oxide facies is the most important, economically, of the iron formation facies. 3. Thick primary sections of iron formation are desirable. 4. Repetition of favourable beds by folding or faulting may be an essential factor in generating widths that are mineable (30 to 150 m). 5. Metamorphism increases grain size, improves metallurgical recovery. 6. Metamorphic mineral assemblages reflect the mineralogy of primary sedimentary facies. 7. Basin analysis and sedimentation modelling indicate controls for facies development, and help define location and distribution of different iron formation facies. |

| | |

Author | | G.A. Gross |

36

9. MINERALIZATION

Mineralization of economic interest on the Property is oxide facies iron formation. The oxide iron formation (“OIF”) consists mainly of semi-massive bands, or layers, and disseminations of magnetite and/or specular hematite (specularite) in recrystallized chert and interlayered with bands (beds) of chert with minor carbonate and iron silicates. Silicate iron formation (“SIF”) also is prevalent on the Property. SIF consists mainly of amphiboles and chert, often associated with carbonate and contains magnetite or specularite in minor amounts.