Exhibit 96.3

SEC Technical Report Summary

Sal de Vida Lithium Brine Project

Prepared by:

Montgomery & Associates Consultores Limitada

1550 East Prince Road, Tucson, Arizona 85719 United States of America

and

Gunn Metallurgy

58 Deerhurst Rd, Brookfield 4069 Australia

Prepared for:

Allkem Limited

Riparian Plaza—Level 35

71 Eagle Street

Brisbane, Queensland 4000, Australia

Report Date: August 31, 2023

Amended Date: November 15, 2023

Effective Date: June 30, 2023

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| CONTENTS | |

| List of Tables | | |

| List of Figures | | |

| Contents | |

|

| 1. | Executive Summary | 1 |

| | 1.1 | Background | 1 |

| | 1.2 | Property Description and Ownership | 2 |

| | 1.3 | Geology and Mineralization | 2 |

| | 1.4 | Status of Exploration Activities | 3 |

| | 1.5 | Development and Operations | 4 |

| | 1.5.1 | Recovery Methods | 4 |

| | 1.5.2 | Process Facility Design | 4 |

| | 1.5.3 | Project Infrastructure | 6 |

| | 1.5.4 | Environmental and Social | 7 |

| | 1.6 | Mineral Resource Estimate | 8 |

| | 1.7 | Mineral Reserve Estimate | 10 |

| | 1.8 | Capital and Operating Cost Estimates | 13 |

| | 1.8.1 | Capital Cost Estimate | 13 |

| | 1.8.2 | Operating Cost Estimate | 14 |

| | 1.8.3 | Market Studies | 14 |

| | 1.8.4 | Contracts | 15 |

| | 1.9 | Economic Analysis–Stage 1 Only | 15 |

| | 1.9.1 | Financial Evaluation – Stage 1 Only | 15 |

| | 1.9.2 | Sensitivity Analysis – Stage 1 Only | 16 |

| | 1.10 | Additional Information–Stage 2 Expansion | 17 |

| | 1.10.1 | Stage 2 Description and Layout | 17 |

| | 1.10.2 | Stage 2 Infrastructure | 18 |

| | 1.10.3 | Stage 2 Permitting | 20 |

| | 1.10.4 | Stage 2 Capex and Opex | 21 |

| | 1.10.5 | Stage 2 Economic Analysis | 22 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| | 1.10.6 | Stage 2 Risk Management | 23 |

| | 1.10.7 | Stage 2 Conclusions and Recommendations | 23 |

| | 1.11 | Project Risks and Opportunities – Stages 1 and 2 | 24 |

| | 1.11.1 | Risks | 24 |

| | 1.11.2 | Opportunities | 25 |

| | 1.12 | Conclusions and QP Recommendations – Stages 1 and 2 | 26 |

| | 1.12.1 | Recommendations | 26 |

| | 1.13 | Revision Notes | 28 |

| 2. | Introduction | 29 |

| | 2.1 | Terms of Reference | 29 |

| | 2.2 | Qualified Persons and Site Visits | 29 |

| | 2.2.1 | Qualified Persons | 29 |

| | 2.2.2 | Site Visits | 31 |

| | 2.3 | Effective Date | 31 |

| | 2.3.1 | Previous Technical Reports | 31 |

| | 2.4 | Other Sources of information | 32 |

| | 2.5 | Specific Characteristics of Lithium Brine Projects | 32 |

| | 2.6 | Units of Measure & Glossary of Terms | 33 |

| | 2.6.1 | Currency | 33 |

| | 2.6.2 | Units and Abbreviations | 33 |

| 3. | Property Description | 36 |

| | 3.1 | Property Location, Country, Regional and Government Setting | 36 |

| | 3.2 | Property and Titles in Argentina | 37 |

| | 3.2.1 | Mining Title | 40 |

| | 3.2.2 | Surface Rights | 42 |

| | 3.2.3 | Water Rights | 42 |

| | 3.2.4 | Fraser Institute Policy Perception Index | 43 |

| | 3.3 | Ownership | 43 |

| | 3.4 | Surface Rights | 44 |

| | 3.5 | Water Rights | 45 |

| | 3.6 | Easements | 45 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| | 3.7 | Third-Party Rights | 47 |

| | 3.8 | Mining Royalties | 47 |

| | 3.9 | Permitting Considerations | 48 |

| | 3.10 | Environmental Considerations | 48 |

| | 3.11 | Social License Considerations | 49 |

| | 3.12 | Conclusion | 49 |

| 4. | Accessibility, Climate, Physiography, Local Resources, and Infrastructure | 50 |

| | 4.1 | Physiography | 50 |

| | 4.2 | Accessibility | 50 |

| | 4.3 | Climate | 51 |

| | 4.4 | Local Resources and Infrastructure | 51 |

| | 4.5 | Conclusion | 52 |

| 5. | History | 53 |

| | 5.1 | Historical Exploration and Drill Programs | 53 |

| | 5.2 | Historical Resource and Reserve Estimates | 54 |

| | 5.3 | Historical Production | 54 |

| 6. | Geological Setting, Mineralization and Deposit | 55 |

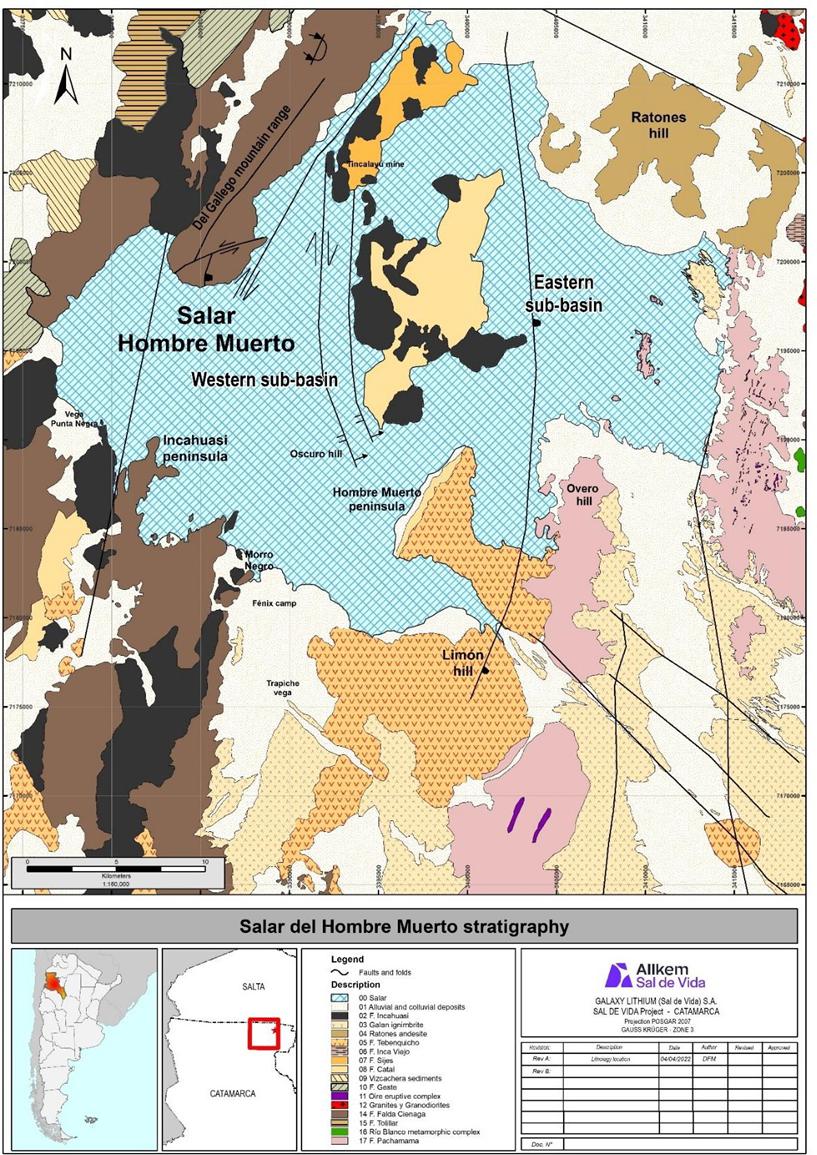

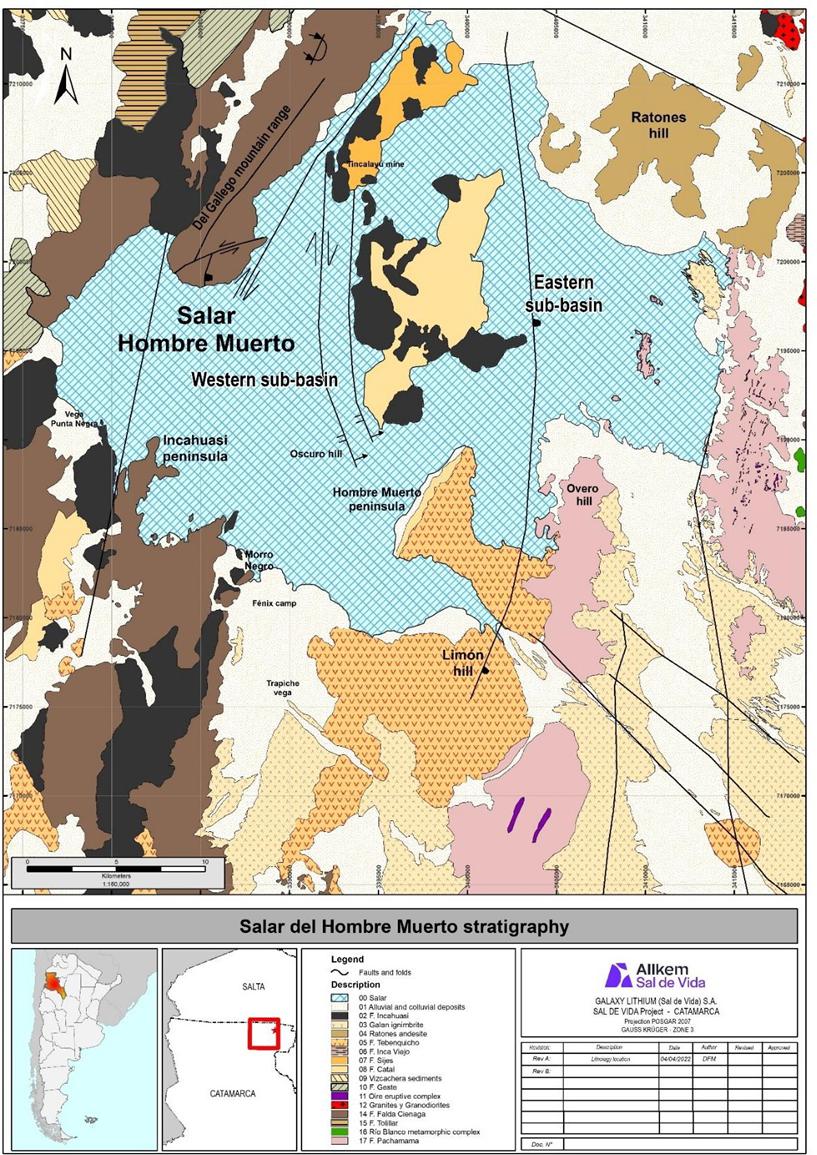

| | 6.1 | Regional Geology | 55 |

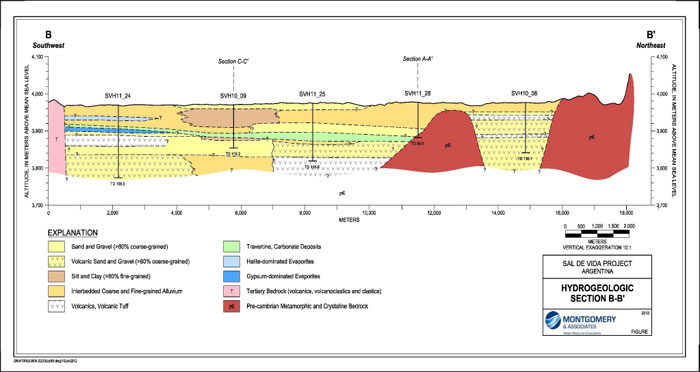

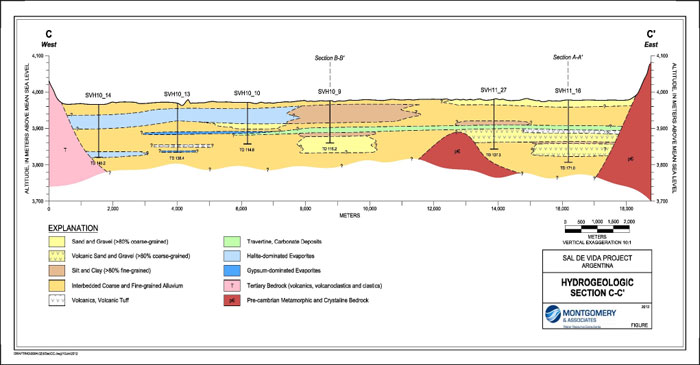

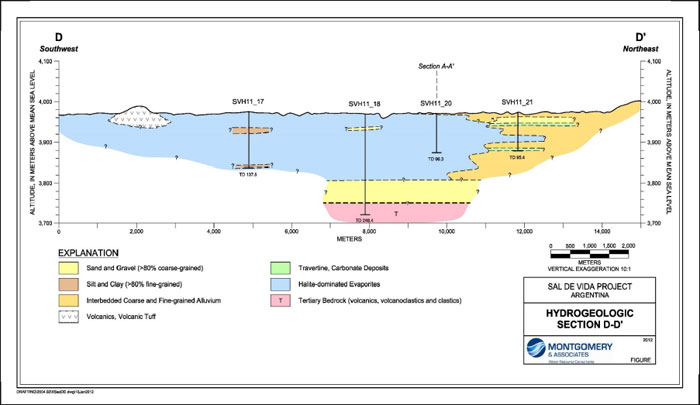

| | 6.2 | Local & Property Geology | 55 |

| | 6.3 | Deposit Description | 58 |

| | 6.3.1 | Introduction | 58 |

| | 6.3.2 | Hombre Muerto Basin | 58 |

| | 6.3.3 | Hydrogeological Units | 59 |

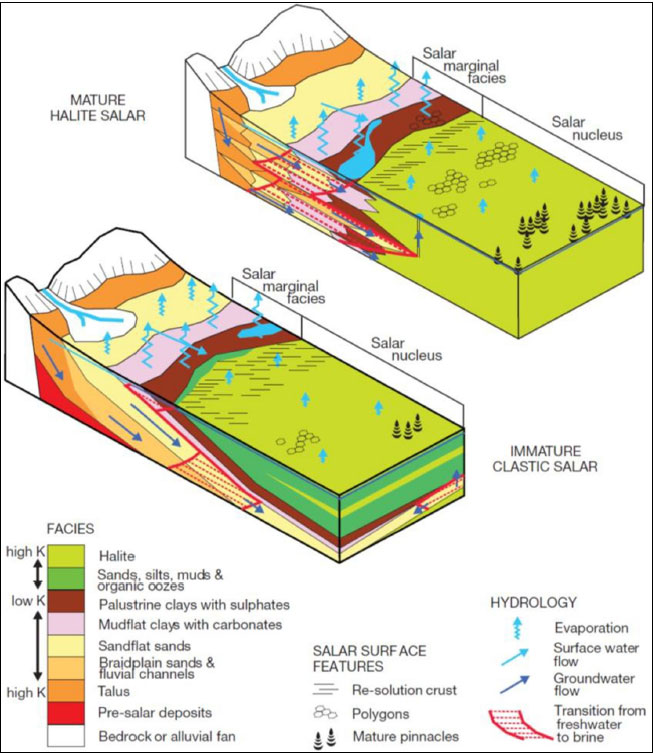

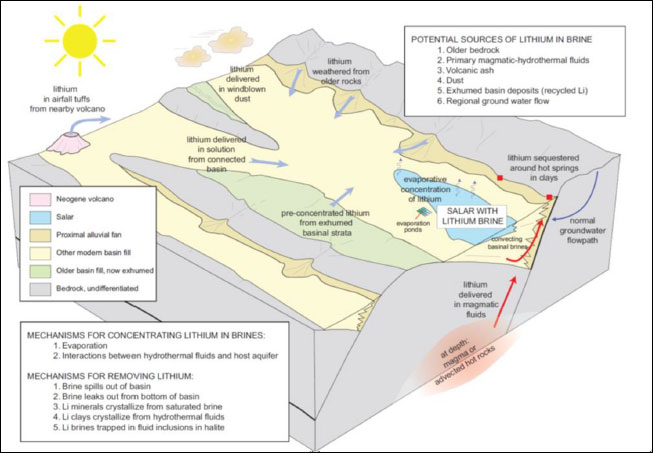

| | 6.4 | Deposit Model | 66 |

| | 6.5 | Comments on Geological Setting, Mineralization, and Deposit Types | 70 |

| 7. | Exploration | 71 |

| | 7.1 | Historical Exploration | 71 |

| | 7.2 | Grids and Surveys | 71 |

| | 7.3 | Geophysical Surveys | 71 |

| | 7.4 | Pits and Trenches | 77 |

| | 7.5 | Drilling | 78 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| | 7.5.1 | Phase 1 | 78 |

| | 7.5.2 | Phase 2 | 78 |

| | 7.5.3 | Phase 3 | 78 |

| | 7.5.4 | Phase 4 | 79 |

| | 7.5.5 | Phase 5 | 79 |

| | 7.5.6 | Phase 6 | 79 |

| | 7.5.7 | Logging and Recovery | 83 |

| | 7.5.8 | Collar Surveys by Lithium One | 87 |

| | 7.5.9 | Collar and Downhole Surveys by Galaxy Lithium | 87 |

| | 7.6 | Hydrogeological and Hydrological Studies | 88 |

| | 7.6.1 | Short-Term Pumping Tests | 89 |

| | 7.6.2 | Long-Term Pumping Tests | 92 |

| | 7.6.3 | Raw Water Wells | 96 |

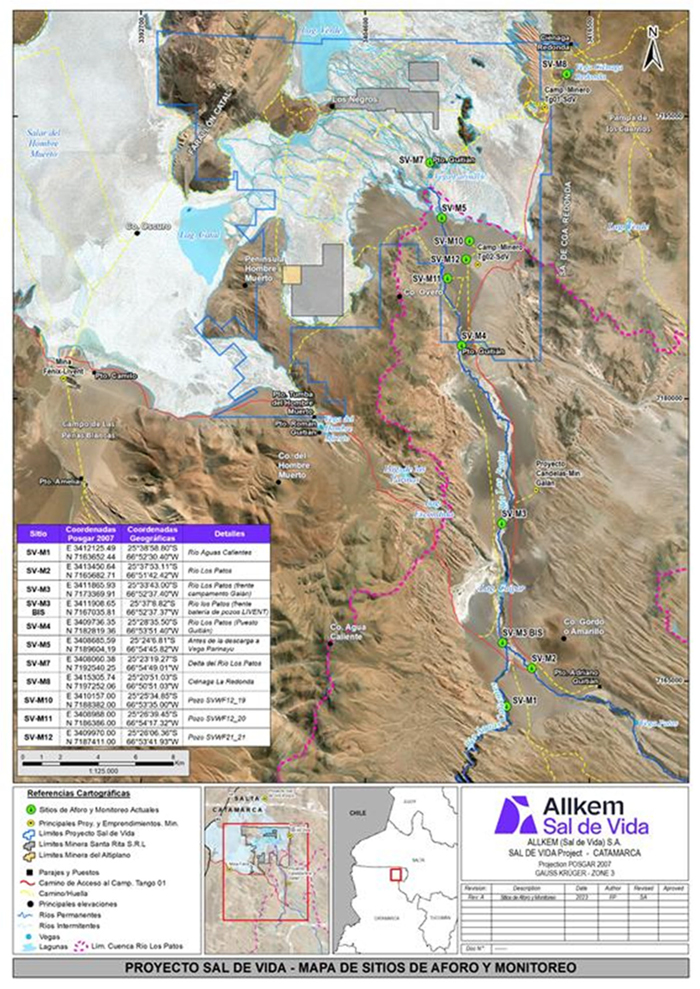

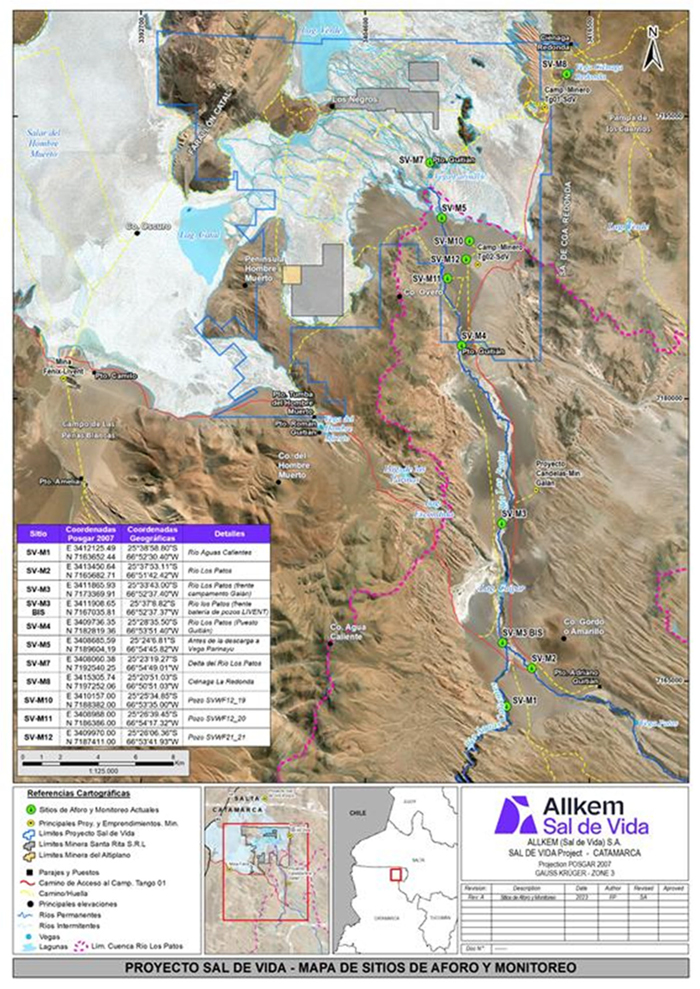

| | 7.6.4 | Stream Gauging | 97 |

| | 7.6.5 | Water Balance | 97 |

| | 7.7 | Geotechnical Considerations | 98 |

| | 7.8 | Conclusions | 98 |

| 8. | Sample Preparation, Analyses and Security | 99 |

| | 8.1 | Sampling Methods | 99 |

| | 8.1.1 | Drainable Porosity Sampling Methodology | 99 |

| | 8.1.2 | Brine Sampling Methodology | 99 |

| | 8.2 | Analytical and Test Laboratories | 103 |

| | 8.3 | Sample Preparation | 103 |

| | 8.4 | Analytical Methods | 103 |

| | 8.4.1 | Drainable Porosity | 103 |

| | 8.4.2 | Total Porosity | 105 |

| | 8.5 | Quality Assurance and Quality Control | 106 |

| | 8.5.1 | Quality Assurance and Quality Control Procedure | 106 |

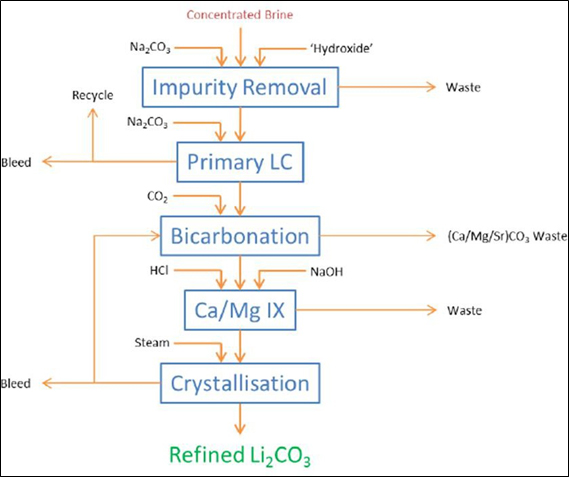

| | 8.5.2 | Anion-Cation Balance | 109 |

| | 8.6 | Databases | 110 |

| | 8.7 | Sample Security | 111 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| | 8.8 | Sample Storage | 111 |

| | 8.9 | Conclusions | 111 |

| 9. | Data Verification | 112 |

| | 9.1 | 2010 Technical Report | 112 |

| | 9.2 | 2011 and 2012 Technical Reports | 112 |

| | 9.3 | 2018 Feasibility Study | 112 |

| | 9.4 | 2021 Feasibility Study | 113 |

| | 9.5 | Verification by the Qualified Person | 113 |

| | 9.6 | Conclusions | 113 |

| 10. | Mineral Processing and Metallurgical Testing | 114 |

| | 10.1 | Initial Brine Characterization and Scoping Studies | 114 |

| | 10.1.1 | Raw Brine Metallurgical Characterization | 114 |

| | 10.1.2 | Final Product | 114 |

| | 10.2 | Metallurgical Laboratory Test-Work Program | 115 |

| | 10.2.1 | History | 115 |

| | 10.2.2 | Evaporation Rate Dynamics | 115 |

| | 10.2.3 | Liming and Concentration Pathway Testwork | 116 |

| | 10.2.4 | Galaxy-Jiangsu Lithium Carbonate Plant | 116 |

| | 10.2.5 | Hazen Research Inc. | 116 |

| | 10.2.6 | Galaxy Testwork | 116 |

| | 10.2.7 | ANSTO | 117 |

| | 10.2.8 | Class A Pan Evaporation Rate Measurement | 123 |

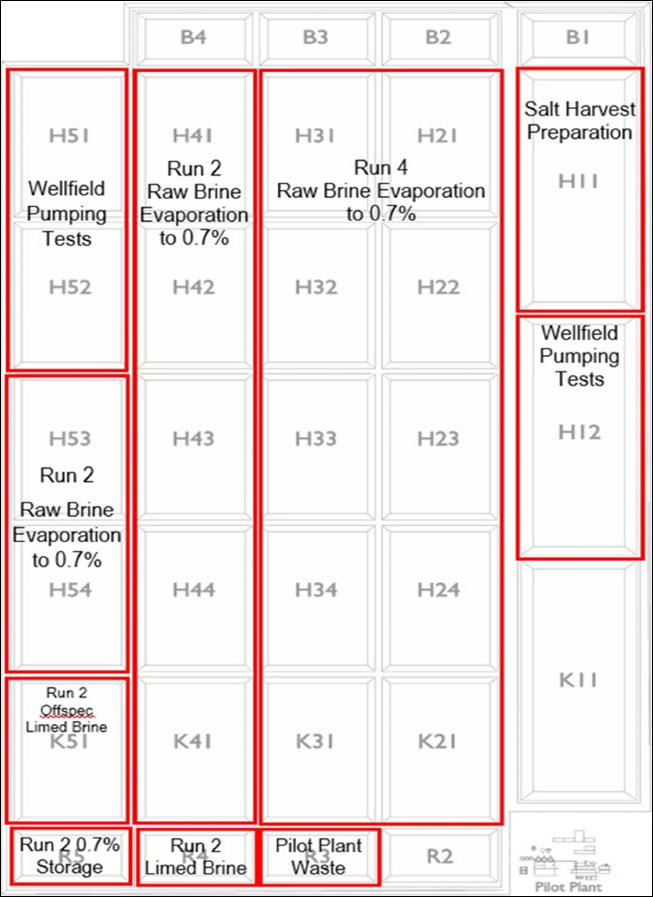

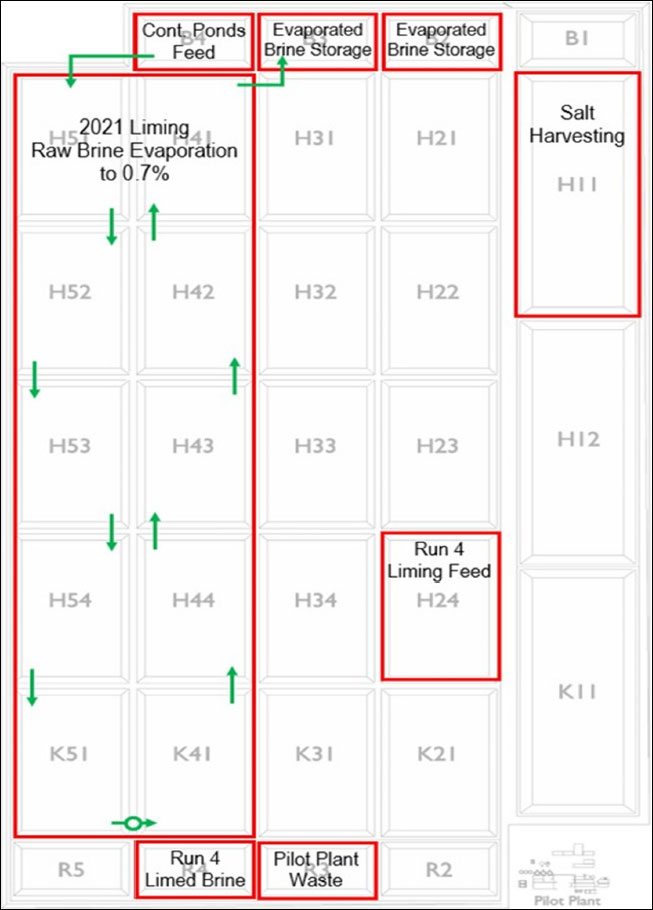

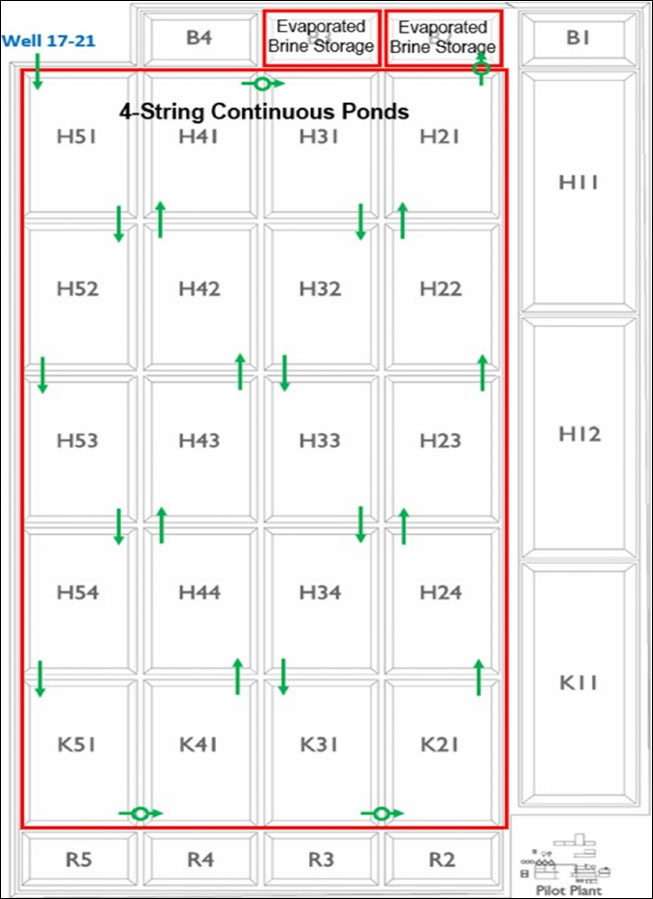

| | 10.2.9 | Pilot Ponds | 124 |

| | 10.2.10 | Pilot Plant | 132 |

| | 10.3 | Products and Recoveries | 142 |

| | 10.3.1 | Process Losses and Recovery | 142 |

| | 10.3.2 | Products | 143 |

| | 10.4 | Metallurgical Variability | 143 |

| | 10.4.1 | Variation in Well Brine | 143 |

| | 10.4.2 | Variations in Process | 144 |

| | 10.5 | Deleterious Elements | 145 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| 11. | Mineral Resource Estimates | 146 |

| | 11.1 | Introduction | 146 |

| | 11.2 | Definition of Hydrogeologic Units | 146 |

| | 11.3 | Mineral Resource Methodology | 147 |

| | 11.4 | Mineral Resource Classification | 148 |

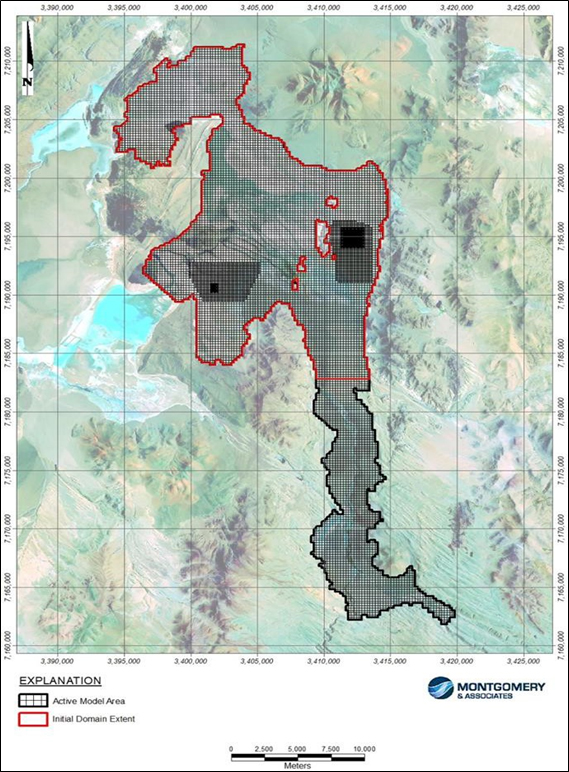

| | 11.5 | Cut-Off Grade | 149 |

| | 11.6 | Mineral Resource Statement | 150 |

| | 11.7 | Uncertainty | 152 |

| | 11.8 | Conclusion | 152 |

| 12. | Mineral Reserves Estimates | 154 |

| | 12.1 | Numerical Model | 154 |

| | 12.1.1 | Numerical Model Design | 154 |

| | 12.1.2 | Grid Specifics | 155 |

| | 12.1.3 | Density Driven Flow and Transport | 157 |

| | 12.1.4 | Numerical Model Boundary Conditions | 158 |

| | 12.1.5 | Modeled Hydraulic Properties | 159 |

| | 12.2 | Numerical Model Calibration | 161 |

| | 12.2.1 | Steady-State Calibration | 161 |

| | 12.2.2 | Transient Calibration | 163 |

| | 12.2.3 | Model Verification | 163 |

| | 12.3 | Predictive Simulation | 163 |

| | 12.3.1 | Projected Pumping | 165 |

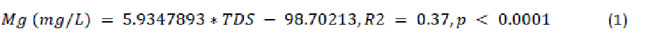

| | 12.3.2 | Conversion of Simulated Total Dissolved Solids to Lithium | 166 |

| | 12.3.3 | Deleterious Elements | 166 |

| | 12.3.4 | Mineral Reserves | 167 |

| | 12.4 | Uncertainty | 172 |

| | 12.5 | Conclusions | 172 |

| 13. | Mining Methods | 174 |

| | 13.1 | Brine Extraction | 174 |

| | 13.2 | Well Materials, Pads, and Infrastructure | 175 |

| | 13.3 | Equipment | 176 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| | 13.4 | Conclusions | 178 |

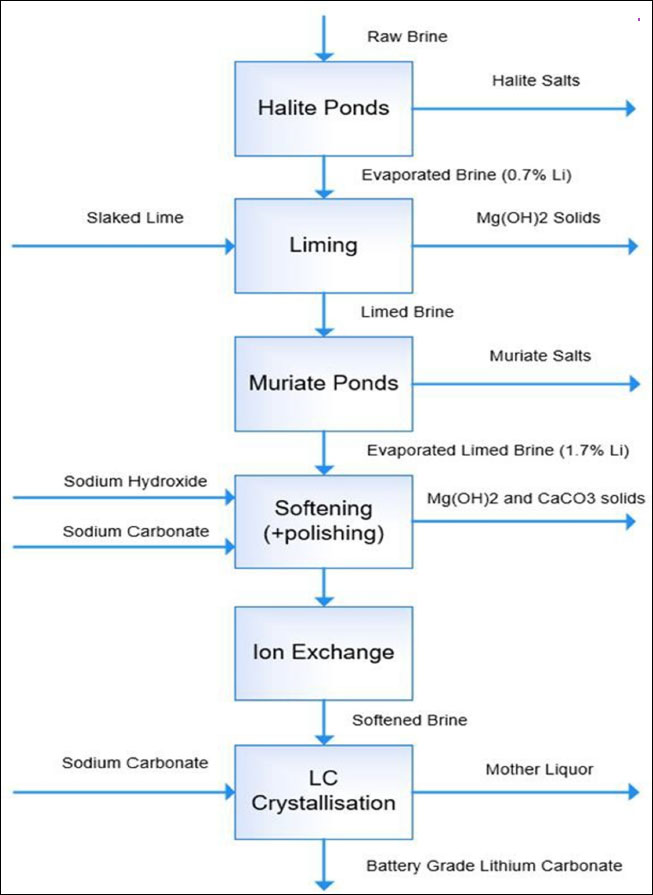

| 14. | Processing and Recovery Methods | 179 |

| | 14.1 | Process Flowsheet and Description | 179 |

| | 14.1.1 | Halite Evaporation Ponds | 180 |

| | 14.1.2 | Liming | 180 |

| | 14.1.3 | Muriate Evaporation Ponds | 182 |

| | 14.1.4 | Softening | 182 |

| | 14.1.5 | Lithium Carbonate Crystallization | 182 |

| | 14.1.6 | Product Finishing | 183 |

| | 14.2 | Process Facilities | 183 |

| | 14.2.1 | Wellfield and Brine Distribution | 186 |

| | 14.2.2 | Solar Evaporation Ponds | 187 |

| | 14.2.3 | Process Plant | 190 |

| | 14.2.4 | Waste Disposal | 194 |

| | 14.3 | Process Control Strategy | 196 |

| | 14.4 | Consumables and Reagents | 197 |

| | 14.4.1 | Water | 197 |

| | 14.4.2 | Steam | 197 |

| | 14.4.3 | Compressed Air | 197 |

| | 14.4.4 | Reagents | 197 |

| | 14.4.5 | Power | 198 |

| | 14.5 | Summary of Mass and Water Balances | 198 |

| | 14.6 | Operations staff | 198 |

| | 14.7 | Conclusions | 198 |

| | 14.8 | Recommendations | 199 |

| 15. | Infrastructure | 200 |

| | 15.1 | Road and logistics | 202 |

| | 15.2 | Built Infrastructure | 203 |

| | 15.3 | Camp Facilities | 204 |

| | 15.4 | Raw Water and RO Water | 204 |

| | 15.5 | Power Generation and Distribution | 205 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| | 15.6 | Fuel storage and Dispensing | 207 |

| | 15.7 | Reagents | 207 |

| | 15.8 | Communication and Control System | 207 |

| | 15.9 | Sewage Treatment Plant | 208 |

| | 15.10 | Fire Protection System | 208 |

| | 15.11 | Drainage System | 208 |

| | 15.12 | Steam System and Water Heating | 209 |

| | 15.13 | Compressed Air System | 209 |

| | 15.14 | Construction Materials | 209 |

| | 15.15 | Security | 210 |

| | 15.16 | Conclusion | 210 |

| | 15.17 | Recommendations | 210 |

| 16. | Market Studies and Contracts | 211 |

| | 16.1 | Overview of the Lithium Industry | 211 |

| | 16.1.1 | Sources of Lithium | 211 |

| | 16.1.2 | Lithium Industry Supply Chain | 213 |

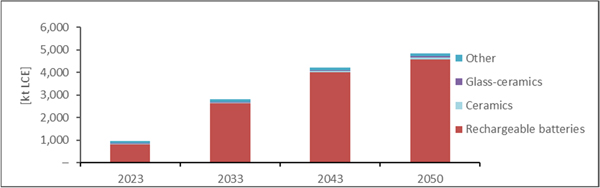

| | 16.1.3 | Global demand for Lithium | 213 |

| | 16.1.4 | Market Balance | 216 |

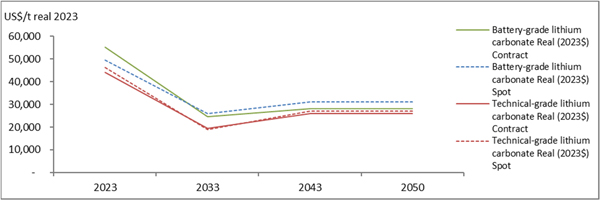

| | 16.2 | Lithium Prices | 216 |

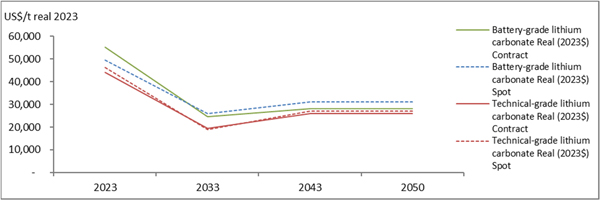

| | 16.2.1 | Lithium Carbonate | 216 |

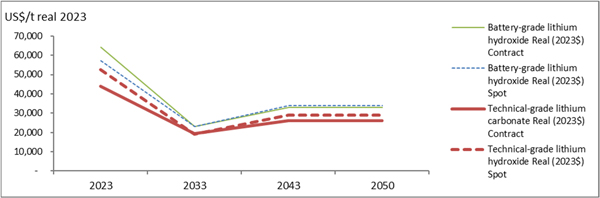

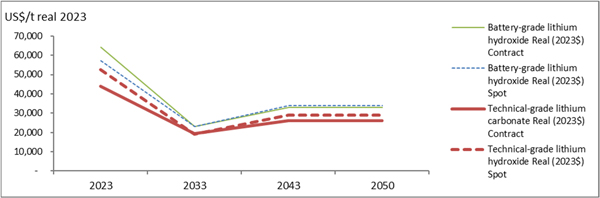

| | 16.2.2 | Lithium Hydroxide | 217 |

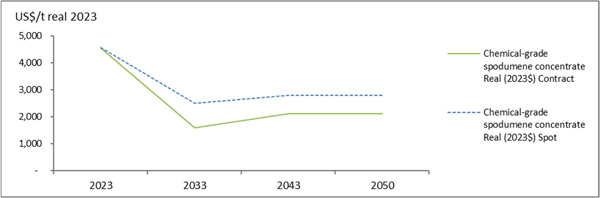

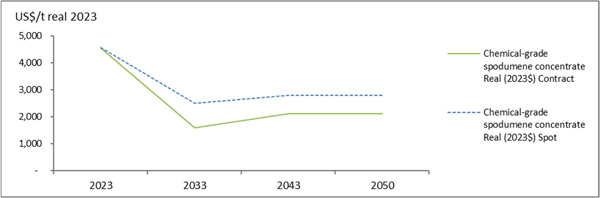

| | 16.2.3 | Chemical Grade Spodumene | 218 |

| | 16.3 | Offtake Agreements | 219 |

| | 16.4 | Risk and Opportunities | 219 |

| | 16.4.1 | Price volatility | 219 |

| | 16.4.2 | Macroeconomic conditions. | 219 |

| | 16.4.3 | Technological developments within battery chemistries | 219 |

| | 16.4.4 | Customer concentration | 220 |

| | 16.4.5 | Competitive environment | 220 |

| | 16.5 | Conclusion | 221 |

| | 16.6 | Recommendations | 221 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| 17. | Environmental Studies, Permitting, Social or Community Impacts | 222 |

| | 17.1 | Corporate Sustainability Principles | 222 |

| | 17.2 | Reference Documents and Permitting Status | 223 |

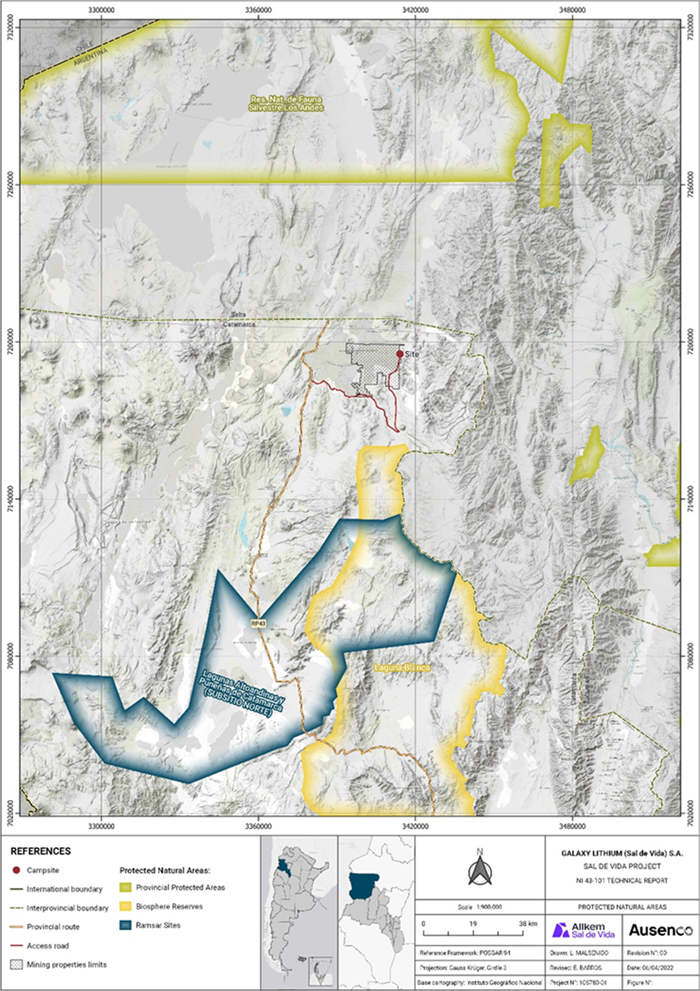

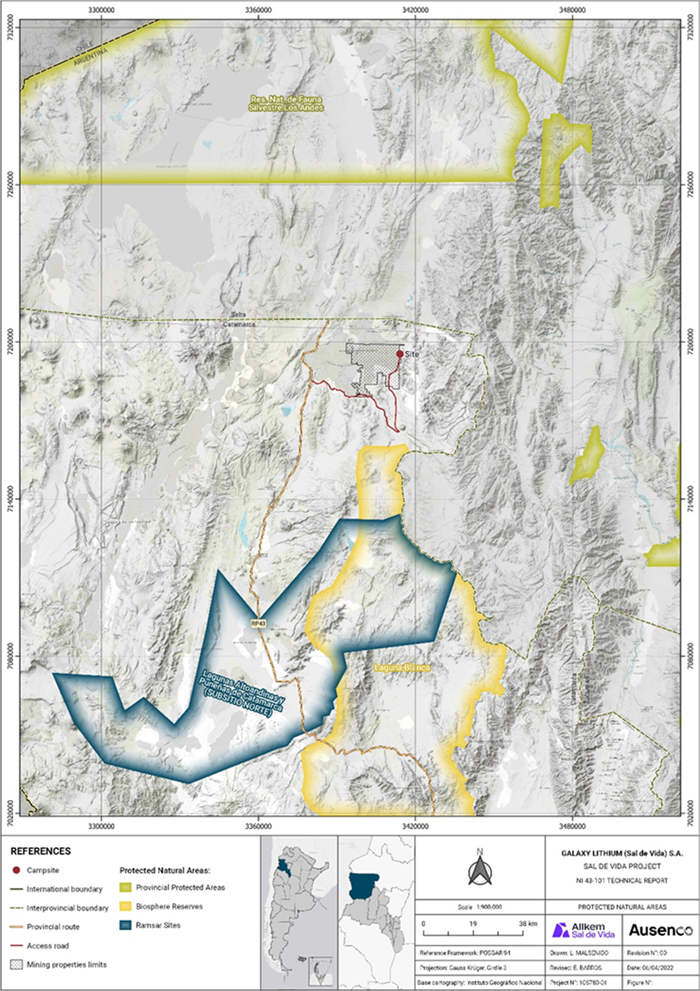

| | 17.3 | Protected Areas | 224 |

| | 17.4 | Environmental Baseline Studies | 226 |

| | 17.4.1 | Water Quality | 227 |

| | 17.4.2 | Air Quality | 230 |

| | 17.4.3 | Soils | 230 |

| | 17.4.4 | Biodiversity Baseline Studies & Monitoring Conducted | 230 |

| | 17.4.5 | Limnology | 231 |

| | 17.4.6 | Ecosystem Characterization | 231 |

| | 17.4.7 | Landscape | 231 |

| | 17.4.8 | Socioeconomic Setting | 232 |

| | 17.4.9 | Archaeology | 232 |

| | 17.4.10 | Mining Waste | 235 |

| | 17.5 | Permitting | 236 |

| | 17.5.1 | Environmental Impact Assessment Permit | 236 |

| | 17.5.2 | Permits Required for Construction and Operation | 238 |

| | 17.5.3 | Water Permit | 239 |

| | 17.6 | Approvals & Permits | 240 |

| | 17.6.1 | Environmental Insurance | 242 |

| | 17.6.2 | Environmental Liabilities | 242 |

| | 17.7 | Social and Community Considerations | 242 |

| | 17.7.1 | Project Setting and Social Baseline Studies | 242 |

| | 17.7.2 | Socioeconomic Aspects | 243 |

| | 17.7.3 | Indigenous Communities | 244 |

| | 17.7.4 | Identification of Social Risks and Opportunities | 245 |

| | 17.7.5 | Community Relations | 246 |

| | 17.8 | Closure and Reclamation | 251 |

| | 17.9 | Conclusions | 252 |

| 18. | Capital and Operating Costs | 253 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| | 18.1.1 | Basis of Capital Cost Estimate | 253 |

| | 18.1.2 | Summary of Capital Cost Estimate | 255 |

| | 18.2 | Operating Costs Estimate | 256 |

| | 18.2.1 | Basis of Operating Cost Estimate | 256 |

| | 18.2.2 | Summary of Operating Cost Estimate | 258 |

| | 18.2.3 | Summary of Operating Cost Estimate by Category | 258 |

| | 18.2.4 | Variable Operating Costs | 259 |

| | 18.2.5 | Fixed Operating Costs | 259 |

| | 18.2.6 | Overhead and Sales Taxes | 260 |

| | 18.3 | Conclusion | 260 |

| | 18.4 | Recommendation | 260 |

| 19. | Economic Analysis | 261 |

| | 19.1 | Forward Looking and Cautionary Statement | 261 |

| | 19.2 | Evaluation Criteria | 262 |

| | 19.3 | Financial Model Parameters | 262 |

| | 19.3.1 | Overview | 262 |

| | 19.3.2 | Production Rate | 263 |

| | 19.3.3 | Process Recoveries | 265 |

| | 19.3.4 | Commodity Prices | 265 |

| | 19.3.5 | Capital and Operating Costs | 265 |

| | 19.3.6 | Taxes | 266 |

| | 19.3.7 | Closure Costs and Salvage Value | 266 |

| | 19.3.8 | Financing | 266 |

| | 19.3.9 | Inflation | 266 |

| | 19.3.10 | Exchange Rate | 266 |

| | 19.4 | Economic Evaluation Results | 267 |

| | 19.5 | Indicative Economics and Sensitivity Analysis | 267 |

| | 19.6 | Sal de Vida Sensitivity Analysis | 268 |

| | 19.7 | Conclusion | 269 |

| | 19.8 | Recommendations | 269 |

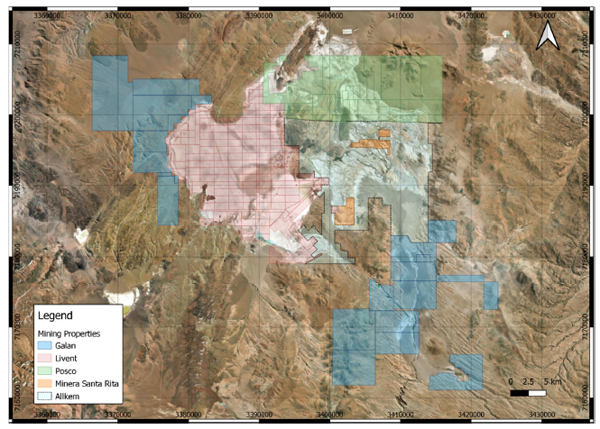

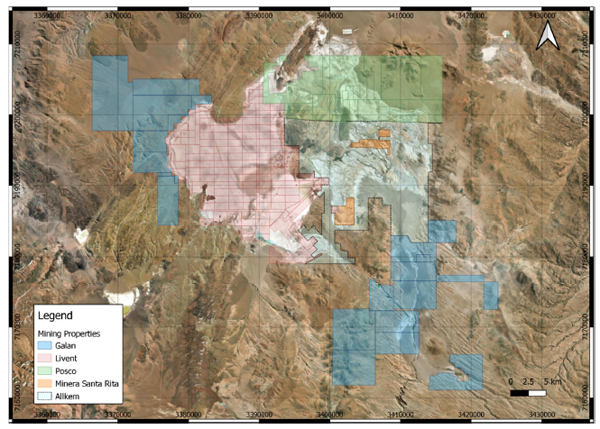

| 20. | Adjacent Properties | 270 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| 21. | Other Relevant Data and Information | 272 |

| | 21.1 | Sal de Vida Project Stage 2 | 272 |

| | 21.1.1 | Stage 2 Modular Expansion | 272 |

| | 21.1.2 | Stage 2 Scope | 272 |

| | 21.1.3 | Stage 2 Permitting | 277 |

| | 21.1.4 | Stage 2 Capex & Opex | 278 |

| | 21.1.5 | Stage 2 Economics | 280 |

| | 21.1.6 | Stage 2 Conclusion | 288 |

| | 21.1.7 | Stage 2 Recommendations | 288 |

| | 21.2 | Risks and Opportunities | 289 |

| | 21.2.1 | Risks | 289 |

| | 21.2.2 | Opportunities | 290 |

| 22. | Interpretation and Conclusions | 291 |

| | 22.1 | Geology and Mineralization | 291 |

| | 22.2 | Exploration, Drilling, and Analytical Data | 291 |

| | 22.3 | Mineral Resources | 292 |

| | 22.4 | Mineral Reserves | 293 |

| | 22.5 | Capital and Operating cost estimates | 295 |

| | 22.6 | Economic Analysis | 295 |

| | 22.7 | SDV Stage 2 expansion | 295 |

| 23. | Recommendations | 296 |

| | 23.1 | Exploration | 296 |

| | 23.2 | Resource Estimate | 296 |

| | 23.2.1 | Resource block model | 296 |

| | 23.2.2 | Block model updates | 297 |

| | 23.3 | Reserve Estimate | 297 |

| | 23.3.1 | Further collection of data | 297 |

| | 23.3.2 | Updating of models | 297 |

| | 23.4 | Environmental Studies | 298 |

| | 23.5 | SDV Stage expansion | 299 |

| 24. | References | 300 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| | 24.1 | List of References | 300 |

| 25. | Reliance on Information Provided by The Registrant | 303 |

| | 25.1 | Introduction | 303 |

| | 25.2 | Mineral Tenure, Surface Rights, and Royalties | 303 |

| | 25.3 | Environmental | 303 |

| | 25.4 | Social and economic impacts | 304 |

| | 25.5 | Markets | 304 |

| | 25.6 | Taxation | 304 |

| 26. | Signature Page | 305 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| LIST OF TABLES | |

| | |

| Table 1-1 – Summary of Brine Resources, Exclusive of Mineral Reserves (Effective June 30, 2023) | 9 |

| Table 1-2 – Summary of Brine Resources, Inclusive of Mineral Reserves (Effective June 30, 2023) | 10 |

| Table 1-3 – Summary of Estimated Proven and Probable Brine Reserves (Effective June 30, 2023) | 12 |

| Table 1-4 – Capital Expenditures by Area: Stage 1 | 14 |

| Table 1-5 – Sustaining CAPEX | 14 |

| Table 1-6 – Operating Cost: Summary | 14 |

| Table 1-7 – Main Economic Results | 16 |

| Table 1-8 – Sal de Vida Infrastructure Facilities | 19 |

| Table 1-9 – Capital Expenditures: Stage 2 (Standalone) | 21 |

| Table 1-10 - Sustaining and Enhancement Capex Stage 2 (Standalone) | 21 |

| Table 1-11 – Estimated Operating Costs by Category.Stage 2 (Standalone) | 22 |

| Table 1-12 – Summary of Sal de Vida Economic Analysis, Stage 2 | 22 |

| Table 1-13 – Project Net Present Value Sensitivity Analysis, Stage 2 | 23 |

| Table 2-1 – Chapter Responsibility | 30 |

| Table 2-2 – Acronyms and Abbreviations | 33 |

| Table 2-3 – Units of Measurement | 34 |

| Table 3-1 – Sal de Vida Mining Concessions | 37 |

| Table 3-2 – Ulexite Usufruct and Commercial Rights | 47 |

| Table 5-1 – Exploration History | 53 |

| Table 6-1 – Lithology Table | 55 |

| Table 6-2 – Sample Data from Exploration Core Holes for Hydrogeological Units | 59 |

| Table 7-1 – Topographic Surveys | 71 |

| Table 7-2 – Geophysical Surveys | 72 |

| Table 7-3 – Drill Summary Table | 80 |

| Table 7-4 – Summary of Well Construction Information for Production Wells and Fresh Water Well | 83 |

| Table 7-5 – Summary of General Geophysical Survey Conducted on Phases 2, 3, 4, 5, and 6 of Drilling Program | 85 |

| Table 7-6 – Summary of Geophysical Surveys Conducted During Phase 6 of the Drilling Program | 86 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| Table 7-7 – Summary of Pumping Tests at Production Wells | 91 |

| Table 7-8 – Summary of Flowrates and Transmissivities from 2021 | 95 |

| Table 8-1 – Lithium Concentration Results from Galaxy and Alex Stewart Labs | 101 |

| Table 8-2 – Basic Analytical Suite (Note: AA = atomic absorption, ICP = inductively-coupled plasma) | 105 |

| Table 10-1 – Characterization of raw brine | 114 |

| Table 10-2 – Initial testwork flowsheet | 115 |

| Table 10-3 – Small scale evaporation results | 118 |

| Table 10-4 – Pilot Plant Runs | 133 |

| Table 10-5 – Battery-Grade Targets | 137 |

| Table 10-6 – 2021 Crystallization Product Summary | 141 |

| Table 10-7 – Breakdown of lithium losses, expressed as a percentage of lithium in the raw brine feed | 143 |

| Table 10-8 – Target and expected product compositions. Expected compositions are based on Pilot Plant Run 7 results | 143 |

| Table 10-9 – Sample brine composition comparison | 144 |

| Table 11-1 – Summary of Drainable Porosity | 146 |

| Table 11-2 – Assigned Drainable Porosity Values | 147 |

| Table 11-3 – Summary of Measured, Indicated, and Inferred Brine Resources, Exclusive of Mineral Reserves (Effective June 30, 2023) | 151 |

| Table 11-4 – Summary of Measured, Indicated, and Inferred Brine Resources, Inclusive of Mineral Reserves (Effective June 30, 2023) | 151 |

| Table 12-1 – Calibrated Hydraulic Parameter Ranges | 160 |

| Table 12-2 – Simulated Stage 1 and 2 Pumping Rates | 165 |

| Table 12-3 – Total Projected Lithium and Lithium Carbonate Pumped | 169 |

| Table 12-4 – Summary of Proven and Probable Brine Reserves (Effective June 30, 2023) | 169 |

| Table 13 1 – Annual numerical values and totals of Life of Mine (LOM) production: Sal de Vida Stage 1 and 2 | 175 |

| Table 13-2 – Plant Mobile Equipment List | 176 |

| Table 14-1 – Stage 1 Reagent Consumption | 198

|

| Table 15-1 – Power consumptions (MWh/year) | 206 |

| Table 17-1 – Environmental Baseline Field Campaigns | 232 |

| Table 17-2 – Exploitation Permits for Sal de Vida Project | 237 |

| Table 17-3 – Sal de Vida permits and status | 240 |

| Table 17-4 – Community agreement compliance meeting minutes/ record | 250 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| Table 18-1 – Capital Expenditures: Stage 1 | 255 |

| Table 18-2 – Sustaining and Enhancement CAPEX | 256 |

| Table 18-3 – Operation Cost: Summary | 258 |

| Table 18-4 – Estimated Operating Cost by Category | 258 |

| Table 18-5 – Cash Operating Cost: Variable | 259 |

| Table 18-6 – Cash Operating Cost: Fixed | 259 |

| Table 19-1 – Annual economic analysis | 263 |

| Table 19-2 – Main Economic Results | 267 |

| Table 19-3 – Sensitivity Analysis NPV | 268 |

| Table 21-1 – Sal de Vida Infrastructure Facilities | 274 |

| Table 21-2 – Stage 2 Capital Expenditures. Stage 2 (Standalone) | 279 |

| Table 21-3 – Sustaining and Enhancement CAPEX. Stage 2 (Standalone) | 280 |

| Table 21-4 – Estimated Operating Costs by Category. Stage 2 (Standalone) | 280 |

| Table 21-5 – Summary of Sal de Vida Economic Analysis. Stage 2 | 282 |

| Table 21-6 – Project Net Present Value Pre-Tax Sensitivity Analysis. Stage 2 | 283 |

| Table 21-7 – Stage 2 Risks to the Project Viability | 287 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| LIST OF FIGURES | |

| | |

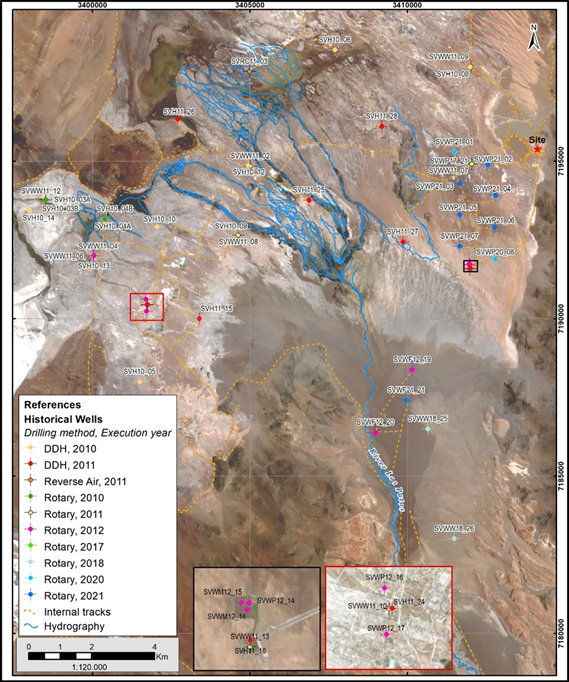

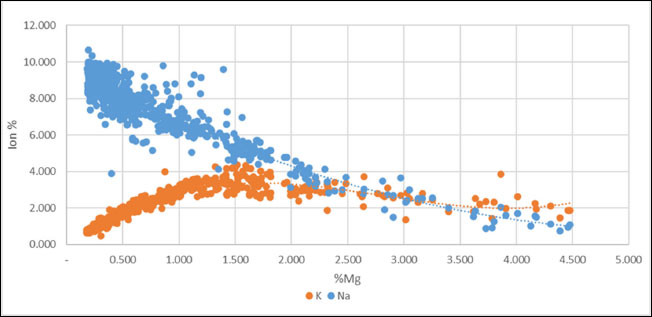

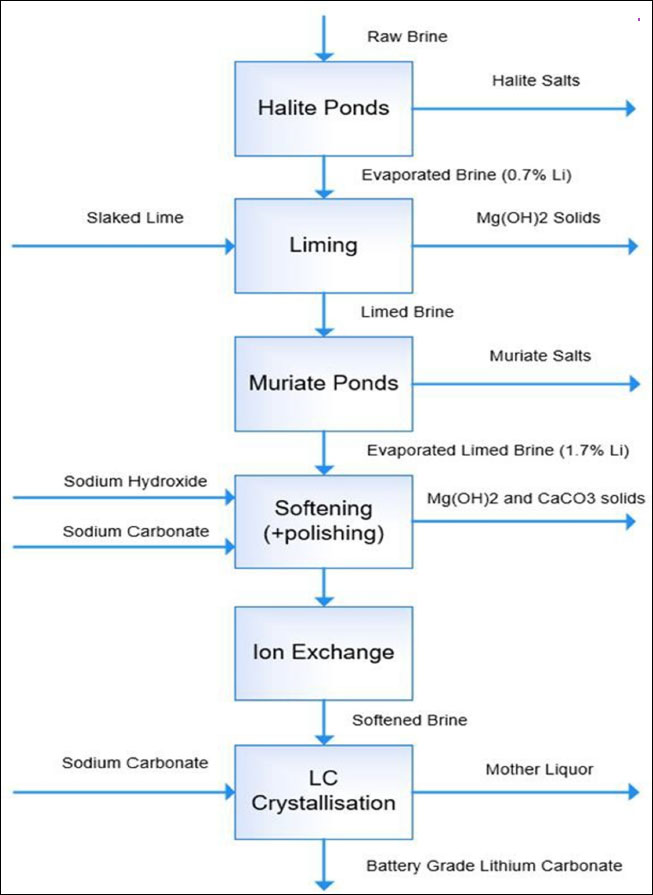

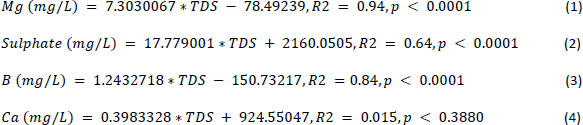

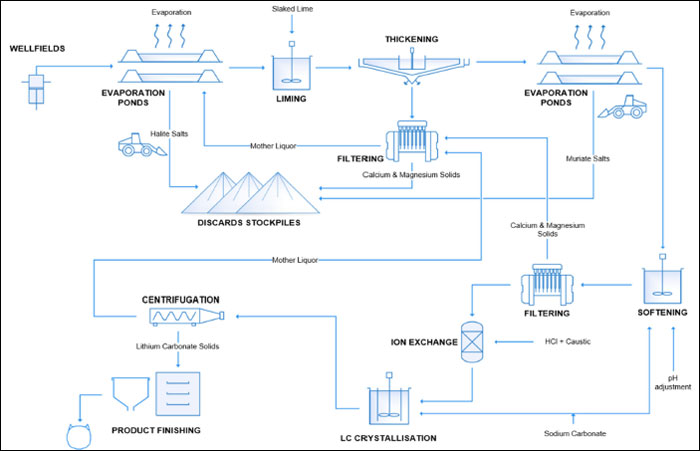

| Figure 1-1 – Sal de Vida Simplified Process Flow Diagram (Figure prepared by Galaxy, 2020. LC = lithium Carbonate) | 5 |

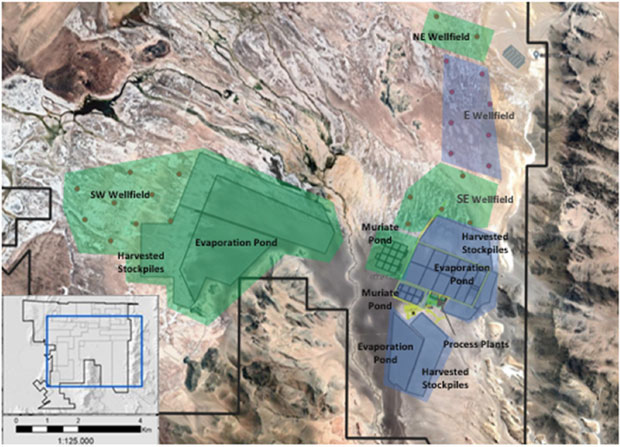

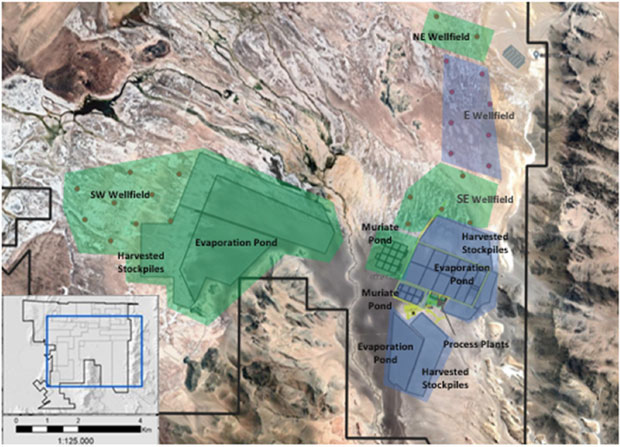

| Figure 1-2 – Sal de Vida Project Layout Plan | 6 |

| Figure 1-3 – Stage 1 Sensitivity Chart | 17 |

| Figure 1-4 – Sal de Vida Stage 2 integrated expansion (Allkem, 2022) | 19 |

| Figure 3-1 – Project Location Plan | 37 |

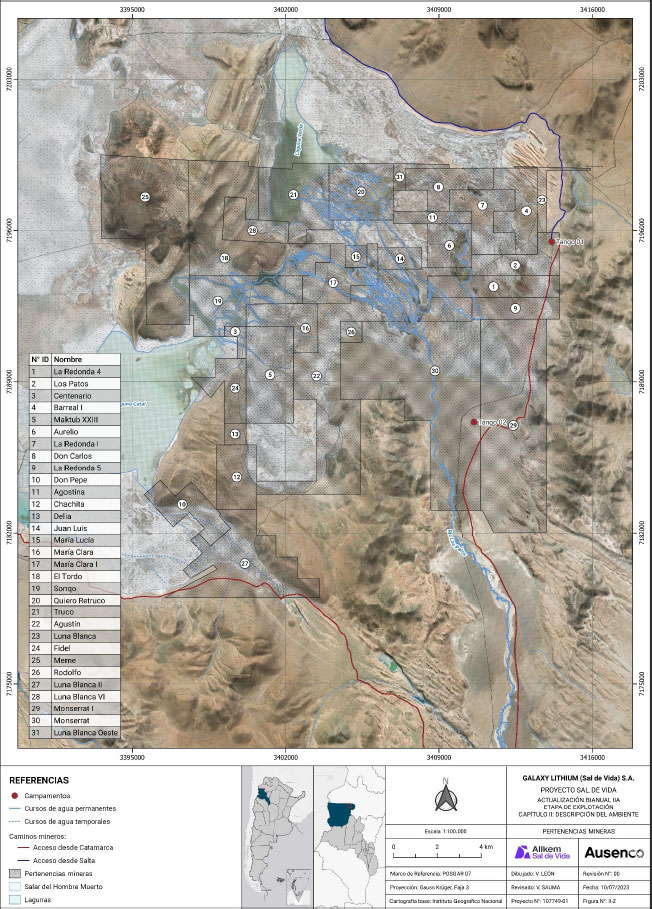

| Figure 3-2 – Claim Location Map (Allkem, 2022) | 39 |

| Figure 3-3 – Sal de Via Project Ownership Structure | 44 |

| Figure 3-4 – Sal de Vida – easements map (Allkem, 2023) | 46 |

| Figure 6-1 – Project Geology Map | 57 |

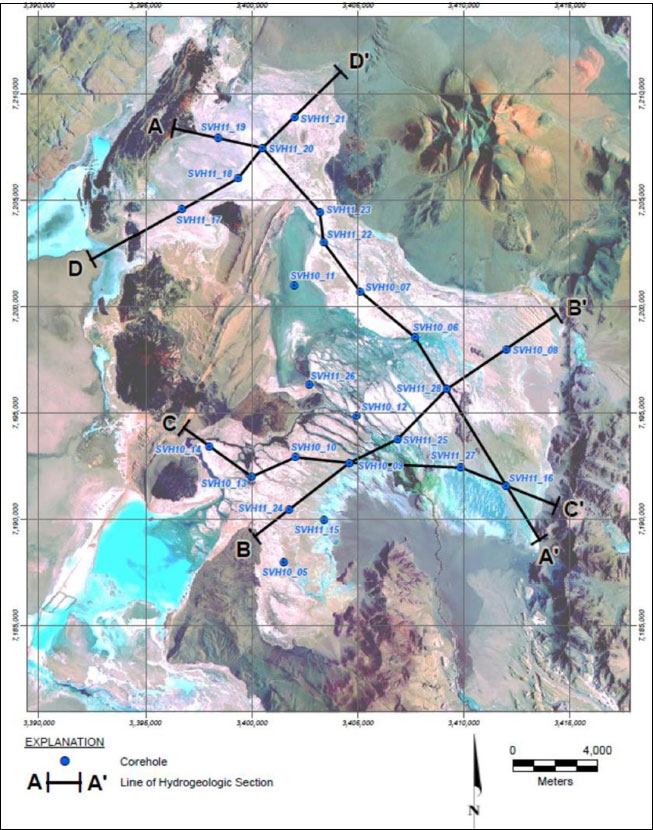

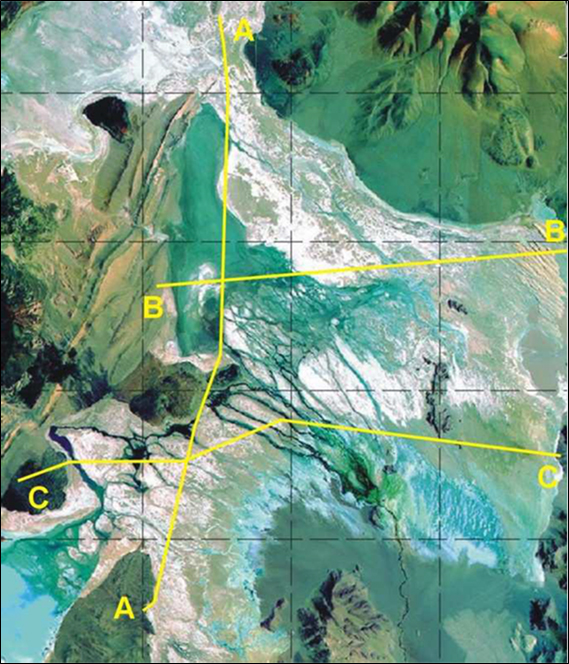

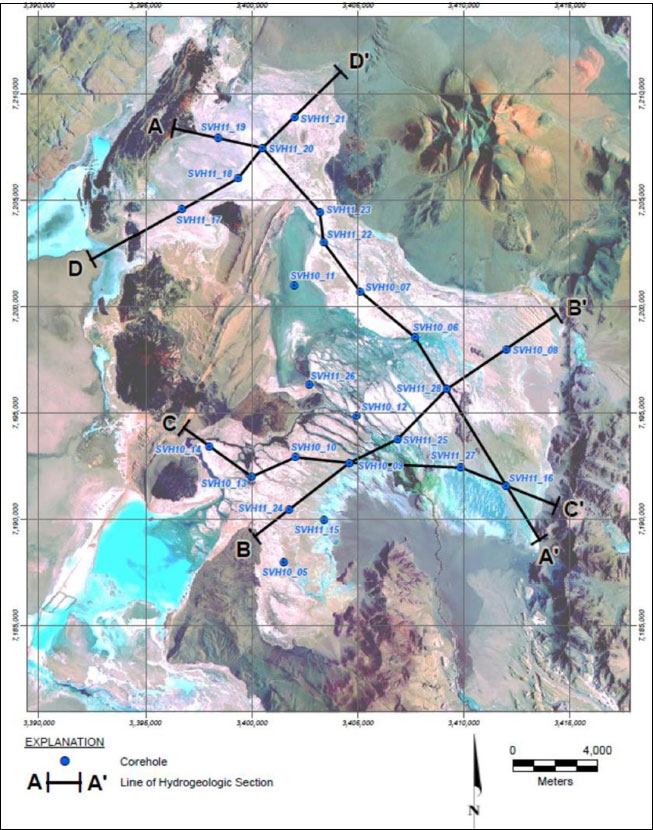

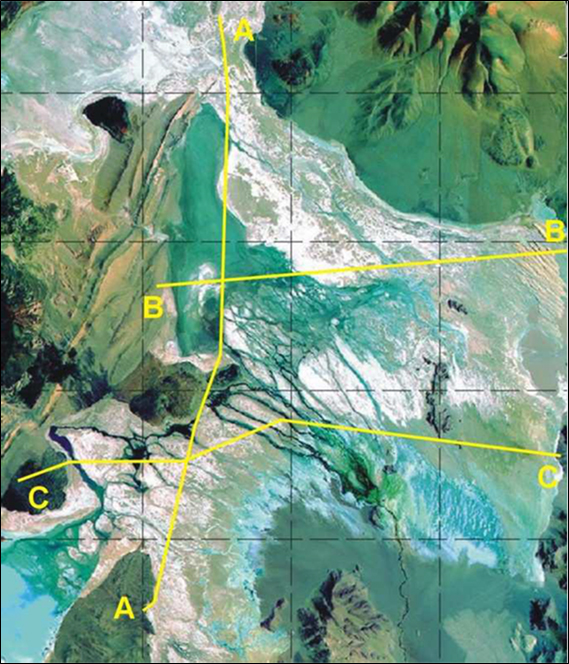

| Figure 6-2 – Hydrogeological Cross-Section Location Plan | 60 |

| Figure 6-3 – Hydrogeological Cross-Section A-A’ | 61 |

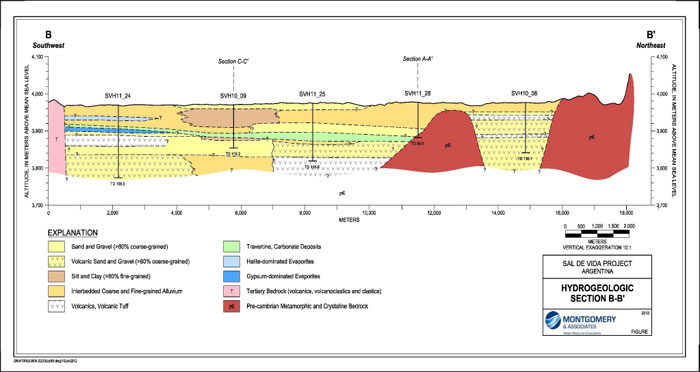

| Figure 6-4 – Hydrogeological Cross-Section B-B’ | 62 |

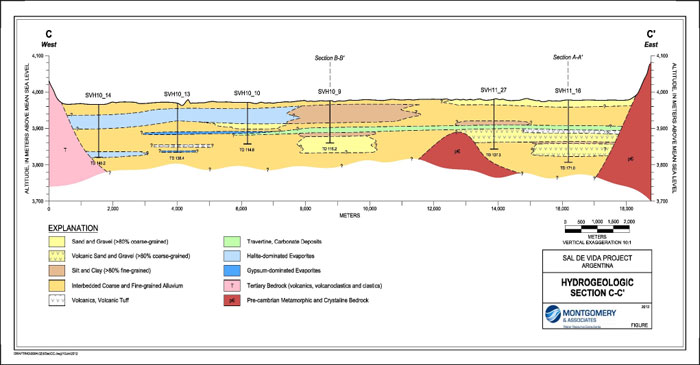

| Figure 6-5 – Hydrogeological Cross-Section C-C’ | 63 |

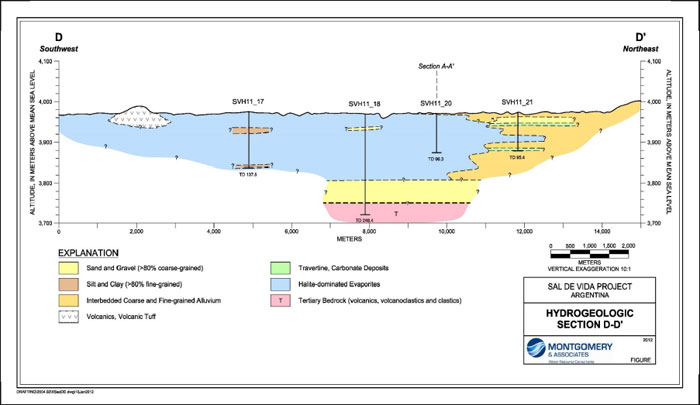

| Figure 6-6 – Hydrogeological Cross-Section D-D’ | 64 |

| Figure 6-7 – Generalized Stratigraphic Columns | 65 |

| Figure 6-8 – Lithium Triangle | 67 |

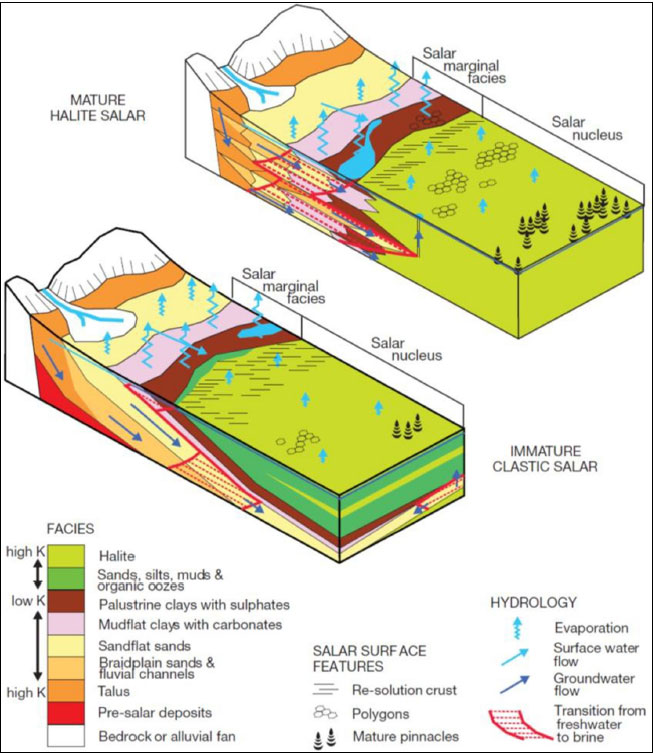

| Figure 6-9 – Schematic Showing Immature Clastic and Mature Halite Salars (Houston et al., 2011) | 68 |

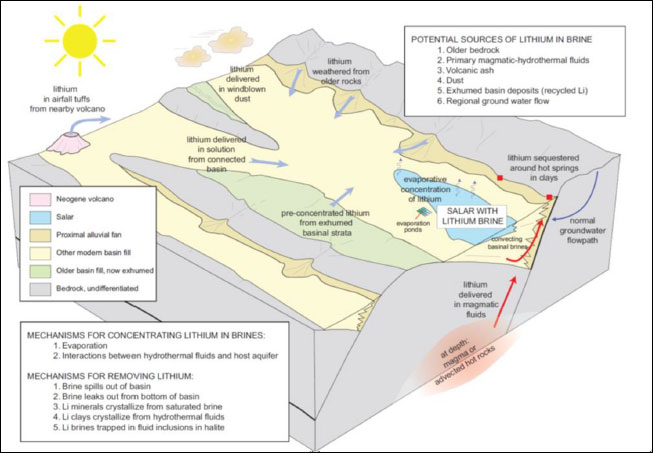

| Figure 6-10 – Schematic Brine Deposit Model Similar to the Sal de Vida Project (Munk et al., 2016) | 70 |

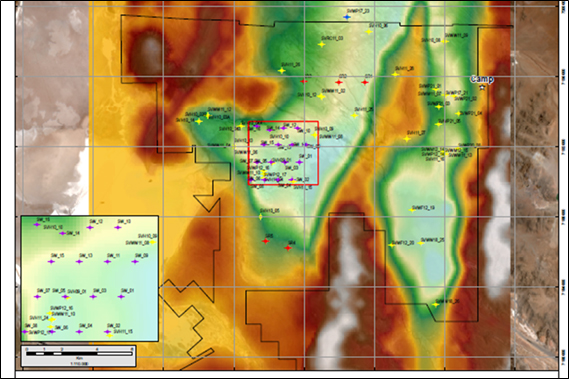

| Figure 7-1 – Location of Year 2021 Gravity Survey Lines | 73 |

| Figure 7-2 – Location Map, Vertical Electric Sounding Points | 74 |

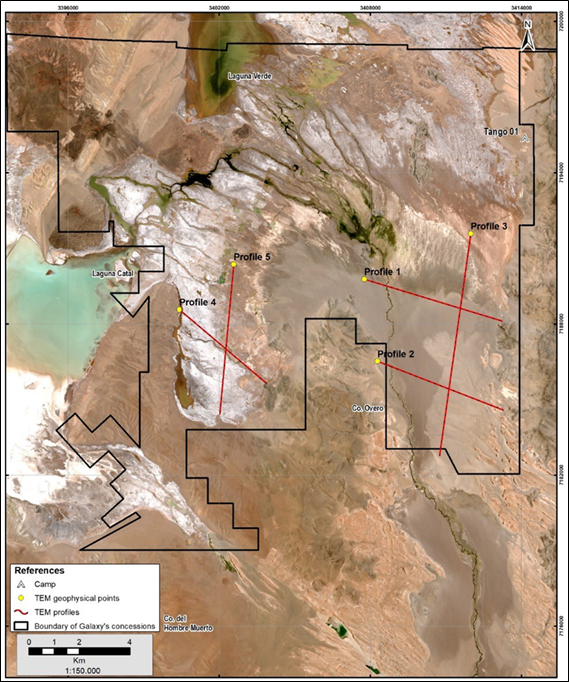

| Figure 7-3 – Location Map, Transient Electromagnetic Survey Profiles | 75 |

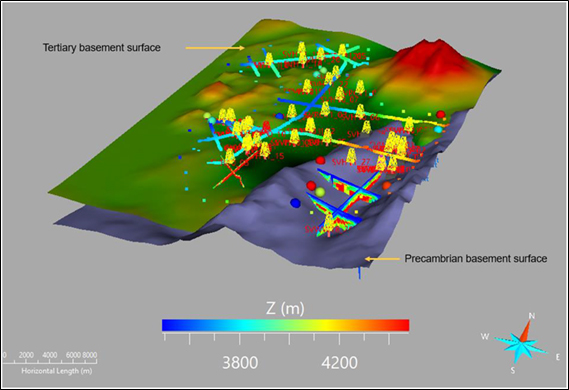

| Figure 7-4 – 2D Plan View of Sal de Vida Basement Map. | 76 |

| Figure 7-5 – 3D Model Update Outcropping Cerro Ratones Northeast Edge | 77 |

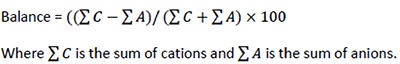

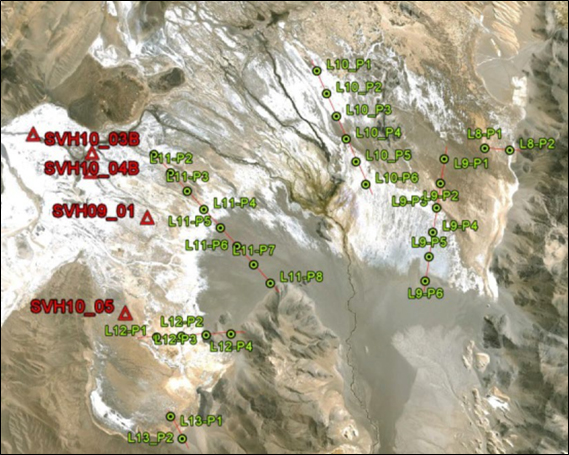

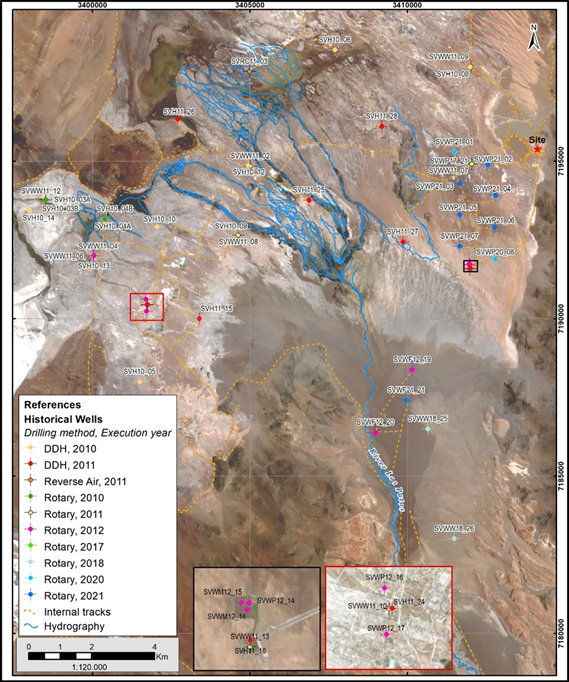

| Figure 7-6 – Drill Collar Location Map | 82 |

| Figure 8-1 – Galaxy Lab Lithium Data vs. Alex Stewart Lab Lithium Data | 102 |

| Figure 10-1 – Simplified Block Flow Diagram | 118 |

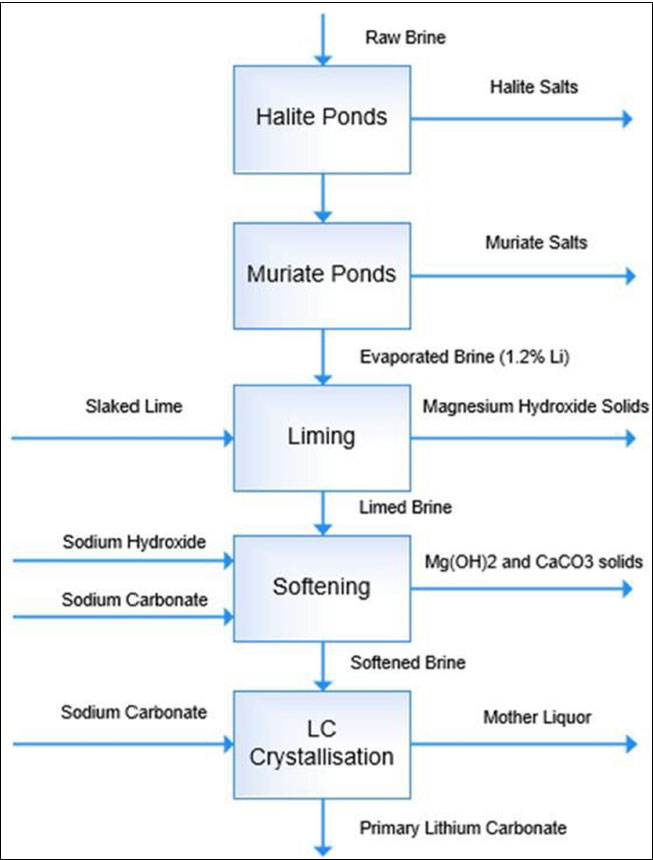

| Figure 10-2 – Recommended Flowsheet | 120 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| Figure 10-3 – Flowsheet Modified Based on ANSTO Testwork | 122 |

| Figure 10-4 – Daily Net Evaporation Measured by Class A Pan Test | 124 |

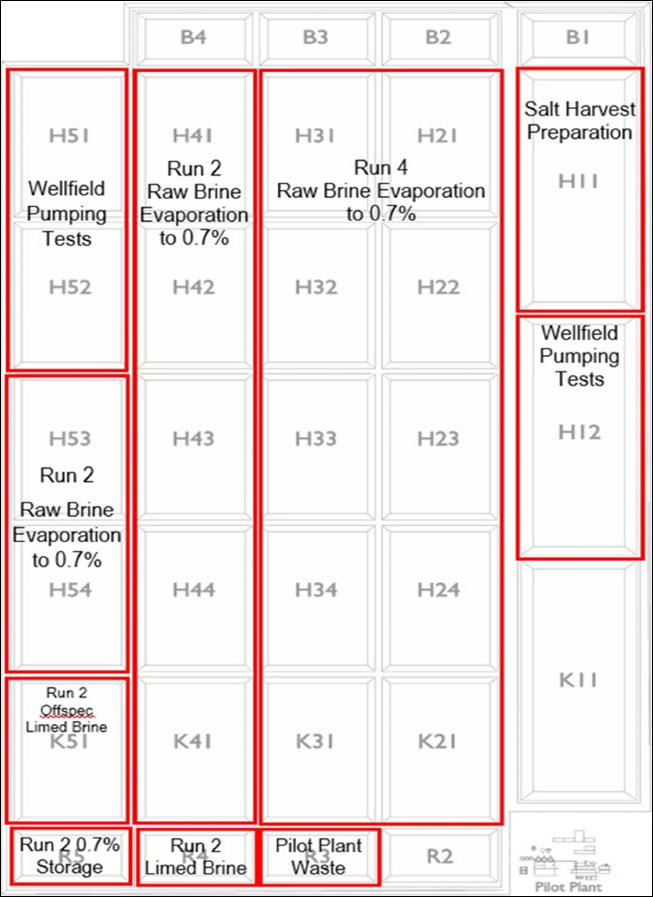

| Figure 10-5 – Pilot Pond Operations Apr 2020 – Feb 2021 | 126 |

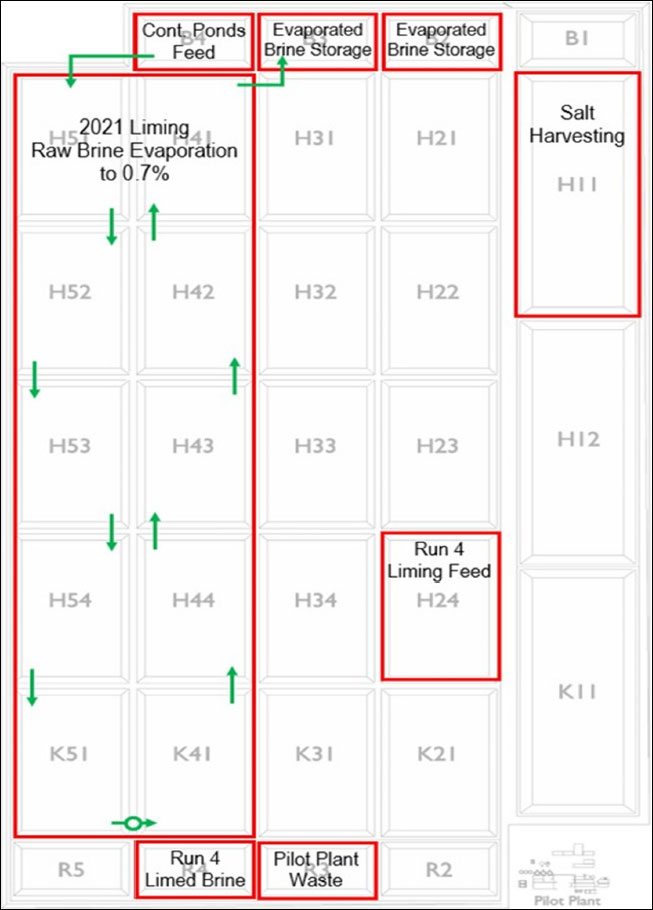

| Figure 10-6 – Pilot Pond Operations Feb 2021 – Feb 2022 | 128 |

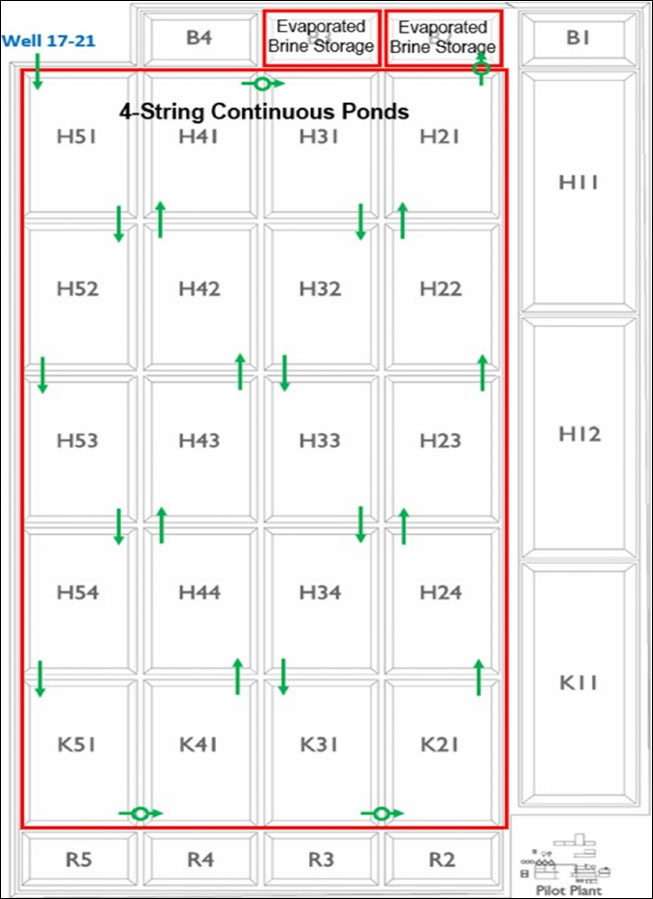

| Figure 10-7 – Pilot Pond Operations Feb 2022 Onward | 130 |

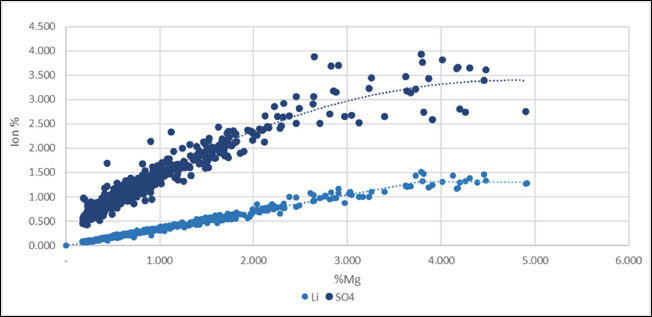

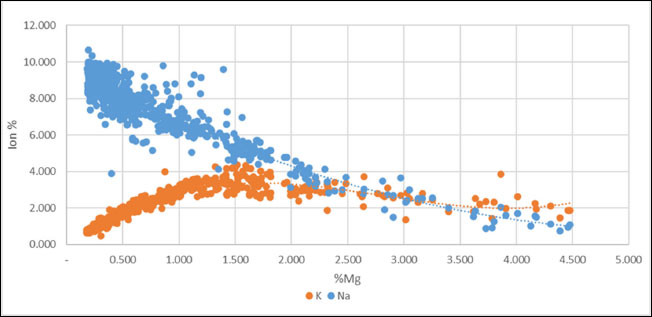

| Figure 10-8 – Sodium and Potassium Concentration Paths from Pilot Ponds (Raw Brine) | 131 |

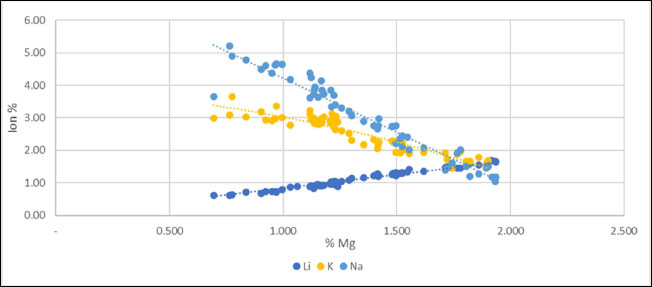

| Figure 10-9 – Lithium and Sulphate Concentration Paths from Pilot Ponds (Raw Brine) | 131 |

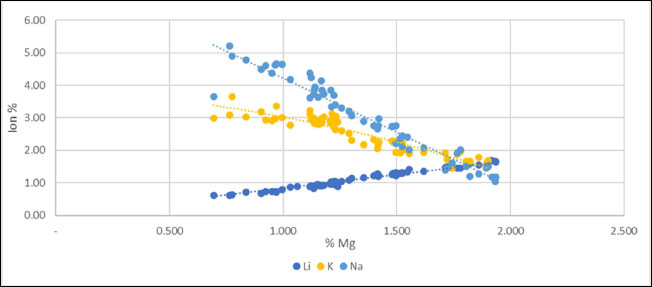

| Figure 10-10 – Lithium, Sodium, and Potassium Concentration Paths from Pilot Ponds (Limed Brine) | 132 |

| Figure 10-11 – Calcium and Sulfate Concentration Paths from Pilot Ponds (Limed Brine) | 132 |

| Figure 10-12 – Flowsheet Modified for Battery-Grade | 138 |

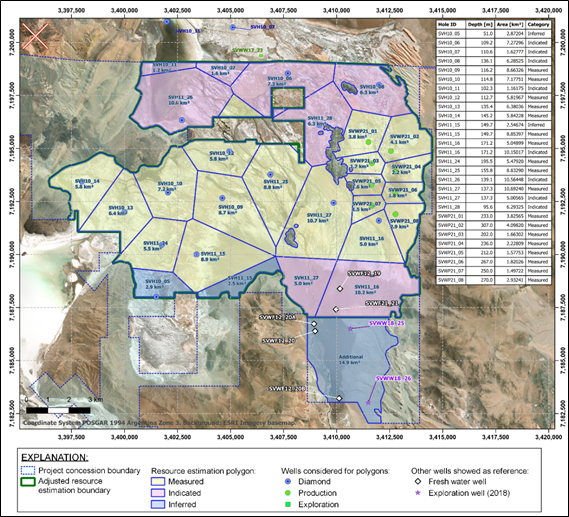

| Figure 11-1 – Location Map Showing Measured, Indicated, and Inferred Lithium Resources | 148 |

| Figure 11-2 – Grade-Tonnage Curve for Different Cutoff Grades | 150 |

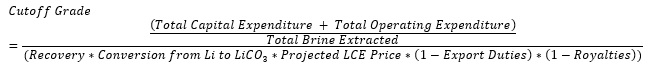

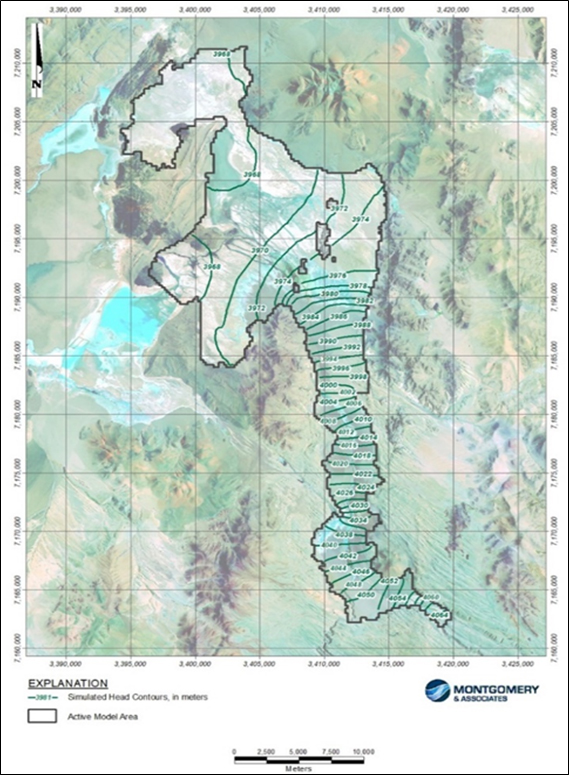

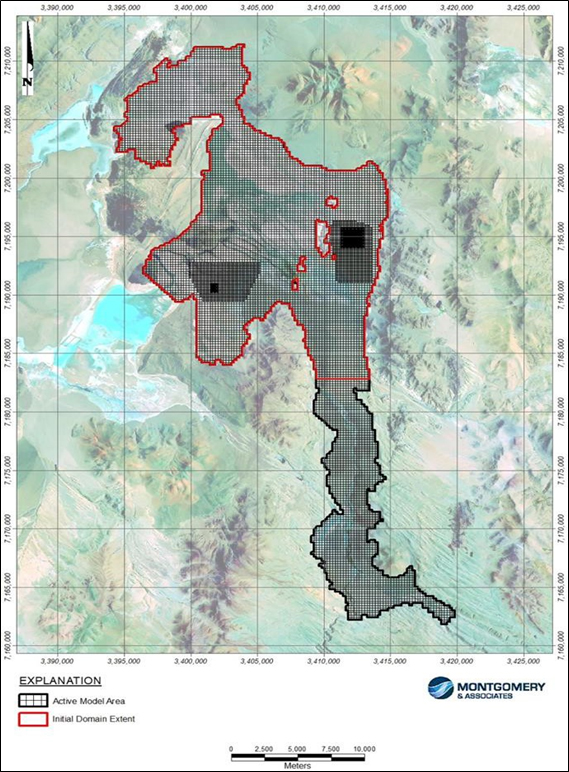

| Figure 12-1 – Numerical Model Domain | 156 |

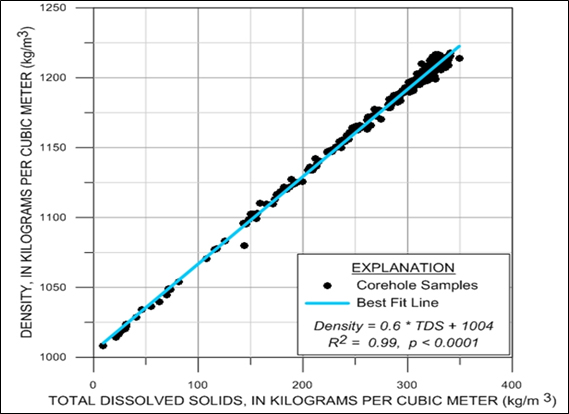

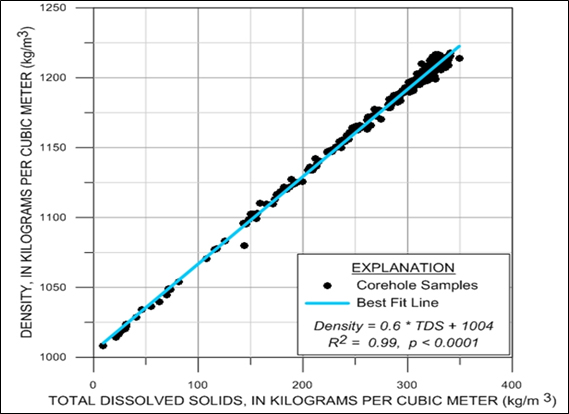

| Figure 12-2 – Relationship Between Total Dissolved Solids and Density for Groundwater (Brine and Freshwater) Samples | 157 |

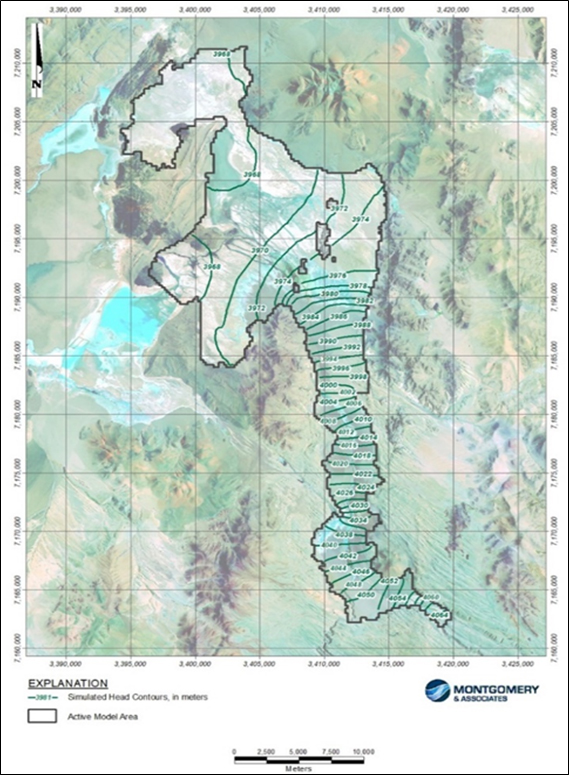

| Figure 12-3 – Simulated Water Table, Steady-State Calibration Model | 162 |

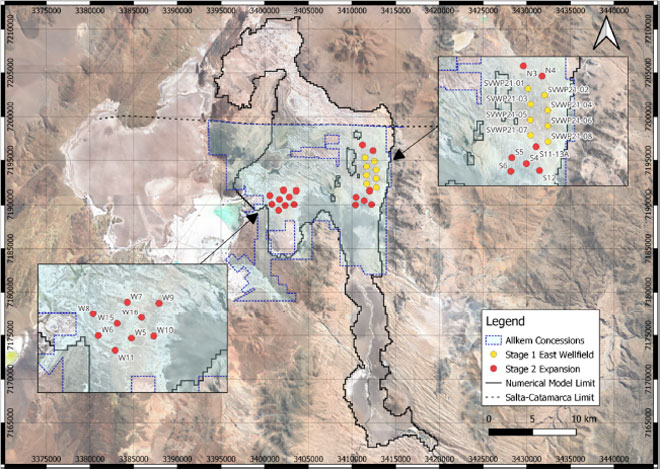

| Figure 12-4 – Simulated Production Well Locations | 164 |

| Figure 12-5 – Yearly Production of Lithium Carbonate Equivalent, Considering Processing Losses | 170 |

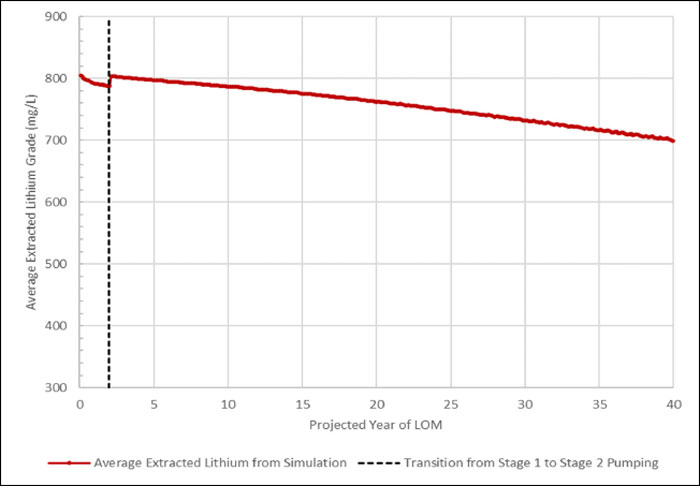

| Figure 12-6 – Flux-Weighted Average of Lithium Extracted from the Production Wells over the Reserve Simulation | 171 |

| Figure 13-1 – Current Production Wellfield Map. | 174 |

| Figure 13-2 – Production Well SVWP21-02 | 176 |

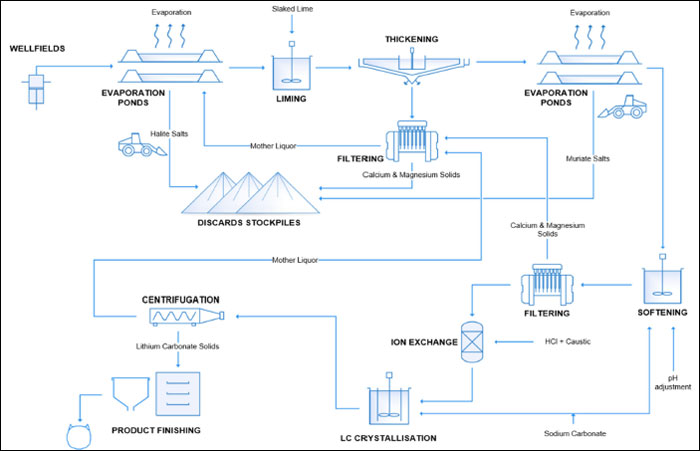

| Figure 14-1 – Sal de Vida Simplified Process Flow Diagram | 181 |

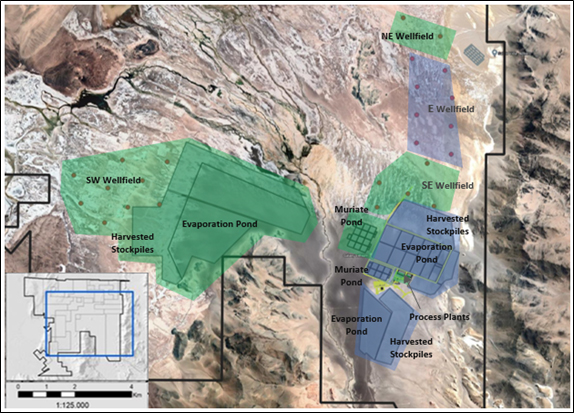

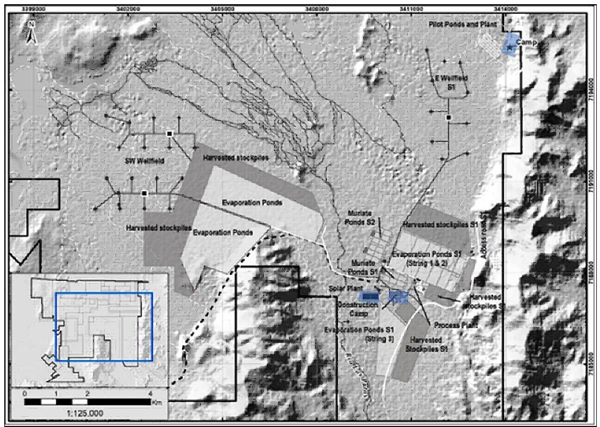

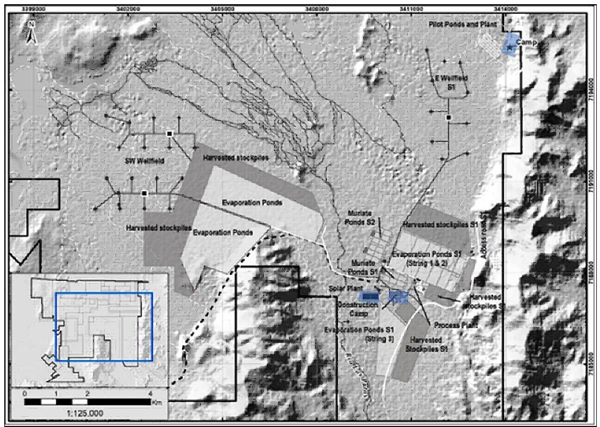

Figure 14-2 – Sal de Vida Layout Plan. (Note: Blue areas represent Stage 1, green areas are Stage 2 facilities)

| 185 |

| Figure 15-1 – Non-Process Infrastructure Layout Plan | 201 |

| Figure 15-2 – Process Area Infrastructure | 202 |

| Figure 16-1 – Lithium Industry Flowchart (Wood Mackenzie) | 213 |

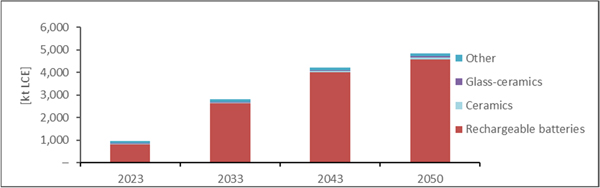

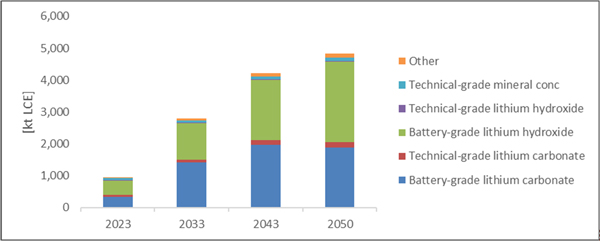

| Figure 16-2 – Global Demand for Lithium by End Use, 2030 – 2050 (Wood Mackenzie) | 214 |

| Figure 16-3 – Global Demand for Lithium by Product, 2023 - 2050 (Wood Mackenzie) | 215 |

| Figure 16-4 – Lithium Carbonate Price Outlook, 2023 – 2050 (Wood Mackenzie) | 217 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| Figure 16-5 – Lithium Hydroxide Price Outlook, 2023 – 2050 (Wood Mackenzie) | 218 |

| Figure 16-6 – Chemical-grade Spodumene Price Outlook, 2023 – 2050 (Wood Mackenzie) | 218 |

| Figure 17-1 – Protected Natural Areas Closest to the Sal de Vida Project | 225 |

| Figure 17-2 – Location of current sites of the groundwater and surface water baseline monitoring program | 229 |

| Figure 19-1 – NPV Sensitivity Chart | 269 |

| Figure 20-1 – Adjacent Properties | 270 |

| Figure 21-1 – Sal de Vida Stage 2 integrated expansion | 274 |

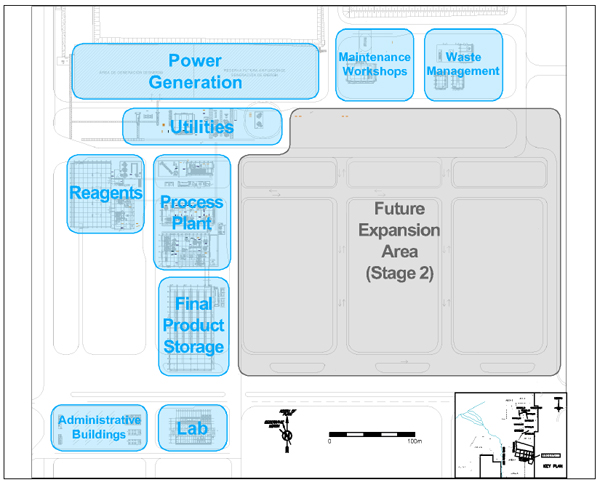

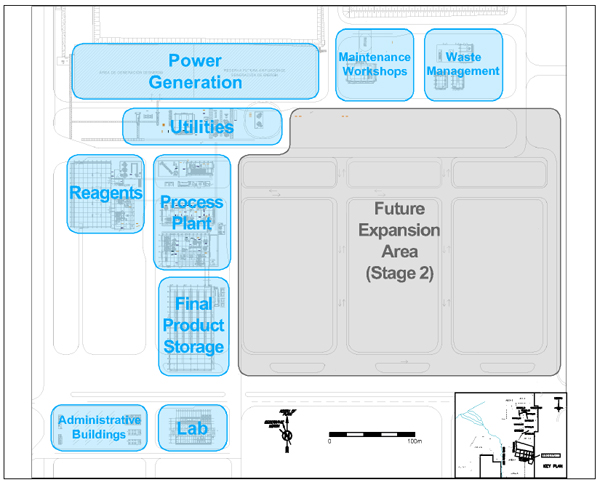

| Figure 21-2 – Process Plant area general layout indicating Stage 2 expansion | 275 |

| Figure 21-3 – Sensitivity Chart, Stage 2 | 286 |

| Figure 21-4 – Qualitative Grouping of Project Risk (Risk Consultant, 2021) | 287 |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

1. Executive Summary

1.1 Background

This report discloses the lithium brine mineral resource for Allkem Limited’s (Allkem’s) Sal de Vida Project (Sal de Vida, SDV or “the Project”). The Project is a planned brine mining and processing facility that has commenced construction of processing infrastructure.

In 2022 the Project embarked on the construction and upgrade of the initial 15,000 tonne per annum (tpa) (SDV Stage 1) Lithium Carbonate Equivalent (LCE) production facility and aims to complete construction in the first half of 2025. The Project further plans a modular 30,000 tpa (15,000 tpa + 15,000 tpa) (SDV Stage 2) expansion which is still in the pre-feasibility study phase. The Project aims to produce 45,000 tpa in total from the planned staged expansions.

This report has been prepared in conformance with the requirements of the Securities and Exchange Commission (SEC) S-K Regulation (Subpart 1300) (the “SK Regulations”). This individual Technical Report is the initial report in support of Allkem’s listing on the New York Stock Exchange (NYSE). This report updates project Mineral Resources, cost estimates, and economics as of the report Effective Date (June 30, 2023).

The Stage 1 wellfield, brine distribution, evaporation ponds, waste (wells and ponds) and Stage 1 process plant cost estimates are AACE Class 2 ±10% (with an accuracy of ±10% and contingency less than 10%). Costs for the 30,000 tpa Stage 2 are AACE Class 4 +30% / - 20% (with an accuracy of ±25% and contingency of 15%) with no escalation of costs in the context of long-term product pricing estimates. This report presents separate economics for Stage 1 (15,000 tpa) currently under construction, followed by a combined Stage 1 and Stage 2 (45,000 tpa) economic assessment.

Lithium production has not commenced at the Sal de Vida site as of the Effective Date. As of the Effective Date, SDV Stage 1 construction is approximately 24% complete. Detailed engineering, quantity estimation, contractor pricing, obtained permits, and social aspects are sufficiently progressed to develop this report to feasibility study level estimate for Stage 1 as defined by the SK Regulations.

SDV Stage 2 is sufficiently developed to report on a Pre-Feasibility Study level.

Updated Mineral Resources and Reserves are being reported as production well drilling campaign progression and greater knowledge of the basin and its geologic setting.

Conclusions, recommendations, and forward-looking statements made by QPs are based on reasonable assumptions and results interpretations. Forward-looking statements cannot be relied upon to guarantee Project performance or outcomes and naturally include inherent risk.

This report was amended to include additional clarifying information in October 2023 and November 2023. The basis of the report is unchanged. The changes and their location in the document are summarized in Chapter 2.1.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

1.2 Property Description and Ownership

Sal de Vida (latitude 25° 24’ 33.71” South, longitude 66° 54’ 44.73” West) is located approximately 200 kilometers (km) south of Olaroz in the high-altitude Puna ecoregion of the Altiplano of northwest Argentina at approximately 4,000 meters (m) above sea level. Sal de Vida is within Salar del Hombre Muerto in the Province of Catamarca.

The main route to the Project site is from the city of San Fernando del Valle de Catamarca via National Route 40 to Belen, and Provincial Route 43 through Antofagasta de la Sierra to the Salar del Hombre Muerto. The road is paved all the way to Antofagasta de la Sierra and continues unpaved for the last 145 km to Salar del Hombre Muerto. The Antofagasta region of Chile is used to export lithium carbonate product and to import key chemicals used in the production of lithium carbonate. The property does not have nearby electrical or natural gas access. The Project will be powered by diesel generators with plans to decarbonize through a combination of natural gas supply and renewable solar power options. Environmental and social permits for the solar power options have been approved.

The climate in Sal de Vida area can be described as typical of a continental, cold, high-altitude desert, with resultant scarce vegetation. The climate allows year around project operation.

Allkem’s mining tenement interests in the Sal de Vida Project are held by Galaxy Lithium (Sal de Vida) S.A., a wholly owned subsidiary of Galaxy Resources Ltd. (Australia) which in turn is 100% owned by Allkem Ltd. since August 2021.

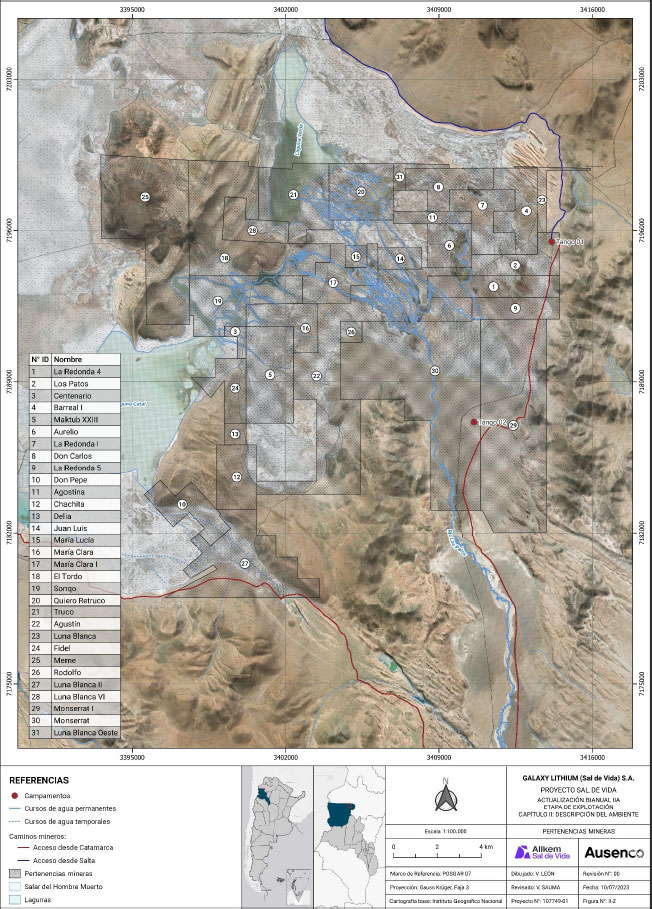

Allkem currently has mineral rights over 26,253 hectares (ha) at Salar del Hombre Muerto, which are held under 31 mining concessions. Allkem has been granted easements related to water, camps, infrastructure, and services enabling the commencement of Stage 1 construction. The Project is not subject to any known environmental liabilities other than those actions and remedies indicated in the Environmental Impact Study approval process.

1.3 Geology and Mineralization

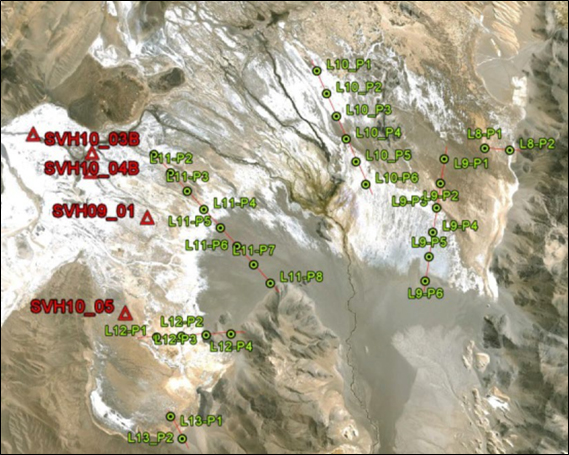

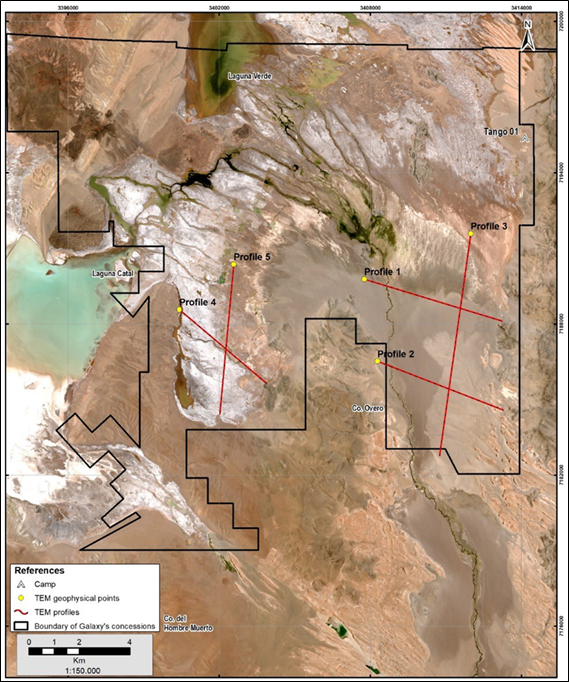

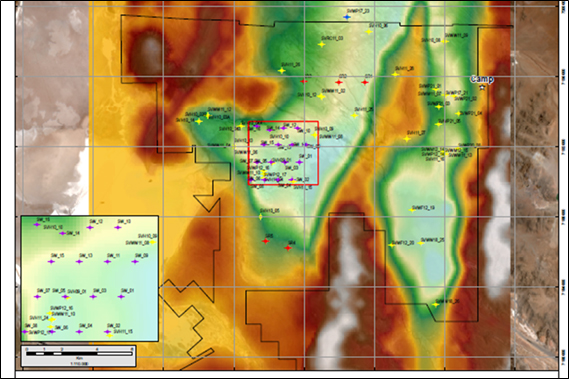

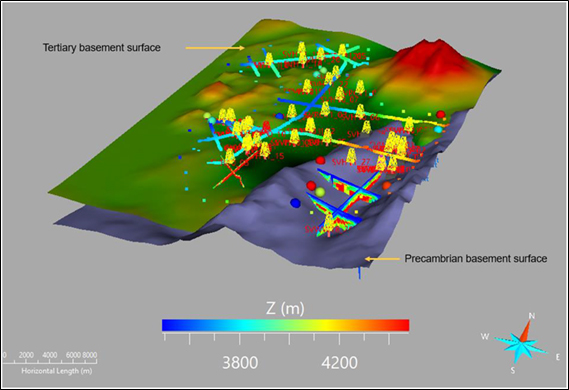

Mineral exploration began in the Salar del Hombre Muerto with shallow pit campaigns to obtain data on near-surface geology, subsurface water levels, brine chemistry, and physical parameters. Multiple geophysical campaigns also were completed for subsurface interpretations including gravity, vertical electric soundings, and transient electromagnetic surveys.

Historical drilling was conducted in several phases that were divided into Phases 1 through 6, with Phase 1 commencing in 2009, and Phase 6 East Wellfield development during the period 2020 to 2021. A total of 40 brine well, core, and reverse circulation (RC) drill holes (5,570 m) have been completed. Downhole geophysical logging was completed for the Phase 4 to Phase 6 programs and consisted of resistivity and spontaneous-potential surveys, with three wells having in addition magnetic-resonance, spectral gamma ray, and image logs. Recovery percentages of drill core were recorded for each core hole; percent recovery was excellent for most of the samples obtained.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Porosity samples were collected during 2010, 2011, and 2012 from intact HQ and NQ size cores. In addition to the depth-specific brine samples obtained by drive points during coring, brine samples used to support the reliability of the depth-specific samples included analyses of brine centrifuged from core samples, brine obtained from low-flow sampling of the exploration core holes, brine samples obtained near the end of the pumping tests in the exploration wells, and brine samples obtained during reverse-circulation air drilling.

1.4 Status of Exploration Activities

Mineral exploration began in the Salar del Hombre Muerto with shallow pit campaigns to obtain data on near-surface geology, subsurface water levels, brine chemistry, and physical parameters. Multiple geophysical campaigns also were completed for subsurface interpretations including gravity, vertical electric soundings, and transient electromagnetic surveys.

Historical drilling was conducted in several phases that are divided into Phase 1 to 6, with Phase 1 commencing in 2009, and Phase 6 East Wellfield development during the period 2020 to 2021. A total of 40 brine well, core, and reverse circulation (RC) drill holes (5,570 m) have been completed. Downhole geophysical logging was completed for the Phase 4 to Phase 6 programs and consisted of resistivity and spontaneous-potential surveys, with three wells having in addition magnetic-resonance, spectral gamma ray, and image logs. Recovery percentages of drill core were recorded for each core hole; percent recovery was excellent for most of the samples obtained.

Porosity samples were collected during 2010, 2011, and 2012 from intact HQ and NQ size cores. In addition to the depth-specific brine samples obtained by drive points during coring, brine samples used to support the reliability of the depth-specific samples included analyses of brine centrifuged from core samples, brine obtained from low-flow sampling of the exploration core holes, brine samples obtained near the end of the pumping tests in the exploration wells, and brine samples obtained during reverse-circulation air drilling.

The exploration activities have been sufficiently progressed to support resource estimation.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

1.5 Development and Operations

1.5.1 Recovery Methods

Galaxy conducted a series of internal and external test work programs to determine the feasibility of producing battery-grade (BG) lithium carbonate (>99.5 wt% purity) with qualified third parties contracted to perform ongoing validation.

Pilot testing was conducted during 2020 and 2021 purpose-built pilot ponds and pilot plant to validate laboratory test work and explore operational considerations. Testing included empirical evaporation performance, process liming, softening, and crystallization test work. The pilot program demonstrated that consistent production of battery grade lithium carbonate can be produced with the Sal de Vida process. Piloting also allowed the site team to develop experience in evaporation ponds and process plant operation while testing a variety of equipment and instrumentation for the industrial-scale plant.

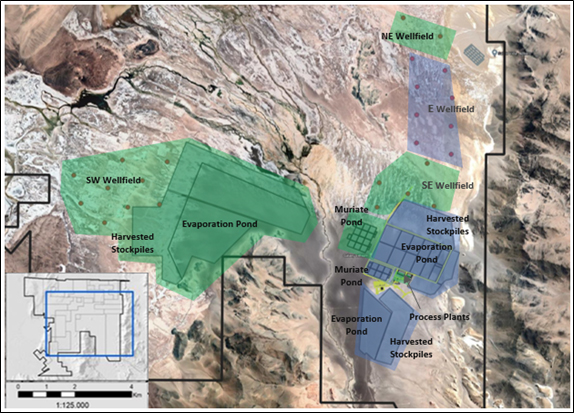

Project facilities are divided into four main areas including wellfield and brine distribution, evaporation ponds, the lithium carbonate plant, and waste tailings disposal stockpile.

1.5.2 Process Facility Design

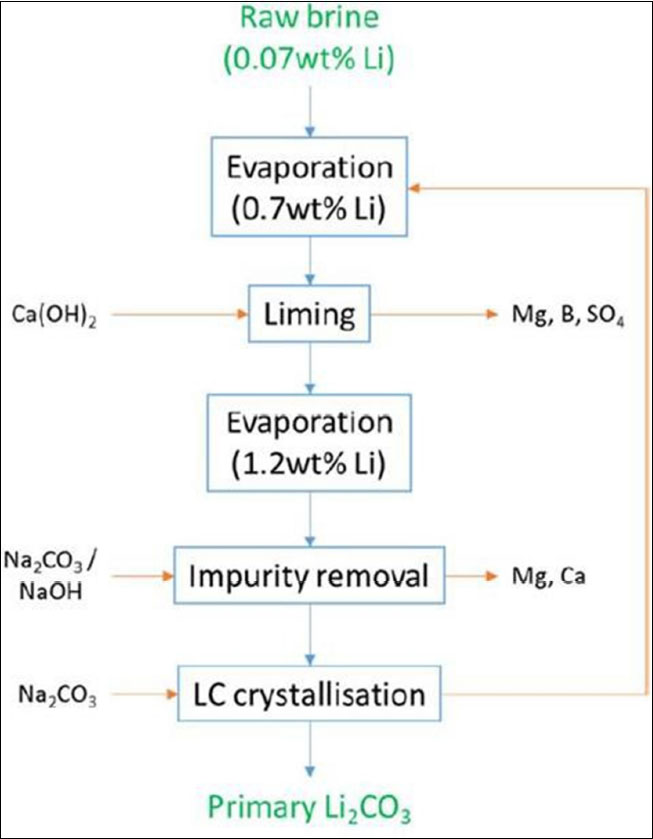

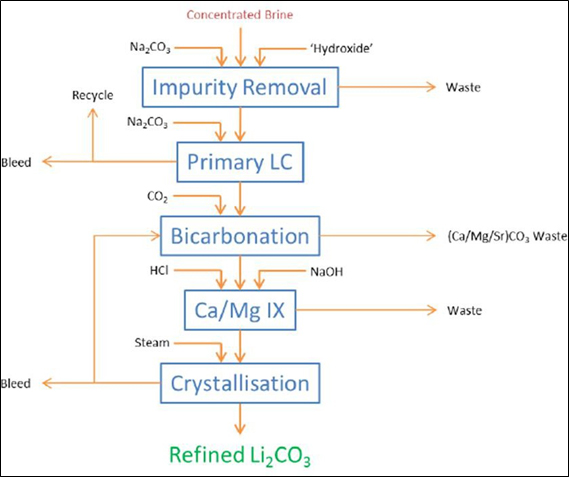

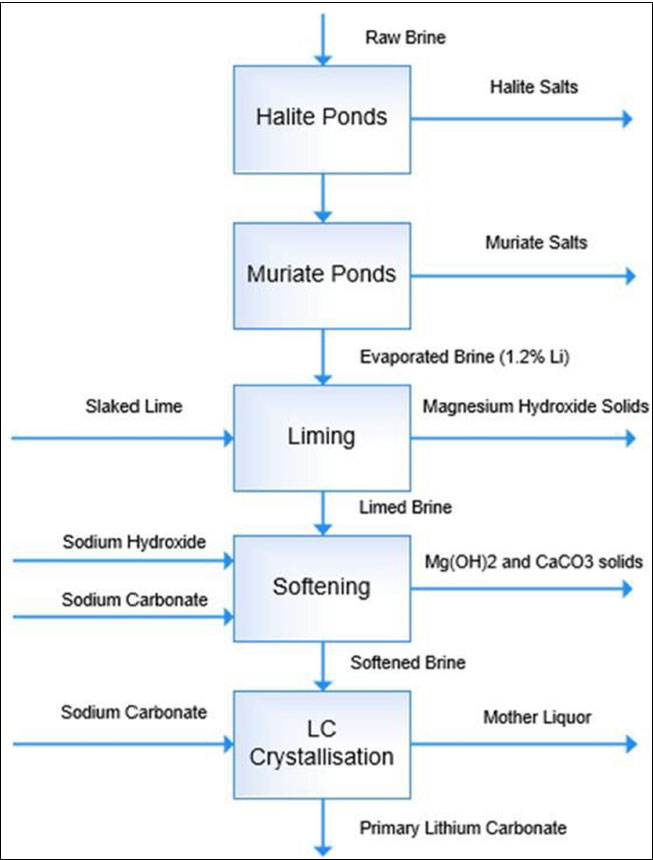

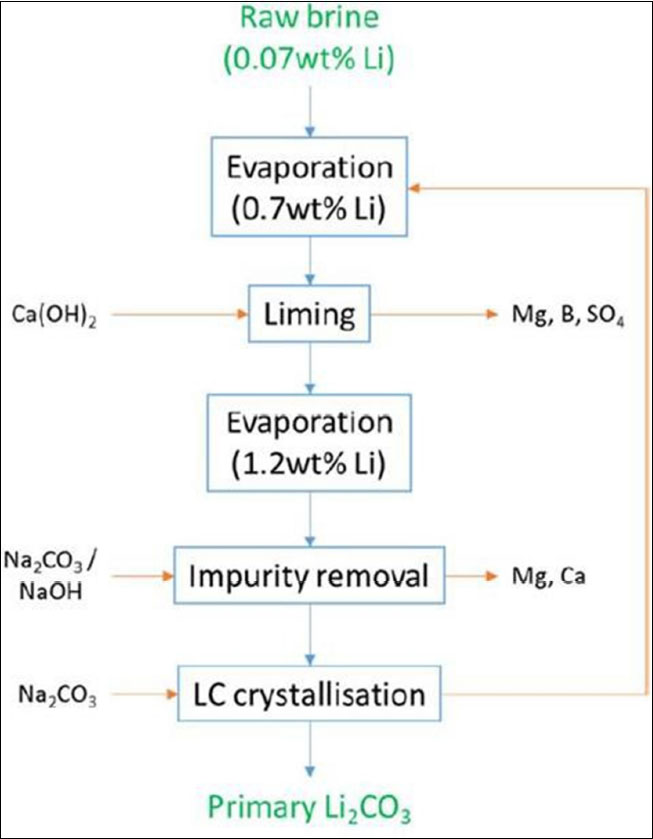

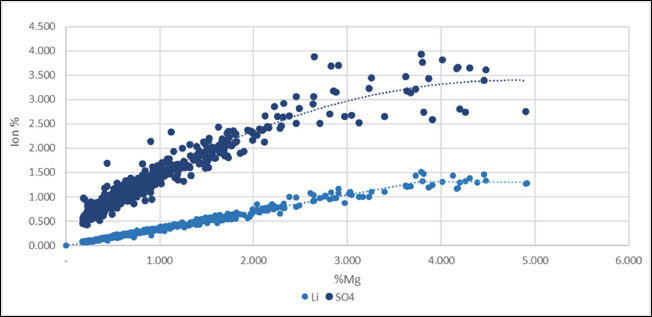

The recovery process of lithium from the brine is summarized below and presented in a flowsheet in Figure 1-1.

The process will commence with brine extracted from wells extending to a depth of up to 280 m into the salar. Brine will be pumped to a series of evaporation ponds, where it will be evaporated and processed at the onsite lithium carbonate plant.

The wellfields will be located directly above the Salar del Hombre Muerto over the salt pan, with minimal infrastructure residing on the surface. The brine distribution systems will traverse the salar to where the evaporation ponds will be located. The production plant will be located adjacent to the evaporation ponds on colluvial sediments. The waste disposal areas will surround the evaporation ponds.

The process facility will be located in an area adjacent to the muriate ponds, and will consist of a lithium carbonate plant, with a liming plant and associated plant infrastructure, such as the power station, fueling, and workshops.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Figure 1-1 – Sal de Vida Simplified Process Flow Diagram (Figure prepared by Galaxy, 2020. LC = lithium Carbonate).

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

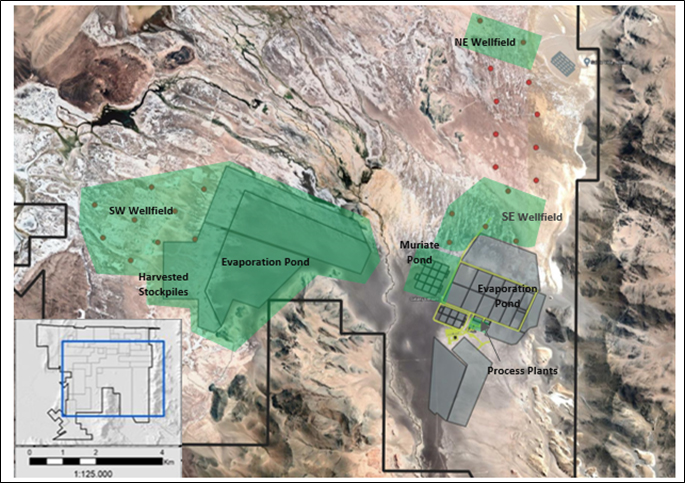

The Life of Mine (LOM) operation, developed in two stages (Figure 1-2), will consist of:

| ● | Wellfield and brine distribution. |

| ● | Solar evaporation ponds. |

| ● | Production plant (liming and lithium carbonate plant). |

Figure 1-2 – Sal de Vida Project Layout Plan1.

1.5.3 Project Infrastructure

The construction of the Sal de Vida Stage 1 project is underway. Brine well fields, and evaporation ponds have progressed. The processing plant construction has commenced with early earthworks and concrete.

Site buildings will include the process plant area, reagent preparation, product storage, maintenance and vehicle workshops, gatehouse, first aid, and administration offices. The permanent accommodation camp will house 330 personnel and will be temporarily expanded with up to 600 additional capacities for the construction phase. Accommodation quantities are deemed sufficient for the required construction schedule and related resourcing.

1 Figure provided by Allkem, 2023. Blue areas represent Stage 1, green areas planned Stage 2 facilities.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Detailed engineering is near completion, providing confidence in estimated quantities and engineering schedules.

Allkem’s current operations at the Olaroz project are of similar nature and process. Internal company policies, standard operating procedures, management systems, and structures will allow sufficiently rigid establishment of initial operations at the Project site and reduce commissioning and ramp-up risk.

International equipment fabrication, local supply chains, logistics, site access, contractor equipment and performance, and labor relations represent inherent construction schedule risk which has been modeled using quantitative stochiometric methods to best predict and manage schedule risk.

Mobile equipment will be required for plant and pond operations. Some transport services will be supplied to Allkem under contract with local companies; however, in most cases, the equipment will be owned and operated by Allkem. Allkem will provide fuel and servicing for all vehicles, except for reagent supply and product logistic requirements off-site.

1.5.4 Environmental and Social

Allkem Sal de Vida Stage 1 has all permits and authorizations in place to construct, operate, and produce lithium carbonate from the project. Environmental Impact Assessment (EIA) is renewed every two years. Other permit details can be found in Section 17.6.

The Project construction and operation provide new employment opportunities and investment in the region, which is expected to have a positive social impact.

Allkem Sal de Vida has a Community Relations Plan (CRP) in place, which has specified programs to ensure a sustainable operation within the regional and local communities. The programs set out commitments that include timeframes and schedules where appropriate and are aligned with Galaxy’s four-pillar focus for social initiatives and projects within its sustainability framework, such as education and employment, sustainable development and culture, health and well-being, and infrastructure.

Environmental baseline studies were performed in the Sal de Vida Project area during a number of field seasons starting in 1997. Study areas included water quality evaluations of the salar and surface waters, water chemistry, water baseline studies, flora, fauna, limnology, phytoplankton, archaeology, air quality, noise, soils, geology, geomorphology, hydrogeology, hydrology, climate, landscape, ecosystem characterization, and socioeconomic considerations. Required environmental approvals were obtained prior to the commencement of construction. Further production permitting will be sourced prior to the commencement of operation.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Allkem has developed a Final Closure Plan and associated capital allocation to close the mine at the end of the exploitation permit period. An option to renew the exploitation permit is possible.

The SDV Project permitting processes sufficiently addressed environmental, community, and socio-economic issues allowing the granting of the required permits for construction. Further permitting is progressed to support commencing operations upon completion of construction.

1.6 Mineral Resource Estimate

This sub-section contains forward-looking information related to Mineral Resource estimates for the Sal de Vida Project. The material factors that could cause actual results to differ from the estimates or conclusions include any significant differences from one or more of the material aspects or assumptions outlined in this sub-section including geological and brine grade interpretations, as well as controls and assumptions related to establishing reasonable prospects for economic extraction.

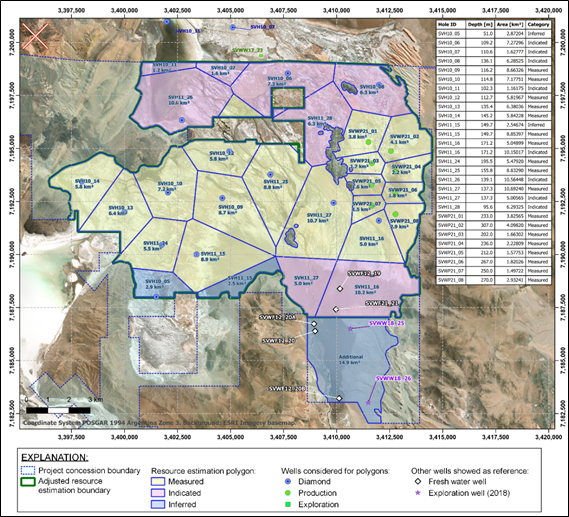

Resource estimation methods to characterize in-situ brine deposits must include two key components: characterization of mineral grade dissolved in the brines, and characterization of the host aquifer drainable porosity that contains the mineral to be estimated. To estimate the total amount of lithium in the brine, the basin was first sectioned into polygons based on the location of exploration drilling, a commonly applied method for lithium brine resource estimates. Each polygon block contained one core drill exploration hole that was analyzed for both depth-specific brine chemistry and drainable porosity. Boundaries between polygon blocks were generally equidistant from the core drill holes and the total well depth was used as the base of the polygons. The total area of polygon blocks used for resource estimates is about 160.9 square kilometers (km2). Within each polygon shown on the surface, the subsurface lithological column was separated into lithologic units. Each interval was assigned a specific thickness and was given a value for drainable porosity and average lithium content based on laboratory analyses of samples collected during exploration drilling. The estimated resource for each polygon was the sum of the products of saturated lithologic unit thickness, polygon area, drainable porosity, and lithium content. The resource estimated for each polygon was independent of adjacent polygons.

The key parameters of brine mineral grade and drainable porosity were analyzed and used to estimate the Measured, Indicated, and Inferred Brine Resources. To classify a polygon as Measured or Indicated, the following factors were considered:

| ● | Level of understanding and reliability of the basin stratigraphy. |

| ● | Level of understanding of the local hydrogeologic characteristics of the aquifer system. |

| ● | Density of drilling and testing in the salar and general uniformity of results within an area. |

| ● | Available pumping test and historical production information. |

Based on the current understanding of the hydrogeological system of the Salar de Hombre Muerto, the additional data on brine occurrence and chemistry, the relative consistency of the hydrogeological and chemical data, confidence in the drilling and sampling results achieved to date, and historical production information (east side), there were sufficient grounds to classify certain polygons as Measured Brine Resources.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Table 1-1 presents the Mineral Resources exclusive of Mineral Reserves (Chapter 12). When calculating Mineral Resources exclusive of Mineral Reserves, a direct correlation was assumed between Measured Resources and Proven Reserves as well as Indicated Resources and Probable Reserves. Mineral Resources were estimated on an in-situ basis; Reserves at a point of reference of brine pumped from the wellheads to the evaporation ponds were subtracted from the Resources inclusive of Reserves. A lithium cut-off grade of 300 mg/l was utilized based on a breakeven cut-off grade for a projected lithium carbonate equivalent price of US$20,000 per tonne over the entirety of the LOM and a grade-tonnage curve. Considering the economic value of the brine against production costs, the applied cut-off grade for the resource estimate (300 mg/l) is believed to be conservative in terms of the overall estimated resource. Intervals of the polygons with grades below the 300 mg/l cut-off grade were not considered in the resource estimate; thus, with these assumptions, a reasonable basis has been established for the prospects of eventual economic extraction.

Table 1-1 – Summary of Brine Resources, Exclusive of Mineral Reserves (Effective June 30, 2023).

| Category | Lithium (Million Tonnes) | Li2CO3 Equivalent (Million Tonnes) | Average Li (mg/l) |

| Measured | 0.58 | 3.07 | 745 |

| Indicated | 0.18 | 0.96 | 730 |

| Total Measured and Indicated | 0.76 | 4.03 | 742 |

| Inferred | 0.12 | 0.65 | 556 |

| 1. | S-K §229.1300 definitions were followed for Mineral Resources and Mineral Reserves. |

| 2. | The Qualified Person(s) for these Resource estimates are the employees of Montgomery & Associates for Sal de Vida. |

| 3. | Comparison of values may not add up due to rounding or the use of averaging methods. |

| 4. | Lithium is converted to lithium carbonate (Li2CO3) with a conversion factor of 5.323. |

| 5. | The estimate is reported in-situ and exclusive of Mineral Reserves, where the lithium mass is representative of what remains in the reservoir after the LOM. To calculate Resources exclusive of Mineral Reserves, a direct correlation was assumed between Proven Reserves and Measured Resources, as well as Probable Reserves and Indicated Resources. Proven Mineral Reserves (from the point of reference of brine pumped to the evaporation ponds) were subtracted from Measured Mineral Resources, and Probable Mineral Reserves (from the point of reference of brine pumped to the evaporation ponds) were subtracted from Indicated Mineral Resources. The average grade for Measured and Indicated Resources exclusive of Mineral Reserves was back calculated based on the remaining brine volume and lithium mass. |

| 6. | The cut-off grade used to report Sal de Vida Mineral Resources and Mineral Reserves is 300 mg/l. |

| 7. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability, there is no certainty that any or all of the Mineral Resources can be converted into Mineral Reserves after application of the modifying factors. |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Mineral Resources are also reported inclusive of Mineral Reserves. The current Mineral Resource estimate, inclusive of Mineral Reserves, for the Sal de Vida Project is summarized in Table 1-2.

Table 1-2 – Summary of Brine Resources, Inclusive of Mineral Reserves (Effective June 30, 2023)

| Category | Lithium (Million Tonnes) | Li2CO3 Equivalent (Million Tonnes) | Average Li (mg/l) |

| Measured | 0.66 | 3.52 | 752 |

| Indicated | 0.56 | 3.00 | 742 |

| Total Measured and Indicated | 1.22 | 6.52 | 747 |

| Inferred | 0.12 | 0.65 | 556 |

| 1. | S-K §229.1300 definitions were followed for Mineral Resources and Mineral Reserves. |

| 2. | The Qualified Person(s) for these Resource estimates are the employees of Montgomery & Associates for Sal de Vida. |

| 3. | Comparison of values may not add up due to rounding or the use of averaging methods. |

| 4. | Lithium is converted to lithium carbonate (Li2CO3) with a conversion factor of 5.323. |

| 5. | The cut-off grade used to report Sal de Vida Mineral Resources and Mineral Reserves is 300 mg/l. |

| 6. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability, there is no certainty that any or all of the Mineral Resources can be converted into Mineral Reserves after application of the modifying factors. |

Factors that may affect the Brine Resource estimate include: locations of aquifer boundaries; lateral continuity of key aquifer zones; presence of fresh and brackish water which have the potential to dilute the brine in the wellfield area; the uniformity of aquifer parameters within specific aquifer units; commodity price assumptions; changes to hydrogeological, metallurgical recovery, and extraction assumptions; density assignments; and input factors used to assess reasonable prospects for eventual economic extraction. Currently, the QPs do not know of any environmental, legal, title, taxation, socio-economic, marketing, political, or other factors that would materially affect the current Resource estimate.

1.7 Mineral Reserve Estimate

This sub-section contains forward-looking information related to Mineral Reserve estimates for the Sal de Vida Project. The material factors that could cause actual results to differ from the estimates or conclusions include any significant differences from one or more of the material aspects or assumptions set forth in this sub-section.

The Mineral Reserve was estimated based on physical pumping of the brine that flows during wellfield pumping using a calibrated numerical model that simulates groundwater flow and solute transport. The method considers modifying factors for converting Mineral Resources to Mineral Reserves in brine deposits, including allowable well field pumping and dilution of brine during pumping, among others.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

A 3D numerical model was constructed using the Groundwater Vistas Version 7 interface and Modflow USG-Transport was utilized to simulate variable-density flow and transport. The active model domain encompasses the clastic sediments and evaporite deposits that comprise the Salar del Hombre Muerto as well as the upgradient alluvial deposits and the Río de los Patos sub-basin. Vertically, the domain was divided into 12 model layers, and the base of the active model domain was set based on the current depth to basement interpretation. The numerical model boundary conditions were designed to be consistent with the conceptual baseline water balance and hydraulic properties were assigned based on the hydrogeological unit and adjusted throughout the calibration process.

Prior to the simulation of future brine production, the numerical model was calibrated to verify assigned model parameters such as hydraulic conductivity and specific storage. The numerical groundwater model was initially calibrated to average, steady-state conditions using the available average on-site field measurements of water levels in observation wells. A transient model calibration to two long-term pumping tests in the East and Southwest Wellfields was conducted to better represent the aquifer’s response to pumping. Furthermore, a model verification period was analyzed with respect to real extracted lithium grades. Total dissolved solids (TDS) in the brine and freshwater were defined as the only solute components in the numerical model to represent the concentration–water density relationship and freshwater–brine interface. The linear relationships with TDS were used to estimate concentrations in pumped brine from the wellfield simulation due to its good correlation with water density.

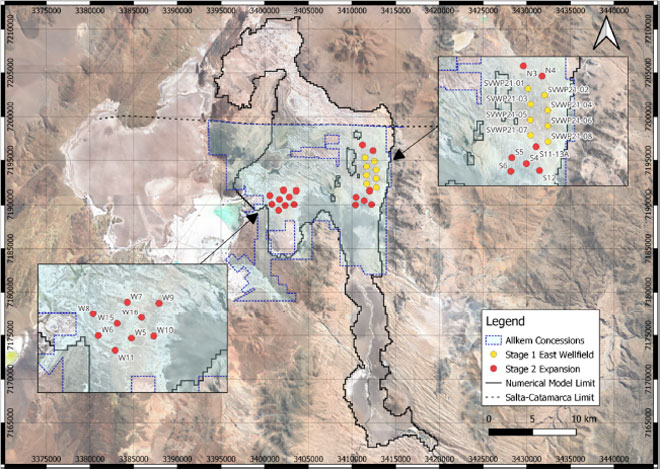

Projected production locations were based on the Measured Resource zones and were configured to reduce well interference during pumping. The Stage 1 pumping from the East Wellfield is expected to produce 15,000 t of LCE per year (assuming processing losses) while Stage 1 and Stage 2 will generate a total of 45,000 t of LCE per year (assuming processing losses), with active pumping from the southwest and eastern portions of the mine concessions. Due to seasonal changes in pond evaporation and maintaining the lithium carbonate target for each stage, the modeled production pumping rates are time-variable on monthly and annual timeframes.

The total lithium to be extracted from the proposed East and Stage 2 Expansion Wellfields was calculated for a total period of 40 years. The model projections used to determine the Brine Reserve, which assumed increasing pumping from both wellfields, indicate that the proposed wellfields should be able to produce a reliable quantity of brine at an average annual rate of approximately 315 l/s in the case of production wells in the eastern portion of the mining concessions and about 191 l/s in the case of the southwest.

Table 1-3 gives results of the Proven and Probable Brine Reserves at the point of reference of brine pumped to the evaporation ponds. A lithium cut-off grade of 300 mg/l was conservatively utilized based on a breakeven cut-off grade for a projected lithium carbonate equivalent price of US$20,000 per tonne over the entirety of the LOM. The average lithium grade of the Proven and Probable Reserves corresponds to 757 mg/l and represents the flux-weighted composite brine collected as brine is routed to the evaporation ponds. Extracted grades at individual production wells and the average Proven and Probable reserve concentration are well above the 300 mg/l cut-off grade, demonstrating that production is economically viable.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Table 1-3 – Summary of Estimated Proven and Probable Brine Reserves (Effective June 30, 2023).

| Reserve Category | Wellfield | Time Period | Average Lithium Grade (mg/l) | Lithium (Million Tonnes) | Li2CO3 Equivalent (Million Tonnes) |

| Proven | Stage 1 East | 1-7 | 785 | 0.031 | 0.163 |

| Proven | Stage 2 Expansion | 3-9 | 807 | 0.053 | 0.282 |

| Total Proven | 799 | 0.084 | 0.445 |

| Probable | Stage 1 East | 8-40 | 726 | 0.147 | 0.780 |

| Probable | Stage 2 Expansion | 10-40 | 763 | 0.237 | 1.261 |

| Total Probable | 748 | 0.383 | 2.041 |

| Total Proven and Probable | 757 | 0.467 | 2.486 |

| 1. | S-K §229.1300 definitions were followed for Mineral Resources and Mineral Reserves. |

| 2. | The Qualified Person(s) for these mineral resource estimates are the employees of Montgomery & Associates for Sal de Vida. |

| 3. | Comparison of values may not add up due to rounding or the use of averaging methods. |

| 4. | Lithium is converted to lithium carbonate (Li2CO3) with a conversion factor of 5.323. |

| 5. | The cut-off grade used to report Sal de Vida Mineral Resources and Mineral Reserves is 300 mg/l. |

During the evaporation and concentration process of the brine, there will be anticipated losses of lithium. Based on the Chapter 10 breakdown of recoveries and current processing method, the amount of recoverable lithium in the evaporation ponds and plant is calculated to be 70% of the total brine pumped to the ponds. This applies to the current processing method which may be subject to improvements at a later date.

The Mineral Reserve was classified according to industry standards for brine projects, as well as the confidence of the numerical model predictions and potential factors that could affect the estimation. Projected production wells were placed in Measured Resource areas. The Qualified Persons (QPs) believe that the Proven and Probable Mineral Reserves were adequately categorized, as described below:

| ● | Proven Reserves were specified for the first 7 years of operation (years 1-7) in the East Wellfield (Stage 1) and years 3-9 for the Stage 2 Expansion Wellfield given that short-term results have higher confidence due to the current model calibration and also the initial portion of the projected LOM has higher confidence due to less expected short-term changes in extraction, water balance components, and hydraulic parameters. |

| ● | Probable Reserves were conservatively assigned after 7 years of operation (years 8-40 in the East Wellfield and years 10-40 for the Stage 2 Expansion Wellfield because the numerical model will be recalibrated and improved in the future due to potential changes in neighboring extraction, water balance components, and hydraulic parameters. |

Regarding risk factors, the Brine Reserve estimate may be affected by the following:

| ● | Assumptions regarding aquifer parameters and total dissolved solids used in the groundwater model for areas where empirical data does not exist. |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| ● | Estimated vertical hydraulic conductivity values partially control the amount of anticipated future dilution in areas where fresh water overlies brine. |

Regardless of these sources of uncertainty, each phase of the Project was conducted in a logical manner, and results were supportable using standard analytical methodologies. In addition, calibration of the numerical model against long-term pumping tests provides solid support for the conceptual hydrogeologic model developed for the Project. Thus, there is a reasonably high-level confidence in the ability of the aquifer system to yield the quantities and grade of brine estimated as Proven and Probable Mineral Reserves. To the extent known by the QPs, there are no known environmental, permitting, legal, title, taxation, socioeconomic, marketing, political or other relevant factors that could affect the Mineral Reserve estimate which are not discussed in this Report.

1.8 Capital and Operating Cost Estimates

Certain information and statements contained in this section and in the report are forward-looking in nature. Actual events and results may differ significantly from these forward-looking statements due to various risks, uncertainties, and contingencies, including factors related to business, economics, politics, competition, and society. All forward-looking statements in this Report are necessarily based on opinions and estimates made as of the date such statements are made and are subject to important risk factors and uncertainties, many of which cannot be controlled or predicted.

The SDV Project Stage 1 is a greenfield project currently in initial stages of construction following sufficient progression of detailed engineering and securing required permitting, and the capital cost does not consider expenditures that have already been absorbed by Allkem in the prior development phases, which are considered to be sunk costs.

1.8.1 Capital Cost Estimate

The Sal de Vida Project overall construction progress reached 24% completion in June 2023. The estimate includes capital cost estimation data developed and provided by Worley, Allkem, and current estimates for completion for Stage 1.

A summary of the estimated direct and indirect capital costs by area is presented in Table 1-4. The capital costs are expressed in an effective exchange rate shown as Allkem’s actual expense. The capital costs tabled are up to mechanical completion and exclusive of commissioning, pre-operating costs, working capital, and first fill or brine inventory.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Table 1-4 – Capital Expenditures by Area: Stage 1.

| Description | Capital Intensity (US$ / t Li2CO3) | CAPEX Breakdown (US$ m) |

| Direct Costs | | |

| General Engineering & Studies | 746 | 11 |

| Wellfields & Brine Distribution | 839 | 13 |

| Evaporation Ponds, Waste & Tailings | 4,555 | 68 |

| LiCO Plant & Reagents | 12,133 | 182 |

| Utilities | 587 | 9 |

| Infrastructure | 1,533 | 23 |

| Total Direct Cost | 20,392 | 306 |

| Owner Costs + Contingency | 4,567 | 69 |

| TOTAL CAPEX | 24,959 | 374 |

The total sustaining and enhancement capital expenditures for Sal de Vida Project over the total Life of Mine (LOM) period are shown in Table 1-5.

Table 1-5 – Sustaining CAPEX.

| Description | Total Year* (US$ m) | Total LOM (US$ m) |

| Sustaining CAPEX | 11 | 434 |

| * Long Term estimated cost per year | | |

1.8.2 Operating Cost Estimate

The operating cost estimate for Sal de Vida Project was prepared by Allkem’s management team. The cost estimate excludes indirect costs such as corporate head office, marketing and sales, exploration, project and technical developments, and other centralized corporate services. The operating cost also does not include royalties, and export taxes to the company.

Table 1-6 provides a summary of the estimated cost for a nominal year of operation. No inflation or escalation provisions were included. Subject to the exceptions and exclusions set forth in this Report.

Table 1-6 – Operating Cost: Summary.

| Operating Cost | Per Tonne LOM (US$ / t Li2CO3) | Total LOM (US$ m) | Total Year* (US$ m) |

| Variable Cost | 2,161 | 1,259 | 32 |

| Fixed Cost | 2,367 | 1,380 | 34 |

| TOTAL OPERATING COST | 4,529 | 2,639 | 66 |

| * Long Term estimated cost per year | | | |

1.8.3 Market Studies

The QPs have relied on external market consultants Wood Mackenzie for lithium market-related demand and price predictions. The lithium supply chain is expected to remain restricted in the short term (2-3 years) with gradual growth in supply in response to growing demand. This is expected to provide a positive price environment for the Project.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

1.8.4 Contracts

As of the date of this Technical Report, Allkem has no existing commercial offtake agreements in place for the sale of lithium carbonate from the Sal de Vida Project.

Allkem is having discussions with potential customers for the Sal de Vida Project. In line with the Sal de Vida Project execution schedule, these discussions are expected to advance to negotiations throughout the course of the Sal de Vida Project.

Orocobre Ltd. and Galaxy Resources Ltd. (now Allkem) have been active participants in lithium markets since 2012 and have been a seller in both lithium concentrate (“concentrate” or “spodumene”) and lithium chemicals markets due to past and present operations. Allkem produces lithium carbonate and concentrate which is sold to various customers in Asia. At present, Allkem is the operating joint venture partner of the Sales de Jujuy Olaroz lithium carbonate facility and operator of the Mt. Cattlin spodumene mine and concentration project.

1.9 Economic Analysis – Stage 1 Only

Certain information and statements contained in this section and in the report are forward-looking in nature. Actual events and results may differ significantly from these forward-looking statements due to various risks, uncertainties, and contingencies, including factors related to business, economics, politics, competition, and society. All forward-looking statements in this Report are necessarily based on opinions and estimates made as of the date such statements are made and are subject to important risk factors and uncertainties, many of which cannot be controlled or predicted.

1.9.1 Financial Evaluation – Stage 1 Only

The Discounted Cash Flow (DCF) model is constructed on a real basis without escalation or inflation of any inputs or variables. The primary outputs of the analysis, on a 100% Project basis, include:

| ● | NPV at a discount rate of 10%. |

| ● | Internal rate of return (IRR), when applicable. |

| ● | Payback period, when applicable. |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

The financial evaluation is dependent on key input parameters and assumptions:

| 1. | Production schedule, including annual brine production, pond evaporation rates, process plant production, and ramp-up schedule. The Sal de Vida Project Stage 1 nominal capacity of annual lithium carbonate is estimated to be 15,000t/year. |

| 2. | Plant recoveries and lithium grades. |

| 3. | Operating, capital, and closure costs for a 40-years operating life. |

| 4. | Operating costs related to wellfields, evaporation ponds, process plant, waste removal, site-wide maintenance and sustaining costs, environmental costs, onsite infrastructure and service costs, and labor costs (including contractors). |

| 5. | Product sales are assumed to be Free on Board (FOB) South America. |

| 6. | For the purpose of this report, the Corporate Rate was 35%. |

| 7. | The economic analysis assumes 100% equity financing. |

| 8. | All estimates outlined herein are expressed in FY2024 prices. All projections are estimated in real terms, and they do not incorporate allocations for inflation, or financial expenses, and all financial assessments are expressed in US dollars. |

The key metrics for the Sal de Vida Project are summarized in Table 1-7.

Table 1-7 – Main Economic Results.

| Summary Economics |

| Production | | |

| LOM | yrs | 40 |

| First Production | Date | 2H CY25 |

| Full Production | Date | 2026 |

| Capacity | tpa | 15,000 |

| Investment | | |

| Development Capital Costs (sunk cost) | US$m | 374 |

| Sustaining Capital Costs | US$m per year | 11 |

| Development Capital Intensity | US$/tpa Cap | 24,959 |

| Cash Flow | | |

| LOM Operating Costs | US$/t LCE | 4,529 |

| Avg Sale Price (TG) | US$/t LCE | 27,081 |

| Financial Metrics | | |

| NPV @ 10% (Pre-Tax) | US$m | 2,006 |

| NPV @ 10% (Post-Tax) | US$m | 1,152 |

| NPV @ 8% (Post-Tax) | US$m | 1,555 |

| IRR (Pre-Tax) | % | 45.5% |

| IRR (Post-Tax) | % | 32.5% |

| Payback After Tax (production start) | yrs | 2.6 |

| Tax Rate | % | 35.0% |

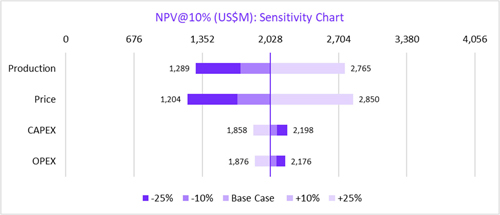

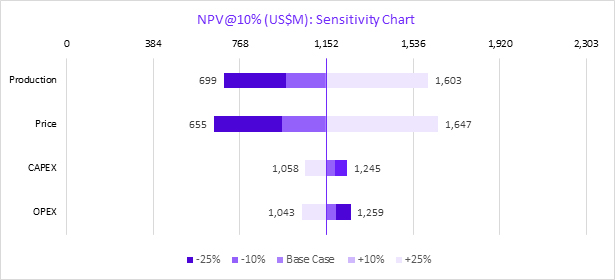

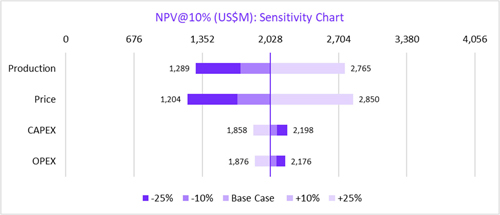

1.9.2 Sensitivity Analysis – Stage 1 Only

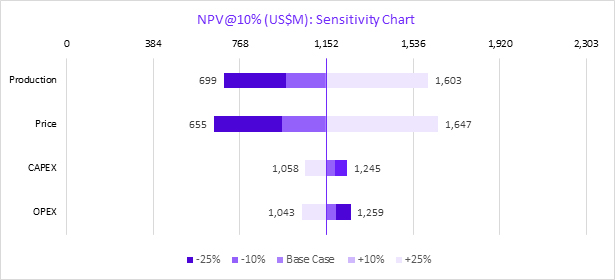

The sensitivity analysis examined the impact of variations in commodity prices, production levels, capital costs, and operating costs on the project’s NPV at a discount rate of 10%.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

As seen in Figure 1-3, the commodity price has the most significant impact on the Sal de Vida Project’s NPV, followed by production levels, OPEX, and CAPEX. Even under adverse market conditions, such as unfavorable price levels, increased costs, and investment challenges, Sal de Vida remains economically viable.

Figure 1-3 – Stage 1 Sensitivity Chart.

Based on the assumptions detailed in this report, the economic analysis of SDV Stage 1 demonstrates positive financial outcomes. The sensitivity analysis further strengthens the project’s viability, as it indicates resilience to market fluctuations and cost changes.

1.10 Additional Information – Stage 2 Expansion

1.10.1 Stage 2 Description and Layout

The Technical report focusses on the current Sal de Vida Stage 1 execution followed by a planned modular Stage 2 expansion.

The Sal de Vida lithium carbonate plants were designed to produce 15,000 tpa of lithium carbonate in Stage 1, with Stage 2 enabling the production of an additional 30,000 tpa through two 15,000 tpa modules. The modular plant design was based on average brine supplies of 26 m3/h for Stage 1 and an additional 52 m3/hr for stage 2 respectively. The design includes an average lithium concentration of 21 g/l in the softening feed. Plants will operate continuously with a design availability of 91%.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

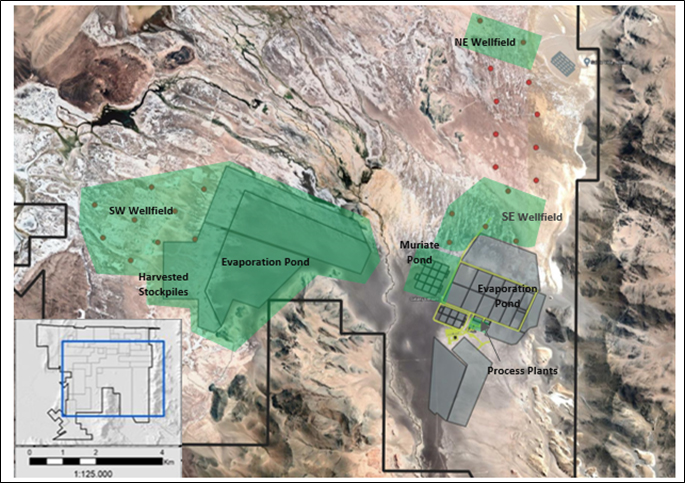

Stage 2 will consist of further expansion of operations as established in Stage 1. All Stage 2 facilities will be located within the Stage 1 Project tenements in the southern sector of the Salar del Hombre Muerto. The wellfield will be located directly above the western sub-basin of the Salar del Hombre Muerto over the salt pan. The brine distribution will traverse the salar southeast towards the evaporation ponds on the alluvial field. The production plant for Stage 2 will be sited adjacent to the production plant for Stage 1. The waste disposal areas will surround the evaporation ponds.

A layout of the Stage 2 expansion as depicted in Figure 1-4.

1.10.2 Stage 2 Infrastructure

Utilities and support infrastructure will be expanded in a modularized fashion as necessary to support Stage 2.

Given that Stage 2 is a planned expansion of SDV Stage 1, certain infrastructures such as roads and camp will either remain the same or experience incremental changes (i.e., an extra tank, genset, or another module). This section includes a description of the main infrastructure located at site, including the facilities outlined in Table 1-8.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Figure 1-4 – Sal de Vida Stage 2 integrated expansion (Allkem, 2022).

Table 1-8 – Sal de Vida Infrastructure Facilities.

| Facility | Stage 2 Expansion (Incremental) |

| Raw water, Reverse Osmosis (RO) water and Demineralized water | Camp – 1 raw water tanks, 1 RO plants and 2 RO water tanks Plant – 6 raw water tanks, 2 RO plants, 2 demineralized water plants |

| Power generation and distribution | Camp – 1 genset (0.6 MW) Wellfield – 16 gensets adjacent to wells Booster Station – 2 x 1.4 MW powerhouses Plant – 8 MW Hybrid generation |

| Fuel storage and dispensing | Camp – NIL Plant – 4 x 75m3 additional diesel tanks or equivalent |

| Camp | Operations – 3 sleeping modules (100 beds) Construction – NIL |

| Sewage treatment plant | Operations – 60 m3 per day Construction – NIL |

| Fire protection system | Camp – NIL |

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

| Facility | Stage 2 Expansion (Incremental) |

| | Plant – Extension of system to cover new buildings |

| Buildings | Camp: ● Medical centre (expansion). ● Kitchen and dining room (expansion). ● Offices (expansion). Plant: ● Process plant building expansion. ● Reagent storage and preparation building expansion. ● Product storage building expansion. ● Administration offices expansion. ● Canteen expansion. ● First aid building expansion. |

| Site roads, causeways and river crossings | ● Main southwestern access road. ● Rio de los Patos river crossing. ● Salt harvesting roads (west). ● SW wellfield road network. |

| Communications | ● Internet service: increase capacity. ● Radio: repeat station (west). |

| Mobile equipment | ● 25 x Heavy Vehicles. ● 25 x Light Vehicles. |

| Steam generation | ● 4 units (6.7 t/hr of saturated steam each) |

| Compressed air | ● 4 units |

1.10.3 Stage 2 Permitting

The physical, biological, and social baseline data for the Project has been collected over the wider area of the Salar de Hombre Muerto since 2011 (ERM, 2011). Specific baseline field campaigns and environmental impact studies will need to be performed as part of the environmental permitting for Stage 2 of the Project. The Stage 2 baseline field campaigns have not commenced as yet.

The Environmental Impact Declaration (DIA) approved in December 2021 was for Stage 1 only. The Stage 2 will require an amendment to the Stage 1 DIA with separate investigations related to the Stage 2 affected areas. The Stage 2 DIA application has not commenced as yet. Further study and basic engineering are required to further define the Stage 2 affected areas and related impacts.

The Sal de Vida Project will require 100-120 m3/hr of raw water for the operation of Stage 1 and 2. The water permits that will be required to take account of the increased water demand to construct and operate Stage 2 have not been applied for yet.

It is estimated that required engineering definition, studies, and permitting application processing will require approximately 18 months based on timelines experienced with Stage 1.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

1.10.4 Stage 2 Capex and Opex

The capital cost estimate for Stage 2 of the Sal de Vida Project was prepared by Allkem based on previously completed studies by Worley Chile S.A. and Worley Argentina S.A. (Collectively, Worley) in collaboration with Allkem. Allkem supplemented previous study estimates with actual construction cost data obtained from the ongoing Sal de Vida Stage 1 construction. The estimate is a Class 4 AACCE with an expected accuracy of +30% / - 20%. The costs are based on Q2 2023 pricing and reflective of the Effective Date.

Capital Cost Estimation for Stage 2 was based on the Sal de Vida Stage 1 AACE class 2 estimate currently in execution. The modularized nature of the project expansion allows for direct cost comparisons from Stage 1 to Stage 2, supplemented by escalation estimation and appropriate contingency.

Table 1-9 summarizes the Stage 2 capital cost estimate.

Table 1-9 – Capital Expenditures: Stage 2 (Standalone).

| Description | Capital Intensity (US$ / t Li2CO3) | CAPEX Breakdown (US$ m) |

| Direct Costs | | |

| General Engineering & Studies | 1,146 | 34 |

| Wellfields & Brine Distribution | 818 | 25 |

| Evaporation Ponds, Waste & Tailings | 4,692 | 141 |

| LiCO Plant & Reagents | 11,408 | 342 |

| Utilities | 546 | 16 |

| Infrastructure | 427 | 13 |

| Total Direct Cost | 19,036 | 571 |

| Owner Costs + Contingency | 2,855 | 86 |

| TOTAL CAPEX | 21,891 | 657 |

The total sustaining and enhancement capital expenditures for Sal de Vida Project Stage 2 are shown in Table 1-10

Table 1-10 - Sustaining and Enhancement Capex Stage 2 (Standalone)

| Description | Total Year* (US$ m) | Total LOM (US$ m) |

| Enhancement CAPEX | – | 39.8 |

| Sustaining CAPEX | 16.7 | 624.9 |

| Total | 17 | 665 |

| * Long Term estimated cost per year | | |

The operating cost estimate (Opex) for Stage 2 of the Sal de Vida Project was prepared by Allkem’s team based on Olaroz Stage 1 experience and progress on the Sal de Vida Stage 1 development The Opex estimate is based on current operational pricing as described in Section 18 of the report. Subject to the exceptions and exclusions set forth in this pre-feasibility study. The summary Opex breakdown is presented in Table 1-11.

Sal de Vida Lithium Brine Project

SEC Technical Report Summary

Table 1-11 – Estimated Operating Costs by Category.Stage 2 (Standalone)

| Description | Per Tonne LOM (US$ / t Li2CO3) | Total LOM (US$ m) | Total Year* (US$ m) |

| Reagents | 1,844 | 2,034 | 55 |

| Labour | 257 | 284 | 7 |

| Energy | 603 | 665 | 17 |

| General & Administration | 432 | 476 | 13 |

| Consumables & Materials | 415 | 457 | 12 |

| SITE CASH COSTS | 3,550 | 3,917 | 104 |

| Transport & Port | 175 | 193 | 5 |

| FOB CASH OPERATING COSTS | 3,726 | 4,110 | 109 |

| * Long Term estimated cost per year | | | |

1.10.5 Stage 2 Economic Analysis

The financial evaluation is dependent on key input parameters and assumptions:

| 1. | Production schedule, including annual brine production, pond evaporation rates, process plant production, and ramp-up schedule. The Sal de Vida Project Stage 2 nominal capacity of annual lithium carbonate is estimated to be 30,000t/year. |

| 2. | Plant recoveries and lithium grades. |

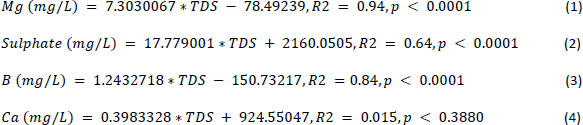

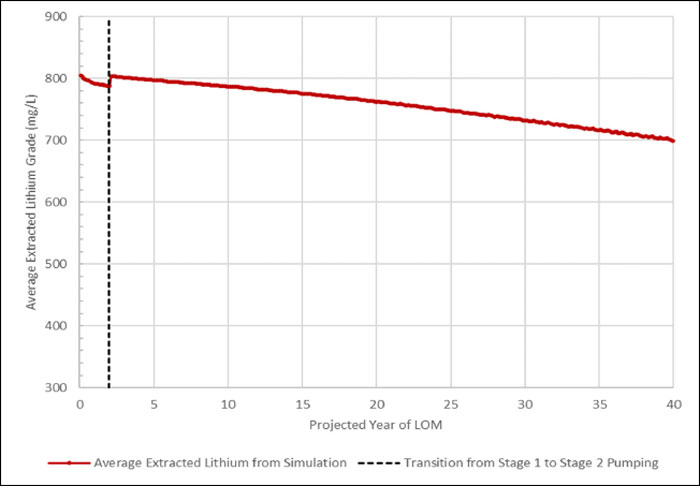

| 3. | Operating, capital, and closure costs for a 37-years operating life. |