UNITED STATES SECURITIES AND EXCHANGE COMMISSION Washington, D.C. 20549 |

|

FORM 10-Q |

[X] QUARTERLY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the quarterly period ended September 30, 2004 OR [ ] TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the transition period from ________________ to ________________ |

Commission File Number: 1-768 |

CATERPILLAR INC. (Exact name of registrant as specified in its charter) |

Delaware (State or other jurisdiction of incorporation) | 37-0602744 (IRS Employer I.D. No.) |

100 NE Adams Street, Peoria, Illinois (Address of principal executive offices) | 61629 (Zip Code) |

Registrant's telephone number, including area code: (309) 675-1000 |

| At September 30, 2004, 341,235,956 shares of common stock of the Registrant were outstanding. |

Page 1

Part I. FINANCIAL INFORMATION

Item 1. Financial Statements

Caterpillar Inc. Consolidated Statement of Results of Operations (Unaudited) (Dollars in millions except per share data) |

| | Three Months Ended |

| | September 30, |

| | 2004 | | 2003 |

|

| |

|

Sales and revenues: | | | | | | | |

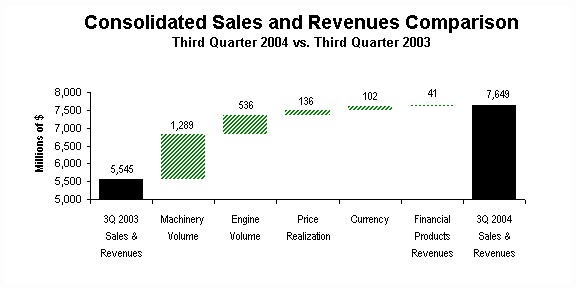

| Sales of Machinery and Engines | $ | 7,175 | | | $ | 5,112 | |

| Revenues of Financial Products | | 474 | | | | 433 | |

| |

|

|

| |

|

|

|

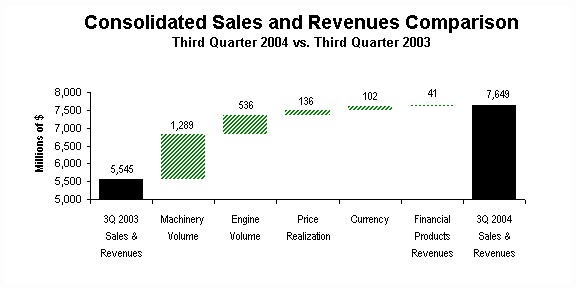

| Total sales and revenues | | 7,649 | | | | 5,545 | |

| | | | | | | | |

Operating costs: | | | | | | | |

| Cost of goods sold | | 5,728 | | | | 4,143 | |

| Selling, general and administrative expenses | | 734 | | | | 627 | |

| Research and development expenses | | 240 | | | | 173 | |

| Interest expense of Financial Products | | 129 | | | | 116 | |

| Other operating expenses | | 140 | | | | 101 | |

| |

|

|

| |

|

|

|

| Total operating costs | | 6,971 | | | | 5,160 | |

| |

|

|

| |

|

|

|

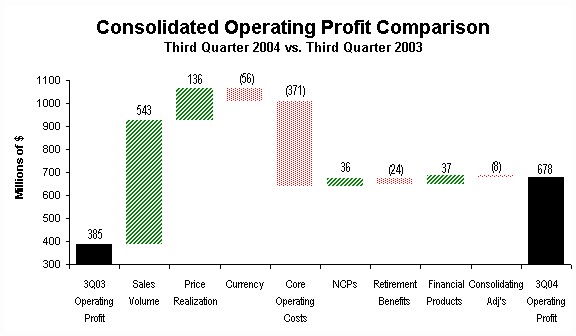

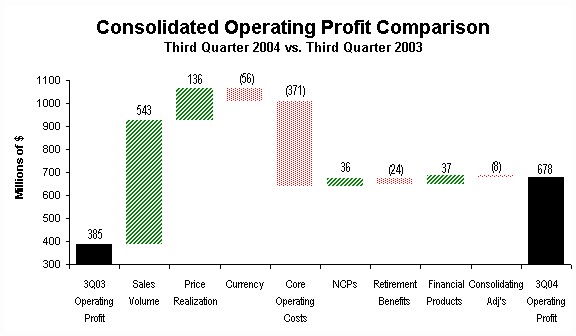

Operating profit | | 678 | | | | 385 | |

| | | | | | | | |

| Interest expense excluding Financial Products | | 60 | | | | 61 | |

| Other income (expense) | | 45 | | | | (40 | ) |

| |

|

|

| |

|

|

|

Consolidated profit before taxes | | 663 | | | | 284 | |

| | | | | | | | |

| Provision for income taxes | | 182 | | | | 69 | |

| |

|

|

| |

|

|

|

| Profit of consolidated companies | | 481 | | | | 215 | |

| | | | | | | | |

| Equity in profit (loss) of unconsolidated affiliated companies | | 17 | | | | 7 | |

| |

|

|

| |

|

|

|

Profit | $ | 498 | | | $ | 222 | |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

Profit per common share | $ | 1.45 | | | $ | 0.64 | |

| | | | | | | | |

Profit per common share - diluted1 | $ | 1.41 | | | $ | 0.62 | |

| | | | | | | | | |

Weighted average common shares outstanding (millions) | | | | | | | |

| | - Basic | | 341.8 | | | | 346.3 | |

| | - Diluted1 | | 353.0 | | | | 356.1 | |

| | | | | | | | |

Cash dividends declared per common share | $ | - | | | $ | - | |

| | | | | | | | |

|

1 Diluted by assumed exercise of stock options, using the treasury stock method. |

See accompanying notes to Consolidated Financial Statements. |

|

Page 2

Caterpillar Inc. Consolidated Statement of Results of Operations (Unaudited) (Dollars in millions except per share data) |

| | Nine Months Ended |

| | September 30, |

| | 2004 | | 2003 |

|

| |

|

Sales and revenues: | | | | | | | |

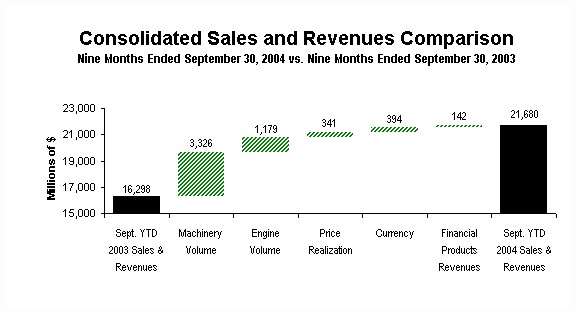

| Sales of Machinery and Engines | $ | 20,277 | | | $ | 15,037 | |

| Revenues of Financial Products | | 1,403 | | | | 1,261 | |

| |

|

|

| |

|

|

|

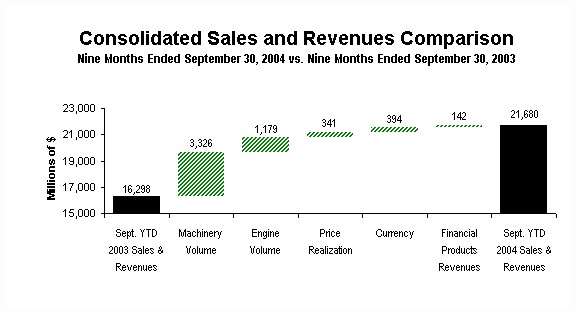

| Total sales and revenues | | 21,680 | | | | 16,298 | |

| | | | | | | | |

Operating costs: | | | | | | | |

| Cost of goods sold | | 15,952 | | | | 12,102 | |

| Selling, general and administrative expenses | | 2,223 | | | | 1,801 | |

| Research and development expenses | | 685 | | | | 494 | |

| Interest expense of Financial Products | | 367 | | | | 354 | |

| Other operating expenses | | 416 | | | | 358 | |

| |

|

|

| |

|

|

|

| Total operating costs | | 19,643 | | | | 15,109 | |

| |

|

|

| |

|

|

|

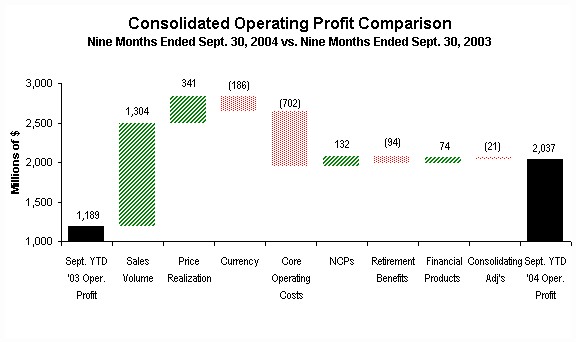

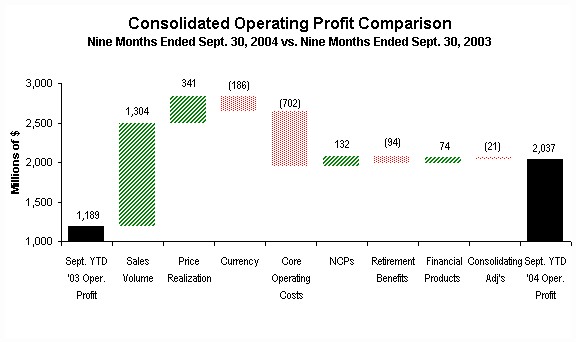

Operating profit | | 2,037 | | | | 1,189 | |

| | | | | | | | |

| Interest expense excluding Financial Products | | 176 | | | | 192 | |

| Other income (expense) | | 135 | | | | 15 | |

| |

|

|

| |

|

|

|

| | | | | | | | |

Consolidated profit before taxes | | 1,996 | | | | 1,012 | |

| | | | | | | | |

| Provision for income taxes | | 549 | | | | 273 | |

| |

|

|

| |

|

|

|

| Profit of consolidated companies | | 1,447 | | | | 739 | |

| | | | | | | | |

| Equity in profit (loss) of unconsolidated affiliated companies | | 37 | | | | 11 | |

| |

|

|

| |

|

|

|

Profit | $ | 1,484 | | | $ | 750 | |

|

|

|

| |

|

|

|

| | | | | | | | |

|

|

|

|

|

|

|

|

|

Profit per common share | $ | 4.34 | | | $ | 2.17 | |

| | | | | | | | |

Profit per common share - diluted1 | $ | 4.19 | | | $ | 2.15 | |

| | | | | | | | | |

Weighted average common shares outstanding (millions) | | | | | | | |

| | | - Basic | | 342.3 | | | | 345.1 | |

| | | - Diluted1 | | 354.2 | | | | 349.0 | |

| | | | | | | | |

Cash dividends declared per common share | $ | .78 | | | $ | .70 | |

| | | | | | | | |

|

1 Diluted by assumed exercise of stock options, using the treasury stock method. |

See accompanying notes to Consolidated Financial Statements. |

|

Page 3

Caterpillar Inc. Consolidated Statement of Changes in Stockholders' Equity For the Nine Months Ended (Unaudited) (Millions of dollars) |

| | September 30, 2004 | | September 30, 2003 |

|

| |

|

Common stock: | | | | | | | | | | | | | | | |

| | Balance at beginning of period | $ | 1, 059 | | | | | | | $ | 1,034 | | | | | |

| | Common shares issued from treasury stock | | 73 | | | | | | | | 2 | | | | | |

| |

|

|

| | | | | |

|

|

| | | | |

| | Balance at end of period | | 1,132 | | | | | | | | 1,036 | | | | | |

| |

|

|

| | | | | |

|

|

| | | | |

Treasury stock: | | | | | | | | | | | | | | | |

| | Balance at beginning of period | | (2,914 | ) | | | | | | | (2,669 | ) | | | | |

| | Shares issued: 2004 - 2,770,916; 2003 - 2,985,265 | | 76 | | | | | | | | 98 | | | | | |

| | Shares repurchased: 2004 - 5,297,000 | | (400 | ) | | | | | | | - | | | | | |

| |

|

|

| | | | | |

|

|

| | | | |

| | Balance at end of period | | (3,238 | ) | | | | | | | (2,571 | ) | | | | |

| |

|

|

| | | | | |

|

|

| | | | |

Profit employed in the business: | | | | | | | | | | | | | | | |

| | Balance at beginning of period | | 8,450 | | | | | | | | 7,849 | | | | | |

| | Profit | | 1,484 | | | $ | 1,484 | | | | 750 | | | $ | 750 | |

| | Dividends declared | | (267 | ) | | | | | | | (242 | ) | | | | |

| |

|

|

| | | | | |

|

|

| | | | |

| | Balance at end of period | | 9,667 | | | | | | | | 8,357 | | | | | |

| |

|

|

| | | | | |

|

|

| | | | |

Accumulated other comprehensive income: | | | | | | | | | | | | | | | |

| | Foreign currency translation adjustment: | | | | | | | | | | | | | | | |

| | | Balance at beginning of period | | 348 | | | | | | | | 86 | | | | | |

| | | Aggregate adjustment for period | | 5 | | | | 5 | | | | 149 | | | | 149 | |

| | |

|

|

| | | | | |

|

|

| | | | |

| | | Balance at end of period | | 353 | | | | | | | | 235 | | | | | |

| | |

|

|

| | | | | |

|

|

| | | | |

| | Minimum pension liability adjustment - consolidated companies: | | | | | | | | | | | | | | | |

| | | Balance at beginning of period (net of tax of: 2004-$460; 2003-$383) | | (934 | ) | | | | | | | (771 | ) | | | | |

| | | Aggregate adjustment for period | | - | | | | - | | | | - | | | | - | |

| | |

|

|

| | | | | |

|

|

| | | | |

| | | Balance at end of period (net of tax of: 2004-$460; 2003-$383) | | (934 | ) | | | | | | | (771 | ) | | | | |

| | |

|

|

| | | | | |

|

|

| | | | |

| | Minimum pension liability adjustment - unconsolidated companies: | | | | | | | | | | | | | | | |

| | | Balance at beginning of period | | (48 | ) | | | | | | | (37 | ) | | | | |

| | | Aggregate adjustment for period | | (1 | ) | | | (1 | ) | | | (1 | ) | | | (1 | ) |

| | |

|

|

| | | | | |

|

|

| | | | |

| | | Balance at end of period | | (49 | ) | | | | | | | (38 | ) | | | | |

| | |

|

|

| | | | | |

|

|

| | | | |

| | Derivative financial instruments: | | | | | | | | | | | | | | | |

| | | Balance at beginning of period (net of tax of: 2004-$54; 2003-$5) | | 104 | | | | | | | | 11 | | | | | |

| | | Gains/(losses) deferred during period (net of tax of: 2004-$4; 2003-$5) | | 8 | | | | 8 | | | | (11 | ) | | | (11 | ) |

| | | (Gains)/losses reclassified to earnings during period (net of tax of: 2004-$17; 2003-$19) | | (33 | ) | | | (33 | ) | | | 39 | | | | 39 | |

| | |

|

|

| | | | | |

|

|

| | | | |

| | | Balance at end of period (net of tax of: 2004-$41; 2003-$19) | | 79 | | | | | | | | 39 | | | | | |

| | |

|

|

| | | | | |

|

|

| | | | |

| | Available-for-sale securities: | | | | | | | | | | | | | | | |

| | | Balance at beginning of period (net of tax of: 2004-$7; 2003-$17) | | 13 | | | | | | | | (31 | ) | | | | |

| | | Gains/(losses) deferred during period (net of tax of: 2004-$1; 2003-$6) | | (2 | ) | | | (2 | ) | | | 31 | | | | 31 | |

| | | (Gains)/losses reclassified to earnings during period (net of tax of 2004-$0; 2003-$9) | | - | | | | - | | | | 5 | | | | 5 | |

| | |

|

|

| | | | | |

|

|

| | | | |

| | | Balance at end of period (net of tax of: 2004-$6; 2003-$2) | | 11 | | | | | | | | 5 | | | | | |

| | |

|

|

| | | | | |

|

|

| | | | |

Total accumulated other comprehensive income | | (540 | ) | | | | | | | (530 | ) | | | | |

|

|

|

| | | | | |

|

|

| | | | |

| | Comprehensive income | | | | | $ | 1,461 | | | | | | | $ | 962 | |

| | | | | |

|

|

| | | | | |

|

|

|

Stockholders' equity at end of period | $ | 7,021 | | | | | | | $ | 6,292 | | | | | |

|

|

|

| | | | | |

|

|

| | | | |

|

See accompanying notes to Consolidated Financial Statements. |

|

Page 4

Caterpillar Inc. Consolidated Statement of Financial Position (Unaudited) (Millions of dollars) |

| | | | September 30, 2004 | | December 31, 2003 |

| | |

| |

|

Assets | | | | | | | |

| | Current assets: | | | | | | | |

| | | Cash and short-term investments | $ | 417 | | | $ | 342 | |

| | | Receivables - trade and other | | 3,790 | | | | 3,666 | |

| | | Receivables - finance | | 8,951 | | | | 7,605 | |

| | | Deferred and refundable income taxes | | 619 | | | | 707 | |

| | | Prepaid expenses | | 1,350 | | | | 1,424 | |

| | | Inventories | | 4,509 | | | | 3,047 | |

| | |

|

|

| |

|

|

|

| | Total current assets | | 19,636 | | | | 16,791 | |

| | | | | | | | | |

| | Property, plant and equipment - net | | 7,303 | | | | 7,290 | |

| | Long-term receivables - trade and other | | 268 | | | | 82 | |

| | Long-term receivables - finance | | 8,326 | | | | 7,822 | |

| | Investments in unconsolidated affiliated companies | | 839 | | | | 800 | |

| | Deferred income taxes | | 516 | | | | 616 | |

| | Intangible assets | | 361 | | | | 239 | |

| | Goodwill | | 1,450 | | | | 1,398 | |

| | Other assets | | 1,695 | | | | 1,427 | |

| |

|

|

| |

|

|

|

Total assets | $ | 40,394 | | | $ | 36,465 | |

|

|

|

| |

|

|

|

Liabilities | | | | | | | |

| | Current liabilities: | | | | | | | |

| | | Short-term borrowings: | | | | | | | |

| | | | Machinery and Engines | | 336 | | | | 72 | |

| | | | Financial Products | | 2,582 | | | | 2,685 | |

| | | Accounts payable | | 3,934 | | | | 3,100 | |

| | | Accrued expenses | | 1,793 | | | | 1,638 | |

| | | Accrued wages, salaries and employee benefits | | 1,345 | | | | 1,802 | |

| | | Dividends payable | | - | | | | 127 | |

| | | Deferred and current income taxes payable | | 235 | | | | 216 | |

| | | Long-term debt due within one year: | | | | | | | |

| | | | Machinery and Engines | | 6 | | | | 32 | |

| | | | Financial Products | | 3,595 | | | | 2,949 | |

| | |

| |

|

| | Total current liabilities | | 13,826 | | | | 12,621 | |

| | | | | | | | | | | |

| | Long-term debt due after one year: | | | | | | | |

| | | Machinery and Engines | | 3,642 | | | | 3,367 | |

| | | Financial Products | | 12,112 | | | | 10,711 | |

| | Liability for postemployment benefits | | 3,234 | | | | 3,172 | |

| | Deferred income taxes and other liabilities | | 559 | | | | 516 | |

| |

|

|

| |

|

|

|

Total liabilities | | 33,373 | | | | 30,387 | |

|

|

|

| |

|

|

|

Stockholders' equity | | | | | | | |

| | Common stock of $1.00 par: | | | | | | | |

| | | Authorized shares: 900,000,000 Issued shares: (09/30/04 and 12/31/03 - 407,447,312) at paid in amount | | 1,132 | | | | 1,059 | |

| | Treasury stock (09/30/04 - 66,211,356; 12/31/03 - 63,685,272) at cost | | (3,238 | ) | | | (2,914 | ) |

| | Profit employed in the business | | 9,667 | | | | 8,450 | |

| | Accumulated other comprehensive income | | (540 | ) | | | (517 | ) |

| |

|

|

| |

|

|

|

Total stockholders' equity | | 7,021 | | | | 6,078 | |

|

|

|

| |

|

|

|

Total liabilities and stockholders' equity | $ | 40,394 | | | $ | 36,465 | |

|

|

|

| |

|

|

|

|

See accompanying notes to Consolidated Financial Statements. |

|

Page 5

Caterpillar Inc. Condensed Consolidated Statement of Cash Flow (Unaudited) (Millions of dollars) |

| | | Nine Months Ended |

| | | September 30, |

| | | 2004 | | 2003 |

| |

| |

|

Cash flow from operating activities: | | | | | | | |

| Profit | $ | 1,484 | | | $ | 750 | |

| Adjustments for non-cash items: | | | | | | | |

| | Depreciation and amortization | | 1,055 | | | | 1,008 | |

| | Other | | (120 | ) | | | 46 | |

| Changes in assets and liabilities: | | | | | | | |

| | Receivables - trade and other | | (461 | ) | | | (220 | ) |

| | Inventories | | (1,225 | ) | | | (294 | ) |

| | Accounts payable and accrued expenses | | 815 | | | | 108 | |

| | Other - net | | (13 | ) | | | 9 | |

| | |

|

|

| |

|

|

|

Net cash provided by operating activities | | 1,535 | | | | 1,407 | |

|

|

|

| |

|

|

|

Cash flow from investing activities: | | | | | | | |

| Capital expenditures - excluding equipment leased to others | | (519 | ) | | | (352 | ) |

| Expenditures for equipment leased to others | | (827 | ) | | | (781 | ) |

| Proceeds from disposals of property,plant and equipment | | 531 | | | | 451 | |

| Additions to finance receivables | | (16,493 | ) | | | (12,245 | ) |

| Collections of finance receivables | | 13,010 | | | | 10,044 | |

| Proceeds from the sale of finance receivables | | 1,434 | | | | 1,472 | |

| Investments and acquisitions (net of cash acquired) | | (284 | ) | | | (26 | ) |

| Other - net | | (193 | ) | | | (55 | ) |

| |

|

|

| |

|

|

|

Net cash used for investing activities | | (3,341 | ) | | | (1,492 | ) |

|

|

|

| |

|

|

|

Cash flow from financing activities: | | | | | | | |

| Dividends paid | | (395 | ) | | | (361 | ) |

| Common stock issued, including treasury shares reissued | | 137 | | | | 81 | |

| | Treasury shares purchased | | (400 | ) | | | - | |

| | Proceeds from long-term debt issued | | 4,532 | | | | 4,233 | |

| | Payments on long-term debt | | (2,615 | ) | | | (2,992 | ) |

| | Short-term borrowings - net | | 563 | | | | (788 | ) |

| |

|

|

| |

|

|

|

Net cash provided by financing activities | | 1,822 | | | | 173 | |

|

|

|

| |

|

|

|

Effect of exchange rate changes on cash | | 59 | | | | - | |

|

|

|

| |

|

|

|

Increase (decrease) in cash and short-term investments | | 75 | | | | 88 | |

| | | | | | | | |

Cash and short-term investments at beginning of period | | 342 | | | | 309 | |

|

|

|

| |

|

|

|

Cash and short-term investments at end of period | $ | 417 | | | $ | 397 | |

|

|

|

| |

|

|

|

|

All short-term investments, which consist primarily of highly liquid investments with original maturities of three months or less, are considered to be cash equivalents. |

See accompanying notes to Consolidated Financial Statements. |

|

Page 6

NOTES TO CONSOLIDATED FINANCIAL STATEMENTS

(Unaudited)

1. A. Financial Statement Presentation

In the opinion of management, all adjustments, consisting only of normal recurring adjustments necessary for a fair presentation of (a) the consolidated results of operations for the three and nine month periods ended September 30, 2004 and 2003, (b) the changes in stockholders' equity for the nine month periods ended September 30, 2004 and 2003, (c) the consolidated financial position at September 30, 2004 and December 31, 2003, and (d) the consolidated statement of cash flow for the nine month periods ended September 30, 2004 and 2003, have been made. Certain amounts for prior periods have been reclassified to conform to the current period financial statement presentation.

The December 31, 2003 balance sheet data included herein is derived from the audited consolidated financial statements included in the Company's annual report on Form 10-K for the year ended December 31, 2003.

B. Nature of Operations

We operate in three principal lines of business:

(1) | Machinery - A principal line of business which includes the design, manufacture and marketing of construction, mining, and forestry machinery - track and wheel tractors, track and wheel loaders, pipelayers, motor graders, wheel tractor-scrapers, track and wheel excavators, backhoe loaders, mining shovels, log skidders, log loaders, off-highway trucks, articulated trucks, paving products, telescopic handlers, skid steer loaders and related parts. Also includes logistics services for other companies. |

(2) | Engines - A principal line of business including the design, manufacture and marketing of engines for Caterpillar machinery, electric power generation systems; on-highway vehicles and locomotives; marine, petroleum, construction, industrial, agricultural and other applications; and related parts. Reciprocating engines meet power needs ranging from 5 to over 22,000 horsepower (4 to over 16 200 kilowatts). Turbines range from 1,600 to 19,500 horsepower (1 000 to 14 500 kilowatts). |

(3) | Financial Products - A principal line of business consisting primarily of Caterpillar Financial Services Corporation (Cat Financial), Caterpillar Insurance Holdings, Inc. (Cat Insurance), Caterpillar Power Ventures Corporation (Cat Power Ventures) and their subsidiaries. Cat Financial provides a wide range of financing alternatives for Caterpillar machinery and engines, Solar gas turbines, as well as other equipment and marine vessels. Cat Financial also extends loans to customers and dealers. Cat Insurance provides various forms of insurance to customers and dealers to help support the purchase and lease of our equipment. Cat Power Ventures is an active investor in independent power projects using Caterpillar power generation equipment an d services. |

Our Machinery and Engines operations are highly integrated. Throughout the Notes, Machinery and Engines represents the aggregate total of these principal lines of business.

C. Stock-Based Compensation

We use the intrinsic value method of accounting for stock-based employee compensation in accordance with Accounting Principles Board Opinion No. 25, "Accounting for Stock Issued to Employees." Therefore, no compensation expense is recognized in association with our options.

Employee stock options granted in years prior to 2004 vest at the rate of one-third per year over the three year period following the date of grant. On June 8, 2004, approximately 8,900,000 stock options were granted to officers and other key employees. In anticipation of delaying vesting until three years after the grant date for future grants, the 2004 grant will vest on December 31, 2004.

The fair value of the options granted in 2004 was estimated using the binomial option-pricing model. We believe this model more accurately reflects the value of the options than using the Black-Scholes option-pricing model. Previous years grants continue to be valued using the Black-Scholes model.

Page 7

Pro forma net profit and profit per share using the binomial option-pricing model for the 2004 grant and the Black-Scholes option- pricing model for 2003 and previous grants were:

| | Three Months Ended September 30, |

(Dollars in millions except per share data) | 2004 | | 2003 |

|

| |

|

Profit, as reported | $ | 498 | | | $ | 222 | |

Deduct: Total stock-based employee compensation expense determined under fair value based method for all awards, net of related tax effects | | (58 | ) | | | (19 | ) |

|

|

|

| |

|

|

|

Pro forma profit | $ | 440 | | | $ | 203 | |

|

|

|

| |

|

|

|

| Profit per share of common stock: | | | | | | | |

| | As reported: | | | | | | | |

| | | Basic | $ | 1.45 | | | $ | 0.64 | |

| | | Diluted | $ | 1.41 | | | $ | 0.62 | |

| | Pro forma: | | | | | | | |

| | | Basic | $ | 1.29 | | | $ | 0.59 | |

| | | Diluted | $ | 1.25 | | | $ | 0.57 | |

| | Nine Months Ended September 30, |

(Dollars in millions except per share data) | 2004 | | 2003 |

|

| |

|

Profit, as reported | $ | 1,484 | | | $ | 750 | |

Deduct: Total stock-based employee compensation expense determined

under fair value based method for all awards, net of related tax effects | | (103 | ) | | | (50 | ) |

|

|

|

| |

|

|

|

Pro forma profit | $ | 1,381 | | | $ | 700 | |

|

|

|

| |

|

|

|

| Profit per share of common stock: | | | | | | | |

| | As reported: | | | | | | | |

| | | Basic | $ | 4.34 | | | $ | 2.17 | |

| | | Diluted | $ | 4.19 | | | $ | 2.15 | |

| | Pro forma: | | | | | | | |

| | | Basic | $ | 4.03 | | | $ | 2.03 | |

| | | Diluted | $ | 3.90 | | | $ | 2.00 | |

| | | | | | | | | | |

|

|

|

|

|

|

|

|

|

|

Pro forma net profit and profit per share for the three and nine month periods ending September 30, 2004 using the Black-Scholes option-pricing model would have been:

| | Three Months Ended

September 30, | | Nine Months Ended September 30, |

(Dollars in millions except per share data) | 2004 | | 2004 |

|

| |

|

Profit, as reported | $ | 498 | | | $ | 1,484 | |

Deduct: Total stock-based employee compensation expense determined

under fair value based method for all awards, net of related tax effects | | (76 | ) | | | (127 | ) |

|

|

|

| |

|

|

|

Pro forma profit | $ | 422 | | | $ | 1,357 | |

|

|

|

| |

|

|

|

| Profit per share of common stock: | | | | | | | |

| | Pro forma: | | | | | | | |

| | | Basic | $ | 1.23 | | | $ | 3.97 | |

| | | Diluted | $ | 1.20 | | | $ | 3.83 | |

| | | | | | | | | | |

|

|

|

|

|

|

|

|

|

|

Page 8

2.The results for the three and nine month periods ended September 30, 2004 are not necessarily indicative of the results for the entire year 2004.

3. Environmental and Legal Matters

The company is regulated by federal, state, and international environmental laws governing our use of substances and control of emissions in all our operations. Compliance with these existing laws has not had a material impact on our capital expenditures, earnings, or competitive position.

We are cleaning up hazardous waste at a number of locations, often with other companies, pursuant to federal and state laws. When it is likely we will pay clean-up costs at a site and those costs can be estimated, the costs are charged against our earnings. In doing that estimate, we do not consider amounts expected to be recovered from insurance companies and others.

The amount accrued for environmental clean-up is not material and is included in "Accrued expenses" in the Statement of Financial Position. If a range of liability estimates is available on a particular site, we accrue at the lower end of that range.

We cannot estimate costs on sites in the very early stages of clean-up. Currently, we have five sites in the very early stages of clean-up, and there is no more than a remote chance that a material amount for clean-up will be required.

Pursuant to a consent decree Caterpillar entered with the EPA, the company was required to meet certain emission standards by October 2002. The decree provides that if engine manufacturers were unable to meet the standards at that time, they would be required to pay a Non-Conformance Penalty (NCP) on each engine sold that did not meet the standard. The amount of the NCP would be based on how close to meeting the standard the engine came - the more out of compliance the higher the penalty. The company began introduction of fully compliant ACERT engines in 2003 and by the end of 2003 Caterpillar was only producing fully compliant engine models. As a result, NCPs are not payable for any engines built in 2004. The company’s operating profit was favorably impacted in the third quarter 2004 and year to date 2004 by $36 million an d $132 million, respectively, due to the absence of NCPs that were recorded in those periods in 2003.

In addition, the consent decree required Caterpillar to pay a fine of $25 million, which was expensed in 1998 and to make investments totaling $35 million in environmental-related products by July 7, 2007. Total qualifying investments to date for these projects are $33 million, of which $2 million was made in the first nine months of 2004. A future benefit is expected to be realized from these environmental projects related to Caterpillar's ability to capitalize on the technologies it developed in complying with its environmental project obligations. In short, Caterpillar expects to receive a positive net return on the environmental projects by being able to market the technology it developed.

We are a party to litigation matters and claims that are normal in the course of our operations, and, while the results of such litigation and claims cannot be predicted with certainty, management believes, based on the advice of counsel, the final outcome of such matters will not have a materially adverse effect on our consolidated financial position.

On January 16, 2002, Caterpillar commenced an action in the Circuit Court of the Tenth Judicial Circuit of Illinois in Peoria, Illinois, against Navistar International Transportation Corporation and International Truck and Engine Corporation (collectively Navistar). The lawsuit arises out of a long-term purchase contract between Caterpillar and Navistar effective May 31, 1988, as amended from time to time (the Purchase Agreement). The pending complaint alleges that Navistar breached its contractual obligations by: (i) paying Caterpillar $8.08 less per fuel injector than the agreed upon price for new unit injectors delivered by Caterpillar; (ii) refusing to pay contractually agreed upon surcharges owed as a result of Navistar ordering less than planned volumes of replacement unit injectors; and (iii) refusing to pay contractually agreed upon interest stemming from Navistar’s late payments. At September 30, 2004, the past due receivable from Navistar regarding the foregoing was $139 million. The pending complaint also has claims alleging that Franklin Power Products, Inc., Newstream Enterprises, and Navistar, collectively and individually, failed to pay the applicable price for shipments of unit injectors to Franklin and Newstream. At September 30, 2004, the past due receivables for the foregoing totaled $12 million. The pending complaint further alleges that Sturman Industries, Inc., and Sturman Engine Systems, Inc., colluded with Navistar to utilize technology that Sturman Industries, Inc., misappropriated from Caterpillar to help Navistar develop its G2 fuel system, and tortiously interfered with the Purchase Agreement and Caterpillar’s prospective economic relationship with Navistar. The pending complaint further alleges that the two parties’ collusion led Navistar to select Sturman Engine Systems , Inc. and another company, instead of Caterpillar, to develop and manufacture the G2 fuel system.

Page 9

On May 7, 2002, International Truck and Engine Corporation (International) commenced an action against Caterpillar in the Circuit Court of DuPage County, Illinois that alleges Caterpillar breached various aspects of a long-term agreement term sheet. In its fourth amended complaint, International seeks a declaration from the court that the term sheet constitutes a legally binding contract for the sale of heavy-duty engines at specified prices through the end of 2006, alleges that Caterpillar breached the term sheet by raising certain prices effective October 1, 2002, and also alleges that Caterpillar breached an obligation to negotiate a comprehensive long-term agreement referenced in the term sheet. International further claims that Caterpillar improperly restricted the supply of heavy-duty engines to Internati onal from June through September 2002, and claims that Caterpillar made certain fraudulent misrepresentations with respect to the availability of engines during this time period. International seeks damages "in an amount to be determined at trial" and injunctive relief. Caterpillar filed an answer denying International's claims and has filed a counterclaim seeking a declaration that the term sheet has been effectively terminated. Caterpillar denies International's claims and will vigorously contest them. On September 24, 2003, the Appellate Court of Illinois, ruling on an interlocutory appeal, issued an order consistent with Caterpillar's position that, even if the court subsequently determines that the term sheet is a binding contract, it is indefinite in duration and was therefore terminable at will by Caterpillar after a reasonable period. Caterpillar anticipates that a trial currently scheduled to begin in the first quarter of 2005 will address all remaining issues in this matter. This matter is not related to the breach of contract action brought by Caterpillar against Navistar currently pending in the Circuit Court of Peoria County, Illinois.

The EU is imposing retaliatory tariffs on certain U.S. origin goods as a result of a WTO decision that found the extraterritorial income exclusion (ETI) provisions of the FSC Repeal and Extraterritorial Income Exclusion Act of 2000 constituted a prohibited export subsidy. These tariffs, which began in March of 2004 at 5 percent, have increased 1 percentage point per month and would increase to 17 percent after one year. Given the makeup of the final retaliation list, some Caterpillar parts and components are subject to these tariffs. We do not believe these tariffs will materially impact our fi nancial results. The company has production facilities in the EU, Russia, Asia, and South America. Products sold into the EU from these plants are not affected by this retaliatory tariff. The American Jobs Creation Act of 2004 (Act), enacted on October 22, 2004, phases-out the ETI provisions. As a result, the EU announced that it plans to end the retaliatory sanctions pending the outcome of a WTO review to determine whether certain provisions of the Act are compliant with the ruling against the FSC/ETI regime. The sanctions are not expected to be lifted officially until January 1, 2005.

4. Inventories

Inventories (principally "last-in, first-out" method) comprise the following:

(Millions of dollars) | September 30, | | December 31, |

| | 2004 | | 2003 |

|

| |

|

| Raw materials | $ | 1,493 | | | $ | 1,105 | |

| Work-in-process | | 691 | | | | 377 | |

| Finished goods | | 2,131 | | | | 1,381 | |

| Supplies | | 194 | | | | 184 | |

|

|

|

| |

|

|

|

| Total inventories | $ | 4,509 | | | $ | 3,047 | |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

5. Intangible Assets and Goodwill

A. Intangible Assets

Intangible assets are comprised of the following:

(Millions of dollars) | September 30, | | December 31, |

| | 2004 | | 2003 |

|

| |

|

| Intellectual property | $ | 203 | | | $ | 126 | |

| Pension-related | | 157 | | | | 157 | |

| Other | | 73 | | | | - | |

|

| |

|

| Total intangible assets - gross | | 433 | | | | 283 | |

| Less: Accumulated amortization of finite lived intangible assets | | (72 | ) | | | (44 | ) |

|

|

|

| |

|

|

|

| Intangible assets - net | $ | 361 | | | $ | 239 | |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

Page 10

During the third quarter of 2004 we acquired finite lived intangible assets of $130 million. (See Note 13 for details on the acquisition of these assets.) Amortization expense for the three and nine months ended September 30, 2004 was $5 million and $16 million, respectively. Amortization expense for the three and nine months ended September 30, 2003 was $6 million and $10 million, respectively. Amortization expense related to intangible assets is expected to be:

(Millions of dollars) |

2004 | | 2005 | | 2006 | | 2007 | | 2008 | | Thereafter |

| |

| |

| |

| |

| |

|

| $ | 21 | | | $ | 20 | | | $ | 19 | | | $ | 16 | | | $ | 14 | | | $ | 128 | |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B. Goodwill

During the third quarter of 2004 we acquired assets with related goodwill of $55 million. (See Note 13 for details on the acquisition of these assets.) No goodwill was impaired or disposed of during the three or nine month periods ended September 30, 2004. No goodwill was acquired or impaired during the three or nine month periods ended September 30, 2003. During the third quarter of 2003 we disposed of assets with related goodwill of $3 million.

6. Unconsolidated Affiliated Companies

Our investment in affiliated companies accounted for by the equity method consists primarily of a 50 percent interest in Shin Caterpillar Mitsubishi Ltd. (SCM) in Japan. Combined financial information of the unconsolidated affiliated companies accounted for using the equity method (generally on a three month lag, e.g., SCM results reflect the periods ending June 30) was as follows:

| | Results of Operations | | Results of Operations |

| | Three Months Ended | | Nine Months Ended |

| | September 30, | | September 30, |

(Millions of dollars) | 2004 | | 2003 | | 2004 | | 2003 |

|

| |

| |

| |

|

| Sales | $ | 986 | | | $ | 805 | | | $ | 2,699 | | | $ | 2,261 | |

| Cost of sales | | 743 | | | | 624 | | | | 2,070 | | | | 1,765 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Gross profit | $ | 243 | | | $ | 181 | | | $ | 629 | | | $ | 496 | |

| | | | | | | | | | | | | | | | |

| Profit (loss) | $ | 35 | | | $ | 17 | | | $ | 81 | | | $ | 27 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Caterpillar's profit (loss) | $ | 17 | | | $ | 7 | | | $ | 37 | | | $ | 11 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| | Financial Position |

| | September 30, | | December 31, |

(Millions of dollars) | 2004 | | 2003 |

|

| |

|

| Assets: | | | | | | | |

| | Current assets | $ | 1,623 | | | $ | 1,494 | |

| | Property, plant and equipment - net | | 1,036 | | | | 961 | |

| | Other assets | | 187 | | | | 202 | |

| |

|

|

| |

|

|

|

| | | 2,846 | | | | 2,657 | |

| Liabilities: | | | | | | | |

| | Current liabilities | | 1,402 | | | | 1,247 | |

| | Long-term debt due after one year | | 286 | | | | 343 | |

| | Other liabilities | | 222 | | | | 257 | |

| |

|

|

| |

|

|

|

| | | | 1,910 | | | | 1,847 | |

| |

|

|

| |

|

|

|

| Ownership | $ | 936 | | | $ | 810 | |

|

|

|

| |

|

|

|

Caterpillar's investment in unconsolidated affiliated companies | | | | | | | |

| | Investment in equity method companies | $ | 470 | | | $ | 432 | |

| | Plus: Investment in cost method companies | | 369 | | | | 368 | |

| |

|

|

| |

|

|

|

| | Total investment in unconsolidated affiliated companies | $ | 839 | | | $ | 800 | |

| |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

Page 11

7.Segment Information

Caterpillar is organized based on a decentralized structure that has established accountabilities to continually improve business focus and increase our ability to react quickly to changes in both the global business cycle and competitors' actions. Our current structure uses a product, geographic matrix organization comprised of multiple profit center and service center divisions.

We have developed an internal measurement system, which is not based on generally accepted accounting principles (GAAP), that is intended to motivate desired behavior and drive performance rather than measure a division's contribution to enterprise results. It is the comparison of actual results to budgeted results that makes our internal reporting valuable to management. Consequently, we believe that segment disclosure based on Statement of Financial Accounting Standards No. 131 (SFAS 131) "Disclosures about Segments of an Enterprise and Related Information" has limited value to our external readers. As a result, in addition to the required SFAS 131 compliant segment information presented below, we are continuing to disclose GAAP-based financial results for our three lines of business (Machinery, Engines, and Financial Products ) in our Management's Discussion and Analysis beginning on page 24.

We made several changes to our segment reporting methodologies in the first quarter of 2004. Most notable are a change in the current cost methodology used to value inventory and cost of sales and a change in the manner that interest expense is charged to profit centers. In addition, certain corporate costs that were charged to segments in prior years are now reported as reconciling items. Prior year amounts have been restated to conform to the new methodology.

Business Segments Three Months Ended September 30, (Millions of dollars) |

|

| | Machinery and Engines | | |

2004 | Asia/Pacific Marketing | Construction & Mining Products | EAME Marketing | Latin America Marketing | Power Products | North America Marketing | All Other | Total | Financing & Insurance Services | Consolidated Total |

| External sales and revenues | $ | 486 | $ | 143 | | $ | 956 | $ | 499 | $ | 2,344 | $ | 2,289 | $ | 399 | $ | 7,116 | $ | 568 | $ | 7,684 | |

| Intersegment sales& revenues | | 191 | | 3,062 | | | 823 | | 210 | | 2,265 | | 105 | | 676 | | 7,332 | | - | | 7,332 | |

| Total sales and revenues | $ | 677 | $ | 3,205 | | $ | 1,779 | $ | 709 | $ | 4,609 | $ | 2,394 | $ | 1,075 | $ | 14,448 | $ | 568 | $ | 15,016 | |

| Accountable profit (loss) | $ | 20 | $ | 252 | | $ | 62 | $ | 45 | $ | 111 | $ | 113 | $ | 185 | $ | 788 | $ | 125 | $ | 913 | |

Accountable assets at September 30, 2004 | $ | 587 | $ | 2,584 | | $ | 1,203 | $ | 720 | $ | 3,855 | $ | 32 | $ | 3,331 | $ | 12,312 | $ | 22,639 | $ | 34,951 | |

|

2003 |

| External sales and revenues | $ | 344 | $ | 68 | | $ | 747 | $ | 290 | $ | 1,711 | $ | 1,612 | $ | 281 | $ | 5,053 | $ | 512 | $ | 5,565 | |

| Intersegment sales & revenues | | 105 | | 2,163 | | | 559 | | 142 | | 1,668 | | 60 | | 659 | | 5,356 | | 1 | | 5,357 | |

| Total sales and revenues | $ | 449 | $ | 2,231 | | $ | 1,306 | $ | 432 | $ | 3,379 | $ | 1,672 | $ | 940 | $ | 10,409 | $ | 513 | $ | 10,922 | |

| Accountable profit (loss) | $ | 21 | $ | 62 | | $ | 25 | $ | 22 | $ | 19 | $ | 82 | $ | 94 | $ | 325 | $ | 98 | $ | 423 | |

Accountable assets at December 31, 2003 | $ | 627 | $ | 2,190 | | $ | 1,018 | $ | 692 | $ | 3,710 | $ | 293 | $ | 2,537 | $ | 11,067 | $ | 20,235 | $ | 31,302 | |

| |

|

Business Segments Nine Months Ended September 30, (Millions of dollars) |

|

| | Machinery and Engines | | |

2004 | Asia/Pacific Marketing | Construction & Mining Products | EAME Marketing | Latin America Marketing | Power Products | North America Marketing | All Other | Total | Financing & Insurance Services | Consolidated Total |

| External sales and revenues | $ | 1,584 | $ | 438 | | $ | 2,843 | $ | 1,265 | $ | 6,211 | $ | 6,722 | $ | 1,076 | $ | 20,139 | $ | 1,745 | $ | 21,884 | |

| Intersegment sales & revenues | | 445 | | 8,993 | | | 2,606 | | 661 | | 6,269 | | 282 | | 1,922 | | 21,178 | | 1 | | 21,179 | |

| Total sales and revenues | $ | 2,029 | $ | 9,431 | | $ | 5,449 | $ | 1,926 | $ | 12,480 | $ | 7,004 | $ | 2,998 | $ | 41,317 | $ | 1,746 | $ | 43,063 | |

| Accountable profit (loss) | $ | 107 | $ | 885 | | $ | 289 | $ | 142 | $ | 215 | $ | 345 | $ | 503 | $ | 2,486 | $ | 344 | $ | 2,830 | |

Accountable assets at September 30, 2004 | $ | 587 | $ | 2,584 | | $ | 1,203 | $ | 720 | $ | 3,855 | $ | 32 | $ | 3,331 | $ | 12,312 | $ | 22,639 | $ | 34,951 | |

| |

2003 |

| External sales and revenues | $ | 1,134 | $ | 179 | | $ | 2,349 | $ | 808 | $ | 4,804 | $ | 4,822 | $ | 799 | $ | 14,895 | $ | 1,490 | $ | 16,385 | |

| Intersegment sales & revenues | | 271 | | 6,557 | | | 1,746 | | 380 | | 4,699 | | 173 | | 1,886 | | 15,712 | | 1 | | 15,713 | |

| Total sales and revenues | $ | 1,405 | $ | 6,736 | | $ | 4,095 | $ | 1,188 | $ | 9,503 | $ | 4,995 | $ | 2,685 | $ | 30,607 | $ | 1,491 | $ | 32,098 | |

| Accountable profit (loss) | $ | 95 | $ | 348 | | $ | 177 | $ | 59 | $ | (30) | $ | 203 | $ | 275 | $ | 1,127 | $ | 258 | $ | 1,385 | |

Accountable assets at December 31, 2003 | $ | 627 | $ | 2,190 | | $ | 1,018 | | 692 | $ | 3,710 | $ | 293 | $ | 2,537 | $ | 11,067 | $ | 20,235 | $ | 31,302 | |

Page 12

Reconciliation of Sales & Revenues: |

(Millions of dollars) | Machinery and Engines | | Financing & Insurance Services | | Consolidating Adjustments | | Consolidated Total |

|

| |

| |

| |

|

Three Months Ended September 30, 2004: | | | | | | | | | | | | | | | |

Total external sales and revenues from business segments | $ | 7,116 | | | $ | 568 | | | $ | - | | | $ | 7,684 | |

| Other | | 59 | | | | (142 | ) | | | 48 | 1 | | | (35 | ) |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Total sales and revenues | $ | 7,175 | | | $ | 426 | | | $ | 48 | | | $ | 7,649 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| | | | | | | | | | | | | | | | |

Three Months Ended September 30, 2003: | | | | | | | | | | | | | | | |

Total external sales and revenues from business segments | $ | 5,053 | | | $ | 512 | | | $ | - | | | $ | 5,565 | |

| Other | | 59 | | | | (33 | ) | | | (46 | )1 | | | (20 | ) |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Total sales and revenues | $ | 5,112 | | | $ | 479 | | | $ | (46 | ) | | $ | 5,545 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

1 Elimination of Financial Products revenues from Machinery and Engines |

|

Reconciliation of Sales & Revenues: |

| Machinery and Engines | | Financing & Insurance Services | | Consolidating Adjustments | | Consolidated Total |

|

| |

| |

| |

|

Nine Months Ended September 30, 2004: | | | | | | | | | | | | | | | |

Total external sales and revenues from business segments | $ | 20,139 | | | $ | 1,745 | | | $ | - | | | $ | 21,884 | |

| Other | | 138 | | | | (204 | ) | | | (138 | )1 | | | (204 | ) |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Total sales and revenues | $ | 20,277 | | | $ | 1,541 | | | $ | (138 | ) | | $ | 21,680 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| | | | | | | | | | | | | | | | |

Nine Months Ended September 30, 2003: | | | | | | | | | | | | | | | |

Total external sales and revenues from business segments | $ | 14,895 | | | $ | 1,490 | | | $ | - | | | $ | 16,385 | |

| Other | | 142 | | | | (96 | ) | | | (133 | )1 | | | (87 | ) |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Total sales and revenues | $ | 15,037 | | | $ | 1,394 | | | $ | (133 | ) | | $ | 16,298 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

1 Elimination of Financial Products revenues from Machinery and Engines |

|

Page 13

Reconciliation of Profit Before Taxes: | | | | | |

(Millions of dollars) | Machinery and Engines | | Financing & Insurance Services | | Consolidated Total |

|

| |

| |

|

Three Months Ended September 30, 2004: | | | | | | | | | | | |

| Total accountable profit from business segments | $ | 788 | | | $ | 125 | | | $ | 913 | |

| Corporate costs | | (141 | ) | | | - | | | | (141 | ) |

| Timing | | (24 | ) | | | - | | | | (24 | ) |

| Methodology differences: | | | | | | | | | | | |

| | Inventory/cost of sales | | - | | | | - | | | | - | |

| | Postretirement benefit expense | | (62 | ) | | | - | | | | (62 | ) |

| | Financing costs | | 9 | | | | - | | | | 9 | |

| | Equity in profit of unconsolidated affiliated companies | | (17 | ) | | | - | | | | (17 | ) |

| | Currency | | (6 | ) | | | - | | | | (6 | ) |

| | Other methodology differences | | (21 | ) | | | 19 | | | | (2 | ) |

| Other | | (7 | ) | | | - | | | | (7 | ) |

|

|

|

| |

|

|

| |

|

|

|

| Total profit before taxes | $ | 519 | | | $ | 144 | | | $ | 663 | |

|

|

|

| |

|

|

| |

|

|

|

Three Months Ended September 30, 2003: | | | | | | | | | | | |

| Total accountable profit from business segments | $ | 325 | | | $ | 98 | | | $ | 423 | |

| Corporate costs | | (163 | ) | | | - | | | | (163 | ) |

| Timing | | 41 | | | | - | | | | 41 | |

| Methodology differences: | | | | | | | | | | | |

| | Inventory/cost of sales | | 8 | | | | - | | | | 8 | |

| | Postretirement benefit expense | | (36 | ) | | | - | | | | (36 | ) |

| | Financing costs | | 11 | | | | - | | | | 11 | |

| | Equity in profit of unconsolidated affiliated companies | | (5 | ) | | | (2 | ) | | | (7 | ) |

| | Currency | | (6 | ) | | | - | | | | (6 | ) |

| | Other methodology differences | | (7 | ) | | | 7 | | | | - | |

| Other | | 13 | | | | - | | | | 13 | |

|

|

|

| |

|

|

| |

|

|

|

| Total profit before taxes | $ | 181 | | | $ | 103 | | | $ | 284 | |

|

|

|

| |

|

|

| |

|

|

|

Reconciliation of Profit Before Taxes: | | | | | |

(Millions of dollars) | Machinery and Engines | | Financing & Insurance Services | | Consolidated Total |

|

| |

| |

|

Nine Months Ended September 30, 2004: | | | | | | | | | | | |

| Total accountable profit from business segments | $ | 2,486 | | | $ | 344 | | | $ | 2,830 | |

| Corporate costs | | (404 | ) | | | - | | | | (404 | ) |

| Timing | | (113 | ) | | | - | | | | (113 | ) |

| Methodology differences: | | | | | | | | | | | |

| | Inventory/cost of sales | | (54 | ) | | | - | | | | (54 | ) |

| | Postretirement benefit expense | | (209 | ) | | | - | | | | (209 | ) |

| | Financing costs | | 35 | | | | - | | | | 35 | |

| | Equity in profit of unconsolidated affiliated companies | | (35 | ) | | | (2 | ) | | | (37 | ) |

| | Currency | | (39 | ) | | | - | | | | (39 | ) |

| | Other methodology differences | | (63 | ) | | | 35 | | | | (28 | ) |

| Other | | 15 | | | | - | | | | 15 | |

|

|

|

| |

|

|

| |

|

|

|

| Total profit before taxes | $ | 1,619 | | | $ | 377 | | | $ | 1,996 | |

|

|

|

| |

|

|

| |

|

|

|

Nine Months Ended September 30, 2003: | | | | | | | | | | | |

| Total accountable profit from business segments | $ | 1,127 | | | $ | 258 | | | $ | 1,385 | |

| Corporate costs | | (346 | ) | | | - | | | | (346 | ) |

| Timing | | 28 | | | | - | | | | 28 | |

| Methodology differences: | | | | | | | | | | | |

| | Inventory/cost of sales | | (3 | ) | | | - | | | | (3 | ) |

| | Postretirement benefit expense | | (122 | ) | | | - | | | | (122 | ) |

| | Financing costs | | 55 | | | | - | | | | 55 | |

| | Equity in profit of unconsolidated affiliated companies | | (7 | ) | | | (4 | ) | | | (11 | ) |

| | Currency | | (7 | ) | | | - | | | | (7 | ) |

| | Other methodology differences | | (16 | ) | | | 27 | | | | 11 | |

| Other | | 22 | | | | - | | | | 22 | |

|

|

|

| |

|

|

| |

|

|

|

| Total profit before taxes | $ | 731 | | | $ | 281 | | | $ | 1,012 | |

|

|

|

| |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 14

Reconciliation of Assets: | | | | | | | | | | | | | | | |

(Millions of dollars) | Machinery and Engines | | Financing & Insurance Services | | Consolidating Adjustments | | Consolidated Total |

|

| |

| |

| |

|

September 30, 2004: | | | | | | | | | | | | | | | |

| Total accountable assets from business segments | $ | 12,312 | | | $ | 22,639 | | | $ | - | | | $ | 34,951 | |

| Items not included in segment assets: | | | | | | | | | | | | | | | |

| | Cash and short-term investments | | 241 | | | | 176 | | | | - | | | | 417 | |

| | Intercompany trade receivables | | 360 | | | | 181 | | | | (553 | ) | | | (12 | ) |

| | Investment in affiliated companies | | 334 | | | | - | | | | (1 | ) | | | 333 | |

| | Investment in Financial Products | | 2,809 | | | | - | | | | (2,809 | ) | | | - | |

| | Deferred income taxes and prepaids | | 2,452 | | | | 87 | | | | (242 | ) | | | 2,297 | |

| | Intangible assets and other assets | | 1,937 | | | | - | | | | - | | | | 1,937 | |

| | Service center assets | | 925 | | | | - | | | | - | | | | 925 | |

| Liabilities included in segment assets | | 1,147 | | | | - | | | | - | | | | 1,147 | |

| Inventory methodology differences | | (2,168 | ) | | | - | | | | - | | | | (2,168 | ) |

| Other | | 602 | | | | - | | | | (35 | ) | | | 567 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Total assets | $ | 20,951 | | | $ | 23,083 | | | $ | (3,640 | ) | | $ | 40,394 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

December 31, 2003: | | | | | | | | | | | | | | | |

| Total accountable assets from business segments | $ | 11,067 | | | $ | 20,235 | | | $ | - | | | $ | 31,302 | |

| Items not included in segment assets: | | | | | | | | | | | | | | | |

| | Cash and short-term investments | | 220 | | | | 122 | | | | - | | | | 342 | |

| | Intercompany trade receivables | | 572 | | | | 397 | | | | (969 | ) | | | - | |

| | Investment in affiliated companies | | 325 | | | | - | | | | - | | | | 325 | |

| | Investment in Financial Products | | 2,547 | | | | - | | | | (2,547 | ) | | | - | |

| | Deferred income taxes and prepaids | | 2,736 | | | | 77 | | | | (228 | ) | | | 2,585 | |

| | Intangible assets and other assets | | 1,874 | | | | - | | | | - | | | | 1,874 | |

| | Service center assets | | 895 | | | | - | | | | - | | | | 895 | |

| Liabilities included in segment assets | | 925 | | | | - | | | | - | | | | 925 | |

| Inventory methodology differences | | (2,035 | ) | | | - | | | | - | | | | (2,035 | ) |

| Other | | 84 | | | | 168 | | | | - | | | | 252 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Total assets | $ | 19,210 | | | $ | 20,999 | | | $ | (3,744 | ) | | $ | 36,465 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8. Available-For-Sale Securities

Caterpillar Insurance and Caterpillar Investment Management, Ltd. had investments in certain debt and equity securities at September 30, 2004 that have been classified as available-for-sale in accordance with Statement of Financial Accounting Standards No. 115 (SFAS 115) and recorded at fair value based upon quoted market prices. These fair values are included in "Other Assets" in the Statement of Financial Position. Unrealized gains and losses arising from the revaluation of available-for-sale securities are included, net of applicable deferred income taxes, in equity ("Accumulated other comprehensive income" in the Statement of Financial Position). Realized gains and losses on sales of investments are determined using the specific identification method for debt instruments and the FIFO method for equity securities. Realized ga ins and losses are included in "Other income (expense)" in the Statement of Results of Operations.

| | September 30, 2004 |

|

|

| | | | Unrealized | | |

| | | | Pretax Net | | |

(Millions of dollars) | Cost Basis | | Gains (Losses) | | Fair Value |

|

| |

| |

|

| Government debt | $ | 233 | | | $ | (1 | ) | | $ | 232 | |

| Corporate bonds | | 331 | | | | 1 | | | | 332 | |

| Equity securities | | 206 | | | | 10 | | | | 216 | |

|

|

|

| |

|

|

| |

|

|

|

| Total | $ | 770 | | | $ | 10 | | | $ | 780 | |

|

|

|

| |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 15

| | December 31, 2003 |

|

|

(Millions of dollars) | Cost Basis | | Unrealized Pretax Net Gains (Losses) | | Fair Value |

|

| |

| |

|

| Government debt | $ | 102 | | | $ | - | | | $ | 102 | |

| Corporate bonds | | 288 | | | | 3 | | | | 291 | |

| Equity securities | | 191 | | | | 21 | | | | 212 | |

|

|

|

| |

|

|

| |

|

|

|

| Total | $ | 581 | | | $ | 24 | | | $ | 605 | |

|

|

|

| |

|

|

| |

|

|

|

Investments in an unrealized loss position that are not other-than-temporarily impaired:

|

| | September 30, 2004 |

|

|

| | Less than 12 months(1) | | More than 12 months(1) | | Total |

|

| |

| |

|

(Millions of dollars) | Fair Value | | Unrealized Losses | | Fair Value | | Unrealized Losses | | Fair Value | | Unrealized Losses |

|

| |

| |

| |

| |

| |

|

| Government debt | $ | 124 | | | $ | 1 | | | $ | 8 | | | $ | - | | | $ | 132 | | | $ | 1 | |

| Corporate bonds | | 132 | | | | 1 | | | | 34 | | | | 2 | | | | 166 | | | | 3 | |

| Equity securities | | 79 | | | | 3 | | | | - | | | | - | �� | | | 79 | | | | 3 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

| Total | $ | 335 | | | $ | 5 | | | $ | 42 | | | $ | 2 | | | $ | 377 | | | $ | 7 | |

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

(1)Indicates length of time that individual securities have been in a continuous unrealized loss position. |

| |

|

The fair value of the available-for-sale debt securities at September 30, 2004, by contractual maturity, is shown below. Expected maturities will differ from contractual maturities because borrowers may have the right to prepay and creditors may have the right to call obligations.

(Millions of dollars) | | Fair Value |

| |

|

| Due in one year or less | | $ | 19 | |

| Due after one year through five years | | $ | 265 | |

| Due after five years through ten years | | $ | 36 | |

| Due after ten years | | $ | 244 | |

|

|

|

|

|

Proceeds from sales of investments in debt and equity securities during the three and nine months ended September 30, 2004 were $208 million and $343 million, respectively. Proceeds were $201 million and $280 million for the three and nine months ended September 30, 2003, respectively. Gross gains of $2 million and $5 million and gross losses of $2 million and $5 million were included in current earnings for the three and nine months ended September 30, 2004, respectively. Gross gains of $3 million and gross losses of $1 million were included in current earnings for the three and nine months ended September 30, 2003, respectively.

In accordance with the application of SFAS 115, we recognized pretax charges of $8 million and $32 million for "other than temporary" declines in the market value of securities in the Cat Insurance investment portfolio for the three and nine months ended September 30, 2003, respectively. These charges were accounted for as realized losses and were included in "Other income (expense)" in the Statement of Results of Operations. The cost basis of the impacted securities were adjusted to reflect these charges. No such charges were recognized through the first nine months of 2004.

9. Derivative Instruments and Hedging Activities

Our earnings and cash flow are subject to fluctuations due to changes in foreign currency exchange rates, interest rates and commodity prices. Our "Risk Management Policy" (policy) allows for the use of derivative financial instruments to prudently manage foreign currency exchange rate, interest rate and commodity price exposure. Our derivative activities are subject to the management, direction and control of our Financial Officers. Risk management practices, including the use of financial derivative instruments, are presented to the Audit Committee of the Board of Directors at least annually.

Page 16

Foreign Currency Exchange Rate Risk

Foreign currency exchange rate movements create a degree of risk by affecting the U.S. dollar value of sales made and costs incurred in foreign currencies. Movements in foreign currency rates also affect our competitive position as these changes may affect business practices and/or pricing strategies of non-U.S. based competitors. Additionally, we have balance sheet positions denominated in foreign currency thereby creating exposure to movements in exchange rates.

Our Machinery and Engines operations purchase, manufacture and sell products in many locations around the world. As we have a diversified revenue and cost base, we manage our future foreign currency cash flow exposure on a net basis. We use foreign currency forward and option contracts to manage unmatched foreign currency cash inflow and outflow. Our objective is to minimize the risk of exchange rate movements that would reduce the U.S. dollar value of our foreign currency cash flow. Our policy allows for managing anticipated foreign currency cash flow for up to four years.

We generally designate as cash flow hedges at inception of the contract any Australian dollar, Brazilian real, British pound, Canadian dollar, euro, Japanese yen, Mexican peso or Singapore dollar forward or option contracts that exceed 90 days in duration. Designation is performed on a specific exposure basis to support hedge accounting. The remainder of Machinery and Engines foreign currency contracts are undesignated. As of September 30, 2004, $62 million of deferred net gains included in equity (“Accumulated other comprehensive income” in the Statement of Financial Position) are expected to be reclassified to current earnings (“Other income (expense)”) over the next twelve months when earnings are negatively affected by the hedged transactions. As of September 30, 2003, this projected reclassification was a gain of $23 million. These amounts are based on September 30, 2004 and September 30, 2003 exchange rates, respectively. The actual amount recorded in other income/expense will vary based on exchange rates at the time the hedged transactions impact earnings. There were no circumstances where hedge treatment was discontinued during the three or nine month periods ended September 30, 2004 or 2003.

In managing foreign currency risk for our Financial Products operations, our objective is to minimize earnings volatility resulting from conversion and the remeasurement of net foreign currency balance sheet positions. Our policy allows the use of foreign currency forward contracts to offset the risk of currency mismatch between our receivables and debt. All such foreign currency forward contracts are undesignated.

Gains / (losses) included in current earnings [Other income (expense)] on undesignated contracts:

|

| | Three Months Ended September 30, |

(Millions of dollars) | 2004 | | 2003 |

|

| |

|

| Machinery and Engines: | | | | | | | |

| | On undesignated contracts | $ | - | | | $ | 1 | |

| | | | | | | | | |

| Financial Products: | | | | | | | |

| | On undesignated contracts | $ | 2 | | | $ | (21 | ) |

Gains / (losses) included in current earnings [Other income (expense)] on undesignated contracts: |

| | Nine Months Ended September 30, |

(Millions of dollars) | 2004 | | 2003 |

|

| |

|

| Machinery and Engines: | | | | | | | |

| | On undesignated contracts | $ | (3 | ) | | $ | 5 | |

| | | | | | | | | |

| Financial Products: | | | | | | | |

| | On undesignated contracts | $ | 19 | | | $ | (71 | ) |

|

|

|

|

|

|

|

|

|

Gains and losses on the Financial Products contracts above are substantially offset by balance sheet remeasurement and conversion gains and losses.

Page 17

Interest Rate Risk

Interest rate movements create a degree of risk by affecting the amount of our interest payments and the value of our fixed rate debt. Our policy is to use interest rate swap agreements and forward rate agreements to manage our exposure to interest rate changes and lower the cost of borrowed funds.

Machinery and Engines operations generally use fixed rate debt as a source of funding. Our objective is to minimize the cost of borrowed funds. Our policy allows us to enter into fixed-to-floating interest rate swaps and forward rate agreements to meet that objective with the intent to designate as fair value hedges at inception of the contract all fixed-to-floating interest rate swaps. Designation as a hedge of the fair value of our fixed rate debt is performed to support hedge accounting. During 2001, our Machinery and Engines operations liquidated all fixed-to-floating interest rate swaps. Deferred gains on liquidated fixed-to-floating interest rate swaps, which were previously designated as fair value hedges, are being amortized to earnings ratably over the remaining life of the hedged debt. We designate as cash flow hedges at inception of the contract all forward rate agreements. Designation as a hedge of the anticipated issuance of debt is performed to support hedge accounting. Machinery and Engines forward rate agreements are 100 percent effective.

Financial Products operations have a "match funding" objective whereby, within specified boundaries, the interest rate profile (fixed rate or floating rate) of their debt portfolio matches the interest rate profile of their receivables. In connection with that objective, we use interest rate derivative instruments to modify the debt structure to match the receivable portfolio. This "match funding" reduces the volatility of margins between interest-bearing assets and interest-bearing liabilities, regardless of which direction interest rates move. We also use these instruments to gain an economic and/or competitive advantage through lower cost of borrowed funds. This is accomplished by changing the characteristics of existing debt instruments or entering into new agreements in combination with the issuance of new debt.

Our policy allows us to use floating-to-fixed, fixed-to-floating, and floating-to-floating interest rate swaps to meet the "match funding" objective. To support hedge accounting, we designate fixed-to-floating interest rate swaps as fair value hedges of the fair value of our fixed rate debt at inception of the contract. Financial Products policy is to designate most floating-to-fixed interest rate swaps as cash flow hedges of the variability of future cash flows at inception of the contract. During 2002, our Financial Products operations liquidated four fixed-to-floating interest rate swaps. As a result, the fair value adjustment of the original debt is being amortized to earnings ratably over the remaining life of the hedged debt.

Gains / (losses) included in current earnings [Other income (expense)]:

|

| | Three Months Ended September 30, |

(Millions of dollars) | 2004 | | 2003 |

|

| |

|

| Fixed-to-floating interest rate swaps | | | | | | | |

| | Machinery and Engines: | | | | | | | |

| | | Gain/(loss) on liquidated swaps | | 1 | | | | 1 | |

| | Financial Products: | | | | | | | |

| | | Gain/(loss) on designated interest rate derivatives | | 42 | | | | 1 | |

| | | Gain/(loss) on hedged debt | | (42 | ) | | | (1 | ) |

| | |

|

|

| |

|

| | | | $ | 1 | | | $ | 1 | |

| | |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 18

Gains / (losses) included in current earnings [Other income (expense)]:

|

| | Nine Months Ended September 30, |

(Millions of dollars) | 2004 | | 2003 |

|

| |

|

| Fixed-to-floating interest rate swaps | | | | | | | |

| | Machinery and Engines: | | | | | | | |

| | | Gain/(loss) on liquidated swaps | | 3 | | | | 5 | |

| | Financial Products: | | | | | | | |

| | | Gain/(loss) on designated interest rate derivatives | | 3 | | | | 9 | |

| | | Gain/(loss) on hedged debt | | (3 | ) | | | (9 | ) |

| | | Gain/(loss) on liquidated swaps - included in interest expense | | 1 | | | | 1 | |

| | |

|

|

| |

|

|

|

| | | | $ | 4 | | | $ | 6 | |

| | |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

As of September 30, 2004 and 2003, $10 million and $21 million, respectively, of deferred net losses included in equity (“Accumulated other comprehensive income” in the Statement of Financial Position), related to Financial Products floating-to-fixed interest rate swaps, is expected to be reclassified to current earnings (“Interest expense of Financial Products”) over the next twelve months.

The reclassification of the remaining deferred amount to current earnings ("Other income (expense)") will occur over a maximum of 27 years. There were no circumstances where hedge treatment was discontinued during the three or nine month periods ended September 30, 2004 or 2003.

Commodity Price Risk

Commodity price movements create a degree of risk by affecting the price we must pay for certain raw material. Our policy is to use commodity forward and option contracts to manage the commodity risk and reduce the cost of purchased materials.

Our Machinery and Engines operations purchase aluminum, copper and nickel embedded in the components we purchase from suppliers. Our suppliers pass on to us price changes in the commodity portion of the component cost.

Our objective is to minimize volatility in the price of these commodities. Our policy allows us to enter commodity forward and option contracts to lock in the purchase price of the commodities within a four-year horizon. All such commodity forward and option contracts are undesignated. Gains on the undesignated contracts of $6 million and $11 million were recorded in current earnings ("Other income (expense)") for the three and nine months ended September 30, 2004. Gains on the undesignated contracts of $7 million and $8 million were recorded in current earnings ("Other income (expense)") for the three and nine months ended September 30, 2003.

10. Guarantees and product warranty

We have guaranteed to repurchase loans of certain Caterpillar dealers from the Dealer Capital Asset Trust (DCAT) in the event of default. These guarantees arose in conjunction with Cat Financial's relationship with third party dealers who sell Caterpillar equipment. These guarantees have terms ranging from one to four years and are secured primarily by dealer assets. At September 30, 2004 and December 31, 2003 amounts outstanding under these guarantees were $364 million and $380 million, respectively. The related book value was $10 million and $5 million at September 30, 2004 and December 31, 2003, respectively.

Our product warranty liability is determined by applying historical claim rate experience to the current field population and dealer inventory. Effective in the third quarter 2004, we revised our process to utilize more detailed claim rates by product. This provides more comprehensive information for management. This change did not have a material impact on our financial statements.

(Millions of dollars) | 2004 |

|

|

| Warranty liability, January 1 | $ | 622 | |

| Payments | | (389 | ) |

| Provision for warranty | | 497 | |

| Other | | 25 | 1 |

|

|

|

|

| Warranty liability, September 30 | $ | 755 | |

|

|

|

|

|

1 Additions due to acquisitions | | | |

|

|

|

|

Page 19

(Millions of dollars) | 2003 |

|

|

| Warranty liability, January 1 | $ | 693 | |

| Payments | | (484 | ) |

| Provision for warranty | | 413 | |

|

|

|

|

| Warranty liability, December 31 | $ | 622 | |

|

|

|

|

|

|

|

|

11. Computations of Profit Per Share

| | | | Three Months Ended September 30, |

(Dollars in millions except per share data) | 2004 | | 2003 |

|

| |

|

| I. | | Profit for the period (A): | $ | 498 | | | $ | 222 | |

| | |

|

|

| |

|

|

|

| II. | | Determination of shares (millions): | | | | | | | |

| | | Weighted average number of common shares outstanding (B) | | 341.8 | | | | 346.3 | |

| | | Shares issuable on exercise of stock options, net of shares assumed to be purchased out of proceeds at average market price | | 11.2 | | | | 9.8 | |

| | |

|

|

| |

|

|

|

| | | Average common shares outstanding for fully diluted computation (C) | | 353.0 | | | | 356.1 | |

| | |

|

|

| |

|

|

|

| III. | | Profit per share of common stock: | | | | | | | |

| | | Assuming no dilution (A/B) | $ | 1.45 | | | $ | 0.64 | |

| | | Assuming full dilution (A/C) | $ | 1.41 | | | $ | 0.62 | |

| | | | Nine Months Ended September 30, |

(Dollars in millions except per share data) | 2004 | | 2003 |

|

| |

|

| I. | | Profit for the period (A): | $ | 1,484 | | | $ | 750 | |

| | |

|

|

| |

|

|

|

| II. | | Determination of shares (millions): | | | | | | | |

| | | Weighted average number of common shares outstanding (B) | | 342.3 | | | | 345.1 | |

| | | Shares issuable on exercise of stock options, net of shares assumed to be purchased out of proceeds at average market price | | 11.9 | | | | 3.9 | |

| | |

|

|

| |

|

|

|

| | | Average common shares outstanding for fully diluted computation (C) | | 354.2 | | | | 349.0 | |

| | |

|

|

| |

|

|

|

| III. | | Profit per share of common stock: | | | | | | | |

| | | Assuming no dilution (A/B) | $ | 4.34 | | | $ | 2.17 | |

| | | Assuming full dilution (A/C) | $ | 4.19 | | | $ | 2.15 | |

|

|

|

|

|

|

|

|

|

|

Stock options to purchase 8,973,264 shares of common stock at a weighted average price of $77.28 were outstanding as of September 30, 2004, but were not included in the computation of diluted profit per share because the options’ exercise price was greater than the average market price of the common shares on September 30, 2004. In 2003, all stock options were included in the computation of diluted profit per share.

Page 20

12. Postretirement Benefits

A. Pension and postretirement benefit costs

| | | | (Millions of Dollars) |

| | | | U.S. Pension Benefits | | Non-U.S. Pension Benefits | | Other Postretirement Benefits |

| | |

| |

| |

|

| | September 30, | | September 30, | | September 30, |

| | 2004 | | 2003 | | 2004 | | 2003 | | 2004 | | 2003 |

|

| |

| |

| |

| |

| |

|

For the three months ended: | | | | | | | | | | | | | | | | | | | | | | | |

Components of net periodic benefit cost: | | | | | | | | | | | | | | | | | | | | | | | |