Exhibit 99.88

AMENDED AND RESTATED

| Camino Rojo Preliminary Economic Assessment | | NI 43-101 Technical Report |

Preliminary Economic Assessment

Amended NI 43-101 Technical Report on the Camino Rojo Gold Project

Municipality of Mazapil, Zacatecas, Mexico

Prepared for:

1240 – 1140 West Pender Street

Vancouver, BC, V6E 4G1

Canada

Prepared by:

| |  | Kappes, Cassiday & Associates 7950 Security Circle Reno, NV 89506 | |

Report Date: June 19, 2018 Mineral Resource Effective Date: April 27, 2018

Amended: March 11, 2019 | Authors: Carl Defilippi, KCA, RM SME Dr. Matthew Gray, RGI, CPG Michael Hester, IMC, FAusIMM |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-1 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

TABLE OF CONTENTS

| | 1.1 | Introduction and Overview | 1-1 |

| | | | |

| | 1.2 | Property Description and Ownership | 1-2 |

| | | | |

| | 1.3 | Geology & Mineralization | 1-2 |

| | | | |

| | 1.4 | Exploration and Drilling | 1-3 |

| | | | |

| | 1.5 | Metallurgical Testwork | 1-4 |

| | | | |

| | 1.6 | Mineral Resource Estimate | 1-4 |

| | | | |

| | 1.7 | Mining Methods | 1-6 |

| | | | |

| | 1.8 | Recovery Methods | 1-7 |

| | | | |

| | 1.9 | Infrastructure | 1-7 |

| | | | |

| | 1.10 | Environmental Studies, Permitting and Social or Community Impact | 1-8 |

| | | | |

| | 1.11 | Capital and Operating Costs | 1-9 |

| | | | |

| | 1.12 | Economic Analysis | 1-10 |

| | | | |

| | 1.13 | Interpretations and Conclusions | 1-13 |

| | 1.13.1 | Conclusions | 1-13 |

| | | | |

| | 1.13.2 | Opportunities | 1-14 |

| | | | |

| | 1.13.3 | Risks | 1-14 |

| | 2.1 | Introduction and Overview | 2-1 |

| | | | |

| | 2.2 | Project Scope and Terms of Reference | 2-2 |

| | 2.2.1 | Scope of Work | 2-2 |

| | | | |

| | 2.2.2 | Terms of Reference | 2-3 |

| | 2.3 | Sources of Information | 2-4 |

| | | | |

| | 2.4 | Qualified Persons and Site Visits | 2-4 |

| | | | |

| | 2.5 | Forward Looking Information | 2-5 |

| | | | |

| | 2.6 | Frequently Used Acronyms, Abbreviations, Definitions and Units of Measure | 2-8 |

| | 3.0 | RELIANCE ON OTHER EXPERTS | 3-1 |

| | | | |

| | 4.0 | PROPERTY DESCRIPTION AND LOCATION | 4-1 |

| | 4.1 | Area and Location | 4-1 |

| | | | |

| | 4.2 | Claims and Title | 4-2 |

| | 4.2.1 | Orla Control of Mining Concessions via Acquisition from Minera Peñasquito SA de CV | 4-6 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-2 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| | 4.3 | Surface Rights | 4-7 |

| | | | |

| | 4.4 | Environmental Liability | 4-11 |

| | | | |

| | 4.5 | Permits | 4-11 |

| | | | |

| | 4.6 | Access, Title, Permit and Security Risks | 4-12 |

| | 4.6.1 | Access Risks | 4-12 |

| | | | |

| | 4.6.2 | Title Risks | 4-12 |

| | | | |

| | 4.6.3 | Permit Risks | 4-12 |

| | | | |

| | 4.6.4 | Security Risks | 4-13 |

| | 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES AND PHYSIOGRAPHY | 5-1 |

| | 5.1 | Accessibility | 5-1 |

| | | | |

| | 5.2 | Physiography, Climate and Vegetation | 5-3 |

| | | | |

| | 5.3 | Local Resources and Infrastructure | 5-4 |

| | 6.1 | Prior Ownership | 6-1 |

| | | | |

| | 6.2 | Prior Exploration | 6-1 |

| | | | |

| | 6.3 | Historical Metallurgical Studies | 6-3 |

| | | | |

| | 6.4 | Historical Resource Estimates | 6-4 |

| | 6.4.1 | Canplats | 6-4 |

| | | | |

| | 6.4.2 | Goldcorp | 6-4 |

| | 7.0 | GEOLOGICAL HISTORY AND MINERALIZATION | 7-1 |

| | 7.1 | Sources of Information | 7-1 |

| | | | |

| | 7.2 | Regional Geology | 7-1 |

| | | | |

| | 7.3 | Local and Property Geology | 7-4 |

| | 7.3.1 | General Deposit Geology | 7-4 |

| | | | |

| | 7.3.2 | Structural Setting | 7-7 |

| | | | |

| | 7.3.3 | Mineralized Zones | 7-7 |

| | | | |

| | 7.3.4 | Alteration | 7-11 |

| | 7.4 | Oxidation | 7-11 |

| | | | |

| | 7.5 | Conclusions | 7-14 |

| | 8.0 | DEPOSIT TYPES | 8-1 |

| | | | |

| | 9.0 | EXPLORATION | 9-1 |

| | | | |

| | 10.0 | DRILLING | 10-1 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-3 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| | 10.1 | General | 10-1 |

| | | | |

| | 10.2 | Canplats Drilling | 10-2 |

| | | | |

| | 10.3 | Goldcorp Drilling | 10-2 |

| | | | |

| | 10.4 | Sampling | 10-4 |

| | | | |

| | 10.5 | Conclusions | 10-4 |

| | 11.0 | SAMPLE PREPARATION, ANALYSES AND SECURITY | 11-1 |

| | 11.1 | Sample Preparation | 11-1 |

| | | | |

| | 11.2 | Analyses | 11-1 |

| | | | |

| | 11.3 | QA/QC Programs | 11-2 |

| | 11.3.1 | Canplats QA/QC Program | 11-2 |

| | | | |

| | 11.3.2 | Goldcorp QA/QC Program | 11-2 |

| | 12.0 | DATA VERIFICATION | 12-1 |

| | | | |

| | 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 13-1 |

| | 13.1 | Canplats (2009) | 13-1 |

| | | | |

| | 13.2 | Goldcorp (2010-2015) | 13-3 |

| | 13.2.1 | Kappes, Cassiday & Associates (2010-2015) | 13-3 |

| | | | |

| | 13.2.2 | Blue Coast Research Metallurgy (2012-2013) | 13-10 |

| | | | |

| | 13.2.3 | Hazen Research (2014) | 13-11 |

| | | | |

| | 13.2.4 | Comminution Testing | 13-12 |

| | 13.3 | Conclusions from Metallurgical Programs | 13-13 |

| | 13.3.1 | Crush Size and Recovery | 13-13 |

| | | | |

| | 13.3.2 | Leach Cycle | 13-16 |

| | | | |

| | 13.3.3 | Reagent Consumption Projection | 13-16 |

| | | | |

| | 13.3.4 | Conclusions and Key Design Parameters | 13-17 |

| | 13.4 | Sulphide Mineralization Discussion | 13-18 |

| | 14.0 | MINERAL RESOURCE ESTIMATES | 14-1 |

| | 14.1.1 | Metal Prices for Mineral Resources | 14-4 |

| | | | |

| | 14.1.2 | Cost and Recovery Estimates for Mineral Resources | 14-4 |

| | | | |

| | 14.1.3 | Parameters for Mill Material | 14-7 |

| | | | |

| | 14.1.4 | Additional Information | 14-8 |

| | 14.2 | Description of the Block Model | 14-11 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-4 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| | 14.2.2 | Geologic Controls | 14-11 |

| | | | |

| | 14.2.3 | Cap Grades and Compositing | 14-21 |

| | | | |

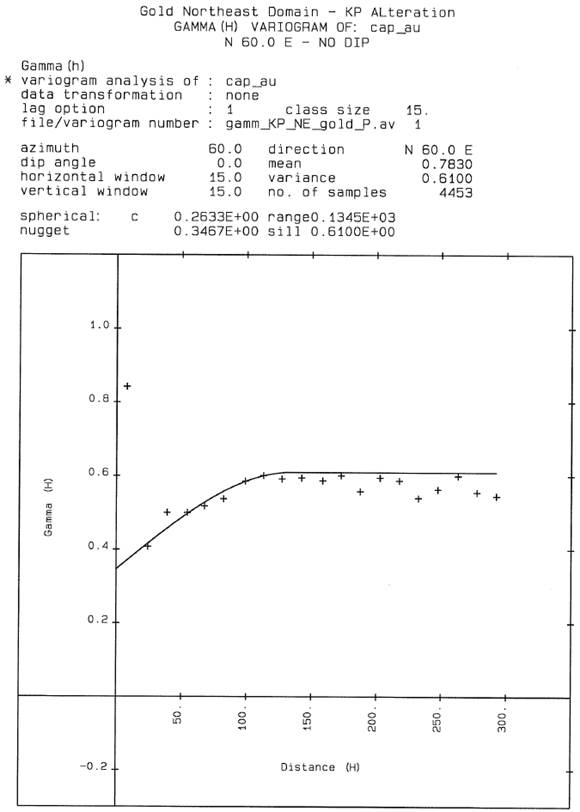

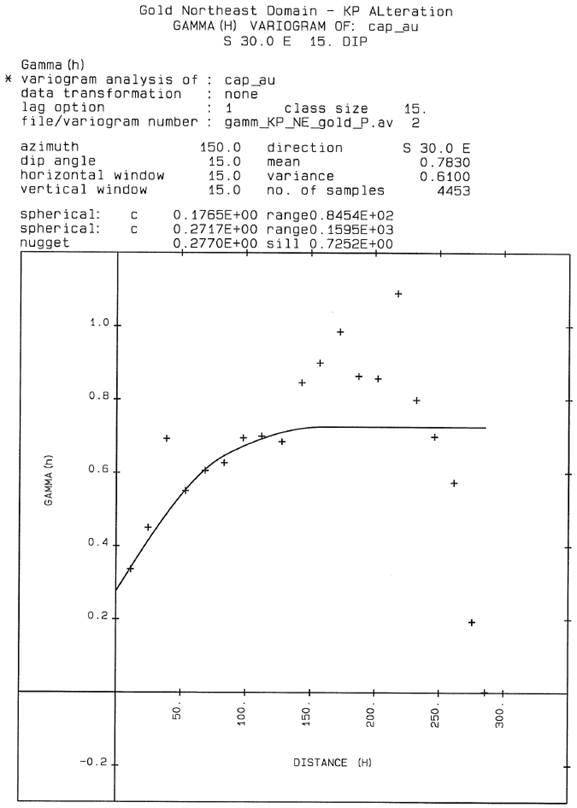

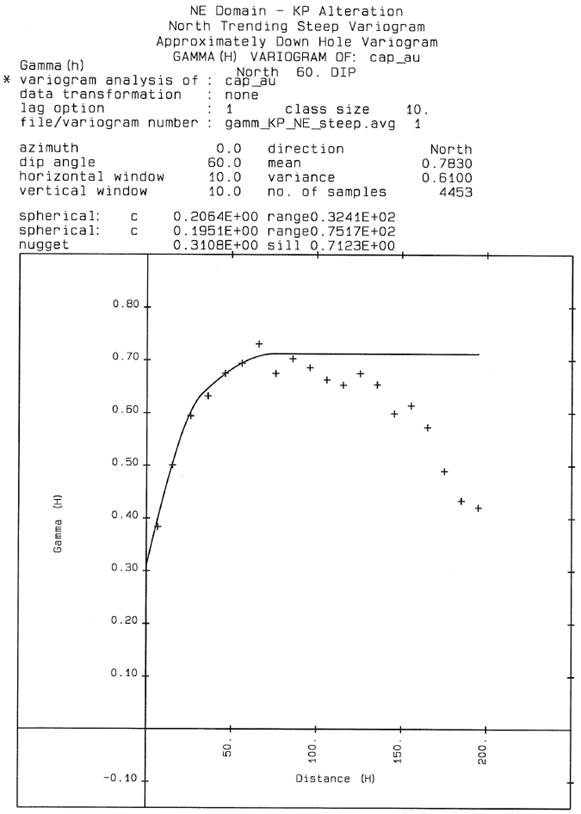

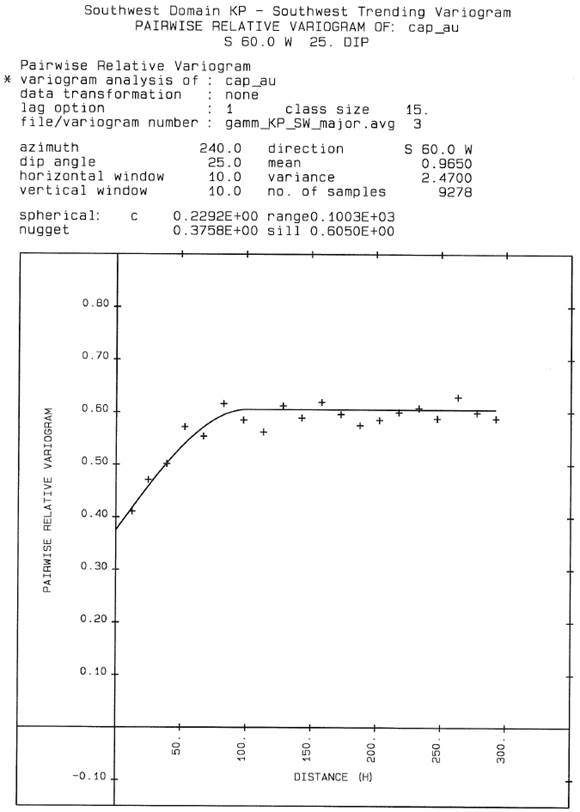

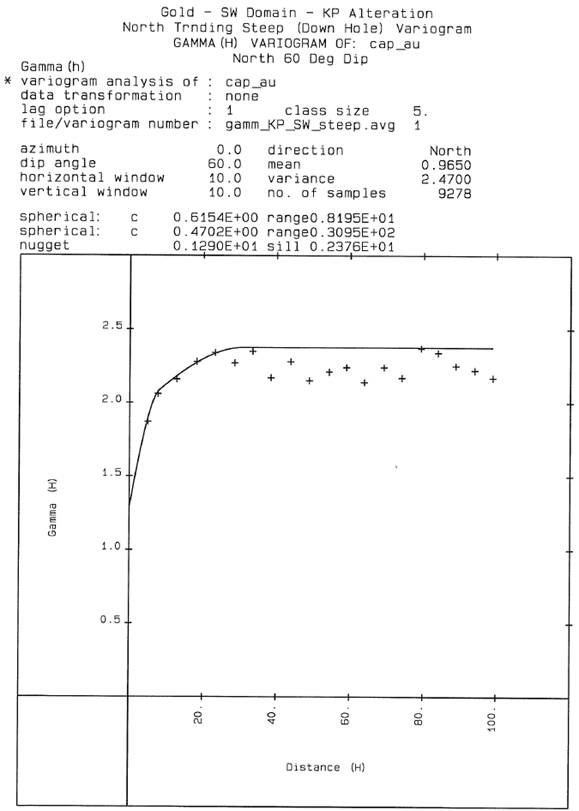

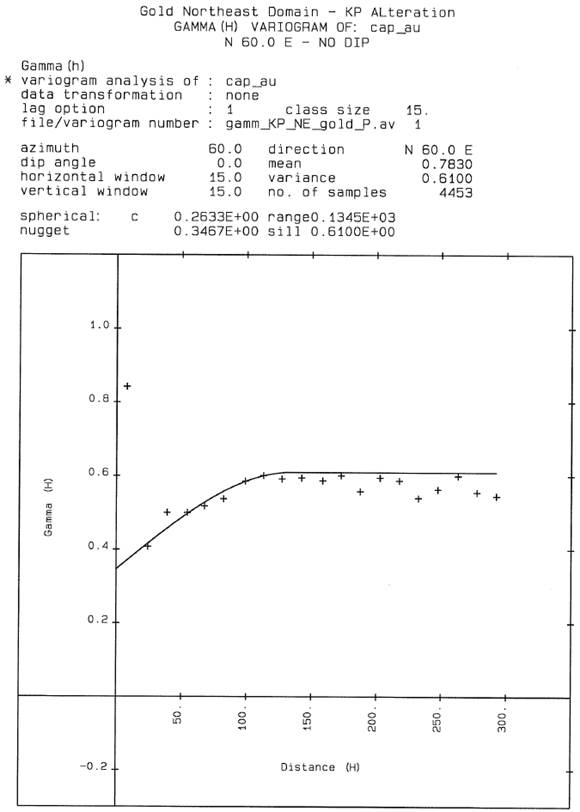

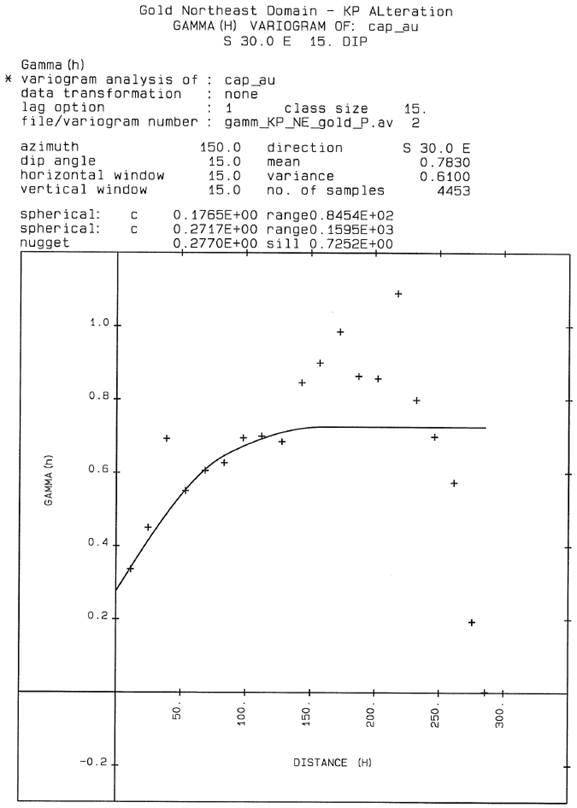

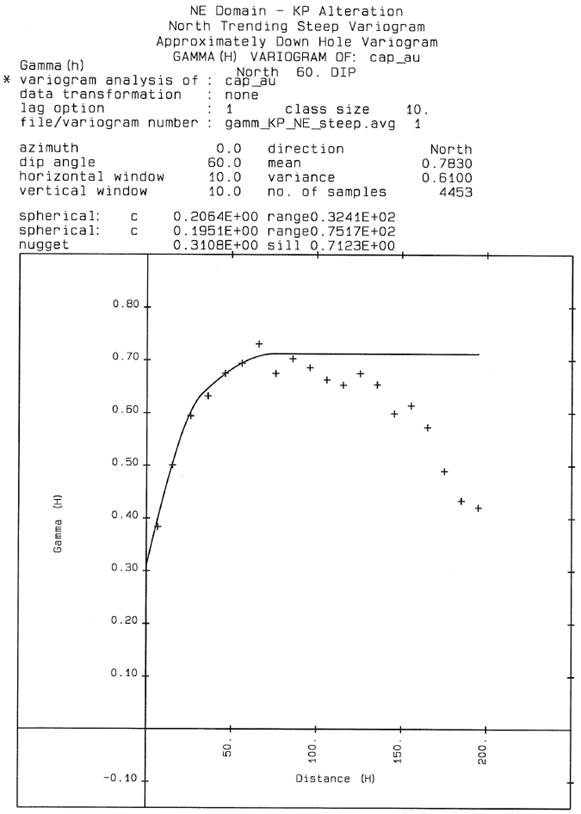

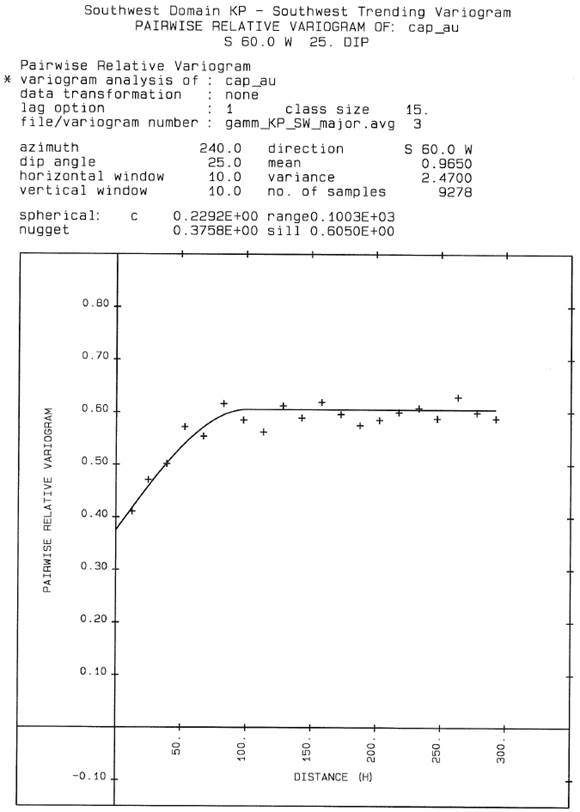

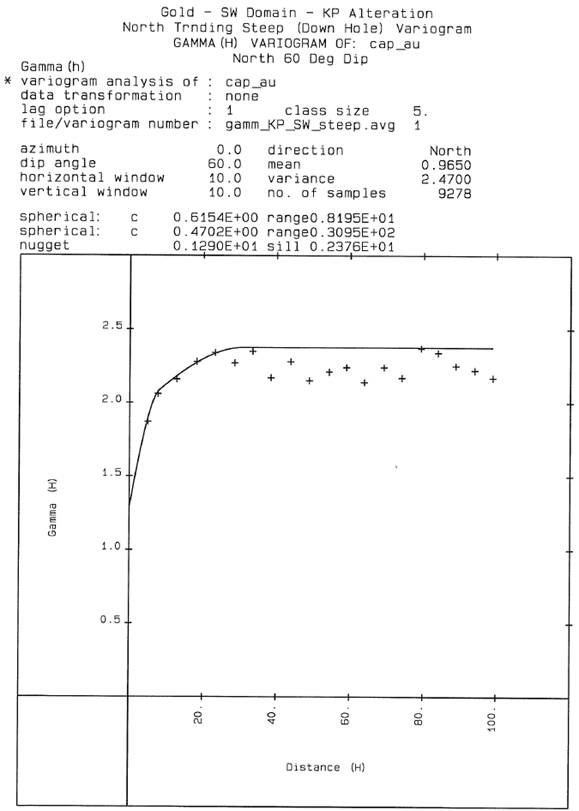

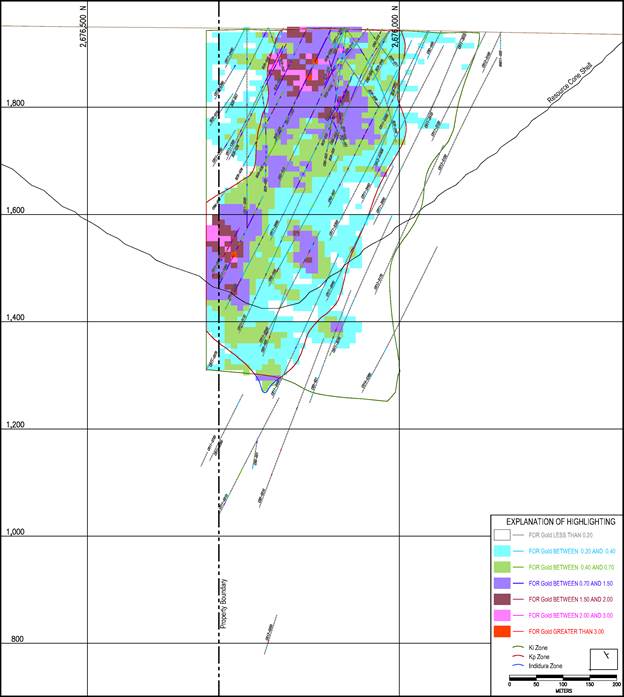

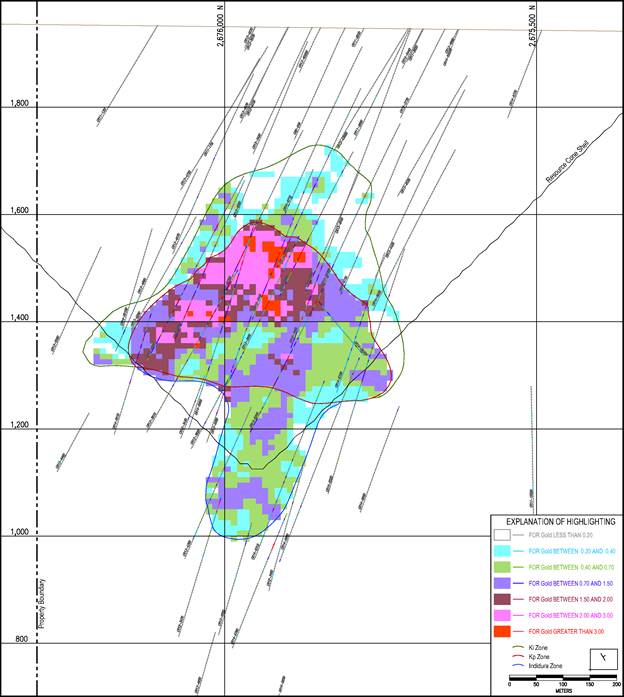

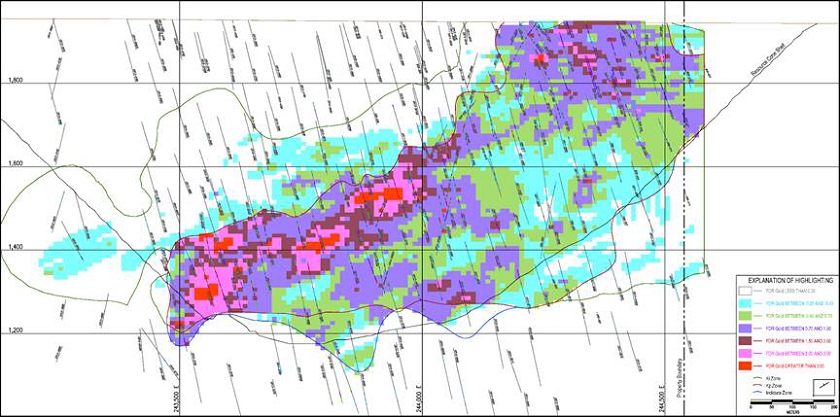

| | 14.2.4 | Variograms | 14-28 |

| | | | |

| | 14.2.5 | Block Grade Estimation | 14-35 |

| | | | |

| | 14.2.6 | Resource Classification | 14-39 |

| | | | |

| | 14.2.7 | Bulk Density | 14-45 |

| | 15.0 | MINERAL RESERVE ESTIMATE | 15-1 |

| | | | |

| | 16.0 | MINING METHODS | 16-1 |

| | 16.1 | Operating Parameters and Criteria | 16-1 |

| | | | |

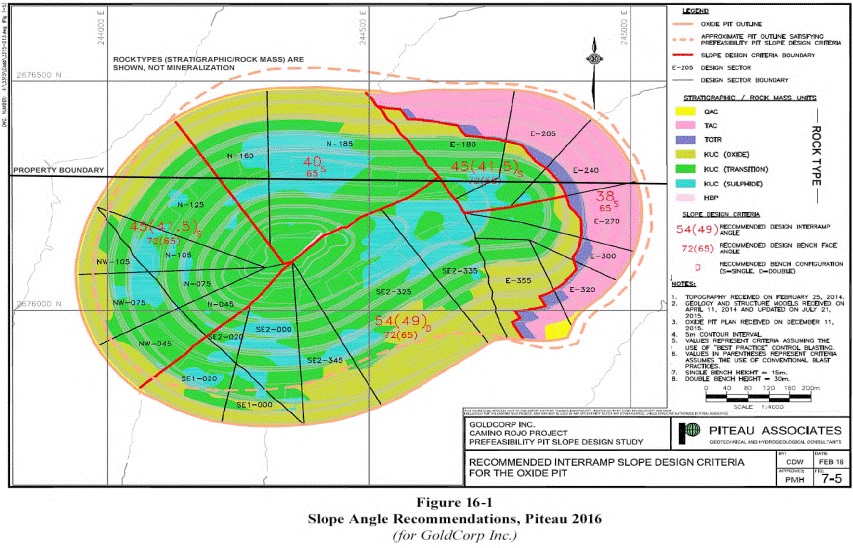

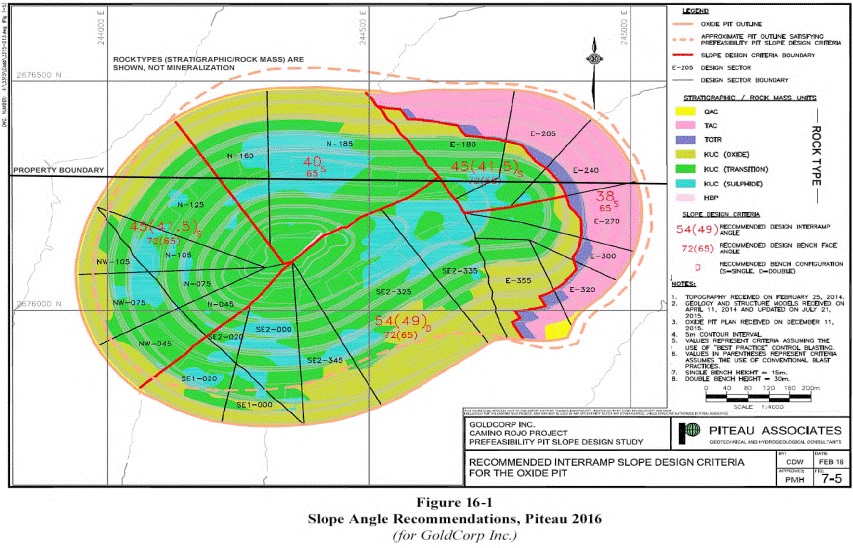

| | 16.2 | Slope Angles | 16-2 |

| | | | |

| | 16.3 | Economic Parameters | 16-4 |

| | | | |

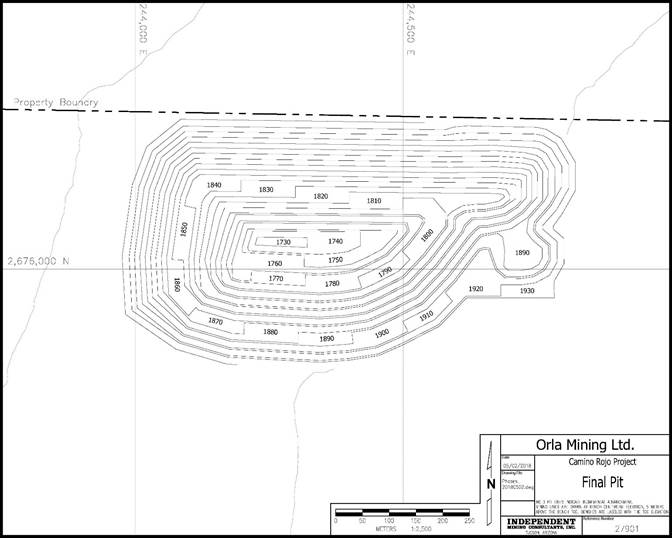

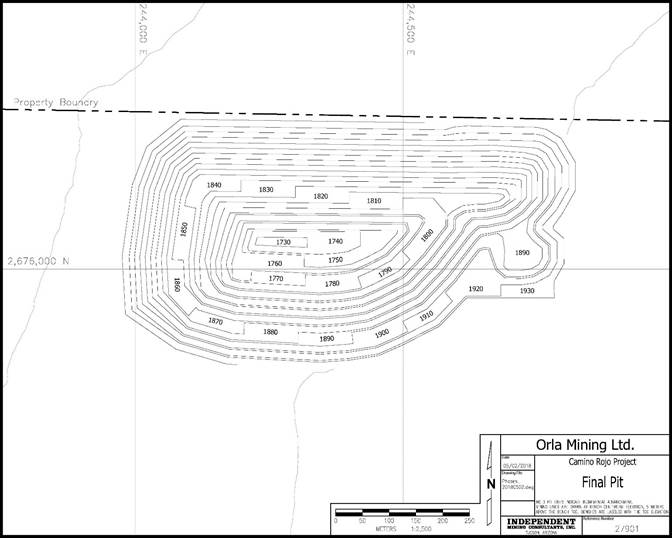

| | 16.4 | Final Pit Design | 16-6 |

| | | | |

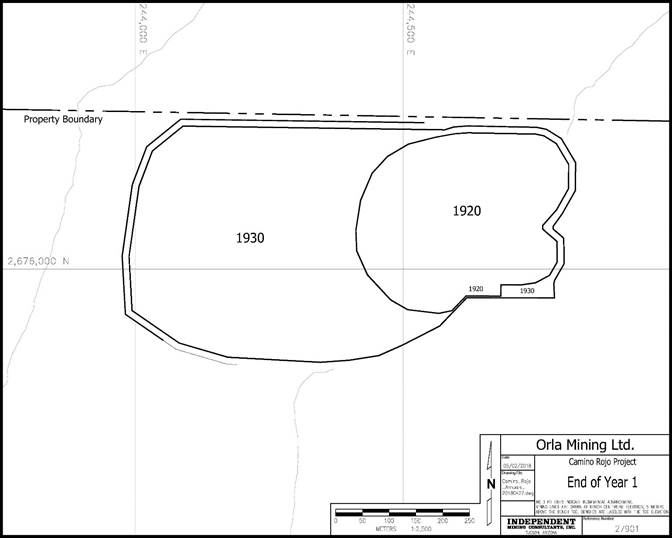

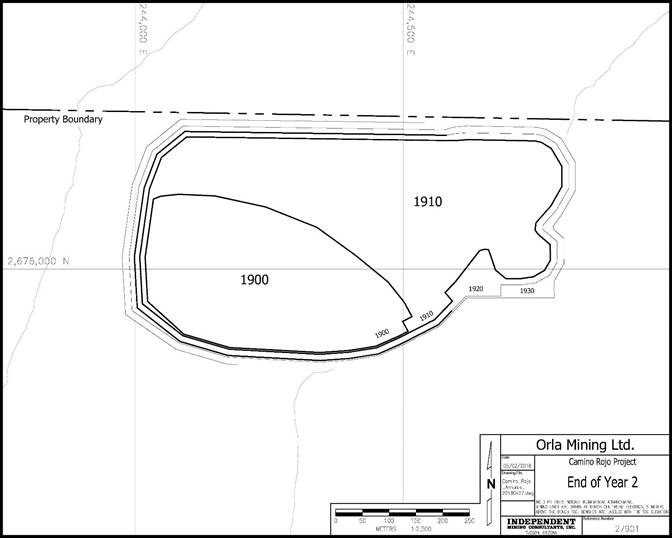

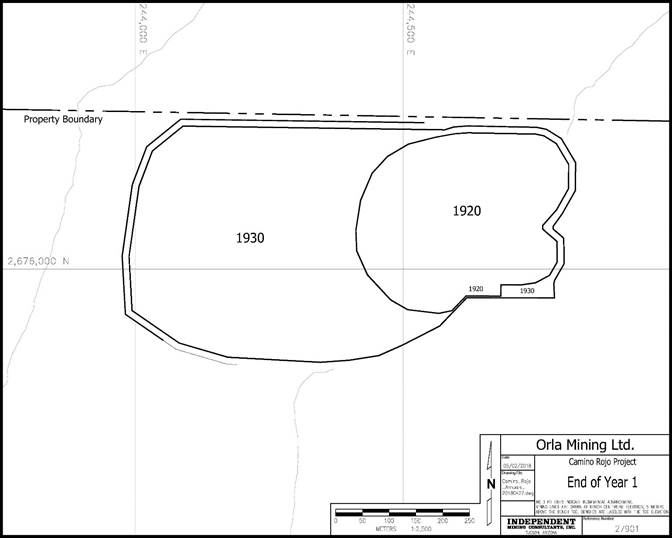

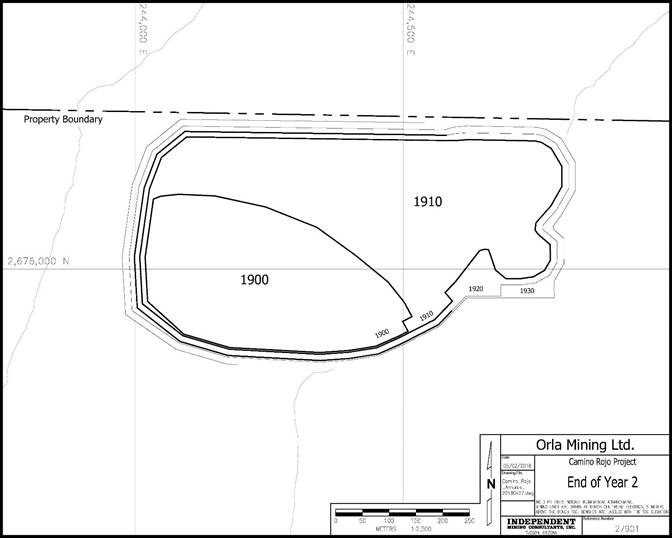

| | 16.5 | Mine Production Schedule | 16-7 |

| | | | |

| | 16.6 | Waste Storage Area and Stockpile | 16-18 |

| | | | |

| | 16.7 | Mining Equipment | 16-20 |

| | 17.1 | Process Design Basis | 17-1 |

| | | | |

| | 17.2 | Crushing | 17-5 |

| | | | |

| | 17.3 | Reclamation and Stacking | 17-5 |

| | | | |

| | 17.4 | Leach Pad Design | 17-8 |

| | | | |

| | 17.5 | Solution Application and Storage | 17-10 |

| | | | |

| | 17.6 | Process Water Balance | 17-11 |

| | | | |

| | 17.7 | Merrill-Crowe Recovery Plant | 17-13 |

| | 17.7.1 | Refinery | 17-14 |

| | | | |

| | 17.7.2 | Process Reagents and Consumables | 17-15 |

| | 18.0 | PROJECT INFRASTRUCTURE | 18-1 |

| | 18.1.1 | Existing Installations | 18-1 |

| | | | |

| | 18.1.2 | Site Roads | 18-1 |

| | | | |

| | 18.1.3 | Mine Haulage Road | 18-1 |

| | | | |

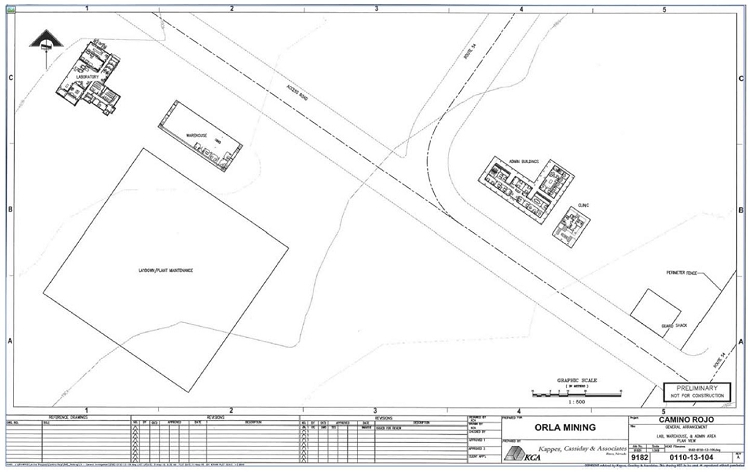

| | 18.1.4 | Project Buildings | 18-1 |

| | | | |

| | 18.1.5 | Mine Camp | 18-4 |

| | | | |

| | 18.1.6 | Laboratory | 18-4 |

| | | | |

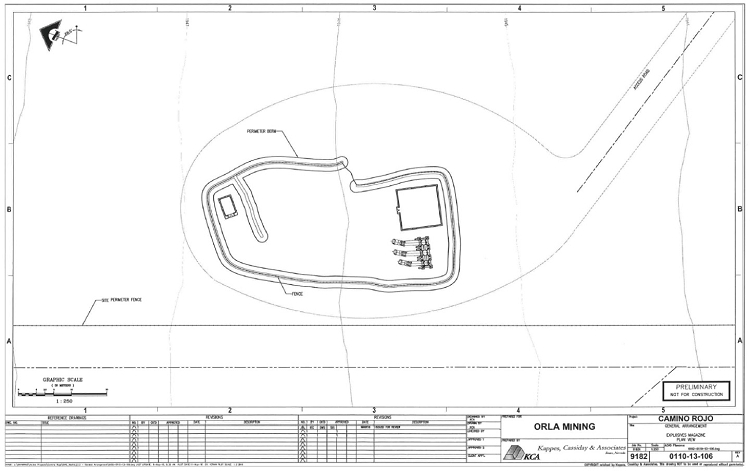

| | 18.1.7 | Fuel Storage and Dispensing | 18-4 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-5 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| | 18.2 | Power Supply, Communication Systems & IT | 18-6 |

| | 18.2.1 | Power Supply | 18-6 |

| | | | |

| | 18.2.2 | Site Power Distribution | 18-6 |

| | | | |

| | 18.2.3 | Communication Systems & IT | 18-6 |

| | 18.3.1 | Water Balance | 18-6 |

| | | | |

| | 18.3.2 | Potable and Domestic Water | 18-7 |

| | | | |

| | 18.3.3 | Fire Water and Protection | 18-7 |

| | 19.0 | MARKET STUDIES AND CONTRACTS | 19-1 |

| | | | |

| | 20.0 | ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT | 20-1 |

| | 20.1 | Environmental Studies | 20-1 |

| | 20.1.1 | Project Area Description | 20-1 |

| | | | |

| | 20.1.2 | Environmental Management Plans | 20-2 |

| | | | |

| | 20.1.3 | Waste Handling | 20-4 |

| | | | |

| | 20.1.4 | Reclamation | 20-5 |

| | | | |

| | 20.1.5 | Closure Activities – Heap Leach Facilities | 20-7 |

| | | | |

| | 20.1.6 | Post Closure Activities | 20-10 |

| | 20.2 | Permitting | 20-12 |

| | | | |

| | 20.3 | Social and Community Impact | 20-16 |

| | 21.0 | CAPITAL AND OPERATING COSTS | 21-1 |

| | 21.1 | Capital Expenditures | 21-2 |

| | 21.1.1 | Mining Capital Costs | 21-4 |

| | | | |

| | 21.1.2 | Process and Infrastructure Capital Cost Estimate | 21-6 |

| | | | |

| | 21.1.3 | Construction Indirect and Other Owner’s Costs | 21-11 |

| | | | |

| | 21.1.4 | Initial Fills Inventory | 21-11 |

| | | | |

| | 21.1.5 | Contingency | 21-11 |

| | | | |

| | 21.1.6 | Working Capital | 21-11 |

| | | | |

| | 21.1.7 | Sustaining Capital | 21-12 |

| | 21.2.1 | Mining Operating Costs | 21-13 |

| | | | |

| | 21.2.2 | Process and G&A Operating Costs | 21-18 |

| | 21.3 | Reclamation & Closure Costs | 21-21 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-6 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| | 22.0 | ECONOMIC ANALYSIS | 22-1 |

| | 22.1 | Summary | 22-1 |

| | | | |

| | 22.2 | Sensitivity | 22-10 |

| | 23.0 | ADJACENT PROPERTIES | 23-1 |

| | | | |

| | 24.0 | OTHER RELEVANT DATA AND INFORMATION | 24-1 |

| | | | |

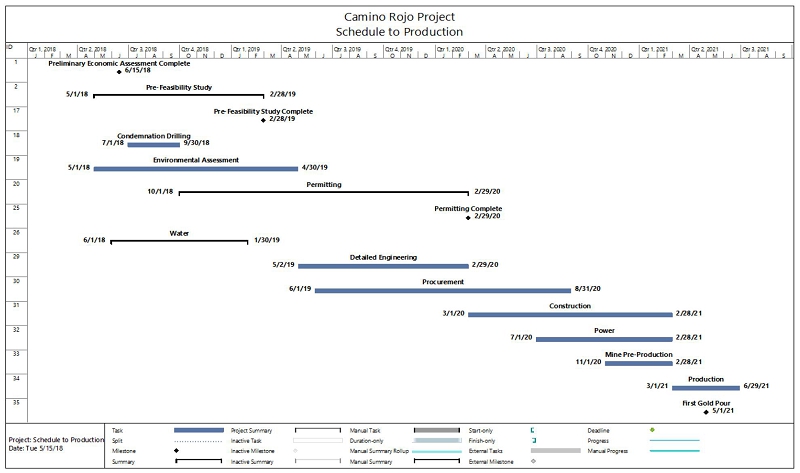

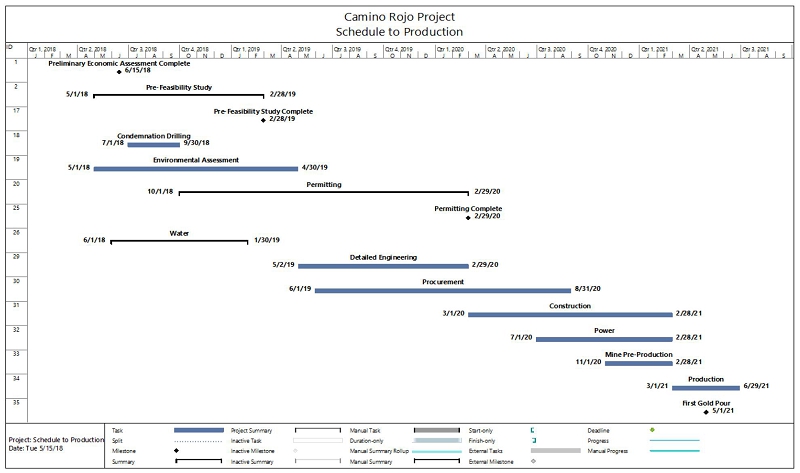

| | 24.1 | Project Implementation | 24-1 |

| | 24.2 | Sulphides | 24-3 |

| | | | |

| | 24.3 | Other Cases | 24-3 |

| | 25.0 | INTERPRETATIONS AND CONCLUSIONS | 25-1 |

| | 25.1.1 | Mining | 25-1 |

| | | | |

| | 25.1.2 | Metallurgy and Process | 25-1 |

| | 25.2.1 | Mineral Resource | 25-2 |

| | | | |

| | 25.2.2 | Mining | 25-2 |

| | | | |

| | 25.2.3 | Metallurgy and Process | 25-2 |

| | | | |

| | 25.2.4 | New Mineral Zones | 25-2 |

| | 25.3.1 | Mineral Resource | 25-3 |

| | | | |

| | 25.3.2 | Mining | 25-3 |

| | | | |

| | 25.3.3 | Metallurgy and Process | 25-4 |

| | | | |

| | 25.3.4 | Other Risks | 25-4 |

| | 26.0 | RECOMMENDATIONS | 26-1 |

| | | | |

| | 27.0 | REFERENCES | 27-1 |

| | | | |

| | 28.0 | DATE AND SIGNATURE PAGE | 28-1 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-7 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

LIST OF FIGURES

| Figure 1-1 After-Tax IRR vs. Gold Price, Capital Cost, and Operating Cost | 1-13 |

| | |

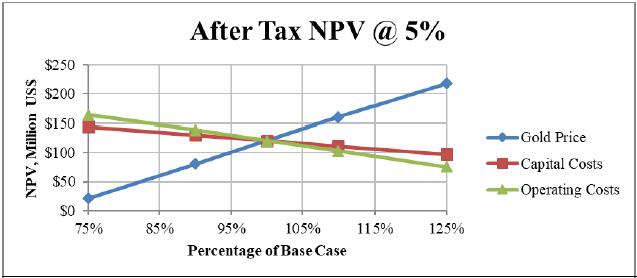

| Figure 1-2 NPV @ 5% vs. Gold Price, Capital Cost, and Operating Cost | 1-13 |

| | |

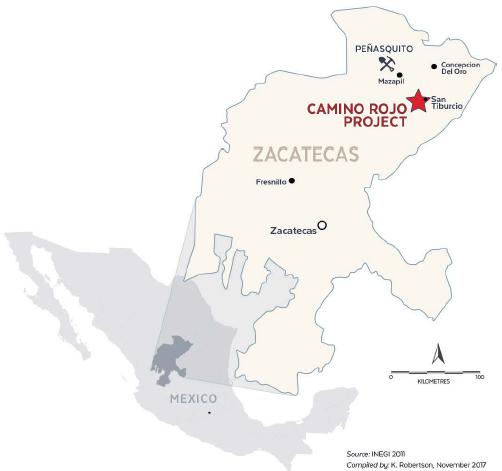

| Figure 4-1 Location Map, Camino Rojo Project | 4-2 |

| | |

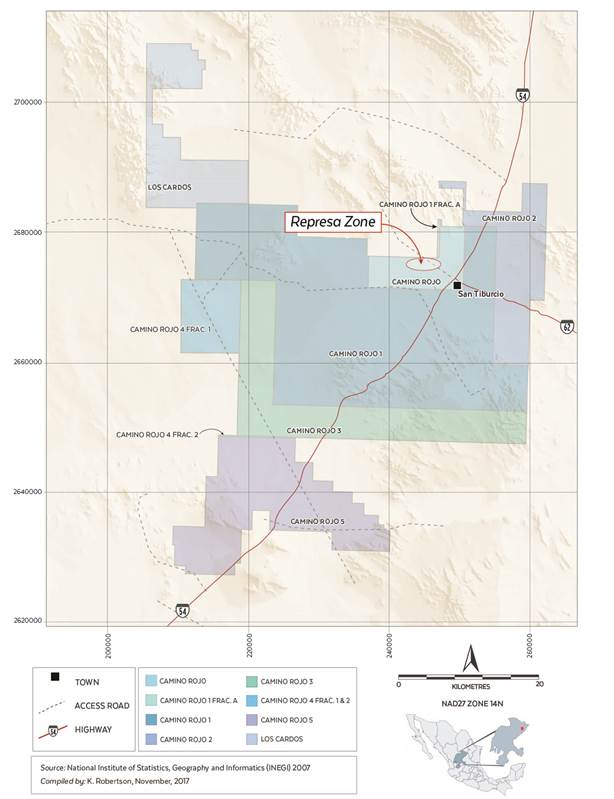

| Figure 4-2 Mining Concessions, Camino Rojo Project | 4-5 |

| | |

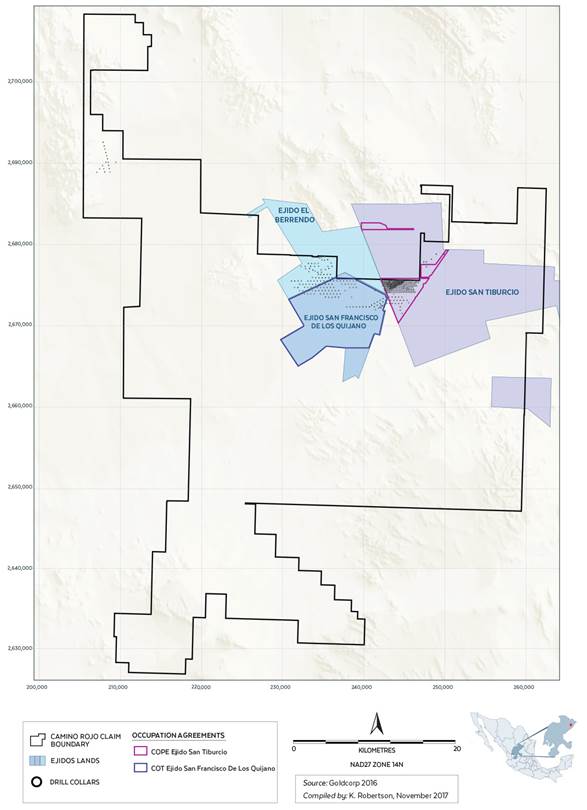

| Figure 4-3 Surface Rights in Project Area | 4-8 |

| | |

| Figure 5-1 Project Location and Regional Infrastructure | 5-2 |

| | |

| Figure 5-2 View of Typical Topography and Vegetation at Camino Rojo | 5-3 |

| | |

| Figure 6-1 Historical Drillhole Locations and Project Claim Boundaries | 6-3 |

| | |

| Figure 7-1 Regional Geologic Map (Servicio Geologico Mexicano, 2000) | 7-3 |

| | |

| Figure 7-2 Local Geology, Camino Rojo Deposit (Servicio Geologico Mexicano, 2014) | 7-5 |

| | |

| Figure 7-3 Drillcore from CR12-345D, 818m | 7-6 |

| | |

| Figure 7-4 Drillcore from CR12-345D, 254m | 7-6 |

| | |

| Figure 7-5 Drillcore from CR12-345D, 993m | 7-7 |

| | |

| Figure 7-6 Drillcore from CR12 345D, 395m | 7-9 |

| | |

| Figure 7-7 Drillcore from CR12 345D, 727m | 7-10 |

| | |

| Figure 7-8 Drillcore from CR11 267D, 490m | 7-10 |

| | |

| Figure 7-9 Drillcore from CR11 267D, 473m | 7-11 |

| | |

| Figure 7-10 Drillcore from CR11 258D, 256m | 7-13 |

| | |

| Figure 7-11 Drillcore from CR11 258D, 257m | 7-13 |

| | |

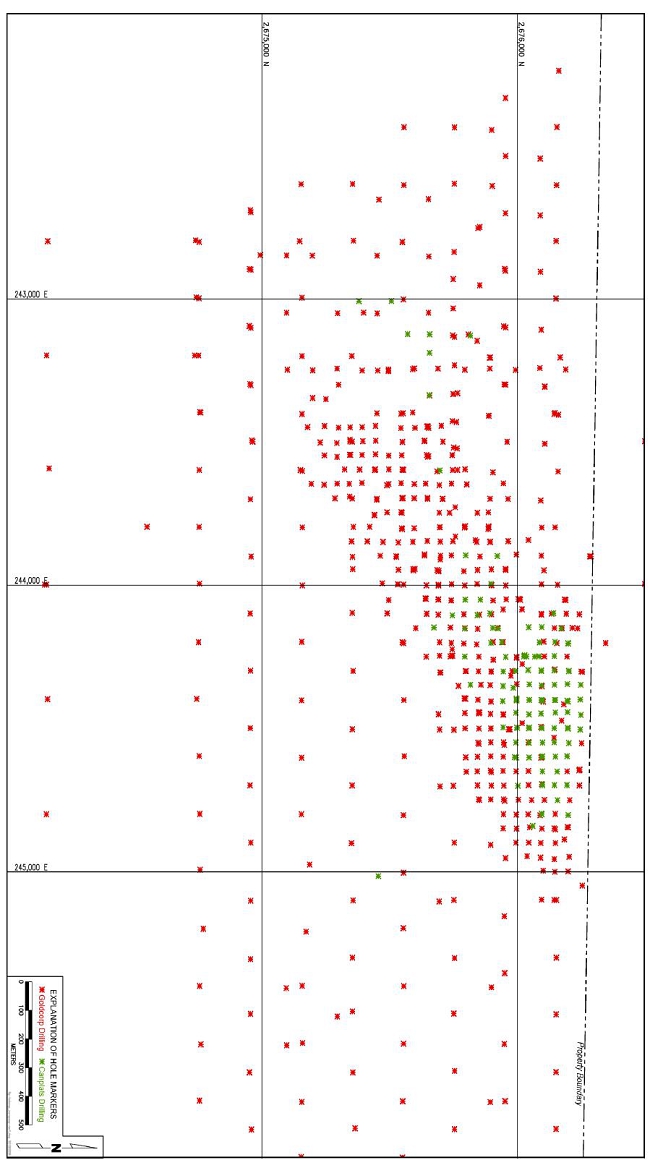

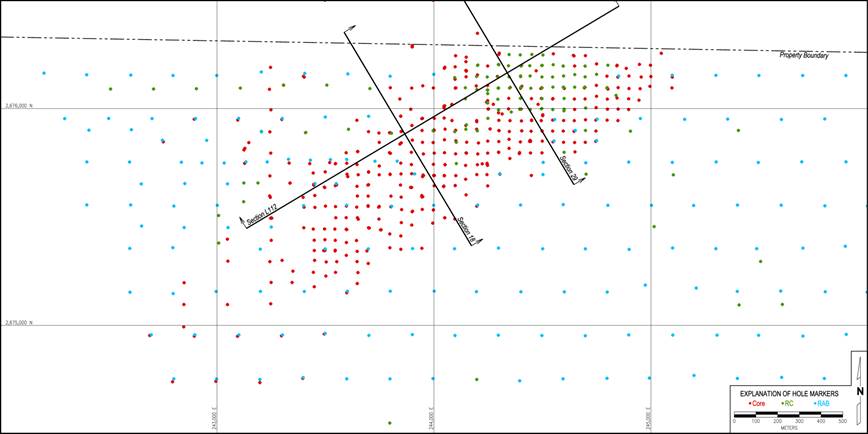

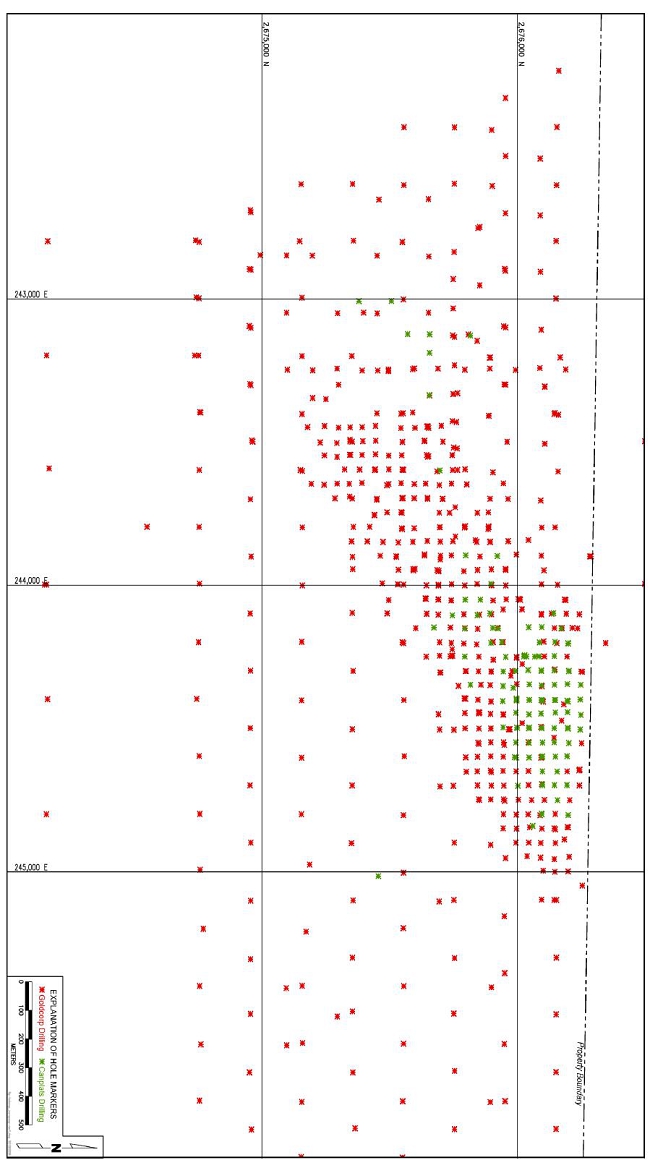

| Figure 10-1 Drilling by Type, IMC 2018 | 10-5 |

| | |

| Figure 10-2 Drilling by Company, IMC 2018 | 10-6 |

| | |

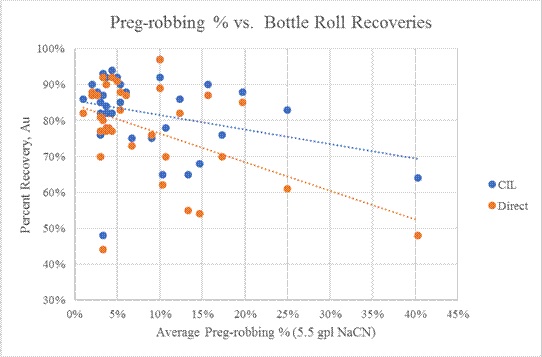

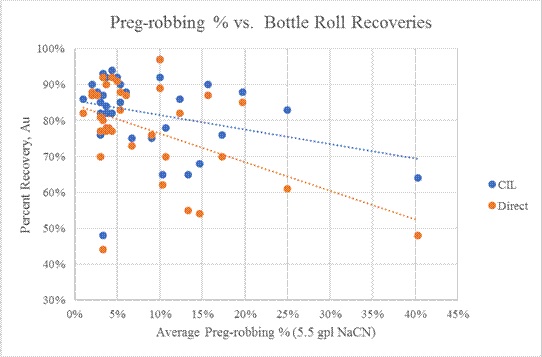

| Figure 13-1 Preg-Robbing Percentage vs. CIL and Direct Bottle Roll Leach Test Recoveries | 13-8 |

| | |

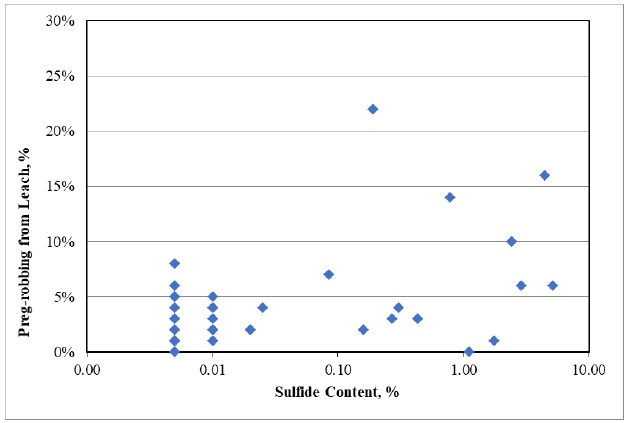

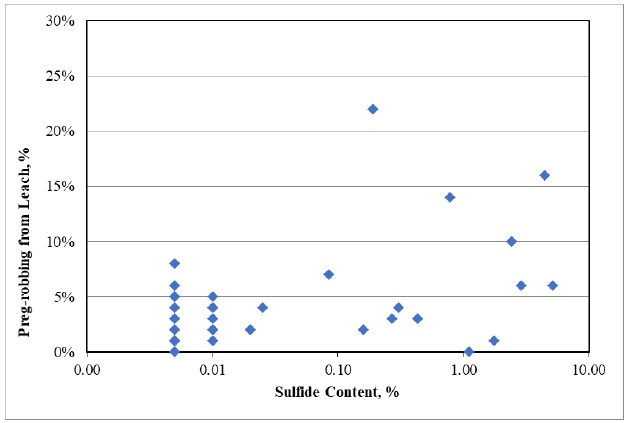

| Figure 13-2 Preg-Robbing from Leach Percentage vs. Sulphide Content | 13-9 |

| | |

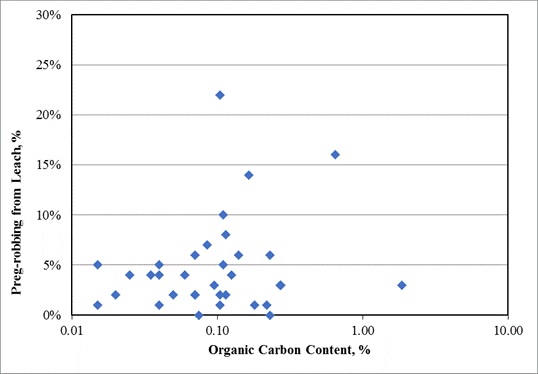

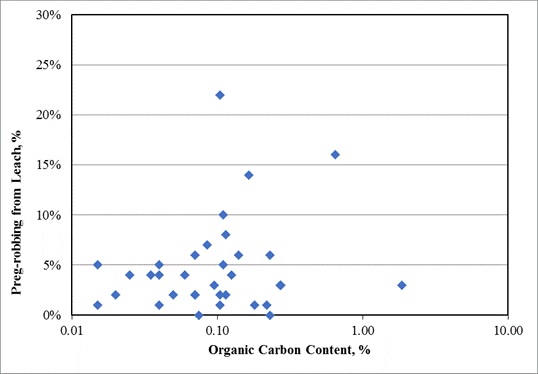

| Figure 13-3 Preg-Robbing from Leach Percentage vs. Organic Carbon Content | 13-9 |

| | |

| Figure 13-4 Preg-Robbing from Leach Percentage vs. Organic Carbon Content | 13-10 |

| | |

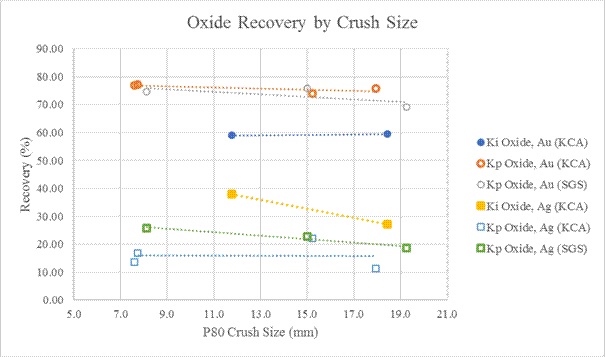

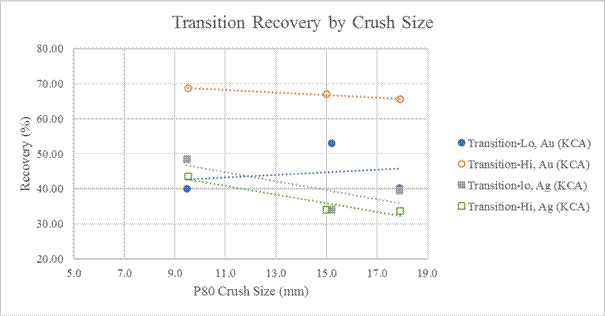

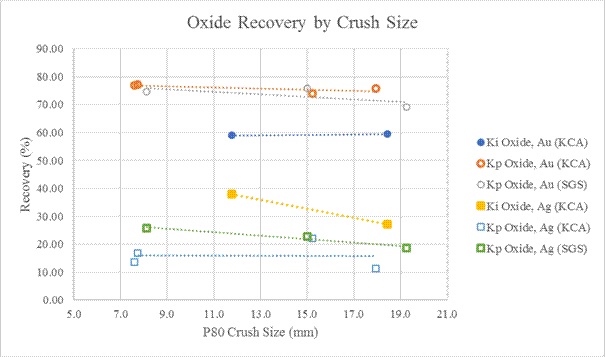

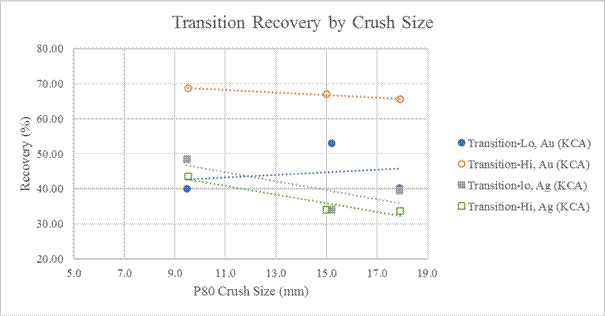

| Figure 13-5 Oxide Recovery vs. Crush Size | 13-14 |

| | |

| Figure 13-6 Transition Recovery vs. Crush Size | 13-15 |

| | |

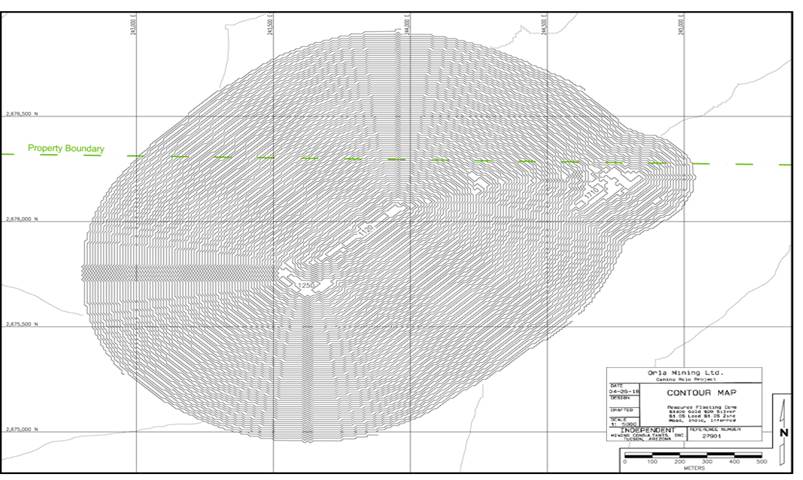

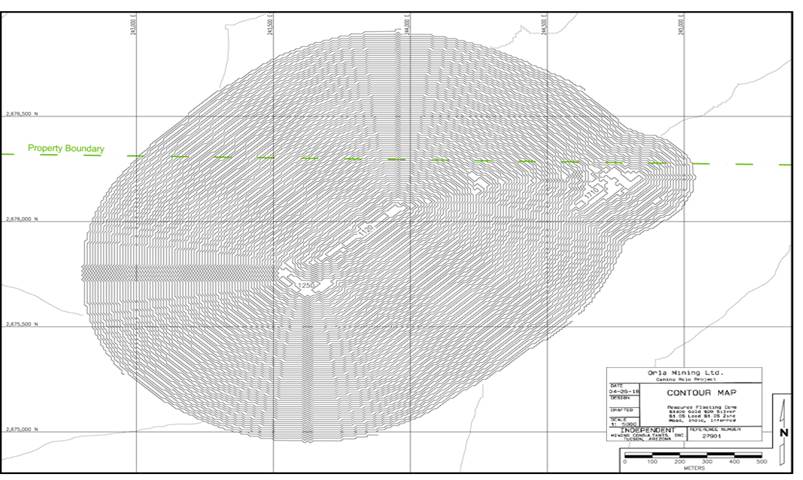

| Figure 14-1 Mineral Resource Cone Shell, IMC 2018 | 14-10 |

| | |

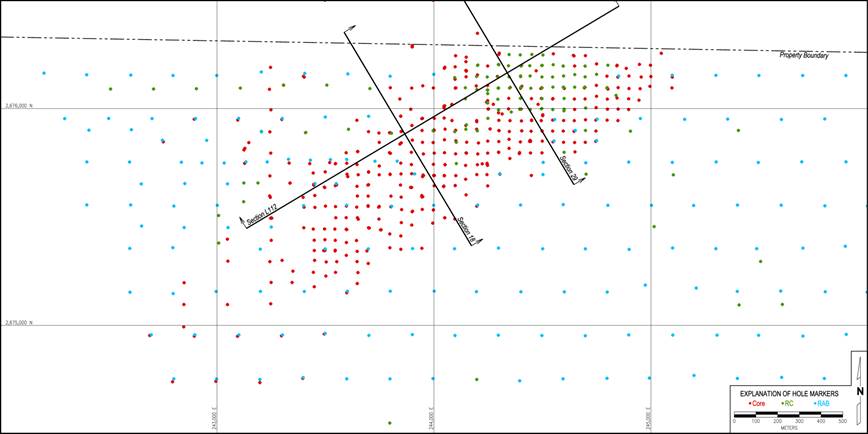

| Figure 14-2 Hole and Cross Section Locations, IMC 2018 | 14-13 |

| | |

| Figure 14-3 Lithology on Section L112, IMC 2018 | 14-14 |

| | |

| Figure 14-4 Alteration on Section L112, IMC 2018 | 14-16 |

| | |

| Figure 14-5 Alteration on Section 18, IMC 2018 | 14-17 |

| | |

| Figure 14-6 Alteration on Section 29, IMC 2018 | 14-18 |

| | |

| Figure 14-7 Oxidation Zones on Section 29, IMC 2018 | 14-19 |

| | |

| Figure 14-8 Estimation Domains on Section L112, IMC 2018 | 14-20 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-8 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| Figure 14-9 Probability Plot of Gold Assays by Alteration Type – NE Domain | 14-25 |

| | |

| Figure 14-10 Probability Plot of Gold 5m Composites by Alteration Type – NE Domain | 14-25 |

| | |

| Figure 14-11 Probability Plot of Gold Assays by Alteration Type – SW Domain | 14-26 |

| | |

| Figure 14-12 Probability Plot of Gold 5m Composites by Alteration Type – SW Domain | 14-26 |

| | |

| Figure 14-13 Probability Plot of Gold Assays by Alteration Type – Indidura | 14-27 |

| | |

| Figure 14-14 Probability Plot of Gold 5m Composites by Alteration Type – Indidura | 14-28 |

| | |

| Figure 14-15 NE Domain Gold Variogram – Primary Axis | 14-30 |

| | |

| Figure 14-16 NE Domain Gold Variogram – Secondary Axis | 14-31 |

| | |

| Figure 14-17 NE Domain Gold Variogram – Tertiary Axis | 14-32 |

| | |

| Figure 14-18 SW Domain Gold Variogram – Primary Axis | 14-33 |

| | |

| Figure 14-19 SW Domain Gold Variogram – Down Hole Variogram | 14-34 |

| | |

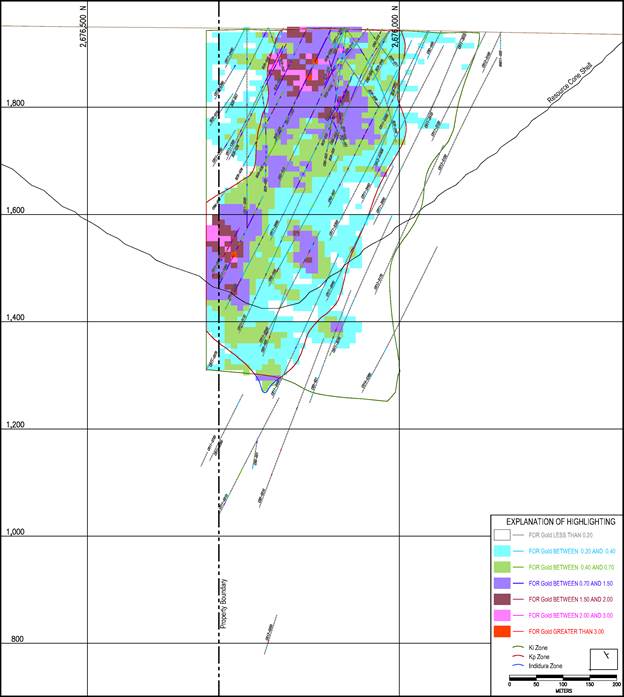

| Figure 14-20 Gold Grades on Section 29, IMC 2018 | 14-36 |

| | |

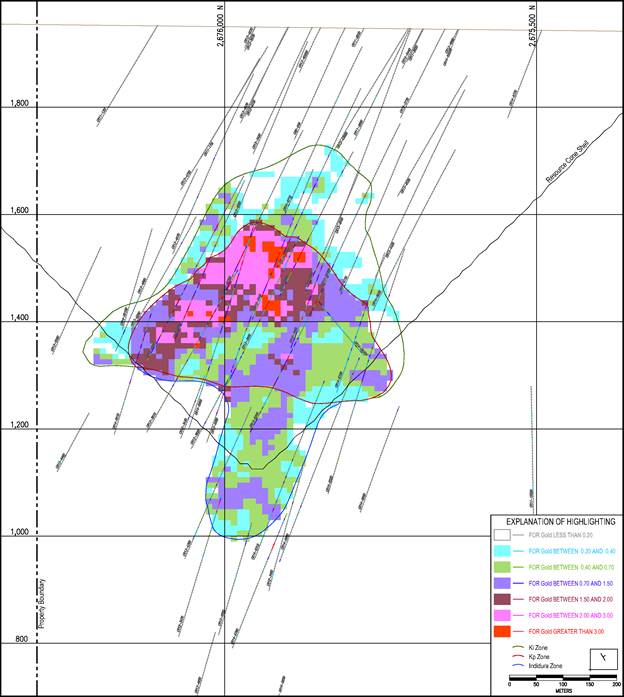

| Figure 14-21 Gold Grades on Section 18, IMC 2018 | 14-37 |

| | |

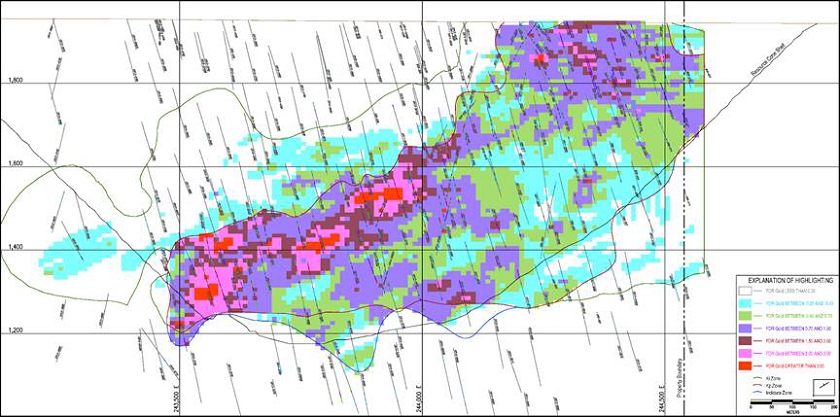

| Figure 14-22 Gold Grades on Section L112, IMC 2018 | 14-38 |

| | |

| Figure 14-23 Average Distance to Nearest 3 and 4 Holes – NE Domain | 14-40 |

| | |

| Figure 14-24 Average Distance to Nearest 3 and 4 Holes – SW Domain | 14-41 |

| | |

| Figure 14-25 Average Distance to Nearest 3 and 4 Holes – Indidura | 14-42 |

| | |

| Figure 14-26 Resource Class on Section 18, IMC 2018 | 14-43 |

| | |

| Figure 14-27 Resource Class on Section 29, IMC 2018 | 14-44 |

| | |

| Figure 16-1 Slope Angle Recommendations, Piteau 2016 | 16-3 |

| | |

| Figure 16-2 Final Pit, IMC 2018 | 16-8 |

| | |

| Figure 16-3 End of Year 1, IMC 2018 | 16-12 |

| | |

| Figure 16-4 End of Year 2, IMC 2018 | 16-13 |

| | |

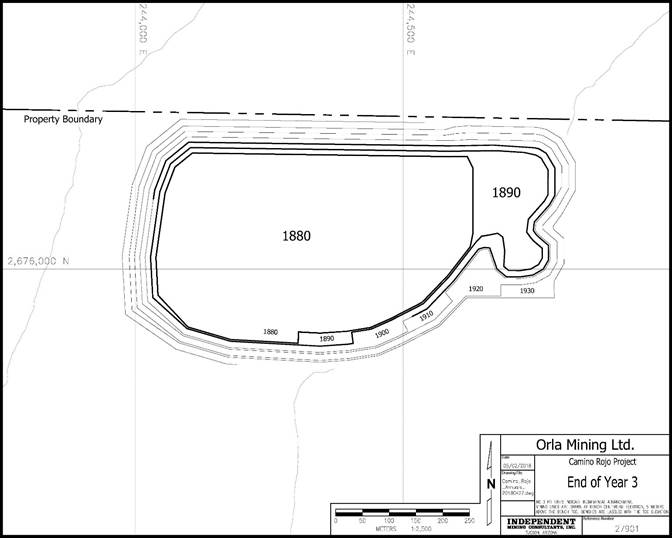

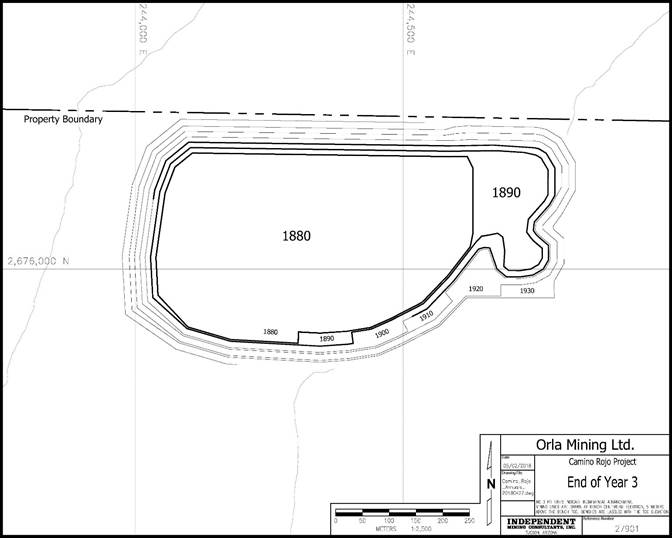

| Figure 16-5 End of Year 3, IMC 2018 | 16-14 |

| | |

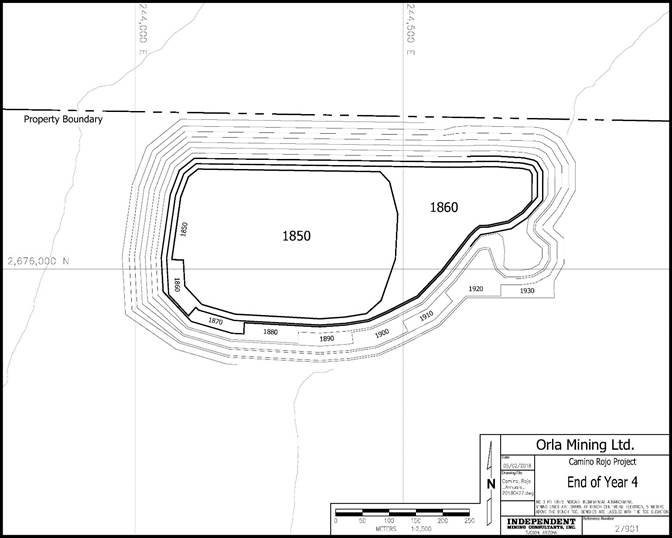

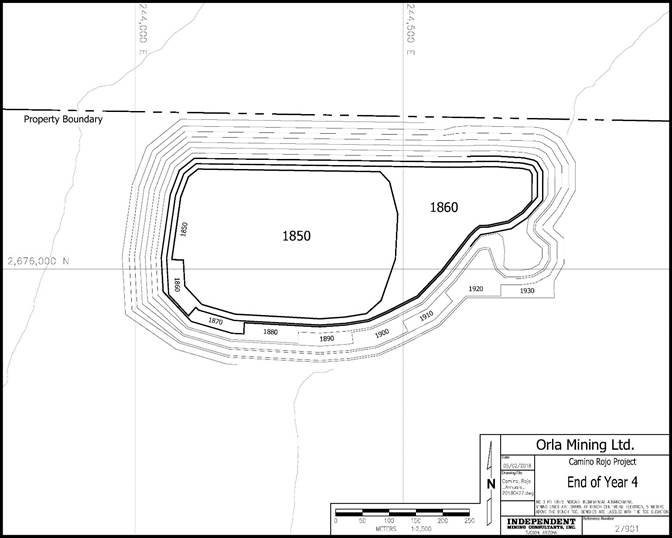

| Figure 16-6 End of Year 4, IMC 2018 | 16-15 |

| | |

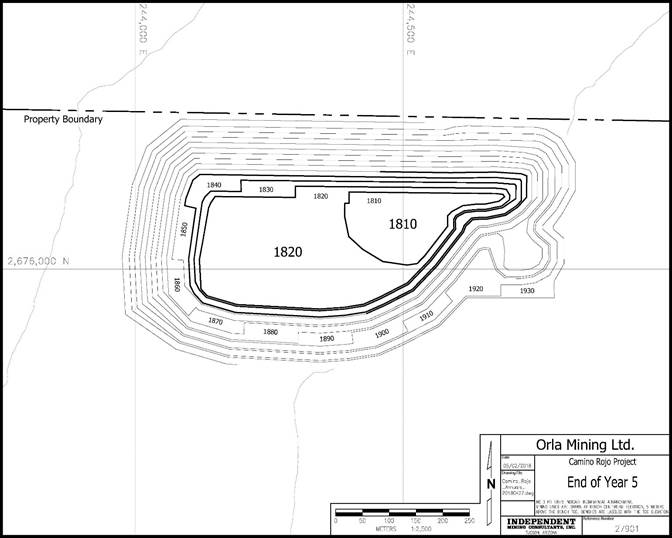

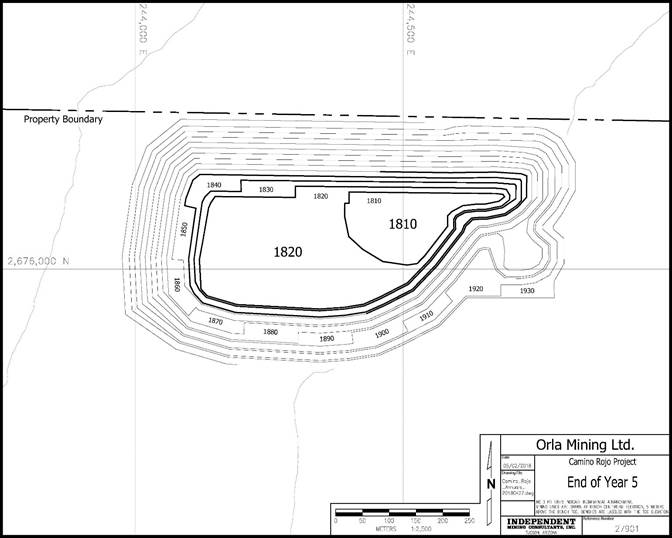

| Figure 16-7 End of Year 5, IMC 2018 | 16-16 |

| | |

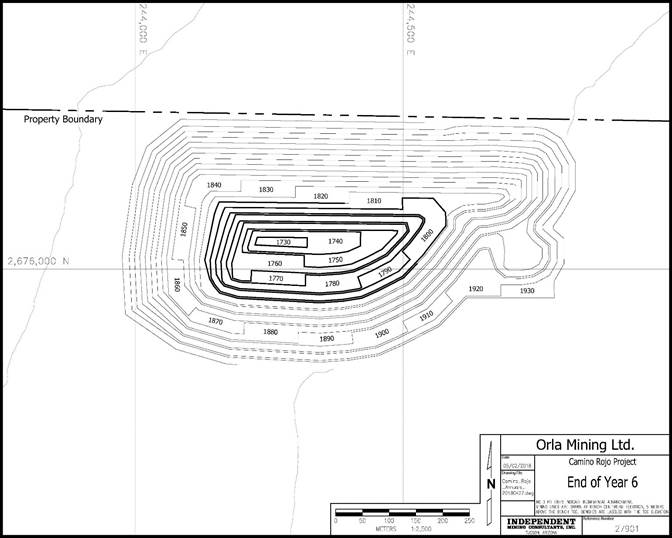

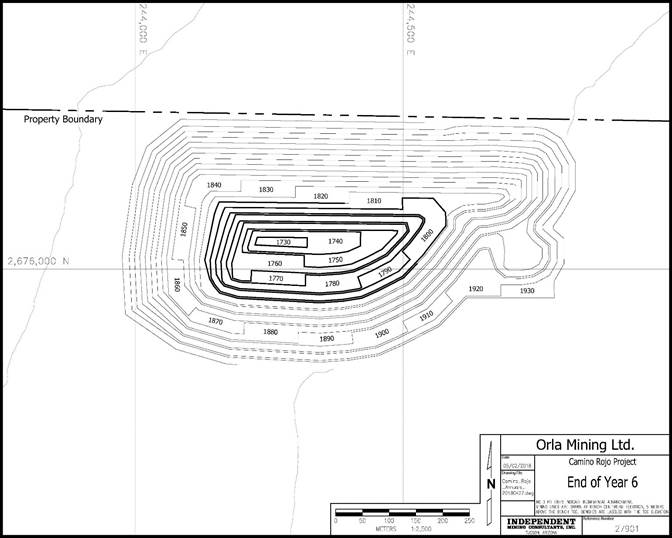

| Figure 16-8 End of Year 6, IMC 2018 | 16-17 |

| | |

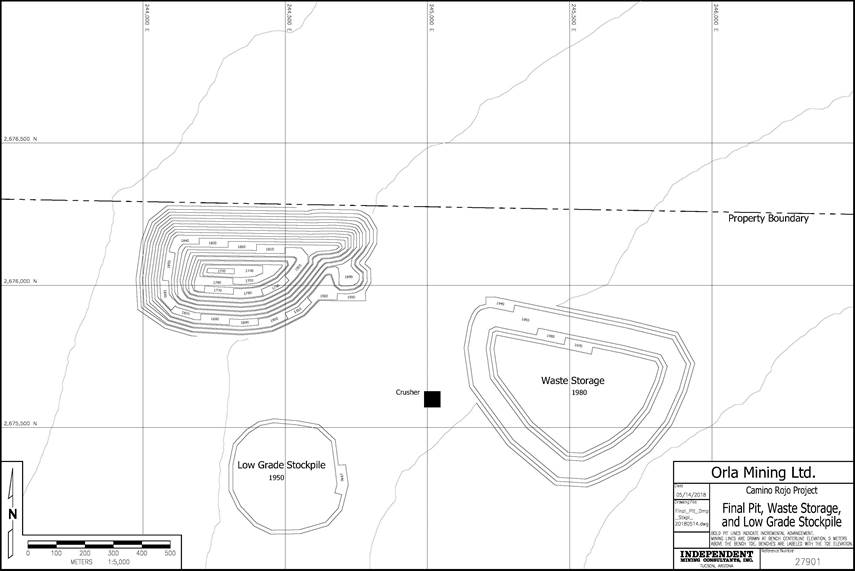

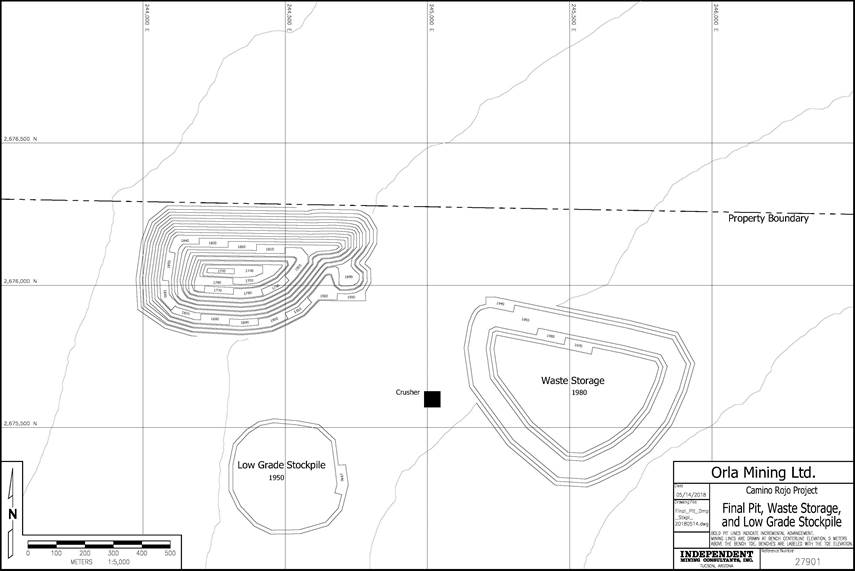

| Figure 16-9 Mine Waste Storage Area, IMC 2018 | 16-19 |

| | |

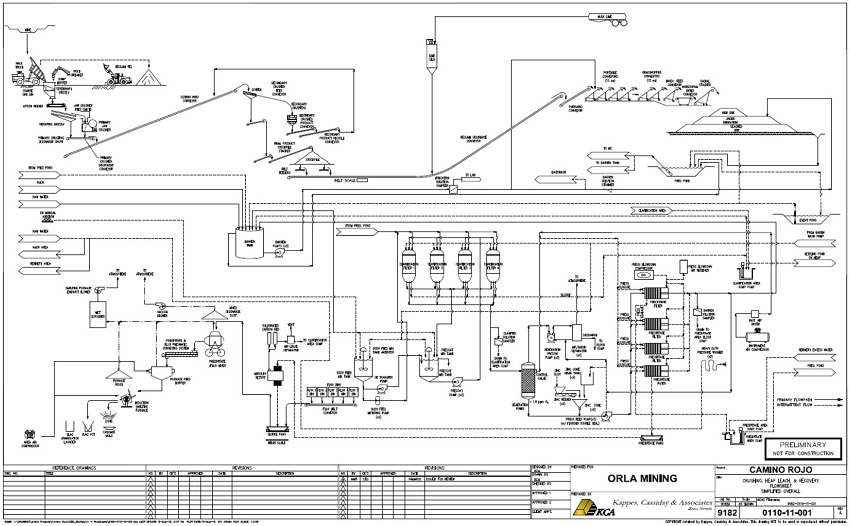

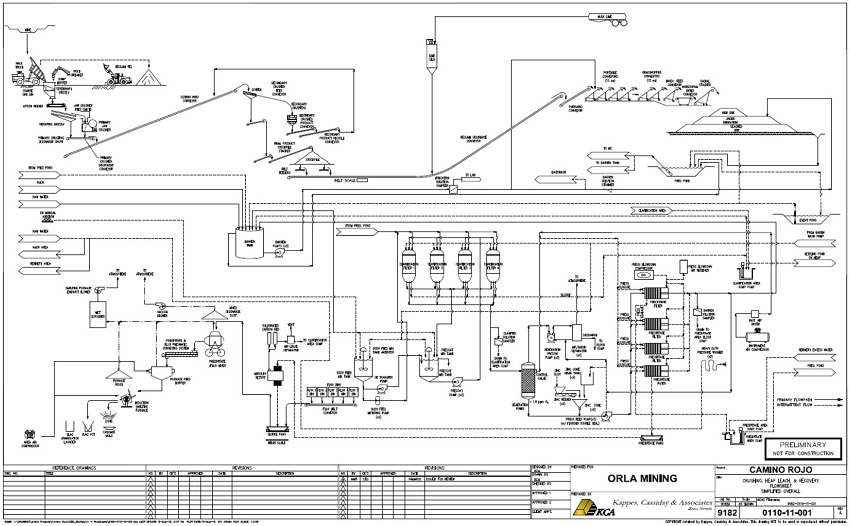

| Figure 17-1 Mine Process Overall Flowsheet | 17-3 |

| | |

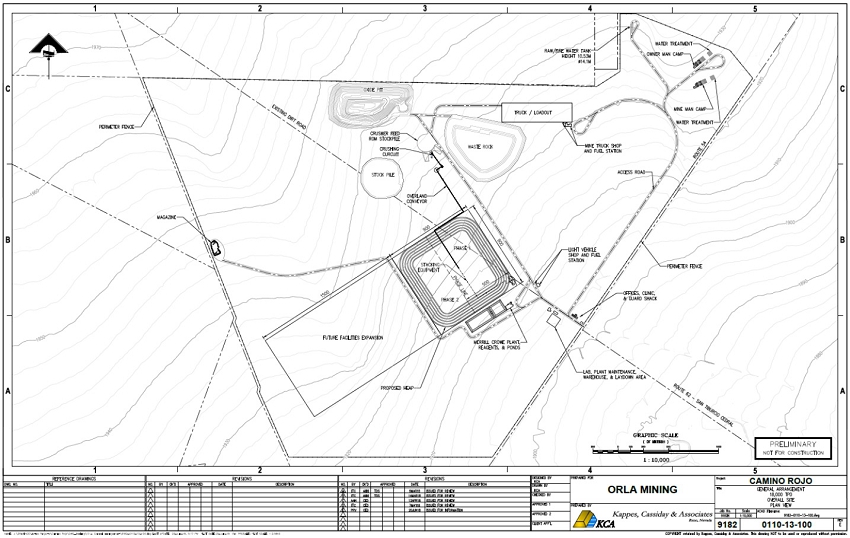

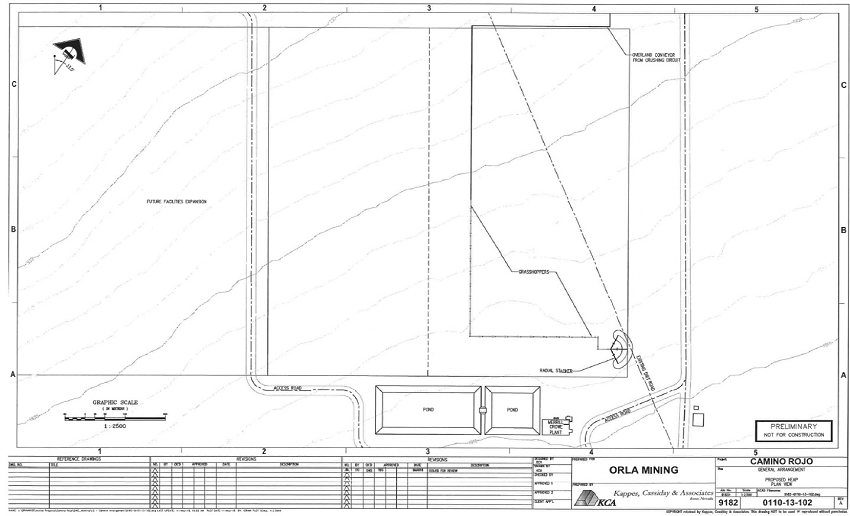

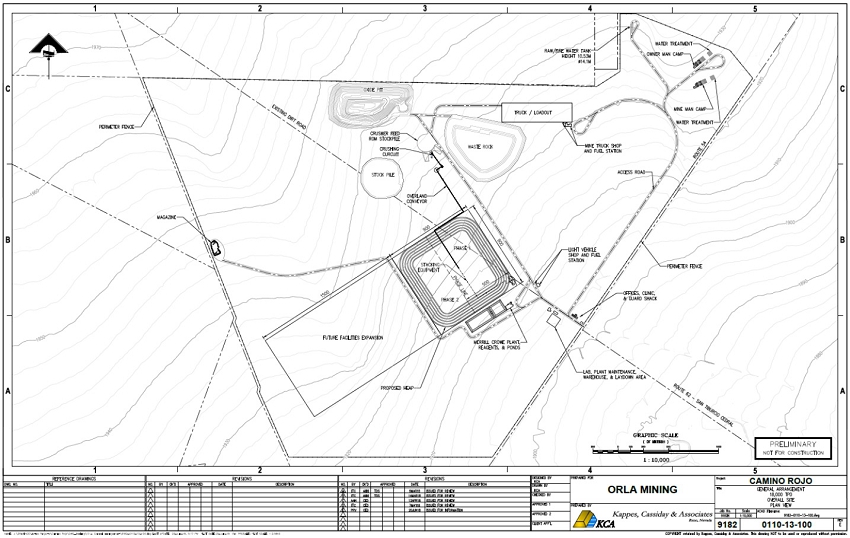

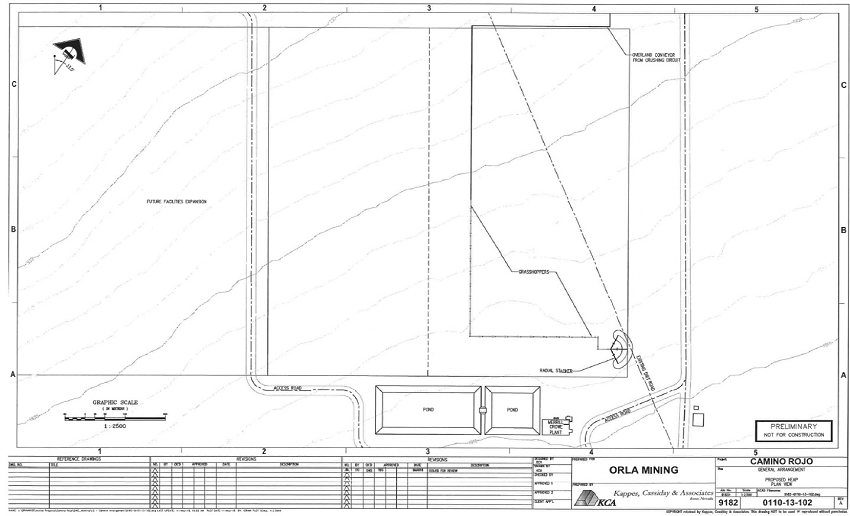

| Figure 17-2 Mine General Arrangement | 17-4 |

| | |

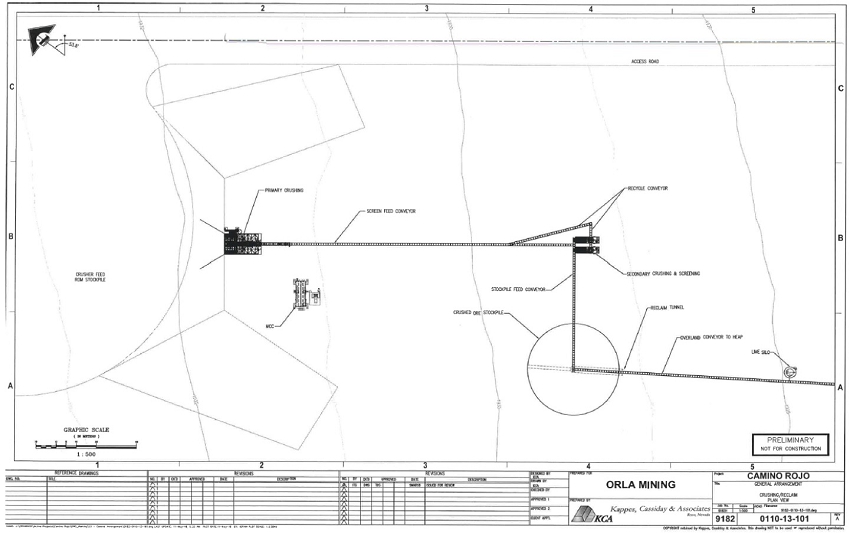

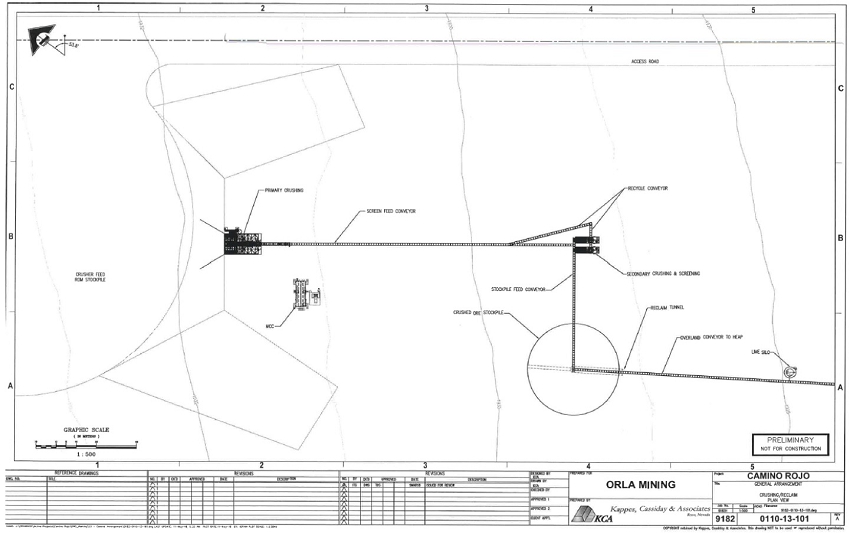

| Figure 17-3 Crushing & Reclaim | 17-7 |

| | |

| Figure 17-4 Heap Leach Pad | 17-9 |

| | |

| Figure 17-5 Merrill-Crowe Recovery Plant | 17-17 |

| | |

| Figure 18-1 Mine Truck Shop | 18-2 |

| | |

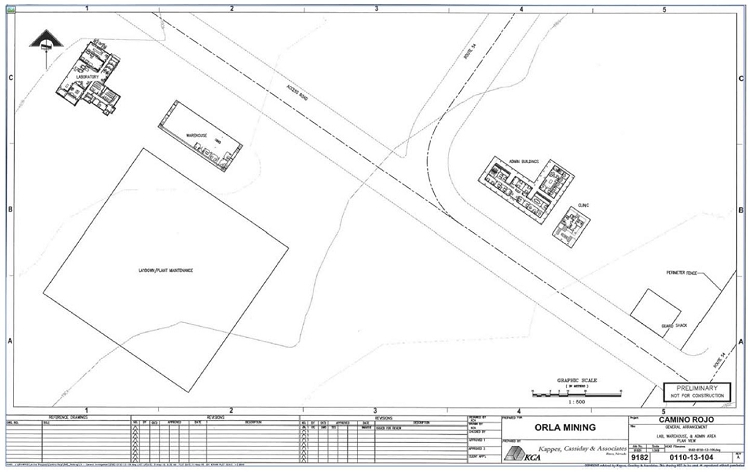

| Figure 18-2 Lab, Warehouse and Administration Buildings | 18-3 |

| | |

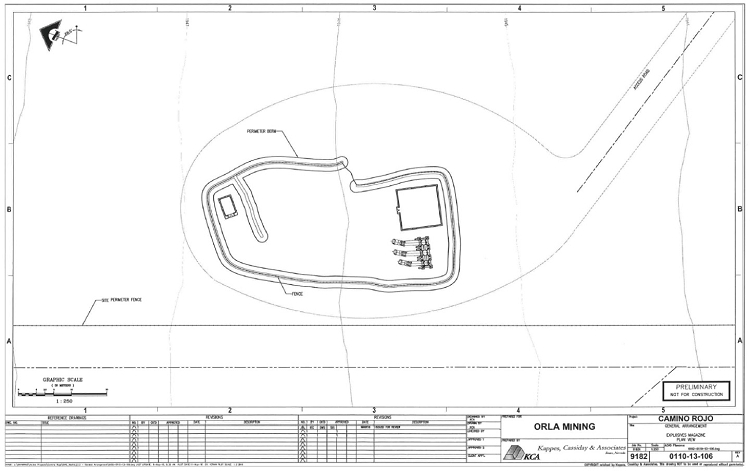

| Figure 18-3 Explosives Magazine Site | 18-5 |

| | |

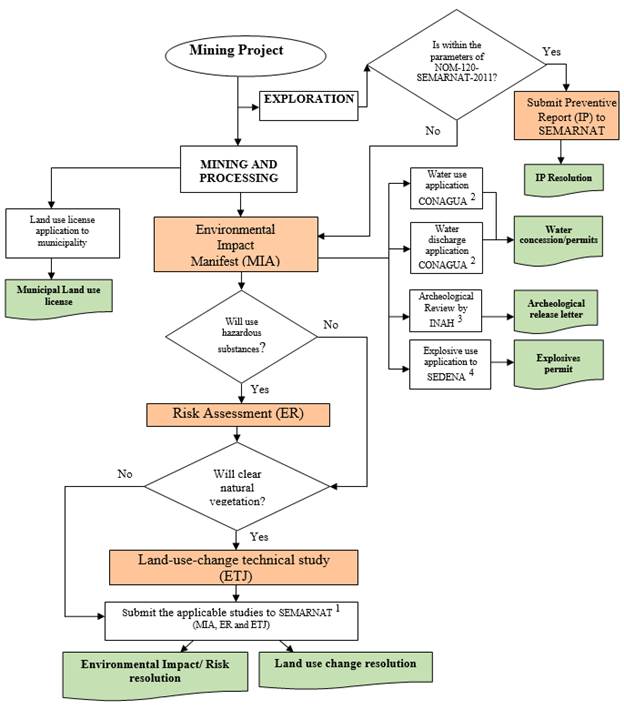

| Figure 20-1 Permitting Process Flowsheet | 20-15 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-9 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| Figure 22-1 After Tax Sensitivity – IRR | 22-11 |

| | |

| Figure 22-2 After Tax Sensitivity – NPV @ 0% | 22-11 |

| | |

| Figure 22-3 After Tax Sensitivity – NPV @ 5% | 22-12 |

| | |

| Figure 24-1 Project Development & Implementation Schedule | 24-2 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-10 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

LIST OF TABLES

| Table 1-1 Resource Summary | 1-5 |

| | |

| Table 1-2 Capital Cost Summary | 1-9 |

| | |

| Table 1-3 Operating Cost Summary | 1-10 |

| | |

| Table 1-4 Economic Analysis Summary | 1-12 |

| | |

| Table 2-1 Table of Responsibilities by Section | 2-7 |

| | |

| Table 4-1 Listing of Mining Concessions | 4-4 |

| | |

| Table 6-1 2016 Camino Rojo Historical Proven and Probable Mineral Reserve Estimate | 6-5 |

| | |

| Table 6-2 2016 Camino Rojo Historical Measured and Indicated Mineral Resource Estimate | 6-5 |

| | |

| Table 6-3 2016 Camino Rojo Historical Inferred Mineral Resource Estimate | 6-5 |

| | |

| Table 10-1 Summary of Camino Rojo Drilling, 2007-2015 | 10-1 |

| | |

| Table 13-1 Oxide Column Test Results SGS Mineral Services Minerals | 13-2 |

| | |

| Table 13-2 Transition Column Test Results SGS Mineral Services Minerals | 13-2 |

| | |

| Table 13-3 KCA 2010 Column Leach Test Results on Composites | 13-4 |

| | |

| Table 13-4 KCA 2012 Summary of Column Leach Test Results by Material Type | 13-5 |

| | |

| Table 13-5 KCA 2015 Column Leach Test Results by Lithology | 13-6 |

| | |

| Table 13-6 Preg-Robbing Data Comparison for Camino Rojo | 13-7 |

| | |

| Table 13-7 Summary of Flotation Composite Feed Grades | 13-11 |

| | |

| Table 13-8 Lead Flotation Concentrate Grades | 13-11 |

| | |

| Table 13-9 Zinc Flotation Concentrate Grades | 13-11 |

| | |

| Table 13-10 Comminution Test Results Summary | 13-12 |

| | |

| Table 13-11 Comminution Test Results by Alteration Type | 13-13 |

| | |

| Table 13-12 Estimated Recoveries by Material Type for P80 38mm Crush Size | 13-16 |

| | |

| Table 13-13 Projected Field Cyanide Consumptions by Material Type | 13-17 |

| | |

| Table 13-14 Projected Field Lime Consumptions by Material Type | 13-17 |

| | |

| Table 13-15 Distribution of Metals to Various Sulphide Products | 13-19 |

| | |

| Table 14-1 Mineral Resource | 14-3 |

| | |

| Table 14-2 Economic Parameters for Mineral Resource Estimate | 14-6 |

| | |

| Table 14-3 Treatment Costs for Lead and Zinc Concentrates | 14-8 |

| | |

| Table 14-4 Camino Rojo Model Rock Types (lith) | 14-11 |

| | |

| Table 14-5 Camino Rojo Alteration Types (alt) | 14-12 |

| | |

| Table 14-6 Camino Rojo Oxide-Sulphide Model (oxide) | 14-15 |

| | |

| Table 14-7 Camino Rojo Estimation Domains (domain) | 14-15 |

| | |

| Table 14-8 Cap Grades and Number of Assays Capped | 14-21 |

| | |

| Table 14-9 Summary Statistics of Assays | 14-23 |

| | |

| Table 14-10 Summary Statistics of 5m Composites | 14-24 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-11 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| Table 14-11 Specific Gravity and Bulk Density | 14-45 |

| | |

| Table 16-1 Economic Parameters for Mine Design | 16-6 |

| | |

| Table 16-2 Mine Production Schedule | 16-9 |

| | |

| Table 16-3 Proposed Plant Production Schedule | 16-10 |

| | |

| Table 16-4 Proposed Plant Production Schedule by Material Type | 16-11 |

| | |

| Table 16-5 Mine Major Equipment Fleet Requirement | 16-20 |

| | |

| Table 17-1 Processing Design Criteria Summary | 17-2 |

| | |

| Table 17-2 Site-Wide Average Year Water Requirements | 17-12 |

| | |

| Table 17-3 Projected Annual Reagents and Consumables | 17-15 |

| | |

| Table 20-1 Permits Required for Mine Construction | 20-13 |

| | |

| Table 20-2 Permits Required for Mine Operation and Closure | 20-14 |

| | |

| Table 21-1 Capital Cost Summary | 21-1 |

| | |

| Table 21-2 LOM Operating Cost Summary | 21-1 |

| | |

| Table 21-3 Summary of Pre-Production Capital Costs by Area | 21-3 |

| | |

| Table 21-4 Mining Capital Costs | 21-5 |

| | |

| Table 21-5 Summary of Pre-Production Capital Costs by Discipline | 21-8 |

| | |

| Table 21-6 Process Mobile Equipment | 21-10 |

| | |

| Table 21-7 Contract Mining Cost Summary | 21-14 |

| | |

| Table 21-8 Contract Mining Equipment Depreciation | 21-17 |

| | |

| Table 21-9 Contractor Equipment Depreciation | 21-18 |

| | |

| Table 21-10 Process, Support & G&A Operating Cost | 21-19 |

| | |

| Table 22-1 Key Economic Parameters | 22-3 |

| | |

| Table 22-2 Economic Analysis Summary | 22-4 |

| | |

| Table 22-3 Cash Flow Model | 22-5 |

| | |

| Table 22-4 Sensitivity Analysis Results | 22-10 |

| | |

| Table 26-1 Recommendations | 26-3 |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-12 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

1.0 EXECUTIVE SUMMARY

1.1 Introduction and Overview

The Camino Rojo project, located in Zacatecas State, Mexico, is 100% owned by Orla Mining Limited (Orla). At the request of Orla, this report was prepared by Kappes, Cassiday and Associates (KCA), Independent Mining Consultants, Inc. (IMC), and Resource Geosciences Incorporated (RGI).

The purposes of this Technical Report are as follows:

| · | Develop an NI 43-101 compliant Mineral Resource for the Camino Rojo deposit, |

| · | Present the results of a Preliminary Economic Analysis (PEA) for the implementation of open pit mining and heap leaching to recover the gold and silver mineralization, and |

| · | Propose additional work required for Preliminary Feasibility or Feasibility level studies. |

This PEA is preliminary in nature and it includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves and there is no certainty that the PEA will be realized. The project considers open pit mining of approximately 42.5 million tonnes of material with an estimated grade of 0.71 g/t gold and 13.6 g/t silver. Material from the pit will be crushed to 80% passing 38mm (100% passing 66mm), conveyor stacked onto a heap leach pad and leached using a low concentration sodium cyanide solution. Pregnant solution from the heap leach will be processed in a Merrill-Crowe recovery plant where gold and silver will be precipitated from deaerated pregnant solution with zinc dust. The resulting precious metal sludge will be filtered and dried in a mercury retort to produce the final doré product.

The average processing throughput for the Camino Rojo project is 18,000 tonnes of material per day. The project will be developed in two stages with expansion of the leach pad and addition of conveying equipment occurring in Year 2 of operation. The scope of this study includes a mine production schedule, as well as costing for all process components and infrastructure required for the operation. This report also presents a mineral resource estimate. The PEA is based on the oxide and transitional portion of this resource.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-1 |

| AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

1.2 Property Description and Ownership

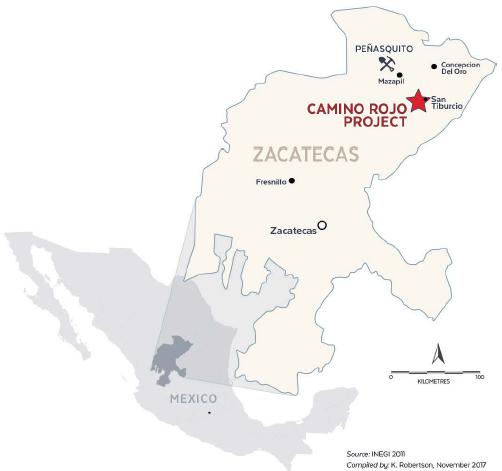

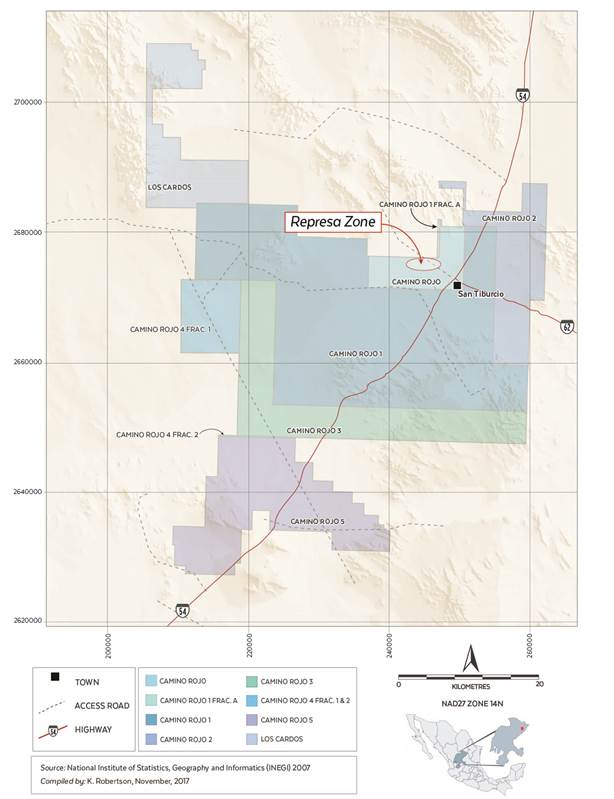

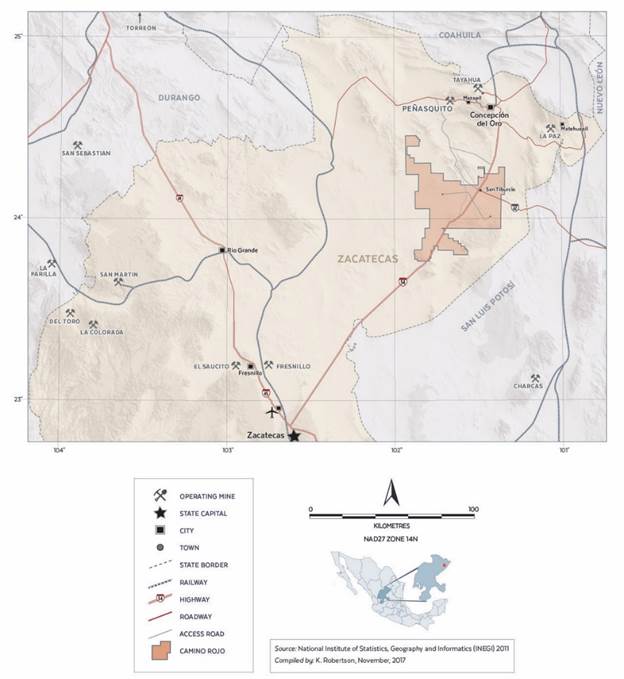

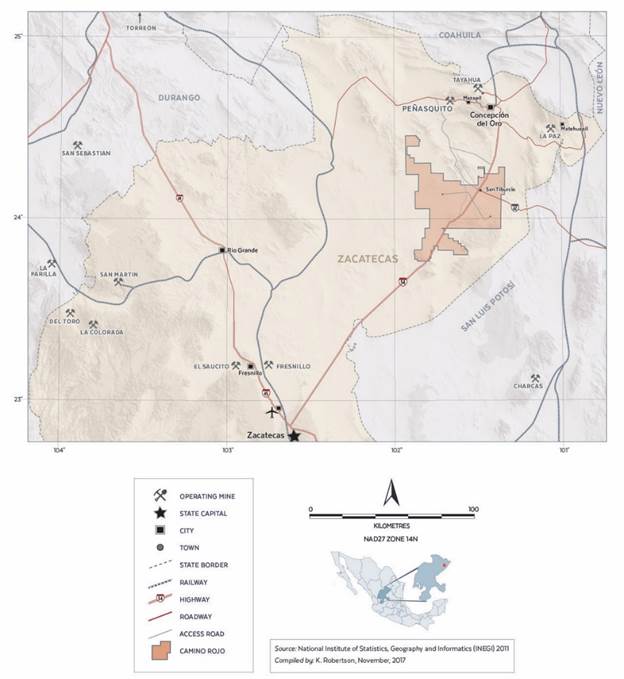

The Camino Rojo project is located in the Municipality of Mazapil, State of Zacatecas, near the village of San Tiburcio. The project lies 190 km NE of the city of Zacatecas, 48 km S-SW of the town of Concepcion del Oro, Zacatecas, and 54 km S-SE of Goldcorp’s Peñasquito Mine. The project area is centered at approximately 244150E 2675900N UTM NAD27 Zone 14N.

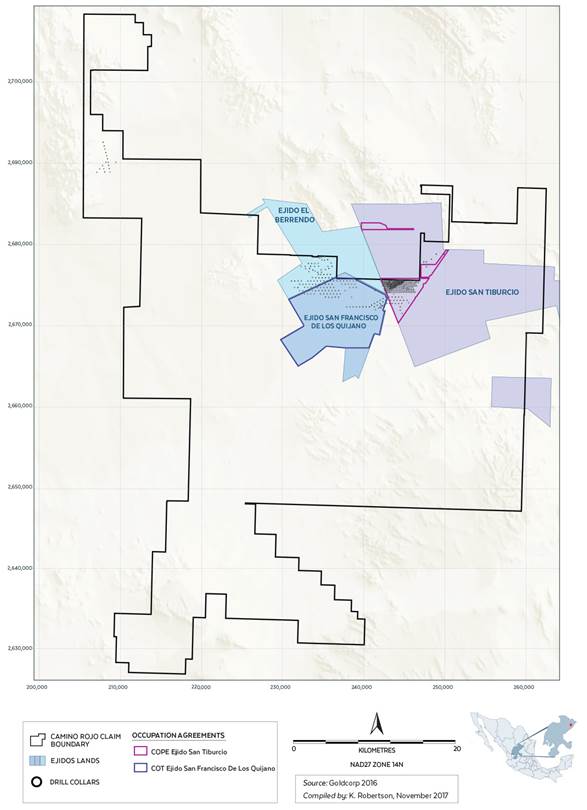

The project mineral rights are held by Orla’s Mexican subsidiary Minera Camino Rojo S.A. de C.V. (MCR) in 8 mining concessions covering approximately 2,059 square kilometers. Surface rights are held by the Ejido San Tiburcio, a communal agrarian cooperative. Exploration has been carried out under the authority of agreements between the project operators and the Ejido San Tiburcio. There is a temporary occupation with right to expropriate agreement in place with the Ejido San Tiburcio that covers all the area of the resource and area of potential development described in this report. MCR has water rights for sufficient volumes of water to develop the project.

1.3 Geology & Mineralization

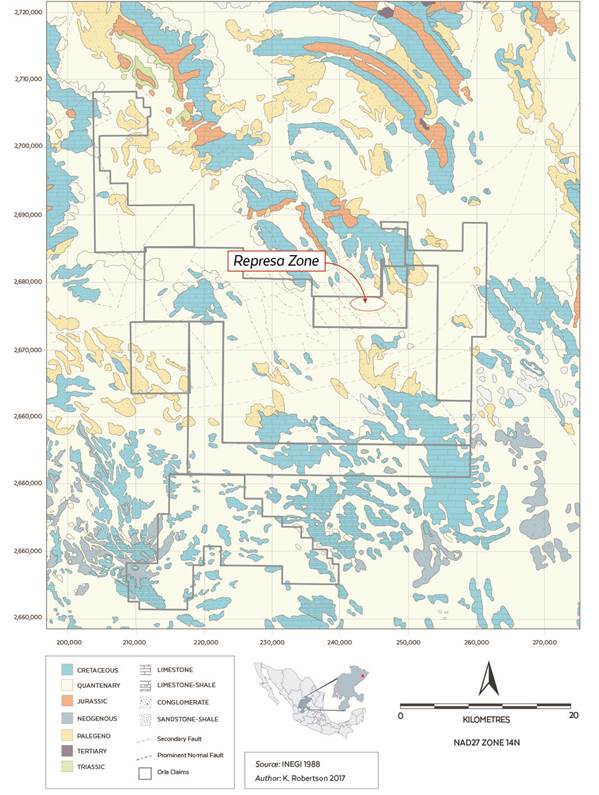

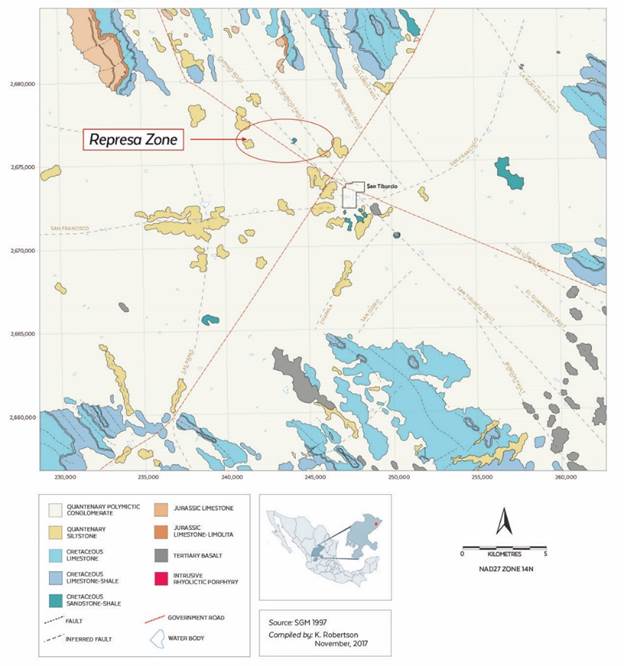

The Camino Rojo project comprises intrusive related, clastic sedimentary strata hosted, polymetallic Au, Ag, As, Zn, and Pb mineralization.

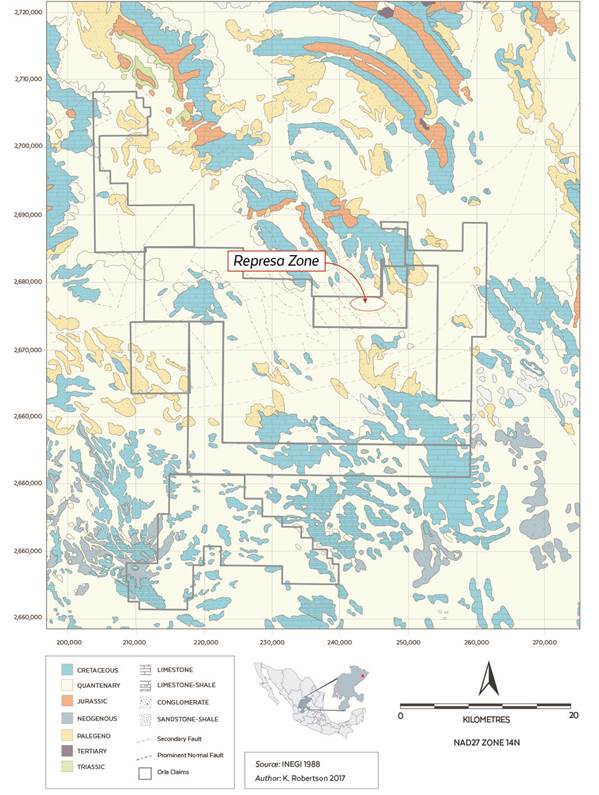

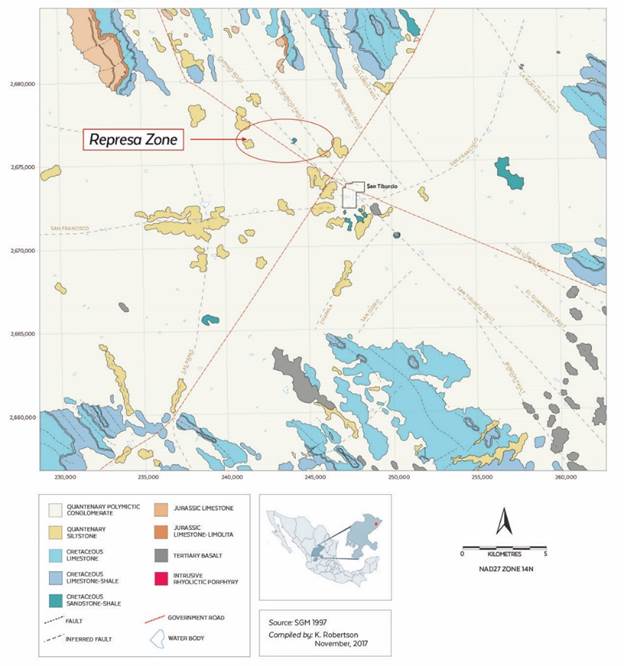

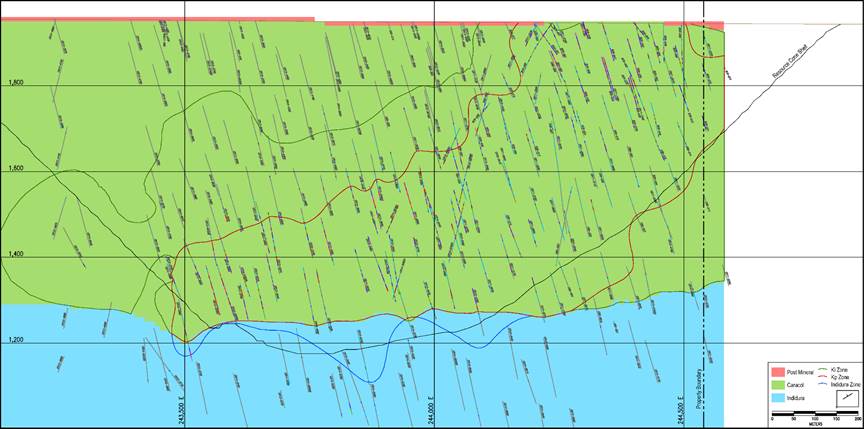

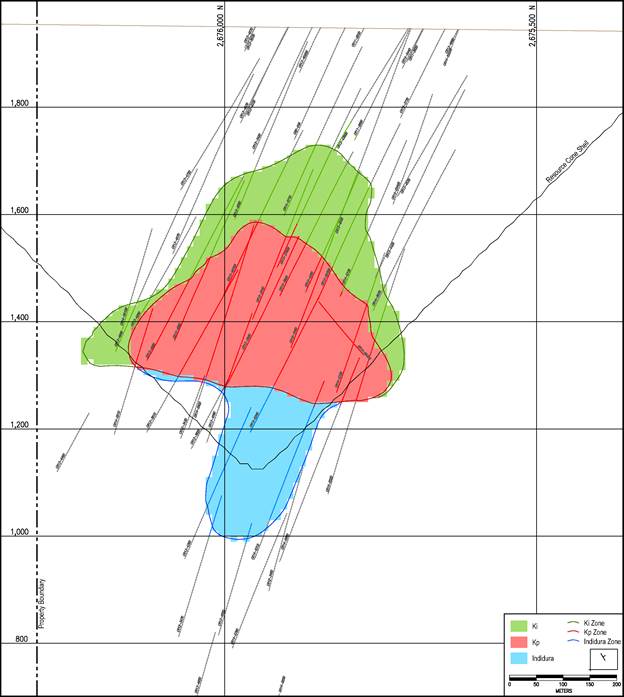

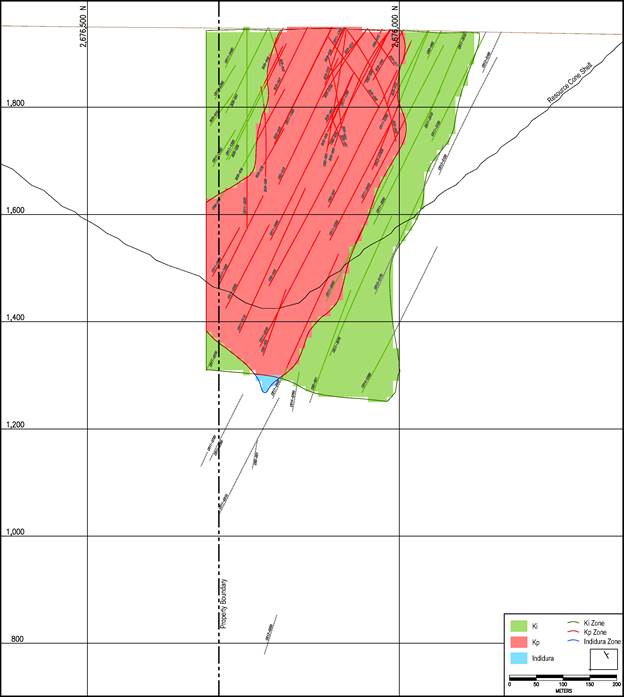

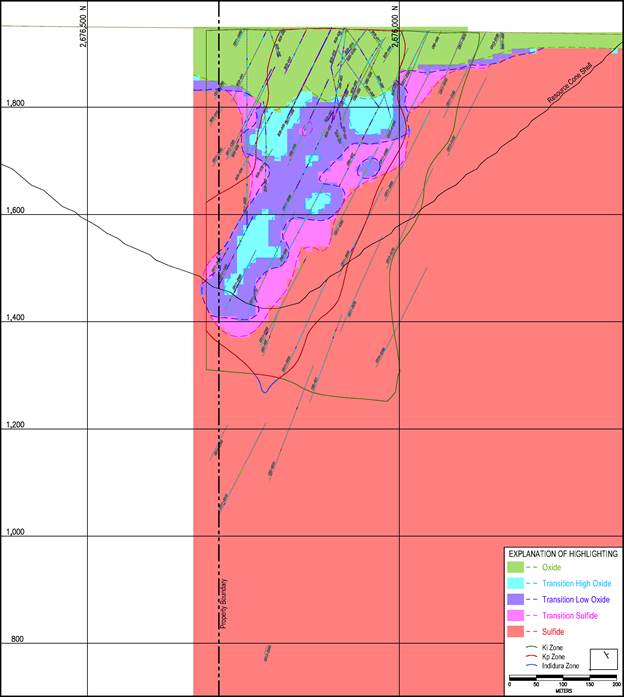

The Camino Rojo deposit is hosted by Cretaceous submarine sedimentary strata, dominantly clastic. The most important mineralization host is the Caracol Formation, a rhythmically interbedded sequence of weakly calcareous turbiditic sandstones, siltstones and shales. The underlying Indidura Formation, comprised of regularly bedded reduced siltstones and shales, and the Cuesta del Cura limestone, now recrystallized to white fine grained marble, host a minor amount of sulphide mineralization, but are inconsequential hosts of oxide mineralization. The gold-silver-lead-zinc deposit is situated above, and extends down into, a zone of feldspathic hornfels developed in the sedimentary strata, and variably mineralized dacitic dikes. The mineralized zones correspond to zones of sheeted sulfidic veins and veinlet networks, creating a bulk-mineable style of gold mineralization. Skarn mineralization has been encountered in the deeper portions of the system. The observed geologic and geochemical characteristics of the gold-silver-lead-zinc deposit at Camino Rojo are consistent with those of a distal oxidized gold skarn deposit. The metal suite and style of mineralization at Camino Rojo are similar to the intrusion-related deposits in the Caracol Formation and underlying carbonate rocks adjacent to the diatremes at Peñasquito.

For purposes of this study, only the economic potential of the oxide and partially oxidized transitional mineralization amenable to Au and Ag recovery via standard cyanide heap leach processing, is evaluated.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-2 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

1.4 Exploration and Drilling

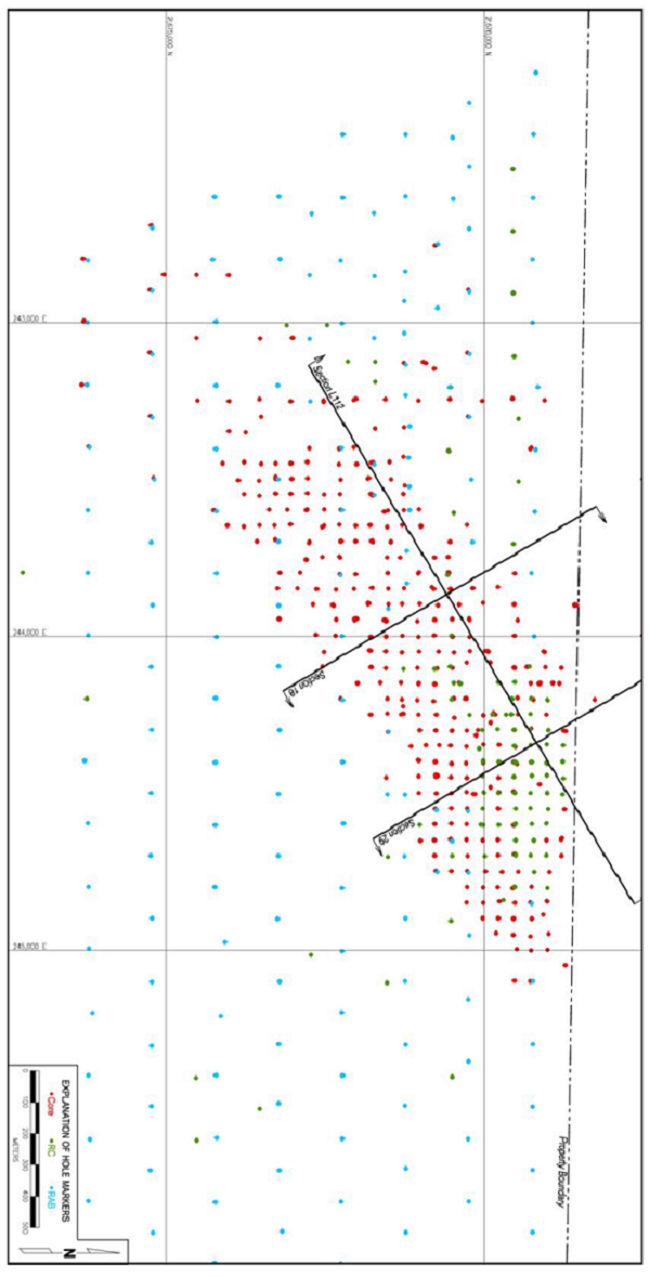

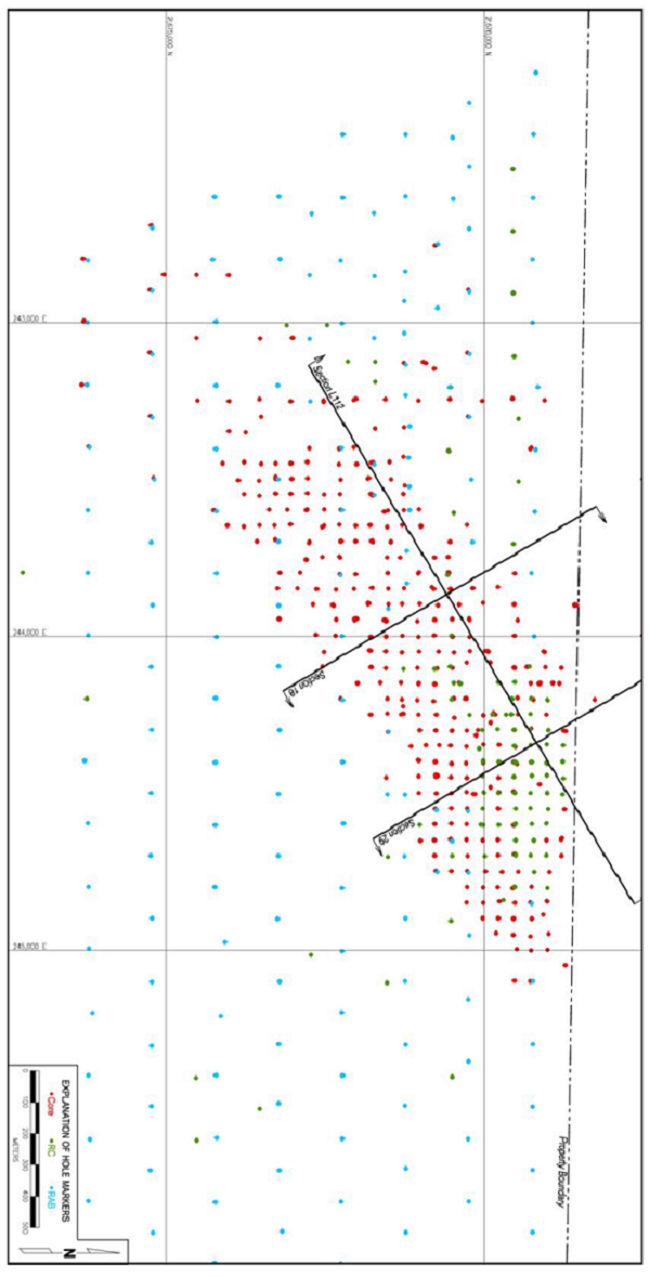

The Camino Rojo deposit was discovered in mid-2007 and was originally entirely concealed beneath post-mineral cover in a broad, low relief alluvial valley adjacent to the western flank of the Sierra Madre Oriental. Mineralized road ballast placed on a dirt road near San Tiburcio, Zacatecas, was traced to its source by geologists Perry Durning and Bud Hillemeyer from La Cuesta International, working under contract to Canplats Resources Corporation (Canplats). A shallow pit excavated through a thin veneer of alluvium, located adjacent to a stock pond (represa) was the discovery exposure of the deposit. Canplats began concurrent programs of surface geophysics and reverse-circulation drilling in late 2007, which continued into 2008.

The initial drilling was focused on a 450m x 600m gold in rock geochemical anomaly named the Represa zone. Core drilling began in 2008. The geophysical survey defined two principal areas of high chargeability: one centered on the Represa zone and another 1 km to the west named the Don Julio zone. The elevated chargeability zones were interpreted as large volumes of sulphide mineralized rocks. Drilling by Canplats, and later drilling by Goldcorp Inc. (Goldcorp), confirmed the presence of extensive sulphide mineralization at depth in the Represa zone, and much lower quantities of sulphide minerals at Don Julio.

By August of 2008, Canplats drilled a total of 92 reverse-circulation, and 30 diamond-core holes, for a total of 23,988m and 16,044m respectively, mainly focused in the Represa zone.

Canplats was acquired by Goldcorp in early 2010. Validation, infill, condemnation, and expansion drilling began in January 2011. By the end of 2015, a total of 279,788m of new core drilling in 415 drillholes and 20,569m of new RC drilling in 96 drillholes was completed in the Represa and Don Julio zones and their immediate surroundings. An additional 31,286m of shallow RAB-style, RC drilling in 306 drillholes was completed, with most of the RAB drilling testing other exploration targets within the concession. Airborne gravity, magnetic and TEM surveys were also carried out.

As of the end of 2015 a total of 295,832m in 445 diamond core holes, 44,557m in 188 RC drillholes, and 31,286m of RAB drilling had been completed. Orla acquired the project from Goldcorp in 2017 and through the effective date of this report, has completed approximately 1,850m of additional drilling in 10 diamond core holes for metallurgical sampling and 1,900m of drilling in 6 reverse circulation holes testing for water.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-3 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

1.5 Metallurgical Testwork

Metallurgical test work programs on the Camino Rojo project were commissioned by the prior operators of the project, Canplats Mexico and Goldcorp, and are considered as historical data. No metallurgical studies have been conducted by Orla at this time.

Based on the metallurgical data available, the Camino Rojo deposit shows significant variability in gold recoveries based on material type and geological domain with preg-robbing organic carbon being the only significant deleterious element identified. In general, recoveries for gold and silver are good and will yield acceptable results using conventional heap leaching methods with cyanide.

Key design parameters from the metallurgical test work are summarized below:

| · | Crush size of 80% passing 38mm. |

| · | Estimated gold recoveries (including 2% field deduction) of 70%, 58%, 60% and 49% for Kp Oxide, Ki Oxide, Transition-hi and Transition-lo materials, respectively. |

| · | Estimated silver recoveries (including 3% field deduction) of 13%, 20%, 17% and 20% for Kp Oxide, Ki Oxide, Transition-hi and Transition-lo materials, respectively. |

| · | Design leach cycle of 80 days. |

| · | Average cyanide consumption of 0.35 kg/t material. |

| · | Average lime consumption of 1.25 kg/t material. |

Additional column leach tests should be conducted to confirm recoveries at coarser crush sizes, especially for the Ki material type which has very little data available, in an effort to mitigate any associated risk.

1.6 Mineral Resource Estimate

The mineral resource includes potential mill resources and the potential heap leach resources, which are oxide dominant and are the emphasis of this PEA study.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-4 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

For the leach resource, measured and indicated mineral resources amount to 100.8 million tonnes at 0.734 g/t gold, 12.67 g/t silver, 0.21% lead, and 0.37% zinc. Contained metal amounts to 2.38 million ounces gold, 41.1 million ounces of silver, 455.8 million pounds of lead, and 814.8 million pounds of zinc. Inferred mineral resource is an additional 4.9 million tonnes at 0.772 g/t gold, 5.60 g/t silver, 0.07% lead, and 0.24% zinc. Contained metal amounts to 120,600 ounces of gold, 874,000 ounces of silver, 7.0 million pounds of lead, and 25.9 million pounds of zinc for the inferred mineral resource.

For the mill resource, measured and indicated mineral resources amount to 254.1 million tonnes at 0.889 g/t gold, 7.50 g/t silver, 0.07% lead, and 0.26% zinc. Contained metal amounts to 7.3 million ounces gold, 61.3 million ounces of silver, 402.0 million pounds of lead, and 1.46 billion pounds of zinc. Inferred mineral resource is an additional 60.3 million tonnes at 0.875 g/t gold, 7.90 g/t silver, 0.05% lead, and 0.23% zinc. Contained metal amounts to 1.7 million ounces of gold, 15.3 million ounces of silver, 68.1 million pounds of lead, and 310.8 million pounds of zinc for the inferred mineral resource. Table 1-1 presents a summary of the resource.

Table 1-1

Resource Summary

| Re source Type | | NSR Cog

($/t) | | | Kt | | | NSR

($/t) | | | Gold

(g/t) | | | Silver (g/t) | | | Lead

(%) | | | Zinc

(%) | | | Gold

(koz) | | | Silver

(koz) | | | Lead

(mlb) | | | Zinc

(mlb) | |

| Leach Resource: | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Measured Mineral Resource | | | 5.06 | | | | 16,147 | | | | 23.65 | | | | 0.794 | | | | 15.44 | | | | 0.26 | | | | 0.39 | | | | 412.1 | | | | 8,014 | | | | 92.1 | | | | 140.6 | |

| Indicated Mineral Resource | | | 5.06 | | | | 84,692 | | | | 20.07 | | | | 0.723 | | | | 12.15 | | | | 0.19 | | | | 0.36 | | | | 1,969.3 | | | | 33,076 | | | | 363.7 | | | | 674.3 | |

| Meas/Ind Mineral Resource | | | 5.06 | | | | 100,839 | | | | 20.64 | | | | 0.734 | | | | 12.67 | | | | 0.21 | | | | 0.37 | | | | 2,381.3 | | | | 41,091 | | | | 455.8 | | | | 814.8 | |

| Inferred Mineral Resource | | | 5.06 | | | | 4,858 | | | | 18.13 | | | | 0.772 | | | | 5.60 | | | | 0.07 | | | | 0.24 | | | | 120.6 | | | | 874 | | | | 7.0 | | | | 25.9 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Mill Resource: | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Measured Mineral Resource | | | 13.72 | | | | 9,818 | | | | 39.27 | | | | 0.864 | | | | 7.45 | | | | 0.08 | | | | 0.28 | | | | 272.6 | | | | 2,352 | | | | 16.4 | | | | 60.1 | |

| Indicated Mineral Resource | | | 13.72 | | | | 244251 | | | | 39.98 | | | | 0.890 | | | | 7.50 | | | | 0.07 | | | | 0.26 | | | | 6,992.2 | | | | 58,934 | | | | 385.6 | | | | 1,398.2 | |

| Meas/Ind Mineral Resource | | | 13.72 | | | | 254,069 | | | | 39.95 | | | | 0.889 | | | | 7.50 | | | | 0.07 | | | | 0.26 | | | | 7,264.8 | | | | 61,286 | | | | 402.0 | | | | 1,458.3 | |

| Inferred Mineral Resource | | | 13.72 | | | | 60,342 | | | | 39.04 | | | | 0.875 | | | | 7.90 | | | | 0.05 | | | | 0.23 | | | | 1,696.9 | | | | 15,334 | | | | 68.1 | | | | 310.8 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Total Mineral Re source | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Measured Mineral Resource | | | | | | | 25,965 | | | | 29.55 | | | | 0.820 | | | | 12.42 | | | | 0.19 | | | | 0.35 | | | | 684.6 | | | | 10,367 | | | | 108.5 | | | | 200.7 | |

| Indicated Mineral Resource | | | | | | | 328,943 | | | | 34.86 | | | | 0.847 | | | | 8.70 | | | | 0.10 | | | | 0.29 | | | | 8,961.5 | | | | 92,010 | | | | 749.3 | | | | 2,072.5 | |

| Meas/Ind Mineral Resource | | | | | | | 354,908 | | | | 34.47 | | | | 0.845 | | | | 8.97 | | | | 0.11 | | | | 0.29 | | | | 9,646.1 | | | | 102,377 | | | | 857.8 | | | | 2,273.2 | |

| Inferred Mineral Resource | | | | | | | 65,200 | | | | 37.49 | | | | 0.867 | | | | 7.73 | | | | 0.05 | | | | 0.23 | | | | 1,817.5 | | | | 16,208 | | | | 75.2 | | | | 336.8 | |

Notes:

| (1) | The mineral resource is effective as of April 27, 2018. |

| (2) | Columns may not sum exactly due to rounding. |

| (3) | Mineral resources that are not mineral reserves do not have demonstrated economic viability. |

| (4) | Mineral resources for leach material are based on prices of $1400/oz gold and $20/oz silver. |

| (5) | Mineral resources for mill material are based on prices of $1400/oz gold, $20/oz silver, $1.05/lb lead, and $1.25/lb zinc. |

| (6) | Mineral resources are based on NSR cut-off grades of $5.06/t for leach material and $13.72/t for mill material. |

| (7) | NSR value for leach material is as follows: |

Kp Oxide: NSR ($/t) = 30.77 x gold (g/t) + 0.080 x silver (g/t), based on gold recovery of 70% and silver recovery of 13%

Ki Oxide: NSR ($/t) = 25.49 x gold (g/t) + 0.123 x silver (g/t), based on gold recovery of 58% and silver recovery of 20%

Tran-Hi: NSR ($/t) = 26.37 x gold (g/t) + 0.104 x silver (g/t), based on gold recovery of 60% and silver recovery of 17%

Tran-Lo: NSR ($/t) = 21.54 x gold (g/t) + 0.123 x silver (g/t), based on gold recovery of 49% and silver recovery of 20%

Kappes, Cassiday & Associates June 19, 2018

| Page 1-5 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| (8) | NSR value for mill material is 36.75 x gold (g/t) + 0.429 x silver (g/t) + 10.75 x lead (%) + 12.37 x zinc (%), based on recoveries of 86% gold, 76% silver, 60% lead, and 64% zinc. |

| (9) | Table 14-2 accompanies this Mineral Resource statement and shows all relevant parameters. |

| (10) | The mineral resource estimate assumes that the floating pit cone used to demonstrate reasonable prospects for eventual economic extraction extends onto land held by the Adjacent Owner (as defined herein). Any potential development of the Camino Rojo Project that includes an open pit encompassing the entire mineral resource estimate would be dependent on obtaining an agreement with the Adjacent Owner. |

All of the mineralization comprised in the mineral resource estimate with respect to the Camino Rojo Project is contained on mineral titles controlled by Orla. However, the mineral resource estimate assumes that the north wall of the conceptual floating pit cone used to demonstrate reasonable prospects for eventual economic extraction extends onto lands where mineral title is held by Fresnillo PLC (the “Adjacent Owner”) and that waste would be mined on the Adjacent Owner’s mineral titles. Any potential development of the Camino Rojo Project that includes an open pit encompassing the entire mineral resource estimate would be dependent on obtaining an agreement with the Adjacent Owner. It is estimated that approximately two-thirds of the mineral resource estimate is dependent on an agreement being obtained with the Adjacent Owner. Delays in, or failure to obtain, an agreement with the Adjacent Owner to conduct mining operations on its mineral titles would affect the development of a significant portion of the mineral resources of the Camino Rojo Project that are not included in the PEA, in particular by limiting access to significant mineralized material at depth. Orla intends to seek an agreement with the Adjacent Owner in order to maximize the potential to develop a mine that exploits the full mineral resource. There can be no assurance that Orla will be able to negotiate such agreement on terms that are satisfactory to Orla or that there will not be delays in obtaining the necessary agreement.

1.7 Mining Methods

The Camino Rojo mine will be a conventional open pit mine. Mine operations will consist of drilling medium diameter blast holes (approximately 17cm), blasting with either explosive slurries or ANFO (ammonium nitrate/fuel oil) depending on water conditions, and loading into large off-road trucks with hydraulic shovels and wheel loaders.

Resource will be delivered to the primary crusher and waste to the waste storage facility southeast of the pit. There will also be a low-grade stockpile facility to store marginal resource for processing at the end of commercial pit operations. There will be a fleet of track dozers, rubber tired dozers, motor graders and water trucks to maintain the working areas of the pit, waste storage areas, and haul roads. The mine is scheduled to operate two 10 hour shifts per day for 365 days per year.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-6 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

Due to space limitations there is only one mining phase, the final pit. The final pit design is based on the results of a floating cone analysis using the parameters discussed in the mineral resource estimate.

The mine plan is constrained by the Adjacent Owner concession boundary on the north side of the pit. The PEA is based on only a portion of the total mineral resource estimate and was prepared on the assumption that no mining activities would occur on the Adjacent Owner’s mineral titles. Accordingly, delays in, or failure to obtain, an agreement with the Adjacent Owner to conduct mining operations on its mineral titles would have no impact on the timetable or cost of development of the potential mine modelled in the PEA.

1.8 Recovery Methods

Test work results developed by KCA and others have indicated that the Camino Rojo mineral is amenable to heap leaching for the recovery of gold and silver. The material will be mined by standard open pit mining methods and crushed at a rate of 18,000 tpd to 80% passing 38mm (100% passing 66mm) using a two-stage closed crushing circuit and conveyor stacked on the leach pad in 10m lifts. Lime will be added to the material for pH control before being stacked and leached with a dilute sodium cyanide solution. Pregnant solution will flow by gravity to a pregnant solution pond before being pumped to a Merrill-Crowe plant for metal recovery. Gold and silver will be precipitated from the pregnant solution via zinc cementation. The precious metal precipitate is dewatered using filters, dried in a mercury retort to remove mercury values, and smelted to produce the final doré product.

The process has been designed to process 6.57 million tonnes per year at an average processing rate of 18,000 tpd. The project has an estimated mine life of 6.6 years.

Electric power will be provided by line power to all elements of the process.

An event pond is included to collect contact solution from storm events. Solution collected will be returned to the process as soon as practical.

1.9 Infrastructure

Existing infrastructure for the Camino Rojo project includes a 20-person exploration camp and dirt and gravel roads throughout the project site. Internet and limited cellular communications are currently available, though these systems will need to be expanded for operations.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-7 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

Primary access to the project site is by the paved four-lane Mexican Highway 54 which runs along the project site. An additional 8.4 km of site roads will be constructed to allow access to all project facilities for maintenance, transportation of personnel, deliveries, and hauling of material.

Power will be supplied by a 115 kVA overhead power line and distributed at 4160 V. Power will be stepped down as needed to 460 V or 110/220 V. Emergency power will be provided by two diesel-fired generators, which are sized to supply power to the process solution pumping systems and other critical process equipment.

Water for operations will be provided by water wells. Average make-up water required is estimated at 112 m3/h.

Project buildings will primarily be prefabricated steel buildings or concrete masonry unit buildings and include an administration building, mine truck shop, warehouse, laboratory, guard house, clinic, refinery and MCCs (motor control centers).

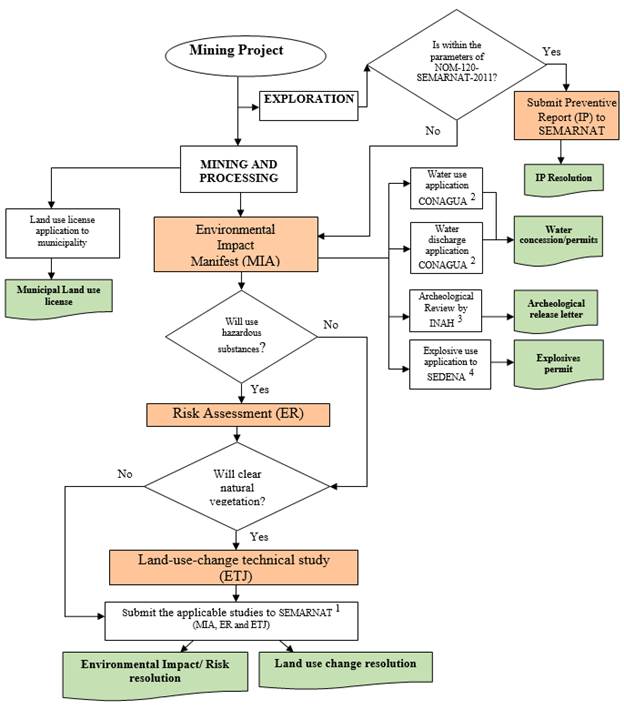

1.10 Environmental Studies, Permitting and Social or Community Impact

Exploration and mining activities in Mexico are subject to control by the Federal agency of the Secretaria del Medio Ambiente y Recursos Naturales (Secretary of the Environment and Natural Resources), known by its acronym SEMARNAT, which has authority over the two principal Federal permits:

| i. | A Manifesto de Impacto Ambiental (Environmental Impact Statement), known by its acronym as an MIA accompanied by a Estudio de Riesgo (Risk Study, hereafter referred to as ER) and: |

| ii. | A Cambio de Uso de Suelo (Land Used Change) permit, known by its acronym as a CUS, supported by an Estudio Tecnico Justificativo (Technical Justification Study, known by its acronym ETJ). |

Thus far exploration work at Camino Rojo has been conducted under the auspices of two separate MIA permits and corresponding CUS permits. These permits allow for extensive exploration drilling but are not sufficient for mine construction or operation. In April 2018, Orla hired independent environmental permitting consultants to design and implement baseline environmental studies of the Camino Rojo project, and to work with Orla’s consultant engineers to collect the data required for obtaining a Manifesto de Impacto Ambiental (Environmental Impact Statement) and Cambio de Uso de Suelo (Land Use Change) permit.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-8 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

The project is not located in an area with any special Federal environmental protection designation and no factors have been identified that would be expected to hinder authorization of required Federal and State environmental permits. Properly prepared MIA and CUS applications and mine operating permits for a project that does not affect federally protected biospheres or ecological reserves can usually be approved in 12 months.

In April 2018, Orla commissioned independent consultants to work with Minera Camino Rojo community relations staff to assess social and community impacts of development of the Camino Rojo project. The project has a long association with the local communities, including Community and Social Responsibility Agreements as described in Section 4.3 of this report.

1.11 Capital and Operating Costs

Capital and operating costs for the process and general administration components of the Camino Rojo project PEA were estimated by KCA. Costs for the mining components were provided by IMC. All costs are presented in first quarter 2018 US dollars. Estimated costs are considered to have an accuracy of +/-25% for capital costs and +/-20% for operating costs.

The total capital cost for the Project is US$153.8 million, including US$13.8 million in working capital and not including reclamation and closure costs, IVA (value added tax) or other taxes; all IVA is assumed to be fully refundable. Table 1-2 presents the capital requirements for the Camino Project.

Table 1-2

Capital Cost Summary

| Description | | Cost (US$) | |

| Pre-Production Capital | | $ | 120,199,000 | |

| Working Capital & Initial Fills | | $ | 13,789,000 | |

| Mining Contractor Mobilization & Preproduction | | $ | 4,926,000 | |

| Sustaining Capital – Mine & Process | | $ | 14,871,000 | |

| Total excluding IVA | | $ | 153,785,000 | |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-9 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

All equipment and material requirements are based on the design information described in this report. Budgetary capital costs for process related components have been estimated primarily based on quotes from similar projects in KCA’s database and cost guide data at the time this report was initially completed in June 2018. Where quotes were not available at the time, reasonable cost estimates or allowances were made. All capital cost estimates are based on the purchase of equipment quoted new from the manufacturer or to be fabricated new.

The average life of mine operating cost for the Project is US$8.02 per tonne of material processed. Table 1-3 presents the operating cost requirements for the Camino Rojo Project.

Table 1-3

Operating Cost Summary

| Description | | LOM Cost (US$/t) | |

| Mine | | $ | 3.05 | |

| Process & Support Services | | $ | 3.20 | |

| Site G & A | | $ | 1.77 | |

| Total | | $ | 8.02 | |

Mining operating costs have been estimated by IMC and are based on contract mining at US$1.81 per tonne of material moved. Process operating costs have been estimated from first principles. Labor costs were estimated using project specific staffing, salary and wage and benefit requirements. Unit consumptions of materials, supplies, power, water and delivered supply costs were also estimated.

The process operating costs presented are based upon the ownership of all process production equipment and site facilities. The owner will employ and direct all operating maintenance and support personnel for all site activities.

IVA is not included in the operating costs.

1.12 Economic Analysis

Based on the estimated production parameters, capital costs, and operating costs, a cash flow model was prepared by KCA for the economic analysis of the Camino Rojo project. The project economics were evaluated using a discounted cash flow (DCF) method, which measures the Net Present Value (NPV) of future cash flow streams.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-10 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

The final economic model was developed by KCA, with input from Orla, using the following assumptions:

| · | Period of Analysis of nine years (includes one year of pre-production and investment, seven years of production and one year for reclamation and closure). |

| · | Gold price of US$1,250/oz and silver price of US$17/oz. |

| · | Processing rate of 18,000 tonnes per day material. |

| · | Gold and silver recoveries as discussed in Section 13.0. |

| · | Capital and operating costs as developed in Section 21.0. |

The project economics based on these criteria from the cash flow model are summarized in Table 1-4.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-11 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

Table 1-4

Economic Analysis Summary

| Economic Analysis | | | | | |

| Internal Rate of Return (IRR), Pre-Tax | | | 38.1 | % | | |

| Internal Rate of Return (IRR), After-Tax | | | 24.5 | % | | |

| Average Annual Cashflow (Pre-Tax) | | $ | 60 | | | M |

| NPV @ 5% (Pre-Tax) | | $ | 231 | | | M |

| Average Annual Cashflow (After-Tax) | | $ | 43 | | | M |

| NPV @ 5% (After-Tax) | | $ | 121 | | | M |

| Gold Price Assumption | | $ | 1,250 | | | /Ounce |

| Silver Price Assumption | | $ | 17 | | | /Ounce |

| Pay-Back Period (Rears based on After-Tax) | | | 3.3 | | | Years |

| | | | | | | |

| Capital Costs (Excluding IVA) | | | | | | |

| Initial Capital | | $ | 125 | | | M |

| Working Capital & Initial Fills | | $ | 14 | | | M |

| LOM Sustaining Capital | | $ | 15 | | | M |

| | | | | | | |

| Operating Costs (Average LOM) | | | | | | |

| Mining | | $ | 3.05 | | | /Tonne processed |

| Processing & Support | | $ | 3.20 | | | /Tonne processed |

| G&A | | $ | 1.77 | | | /Tonne processed |

| Total Operating Cost | | $ | 8.02 | | | /Tonne processed |

| Total By-Product Cash Cost | | $ | 499 | | | /Ounce Au |

| All-in Sustaining Cost | | $ | 555 | | | /Ounce Au |

| | | | | | | |

| Production Data | | | | | | |

| Life of Mine | | | 6.6 | | | Years |

| Total Tonnes to Crusher | | | 42,477,000 | | | Tonnes |

| Grade Au (Avg.) | | | 0.71 | | | g/t |

| Grade Ag (Avg.) | | | 13.56 | | | g/t |

| Contained Au oz | | | 966,000 | | | Ounces |

| Contained Ag oz | | | 18,517,000 | | | Ounces |

| Mine Throughput per day | | | 18,000 | | | Tonnes/day |

| Mine Throughput per year | | | 6,570,000 | | | Tonnes/year |

| Metallurgical Recovery Au (Overall) | | | 67 | % | | |

| Metallurgical Recovery Ag (Overall) | | | 15 | % | | |

| Average Annual Gold Production | | | 97,472 | | | Ounces |

| Average Annual Silver Production | | | 415,981 | | | Ounces |

| Total Gold Produced | | | 642,382 | | | Ounces |

| Total Silver Produced | | | 2,741,485 | | | Ounces |

| LOM Strip Ratio | | | 0.58:1 | | | |

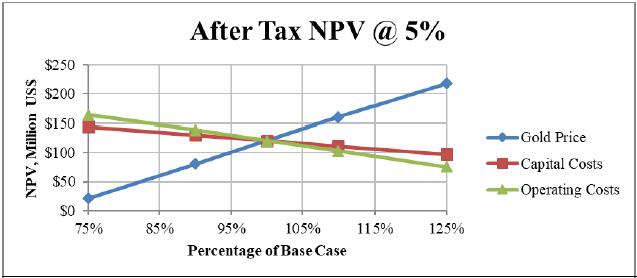

A sensitivity analysis was performed on the project economics. Figure 1-1 and Figure 1-2 are charts showing the relative sensitivity to a number of parameters.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-12 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

Figure 1-1

After-Tax IRR vs. Gold Price, Capital Cost, and Operating Cost

Figure 1-2

NPV @ 5% vs. Gold Price, Capital Cost, and Operating Cost

1.13 Interpretations and Conclusions

1.13.1 Conclusions

The work that has been completed to date has demonstrated that Camino Rojo is potentially a technically and economically viable project and justifies additional work, including a pre-feasibility or feasibility study.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-13 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

The project has been designed as an open-pit mine with heap leach for recovery of gold and silver from oxide and transition material with a life of mine production of 42.5 million tonnes with an average grade of 0.71 g/t Au and 13.6 g/t Ag. Metallurgical test work on the material to date shows acceptable recoveries for gold and silver with low to moderate reagent consumptions. Cement agglomeration does not appear to be required.

Leachable material will be crushed to P80 38mm, stockpiled, reclaimed and conveyor stacked onto the heap leach pad at an average rate of 18,000 tpd. Stacked material will be leached using low grade sodium cyanide solution and the resulting pregnant leach solution will be processed in a Merrill-Crowe plant for the recovery of gold and silver by zinc cementation.

1.13.2 Opportunities

Key opportunities for the Camino Rojo project include:

| · | Based on test work to date, metal recoveries are relatively insensitive to crush size and the same results may be achievable at coarser material sizes, which would result in lower capital and operating costs. |

| · | If an agreement can be achieved with the owner of the adjoining claim, there would be an increase in the amount of material that could potentially be mined and processed with the same general mine and process plan as the PEA is based upon. This would be positive for the project economics. |

1.13.3 Risks

Risks for the Camino Rojo project include:

| · | Camino Rojo considers contract mining. There is a risk that the selected mining contractor may require financial assistance from the owner, which may increase costs. |

| · | Metallurgical results for the Camino Rojo project are based on information and data that have been extrapolated from results from historical test work and are speculative due to lack of direct confirmatory test work. There is a risk that the results may be overstated. |

| · | Carbonaceous material with preg-robbing characteristics has been identified, which may reduce overall heap performance and metal recovery if processed. |

| · | Additional studies on the proposed power line to site, including approval from the Mexican CFE, is required to confirm the proposed power line is feasible. Based on the results of these studies, an alternative power supply method may be required which may increase project costs. |

Kappes, Cassiday & Associates June 19, 2018

| Page 1-14 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

1.14 Recommendations

Based on the results of the PEA, KCA and IMC recommend the following additional work:

| · | The project should proceed to the prefeasibility or feasibility study level; |

| · | Additional studies and cost estimates for delivery of line power to the project site should be completed; |

| · | Confirmatory metallurgical test work should be completed on representative samples for each mineral type, specifically column leach tests on coarse crushed material; |

| · | Perform geotechnical and hydrogeological studies at the proposed heap, pit and processing areas; |

RGI recommends drilling an additional 5,000m to further evaluate the known sulphide resource, and implementation of an exploration program, including 7,500m of drilling, to seek additional resources within the project concessions.

The total estimated cost to complete the recommended work is US$7.5 million.

Kappes, Cassiday & Associates June 19, 2018

| Page 1-15 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

2.0 INTRODUCTION

2.1 Introduction and Overview

This Technical Report is issued to Orla Mining Ltd. (Orla). Orla is listed on the TSX Venture Exchange (TSX VENTURE: OLA) and holds a 100% interest in the Camino Rojo deposit through its Mexican subsidiary Minera Camino Rojo S.A. de C.V (MCR). This report was prepared by Kappes, Cassiday and Associates (KCA), Resource Geosciences Incorporated (RGI) and Independent Mining Consultants, Inc. (IMC).

This Technical Report was amended on March 11, 2019 to address certain comments from the British Columbia Securities Commission in connection with Orla’s filing of a preliminary base shelf prospectus. There has been no change to the Mineral Resource estimate or the PEA (as defined below)

The purposes of this Technical Report are as follows:

| | · | Develop an NI 43-101 compliant Mineral Resource for the Camino Rojo deposit, |

| | · | Present the results of a Preliminary Economic Analysis (PEA) for the implementation of open pit mining and heap leaching to recover the gold and silver mineralization, and |

| | · | Propose additional work required for Preliminary Feasibility or Feasibility level studies. |

The project considers open pit mining of approximately 42.5 million tonnes of material with an estimated grade of 0.71 g/t gold and 13.6 g/t silver. Material from the pit will be crushed to 80% passing 38mm (100% passing 66mm), conveyor stacked onto a heap leach pad and leached using a low concentration sodium cyanide solution. Pregnant solution from the heap leach will be processed in a Merrill-Crowe recovery plant where gold and silver will be precipitated from deaerated pregnant solution with zinc dust. The resulting precious metal sludge will be filtered and dried in a mercury retort to produce the final doré product.

The average processing throughput for the Camino Rojo project is 18,000 tonnes of material per day and will be developed in two stages with expansion of the leach pad and addition of conveying equipment occurring in Year 2 of operation. The scope of this study includes development of a preliminary mine production schedule, as well as preliminary-level costing for all process components and infrastructure required for the operation.

Kappes, Cassiday & Associates June 19, 2018

| Page 2-1 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

This study considers the potential viability of mineral resources for the proposed development option and includes:

| | · | a mineral resource estimate; |

| | · | historical exploration work, description of the property, geology and nature of mineralization; |

| | · | evaluations of processing options and plant throughputs; |

| | · | analysis of infrastructure and logistic strategies; |

| | · | new costing studies; and |

| | · | a preliminary economic model based upon the results of those studies. |

The property description, including reporting on historical exploration work, geology and mineralization, environmental review and assessment of regulatory requirements and adjacent properties have previously been published by RGI by Matthew Gray in a report with a 13 January 2018 effective date titled, “CSA NI43-101 Technical Report on the Camino Rojo Project, Municipio of Mazapil, Zacatecas, Mexico.” (the January Report). The report was written in compliance with disclosure and reporting requirements set forth in National Instrument “Standards of Disclosure for Mineral Projects” (NI 43-101).

This Technical Report supersedes the January Report.

2.2 Project Scope and Terms of Reference

2.2.1 Scope of Work

The purpose of this Technical Report is to provide a mineral resource estimate for the Camino Rojo deposit and a preliminary economic analysis of a conceptual mining and processing project treating the oxide and transition materials detailed in the mineral resource estimate.

KCA’s scope of work for the project is summarized as follows:

| | · | Review of historical metallurgical tests and interpretation, |

| | · | Plant design and recovery methods, |

| | · | Infrastructure process capital and operating costs, |

| | · | Overall report preparation and compilation. |

Kappes, Cassiday & Associates June 19, 2018

| Page 2-2 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

IMC’s scope of work for the project is summarized as follows:

| | · | Audit the drillhole database for the Camino Rojo deposit, |

| | · | Develop the mineral resource block model for the deposit, |

| | · | Estimate NI 43-101 compliant mineral resource, |

| | · | Develop an operational mine plan for the open pit, and |

| | · | Estimate mine equipment requirements, mine capital costs, mine operating costs, and contract mining costs for the project. |

RGI’s scope of the work for the project is summarized as follows:

| | · | Create a property description, including reporting on historical exploration work, geology and mineralization, environmental liabilities, location, access, physiography, infrastructure, claim ownership, and surface rights ownership, |

| | · | Assessment of regulatory requirements and description of the steps required to obtain construction and operating permits for the mine plan described in this report, |

| | · | Assess risks to project development related to access, title, permits, and security. |

The scope of this report also includes a study of information obtained from public documents; other literature sources cited; review of historical metallurgical tests and programs conducted to date; cost information from public documents and recent estimates from previous studies conducted by KCA.

This PEA is intended to provide the project’s preliminary economics and to give guidance for the implementation of the Camino Rojo project.

2.2.2 Terms of Reference

The units of measure presented in this report, unless noted otherwise, are in the metric system. The currency used for all costs is presented in US dollars (US$), unless specified otherwise. The costs were estimated based on quotes and cost data as of 1st quarter 2018.

The economic evaluation of the Project has been conducted on a constant dollar basis (Q1 2018) with a gold price of US$1,250/oz and a silver price of US$17/oz for the Base Case. Economic evaluation is done on a Project-basis and from the point of view of a private investor, after deductions for royalties, income taxes, and various mining taxes and duties paid to the government of Mexico. An exchange ratio of 18 pesos = 1.00 US$ was used for any costs converted from Mexican currency.

Kappes, Cassiday & Associates June 19, 2018

| Page 2-3 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

2.3 Sources of Information

The primary sources of information used for this study include:

| | · | The digital drillhole database. This was developed during the Canplats and Goldcorp tenure. |

| | · | The original assay certificates for the holes. |

| | · | Various geologic solids that were developed (interpreted) by Orla geologists. |

| | · | Various reports, including previous technical reports, on sampling methodology, quality control and quality assurance (QA/QC), resource modeling, geotechnical and slope stability, mine planning, and economic evaluations. These were developed by Canplats, Goldcorp, and various consultants. |

| | · | Various reports on metallurgical testing, process recovery, and mineral processing that were developed by Canplats, Goldcorp, and other consultants. |

| | · | Published reports on Mexican taxes and duties. |

KCA, IMC, and RGI reviewed the data and only used data that were deemed reliable for this report.

2.4 Qualified Persons and Site Visits

Table 2-1 shows QP’s responsible for each section of this Technical Report.

The new processing studies, cost estimations, and financial analysis and review of historical metallurgical data were conducted by KCA under the auspices of Carl Defilippi, of Reno, NV. Mr. Defilippi is an independent qualified person under NI 43-101, and last visited the site on 20 and 21 of February 2018.

Matthew D. Gray, Ph.D., C.P.G, the Qualified Person responsible for Sections 4 through 9, Section 20 and Section 23 of this report, conducted field visits to the Camino Rojo Gold Project, Zacatecas, Mexico, during the period 12 to 13 December 2016 as part of Orla’s due diligence review of the project, which at the time was owned and operated by Goldcorp, and visited again during the period 19 to 22 February 2018.

Kappes, Cassiday & Associates June 19, 2018

| Page 2-4 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

Prior to the field visit and data review conducted for the purposes of this Technical Report, Dr. Gray had been directly involved in mineral exploration programs in the region but had not conducted examinations of the Camino Rojo project.

Michael G. Hester, Vice President and Principal Mining Engineer for IMC, is an independent Qualified Person. Mr. Hester is responsible for the mineral resource estimate, the mine plan used for the PEA study, and the mine capital and operating cost estimates. Mr. Hester visited the site on 20 and 21 February 2018 for two days.

There is no affiliation between Mr. Defilippi, Dr. Gray and Mr. Hester and Orla except that of an independent consultant / client relationship and each author is considered to be independent of Orla as described in Section 1.5 of NI 43-101.

The effective date of the mineral resource is April 27, 2018. The effective date of this PEA is June 19, 2018.

2.5 Forward Looking Information

The results of the PEA, and the mineral resource estimates represent forward-looking information that is subject to a number of known and unknown risks, uncertainties and other factors that may cause actual results to differ materially from those presented here. Forward-looking statements in this technical report include, but are not limited to, statements with respect to future metal prices, exchange rates; taxation; smelter and refinery terms; assumed mining and metallurgical recovery factors; net present value; internal rate of return; sensitivities on parameters; the estimation of mineral resources; the realization of estimates; the timing and amount of estimated future production, costs of production; capital expenditures; operating costs; technological changes to the mining, processing and waste disposal activities outlined; permitting time lines; requirements for additional capital; government regulation of mining operations; environmental risks; ability to retain social license for operations; unanticipated reclamation expenses; title disputes or claims; upside opportunities, pit wall angles, larger crush size and increase in the recoveries; ability to reach agreement with the Adjacent Owner; and limitations on insurance coverage.

Kappes, Cassiday & Associates June 19, 2018

| Page 2-5 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

Forward-looking statements are based on the beliefs, estimates and opinions on the date the statements are made. Certain material assumptions regarding such forward-looking statements are discussed in this report. Forward-looking statements involve significant known and unknown risks and uncertainties, which could cause actual results to differ materially from those anticipated. These risks include, but are not limited to: risks related to uncertainties inherent in the preparation of preliminary economic assessments, drill results and the estimation of mineral resources, including changes in the economic parameters; changes in Project parameters as mine, process and closure plans continue to be refined, possible variations in mineral resources, grade, dilution, or recovery rates; geotechnical and hydrogeological considerations during mining; failure of plant, equipment or processes to operate as anticipated; shipping delays and regulations; accidents, labor disputes and other risks of the mining industry; and delays in obtaining governmental approvals; risks relating to not securing agreements with third parties or not receiving required permits.

Kappes, Cassiday & Associates June 19, 2018

| Page 2-6 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

Table 2-1

Table of Responsibilities by Section

| Section | Section Title | QP |

| 1 | Summary | All |

| 2 | Introduction | C. Defilippi, KCA |

| 3 | Reliance on Other Experts | C. Defilippi, KCA |

| 4 | Property Description and Location | M. Gray, RGI |

| 5 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | M. Gray, RGI |

| 6 | History | M. Gray, RGI |

| 7 | Geological Setting and Mineralization | M. Gray, RGI |

| 8 | Deposit Types | M. Gray, RGI |

| 9 | Exploration | M. Gray, RGI |

| 10 | Drilling | M. Hester, IMC |

| 11 | Sample Preparation, Analyses and Security | M. Hester, IMC |

| 12 | Data Verification | M. Hester, IMC |

| 13 | Mineral Processing and Metallurgical Testing | C. Defilippi, KCA |

| 14 | Mineral Resource Estimates | M. Hester, IMC |

| 15 | Mineral Reserve Estimates | N/A |

| 16 | Mining Methods | M. Hester, IMC |

| 17 | Recovery Methods | C. Defilippi, KCA |

| 18 | Project Infrastructure | C. Defilippi, KCA |

| 19 | Market Studies and Contracts | C. Defilippi, KCA |

| 20 | Environmental Studies, Permitting and Social or Community Impact | M. Gray, RGI |

| 21 | Capital and Operating Costs | C. Defilippi (KCA) / M. Hester (IMC) |

| 22 | Economic Analyses | C. Defilippi, KCA |

| 23 | Adjacent Properties | M. Gray, RGI |

| 24 | Other Relevant Data and Information | All |

| 25 | Interpretation and Conclusions | All |

| 26 | Recommendations | All |

| 27 | References | All |

Kappes, Cassiday & Associates June 19, 2018

| Page 2-7 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

2.6 Frequently Used Acronyms, Abbreviations, Definitions and Units of Measure

All costs are presented in United States dollars. Units of measurement are metric. Only common and standard abbreviations were used wherever possible. A list of abbreviations used is as follows:

| Distances: | mm | – millimeter |

| | cm | – centimeter |

| | m | – meter |

| | km | – kilometer |

| | mbgl | – meters below ground level |

| Areas: | m2 or sqm | – square meter |

| | ha | – hectare |

| | km2 | – square kilometer |

| Weights: | oz | – troy ounces |

| | Koz | – 1,000 troy ounces |

| | mlb | – million pounds (imperial) |

| | g | – grams |

| | kg | – kilograms |

| | T or t | – tonne (1000 kg) |

| | Kt | – 1,000 tonnes |

| | Mt | – 1,000,000 tonnes |

| Time: | min | – minute |

| | h or hr | – hour |

| | op hr | – operating hour |

| | d | – day |

| | yr | – year |

| | Ma | – Mega-annum (one million years) |

| Volume/Flow: | m3 or cu m | – cubic meter |

| | m3/h | – cubic meters per hour |

| | L/s | – liters per second |

| Assay/Grade: | g/t | – grams per tonne |

| | g Au/t | – grams gold per tonne |

| | g Ag/t | – grams silver per tonne |

| | g Cu/t | – grams copper per tonne |

| | ppm | – parts per million |

Kappes, Cassiday & Associates June 19, 2018

| Page 2-8 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| | ppb | – parts per billion |

| Other: | TPD or tpd | – metric tonnes per day |

| | ktpy | – 1000 tonnes per year |

| | m3/h/m2 | – cubic meters per hour per square meter |

| | Lph/m2 | – liters per hour per square meter |

| | L/s/km2 | – liters per second per square kilometers |

| | g/L | – grams per liter |

| | kph | – kilometers per hour |

| | Ag | – silver |

| | Au | – gold |

| | Hg | – mercury |

| | US$ or $ | – United States dollar |

| | MXN | – Mexican Peso |

| | NaCN | – sodium cyanide |

| | TSS | – total suspended solids |

| | TDS | – total dissolved solids |

| | RAB | – rotary air blast |

| | RC | – reverse circulation |

| | TEM | – transient electromagnetic |

| | DDH | – diamond drill boreholes |

| | LOM | – Life of Mine |

| | kWh | – Kilowatt-hours |

| | kN | – Kilonewton |

| | P80 | – 80% passing |

Kappes, Cassiday & Associates June 19, 2018

| Page 2-9 |

| | AMENDED AND RESTATED |

| Camino Rojo Preliminary Economic Assessment | NI 43-101 Technical Report |

| 3.0 | RELIANCE ON OTHER EXPERTS |

KCA, RGI and IMC have taken all reasonable care in producing the information contained in this report. The information, conclusions and estimates contained in this report are consistent with the industry best practice guidelines, based on information available at the time of preparation and assumptions, conditions and qualifications set forth in this report.

The authors of this Technical Report are not experts in Mexican legal or environmental matters. Accordingly, for certain information pertaining solely to legal and environmental matters contained in Sections 4.2, 4.3, 4.5 and 4.6 the authors have relied upon:

| · | Mining concession title opinion provided by Lic. Mauricio Heiras, Mexican legal counsel for Orla on 28 June 2017 (Heiras, 2017) and in a report dated 6 January 2018 (Heiras, 2018). |

| · | Land access agreement summaries provided by Lic. Mauricio Heiras, Mexican legal counsel for Orla in a report dated 28 June 2017 (Heiras, 2017) and a report dated 6 January 2018 (Heiras, 2018). |

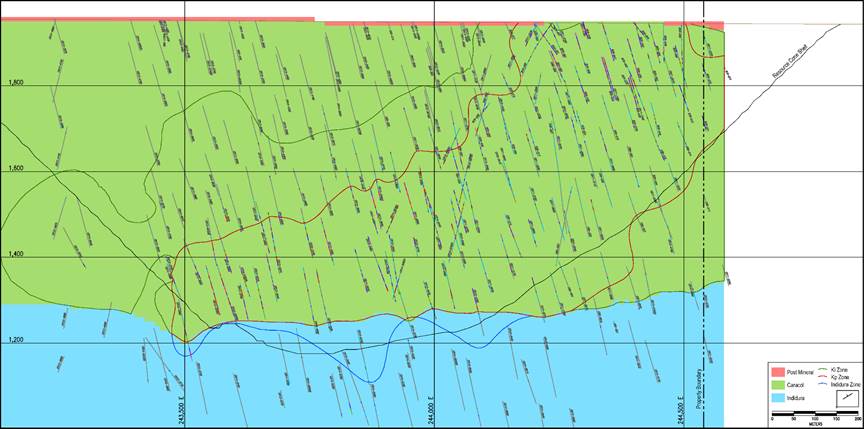

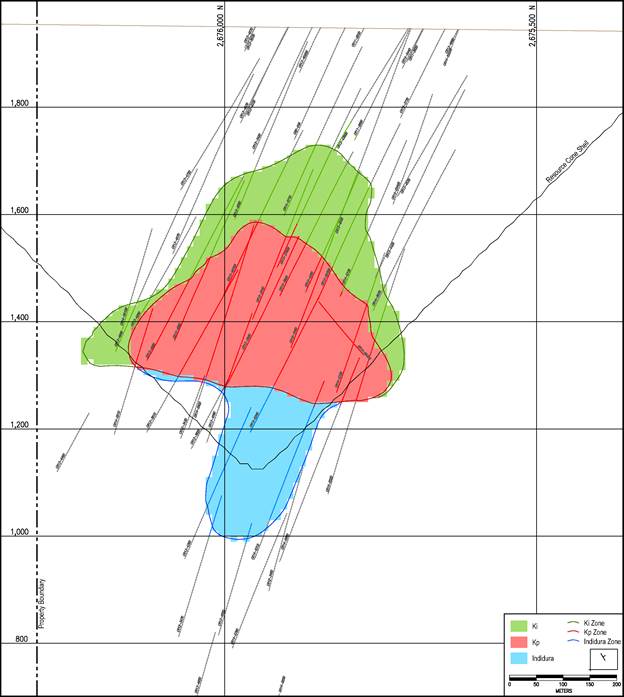

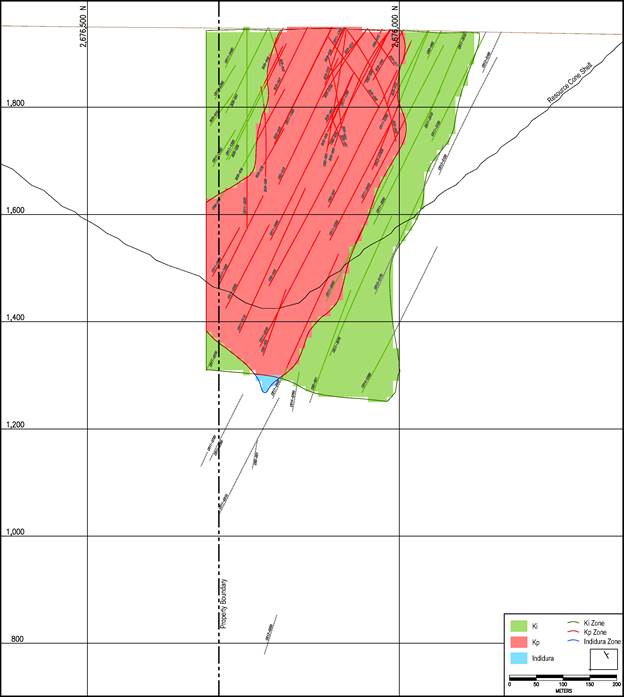

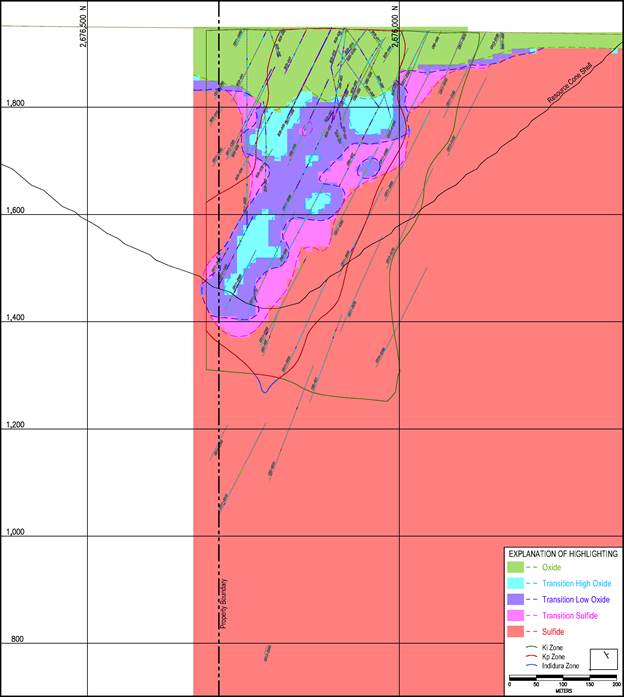

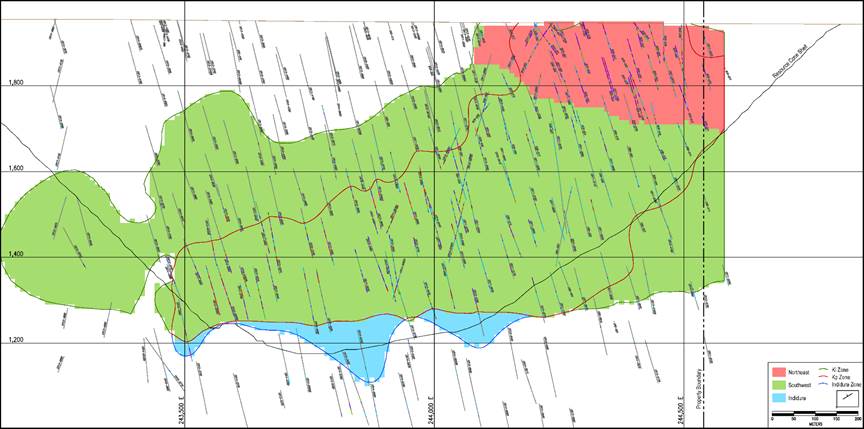

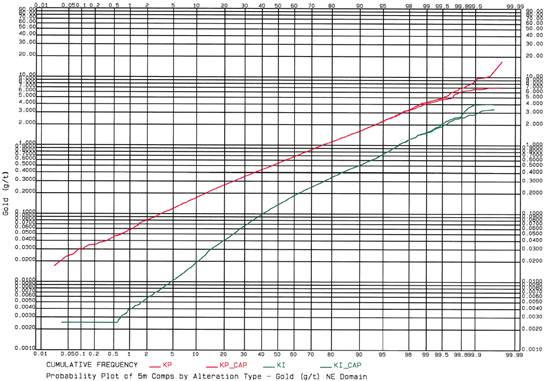

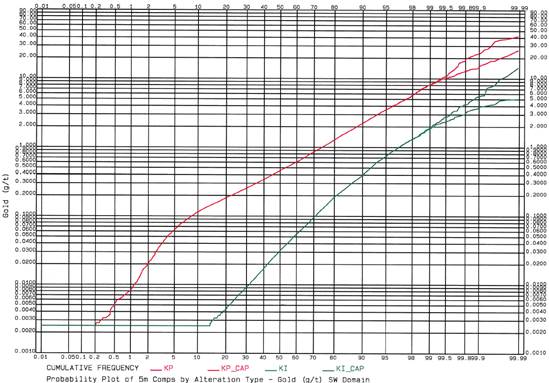

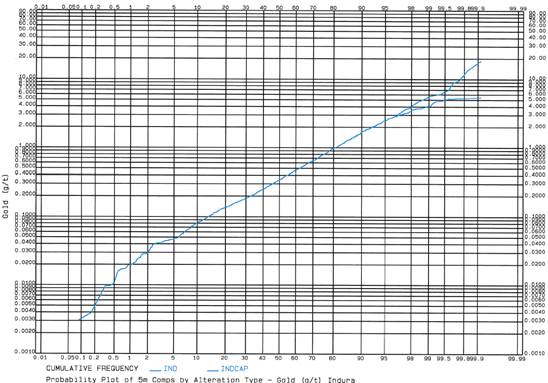

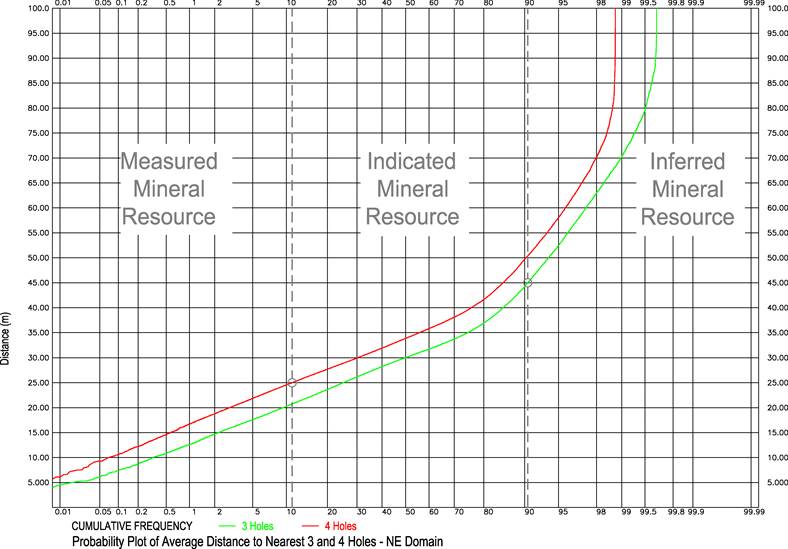

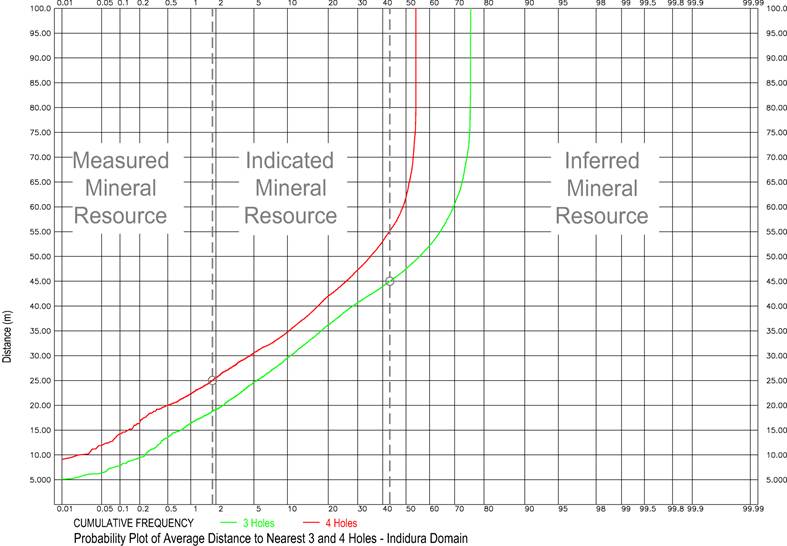

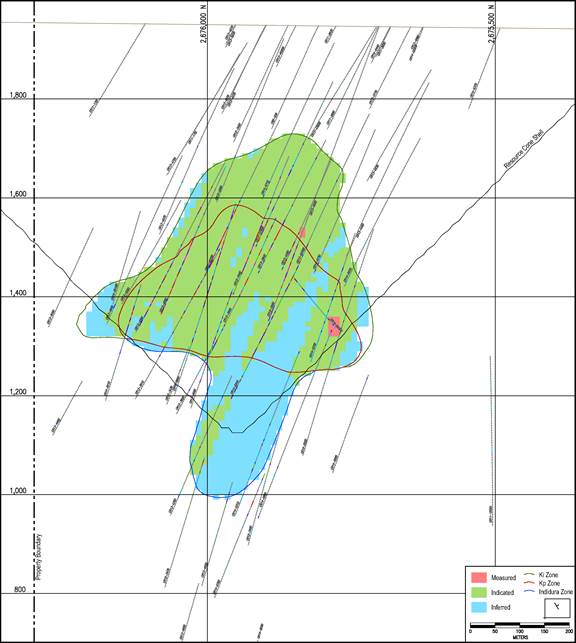

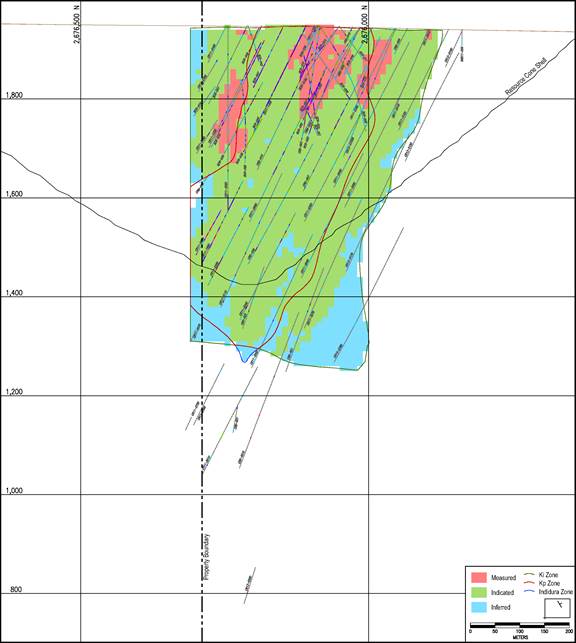

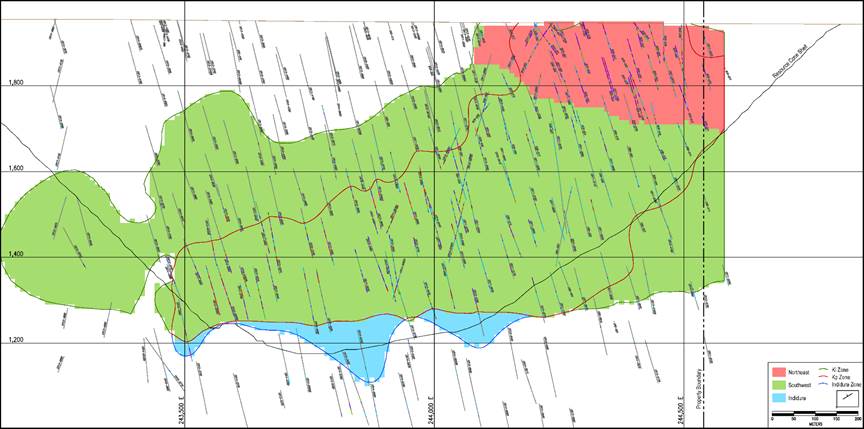

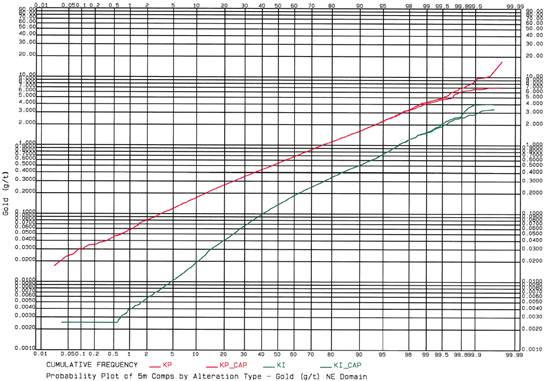

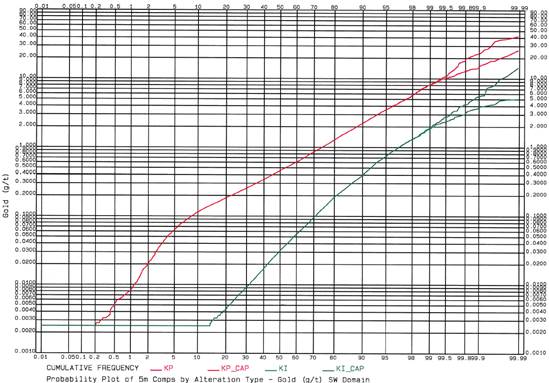

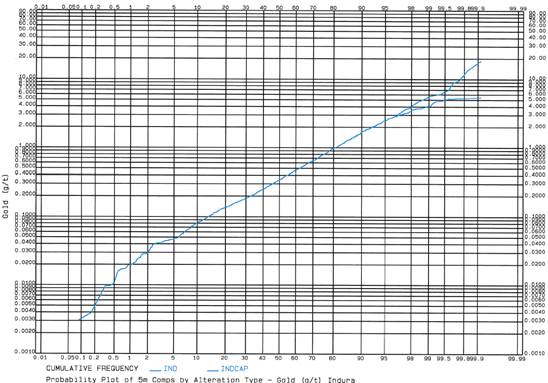

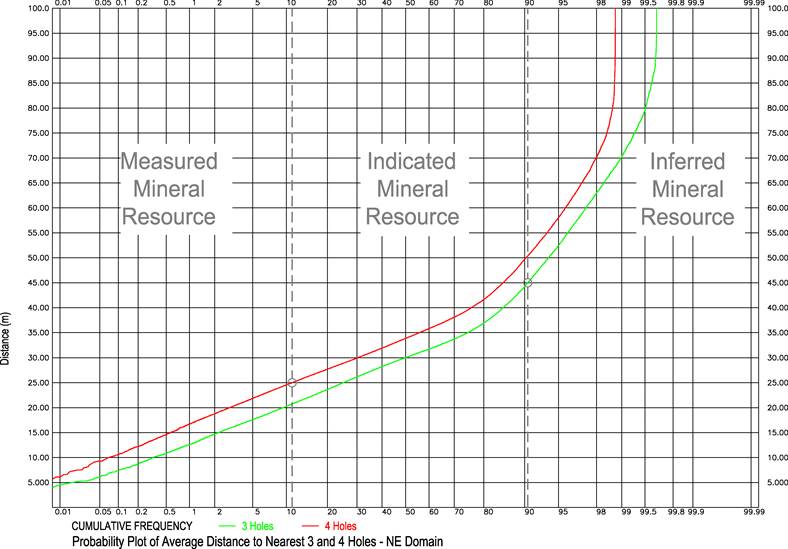

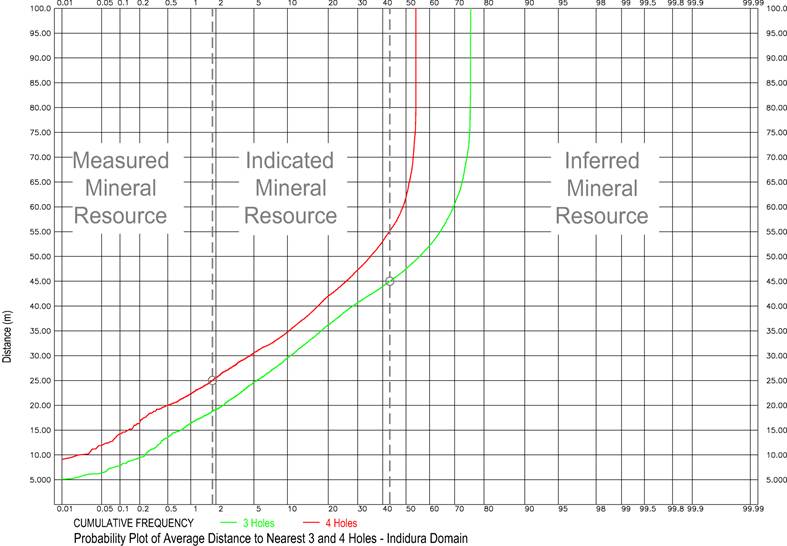

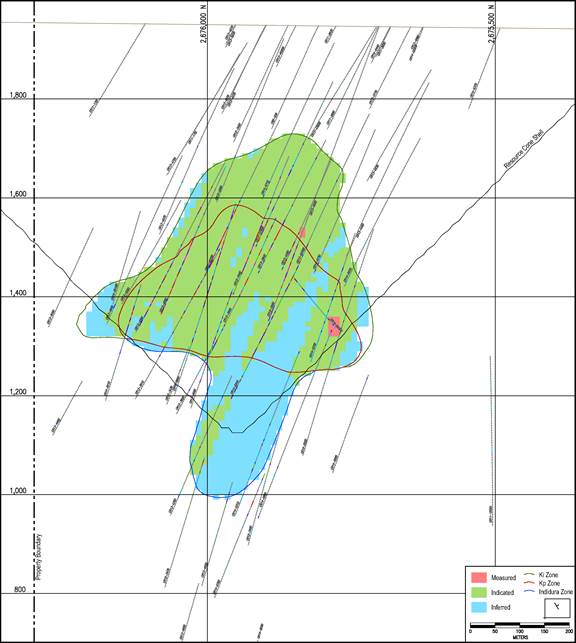

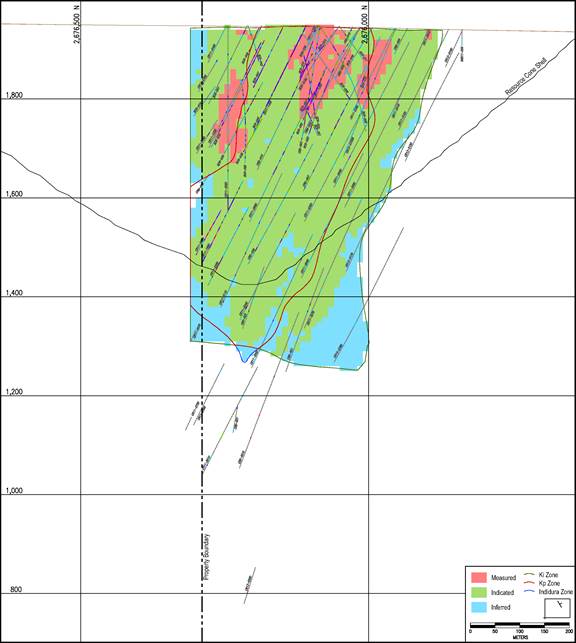

| · | Environmental permitting information contained in a report prepared by Lic. Mauricio Heiras, Mexican legal counsel for Orla, dated 28 June 2017 (Heiras, 2017) and a public domain Federal report (CONANP, 2014). |