Exhibit 96.2

Rochester Operations

Nevada

Technical Report Summary

Prepared for: Coeur Mining, Inc. | Prepared by: Mr Christopher Pascoe, RM SME Mr. Brandon MacDougall, P.E. Mr. Matthew Bradford, RM SME Mr. Matthew Hoffer, P.G. |

| |

Report current as at: December 31, 2021 |

Date and Signature Page

The following Qualified Persons, who are employees of Coeur Mining, Inc. or its subsidiaries, prepared this technical report summary, entitled “Rochester Operations, Nevada, Technical Report Summary” and confirm that the information in the technical report summary is current as at December 31, 2021 and filed on February 16, 2022.

/s/ Christopher Pascoe

Christopher Pascoe, RM SME

/s/ Brandon MacDougall

Brandon MacDougall, P.E.

/s/ Matthew Bradford

Matthew Bradford, RM SME

/s/ Matthew Hoffer

Matthew Hoffer, P.G.

| CONTENTS |

| |

| 1.0 | EXECUTIVE SUMMARY | 1-1 |

| 1.1 | Introduction | 1-1 |

| 1.2 | Terms of Reference | 1-1 |

| 1.3 | Property Setting | 1-1 |

| 1.4 | Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements | 1-2 |

| 1.5 | Geology and Mineralization | 1-2 |

| 1.6 | History and Exploration | 1-3 |

| 1.7 | Drilling and Sampling | 1-3 |

| 1.8 | Data Verification | 1-4 |

| 1.9 | Metallurgical Test Work | 1-5 |

| 1.10 | Mineral Resource Estimation | 1-6 |

| 1.10.1 | Estimation Methodology | 1-6 |

| 1.10.2 | Mineral Resource Statement | 1-7 |

| 1.10.3 | Factors That May Affect the Mineral Resource Estimate | 1-8 |

| 1.11 | Mineral Reserve Estimation | 1-9 |

| 1.11.1 | Estimation Methodology | 1-9 |

| 1.11.2 | Mineral Reserve Statement | 1-9 |

| 1.11.3 | Factors That May Affect the Mineral Reserve Estimate | 1-10 |

| 1.12 | Mining Methods | 1-10 |

| 1.13 | Recovery Methods | 1-11 |

| 1.14 | Infrastructure | 1-12 |

| 1.15 | Markets and Contracts | 1-13 |

| 1.15.1 | Market Studies | 1-13 |

| 1.15.2 | Commodity Pricing | 1-13 |

| 1.15.3 | Contracts | 1-14 |

| 1.16 | Environmental, Permitting and Social Considerations | 1-14 |

| 1.16.1 | Environmental Studies and Monitoring | 1-14 |

| 1.16.2 | Closure and Reclamation Considerations | 1-14 |

| 1.16.3 | Permitting | 1-14 |

| 1.16.4 | Social Considerations, Plans, Negotiations and Agreements | 1-15 |

| 1.17 | Capital Cost Estimates | 1-15 |

| 1.18 | Operating Cost Estimates | 1-15 |

| 1.19 | Economic Analysis | 1-18 |

| 1.19.1 | Forward-Looking Information Caution | 1-18 |

| 1.19.2 | Methodology and Assumptions | 1-18 |

| 1.19.3 | Economic Analysis | 1-18 |

| 1.19.4 | Sensitivity Analysis | 1-19 |

| 1.20 | Risks and Opportunities | 1-19 |

| 1.20.1 | Risks | 1-19 |

| 1.20.2 | Opportunities | 1-21 |

| 1.21 | Conclusions | 1-21 |

| 1.22 | Recommendations | 1-21 |

| 2.0 | INTRODUCTION | 2-1 |

| 2.1 | Registrant | 2-1 |

| 2.2 | Terms of Reference | 2-1 |

| 2.2.1 | Report Purpose | 2-1 |

| 2.2.2 | Terms of Reference | 2-1 |

| 2.3 | Qualified Persons | 2-4 |

| 2.4 | Site Visits and Scope of Personal Inspection | 2-4 |

| 2.5 | Report Date | 2-4 |

| 2.6 | Information Sources and References | 2-5 |

| 2.7 | Previous Technical Report Summaries | 2-5 |

| 3.0 | PROPERTY DESCRIPTION | 3-1 |

| 3.1 | Property Location | 3-1 |

| 3.2 | Ownership | 3-1 |

| 3.3 | Mineral Title | 3-1 |

| 3.3.1 | Tenure Holdings | 3-1 |

| 3.3.2 | Tenure Maintenance Requirements | 3-1 |

| 3.4 | Property Agreements | 3-4 |

| 3.4.1 | Pershing County Road Maintenance Agreement | 3-4 |

| 3.4.2 | Pipeline, Electric Power Line, and Telephone Line License | 3-4 |

| 3.4.3 | Rights of Way | 3-4 |

| 3.5 | Surface Rights | 3-5 |

| 3.6 | Water Rights | 3-5 |

| 3.7 | Royalties | 3-5 |

| 3.7.1 | Asarco Royalty | 3-5 |

| 3.7.2 | Nelsen, Stice, and Kilrain Royalty | 3-7 |

| 3.7.3 | Davis Royalty | 3-7 |

| 3.7.4 | Midway Gold US Inc. and Barrick Royalty | 3-7 |

| 3.8 | Encumbrances | 3-7 |

| 3.8.1 | Credit Agreement | 3-7 |

| 3.8.2 | Permitting Requirements | 3-8 |

| 3.8.3 | Permitting Timelines | 3-8 |

| 3.8.4 | Permit Conditions | 3-8 |

| 3.8.5 | Violations and Fines | 3-8 |

| 3.9 | Significant Factors and Risks That May Affect Access, Title or Work Programs | 3-8 |

| 4.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 4-1 |

| 4.1 | Physiography | 4-1 |

| 4.2 | Accessibility | 4-1 |

| 4.3 | Climate | 4-1 |

| 4.4 | Infrastructure | 4-2 |

| 5.0 | HISTORY | 5-1 |

| 5.1 | Project Ownership History | 5-1 |

| 5.2 | Exploration and Development History | 5-1 |

| 6.0 | GEOLOGICAL SETTING, MINERALIZATION, AND DEPOSIT | 6-1 |

| 6.1 | Deposit Type | 6-1 |

| 6.2 | Regional Geology | 6-1 |

| 6.3 | Local Geology | 6-3 |

| 6.3.1 | Lithologies | 6-3 |

| 6.3.2 | Structure | 6-6 |

| 6.3.3 | Metamorphism and Alteration | 6-6 |

| 6.3.4 | Mineralization | 6-6 |

| 6.4 | Property Geology | 6-7 |

| 6.4.1 | Rochester | 6-7 |

| 6.4.1.1 | Deposit Dimensions | 6-7 |

| 6.4.1.2 | Lithologies | 6-7 |

| 6.4.1.3 | Structure | 6-7 |

| 6.4.1.4 | Alteration | 6-8 |

| 6.4.1.5 | Mineralization | 6-8 |

| 6.4.2 | Nevada Packard | 6-11 |

| 6.4.2.1 | Deposit Dimensions | 6-11 |

| 6.4.2.2 | Lithologies | 6-11 |

| 6.4.2.3 | Structure | 6-11 |

| 6.4.2.4 | Alteration | 6-11 |

| 6.4.2.5 | Mineralization | 6-11 |

| 7.0 | EXPLORATION | 7-1 |

| 7.1 | Exploration | 7-1 |

| 7.1.1 | Grids and Surveys | 7-1 |

| 7.1.2 | Geological Mapping | 7-1 |

| 7.1.3 | Geochemistry | 7-1 |

| 7.1.4 | Geophysics | 7-2 |

| 7.1.5 | Qualified Person’s Interpretation of the Exploration Information | 7-2 |

| 7.1.6 | Exploration Potential | 7-2 |

| 7.2 | Drilling | 7-4 |

| 7.2.1 | Overview | 7-4 |

| 7.2.2 | Drilling Excluded For Estimation Purposes | 7-4 |

| 7.2.3 | Drill Methods | 7-4 |

| 7.2.4 | Logging | 7-16 |

| 7.2.5 | Recovery | 7-18 |

| 7.2.6 | Collar Surveys | 7-18 |

| 7.2.7 | Down Hole Surveys | 7-18 |

| 7.2.8 | Comment on Material Results and Interpretation | 7-18 |

| 7.3 | Hydrogeology | 7-19 |

| 7.3.1 | Sampling Methods and Laboratory Determinations | 7-19 |

| 7.3.2 | Hydrogeology | 7-19 |

| 7.3.3 | Comment on Results | 7-20 |

| 7.3.4 | Groundwater Models | 7-20 |

| 7.3.5 | Water Balance | 7-21 |

| 7.4 | Geotechnical | 7-21 |

| 7.4.1 | Sampling Methods and Laboratory Determinations | 7-21 |

| 7.4.2 | Comment on Results | 7-22 |

| 8.0 | SAMPLE PREPARATION, ANALYSES, AND SECURITY | 8-1 |

| 8.1 | Sampling Methods | 8-1 |

| 8.1.1 | Reverse Circulation | 8-1 |

| 8.1.2 | Core | 8-1 |

| 8.1.3 | Grade Control | 8-1 |

| 8.2 | Sample Security Methods | 8-2 |

| 8.3 | Density Determinations | 8-2 |

| 8.4 | Analytical and Test Laboratories | 8-2 |

| 8.5 | Sample Preparation | 8-3 |

| 8.5.1 | Pre-2008 | 8-3 |

| 8.5.2 | 2008–Current | 8-3 |

| 8.6 | Analysis | 8-3 |

| 8.6.1 | Coeur Pre-2008 | 8-3 |

| 8.6.2 | 2008–2011 | 8-4 |

| 8.6.3 | 2012–Current | 8-4 |

| 8.6.4 | Multi-element Analysis | 8-6 |

| 8.6.5 | Alio Gold | 8-7 |

| 8.7 | Quality Assurance and Quality Control | 8-7 |

| 8.7.1 | Coeur Pre-2008 | 8-7 |

| 8.7.2 | 2008–2015 | 8-8 |

| 8.7.3 | 2016–Current | 8-8 |

| 8.7.4 | Alio Gold Results | 8-9 |

| 8.8 | Database | 8-9 |

| 8.9 | Qualified Person’s Opinion on Sample Preparation, Security, and Analytical Procedures | 8-9 |

| 9.0 | DATA VERIFICATION | 9-1 |

| 9.1 | Internal Data Verification | 9-1 |

| 9.1.1 | Rochester Review | 9-1 |

| 9.1.2 | Nevada Packard Review | 9-2 |

| 9.1.3 | Nevada Packard Stockpiles | 9-3 |

| 9.1.4 | South and Charlie Stockpiles | 9-4 |

| 9.1.5 | Rochester In-Pit Stockpile | 9-4 |

| 9.2 | External Data Verification | 9-4 |

| 9.3 | Data Verification by Qualified Person | 9-5 |

| 9.4 | Qualified Person’s Opinion on Data Adequacy | 9-5 |

| 10.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 10-1 |

| 10.1 | Test Laboratories | 10-1 |

| 10.2 | Metallurgical Test Work | 10-1 |

| 10.2.1 | Rochester | 10-1 |

| 10.2.2 | Packard | 10-1 |

| 10.2.3 | Current Metallurgical Testing | 10-2 |

| 10.3 | Recovery Estimates | 10-3 |

| 10.4 | Metallurgical Variability | 10-7 |

| 10.5 | Deleterious Elements | 10-7 |

| 10.6 | Qualified Person’s Opinion on Data Adequacy | 10-8 |

| 11.0 | MINERAL RESOURCE ESTIMATES | 11-1 |

| 11.1 | Introduction | 11-1 |

| 11.2 | Geological Model | 11-1 |

| 11.3 | Exploratory Data Analysis | 11-3 |

| 11.4 | Density | 11-3 |

| 11.5 | Composites | 11-3 |

| 11.6 | Grade Capping/Outlier Restrictions | 11-4 |

| 11.7 | Variography | 11-4 |

| 11.8 | Interpolation | 11-4 |

| 11.9 | Block Model Validation | 11-8 |

| 11.10 | Classification of Mineral Resources | 11-9 |

| 11.10.1 | Mineral Resource Confidence Classification | 11-9 |

| 11.10.2 | Uncertainties Considered During Confidence Classification | 11-9 |

| 11.11 | Reasonable Prospects of Economic Extraction | 11-9 |

| 11.11.1 | Input Assumptions | 11-9 |

| 11.11.2 | Commodity Price | 11-13 |

| 11.11.3 | Cut-off | 11-14 |

| 11.11.4 | QP Statement | 11-14 |

| 11.12 | Mineral Resource Statement | 11-15 |

| 11.13 | Uncertainties (Factors) That May Affect the Mineral Resource Estimate | 11-20 |

| 12.0 | MINERAL RESERVE ESTIMATES | 12-1 |

| 12.1 | Introduction | 12-1 |

| 12.2 | Development of Mining Case | 12-1 |

| 12.3 | Designs | 12-1 |

| 12.4 | Input Parameters | 12-1 |

| 12.5 | Net Smelter Return Cut-off | 12-2 |

| 12.6 | Cut-Off Grades | 12-2 |

| 12.7 | Surface Topography | 12-3 |

| 12.8 | Density and Moisture | 12-3 |

| 12.9 | Dilution and Mine Losses | 12-3 |

| 12.10 | Mineral Reserve Statement | 12-4 |

| 12.11 | Uncertainties (Factors) That May Affect the Mineral Reserve Estimate | 12-4 |

| 13.0 | MINING METHODS | 13-1 |

| 13.1 | Introduction | 13-1 |

| 13.2 | Geotechnical Considerations | 13-1 |

| 13.3 | Hydrogeological Considerations | 13-1 |

| 13.4 | Design Considerations | 13-2 |

| 13.5 | Blasting and Explosives | 13-3 |

| 13.6 | Grade Control and Production Monitoring | 13-3 |

| 13.7 | Waste Rock and Backfill | 13-6 |

| 13.8 | Production Schedule | 13-6 |

| 13.9 | Equipment | 13-11 |

| 13.10 | Personnel | 13-11 |

| 14.0 | RECOVERY METHODS | 14-1 |

| 14.1 | Process Method Selection | 14-1 |

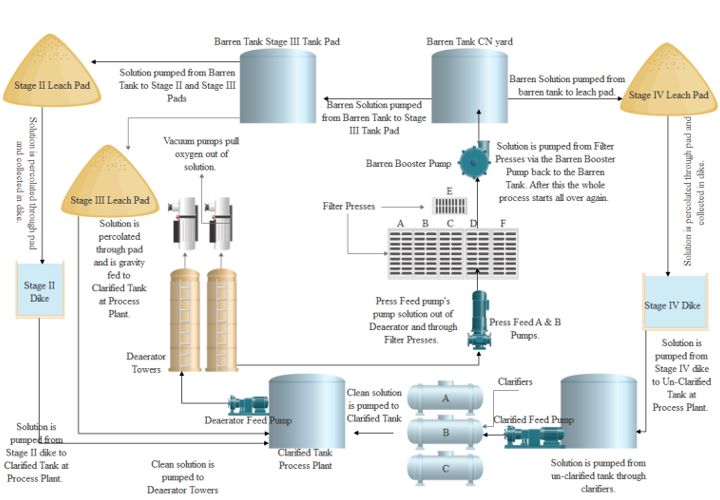

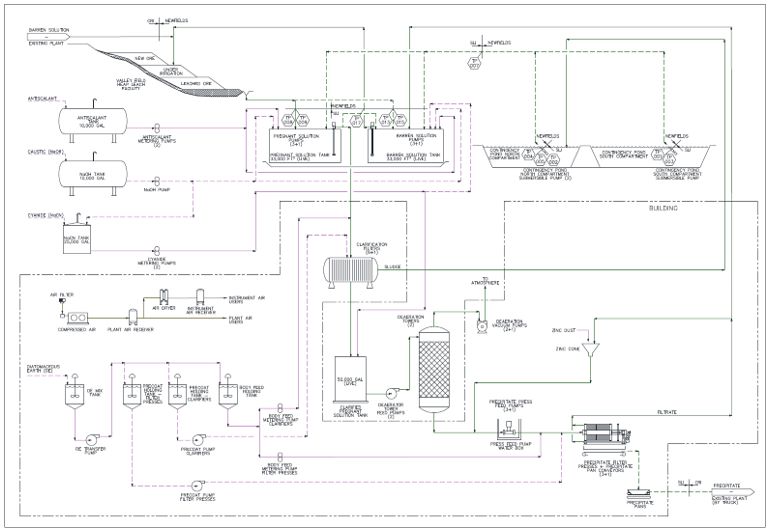

| 14.2 | Flowsheet | 14-1 |

| 14.3 | Process Plant | 14-1 |

| 14.3.1 | Overview | 14-1 |

| 14.3.2 | Heap Leach Pads | 14-4 |

| 14.3.3 | Merrill-Crowe Plant | 14-5 |

| 14.4 | Equipment Sizing | 14-6 |

| 14.5 | Power and Consumables | 14-6 |

| 14.6 | Personnel | 14-6 |

| 15.0 | INFRASTRUCTURE | 15-1 |

| 15.1 | Roads and Logistics | 15-3 |

| 15.2 | Stockpiles | 15-3 |

| 15.3 | Waste Rock Storage Facilities | 15-5 |

| 15.4 | Water Management | 15-5 |

| 15.5 | Water Supply | 15-5 |

| 15.6 | Power and Electrical | 15-6 |

| 15.7 | Fuel | 15-7 |

| 16.0 | MARKET STUDIES AND CONTRACTS | 16-1 |

| 16.1 | Markets | 16-1 |

| 16.2 | Commodity Price Forecasts | 16-1 |

| 16.3 | Contracts | 16-2 |

| 16.4 | QP Statement | 16-3 |

| 17.0 | ENVIRONMENTAL STUDIES, PERMITTING, AND PLANS, NEGOTIATIONS, OR AGREEMENTS WITH LOCAL INDIVIDUALS OR GROUPS | 17-1 |

| 17.1 | Baseline and Supporting Studies | 17-1 |

| 17.2 | Environmental Considerations/Monitoring Programs | 17-1 |

| 17.2.1 | Environmental Protection Measures | 17-1 |

| 17.2.2 | Jurisdictional Wetlands and Waters of the United States | 17-2 |

| 17.3 | Closure and Reclamation Considerations | 17-2 |

| 17.4 | Permitting | 17-5 |

| 17.4.1 | Current Permits | 17-5 |

| 17.4.2 | POA 11 | 17-5 |

| 17.5 | Social Considerations, Plans, Negotiations and Agreements | 17-5 |

| 17.6 | Qualified Person’s Opinion on Adequacy of Current Plans to Address Issues | 17-8 |

| 18.0 | CAPITAL AND OPERATING COSTS | 18-1 |

| 18.1 | Introduction | 18-1 |

| 18.2 | Capital Cost Estimates | 18-1 |

| 18.2.1 | Basis of Estimate | 18-1 |

| 18.2.2 | Capital Cost Summary | 18-2 |

| 18.3 | Operating Cost Estimates | 18-2 |

| 18.3.1 | Basis of Estimate | 18-2 |

| 18.3.2 | Operating Cost Summary | 18-2 |

| 18.4 | QP Statement | 18-5 |

| 19.0 | ECONOMIC ANALYSIS | 19-1 |

| 19.1 | Forward-looking Information Caution | 19-1 |

| 19.2 | Methodology Used | 19-1 |

| 19.3 | Financial Model Parameters | 19-1 |

| 19.3.1 | Mineral Resource, Mineral Reserve, and Mine Life | 19-1 |

| 19.3.2 | Metallurgical Recoveries | 19-1 |

| 19.3.3 | Smelting and Refining Terms | 19-2 |

| 19.3.4 | Metal Prices | 19-2 |

| 19.3.5 | Capital and Operating Costs | 19-2 |

| 19.3.6 | Working Capital | 19-2 |

| 19.3.7 | Taxes and Royalties | 19-2 |

| 19.3.8 | Closure Costs and Salvage Value | 19-2 |

| 19.3.9 | Financing | 19-2 |

| 19.3.10 | Inflation | 19-3 |

| 19.4 | Economic Analysis | 19-3 |

| 19.5 | Sensitivity Analysis | 19-3 |

| 20.0 | ADJACENT PROPERTIES | 20-1 |

| 21.0 | OTHER RELEVANT DATA AND INFORMATION | 21-1 |

| 22.0 | INTERPRETATION AND CONCLUSIONS | 22-1 |

| 22.1 | Introduction | 22-1 |

| 22.2 | Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements | 22-1 |

| 22.3 | Geology and Mineralization | 22-1 |

| 22.4 | Exploration, Drilling, and Sampling | 22-1 |

| 22.5 | Data Verification | 22-2 |

| 22.6 | Metallurgical Test Work | 22-2 |

| 22.7 | Mineral Resource Estimates | 22-3 |

| 22.8 | Mineral Reserve Estimates | 22-3 |

| 22.9 | Mining Methods | 22-4 |

| 22.10 | Recovery Methods | 22-4 |

| 22.11 | Infrastructure | 22-4 |

| 22.12 | Market Studies | 22-5 |

| 22.13 | Environmental, Permitting and Social Considerations | 22-6 |

| 22.14 | Capital Cost Estimates | 22-6 |

| 22.15 | Operating Cost Estimates | 22-7 |

| 22.16 | Economic Analysis | 22-7 |

| 22.17 | Risks and Opportunities | 22-7 |

| 22.17.1 | Risks | 22-7 |

| 22.17.2 | Opportunities | 22-8 |

| 22.18 | Conclusions | 22-9 |

| 23.0 | RECOMMENDATIONS | 23-1 |

| 24.0 | REFERENCES | 24-1 |

| 24.1 | Bibliography | 24-1 |

| 24.2 | Abbreviations and Units of Measure | 24-2 |

| 24.3 | Glossary of Terms | 24-6 |

| 25.0 | RELIANCE ON INFORMATION PROVIDED BY THE REGISTRANT | 25-1 |

| 25.1 | Introduction | 25-1 |

| 25.2 | Macroeconomic Trends | 25-1 |

| 25.3 | Markets | 25-1 |

| 25.4 | Legal Matters | 25-1 |

| 25.5 | Environmental Matters | 25-1 |

| 25.6 | Stakeholder Accommodations | 25-2 |

| 25.7 | Governmental Factors | 25-2 |

| 25.8 | Internal Controls | 25-2 |

| 25.8.1 | Exploration and Drilling | 25-2 |

| 25.8.2 | Mineral Resource and Mineral Reserve Estimates | 25-3 |

| 25.8.3 | Risk Assessments | 25-3 |

| TABLES |

| |

| Table 1‑1: | Summary of Gold and Silver Measured and Indicated Mineral Resources, Rochester, Nevada Packard, and Stockpiles, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 1-8 |

| Table 1‑2: | Summary of Gold and Silver Inferred Mineral Resources, Rochester, Nevada Packard, and Stockpiles, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price)) | 1-8 |

| Table 1‑3: | Summary of Gold and Silver Proven and Probable Mineral Reserve Estimates, as at December 31, 2021 (based on US$1,400/oz gold price and US$20/oz silver price) | 1-11 |

| Table 1‑4: | Capital Cost Estimate Summary | 1-16 |

| Table 1‑5: | Operating Cost Estimate Summary | 1-17 |

| Table 1‑6: | Summary Cashflow Table | 1-19 |

| Table 1‑7: | NPV Sensitivity | 1-20 |

| Table 2‑1: | QP Chapter Responsibilities | 2-5 |

| Table 3‑1: | Mineral Tenure Summary Table | 3-2 |

| Table 5‑1: | Exploration and Development History | 5-2 |

| Table 7‑1: | Property Drill Summary Table | 7-5 |

| Table 7‑2: | Drill Summary Table, Rochester | 7-11 |

| Table 7‑3: | Drill Summary Table, Nevada Packard | 7-12 |

| Table 8‑1: | Historical Primary and Secondary Laboratory Analysis Methods (2008–2011) | 8-5 |

| Table 10‑1: | Metallurgical Test Work Summary Table | 10-3 |

| Table 10‑2: | Leach Pad Recoveries to Date | 10-4 |

| Table 10‑3: | Historical Crushed and ROM Product Recoveries | 10-4 |

| Table 10‑4: | Stage III Crushed and ROM Product Recoveries | 10-6 |

| Table 10‑5: | Stage VI Recovery Confidence Intervals | 10-6 |

| Table 10‑6: | Ultimate Recovery Summary by Ore Type | 10-8 |

| Table 11‑1: | Capping Statistics for Rochester Silver Composites | 11-5 |

| Table 11‑2: | Capping Statistics for Rochester Gold Composites | 11-6 |

| Table 11‑3: | Capping Statistics for Nevada Packard Silver Composites | 11-7 |

| Table 11‑4: | Capping Statistics for Nevada Packard Gold Composites | 11-7 |

| Table 11‑5: | Confidence Classifications | 11-10 |

| Table 11‑6: | Operating Cost and Cut-offs for Mineral Resource Estimates | 11-13 |

| Table 11‑7: | Metallurgical Process Recoveries Used in Rochester Mineral Resources NSR Cutoff Calculations | 11-15 |

| Table 11‑8: | Gold and Silver Measured and Indicated Mineral Resources, Rochester, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-16 |

| Table 11‑9: | Gold and Silver Inferred Mineral Resources, Rochester, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-16 |

| Table 11‑10: | Gold and Silver Measured and Indicated Mineral Resources, Nevada Packard, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-16 |

| Table 11‑11: | Gold and Silver Inferred Mineral Resources, Nevada Packard, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-17 |

| Table 11‑12: | Gold and Silver Measured and Indicated Mineral Resources, Rochester Stockpile (South-Charlie and In-pit), as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-17 |

| Table 11‑13: | Gold and Silver Inferred Mineral Resources, Rochester Stockpile (South-Charlie and In-pit), as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-17 |

| Table 11‑14: | Gold and Silver Measured and Indicated Mineral Resources, Nevada Packard Stockpile as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-18 |

| Table 11‑15: | Gold and Silver Inferred Mineral Resources, Nevada Packard Stockpile Inferred Mineral Resource Statement as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-18 |

| Table 11‑16: | Summary of Gold and Silver Measured and Indicated Mineral Resources, Rochester, Nevada Packard, and Stockpiles, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price) | 11-19 |

| Table 11‑17: | Summary of Gold and Silver Inferred Mineral Resources, Rochester, Nevada Packard, and Stockpiles, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price)) | 11-19 |

| Table 12‑1: | Pit Shell Input Parameters | 12-2 |

| Table 12‑2: | LOM Operating Cost and Cut-offs for Mineral Reserve Estimates | 12-3 |

| Table 12‑3: | Gold and Silver Proven and Probable Mineral Reserves, Rochester, as at December 31, 2021 (based on US$1,400/oz gold price and US$20/oz silver price) | 12-5 |

| Table 12‑4: | Gold and Silver Proven and Probable Mineral Reserves, Nevada Packard, as at December 31, 2021 (based on US$1,400/oz gold price and US$20/oz silver price) | 12-5 |

| Table 12‑5: | Gold and Silver Proven and Probable Mineral Reserves, Rochester Stockpile (South and Charlie) as at December 31, 2021 (based on US$1,400/oz gold price and US$20/oz silver price) | 12-6 |

| Table 12‑6: | Gold and Silver Proven and Probable Mineral Reserves, Nevada Packard Stockpile, as at December 31, 2021 (based on US$1,400/oz gold price and US$20/oz silver price) | 12-6 |

| Table 12‑7: | Summary of Gold and Silver Mineral Reserve Estimates, as at December 31, 2021 (based on US$1,400/oz gold price and US$20/oz silver price) | 12-7 |

| Table 13‑1: | Rochester Zone Solid Pit Slope Design Criteria | 13-2 |

| Table 13‑2: | Nevada Packard Pit Slope Design Criteria by Material Type | 13-2 |

| Table 13‑3: | Pit Design Assumptions | 13-3 |

| Table 13‑4: | Rochester LOM Production Schedule (2022–2028) | 13-7 |

| Table 13‑5: | Rochester LOM Production Schedule (2029–2034) | 13-8 |

| Table 13‑6: | Nevada Packard LOM Production Schedule | 13-9 |

| Table 13‑7: | Combined LOM Production Schedule, Rochester and Nevada Packard | 13-10 |

| Table 13‑8: | LOM Equipment List | 13-11 |

| Table 14‑1: | Approximate Heap Leach Volumes | 14-5 |

| Table 14‑2: | Stage IV Heap Leach Pad Design Criteria | 14-6 |

| Table 14‑3: | Major Process Equipment | 14-7 |

| Table 14‑4 | Power Requirements | 14-8 |

| Table 17‑1: | Monitoring Components, Permit, Plans and Agencies | 17-3 |

| Table 17‑2: | Rochester Pit Waste Rock Management Procedures | 17-4 |

| Table 18‑1: | Estimated Capital Expenditures by Year ($M) | 18-3 |

| Table 18‑2: | Operating Costs by Year ($M) | 18-4 |

| Table 19‑1: | Tax Rates for Primary Taxes | 19-3 |

| Table 19‑2: | Cashflow Summary Table | 19-4 |

| Table 19‑3: | Annualized Cashflow (2022–2035) | 19-5 |

| Table 19‑4: | Annualized Cashflow (2036–2040) | 19-6 |

| Table 19‑5: | NPV Sensitivity | 19-7 |

| FIGURES |

| | | |

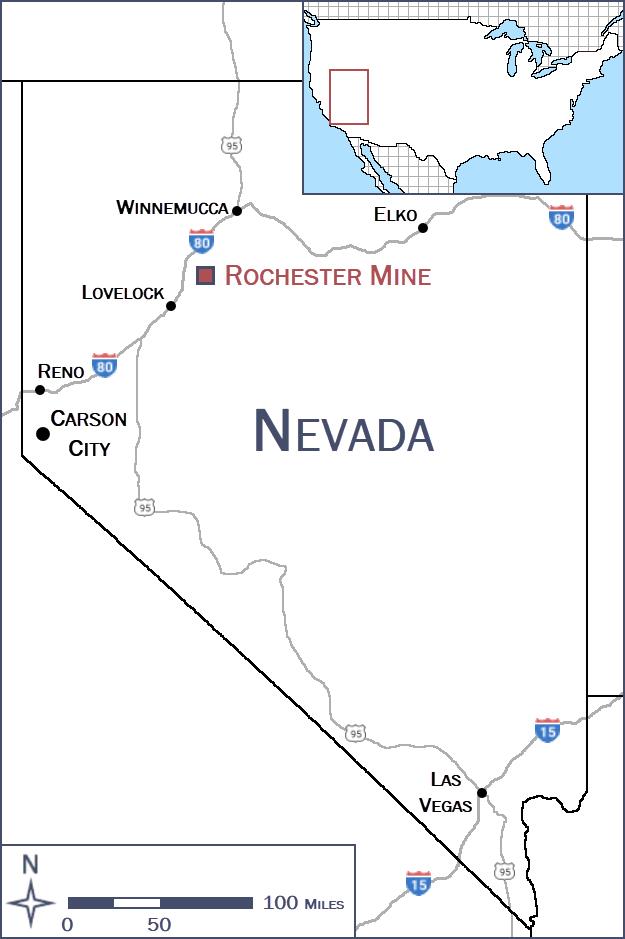

| Figure 2‑1: | Project Location Plan | 2-2 |

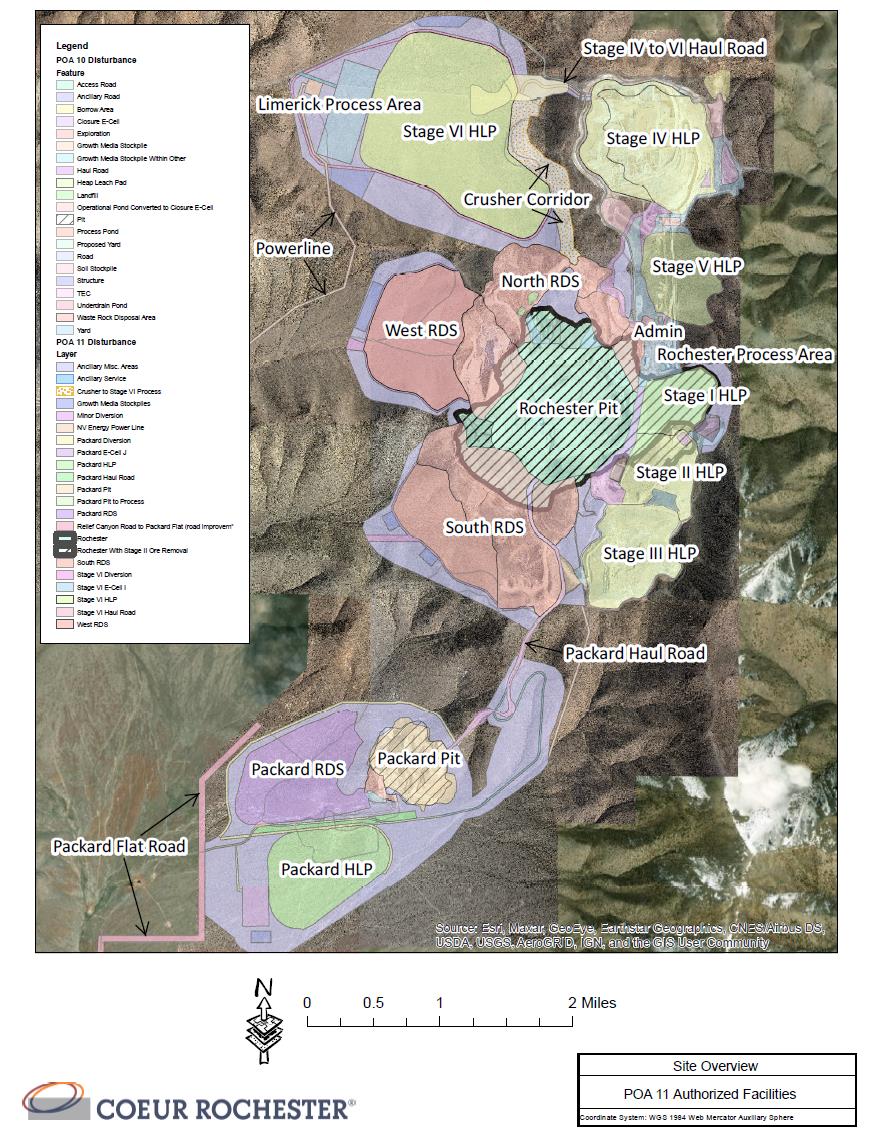

| Figure 2‑2: | Mining Operations Layout Plan | 2-3 |

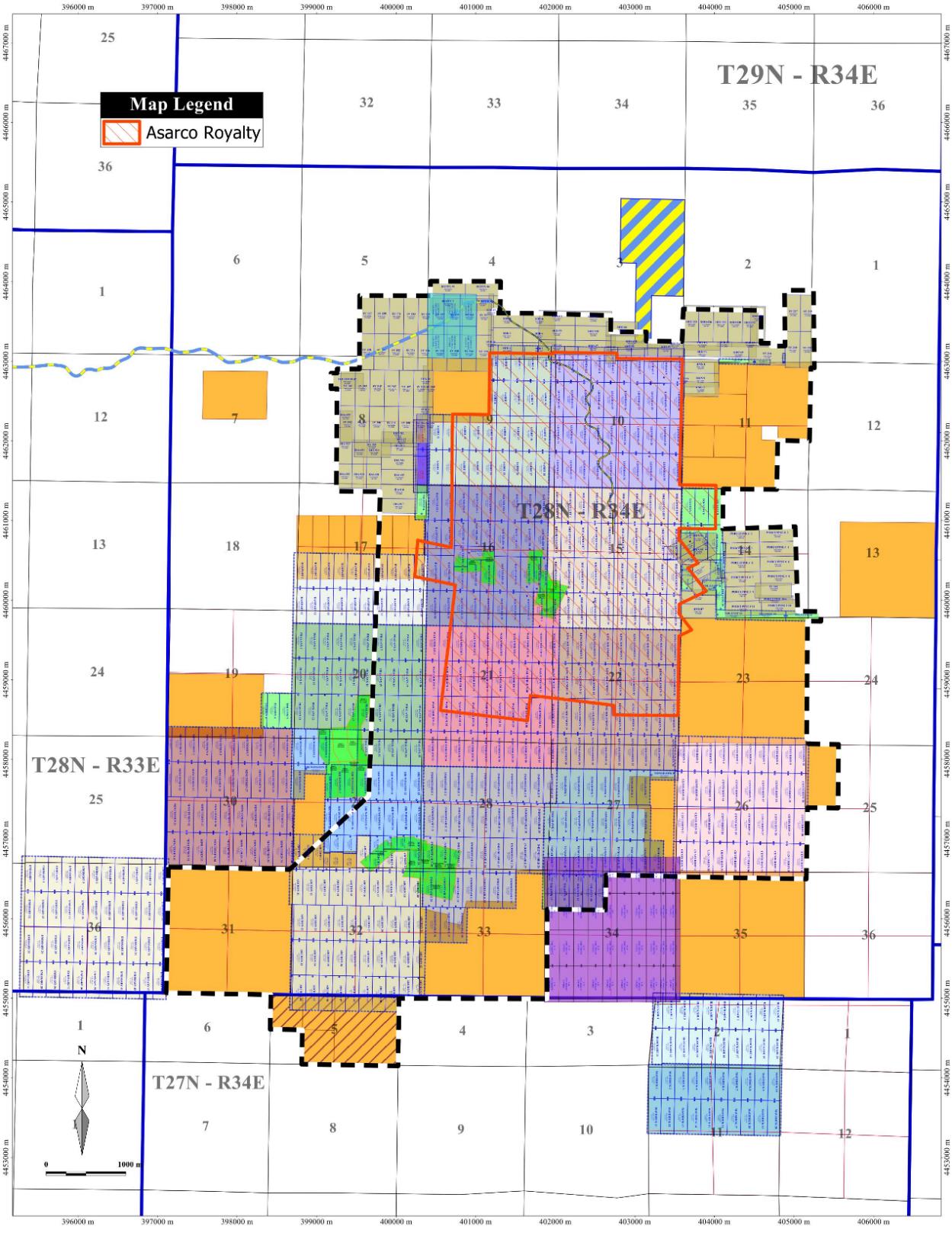

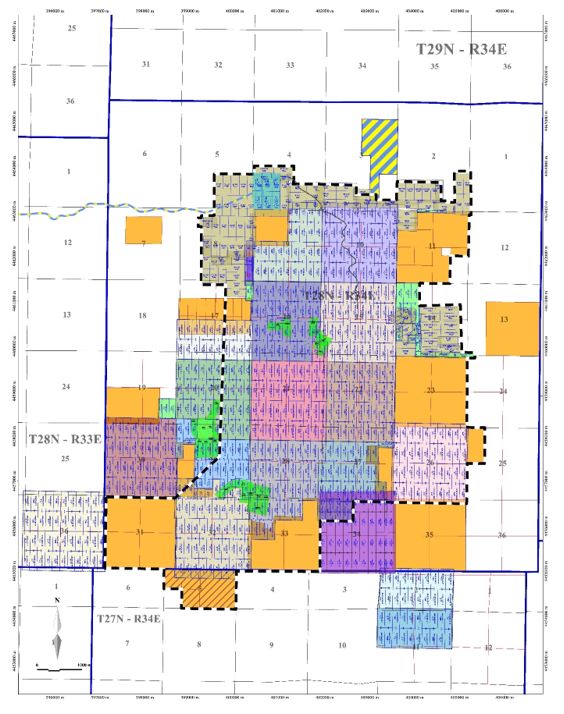

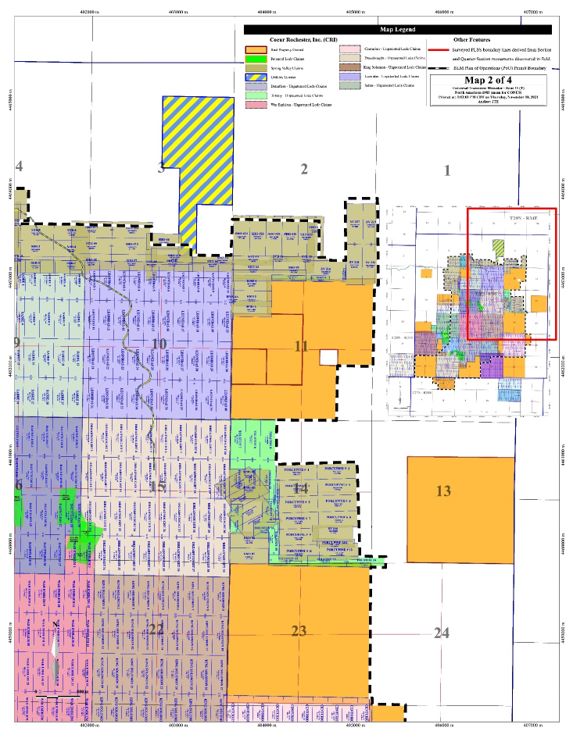

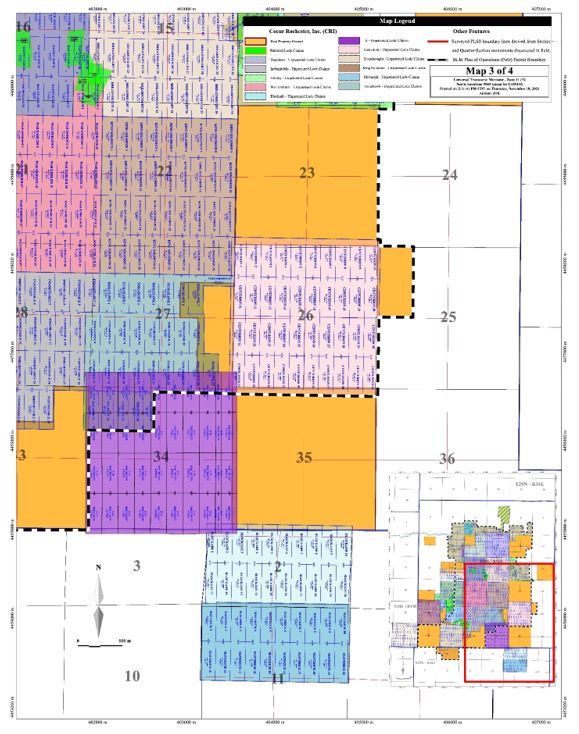

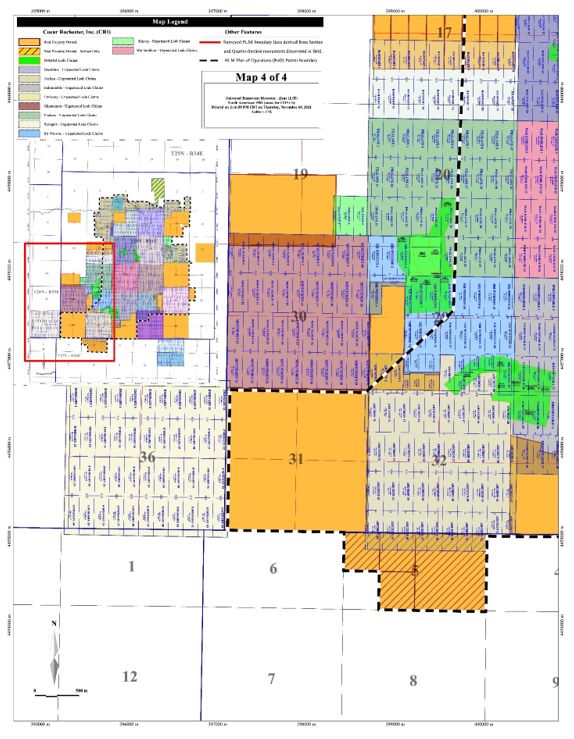

| Figure 3‑1: | Mineral Tenure Location Map | 3-3 |

| Figure 3‑2: | Claims Subject to Royalties Plan | 3-6 |

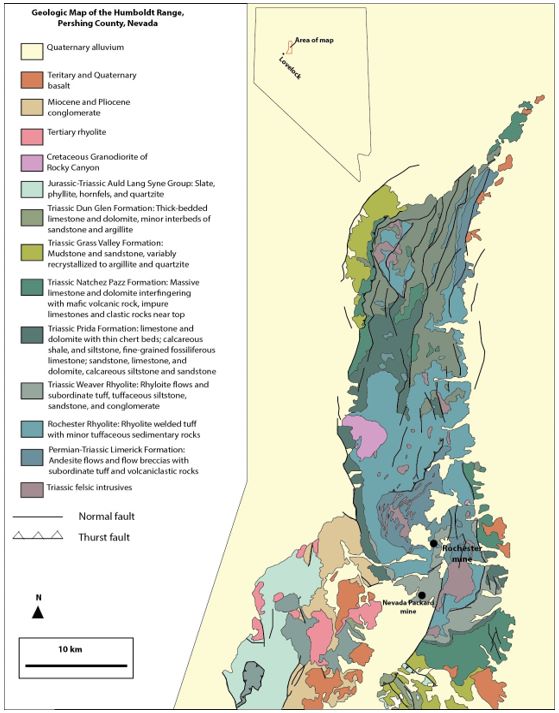

| Figure 6‑1: | Regional Geology Plan | 6-2 |

| Figure 6‑2: | Project Geology Plan | 6-4 |

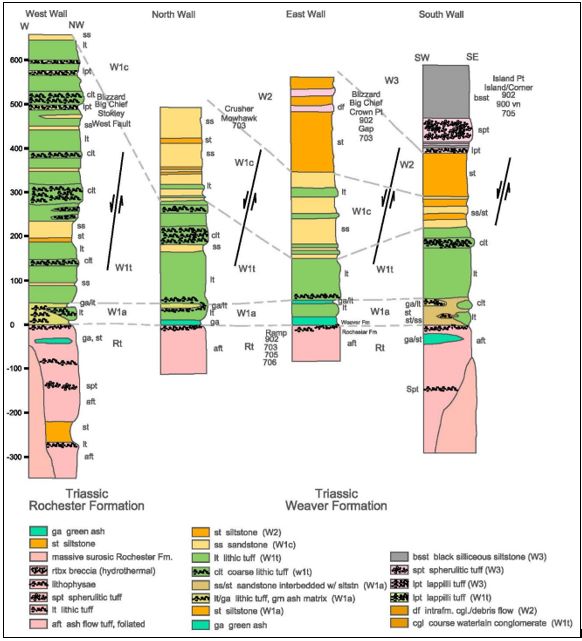

| Figure 6‑3: | Stratigraphic Column | 6-5 |

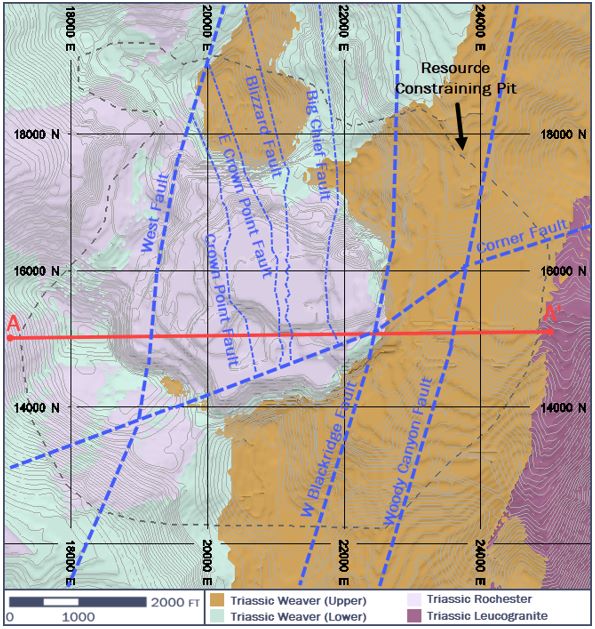

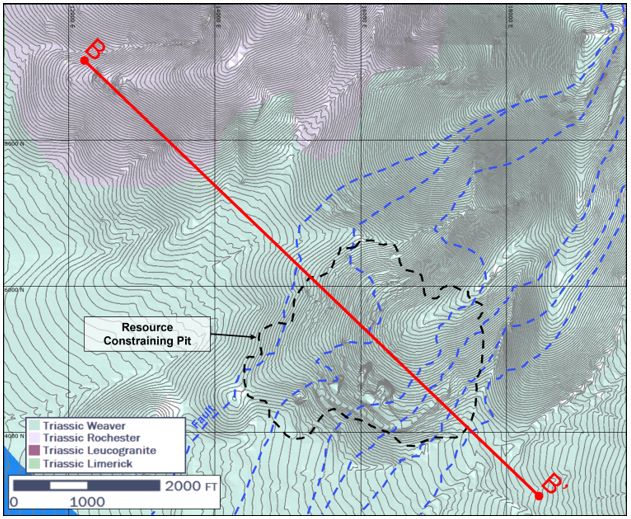

| Figure 6‑4: | Geological Plan, Rochester | 6-9 |

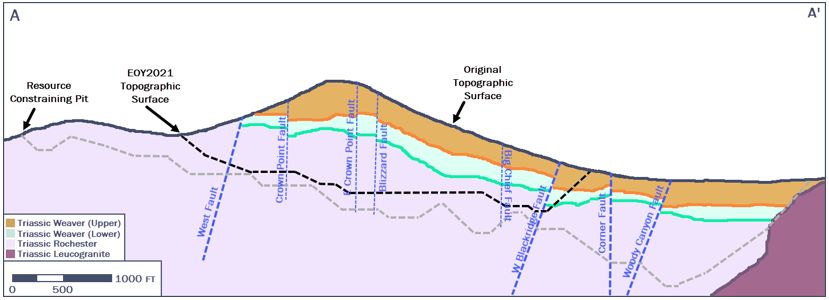

| Figure 6‑5: | Geological Cross Section, Rochester | 6-10 |

| Figure 6‑6: | Geological Plan, Nevada Packard | 6-12 |

| Figure 6‑7: | Geological Cross Section, Nevada Packard | 6-13 |

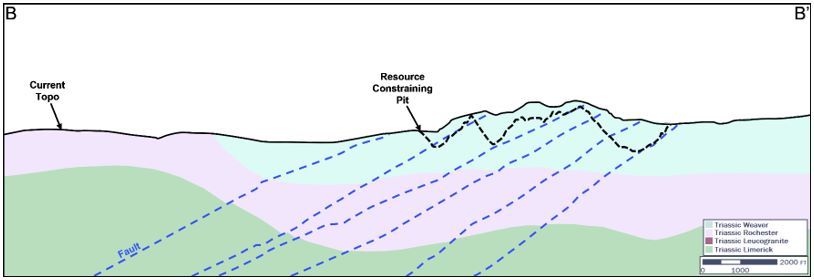

| Figure 7‑1: | Exploration Prospects | 7-3 |

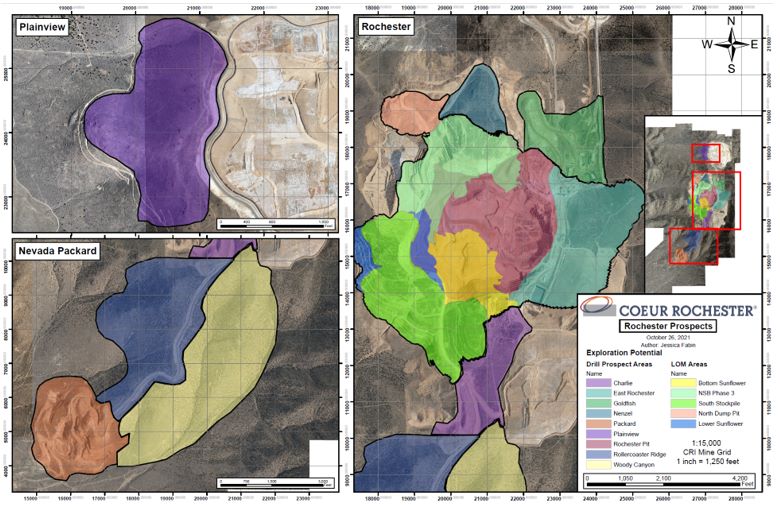

| Figure 7‑2: | Project Drill Collar Location Plan | 7-10 |

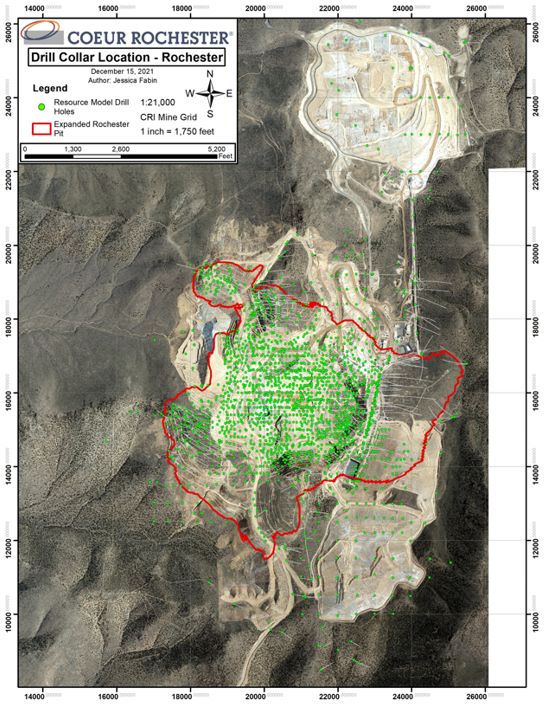

| Figure 7‑3: | Drill Collar Location Plan, Rochester | 7-13 |

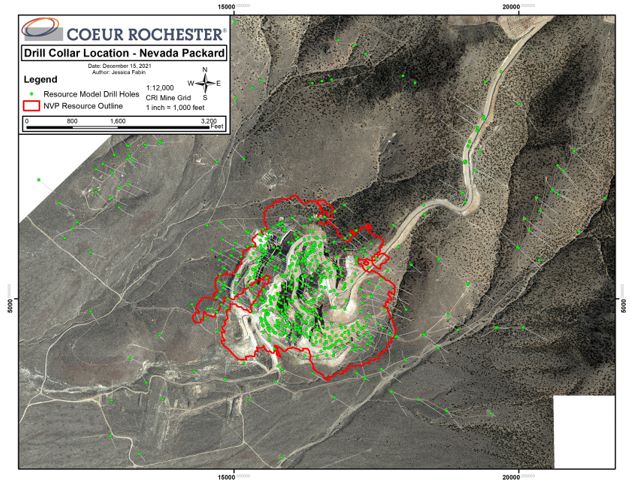

| Figure 7‑4: | Drill Collar Location Plan, Nevada Packard | 7-14 |

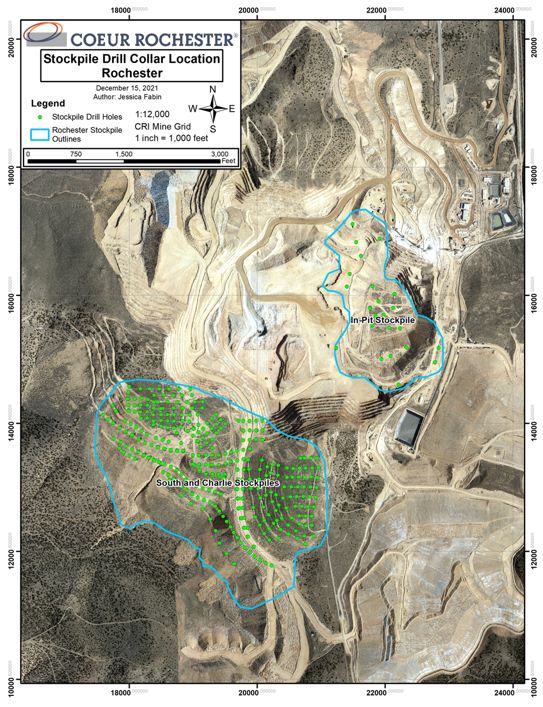

| Figure 7‑5: | Rochester Stockpile Drill Collar Location Map | 7-15 |

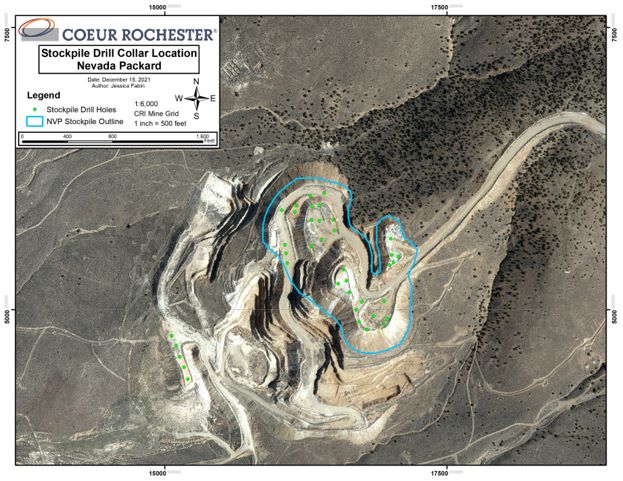

| Figure 7‑6: | Nevada Packard Stockpile Drill Collar Location Map | 7-16 |

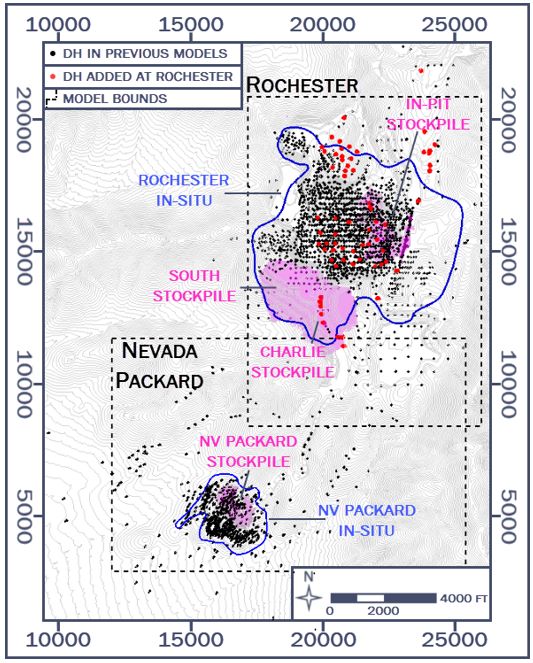

| Figure 11‑1: | Rochester and Nevada Packard Model Areas | 11-2 |

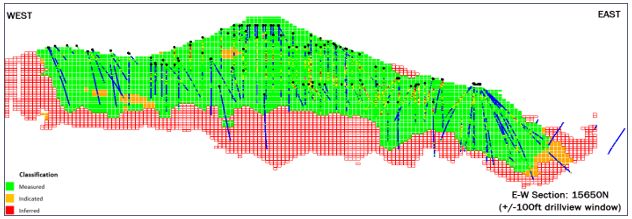

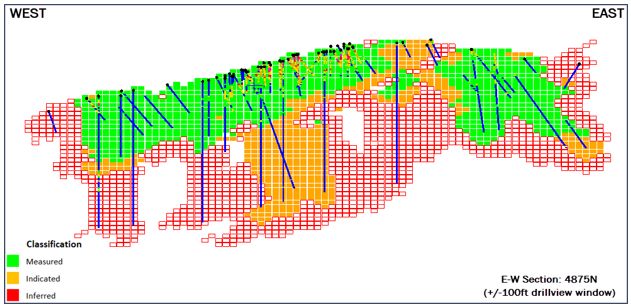

| Figure 11‑2: | Cross-Sectional View Of Rochester Model Classification | 11-11 |

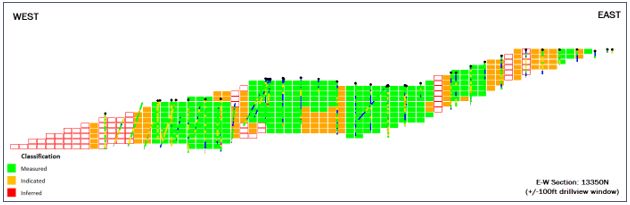

| Figure 11‑3: | Cross-Sectional View Of South-Charlie Stockpile Model Classification | 11-11 |

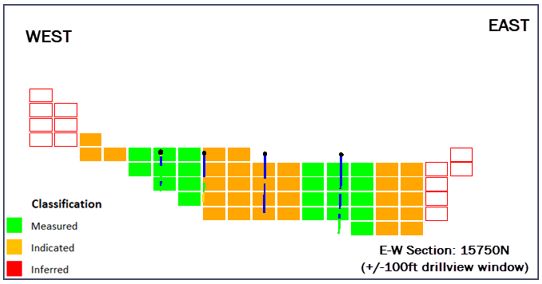

| Figure 11‑4: | Cross-Sectional View Of Rochester In Pit Stockpile Model Classification | 11-12 |

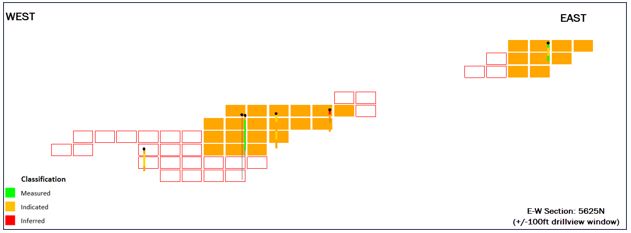

| Figure 11‑5: | Cross-sectional View Of Nevada Packard Model Classification | 11-12 |

| Figure 11‑6: | Cross-sectional View Of Nevada Packard Stockpile Model Classification | 11-13 |

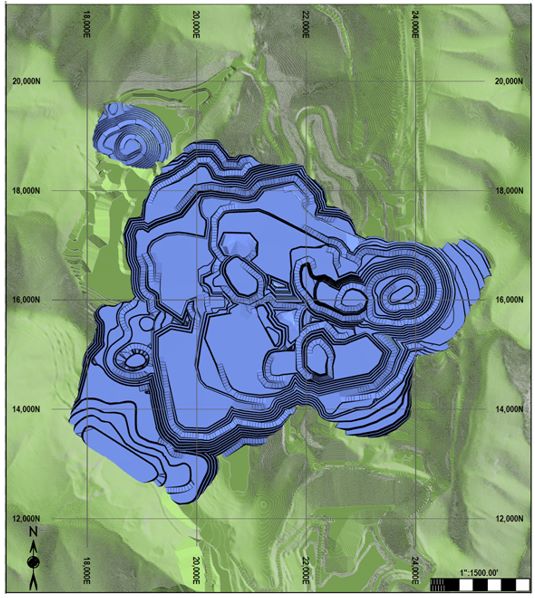

| Figure 13‑1: | 2020 Rochester LOM Pit Design (final pit outline) | 13-4 |

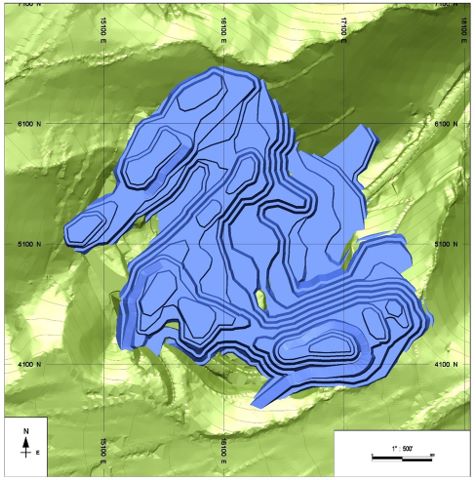

| Figure 13‑2: | 2020 Nevada Packard LOM Pit Design (final pit outline) | 13-5 |

| Figure 14‑1: | Process Flowsheet, Rochester | 14-2 |

| Figure 15‑1: | POA 11 Authorized Facilities at Rochester | 15-4 |

Appendix A: Mineral Tenure

Mr. Christopher Pascoe, RM SME, Mr. Brandon MacDougall, P.E., Mr. Matthew Bradford, RM SME, and Mr. Matthew Hoffer, P.G., prepared a technical report summary (the Report) for Coeur Mining, Inc. (Coeur), on the Rochester Gold Operations (the Rochester Operations or the Project), located in Nevada.

Coeur’s wholly-owned subsidiary, Coeur Rochester, Inc. (Coeur Rochester) is the operating entity.

The Report was prepared to be attached as an exhibit to support mineral property disclosure, including mineral reserve and mineral resource estimates, for the Rochester Operations in Coeur’s Form 10-K for the year ended December 31, 2021.

Mineral resources and mineral reserves are reported for Rochester and Nevada Packard. Mineral reserves are also estimated for material in stockpiles.

Unless otherwise indicated, all financial values are reported in United States (US) currency (US$) including all operating costs, capital costs, cash flows, taxes, revenues, expenses, and overhead distributions. Unless otherwise indicated, the US customary system is used in this Report. Mineral resources and mineral reserves are reported using the definitions in Item 1300 of Regulation S–K (17 CFR Part 229) (SK1300). Illustrations, where specified in SK1300, are provided in the relevant Chapters of report where that content is requested. The Report uses US English.

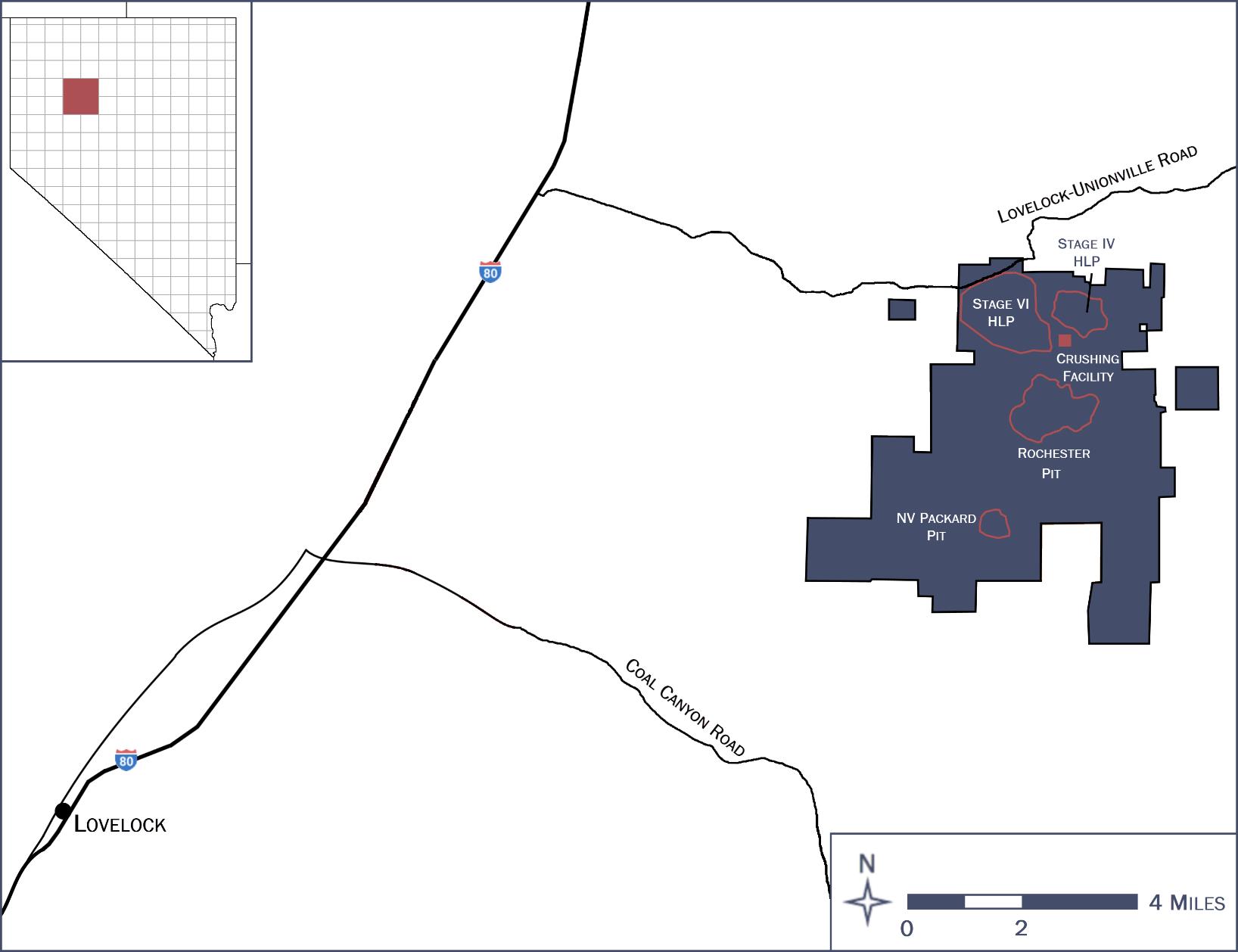

The Rochester Operations are located in the Humboldt Range of northwestern Nevada, approximately 13 miles east of Interstate 80 from the Oreana–Rochester exit, and 26 miles northeast of the City of Lovelock in Pershing County, Nevada. Lovelock, located approximately 90 miles northeast of Reno, Nevada, is the nearest town.

Primary access to Rochester is by way of the Limerick Canyon Road from Interstate Highway 80 (I-80) at the Oreana-Rochester exit (Exit 119). Primary access to Nevada Packard is by way of a two-mile haulage road from the Rochester Pit located on land controlled by Coeur Rochester.

The climate in the Rochester Operations area is typical of north–central Nevada, with hot summers and cold winters. Operations are conducted year-round.

The Rochester Operations are located within the basin-and-range physiographic province in the north–south trending Humboldt Range. The operations area encompasses elevations ranging from 4,960 ft at the Nevada Packard deposit, to approximately 7,090 ft at the highest point of the Rochester Operations. Vegetation is sparse, consisting of high desert grasses and shrubs with a sparse assortment of trees in the higher elevations.

| 1.4 | Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements |

The entire Project area covers 17,004 net acres, consisting of 761 owned and 13 leased federal unpatented lode claims and six (6) owned federal unpatented placer claims, totalling 11,625 net acres of public land owned and 269 net acres of public land leased, in total 11,894 acres of public land; 21 patented lode claims consisting of 357 acres; and interests owned in 4,793 gross acres of additional real property.

The federal mining claims and fee lands provide Coeur with the required surface rights to support the life-of-mine (LOM) plan.

An agreement is in place with Pershing County for road maintenance. Coeur also has a nonexclusive pipeline, electric power line, and telephone line license in place, which is maintained with an annual fee payment. Coeur also holds a number of rights-of-way granted by the Bureau of Land Management (BLM).

Coeur holds a number of water right permits issued by the Nevada Division of Water Resources. These permits allow Coeur to appropriate water in the Buena Vista Valley Hydrographic Sub-Basin and the Packard Valley Sub-Basin. The water right permits held by Coeur are sufficient to operate under the current LOM plan.

There are a number of royalties payable on the claims. However, the only royalty that would be payable in the current LOM plan is to Asarco, and that royalty is tied to the silver price. The royalty is payable when the average quarterly market price of silver equals or exceeds $26.58/oz Ag, indexed for inflation, up to a maximum rate of 5% with the condition that the Rochester mine achieves positive cash flow for the applicable year. If cash flow is negative in any calendar year, the maximum royalty payable is $250,000.

The Rochester property is secured pursuant to Coeur’s revolving credit facility.

| 1.5 | Geology and Mineralization |

Mineralization in the Rochester district exhibits characteristics of both low-sulfidation and intermediate-sulfidation precious metal systems, complicated by supergene enrichment processes and significant oxidation.

The Rochester and Nevada Packard mines are located on the southern flank of the Humboldt Range within the Basin-and-Range province, where late Tertiary extension created large listric normal faults bounding generally north–south-trending mountain ranges and adjacent down-dropped valleys. Tertiary volcanism produced the Limerick, Rochester, and Weaver Formations of the Koipato Group. Both the Rochester and Nevada Packard deposits are hosted in predominately rhyolitic flows and tuffs of the Koipato Group.

A major structural feature within the southern portion of the Humboldt Range is the Black Ridge fault system, which is an extensive shear zone that is, in places, hundreds of feet wide. Most of the Rochester silver–gold mineralization occurs in hanging wall faults, splays, and cross-faults within the Black Ridge system.

Mineralization is structurally controlled. Economic mineralization is hosted mainly in the oxide zone, where the Rochester–Weaver Formation contact is the primary host for silver–gold mineralization, followed and influenced by mineralized fault zones with associated fracture, stockwork and disseminated mineralization away from the faults. The contact is extensively brecciated and healed by silica in both the Rochester and Weaver Formations. Quartz veins and veinlets typically exhibit both parallel and cross-cutting features, indicating multiple mineralizing events.

Acanthite and chlorargyrite are the most abundant oxide silver phases. Below the oxidation zone, the hypogene profile is preserved, with the main minerals including pyrite, sphalerite, galena, argentiferous tetrahedrite, chalcopyrite, arsenopyrite, and pyrargyrite.

| 1.6 | History and Exploration |

Mineralization was discovered in the area in the early 1900s. Where known, the following companies have had involvement in the Project area, prior to Coeur’s Project interest: Rochester Hills Mining Co., Rochester Mines Co., Nevada Packard Mines Co., Rochester Silver Corp., Nenzel Crown Point Mining Co., Rochester Consolidated Mines Co., Western Properties Co., Silver State Mines Co., Asarco, Nevada Packard Mines Company, Cordero Mining Company, D.Z. Exploration, the Nevada Packard Joint Venture, Wharf Resources, Rye Patch Gold, and Alio Gold. Work completed included production from underground workings during the earlier 20th century, grab sampling, mud rotary, percussion, and reverse circulation (RC) drilling, metallurgical test work, production scale heap leach test work, and permitting activities.

Coeur acquired the Rochester property from Asarco in 1983, and the Nevada Packard property in 1996, from local prospectors. Work completed includes geological mapping, geochemical sampling (soil, rock chip, stream sediment), ground and airborne geophysical surveys (induced polarization, gravity, magnetic) RC and limited core drilling, mining studies, permitting activities, metallurgical test work, mineral resource and mineral reserve estimates, open pit mining, and heap leaching. Mining commenced in 1986 from the Rochester open pit and in 2003 from the Nevada Packard open pit.

The Rochester deposit remains open at depth in areas where earlier drilling terminated in potentially economic grades. Several structural trends are being explored where the structures exit the pit walls. These areas are targeted based on grade and structural mapping. The area northwest of the pit is considered to have the most potential.

The drill database for the Project area contains 3,461 drill holes (1,563,181 ft). These data are primarily reverse circulation (RC) holes with limited core drilling. Core and RC drilling supports mineral resource estimation.

There are 588 drillholes completed by multiple operators that are flagged in the acQuire drill hole database to be excluded from the resource estimates. The drill holes are excluded due to unvalidated collar, survey, and/or analytical data. Of these drill holes, 529 are excluded from the Rochester model, 42 are excluded from the Nevada Packard model, and two are excluded from the stockpile model.

Depending on the drill program and drill type, geological data that could be collected from drill hole logging included location details, recovery data, rock character, lithology, alteration (type/degree), quartz veining, sulfide presence, oxidation intensity, structural indicators, and accessory mineralogy. Geotechnical data are collected from core holes. Currently, RC chip trays are retained, and core is photographed.

Core recovery is generally good.

Collar survey methods varied, depending on drill campaign, operator and deposit, and could include Total Station and global positioning system (GPS) instruments.

Prior to 1995, drill holes were sporadically down-hole surveyed with gyroscopic instruments. Downhole surveys were used after 1995 for all angled holes and for vertical holes >400 ft deep using either surface recording gyroscopic, Maxibor, or North Seeker gyroscopic instruments.

Coeur samples RC drill cuttings on either 5 ft or 10 ft intervals. Core logging and sampling intervals ranged from a minimum of 1 ft. to a maximum of 10 ft., based on geologic characteristics.

A density of 0.078 st/ft3 was used for both Rochester and Nevada Packard. This density was confirmed by the on-going mining operations and third-party studies.

Independent primary and umpire laboratories used, and where recorded in the database, include American Assay Laboratories in Sparks, Nevada, ALS Chemex, located in Sparks, Nevada (ALS); Pinnacle Laboratories, located in Lovelock, Nevada; Inspectorate/Bureau Veritas Laboratory, located in Sparks, Nevada; Skyline Laboratories, located in Tucson, Arizona; and McClelland Laboratories Inc., located in Sparks, Nevada (McClelland). Depending on the laboratory and time used, accreditations could include ISO17025:2005, ISO9001 and ISO9002. Samples were also submitted to the Rochester mine laboratory, which was not independent and was not ISO-certified. The Rochester mine laboratory is primarily used for grade control analysis.

Sample preparation depended on the analytical laboratory used. Methods included drying; crushing to -⅜ in, primary crushing to ¼ in, secondary crushing to 10 mesh, crushing to 10 mesh (70% passing) and pulverizing to -100 mesh, 150 mesh or 200 mesh (85% or 80% passing).

Analytical methods included:

| • | Gold: one assay ton fire assay, atomic absorption spectroscopy (AAS); fire assay with gravimetric finish; inductively-coupled plasma (ICP) finish |

| • | Silver: fire assay with AAS finish; fire assay with gravimetric finish; ICP finish; ICP atomic emission spectroscopy (AES) finish; ICP emission spectroscopy (ES) finish; ICP optical emission spectroscopy (OES) finish; |

| • | Multi-element: 33-element suite using ICP-ES; 35 element suite using ICP-ES; 45-element suite using ICP-ES or ICP mass spectrometry (MS). |

Prior to 2008, Coeur inserted blanks, duplicates and standard reference materials (standards) into the sample stream. From 2008–2015, insertions included a minimum of 5% standards, 5% blanks, and 7.5% duplicates. On a quarterly basis, 11% of all samples were selected (10% from pulps and 1% from coarse rejects) and sent to ALS for analysis as umpire samples. From 2016 onward, the quality assurance and quality control (QA/QC) program included insertion of blanks, duplicates and standards into the sample stream, and check assaying of selected samples at either Bureau Veritas or McClelland.

Data verification included internal and external database audits. Internal verification included: a detailed review of all documentation and assay data related to each drill hole; drill hole collar audits; and QA/QC reports. External verification was undertaken by third-parties.

The QP personally undertook selected QA/QC verification and participated in programs to verify selected drill data prior to mineral resource estimation. The QP also works on site, and is familiar with the ongoing operations.

The QP is of the opinion that the data verification programs for Project data adequately support the geological interpretations, the analytical and database quality, and therefore support the use of the data in mineral resource and mineral reserve estimation, and in mine planning.

For a portion of the drilling in the Nevada Packard stockpile area where no physical collar or downhole surveys were conducted, the confidence classification for blocks not supported by other drill holes was restricted to inferred.

| 1.9 | Metallurgical Test Work |

Independent metallurgical test work facilities used over the Project life include McClelland Laboratories, Kappes, Cassiday & Assoc., Newfields, FLSmidth and Eagle Engineering. Test work conducted included permeability testing, column leach and bottle roll leach test work. Additionally, bench-top high pressure grind roll (HPGR) test work as well as clay and mineralogical categorization have been performed.

The Rochester Operations have an on-site analytical laboratory that assays process solutions, crusher and run-of-mine (ROM) ore samples, and refinery samples. The on-site metallurgical laboratory is used for column leach test, bottle roll tests, and characterizing the behavior of new ores. The laboratory is not independent.

Current metallurgical test work can include:

| • | Daily samples: contained moisture, size fractions and assayed for precious metal content. Data generated from these daily samples is used to characterize daily production; dry tons produced from each ore source and gold and silver quantities delivered to the leach pad from each ore source; |

| • | Monthly column leach tests and bottle roll leach tests: recovery trends for gold and silver, size by grade recovery, reagent consumption, and permeability. Results are used to forecast leach pad recoveries. |

Metallurgical test work at Rochester, in coordination with modern heap leach modeling programs, continues to refine and confirm expected metal recovery rates and ultimate recovery values. This testing provides better understanding of process optimization of the leach pads, metal inventory in the leach pads, potential cost reduction, increase crusher throughput, and to provide engineering support on future operational planning. Ultimate recovery of Rochester ore is assumed to be 20 years from the date leaching commences.

Coeur uses heap leach recovery models and recovery curves based on test work and operations to forecast recovered gold and silver production from actual and/or forecasted mineralized product placed on the leach pads. The models apply recovery rates to the product type (crushed, ROM), tonnage, depth to liner, contained ounces placed on each leach pad, and various kinetic factors to determine the expected recovered production in each month. The predicted values are compared to actual production to ensure accuracy and provide confidence in the models’ ability to predict ounce production.

Metallurgical test results obtained from several test work programs conducted during the past three years show relatively low variability between several different locations with respect to gold and silver recovery assuming the sulfur content is below 0.7% and the crush size is held constant.

Based on extensive operating experience and test work, there are no known processing factors of deleterious elements that could have a significant effect on the economic extraction of the mineral reserve estimates. None of the deposits contain sufficient quantities of sulfide minerals, organic carbon or silica encapsulation to be categorized as refractory ore

| 1.10 | Mineral Resource Estimation |

| 1.10.1 | Estimation Methodology |

Mineral resources were estimated for Rochester and Nevada Packard, and for the Rochester in-pit, Charlie, South, and Nevada Packard stockpiles.

Geologic modeling can include inputs from in-pit geologic mapping, drill log interpretation and surface mapping. A total of 37 domains were generated for Rochester, seven for Nevada Packard. No domaining was used for the Charlie and South stockpiles. The Nevada Packard stockpile has four zones assigned, based on stockpile location, not geology.

All deposits were subject to exploratory data analysis methods, which included histograms, cumulative probability plots, box and whisker plots, and contact analysis. In general, domains were treated as soft for mineral resource estimation purposes.

Rock types were assigned a density of 0.078 st/ft3 at Rochester and Nevada Packard. The density assumption for stockpile material also 0.078 st/ft3, with a 37% swell factor applied.

All of the models use 10 ft composites. Review of outlier data indicated that gold and silver grade caps should be imposed at Rochester, Nevada Packard, and the South and Charlie stockpiles but no caps were required for the Rochester in-pit and Nevada Packard stockpiles.

Variography was performed on all models in Supervisor to obtain search distances and directions for interpolation.

Ordinary kriging (OK) was selected as the estimation method for all silver and gold domains in the Rochester model. A single pass estimate was completed for each domain. The Rochester search distances varied by domain. All domains were informed by a minimum of two composites, but the maximum number of composites used could vary from 20–32. The maximum number of composites per drill hole was set at four. The minimum number of octants was set at two, and the maximum number of composites per octant was set at eight.

The resource model for the South and Charlie stockpiles uses inverse distance weighting to the second power (ID2) interpolation with 10 ft composites and a 120 ft search distance, using 3–15 samples, with a limit of three samples per drill hole. A minimum of one drill hole was allowed for interpolation. A second estimation pass was applied to blocks that fell outside of the blocks that were estimated in the first pass. The second pass estimate used a search distance of 1,500 ft and a minimum of one sample and maximum of five samples to estimate outlier blocks.

The resource model for the Rochester in-pit stockpile uses a single pass ID2 interpolation with 10 ft composites and a 300 ft search distance, using 3–15 samples, with a limit of three samples per drill hole. A minimum of one drill hole was allowed for interpolation.

OK was selected as the reported estimation method for all silver and gold domains in the Nevada Packard estimate. A single pass estimation was completed for each domain. All domains were informed by a minimum of two composites, but the maximum number of composites used could vary from 24–40. The maximum number of composites per drill hole was set at four. The minimum number of octants was set at two, and the maximum number of composites per octant was set at eight.

The estimation method chosen for the Nevada Packard stockpile model uses ID2 interpolation with 10 ft composites and a 100 x 100 x 50 ft horizontal search ellipse using 1–12 samples, with a limit of two samples per drill hole. A second pass model was created to estimate outlier blocks using an ID2 interpolation with a 200 x 200 x 50 ft search ellipse using the same sample restrictions as the primary pass.

Model validation included visual validation, construction of grade–tonnage curves and comparison of the grade–tonnage curves to the original estimate, swath plots, comparison of block model statistics to the sample assay and composite statistics, and reconciliation with available blast-hole data by comparing the resource OK estimate to an ID2 blast-hole model for the Rochester and Nevada Packard models. No material biases or errors were noted from the reviews.

Mineral resources were classified based on a combination of the variogram range, distance to the nearest composite, number of composites used in the estimate, and number of drill holes used in the estimate.

For each resource estimate, an initial assessment was undertaken that assessed likely infrastructure, mining, and process plant requirements; mining methods; process recoveries and throughputs; environmental, permitting and social considerations relating to the proposed mining and processing methods, and proposed waste disposal, and technical and economic considerations in support of an assessment of reasonable prospects of economic extraction.

Mineral resources amenable to open pit mining were constrained within conceptual pit shells. Stockpile material was estimated within the stockpile dimensions.

The gold price used in resource estimation is based on long-term analyst and bank forecasts, supplemented with research by Coeur’s internal specialists. The estimated timeframe used is the 13-year LOM that supports the mineral reserve estimates. The forecast is US$1,700/oz Au and US$22/oz Ag for the mineral resource estimate.

The NSR cutoff used to tabulate resources within a constraining pit is not required to consider the mining costs and is only required to pay for the process and G&A costs. At Rochester, this equates to a NSR cutoff of $2.55 for oxides and $2.65 for sulfides (≥0.7% total sulfur). At Nevada Packard, this equates to a single NSR cutoff of $3.70 for all material because there are currently no sulfides estimated within the mineral resources there.

| 1.10.2 | Mineral Resource Statement |

Mineral resources are reported using the mineral resource definitions set out in SK1300.The reference point for the estimate is in situ for those estimates within conceptual open pit outlines, and within stockpiles for those estimates of stockpiled material.

Mineral resources are reported exclusive of mineral reserves in Table 1‑1 and Table 1‑2. The estimates are current as at December 31, 2021. Estimates are reported on a 100% ownership basis.

The Qualified Person for the estimate is Mr. Matthew Bradford, RM SME, a Coeur employee.

Table 1‑1: Summary of Gold and Silver Measured and Indicated Mineral Resources, Rochester, Nevada Packard, and Stockpiles, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price)

| Category | Tons (st) | Average Grade (oz/st) | Contained Ounces (oz) | NSR Cut-off (US$/st) | Metallurgical Recovery (%) |

| Au | Ag | Au | Ag | Au | Ag |

| Measured | 191,889,000 | 0.002 | 0.29 | 372,000 | 56,573,000 | 1.50–2.65 | 15.2–93.7 | 0–61.0 |

| Indicated | 39,565,000 | 0.002 | 0.33 | 74,000 | 12,932,000 | 1.50–2.65 | 15.2–93.7 | 0–61.0 |

| Total measured and indicated | 231,454,000 | 0.002 | 0.30 | 443,000 | 69,505,000 | 1.50–2.65 | 15.2–93.7 | 0–61.0 |

Table 1‑2: Summary of Gold and Silver Inferred Mineral Resources, Rochester, Nevada Packard, and Stockpiles, as at December 31, 2021 (based on US$1,700/oz gold price and US$22/oz silver price))

| Category | Tons (st) | Average Grade (oz/st) | Contained Ounces (oz) | NSR Cut-off (US$/st) | Metallurgical Recovery (%) |

| Au | Ag | Au | Ag | Au | Ag |

| Inferred | 128,410,000 | 0.002 | 0.30 | 243,000 | 38,626,000 | 1.50–2.65 | 15.2–93.7 | 0–59.5 |

Notes to accompany mineral resource estimates:

| 1. | The mineral resource estimates are current as of December 31, 2021, and are reported using the definitions in Item 1300 of Regulation S–K (17 CFR Part 229) (SK1300). |

| 2. | The reference point for the mineral resource estimate is in situ and stockpile. The Qualified Person for the estimate is Mr. Matthew Bradford, RM SME, a Coeur employee. |

| 3. | Mineral resources are reported exclusive of mineral reserves on a 100% ownership basis. |

| 4. | Mineral resources for Rochester and Nevada Packard are tabulated within a confining pit shell that uses the following input parameters: metal price Au = $1,700/oz and Ag = $22/oz; oxide recovery Au = 77.7–93.7% and Ag = 59–61%; sulfide recovery Au = 15.2–77.7% and Ag = 0.0–59% with a net smelter return cutoff of $2.55–$3.70/st oxide and $2.65/st sulfide, where the NSR is calculated as resource net smelter return (NSR) = silver grade (oz/ton) * silver recovery (%) * [silver price ($/oz) - refining cost ($/oz)] + gold grade (oz/ton) * gold recovery (%) * [gold price ($/oz) - refining cost ($/oz)]; and variable pit slope angles that approximately average 43º over the life-of-mine. |

| 5. | Rounding of short tons, grades, and troy ounces, as required by reporting guidelines, may result in apparent differences between tons, grades, and contained metal contents. |

| 1.10.3 | Factors That May Affect the Mineral Resource Estimate |

Factors that may affect the mineral resource estimates include: metal price and exchange rate assumptions; changes to the assumptions used to generate the gold equivalent grade cut-off grade; changes in local interpretations of mineralization geometry and continuity of mineralized zones; changes to geological and mineralization shape and geological and grade continuity assumptions; additional drilling, which may change confidence category classification in the pit margins from those assumed in the current pit optimization; additional sampling that may redefine the silver and/or gold grade estimates in certain areas of the resource estimation; density and domain assignments; changes to geotechnical, mining and metallurgical recovery assumptions; Changes to the input and design parameter assumptions that pertain to the assumptions for open pit mining or stockpile rehandling constraining the estimates; and assumptions as to the continued ability to access the site, retain mineral and surface rights titles, maintain environment and other regulatory permits, and maintain the social license to operate.

| 1.11 | Mineral Reserve Estimation |

Mineral reserves were converted from measured and indicated mineral resources. Inferred mineral resources were set to waste.

| 1.11.1 | Estimation Methodology |

Mining rates are primarily driven by crusher capabilities based on their physical configuration and environmental permit limits. The selective mining unit is sized at 50 x 50 x 30 ft. The LOM plan mines material below the water table, which is considered in the existing permitting.

Pit optimizations were done using the Lerchs–Grossmann algorithm using Whittle software. Appropriate cost and mining schedules were applied using cost estimates forecast for the LOM.

Cut-off grades were based on NSR equations. The break-even NSR cutoff grade is equal to the total estimated long-term processing costs (including general and administrative (G&A) costs. Mining costs are a sunk cost for blocks contained inside an economic pit limit and therefore do not need to be included in the break-even cutoff grade. If a given block meets or exceeds the processing cost, it should report to the crusher. If a block is placed in a low-grade stockpile, it must have an NSR value high enough to meet the break-even cutoff grade plus the cost of rehandle. If it does not, it is placed in a sub-grade stockpile that is effectively treated as waste.

The densities used for the mineral reserve estimate are:

| • | In situ (open pit): 0.078 ton/ft3; |

| • | Stockpile: 0.057 ton/ft3. |

The assigned in situ moisture is 3–5% and stockpile material is forecast to average 5% moisture.

No loss or dilution was modelled in the pit optimization runs. Due to the disseminated nature of the deposit, the margins around the orebody are mineralized waste, reducing the impacts of dilution during mining.

Break-even cut-offs are:

| • | Rochester: oxide: US$2.55/st; sulfide US$2.65/st; |

| • | Nevada Packard: oxide: US$3.70/st. There is no sulfide material mined at Nevada Packard. |

| 1.11.2 | Mineral Reserve Statement |

Mineral reserves have been classified using the mineral reserve definitions set out in SK1300 and are reported on a 100% ownership basis. The reference point for the mineral reserve estimate is the point of delivery to the heap leach facilities.

Mineral reserves are current as at December 31, 2021. Mineral reserves are reported in Table 1‑3. The Qualified Person for the estimate is Mr. Brandon MacDougall, P.E., a Coeur Rochester employee.

| 1.11.3 | Factors That May Affect the Mineral Reserve Estimate |

Factors that may affect the mineral resource estimates include: predicted commodity prices; metallurgical recovery forecasts; operating cost assumptions; geotechnical and hydrological assumptions; and permitting and social license assumptions.

Mineral reserves are exploited using conventional open pit methods and equipment.

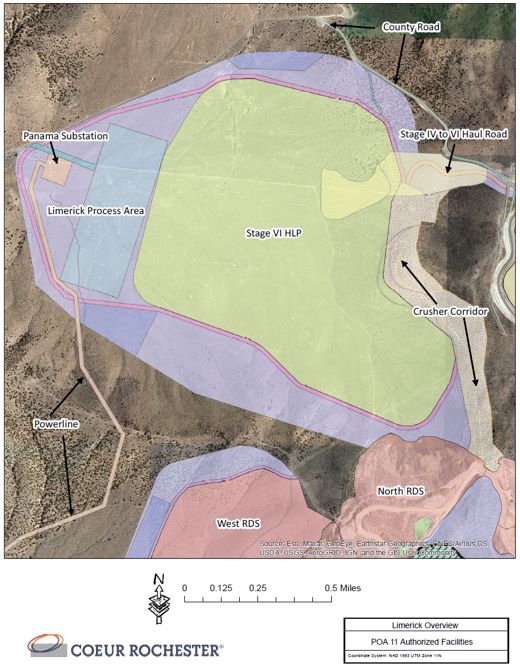

Mining operations at Rochester are currently at planned capacity under the current crusher configuration. The LOM plan will increase production levels in line with the 11th Plan of Operations Amendment (POA 11), which was issued in 2020. POA 11 allows for additional pad capacity, additional waste rock storage facilities (WRSFs), construction of new crushing and process facilities, and extensions of the Rochester pit and continued operations through the end of planned mine life.

Pit slope designs are based on evaluations and reports prepared by third-party consultants. The pit slope design parameters for Rochester and Nevada Packard assume overall pit slope angles that range from 20–51º and 37–52.4º respectively.

Groundwater pumping requirements to support ongoing mine and process operations are anticipated to be completed as needed through existing production wells. As such, hydrogeologic factors have not been considered in this report.

Detailed pit designs and phase plans are based on the economic pit limits and are used to generate a mining production schedule for both pits. Designs assumed 30 ft bench heights, double lane haul road design widths of 88 ft, single lane haul road design widths of 65 ft, and maximum haul road gradients of 10%.

Blasting services are contracted out, and the contractor is responsible for obtaining, securing explosive agents, loading blast holes, and initiating the blasts.

As part of the approved Plan of Operations (PoO), there is a waste rock management plan. All waste rock is placed either inside the pit perimeter as backfill, or outside the pit in approved WRSFs. All waste rock is evaluated to determine if it is potentially acid-generating (PAG).

Rochester annual crusher throughputs for 2022 through to Q3 2023 are based on the limitations of existing crushing facilities and are estimated at 13.9 Mst/a. Crusher throughputs are anticipated to increase to 32.0 Mst/a with the addition of a new crushing system in 2023. Rochester operations are expected to continue through late-2034, a mine life of approximately 12 years. Low grade stockpiles will be processed through the crushing system at the end of mine life during 2033-2034. The Nevada Packard production schedule is based on an assumed crusher throughput of 6 Mst/a. The anticipated LOM for the Nevada Packard deposit 6 years. Nevada Packard stockpiles will be processed at the end of mine life during years 6-7.

Equipment is conventional to open pit operations. The primary equipment fleet includes front-end loaders, hydraulic shovels, blasthole drills and haul trucks.

The personnel requirement for the remaining LOM averages 175 persons.

Table 1‑3: Summary of Gold and Silver Proven and Probable Mineral Reserve Estimates, as at December 31, 2021 (based on US$1,400/oz gold price and US$20/oz silver price)

| Category | Tons (Mst) | Average Grade (oz/st) | Contained Ounces

(koz)

| NSR Cut-off (US$/st) | Metallurgical Recovery (%) |

| Ag | Au | Ag | Au | Ag | Au |

| Total proven | 386,008 | 0.388 | 0.003 | 149,652 | 998 | 2.55–2.65 | 27–61 | 71-95 |

| Total probable | 31,769 | 0.365 | 0.003 | 11,593 | 82 | 2.55–2.65 | 27–61 | 71-95 |

| Total Proven & Probable | 417,777 | 0.386 | 0.003 | 161,245 | 1,080 | 2.55–2.65 | 27–61 | 71-95 |

Notes to accompany mineral reserve estimates:

| 6. | The mineral resource estimates are current as of December 31, 2021, and are reported using the definitions in Item 1300 of Regulation S–K (17 CFR Part 229) (SK1300). |

| 7. | The reference point for the mineral reserve estimate is the point of delivery to the heap leach facilities. The Qualified Person for the estimate is Mr. Brandon MacDougall, P.E., a Coeur Rochester employee. |

| 8. | Mineral reserve estimates are tabulated within a confining pit shell and use the following input parameters: gold price of US$1,400/oz Au and silver price of US$20/oz Au; Rochester oxide recovery Au = 85% and Ag = 59%; Nevada Packard oxide recovery Au = 95% and Ag = 61%; ROM recovery Au = 71% and Ag = 27%; with a Rochester net smelter return cutoff of $2.55/st oxide and US$2.65/st sulfide, and a Packard net smelter return cutoff of $3.70, where the NSR is calculated as resource net smelter return (NSR) = silver grade (oz/ton) * silver recovery (%) * [silver price ($/oz) - refining cost ($/oz)] + gold grade (oz/ton) * gold recovery (%) * [gold price ($/oz) - refining cost ($/oz)]; variable pit slope angles that approximately average 43º over the life-of-mine. |

| 9. | Rounding of short tons, grades, and troy ounces, as required by reporting guidelines, may result in apparent differences between tons, grades, and contained metal contents |

Silver and gold recovery at Rochester is via heap leach with a Merrill-Crowe process to recover metal from the leach solutions. The process design was based on a combination of metallurgical test work, study designs and industry standard practices, together with debottlenecking and optimization activities once the leach pads were operational. The design is conventional to the gold and silver industry and has no novel parameters.

From 1986 through mid-2019, Coeur used a three-stage crushing circuit with cone crushing in the tertiary position to produce a nominal ⅜-in product.

In 2019 Coeur adopted high-pressure grind roll crushing technology to replace cone crushers in the tertiary position. The product gradation and operational parameters of the high-pressure grind roll are being optimized for gradation, permeability, and recovery. Crushed material, and at times ROM ore, is placed on heap leach pads.

The crushing circuit currently consists of a jaw crusher followed by cone crusher and an HPGR in the tertiary position. The crusher is directly truck dump fed. The HPGR product is conveyed to the loadout where it is loaded into haul trucks and truck dumped onto the Stage IV heap leach pad.

Cyanide heap leaching is used to extract silver and gold from the ore. Metal-laden pregnant leach solution is then collected from a drain system and Merrill-Crowe processing is used to recover the precious metal.

The Merrill-Crowe facility is operating and assumptions in this Report were made with reference to actual operational results. Metal production is done using furnace flux-smelt refining. Active leaching of new ore and metal recovery is currently taking place on the Stage II, III and IV heap leach pads from material produced through crushing and ROM placement.

Future processing facilities include the Limerick Merrill-Crowe process plant that is planned to be in operation from 2023 through approximately 2035. This process plant is being sized for 13,750 gpm to process solution and recover ounces from the Stage VI leach pad facility, which has a design capacity of 300 Mst.

Metallurgical recovery forecasts are variable by source and destination, and over the LOM plan silver recoveries will range 27.1%-61.4% and gold recoveries will range 71.2%-95.9%. Full details of the various ore sources and destinations can be found in Table 10-6.

Power is supplied from an electrical grid, with generator backup. Water is supplied from production wells. Major consumables include lime, cyanide and zinc. The plant also consumes antiscalant, diatomaceous earth and refinery flux.

Current personnel requirements are approximately 67 persons for crushing and 70 persons for process. As POA 11 comes online Coeur will require approximately 73 persons for crushing and 93 persons for process. This ramp-up will occur over multiple years as equipment and processes are commissioned.

The majority of the infrastructure required to support operations has been constructed and is operational. This includes: two open pits (Rochester and Nevada Packard); crusher and conveyor system; three active heap leach pads (Stage II, Stage III, and Stage IV), one reclaimed heap leach pad (Stage I), one heap leach pad under construction (Stage VI), and one permitted heap leach pad (Stage V); seven waste rock storage facilities (WRSFs); powerlines; production and monitoring water wells; contingency ponds; potable water treatment plant; water pipelines; site buildings; access, light vehicle, and haul roads; consumables storage; security and fencing; explosives magazines; upper and lower parking areas; and data and communications infrastructure.

Additional infrastructure that will be required to support the LOM plan as envisaged in the approved POA 11 consists of the following major areas: expansion of the two open pits; expansion of selected WRSFs; construction of the Stage VI leach pad; Limerick and Nevada Packard Merrill-Crowe process facilities; Limerick crushing and screening facility; installation of a crusher at Nevada Packard; construction of additional water diversion structures, roads, and pipelines; and upgrades to the electrical system. Low-grade ore is stockpiled in the West WRSF and is segregated from the waste rock for potential future processing.

Seven WRSFs have been constructed. POA 11 includes expansions to existing WRSFs with sufficient capacity to handle all expected waste material over the LOM plan.

When mining activities necessitate removal of spent ore from existing leach pads, the spent ore is moved to one of the other heap leach pad facilities.

The Rochester Operations are a zero-discharge facility and has no on-site water treatment facilities. Non-contact stormwater is diverted around process components in permitted conveyances. Water supply for operations comes from three production wells. There is also a potable water well that supplies potable water to the site.

Power is supplied by NV Energy via a 60 kV transmission line that runs through Rochester Canyon. Power is initially received at the Sage Hen substation and terminates at a second mine-site substation located in American Canyon. Step-down transformers are located at the crushing facilities, the maintenance shop and warehouse building, the process building, and several locations along the Stage III leach pad overland conveyor. Motor control centers, which are located adjacent to these transformers, supply all additional electrical requirements.

Upgrades to the electrical utility system will be required to accommodate the proposed infrastructure associated with POA 11. NV Energy’s existing 60 kV transmission line will need upgrades to meet the load increase associated with the proposed Limerick Canyon and Nevada Packard process plants and associated crushing and conveying systems. The proposed upgrade will include service from NV Energy’s 120 kV system at the Oreana substation and approximately 10 miles of new transmission line. A new substation, the Panama substation, will be constructed in Limerick Canyon, on the west side of the proposed Stage VI heap leach pad.

| 1.15 | Markets and Contracts |

Coeur has established contracts and buyers for the silver and gold doré product from the Rochester Operations and has an internal marketing group that monitors markets for its key products. Together with public documents and analyst forecasts, these data support that there is a reasonable basis to assume that for the LOM plan, that the key products will be saleable at the assumed commodity pricing.

Coeur sells its payable silver and gold production on behalf of its subsidiaries on a spot or forward basis, primarily to multi-national banks and bullion trading houses. Markets for both silver and gold bullion are highly liquid, and the loss of a single trading counterparty would not impact Coeur’s ability to sell its bullion.

Coeur uses a combination of analysis of three-year rolling averages, long-term consensus pricing, and benchmarks to pricing used by industry peers over the past year, when considering long-term commodity price forecasts.

Higher metal prices are used for the mineral resource estimates to ensure the mineral reserves are a sub-set of, and not constrained by, the mineral resources, in accordance with industry-accepted practice.

The long-term gold price forecasts are US$1,400/oz Au and US$20/oz Ag for mineral reserves and US$1,700/oz Au and US$22/oz Ag for mineral resources. The QP considers the price forecasts to be reasonable.

Coeur has a contract with a U.S.-based refiner that refines the doré into silver and gold bullion.

There are numerous contracts in place at the Project to support mine development or processing. Currently there are contracts in place to provide supply for all major commodities used in mining and processing, such as equipment vendors, power, explosives, cyanide, tire suppliers, fuel, and drilling contractors. The terms and rates for these contracts are within industry norms. The contracts are periodically put up for bid or re-negotiated as required.

| 1.16 | Environmental, Permitting and Social Considerations |

An initial PoO was approved by the BLM and Nevada Division of Environmental Protection (NDEP) in February 1986. After the approval of the initial PoO, 11 amendments were submitted from 1988–2017, the most recent being POA 11. POA 11 was considered complete by the BLM in September 2017, which initiated an environmental impact statement (EIS) under the National Environmental Policy Act (NEPA). A Record of Decision (ROD) was issued by the BLM on March 30, 2020. A Reclamation Permit for the POA 11 expansion was issued by NDEP Bureau of Mining Regulation and Reclamation (BMRR) on November 5, 2020, with the surety bond in place with the BLM on November 25, 2020.

| 1.16.1 | Environmental Studies and Monitoring |

Baseline studies and monitoring were required for each mine permit obtained. Groundwater discharge plans and waste rock management plans are in place.

The U.S. Army Corps of Engineers issued a determination on October 16, 2018 that there are no Waters of the United States within and surrounding the Project area. This determination is valid until October 16, 2023.

As the mine plans change, permits will be updated as required. Air permits currently limit production through the crushing circuits to 21.9 Mst/a.

| 1.16.2 | Closure and Reclamation Considerations |

Financial surety sufficient to reclaim mine and processing facilities is up to date and held by the BLM, the primary federal agency responsible for regulatory oversight. The Reclamation Plan associated with the financial surety was updated in 2020 and accepted by both the BLM and NDEP–BMRR.

The reclamation cost estimate for Rochester Operations is approximately $163.7 M based on the 2020 Reclamation Cost Estimate. There is an additional approximate $11.4 M added to account for new disturbances within Nevada Packard. This would bring the total reclamation cost estimate to approximately $175.1 M using 2021 cost models.

The Rochester mine has been in operation since 1986 and obtained the required environmental permits and licenses from the appropriate county, state and federal agencies.

Operational standards and best management practices were established to maintain compliance with applicable county, state and federal regulatory standards and permits.

Under POA 11, early works construction began in September 2020 in Limerick Canyon and the construction will be completed in stages.

| 1.16.4 | Social Considerations, Plans, Negotiations and Agreements |

Coeur Rochester has consistently positively impacted the local community and its economy for more than 30 years. The Rochester Operations generate nearly 1,000 direct and indirect jobs, making it the largest employer in Pershing County.

In 2021, Coeur developed a Communication, Community & Government Engagement Strategy to develop new relationships with local communities and leverage existing support during permit actions or other activities influenced by public opinion.

Coeur supports future local leaders through multiple partnerships, including Lowry High School, Nevada Mining Association's Educational Committee, and Build NV. In addition to scholarship funds, Coeur is helping to develop programs that will prepare students for the workforce.

The company is committed to helping preserve Native American cultural heritage while developing mutually beneficial partnerships. Coeur Rochester has also assisted tribes in obtaining vital personal protective equipment to help reduce the spread of COVID-19.

| 1.17 | Capital Cost Estimates |

Capital cost estimates are at a minimum at a pre-feasibility level of confidence, having an accuracy level of ±25% and a contingency range not exceeding 15%.

The basis of the capital estimates are derived from expected equipment needs and project plans and are determined with the assistance of vendor quotes, previous buying experience and/or experience with construction of similar projects. The capital cost estimate includes consideration of historical capital cost estimates.

Major LOM capital costs include, but are not limited to, POA 11 crusher, Merrill-Crowe plant, heap leach pad construction, new crusher, new tertiary screening, and other infrastructure improvements. The POA 11 mine expansion is expected be completed in 2023. Development of the Nevada Packard mine is expected to break ground in 2025 with production commencing in 2027. This mine will also include a new crusher, Merrill-Crowe plant, heap leach facility, mobile equipment and supporting infrastructure.

Capital expenditure for the LOM is estimated at $641 M. Estimated capital expenditures are summarized in Table 1‑4.

| 1.18 | Operating Cost Estimates |

Operating cost estimates are at a minimum at a pre-feasibility level of confidence, having an accuracy level of ±25% and a contingency range not exceeding 15%.

Operating costs were developed based on historical cost performance and first principal calculations based on current commodity costs, labor rates, and equipment costs. The costs are provided for each major cost center: mining, processing, selling expense, and general and administrative (G&A).

Estimated operating costs are summarized in Table 1‑5. The total LOM operating cost estimate is US$2,246.6 M or US$5.38/t placed.

Table 1‑4: Capital Cost Estimate Summary ($k)

| Years | 2022 | 2023 | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 |

| POA 11/Development | 237,356 | 151,114 | | | | | | | |

| Sustaining | 27,850 | 45,449 | 32,624 | 55,800 | 28,679 | 21,530 | 4,689 | 1,680 | 1,744 |

| Nevada Packard | | | | 7,305 | 41,394 | 359 | 359 | 359 | 359 |

| New Leases | (32,245) | | | | | | | | |

| Total | 232,961 | 196,563 | 32,624 | 63,105 | 70,073 | 21,889 | 5,048 | 2,039 | 2,103 |

| Years | 2031 | 2032 | 2033 | 2034 | 2035 | 2036 | 2037 | 2038 | Total |

| POA 11/Development | | | | | | | | | 388,470 |

| Sustaining | 8,695 | 1,619 | 1,700 | 1,500 | | | | | 233,559 |

| Nevada Packard | 359 | 359 | 359 | | | | | | 51,212 |

| New Leases | | | | | | | | | (32,245) |

| Total | 9,054 | 1,978 | 2,059 | 1,500 | | | | | 640,996 |

Note: Numbers have been rounded.

Table 1‑5: Operating Cost Estimate Summary

| Years | Units | 2022 | 2023 | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 |

| Mining | $US (1,000) | 46,021 | 59,732 | 68,656 | 64,648 | 81,575 | 71,916 | 94,129 | 70,171 | 97,726 |

| $/st moved | 1.90 | 1.46 | 1.39 | 1.41 | 1.35 | 1.46 | 1.38 | 1.44 | 1.36 |

| Process | $US (1,000) | 60,201 | 65,016 | 74,159 | 71,679 | 67,936 | 80,098 | 80,662 | 81,666 | 82,341 |

| $/st placed | 3.54 | 4.29 | 2.31 | 2.23 | 2.07 | 2.09 | 2.09 | 2.14 | 2.16 |

| G&A | $US (1,000) | 21,503 | 21,654 | 22,280 | 22,600 | 21,944 | 22,972 | 22,326 | 22,314 | 22,804 |

| $/st placed | 1.26 | 1.43 | 0.70 | 0.70 | 0.67 | 0.60 | 0.58 | 0.59 | 0.60 |

| Selling Cost | $US (1,000) | 1,205 | 1,422 | 2,240 | 2,829 | 2,834 | 2,084 | 2,035 | 2,367 | 2,885 |

| Total Operating Costs | $US (1,000) | 128,503 | 147,823 | 167,335 | 161,819 | 174,289 | 177,131 | 199,291 | 176,671 | 205,883 |

| $/st placed | 7.58 | 9.76 | 5.22 | 5.03 | 5.30 | 4.62 | 5.15 | 4.64 | 5.40 |

| Years | | 2031 | 2032 | 2033 | 2034 | 2035 | 2036 | 2037 | 2038 | Total |

| Mining | $US (1,000) | 125,072 | 71,804 | 71,649 | 27,417 | | | | | 949,796 |

| $/st moved | 1.30 | 1.31 | 1.35 | 1.10 | | | | | 1.38 |

| Process | $US (1,000) | 81,313 | 83,235 | 70,248 | 53,202 | 13,947 | 6,626 | 2,126 | 2,133 | 976,624 |

| $/st placed | 2.10 | 2.17 | 2.11 | 2.13 | | | | | 2.34 |

| G&A | $US (1,000) | 22,038 | 22,358 | 21,296 | 19,293 | 2,749 | 915 | 692 | 374 | 290,112 |

| $/st placed | 0.57 | 0.58 | 0.64 | 0.77 | | | | | 0.69 |

| Selling Cost | $US (1,000) | 2,671 | 2,772 | 2,093 | 1,795 | 1,148 | 211 | 17 | 1 | 30,027 |

| Total Operating Costs | $US (1,000) | 230,666 | 179,450 | 165,340 | 101,725 | 17,844 | 7,752 | 2,872 | 2,508 | 2,247,329 |

| $/st placed | 5.97 | 4.67 | 4.98 | 4.07 | | | | | 5.38 |

Note: Numbers have been rounded.

| 1.19.1 | Forward-Looking Information Caution |

Results of the economic analysis represent forward- looking information that is subject to several known and unknown risks, uncertainties and other factors that may cause actual results to differ materially from those presented here.

Other forward-looking statements in this Report include, but are not limited to: statements with respect to future metal prices and concentrate sales contracts; the estimation of mineral reserves and mineral resources; the realization of mineral reserve estimates; the timing and amount of estimated future production; costs of production; capital expenditures; costs and timing of the development of new ore zones; permitting time lines; requirements for additional capital; government regulation of mining operations; environmental risks; unanticipated reclamation expenses; title disputes or claims; and, limitations on insurance coverage.

Factors that may cause actual results to differ from forward-looking statements include: actual results of current reclamation activities; results of economic evaluations; changes in Project parameters as mine and process plans continue to be refined, possible variations in mineral reserves, grade or recovery rates; geotechnical considerations during mining; failure of plant, equipment or processes to operate as anticipated; shipping delays and regulations; accidents, labor disputes and other risks of the mining industry; and, delays in obtaining governmental approvals.

| 1.19.2 | Methodology and Assumptions |

Coeur records its financial costs on an accrual basis and adheres to U.S. Generally Accepted Accounting Principles (GAAP).

The financial costs used for this analysis are based on the 2022 LOM budget model. The economic analysis is based on 100% equity financing and is reported on a 100% project ownership basis. The economic analysis assumes constant prices with no inflationary adjustments.

The mineral reserves support a mine life of 13 years with mining complete in 2034 and processing and gold–silver production continuing to 2037. Smelting and refining costs are defined by contract.

The active mining operation ceases in 2034; however, closure costs are estimated to be US$ 175.1 M. For the purposes of the financial model, all costs incurred beyond 2040 are included in the cash flow in 2040.

The NPV at 5% is US$ 348.1 M. As the cashflow is based on existing operations, considerations of payback and internal rate of return are not relevant.

The cashflow is summarized in Table 1‑6.

Table 1‑6: Summary Cashflow Table ($M)

| | LOM Total |

| Gross Revenue | 3,800.2 |

| Operating Costs |

| Mining | (949.8) |

| Process | (976.6) |

| G&A | (290.1) |

| Selling | (30.0) |

| Total Operating Costs | (2,246.6) |

| Other Costs | (1.2) |

| Operating Cashflow | 1,552.5 |

| Capital Expenditures | (641.0) |

| Reclamation | (175.1) |

| Cash Flow bef. Taxes | 736.4 |

| Tax | (48.9) |

| Total Free Cash Flow | 687.5 |

| NPV (5%) | 348.1 |

| 1.19.4 | Sensitivity Analysis |

The sensitivity of the Project to changes in metal prices, metallurgical recovery, sustaining capital costs and operating cost assumptions was tested using a range of 20% above and below the base case values. The NPV sensitivity to these parameters is illustrated in Table 1‑7.

The Project is most sensitive to metal prices, less sensitive to operating costs, and least sensitive to capital costs. Grade sensitivity mirrors the sensitivity to metal price.

| 1.20 | Risks and Opportunities |

Factors that may affect the mineral resource and mineral reserve estimates were identified in Chapter 1.10.3 and Chapter 1.11.3 respectively and discussed in more detail in Chapter 11 and Chapter 12.

Risks include: