Technical Report Summary on the Casa Berardi Mine, Northwestern Québec, Canada

Technical Report RSI-M0206.22001

Prepared For

Prepared For

Hecla Mining Company

6500 North Mineral Drive, Suite 200

Coeur d’Alene, Idaho, USA, 83815

February 2024

Technical Report Summary On the Casa Berardi Mine, Northwestern Québec, Canada

TECHNICAL Report RSI-M0206.22001

Prepared by

RESPEC

210 South Rock Boulevard

Reno, Nevada 89502

Prepared for

Hecla Mining Company

6500 North Mineral Drive, Suite 200

Coeur d’Alene, Idaho, USA, 83815

REPORT DATE: February 15, 2024

EFFECTIVE DATE: December 31, 2023

Project Number M0206.22001

NOTE REGARDING FORWARD-LOOKING INFORMATION

This Technical Report Summary contains “forward-looking statements” within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended (and the equivalent under Canadian securities laws), which are intended to be covered by the safe harbor created by such sections. Words such as “may”, “will”, “should”, “expects”, “intends”, “projects”, “believes”, “estimates”, “targets”, “anticipates” and similar expressions are used to identify these forward-looking statements. Such forward-looking statements include, without limitation, statements regarding Hecla’s expectation for its mines and any related development or expansions, including estimated cash flows, production, revenue, costs, taxes, capital, rates of return, mine plans, material mined and processed, recoveries and grade, future mineralization, future adjustments and sensitivities and other statements that are not historical facts. Other forward-looking statements in this Report may involve, without limitation, the following:

/ Probable Mineral Reserves that have been modified from Indicated Mineral Resource estimates.

/ Assumed commodity prices and exchange rates.

/ Proposed mine and process production plan.

/ Projected mining and process recovery rates.

/ Ability to market the two types of concentrate on favorable terms as shown in the life of mine plan.

/ Sustaining capital costs and proposed operating costs.

/ Assumptions as to closure costs and closure requirements.

/ Assumptions as to ability to obtain remaining outstanding permits.

/ Assumptions about environmental, permitting and social risks.

The material factors or assumptions used to develop such forward-looking statements or forward-looking information include that the Hecla’s plans for development and production will proceed as expected and will not require revision as a result of risks or uncertainties, whether known, unknown or unanticipated, to which Hecla’s operations are subject. Estimates or expectations of future events or results are based upon certain assumptions, which may prove to be incorrect, which could cause actual results to differ from forward-looking statements. Such assumptions, include, but are not limited to: (i) there being no significant change to current geotechnical, metallurgical, hydrological and other physical conditions; (ii) permitting, development, operations and expansion of Hecla’s projects being consistent with current expectations and mine plans; (iii) political/regulatory developments in any jurisdiction in which Hecla operates being consistent with its current expectations; (iv) the exchange rate for the USD/CAD being approximately consistent with current levels; (v) certain price assumptions for gold, silver, lead and zinc ; (vi) prices for key supplies being approximately consistent with current levels; (vii) the accuracy of our current mineral reserve and mineral resource estimates; (viii) there being no significant changes to Hecla’s plans for 2024 and beyond with respect to availability of employees, vendors and equipment; (ix) Hecla’s plans for development and production will proceed as expected and will not require revision as a result of risks or uncertainties, whether known, unknown or unanticipated; (x) sufficient workforce is available and trained to perform assigned tasks; (xi) weather patterns and rain/snowfall within normal seasonal ranges so as not to impact operations; (xii) relations with interested parties, including First Nations and Native Americans, remain productive; (xiii) maintaining availability of water rights; (xv) factors do not arise that reduce available cash balances; and (xiv) there being no material increases in our current requirements to post or maintain reclamation and performance bonds or collateral related thereto.

In addition, material risks that could cause actual results to differ from forward-looking statements include, but are not limited to:

/ Unanticipated reclamation expenses.

/ Unexpected variations in quantity of mineralization, grade or recovery rates.

/ Exploration risks and results, including that mineral resources are not mineral reserves, they do not have demonstrated economic viability and there is no certainty that they can be upgraded to mineral reserves through continued exploration.

/ Geotechnical or hydrogeological considerations during operations being different from what was assumed.

/ Failure of mining methods to operate as anticipated.

/ Operating risks, including but not limited to failure of plant, equipment or processes to operate as anticipated.

/ Accidents and other risks of the mining industry.

/ Silver and other metals price volatility.

/ Currency fluctuations.

/ Increased production costs and variances in ore grade or recovery rates from those assumed in mining plans.

/ Community relations.

/ Conflict resolution and outcome of projects or oppositions.

/ Litigation, political, regulatory, labor, and environmental risks.

/ Inflation causes our costs to rise more than we currently expect.

For a more detailed discussion of such risks and other factors, see Hecla’s 2023 Annual Report on Form 10-K. Hecla does not undertake any obligation to release publicly, revisions to any “forward-looking statement,” including, without limitation, outlook, to reflect events or circumstances after the date of this presentation, or to reflect the occurrence of unanticipated events, except as may be required under applicable securities laws. Investors should not assume that any lack of update to a previously issued “forward-looking statement” constitutes a reaffirmation of that statement. Continued reliance on “forward-looking statements” is at investors’ own risk.

TABLE OF CONTENTS

| | |

1.0 | EXECUTIVE Summary | 1 |

1.1 | Summary | 1 |

1.1.1 | Conclusions | 2 |

1.1.1.1 | Geology and Mineral Resources | 2 |

1.1.1.2 | Mining and Mineral Reserves | 3 |

1.1.1.3 | Mineral Processing | 3 |

1.1.1.4 | Infrastructure | 4 |

1.1.1.5 | Environment | 4 |

1.1.2 | Recommendations | 4 |

1.1.2.1 | Geology and Mineral Resources | 5 |

1.1.2.2 | Mining and Mineral Reserves | 5 |

1.1.2.3 | Mineral Processing | 5 |

1.2 | Economic Analysis | 5 |

1.2.1 | Economic Criteria | 6 |

1.2.1.1 | Physicals | 6 |

1.2.1.2 | Revenue | 6 |

1.2.1.3 | Capital Costs | 7 |

1.2.1.4 | Operating Costs | 7 |

1.2.1.5 | Taxation and Royalties | 7 |

1.2.2 | Cash Flow Analysis | 7 |

1.2.3 | Sensitivity Analysis | 9 |

1.3 | Technical Summary | 9 |

1.3.1 | Property Description | 9 |

1.3.2 | Land Tenure | 9 |

1.3.3 | History | 10 |

1.3.4 | Geological Setting, Mineralization, and Deposit Types | 10 |

1.3.5 | Exploration | 11 |

1.3.6 | Mineral Resource Estimates | 11 |

1.3.7 | Mineral Reserve Estimates | 13 |

1.3.8 | Mining Methods | 14 |

1.3.9 | Processing and Recovery Methods | 15 |

1.3.10 | Infrastructure | 15 |

1.3.11 | Market Studies | 16 |

1.3.12 | Environmental Studies, Permitting and Plans, Negotiations, or Agreements with Local Individuals or Groups | 17 |

1.3.13 | Capital and Operating Cost Estimates | 17 |

| | |

|

2.0 | Introduction | 19 |

2.1 | Site Visit | 19 |

2.2 | Sources of Information | 20 |

2.3 | Units and Abbreviations | 20 |

3.0 | Property Description | 23 |

3.1 | Location | 23 |

3.2 | Land Tenure | 25 |

3.3 | Encumbrances | 28 |

3.4 | Royalties | 28 |

3.5 | Other Significant Factors and Risks | 28 |

4.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 29 |

4.1 | Topography, Elevation and Vegetation | 29 |

4.2 | Climate | 29 |

4.3 | Access | 29 |

4.4 | Local Resources | 29 |

4.5 | Infrastructure | 29 |

5.0 | History | 32 |

5.1 | Exploration and Development History | 32 |

5.1.1 | 1974 to 1996 | 32 |

5.1.2 | Aurizon (1997 to 2013) | 32 |

5.2 | Historical Drilling - 1957 to 2013 | 34 |

5.2.1 | Historical Drilling – Aurizon, 2006 to 2013 | 35 |

5.2.2 | Historical Drilling Lake Shore, 2007 to 2012 | 36 |

5.2.3 | 2008 | 36 |

5.2.4 | 2009 | 37 |

5.2.5 | 2010 | 37 |

5.2.6 | 2012 | 37 |

5.3 | Historical Production | 37 |

6.0 | Geological Setting, Mineralization, and Deposit | 39 |

6.1 | Regional Geology | 39 |

6.2 | Property Geology | 40 |

6.2.1 | Stratigraphic Divisions | 40 |

6.2.2 | Structures | 42 |

6.2.3 | Alteration and Metamorphism | 44 |

6.3 | Mineralization | 45 |

| | |

6.3.1 | Styles of Mineralization | 45 |

6.3.2 | Veins | 45 |

6.3.3 | Stockworks | 46 |

6.3.4 | Gold-Bearing Banded Iron Formation | 46 |

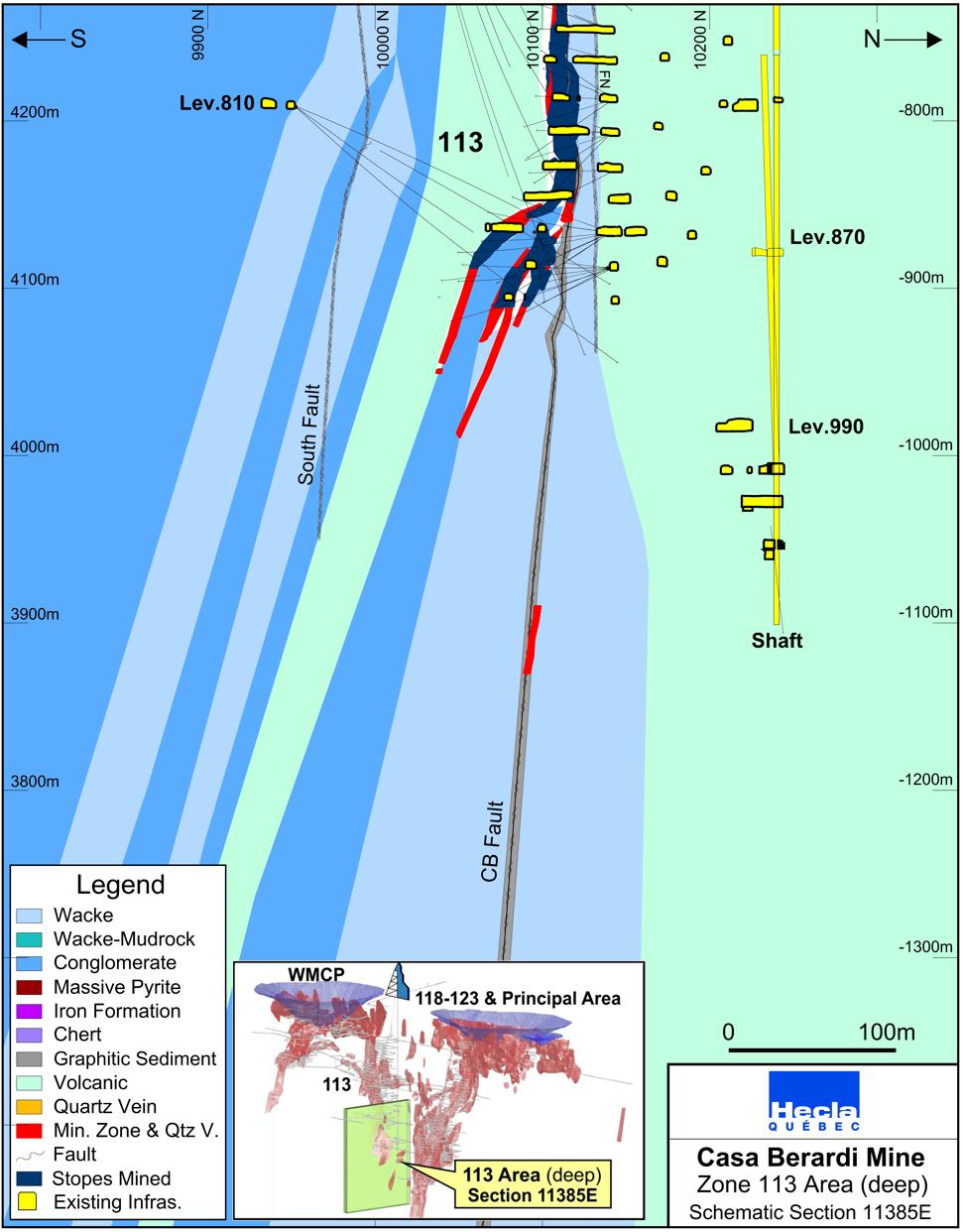

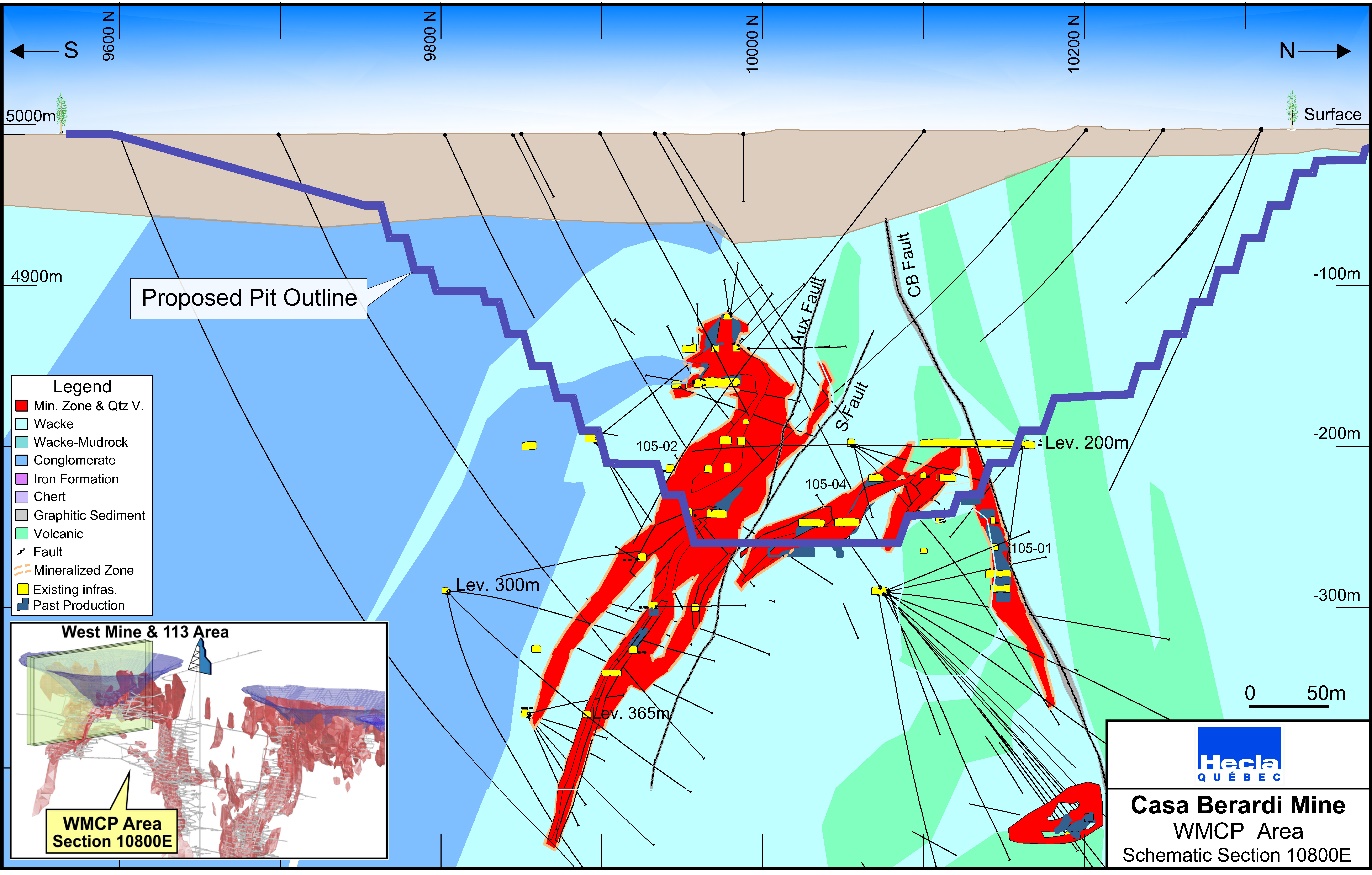

6.3.5 | Mineralization Near the West Mine Infrastructure | 47 |

6.3.6 | Mineralization along the Casa Berardi Fault | 49 |

6.3.7 | Mineralization Between the Casa Berardi and South Faults | 49 |

6.3.8 | Mineralization at the South Fault | 50 |

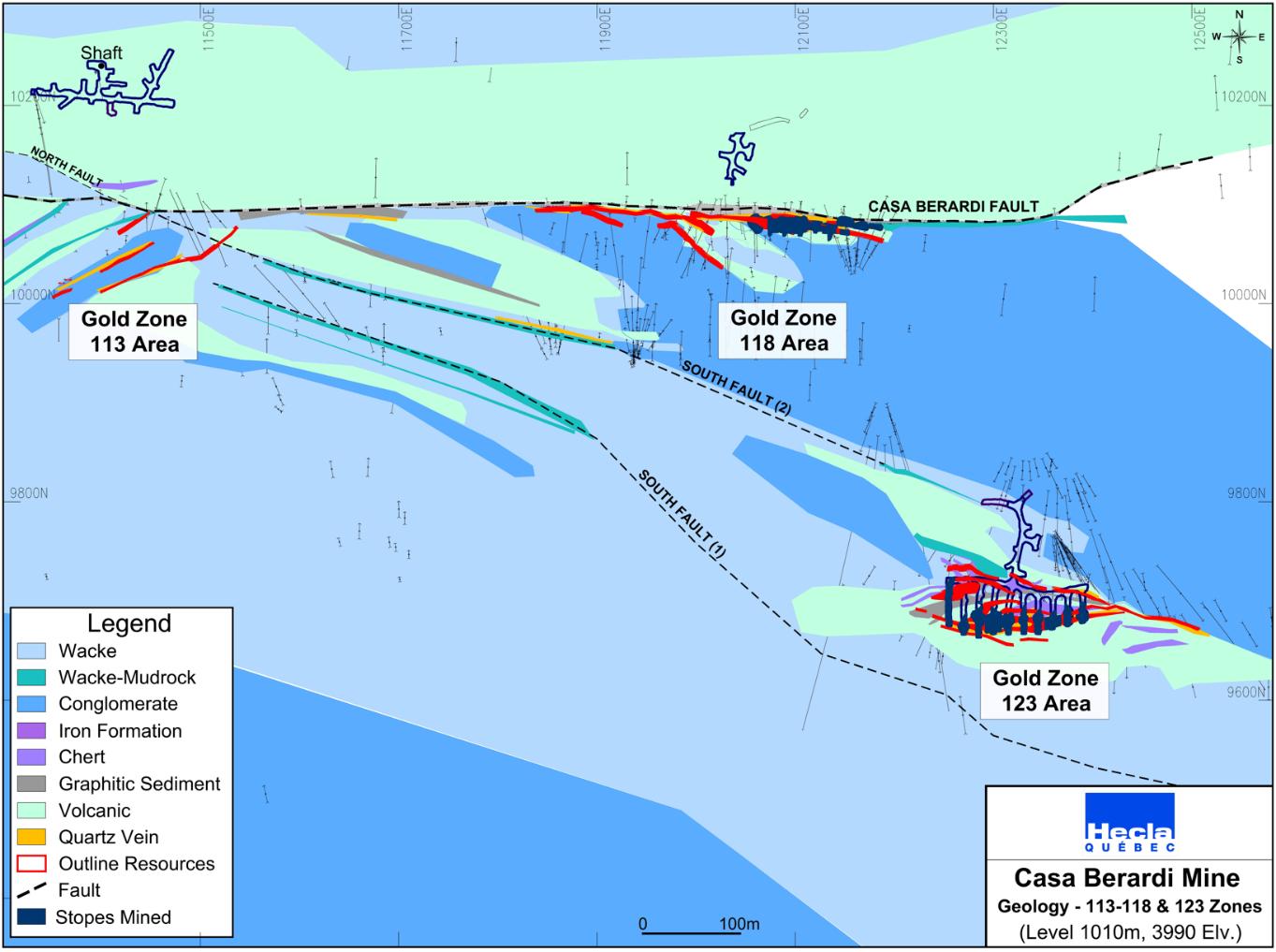

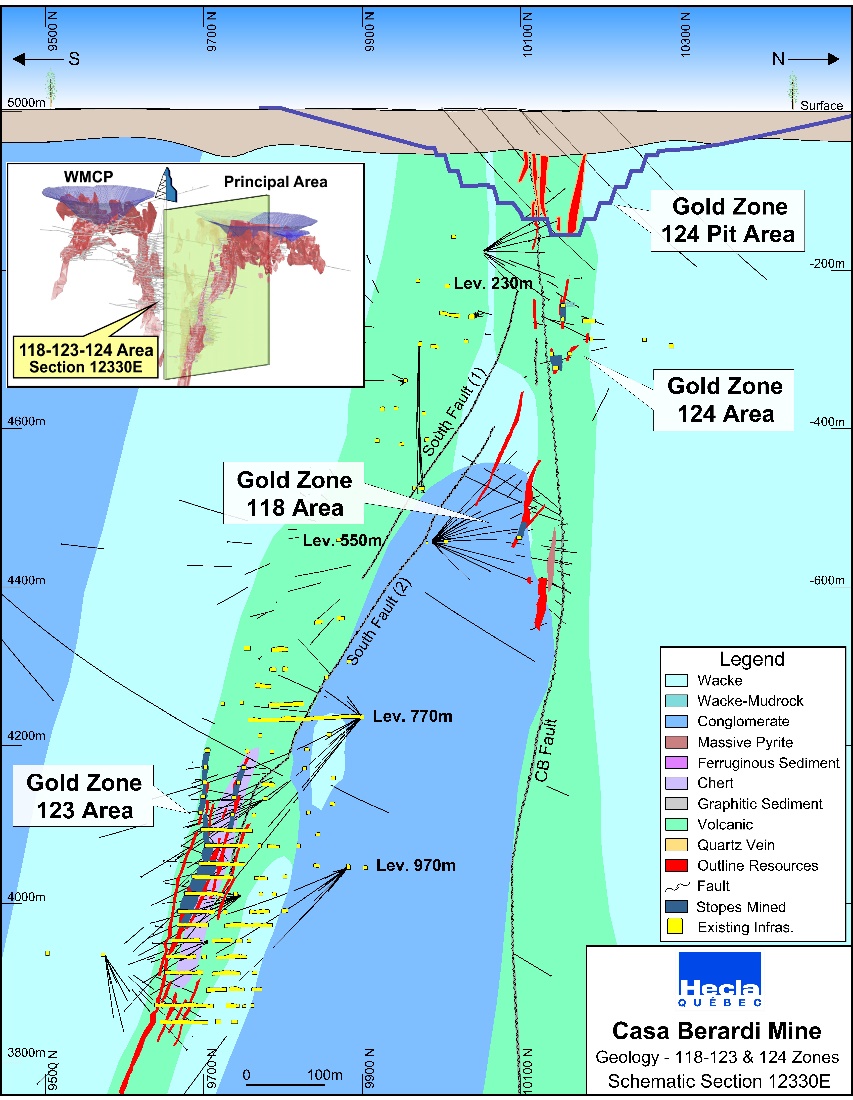

6.3.9 | Mineralization at the 118 Zone | 51 |

6.3.10 | Mineralization at the 123 and 128 Zones | 52 |

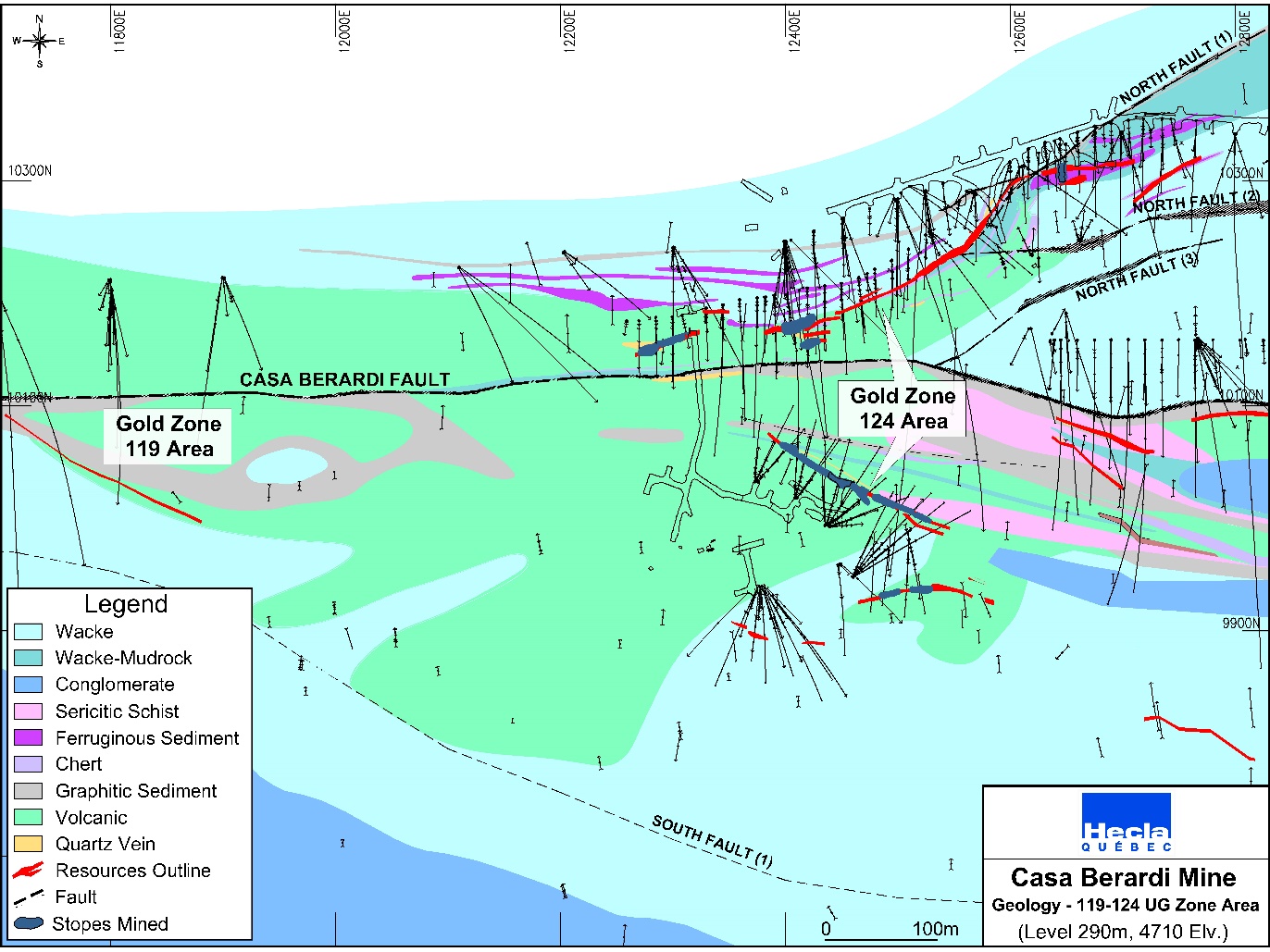

6.3.11 | Mineralization at the Principal Mine Area | 53 |

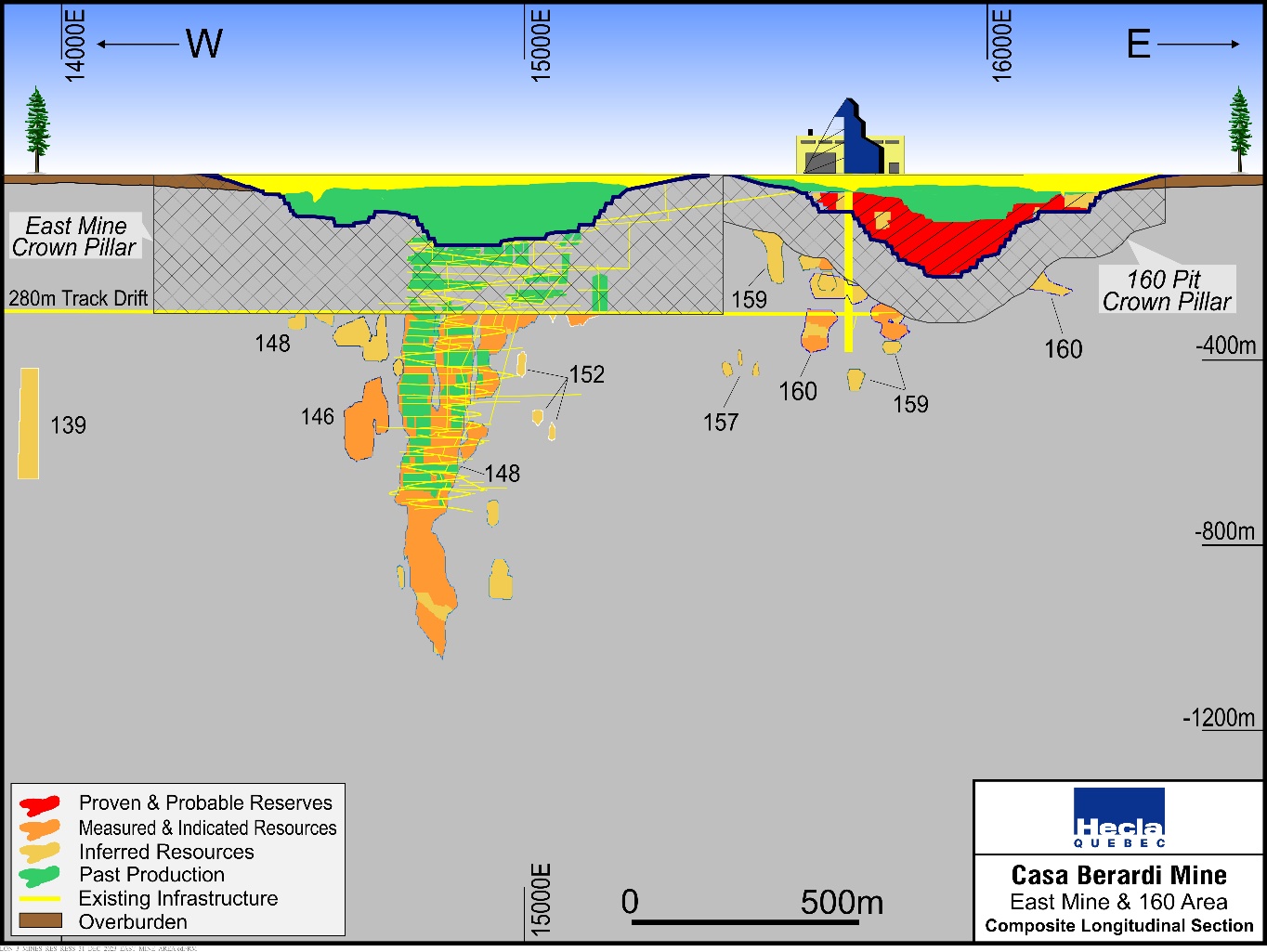

6.3.12 | Mineralization at the East Mine Area | 56 |

6.4 | Deposit Types | 59 |

7.0 | Exploration | 60 |

7.1 | Hecla Exploration 2014 to 2023 | 60 |

7.1.1 | 2016 | 60 |

7.1.2 | 2017 | 60 |

7.1.3 | 2018 | 60 |

7.1.4 | 2019 and 2020 | 61 |

7.1.5 | 2021 | 61 |

7.1.6 | 2022 | 62 |

7.1.7 | 2023 | 62 |

7.2 | Drilling Summary | 62 |

7.3 | Hecla Drilling, 2014 to 2023 | 64 |

7.3.1 | Hecla Drilling Protocols | 66 |

7.4 | Hydrogeology Drill Holes | 68 |

7.5 | Geotechnical Drill Holes | 68 |

7.6 | Comments on Drilling | 69 |

8.0 | Sample Preparation, Analyses, and Security | 70 |

8.1 | Drill Sample Handling Procedures and Sample Security | 70 |

8.1.1 | Core Sampling | 71 |

8.1.2 | Underground Development Heading Samples | 71 |

8.2 | Sample Preparation and Analysis | 72 |

8.2.1 | Mine Laboratory | 72 |

8.2.2 | Swastika | 73 |

8.3 | Historical QA/QC Programs | 73 |

8.4 | Aurizon/Hecla QA/QC Programs | 74 |

8.4.1 | QA/QC Database | 74 |

| | |

8.4.2 | QA/QC Protocols | 74 |

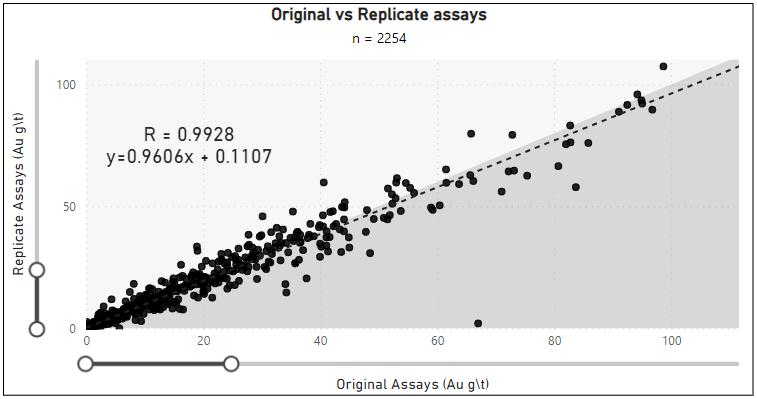

8.4.3 | Pulp Duplicates | 74 |

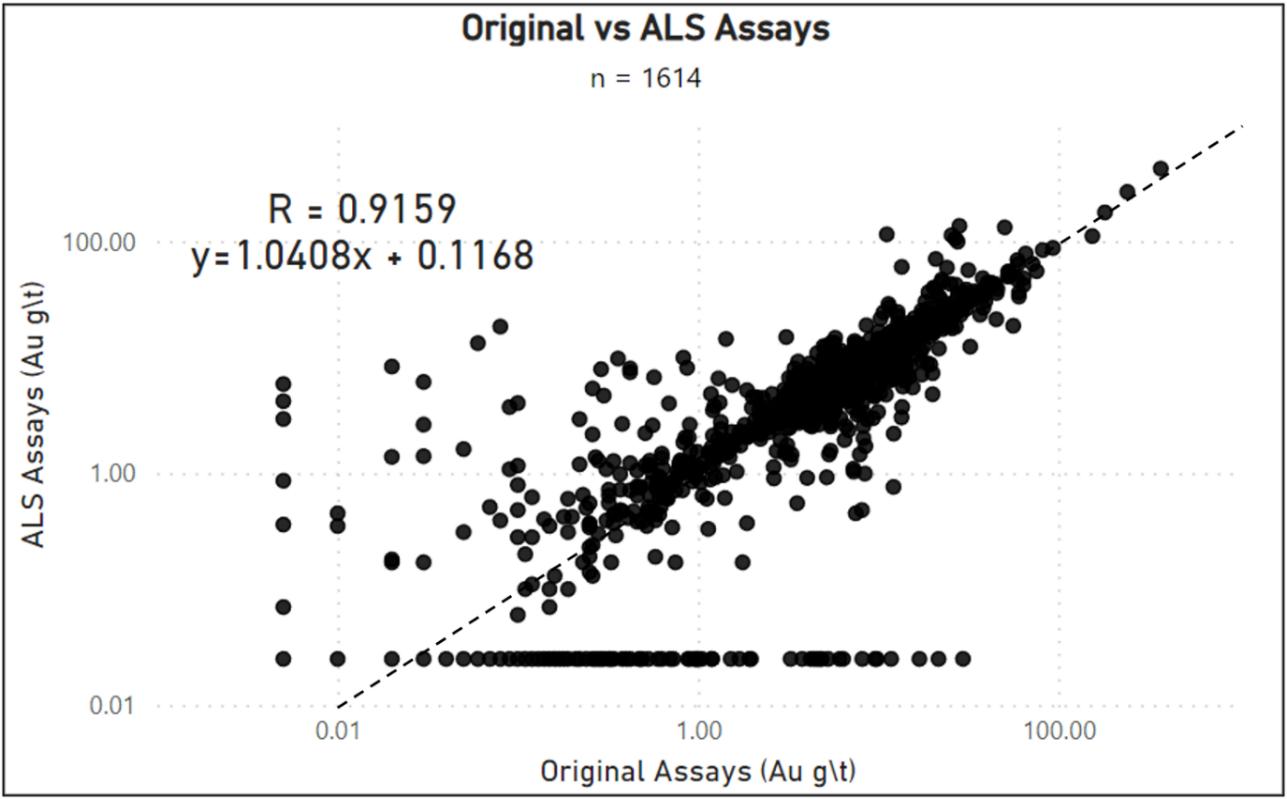

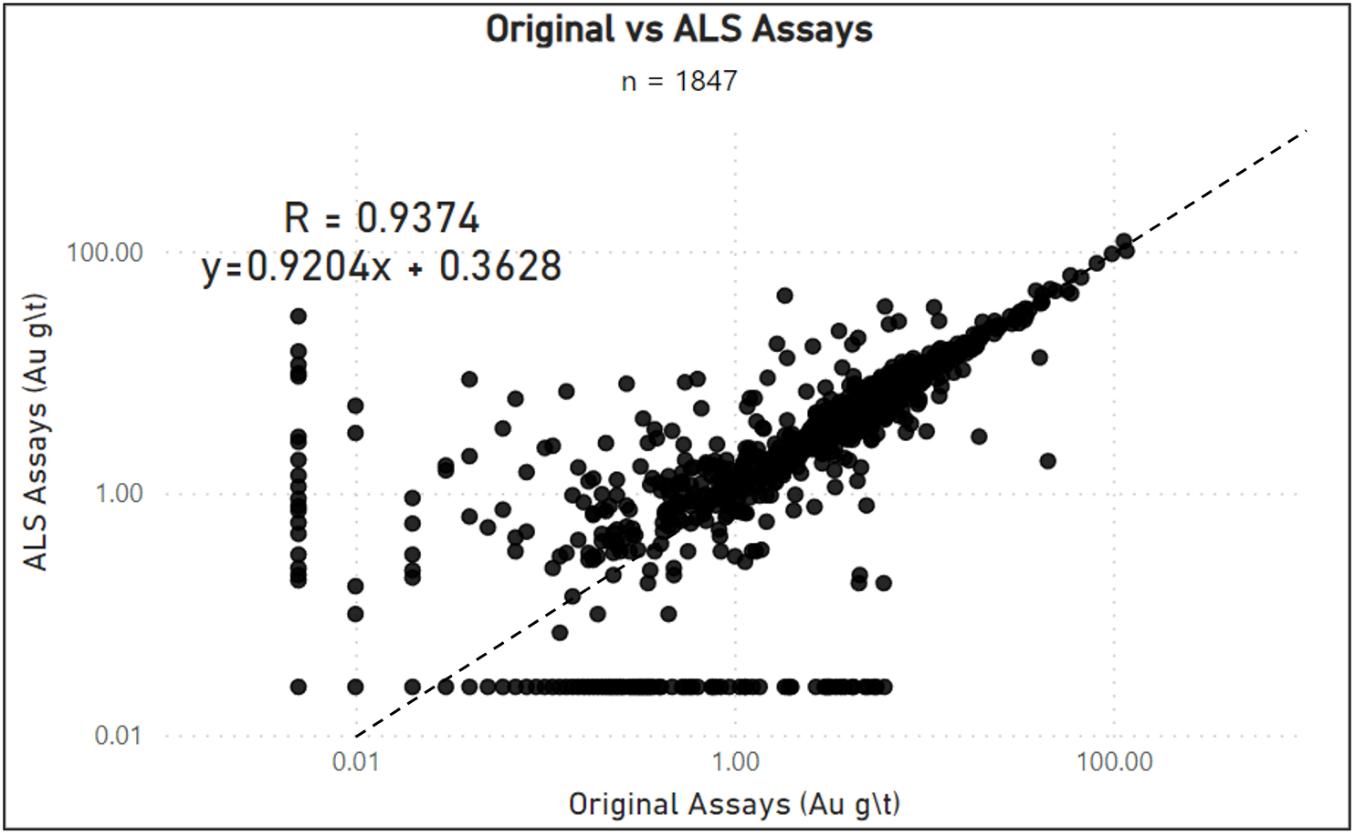

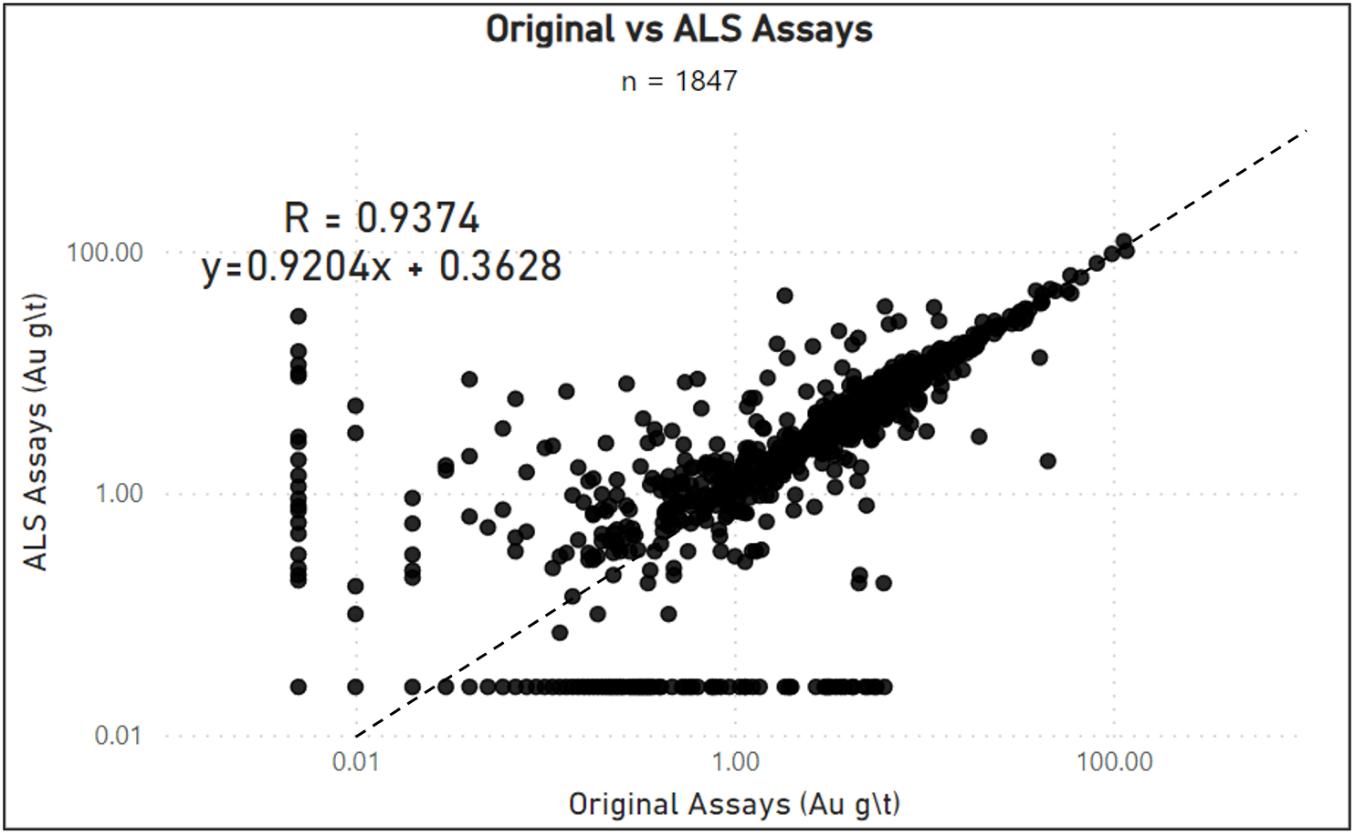

8.4.4 | Pulp External Check Assays | 77 |

8.4.5 | Coarse Reject External Check Assays | 81 |

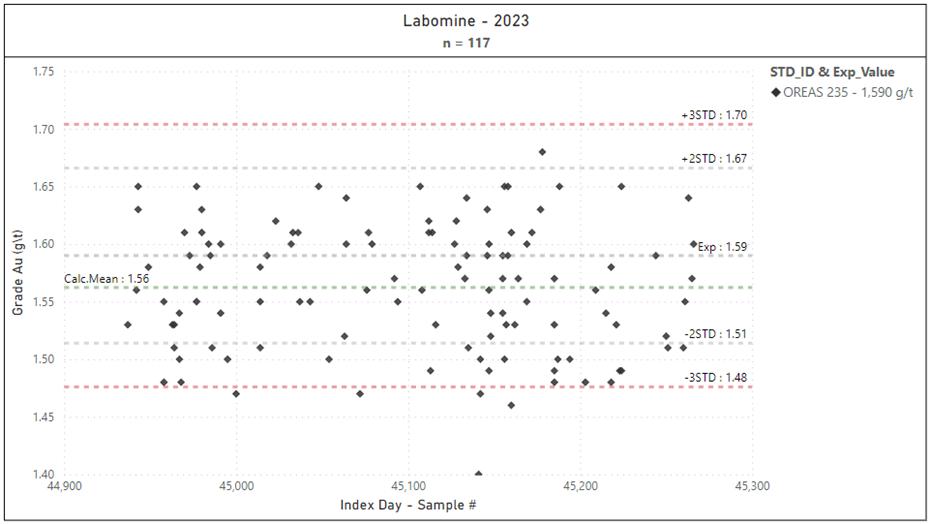

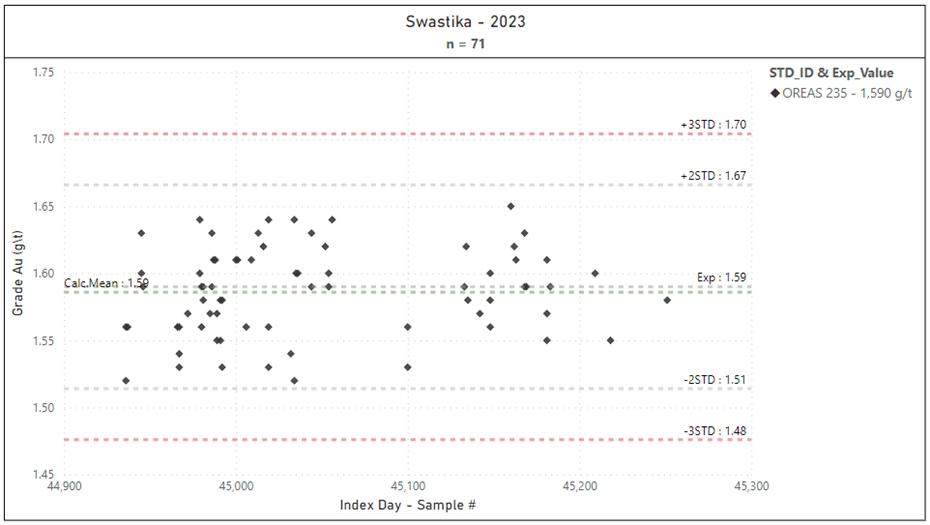

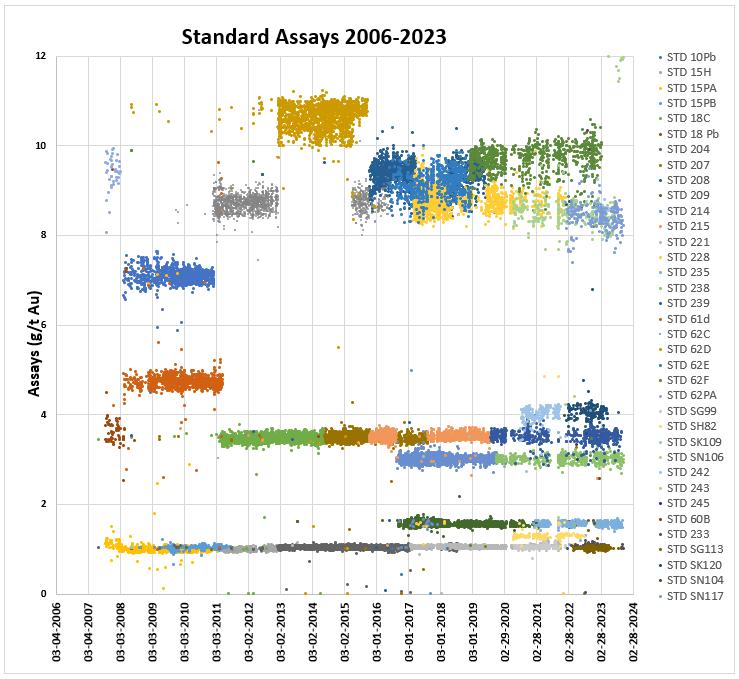

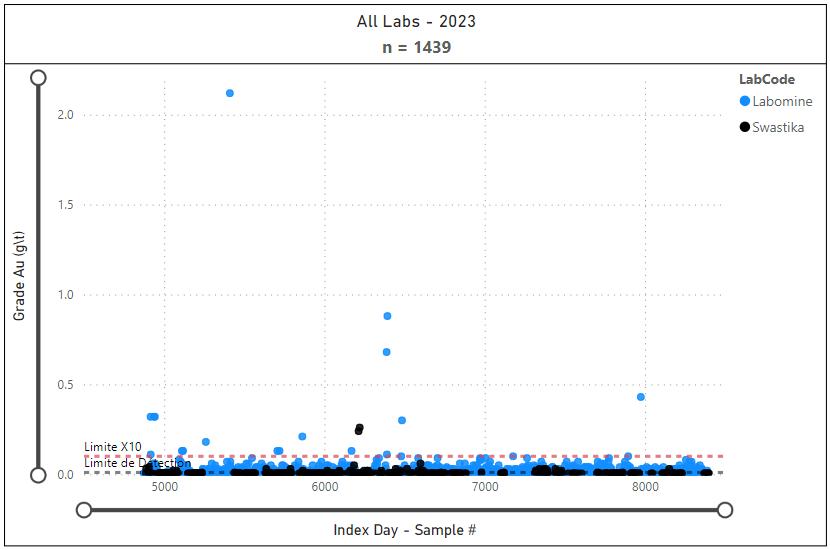

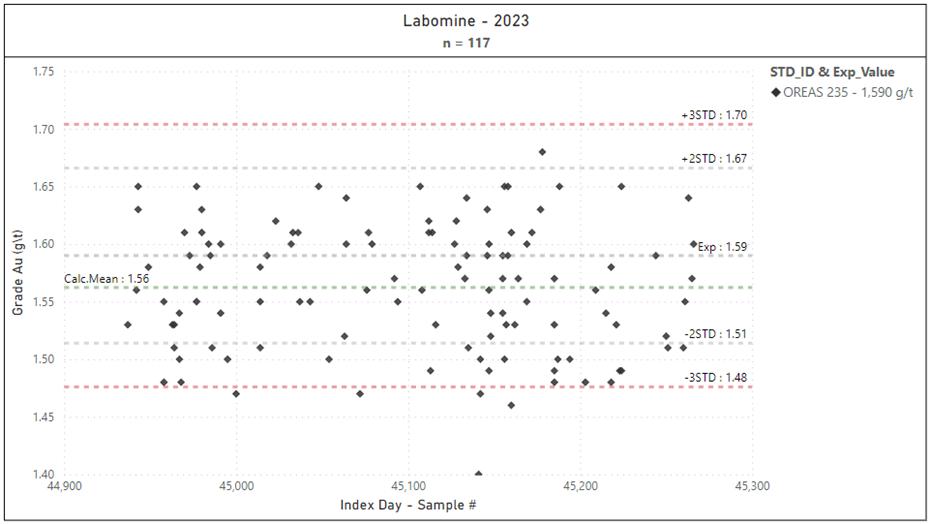

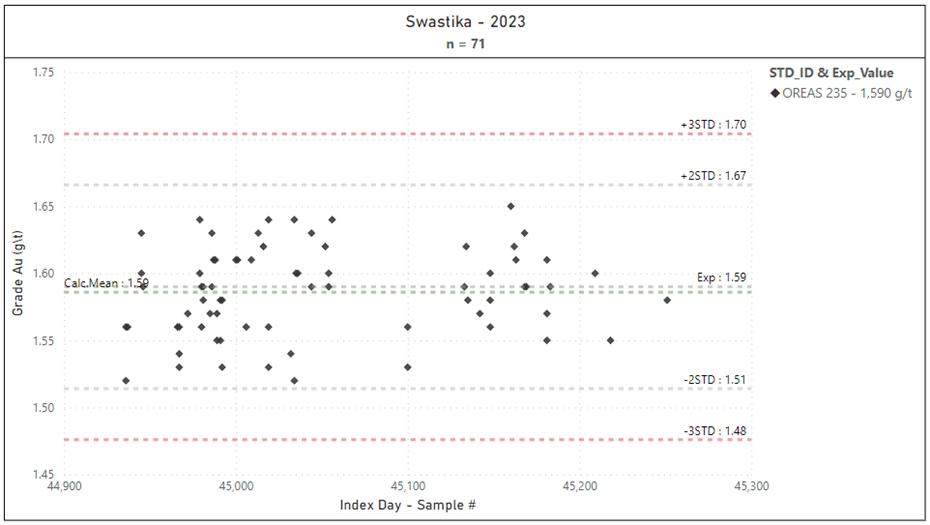

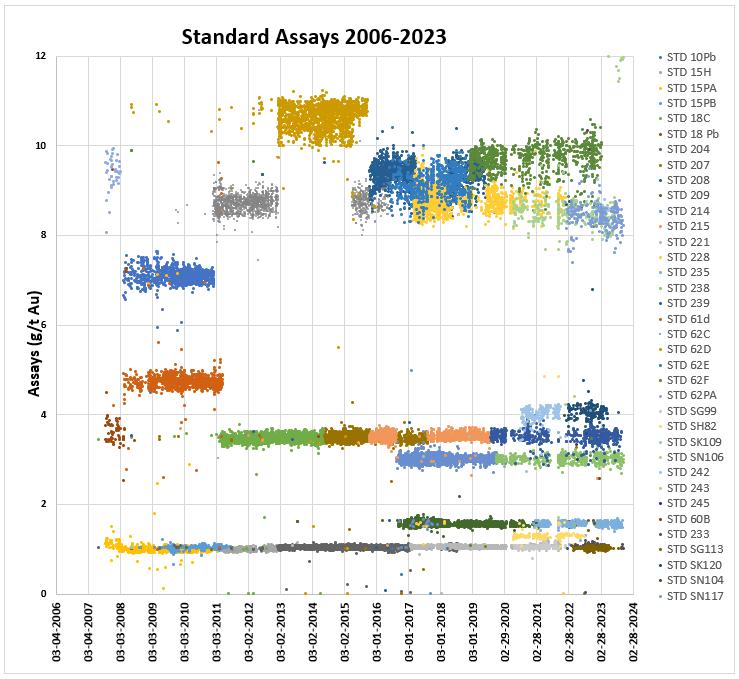

8.4.6 | Certified Reference Materials | 82 |

8.4.7 | Blanks | 95 |

8.5 | Mine Laboratory Internal QA/QC Program | 96 |

8.6 | Reverse-Circulation and Sonic Drilling Samples | 96 |

8.7 | Conclusions and Recommendations | 96 |

9.0 | Data Verification | 99 |

9.1 | Site Visit | 99 |

9.2 | Drill-Hole Database Compilation and Verification by Hecla | 99 |

9.3 | Drill-Hole Database Verification by RESPEC | 100 |

9.3.1 | Phase 1 – Logic Tests | 100 |

9.3.2 | Phase 2 –Assay Data Verification | 101 |

9.4 | Comments on Data Verification | 101 |

10.0 | Mineral Processing and Metallurgical Testing | 103 |

10.1 | Introduction | 103 |

10.2 | Metallurgical Testing | 104 |

10.2.1 | 2020 WMCP Test Program | 104 |

10.2.1.1 Sample Preparation and Analyses | 104 |

10.2.1.2 Comminution Testing by SGS | 106 |

10.2.1.3 Gravity Testing by SGS | 107 |

10.2.1.4 Cyanidation Testing by SGS | 107 |

10.2.2 | 2021 Principal Pit Test Program by Blue Coast | 108 |

10.2.2.1 Sample Preparation and Analyses | 108 |

10.2.2.2 Cyanidation Testing by Blue Coast | 109 |

10.2.3 | 2021 WMCP Flotation Test Program | 110 |

10.2.3.1 2021 Sample Preparation and Analyses by Blue Coast | 110 |

10.2.3.2 2021 Flotation Testing by Blue Coast | 111 |

10.2.3.3 2021 Cyanidation Testing by Blue Coast | 112 |

10.2.4 | 2022 WMCP Phase 2 Test Program | 113 |

10.2.4.1 Part 1 – Variability Test Work 2022 | 114 |

10.2.4.2 Part 2 –2022 Master Composite Test Work by Blue Coast | 116 |

10.2.5 | 2023 WMCP Extension Program by Blue Coast | 120 |

10.2.5.1 2023 Sample Preparation and Analyses | 120 |

10.2.5.2 Flotation Testing | 122 |

10.2.5.3 2023 Gravity Testing by Blue Coast | 128 |

| | |

10.2.5.4 2023 Cyanidation Testing by Blue Coast | 128 |

10.2.5.5 Combined Flowsheet Recovery | 129 |

10.3 | Sulfide Operation Data | 131 |

10.3.1 | Yearly Review | 132 |

10.4 | Recovery Models | 134 |

10.4.1 | Underground (Zones 115/118/121/123/148) | 134 |

10.4.2 | Open Pit | 134 |

10.4.2.1 F134/Principal Pit | 134 |

10.4.2.2 F160 Pit | 134 |

10.4.2.3 WMCP Pit | 135 |

10.5 | Expected Recoveries | 135 |

10.6 | Deleterious Elements | 135 |

10.7 | Conclusions and Recommendations | 135 |

11.0 | Mineral Resource Estimates | 137 |

11.1 | Summary | 137 |

11.2 | Database | 142 |

11.3 | Density Determination | 143 |

11.4 | Geological Interpretation | 145 |

11.5 | Mineralized Envelope Interpretation | 145 |

11.6 | Capping and Compositing | 145 |

11.7 | Block Model Dimensions and Coding | 146 |

11.8 | Mineral Resource Estimation Methodologies | 147 |

11.9 | Mineral Resource Validation | 147 |

11.10 | Mineral Resource Classification | 147 |

11.11 | Casa Berardi Mineral Resources | 150 |

11.12 | Discussion of Mineral Resource Estimates | 156 |

12.0 | Mineral Reserve Estimates | 159 |

12.1 | Underground Mineral Reserves | 161 |

12.2 | Open Pit Mineral Reserves | 162 |

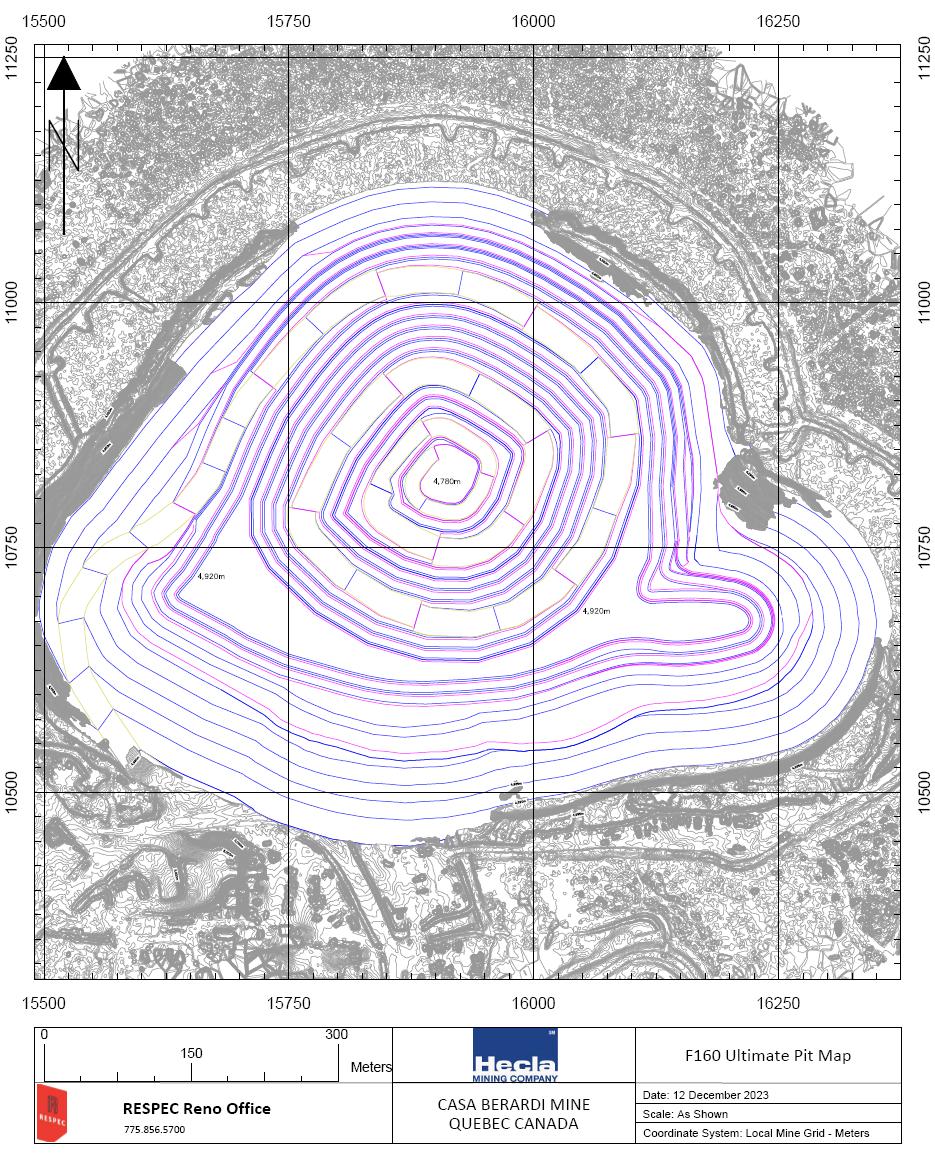

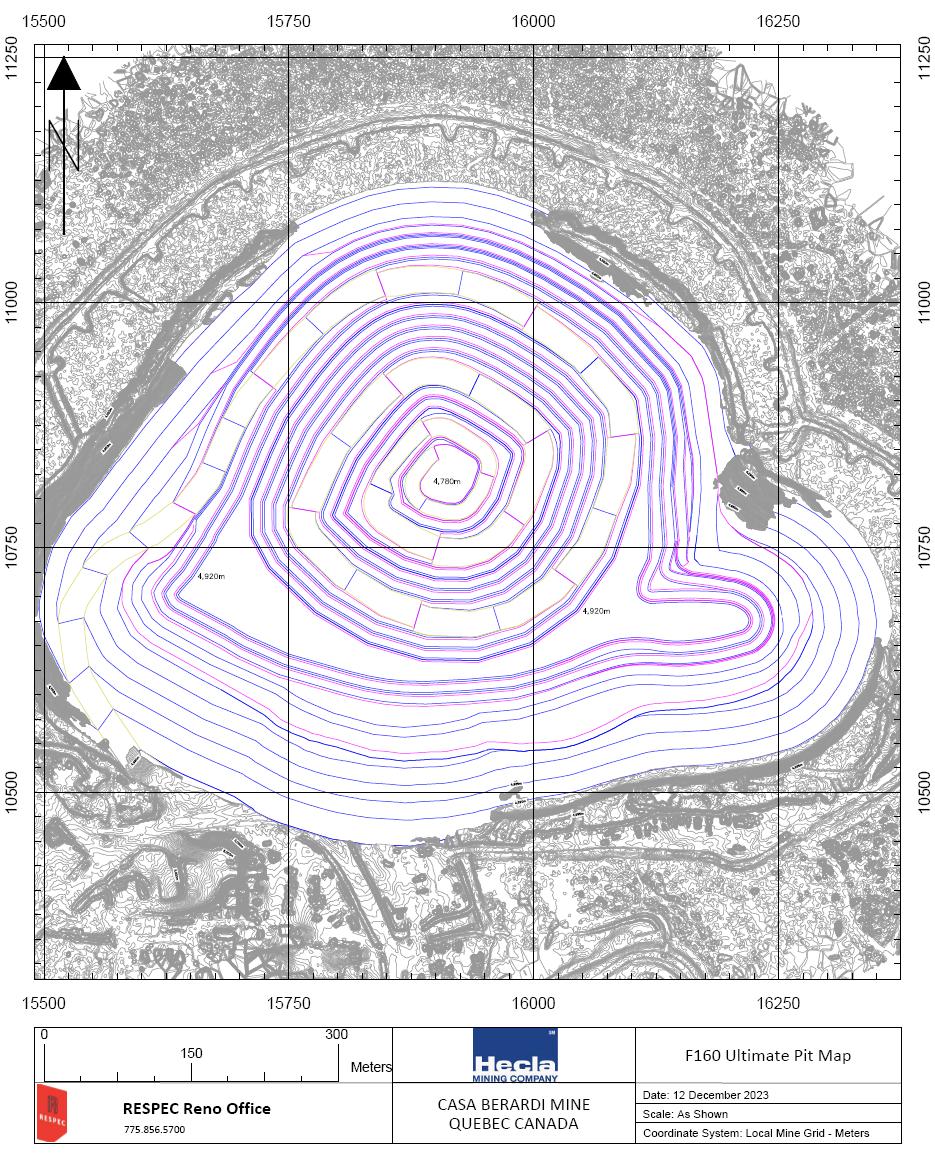

12.2.1 | F160 Pit | 162 |

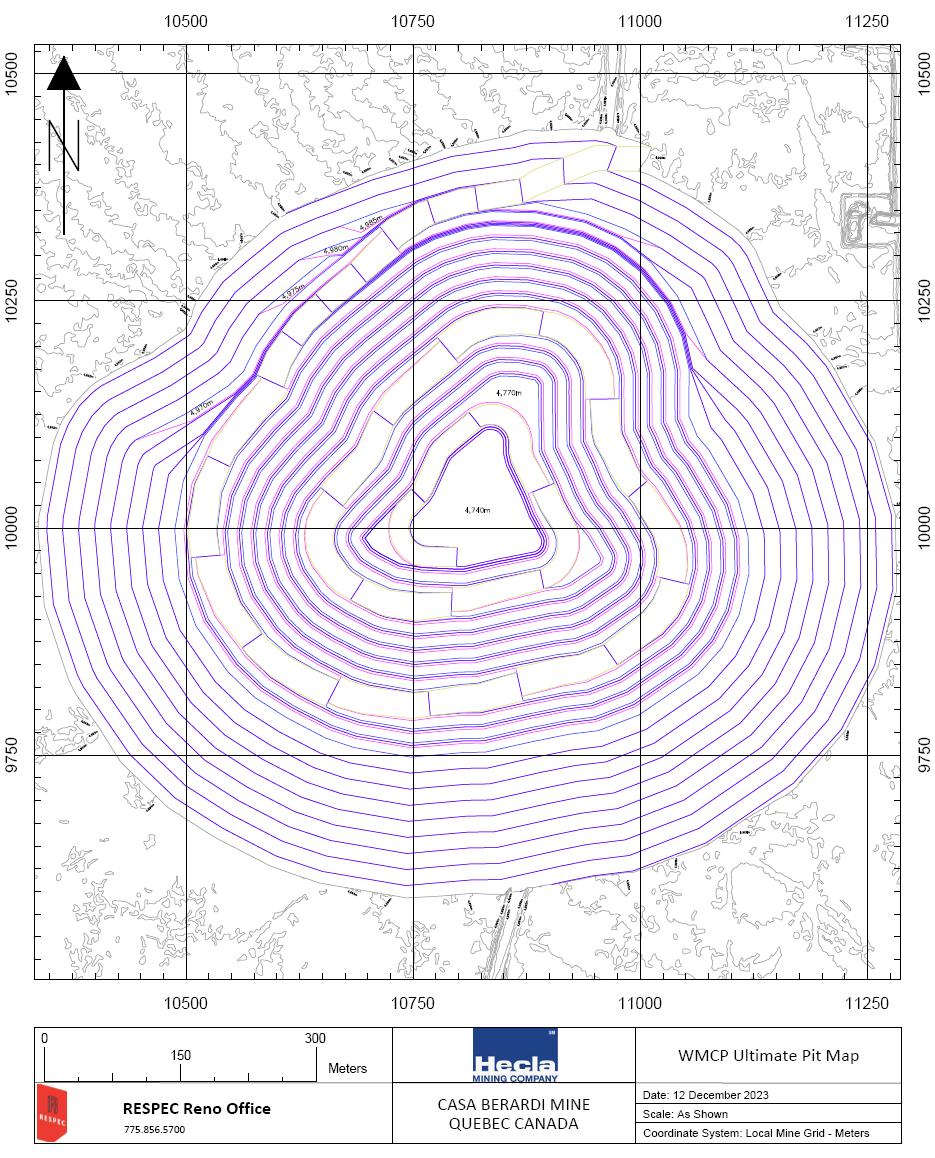

12.2.2 | WMCP Pit | 162 |

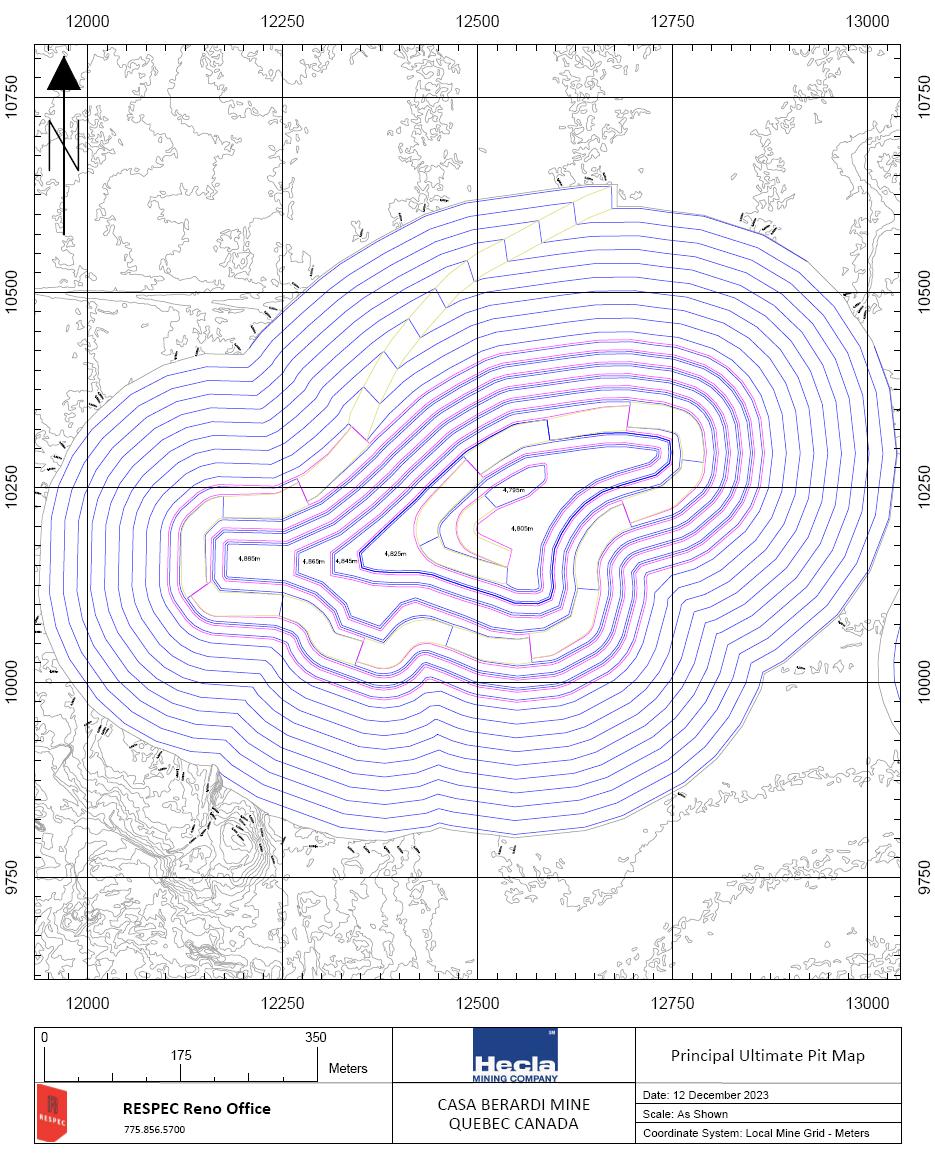

12.2.3 | Principal Pit | 162 |

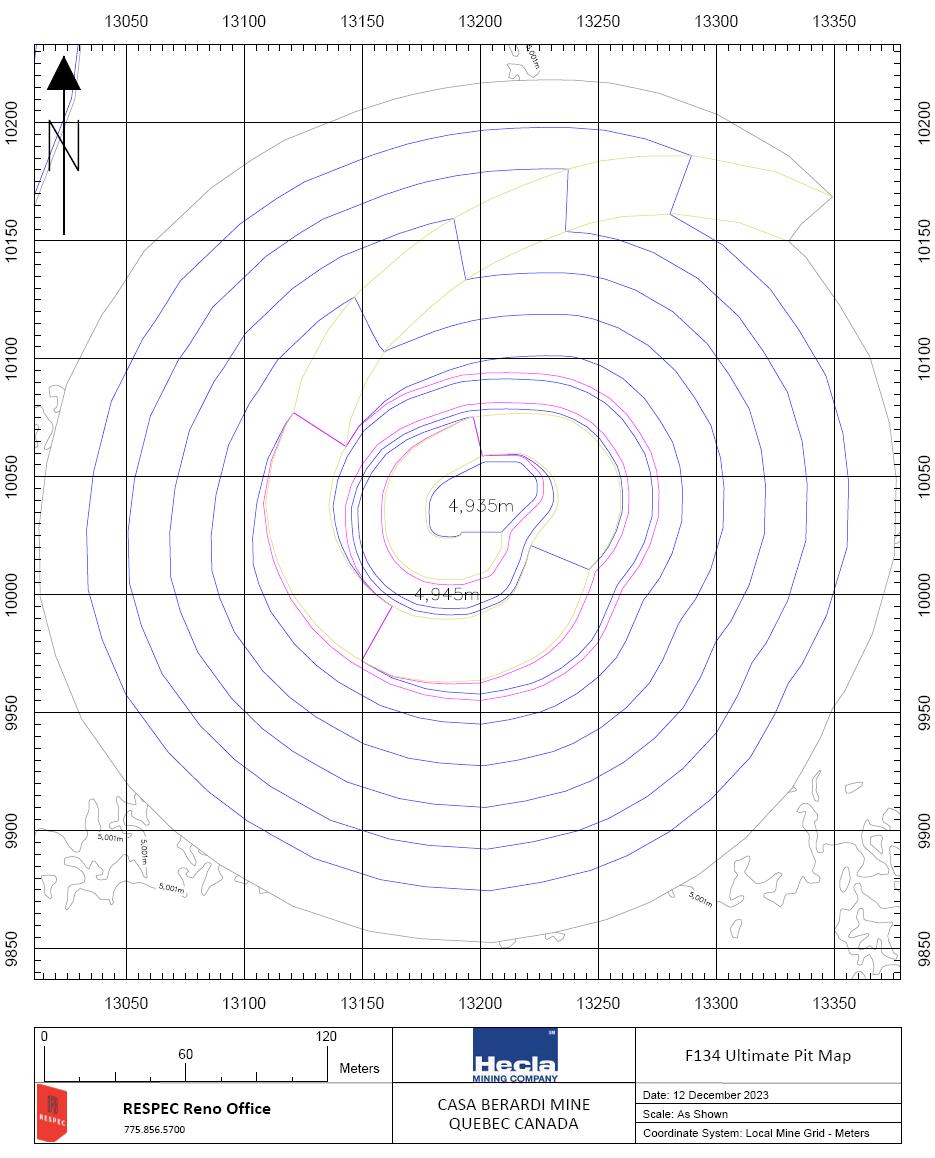

12.2.4 | F134 Pit | 162 |

12.3 | Cutoff Grade | 163 |

12.4 | Dilution and Extraction | 163 |

12.4.1 | Underground Mining | 163 |

12.4.2 | Open Pit Mining | 164 |

12.5 | Estimation Methodology – Open Pit Projects | 165 |

| | |

12.5.1 | F160 Pit | 165 |

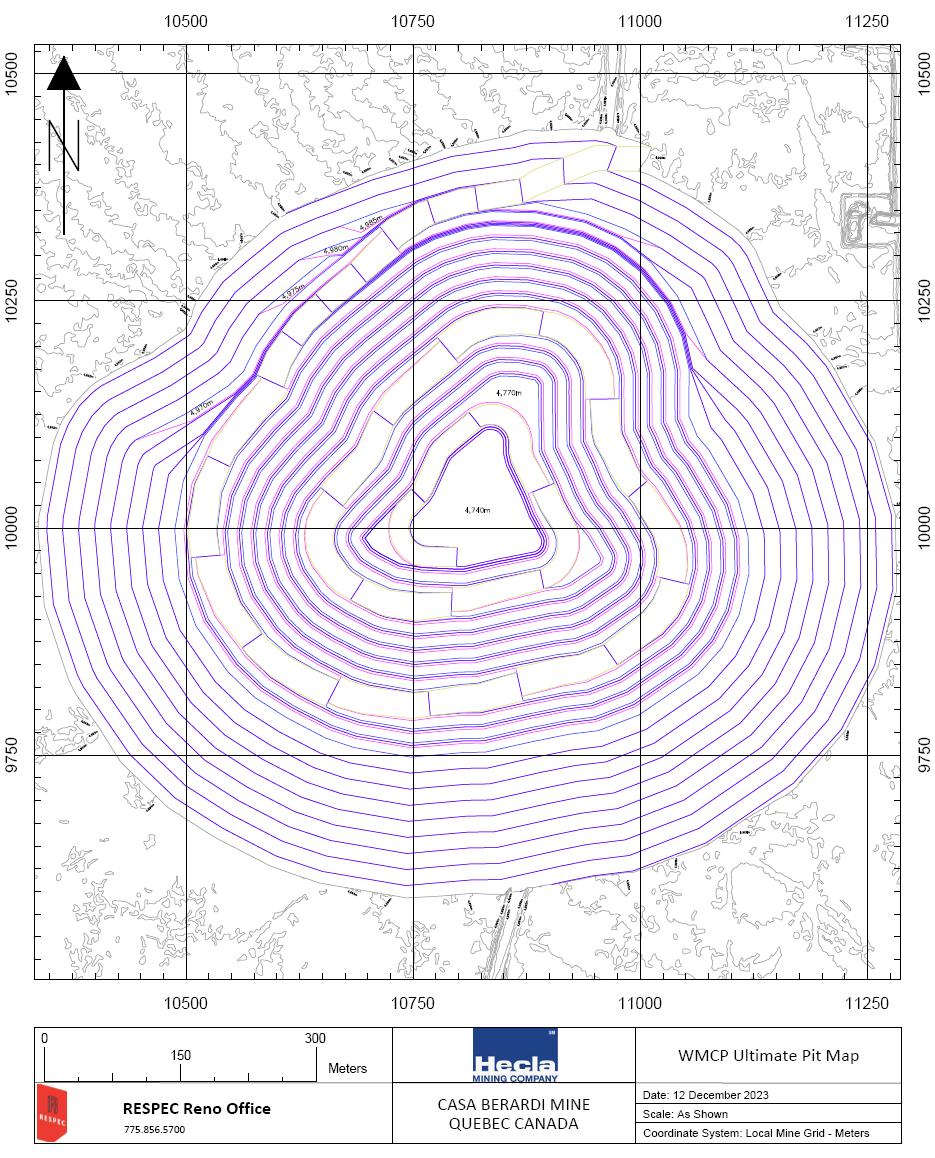

12.5.2 | WMCP Pit | 166 |

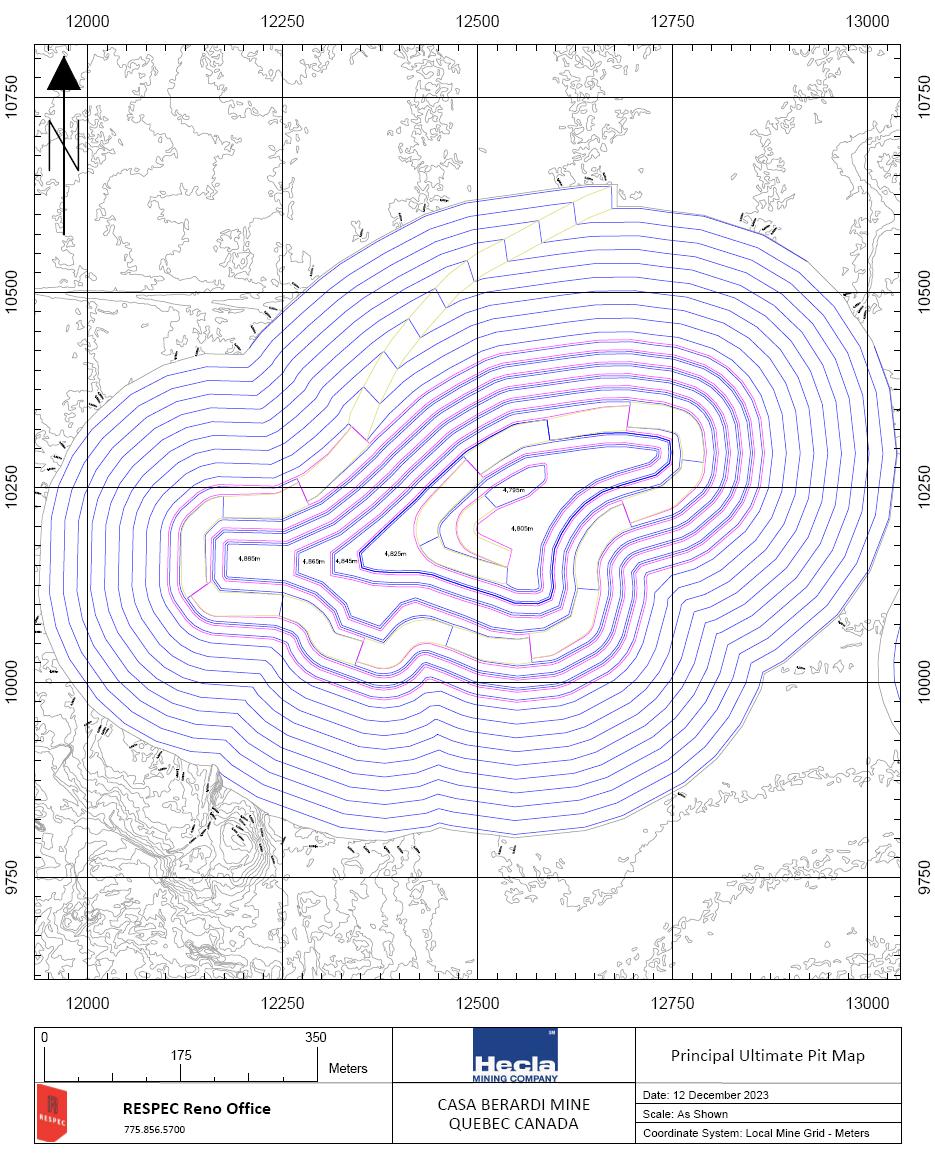

12.5.3 | Principal Pit | 166 |

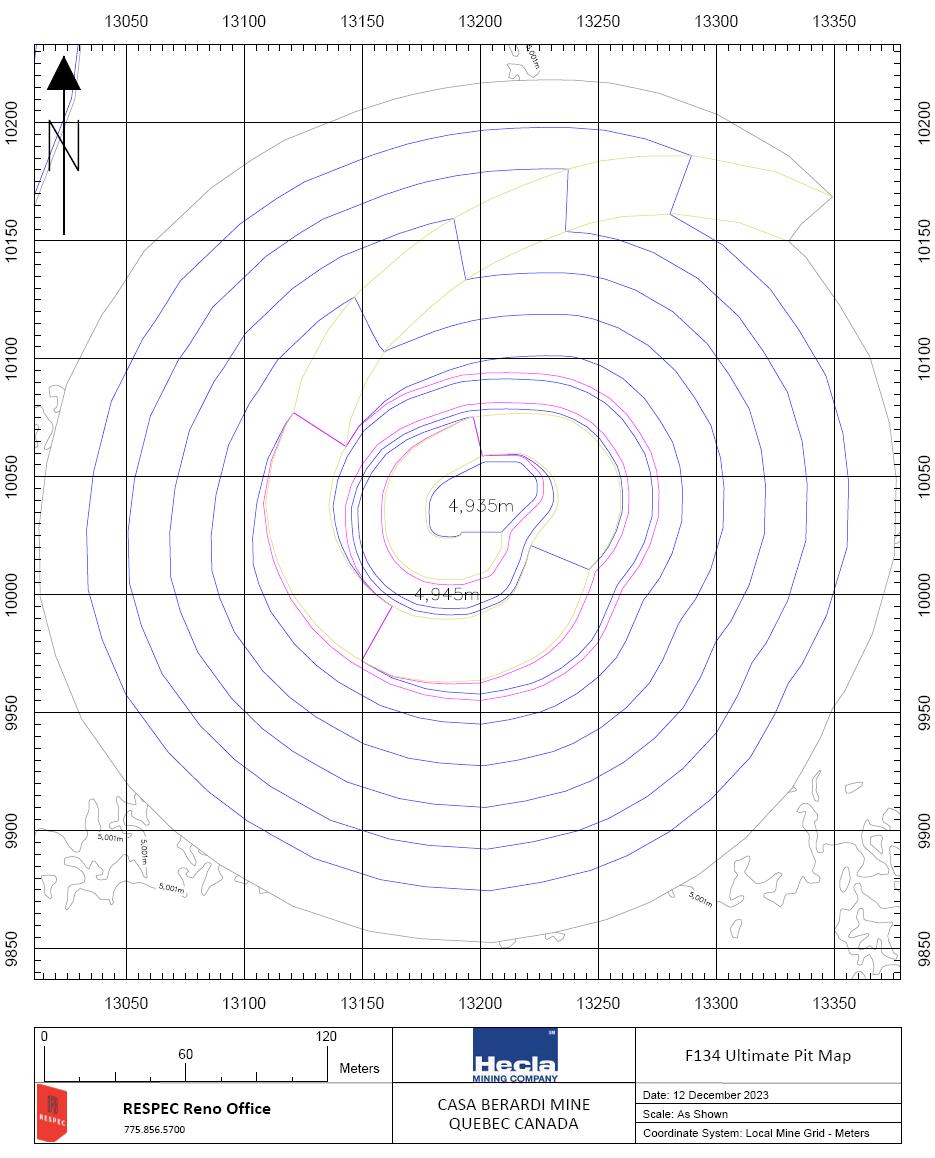

12.5.4 | F134 Pit | 166 |

12.6 | Comparison to Previous Estimates | 167 |

12.7 | Reconciliation | 168 |

13.0 | Mining Methods | 175 |

13.1 | Mining Operations – Underground | 175 |

13.1.1 | Underground Development | 175 |

13.1.1.1 Ground Support | 175 |

13.1.1.2 Development Performance | 176 |

13.1.1.3 Mine Design | 176 |

13.1.2 | West Mine and Principal Area | 176 |

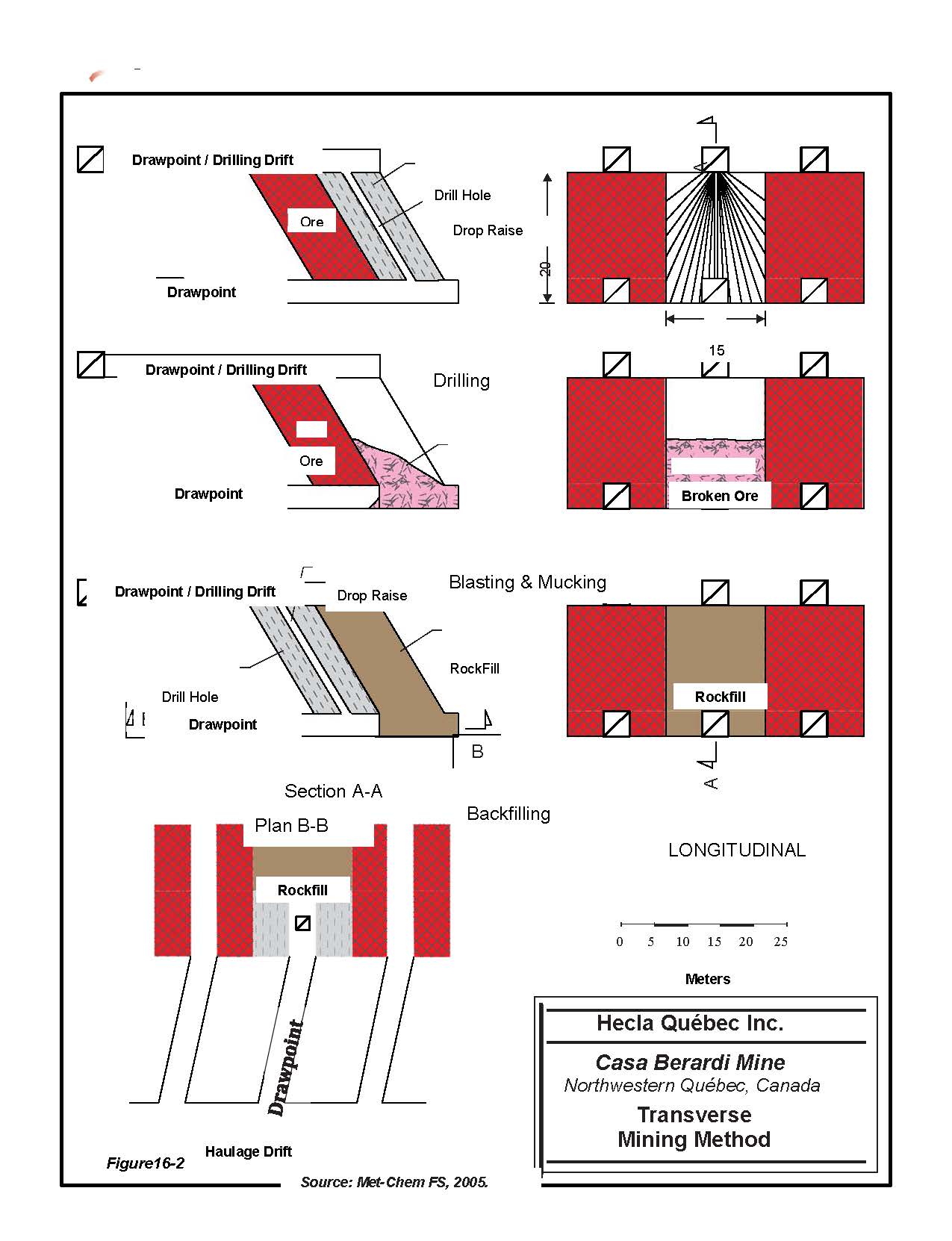

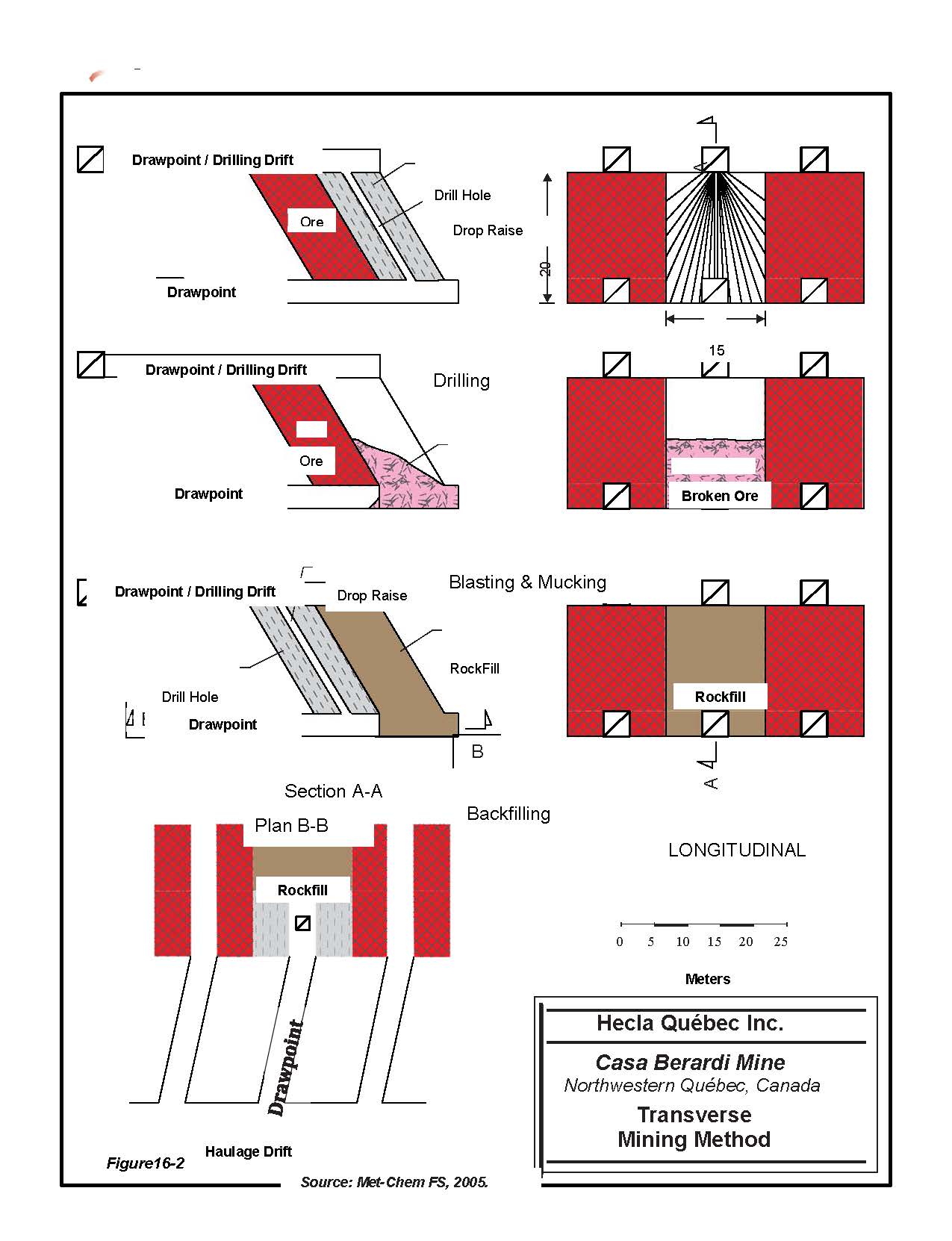

13.1.3 | Transverse Method | 177 |

13.1.4 | Longitudinal Method | 178 |

13.1.5 | Stope Size | 179 |

13.1.6 | East Mine Mining History | 180 |

13.1.7 | Backfill | 180 |

13.1.8 | Mine Equipment | 181 |

13.2 | Ground Stability | 181 |

13.2.1 | Ground Conditions | 181 |

13.2.2 | Ground Testing and Analysis | 182 |

13.2.3 | Operating Practices | 182 |

13.3 | Mine Infrastructure | 183 |

13.3.1 | West Mine Shaft | 183 |

13.3.2 | Ore and Waste Pass Systems | 186 |

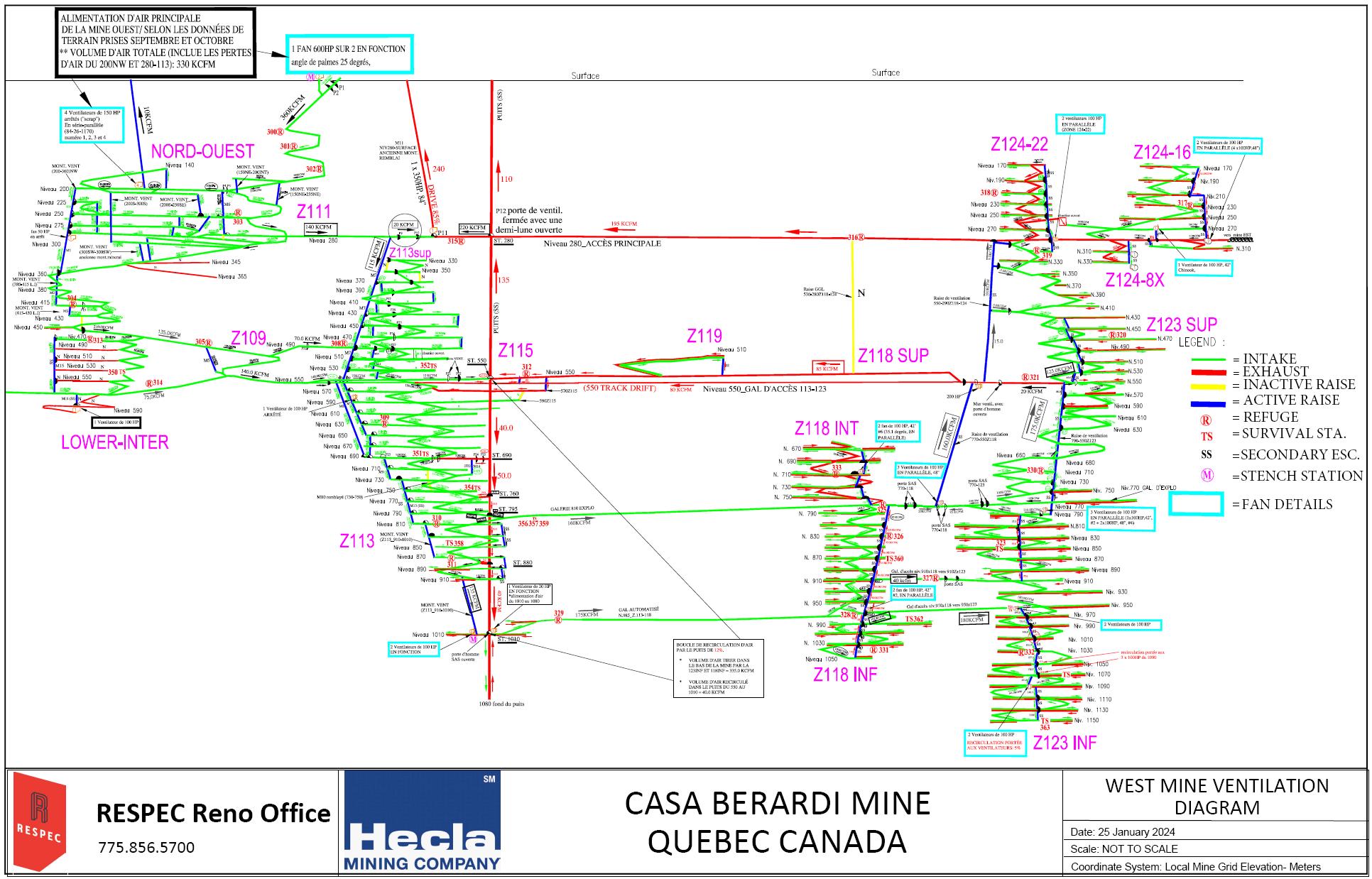

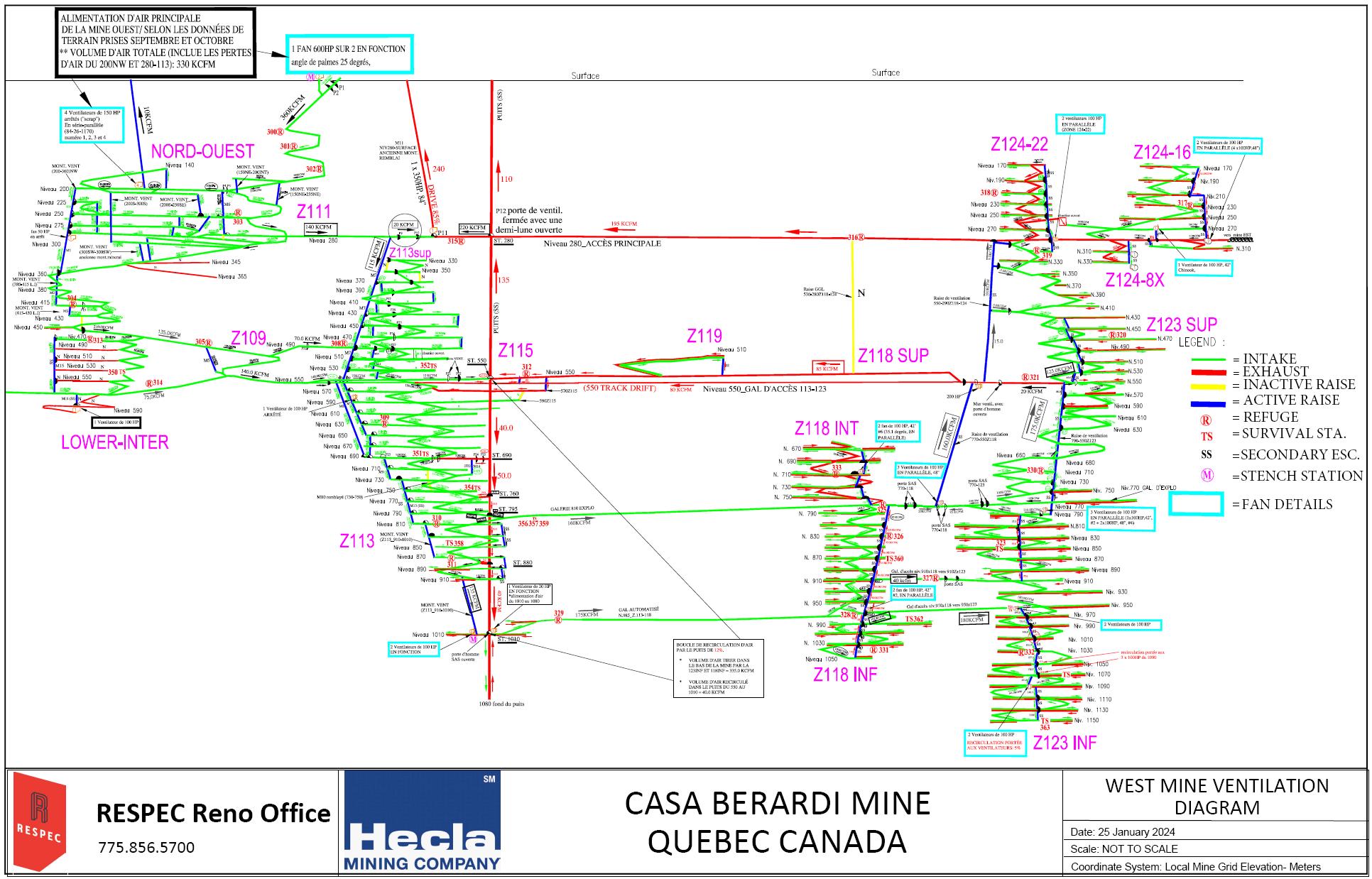

13.3.3 | Ventilation | 186 |

13.3.4 | Maintenance Facilities | 188 |

13.3.5 | Power | 188 |

13.3.6 | Personnel | 190 |

13.4 | Open Pit Mining Operations | 192 |

13.4.1 | Mining Method | 192 |

13.4.2 | Open Pit Design | 192 |

13.4.3 | Slope Parameters – Overburden | 193 |

13.4.4 | Slope Parameters - Rock | 193 |

13.4.5 | Ramp Design | 193 |

13.4.6 | Underground Workings | 194 |

13.4.7 | Open Pit Mining Equipment | 194 |

13.4.8 | Geotechnical/Hydrogeological Considerations | 195 |

| | |

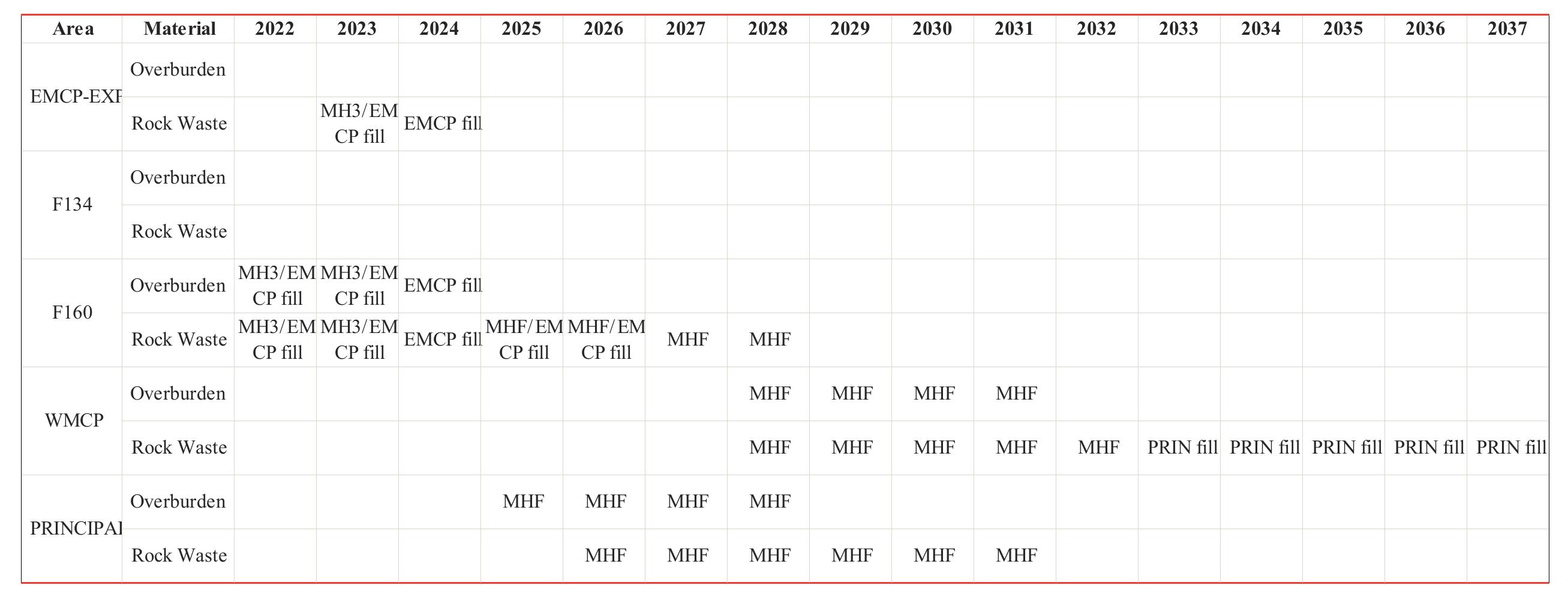

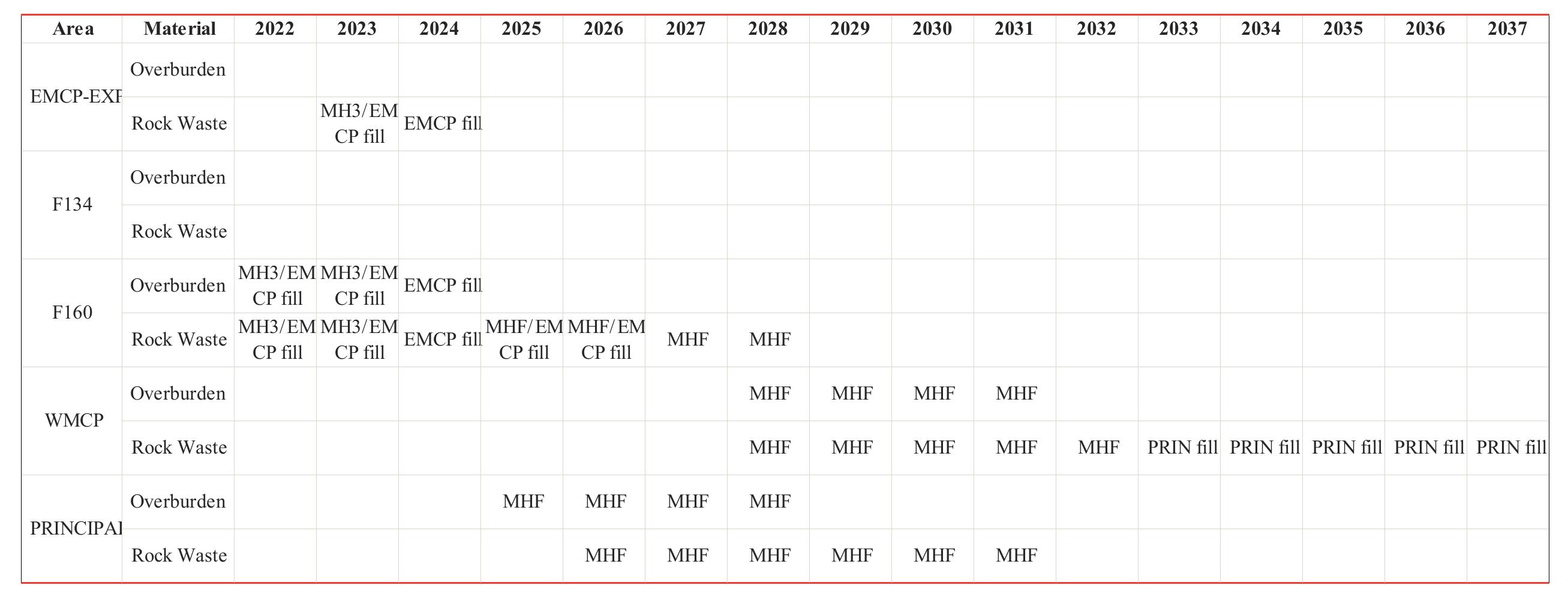

13.4.9 | Material Management | 201 |

13.4.10 Waste Rock Characterization | 201 |

13.4.11 Waste Rock Facility Locations and Construction | 201 |

13.4.12 Overview of Open Pits | 205 |

13.4.12.1 F160 Pit | 205 |

13.4.12.2 F134 Pit | 207 |

13.4.12.3 WMCP Pit | 208 |

13.4.12.4 Principal Pit | 210 |

13.5 | Long-Range Plan | 212 |

13.6 | Life of Mine Plan | 212 |

14.0 | Processing and Recovery Methods | 214 |

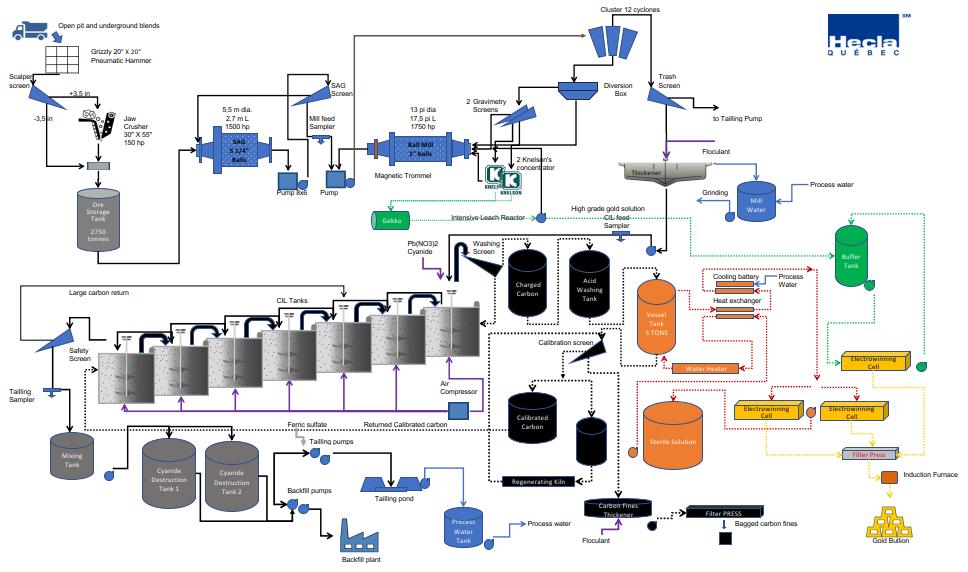

14.1 | Introduction | 214 |

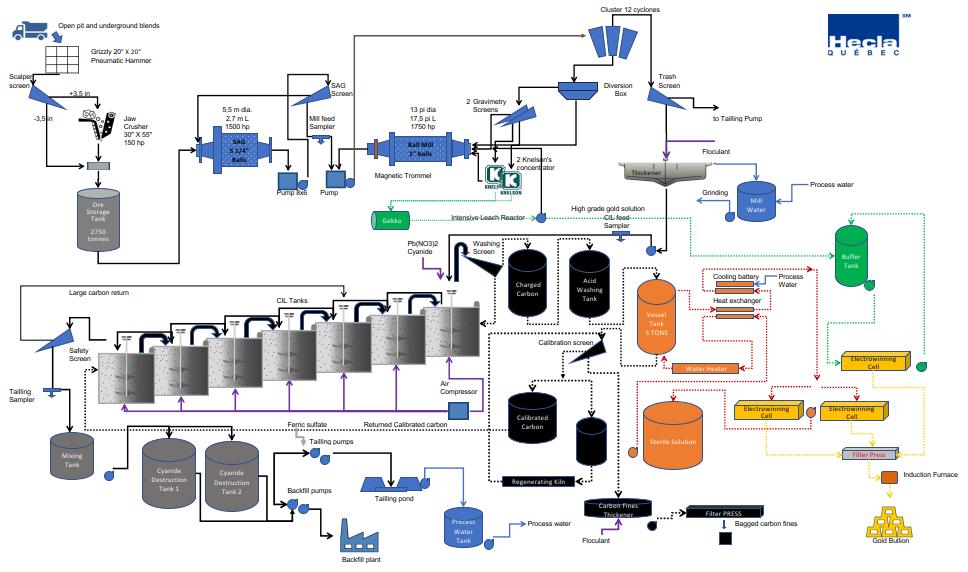

14.2 | Process Description | 214 |

14.2.1 | Crushing | 215 |

14.2.2 | Grinding | 215 |

14.2.3 | Gravity Circuit | 215 |

14.2.4 | CIL Circuit | 215 |

14.2.5 | Carbon Circuit | 216 |

14.2.6 | Elution and Electrowinning Circuits | 216 |

14.2.7 | Major Equipment List | 217 |

14.3 | Energy, Water, and Process Materials Requirements | 218 |

14.4 | Personnel | 219 |

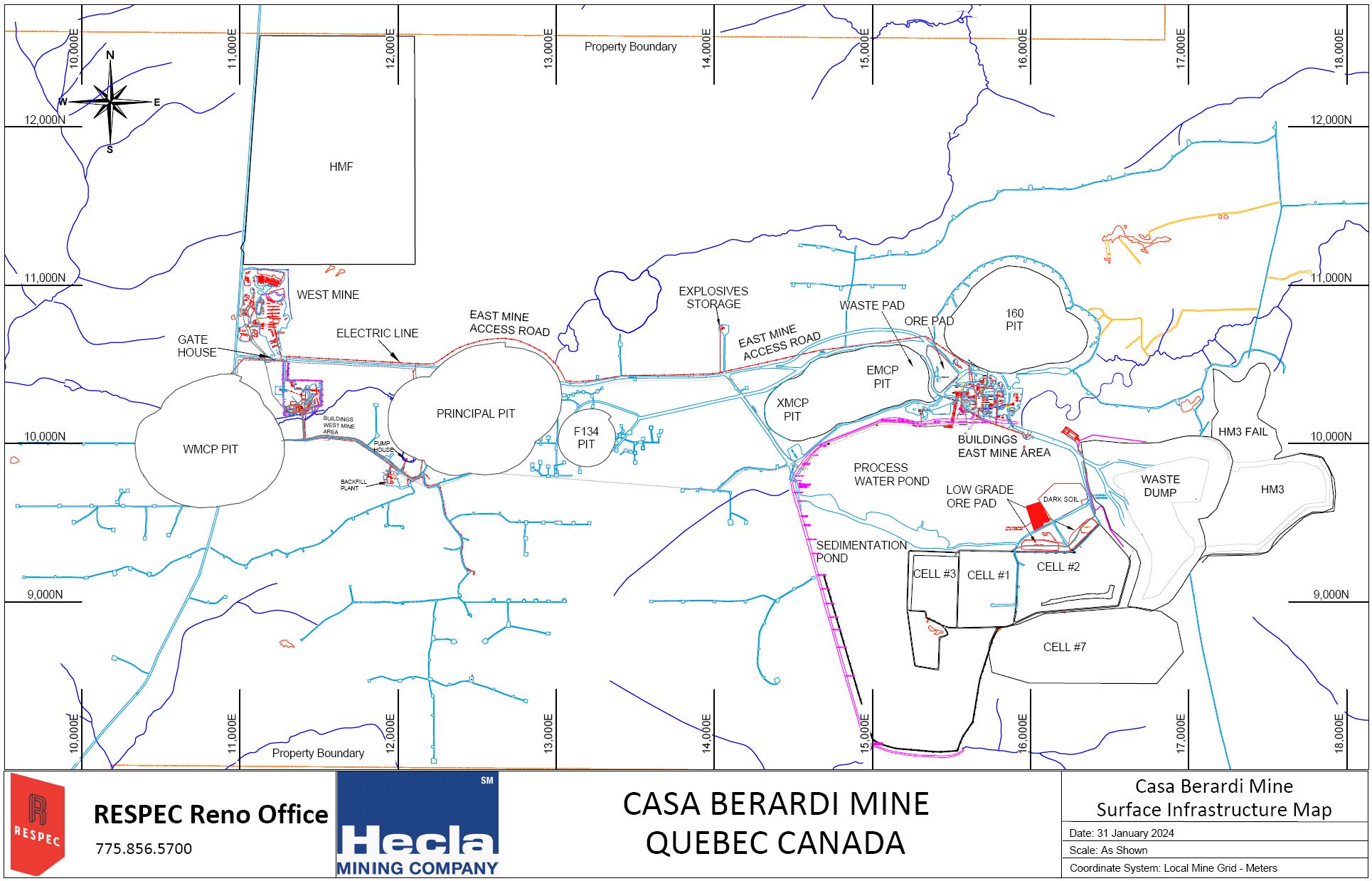

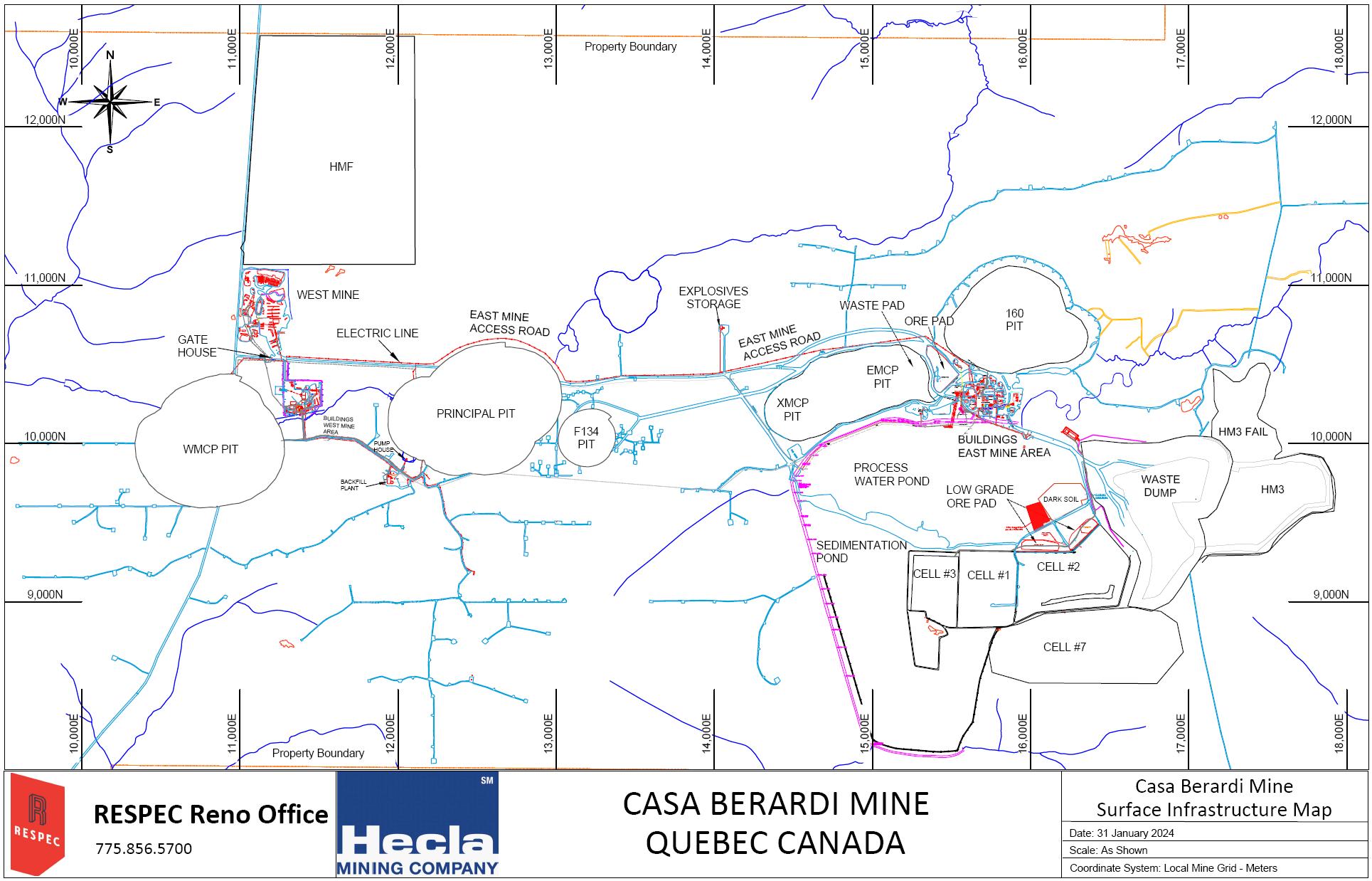

15.0 | Infrastructure | 220 |

15.1 | Roads and Logistics | 220 |

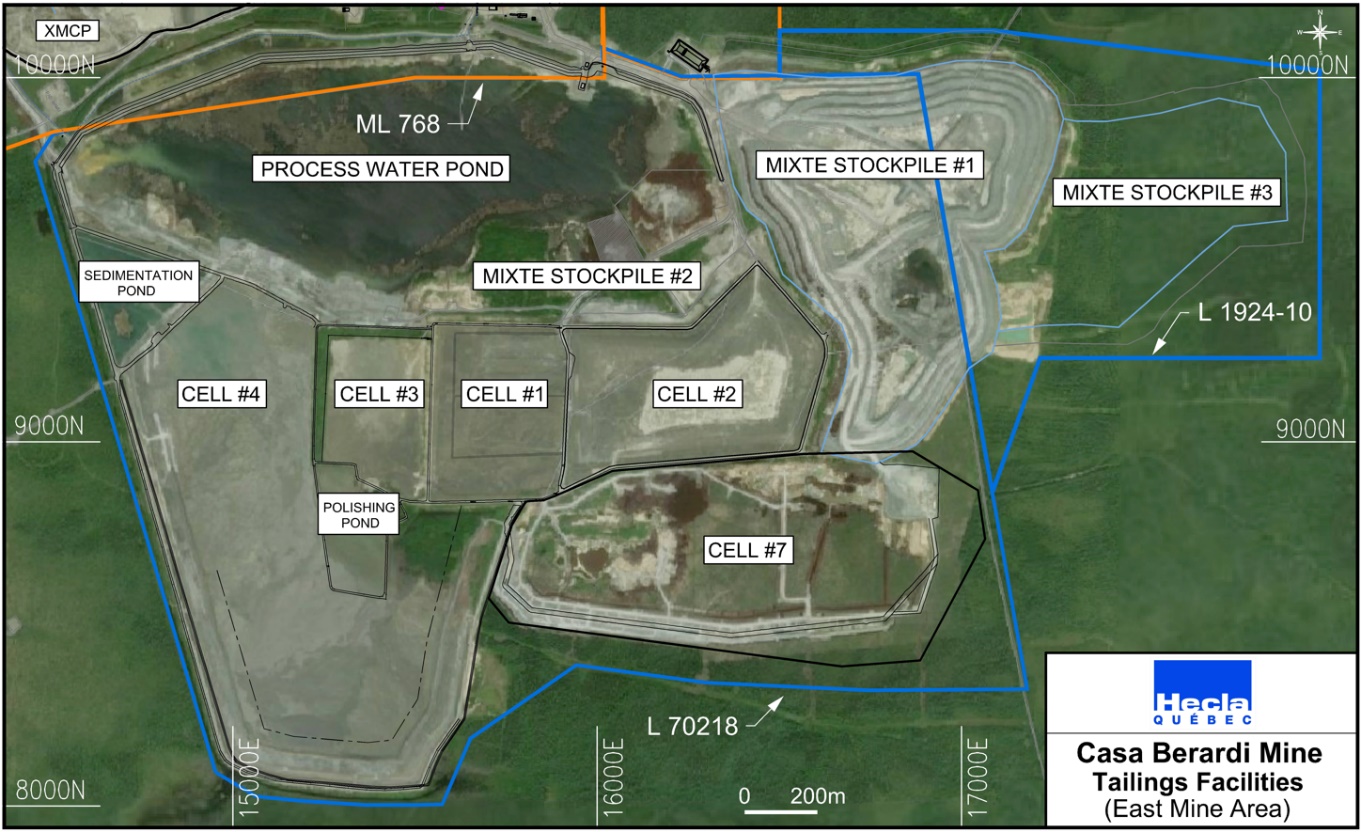

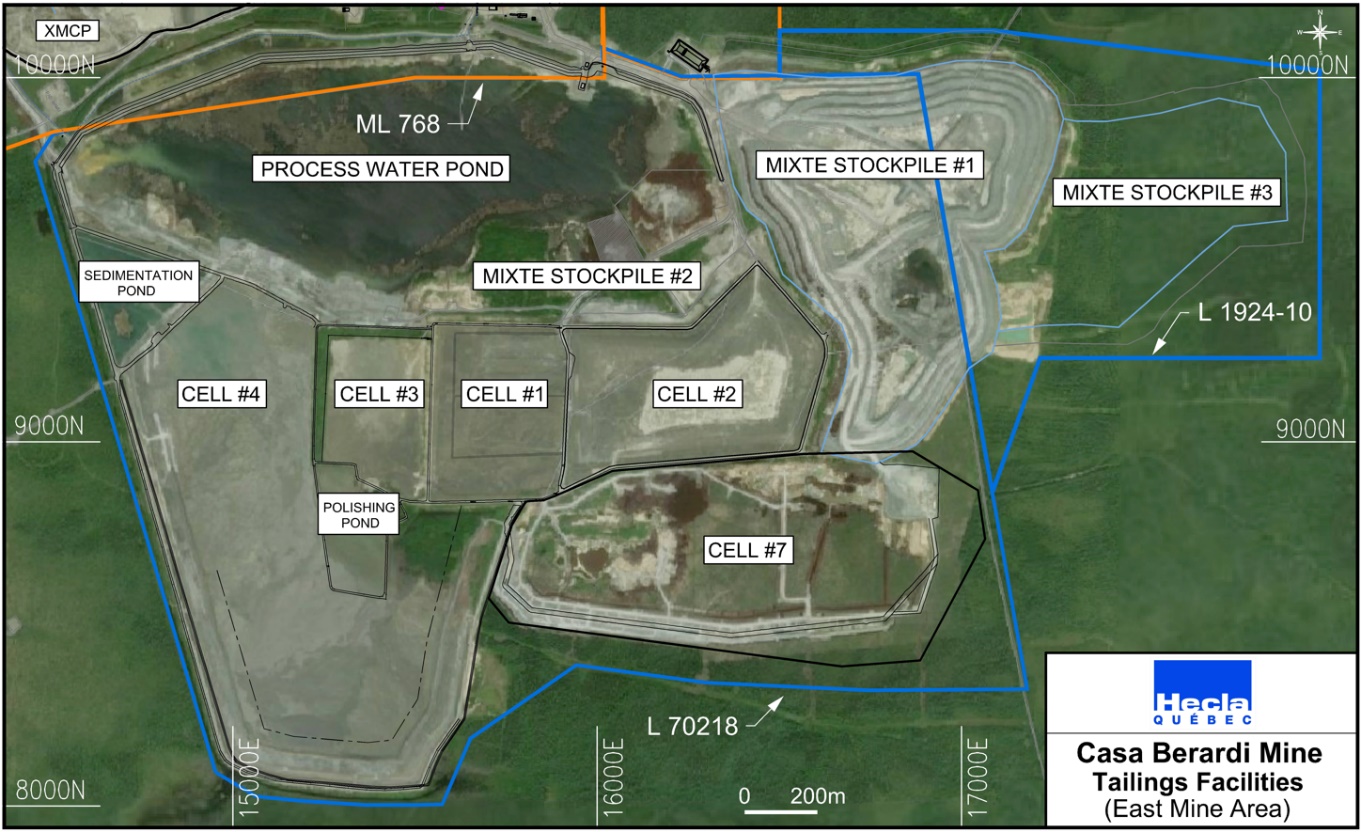

15.1.1 | Tailings Management and Facilities | 226 |

15.1.2 | Waste Rock Management and Stockpiles | 227 |

15.1.3 | Waste rock and overburden | 227 |

15.1.4 | Other Wastes | 228 |

15.1.5 | Water Supply | 228 |

15.1.6 | Water Use | 228 |

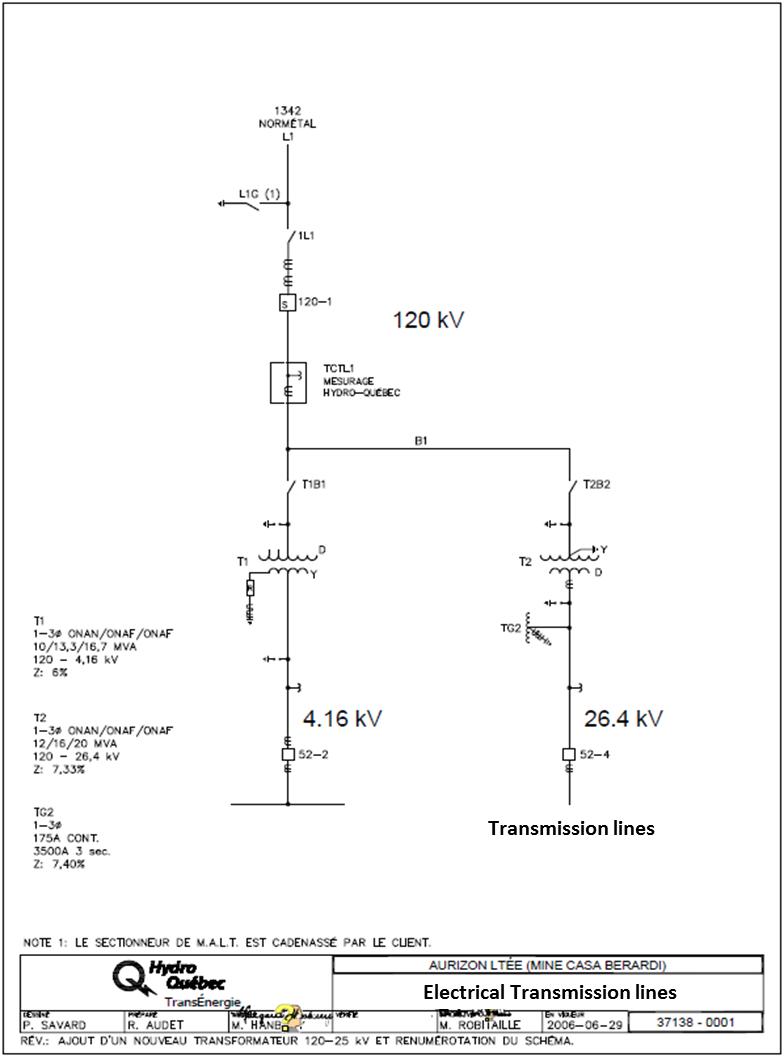

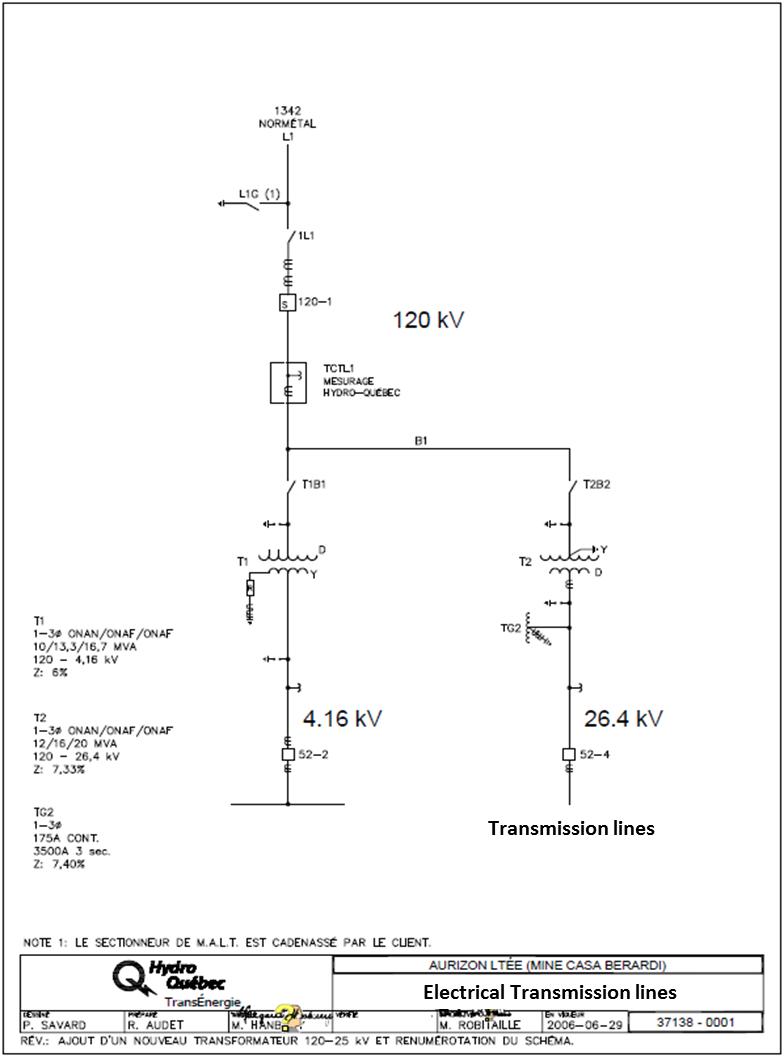

15.1.7 | Power and Electrical | 228 |

15.1.8 | Fuel | 228 |

16.0 | Market Studies | 229 |

16.1 | Markets | 229 |

16.1.1 | Overview | 229 |

16.1.2 | Commodity Price Projections | 229 |

16.2 | Contracts | 230 |

16.2.1 | Refining | 230 |

| | |

16.2.2 | Other Contracts | 230 |

17.0 | Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups | 231 |

17.1 | Environmental Considerations | 231 |

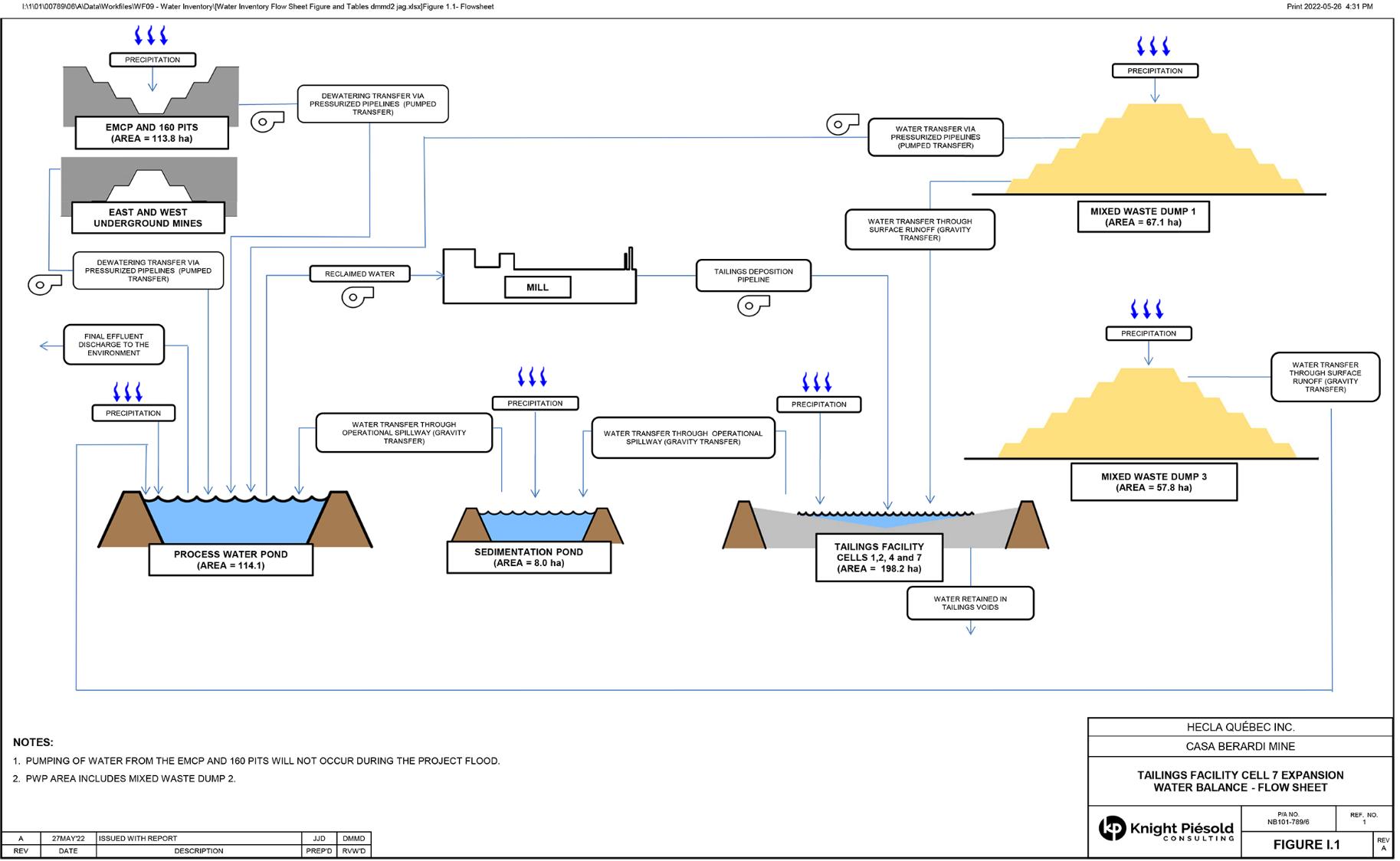

17.2 | Water Management and Effluent Treatment | 232 |

17.2.1 | Water Management | 232 |

17.2.2 | Mine Water Management | 234 |

17.2.3 | TSF Water Management | 234 |

17.2.4 | Environmental Effects of Treated Effluent | 234 |

17.3 | Regulatory Change and Environmental Permits | 234 |

17.3.1 | Regulatory Change | 234 |

17.3.2 | Environmental Permits | 235 |

17.3.3 | Environmental Impact Assessment | 250 |

17.4 | Mine Reclamation and Closure | 250 |

17.5 | Community and Social Aspects | 251 |

17.6 | Comments on Environmental Studies, Permitting, and Community Impact | 251 |

18.0 | Capital and Operating Costs | 253 |

18.1 | Capital Costs | 253 |

18.2 | Operating Costs | 255 |

18.2.1 | LOM Operating Costs | 256 |

19.0 | Economic Analysis | 258 |

19.1 | Economic Criteria | 258 |

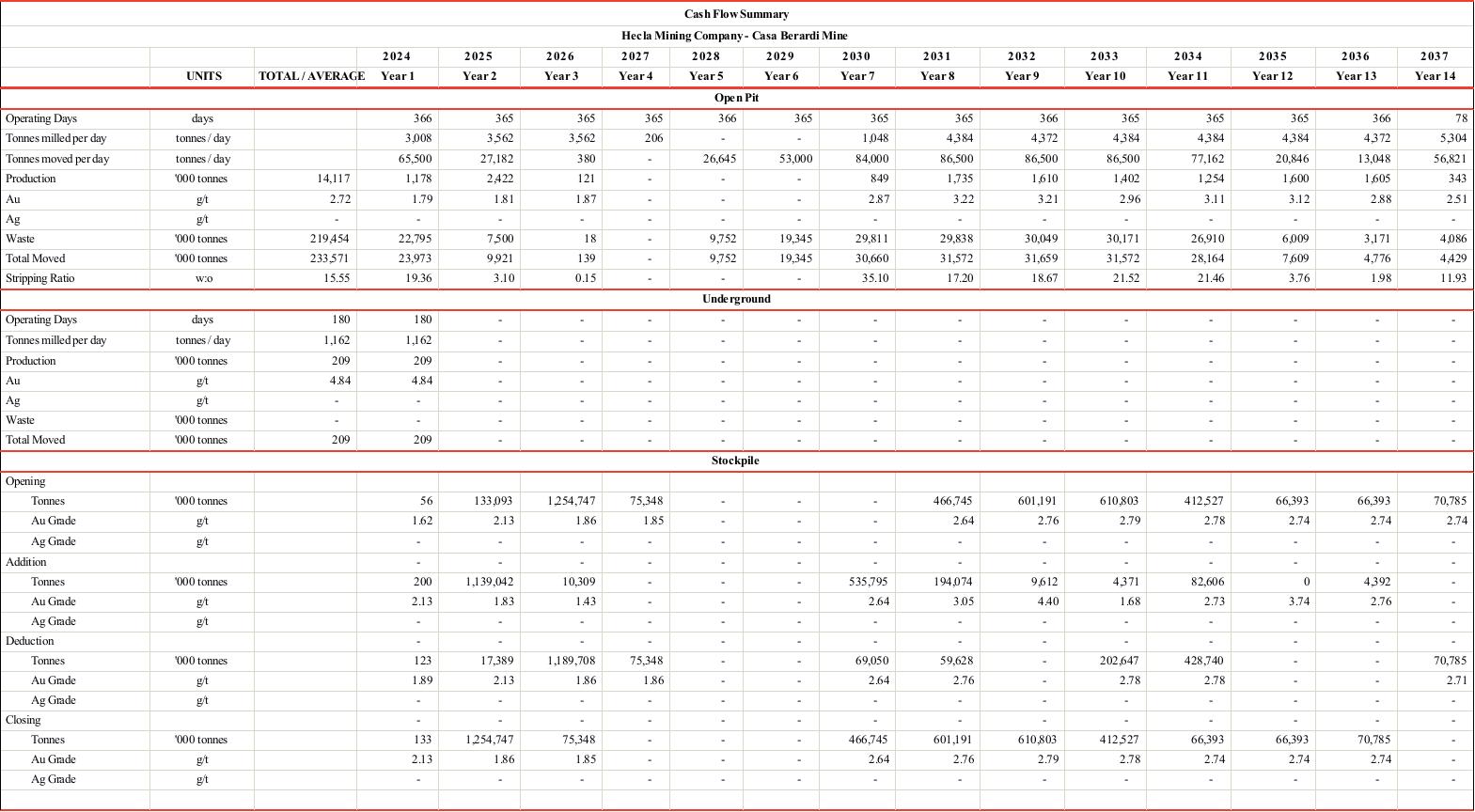

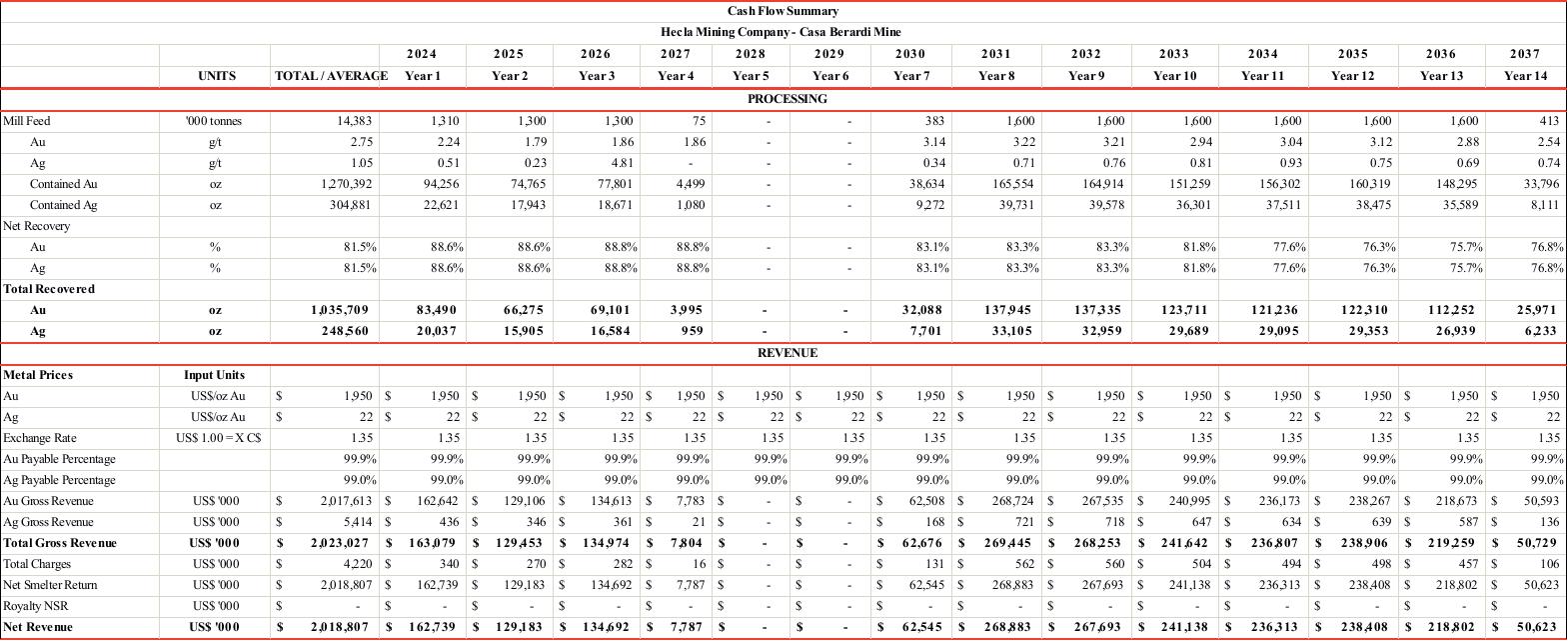

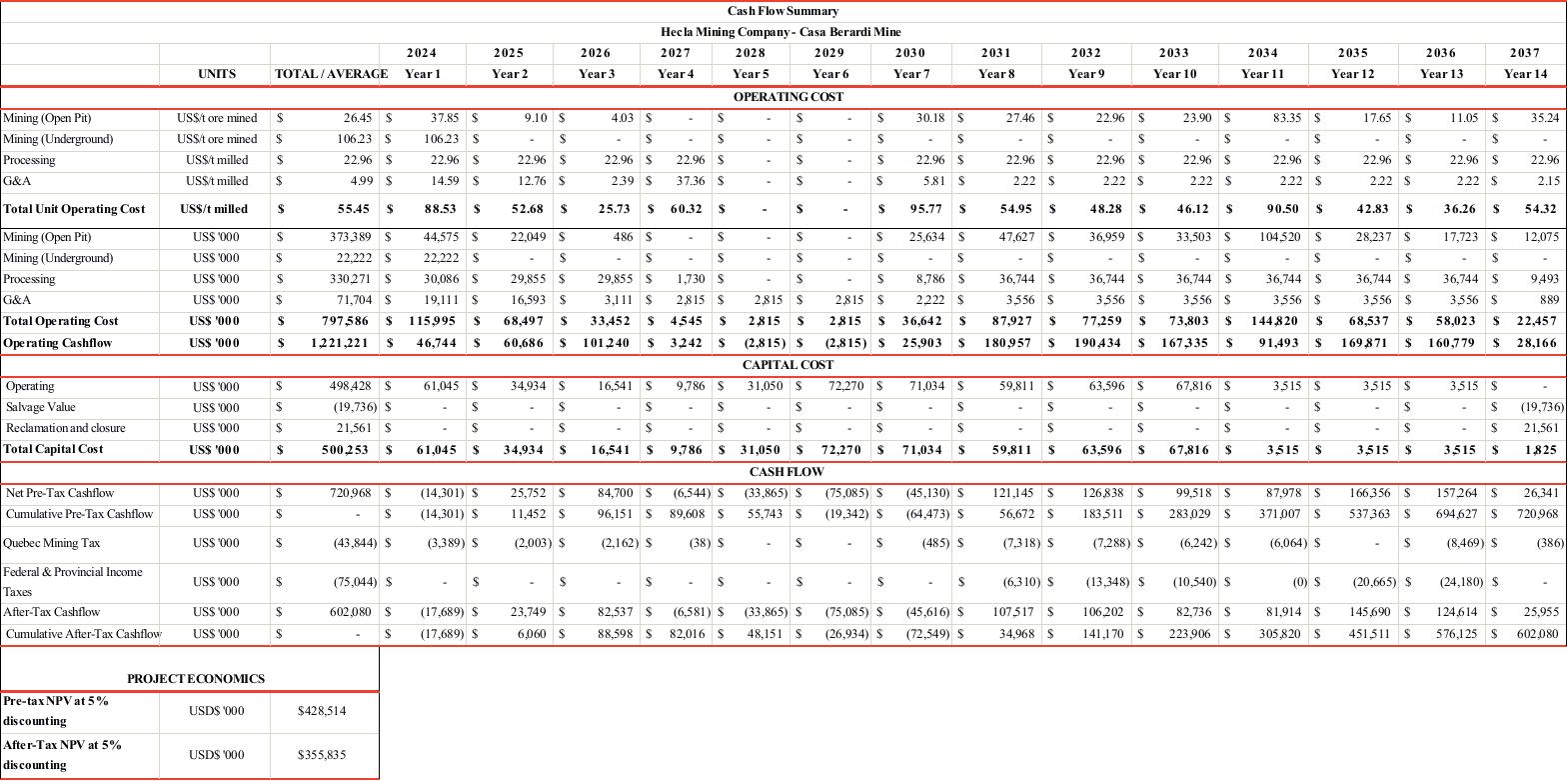

19.1.1 | Physicals | 258 |

19.1.2 | Revenue | 259 |

19.1.3 | Capital Costs | 259 |

19.1.4 | Operating Costs | 259 |

19.1.5 | Taxation and Royalties | 259 |

19.2 | Cash Flow Analysis | 260 |

19.3 | Sensitivity Analysis | 264 |

20.0 | Adjacent Properties | 267 |

21.0 | Other Relevant Data and Information | 267 |

22.0 | Interpretation and Conclusions | 267 |

22.1 | Geology and Mineral Resources | 267 |

22.1.1 | Geology, Mineralization and Deposit Types | 267 |

22.1.2 | Adequacy of Data Used in Estimating the Project Mineral Resources | 267 |

22.1.3 | Mineral Resources | 268 |

| | |

22.1.4 | Exploration Potential | 269 |

22.2 | Mining and Mineral Reserves | 269 |

22.3 | Mineral Processing | 270 |

22.4 | Infrastructure | 270 |

22.5 | Environment | 270 |

23.0 | Recommendations | 271 |

23.1 | Geology and Mineral Resources | 271 |

23.2 | Mining and Mineral Reserves | 272 |

23.3 | Mineral Processing | 272 |

24.0 | References | 273 |

25.0 | Reliance on Information Provided by the Registrant | 278 |

26.0 | Date and Signature Page | 279 |

APPENDIX A Claims Table | 1-A |

A.1 | Claims Table | 2-A |

APPENDIX B Drill-Hole and Rock-Chip Sample Database Structures | 1-B |

B.1 | Drill-Hole and Rock-Chip Sample Database Structures | 2-B |

APPENDIX C Capping Levels | 1-C |

C.1 | Capping Levels | 2-C |

APPENDIX D Comparison of 2023 and 2022 Mineral resource Estimates | 1-D |

D.1 | Mineral Resource Estimates | 2-D |

LIST OF TABLES

| |

Table 1‑1. Life of Mine Indicative Economic Results | 8 |

Table 1‑2. Mineral Resource Estimate Summary – December 31, 2023 | 12 |

Table 1‑3. Summary of Mineral Reserves - December 31,2023 | 14 |

Table 1‑4. LOM Capital Cost Summary | 18 |

Table 1‑5. LOM Operating Cost Summary | 18 |

Table 5‑1. Historical Drilling 1957 through 2013 | 34 |

Table 5‑2. Historical Mine Production 1988 – 1997 | 38 |

Table 5‑3. Casa Berardi Production 2006 to mid-2013 | 38 |

Table 7‑1. Hecla Surface and Underground Drilling 2014 – 2023 | 64 |

Table 7‑2. Hydrogeological Drill Holes Between 2022 & 2023 | 68 |

Table 7‑3. Geotechnical Drill Holes from 2022-2023 | 69 |

Table 8‑1. Pulp Duplicate Summary from 2009 to 2023 | 76 |

Table 8‑2. External Check Assays from 2009 to 2023 | 78 |

Table 8‑3. Reject External Check Assays | 81 |

Table 8‑4. CRM Assay Results | 86 |

Table 8‑5. Casa Berardi Laboratory Program CRMs | 96 |

Table 10‑1. Chemical Assays of Composite Samples | 105 |

Table 10‑2. Comminution Test Results on Composites | 107 |

Table 10‑3. Head Grade Summary | 109 |

Table 10‑4. Head Grade Summary, 2021 Blue Coast Work | 111 |

Table 10‑5. 2021 WMCP Flotation Test Conditions | 111 |

Table 10‑6. 2021 WMCP Flotation Product CIL Stirred Leach Conditions | 112 |

Table 10‑7. Summary of 2021 WMCP Flotation Product CIL Stirred Leach Results | 113 |

Table 10‑8. 2022 WMCP Variability Cyanidation Results | 115 |

Table 25. 2022 Casa Berardi WMCP Master Composite Head Assays | 117 |

Table 10‑10. 2022 Flotation Conditions | 118 |

Table 10‑11. 2023 Casa Berardi WMCP Master Composite Head Assays | 121 |

Table 10‑12. Summary of 2023 Flotation Test Conditions | 124 |

Table 10‑13. Combined Flowsheet Recovery – Non Final Flowsheet | 130 |

Table 10‑14. Combined Flowsheet Recovery –Final Flowsheet | 131 |

Table 10‑15. Casa Berardi Annual Mill Production | 132 |

Table 10‑16. Detailed Yearly Mill Production | 133 |

| |

Table 10‑17. Expected Recovery LOM for all Mining Zones | 135 |

Table 11‑1. Casa Berardi Mineral Resource Estimate Summary – December 31, 2023 | 139 |

Table 11‑2. Open Pit Optimization Parameters Applied to Mineral Resources | 140 |

Table 11‑3. Comparison of December 31, 2023 Versus December 31, 2022 Mineral Resources | 141 |

Table 11‑4. Summary of Core, Reverse Circulation and Sonic Drill Holes and Channel Samples at Casa Berardi | 142 |

Table 11‑5. Descriptive Statistics of Sample Assays in Casa Berardi Drill-Hole Database | 143 |

Table 11‑6. Density Determinations by Zone | 144 |

Table 11‑7. Open Pit Optimization Parameters by Pit | 151 |

Table 11‑8. Underground Mineral Resource Cutoff Grades by Zone | 152 |

Table 11‑9. Underground and Open Pit Mineral Resources by Zone – December 31, 2023 | 152 |

Table 12‑1. Summary of Mineral Reserves – December 31, 2023 | 159 |

Table 12‑2. Mineral Reserves by Zone – December 31, 2023 | 160 |

Table 12‑3. Underground and Open Pit Reserve Cutoff Grades | 163 |

Table 12‑4. Dilution and Extractions Estimates – Underground | 164 |

Table 12‑5. Dilution and Extractions Estimates – Open Pit | 165 |

Table 12‑6. Change in Mineral Reserves 2023 to 2022 | 167 |

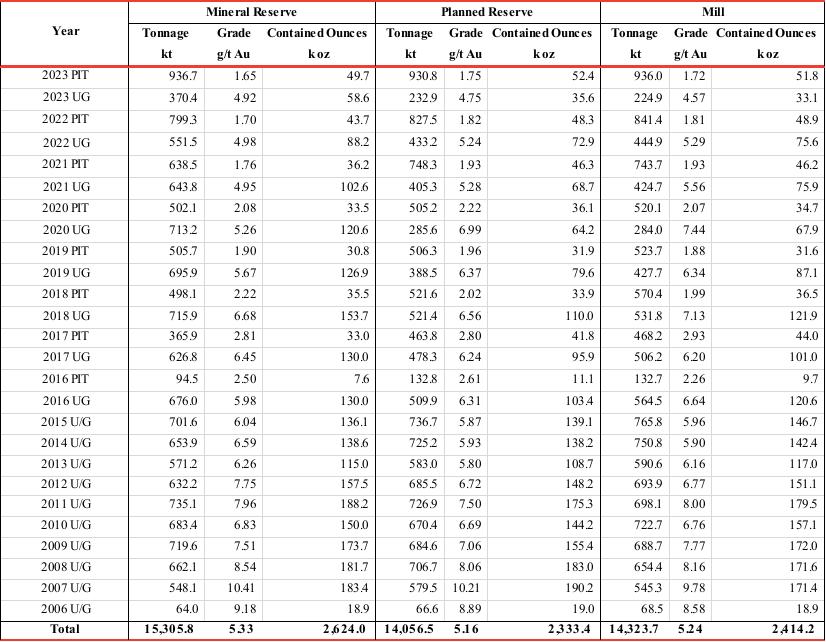

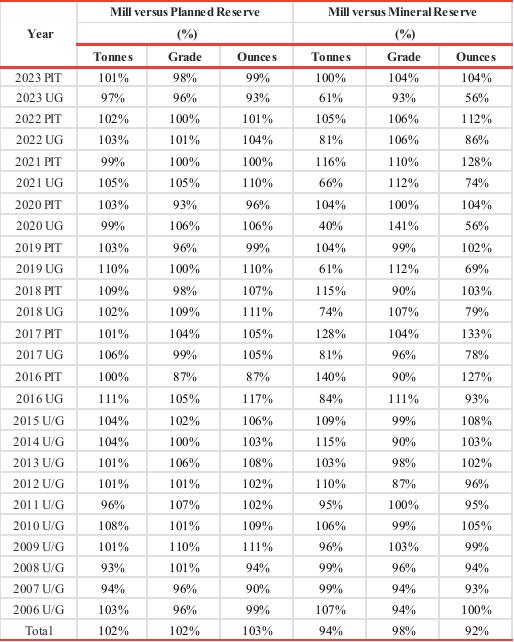

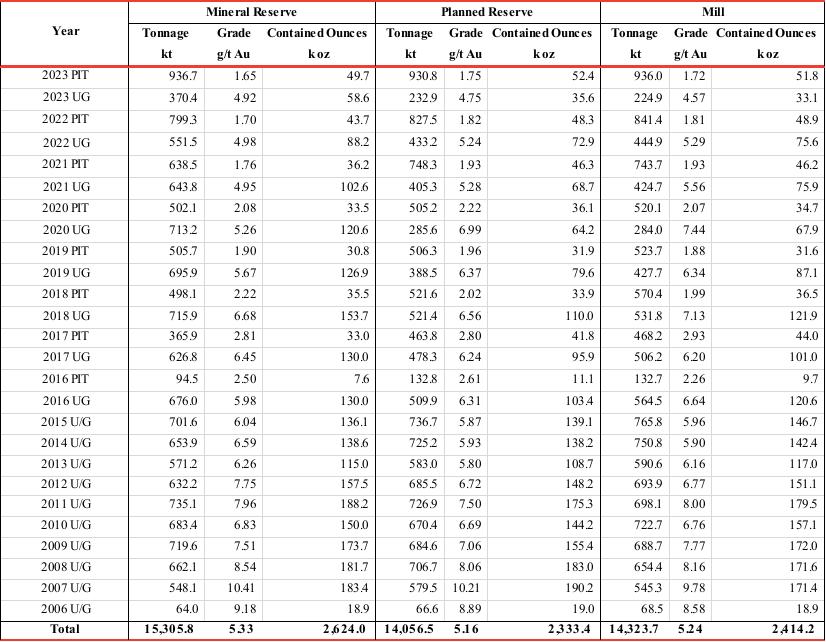

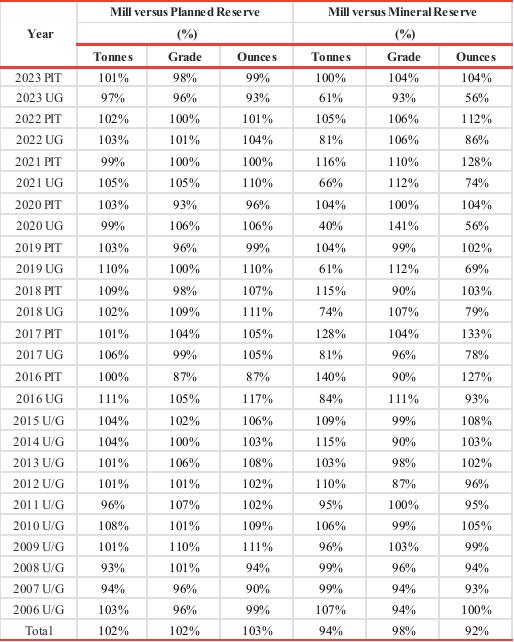

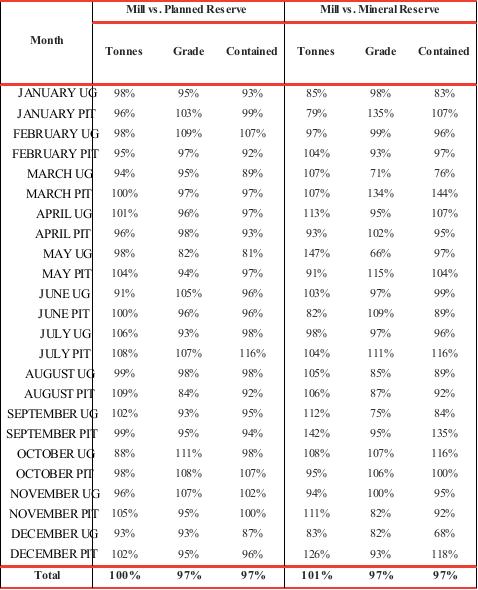

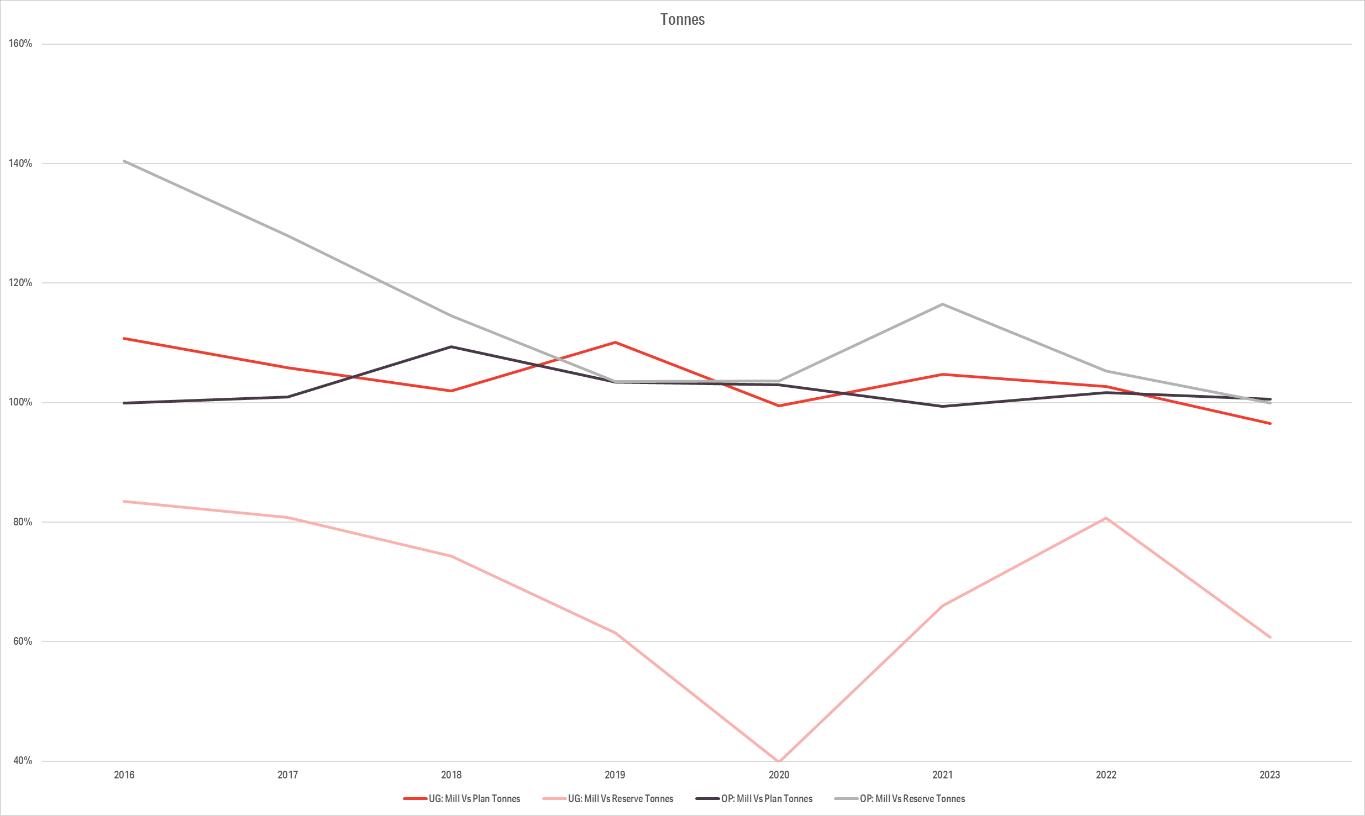

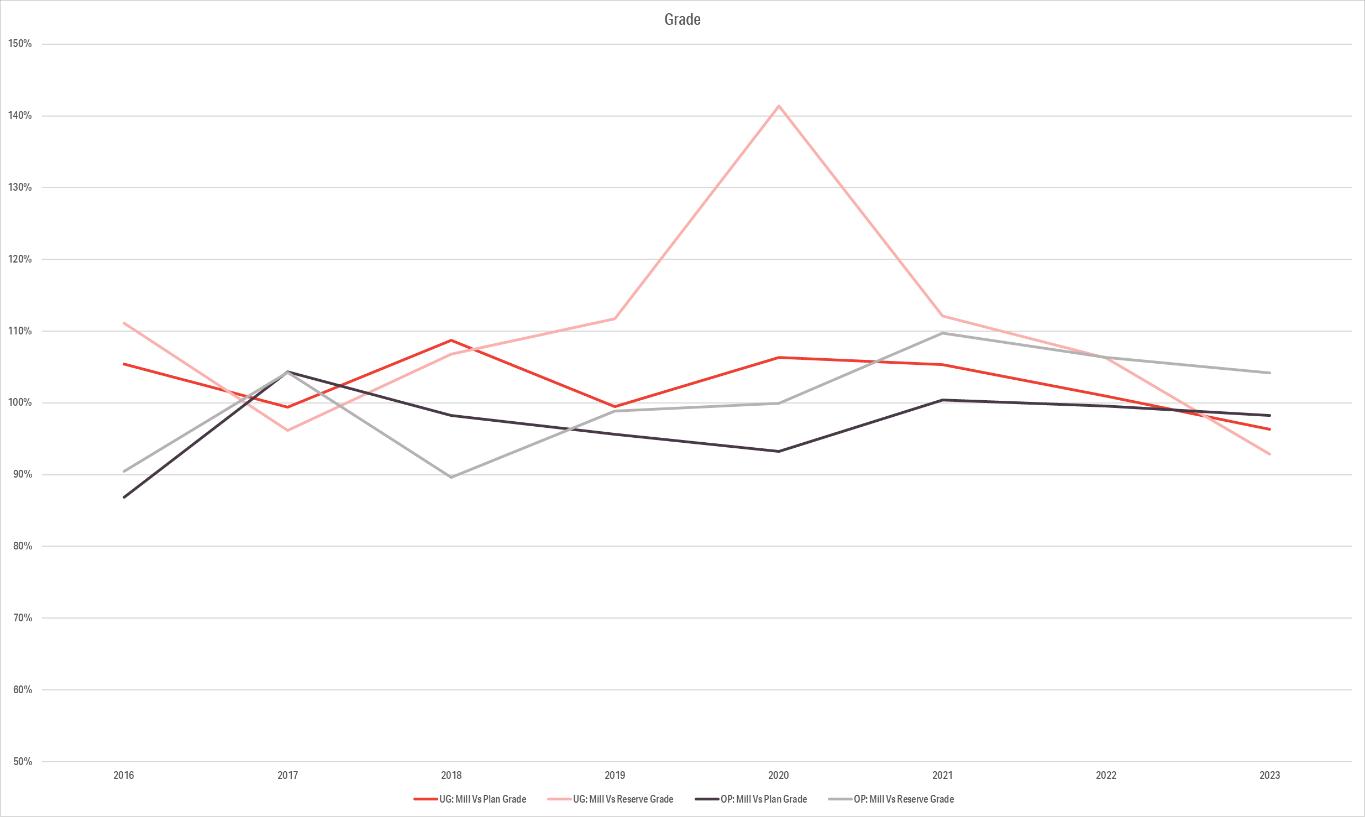

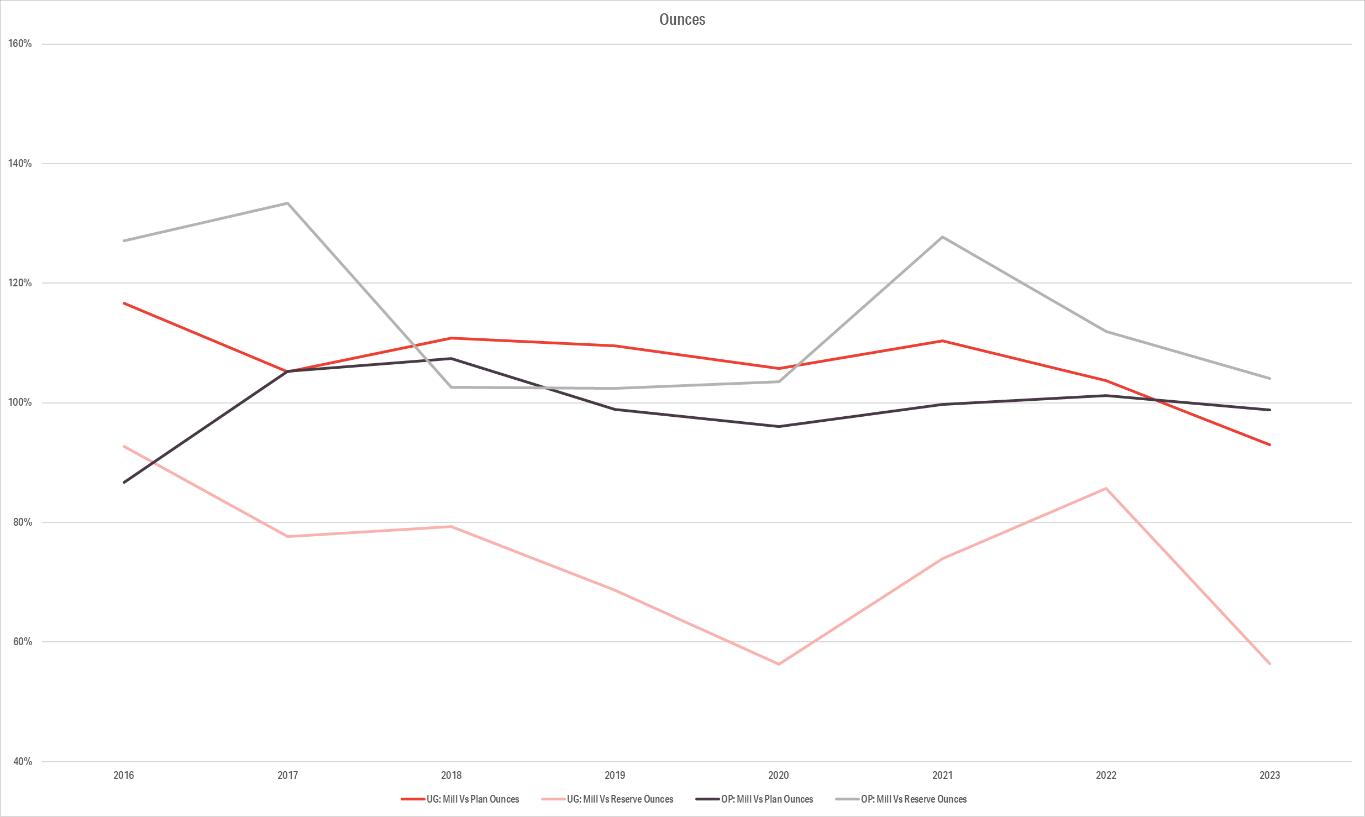

Table 12‑7. Mine-Mill Reconciliation – 2006 to 2023 | 169 |

Table 12‑8. Mine-Mill Reconciliation – 2006 to 2023 | 170 |

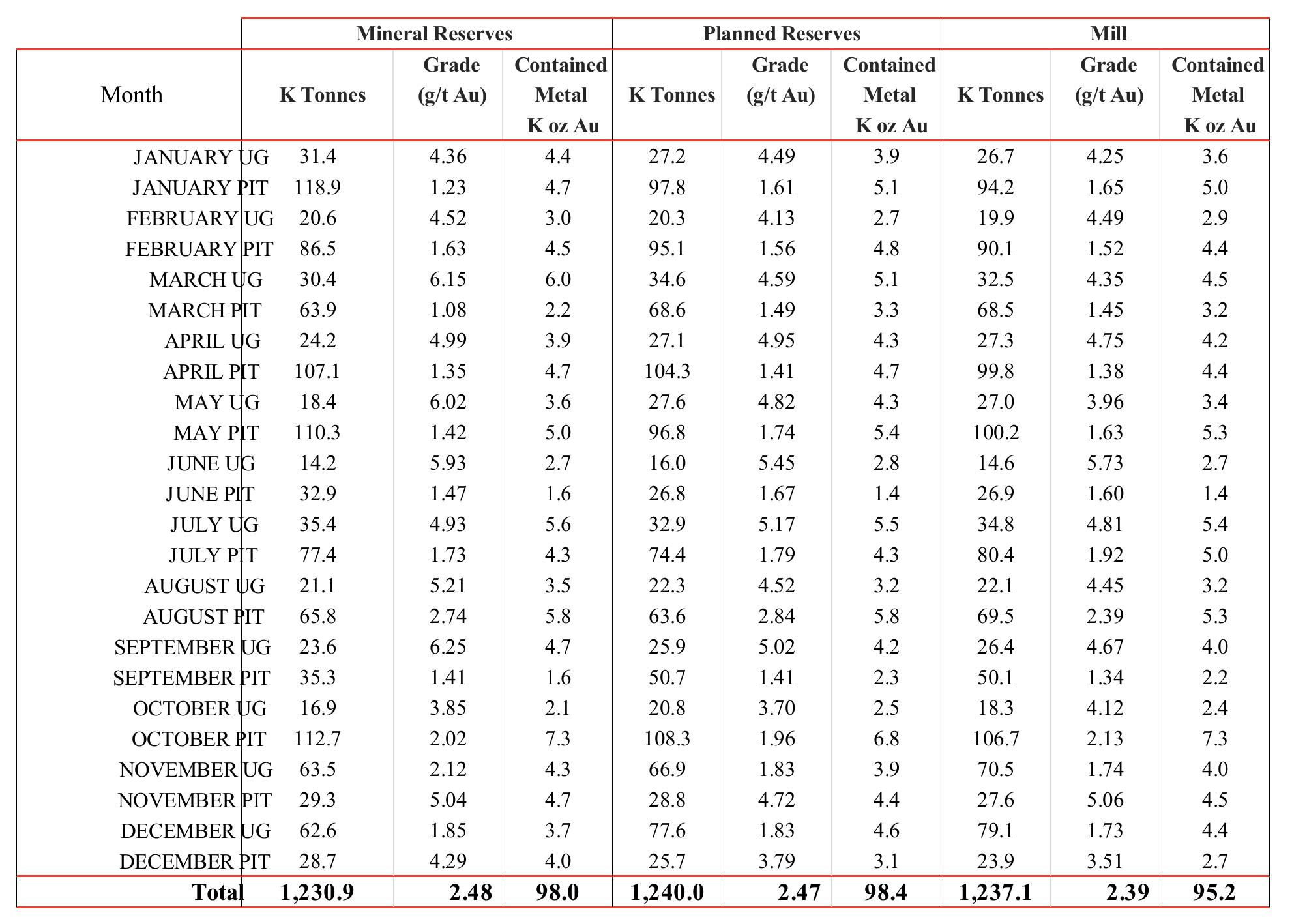

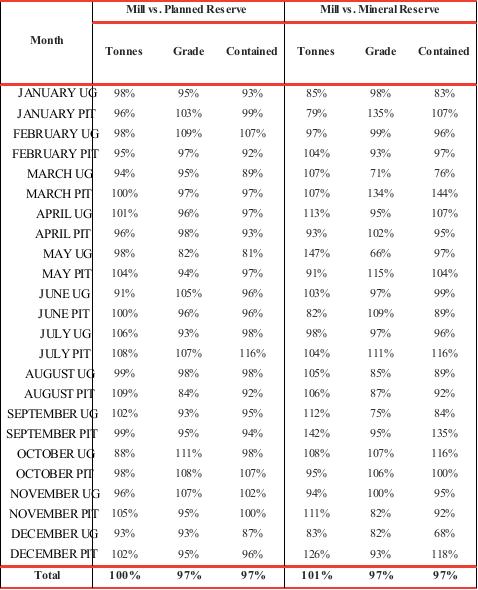

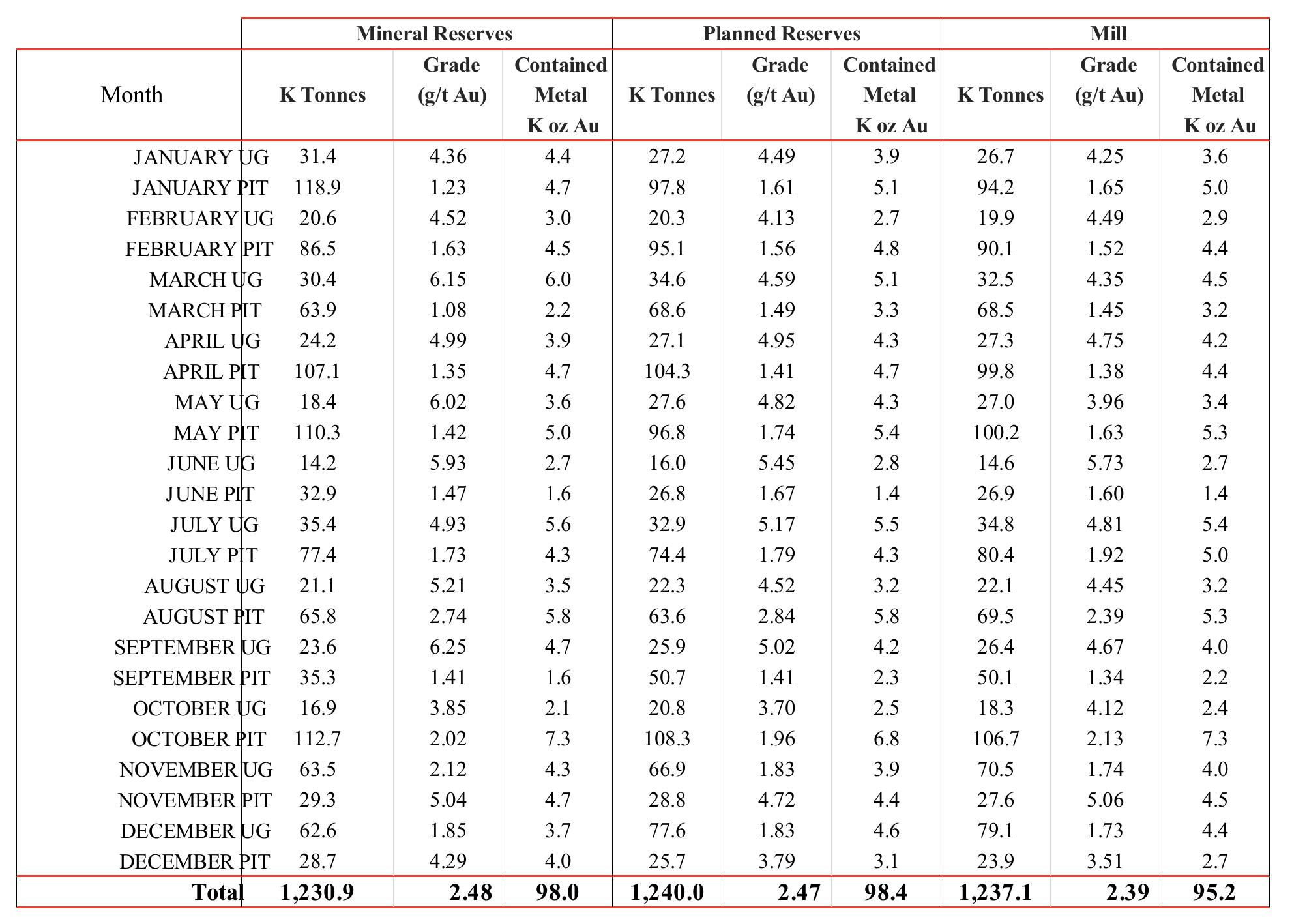

Table 12‑9. Mine-Mill Reconciliation – 2023 | 171 |

Table 12‑10. Mine-Mill Reconciliation – 2023 | 172 |

Table 13‑1. Tonnage per Stope | 179 |

Table 13‑2. Typical Stope Delays and Activity Duration | 179 |

Table 13‑3. Personnel Requirements by Year | 191 |

Table 13‑4. Mine Equipment List Open Pit | 195 |

Table 13‑5. Geotechnical, Geomechanical, Hydrological and Hydrogeological Studies (Underground Mines) | 197 |

Table 13‑6. Geotechnical, Geomechanical, Hydrological and Hydrogeological Studies (Open Pit Mines) | 198 |

Table 13‑7. Dumping Sequencing | 203 |

Table 13‑8. LOM Production Forecast | 213 |

Table 14‑1. Major Equipment List | 217 |

Table 14‑2. Reagent Consumption 2023 | 219 |

Table 16‑1. Hecla Historical Average Realized Metal Prices | 229 |

Table 17‑1. Existing Environmental Permits | 236 |

Table 17‑2. Total Contributions to Regional Organizations from 2018 to 2022 | 251 |

Table 18‑1. LOM Capital Costs | 254 |

| |

Table 18‑2. 2020 and 2021 Operating Cost Data | 256 |

Table 18‑3. LOM Operating Costs | 257 |

Table 18‑4. LOM Unit Operating Costs | 257 |

Table 19‑1. Annual Cash Flow Model | 261 |

Table 19‑2. Sensitivity Analysis Summary | 265 |

LIST OF FIGURES

| |

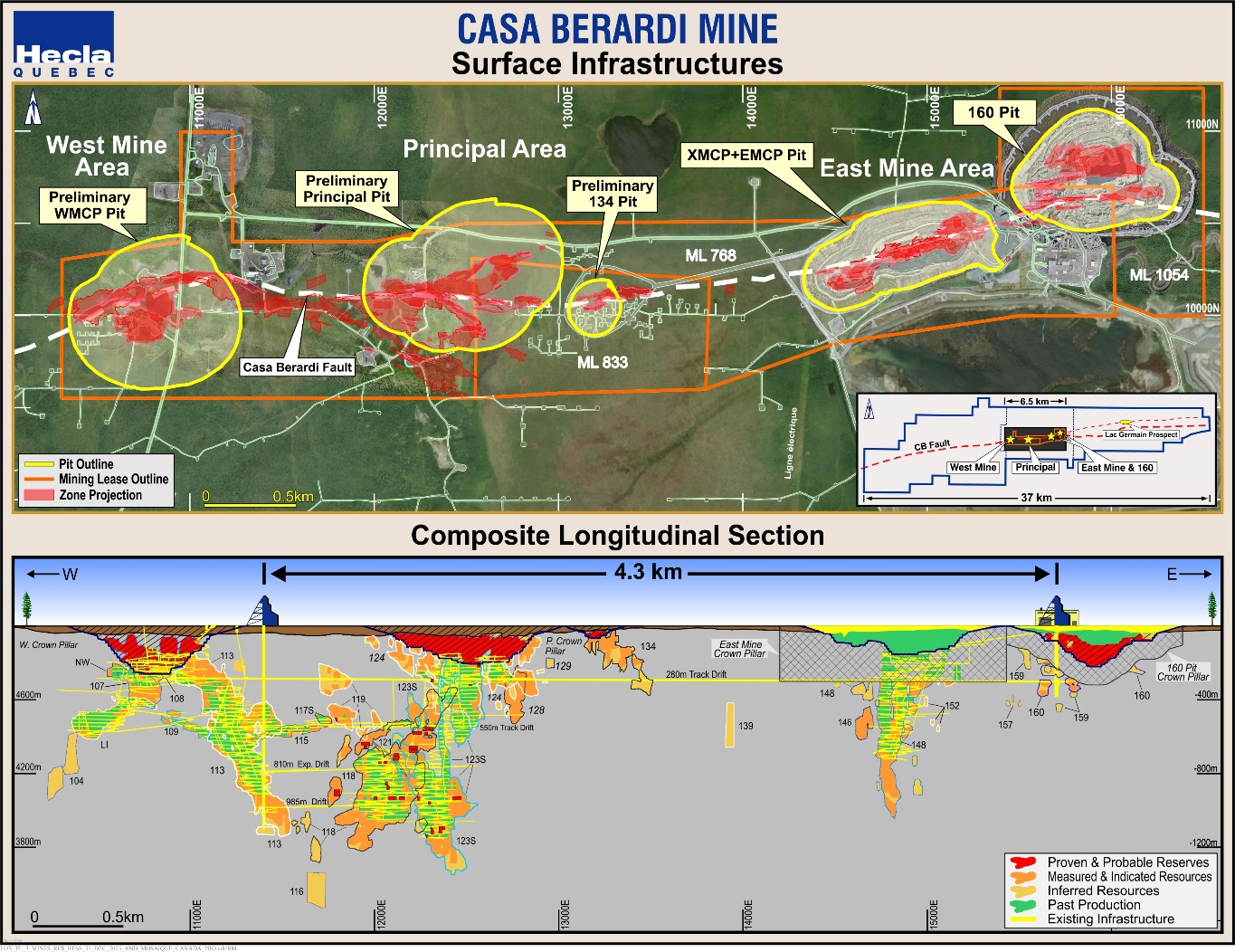

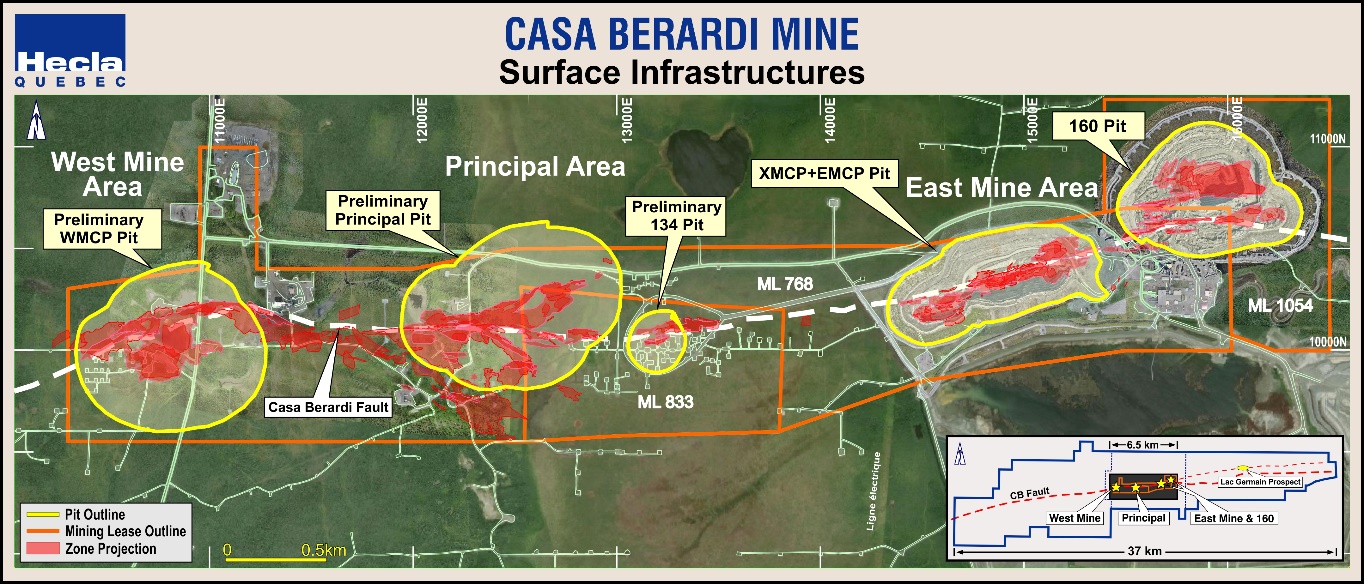

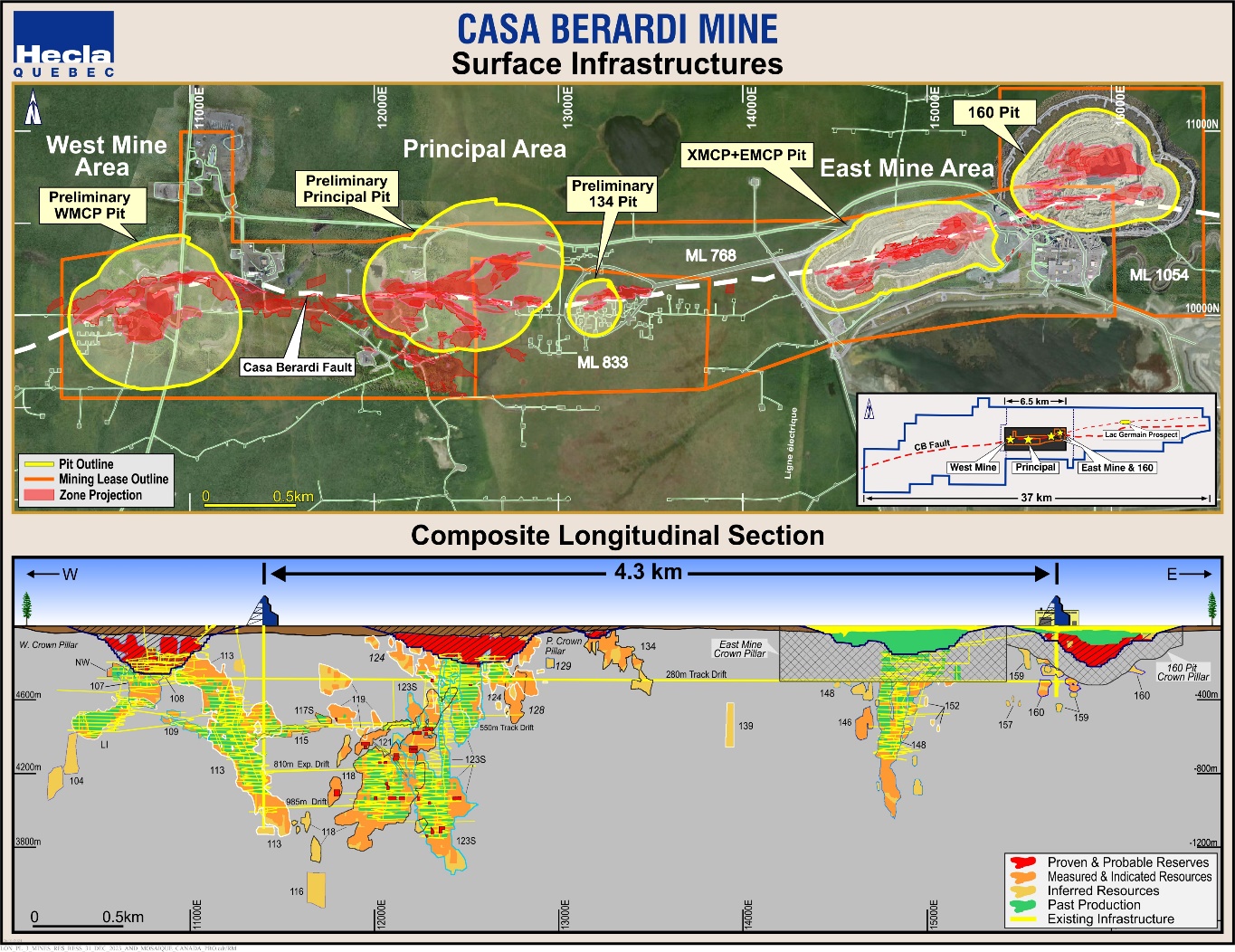

Figure 1‑1. Mine Plan View of Current and Planned Infrastructure with Composite Longitudinal Section | 2 |

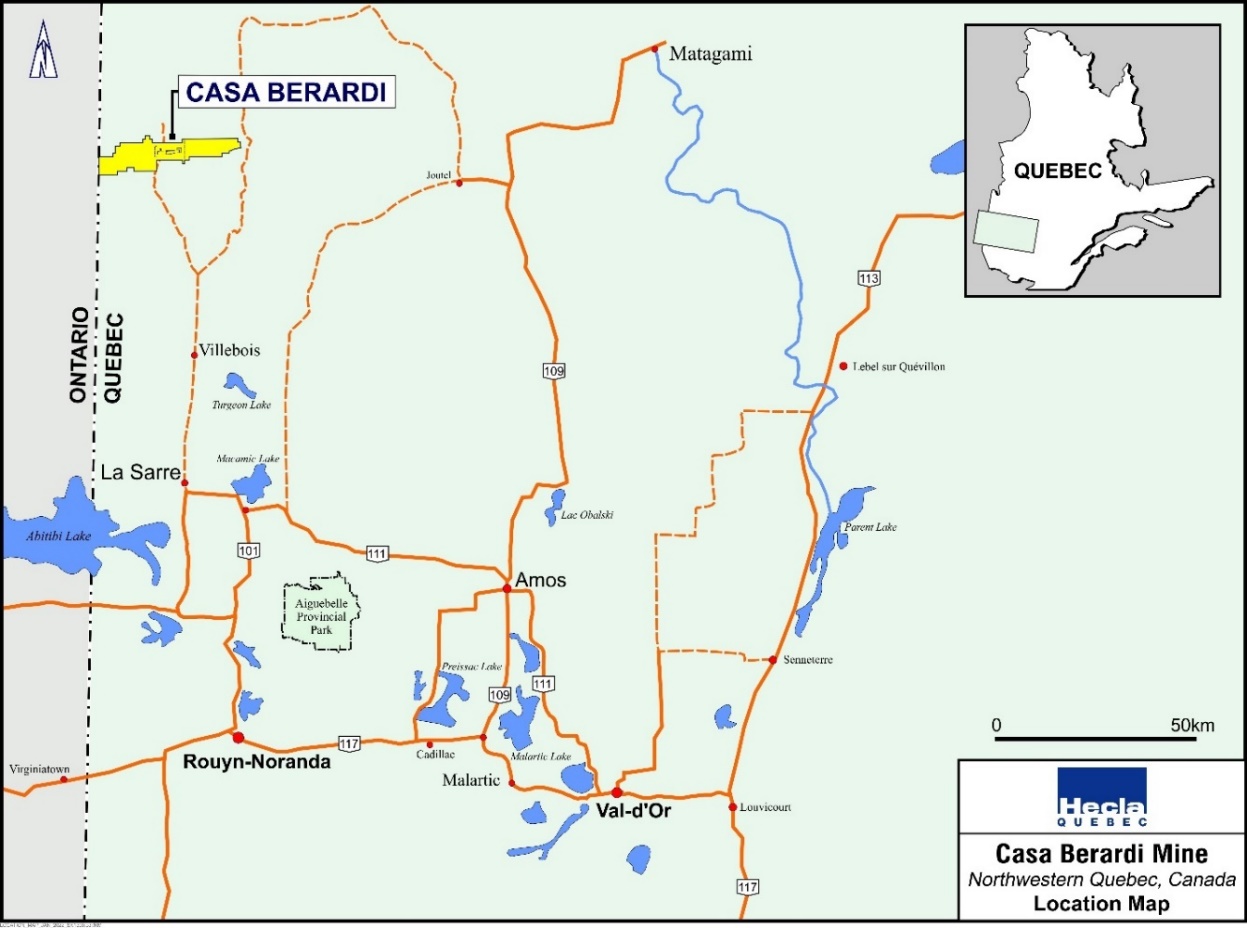

Figure 3‑1. Project Regional Location Map | 23 |

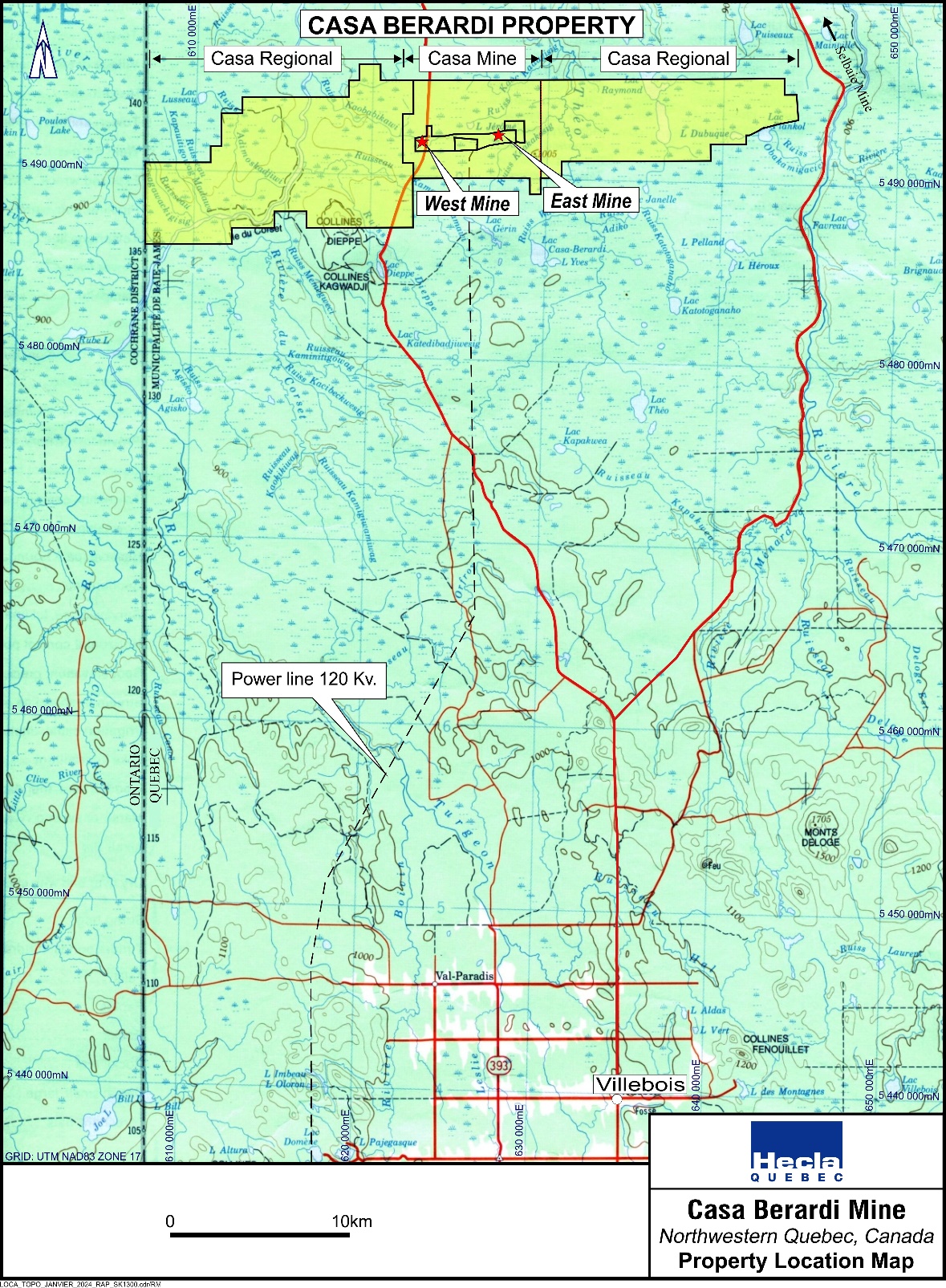

Figure 3‑2. Property Location Map | 24 |

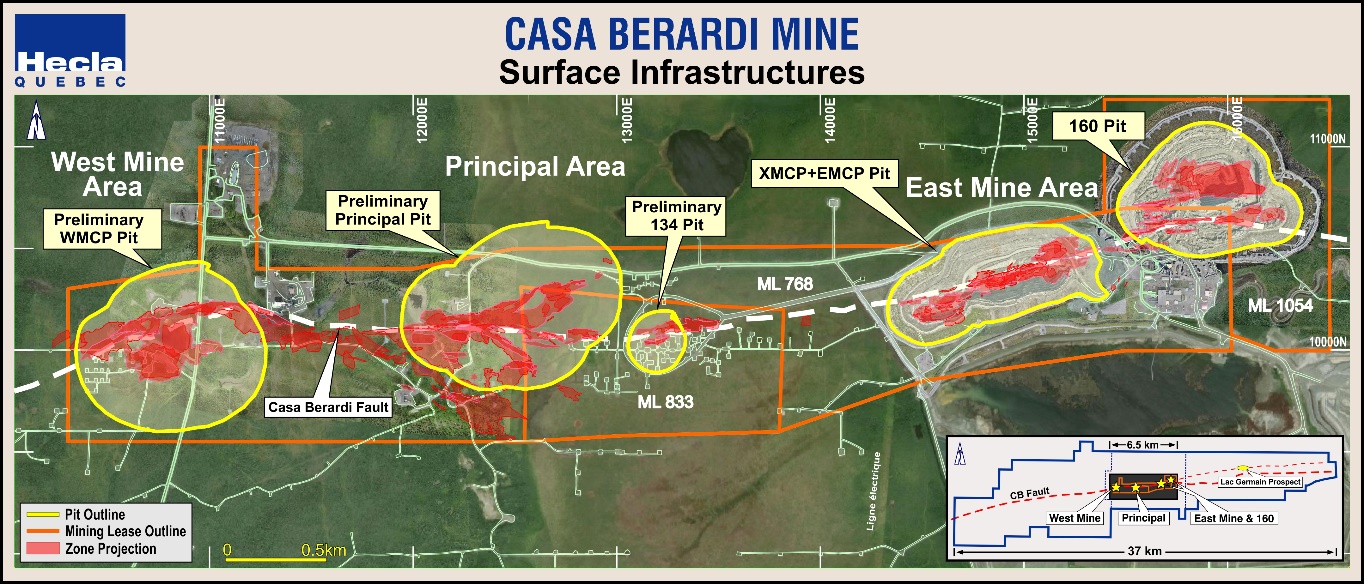

Figure 3‑3. Plan View of Current and Planned Infrastructure | 25 |

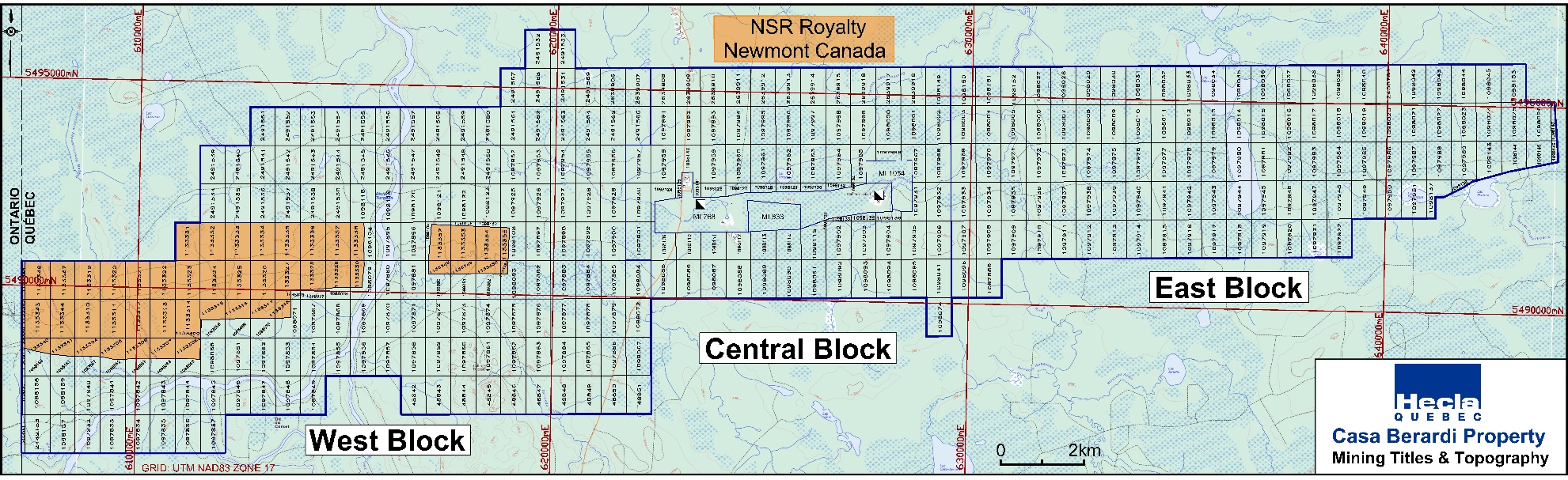

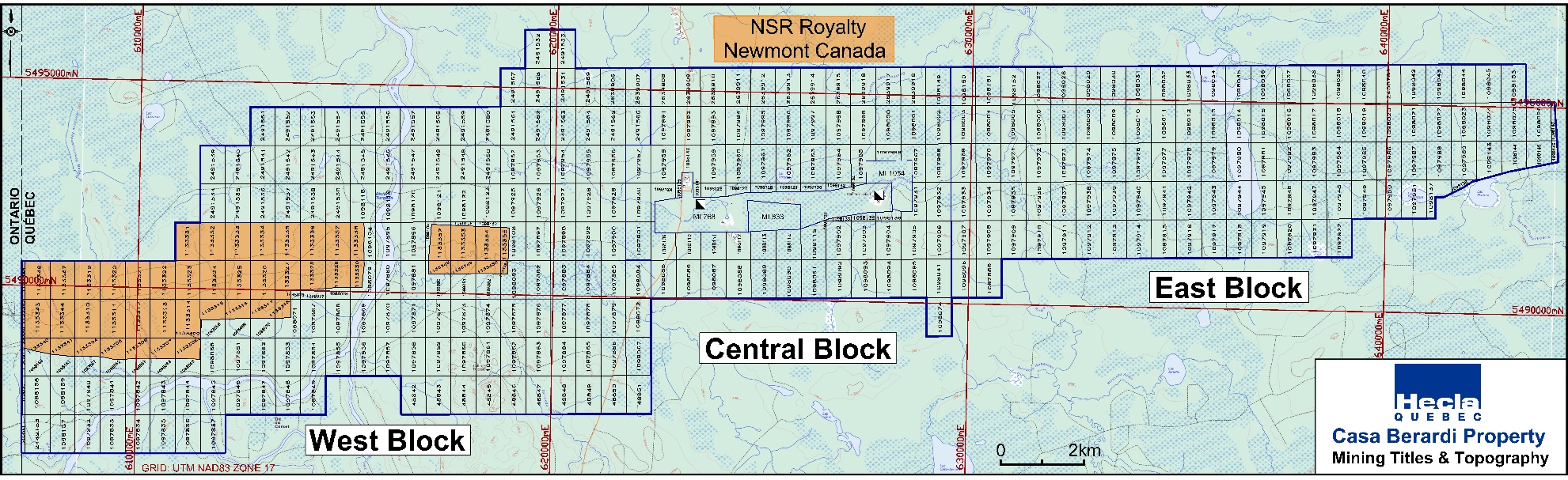

Figure 3‑4. Property Claim Map | 27 |

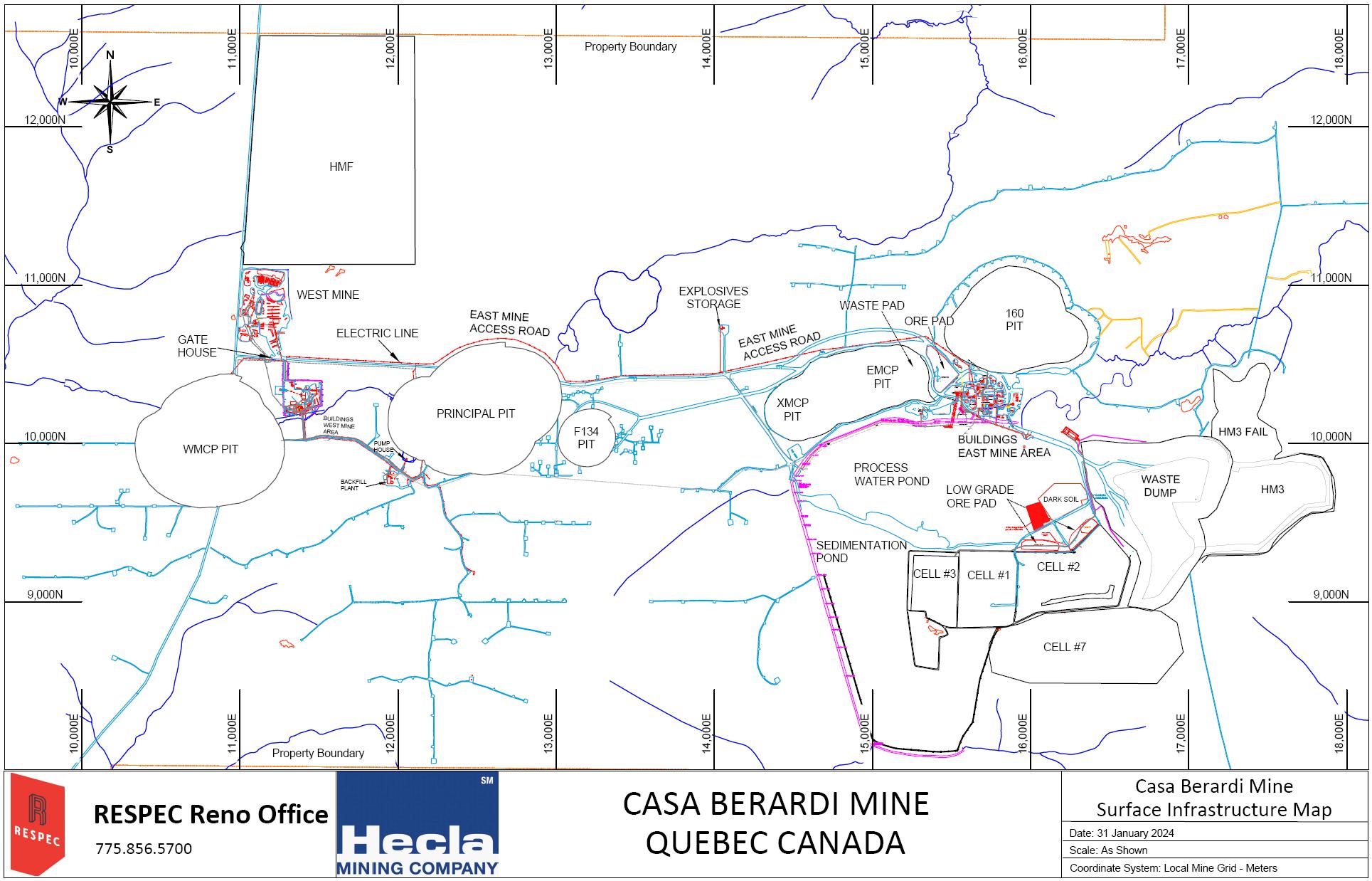

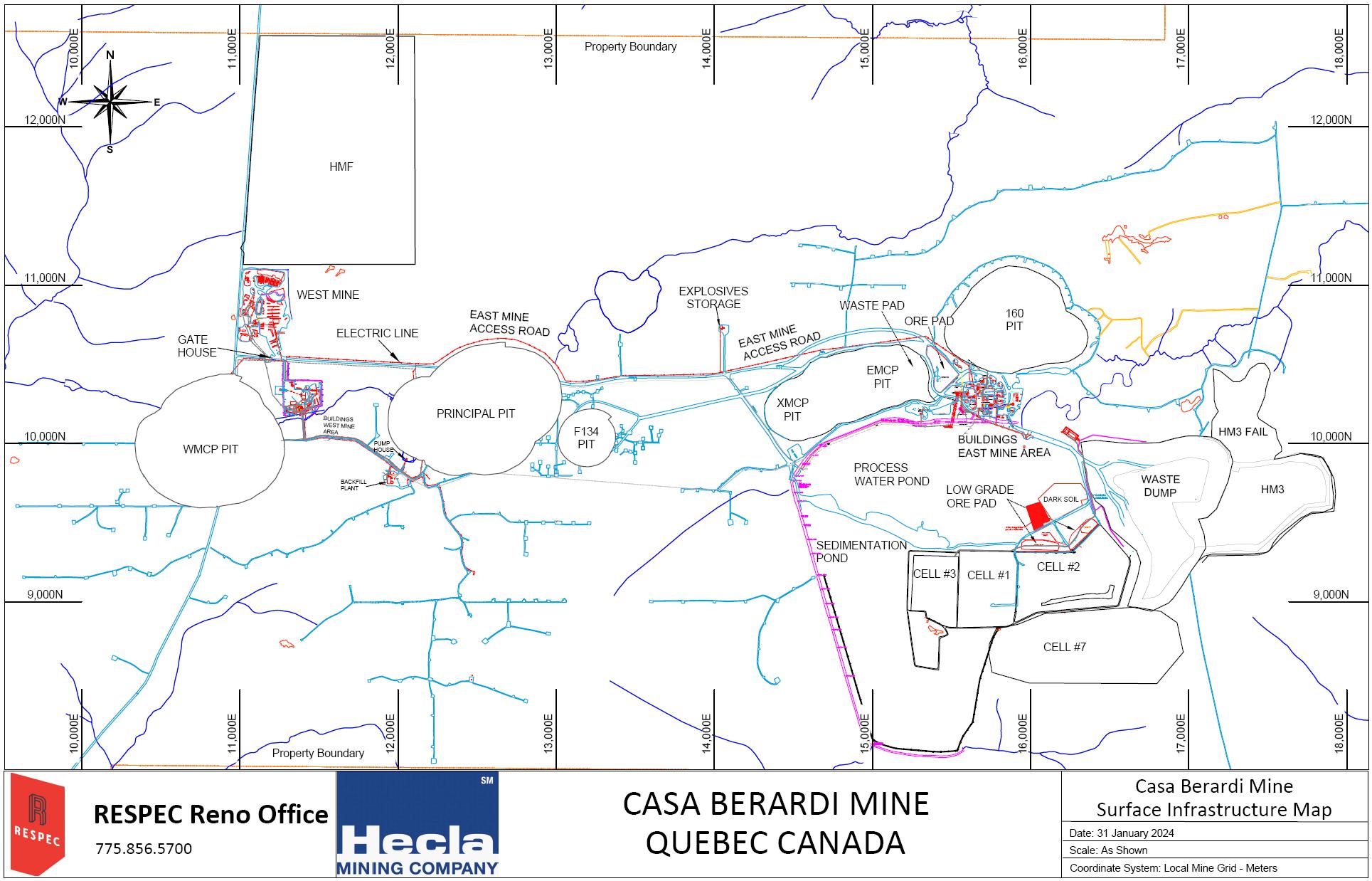

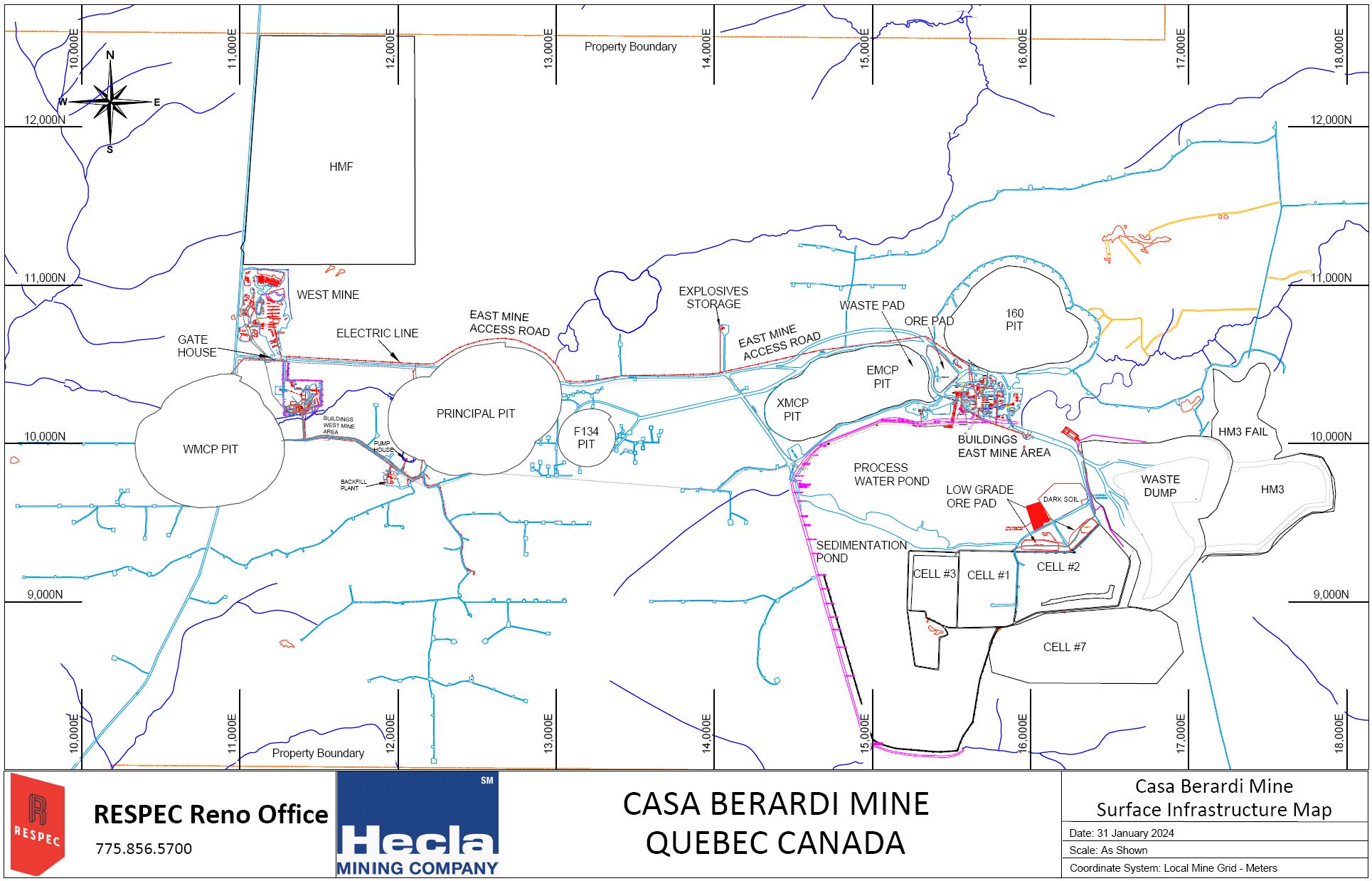

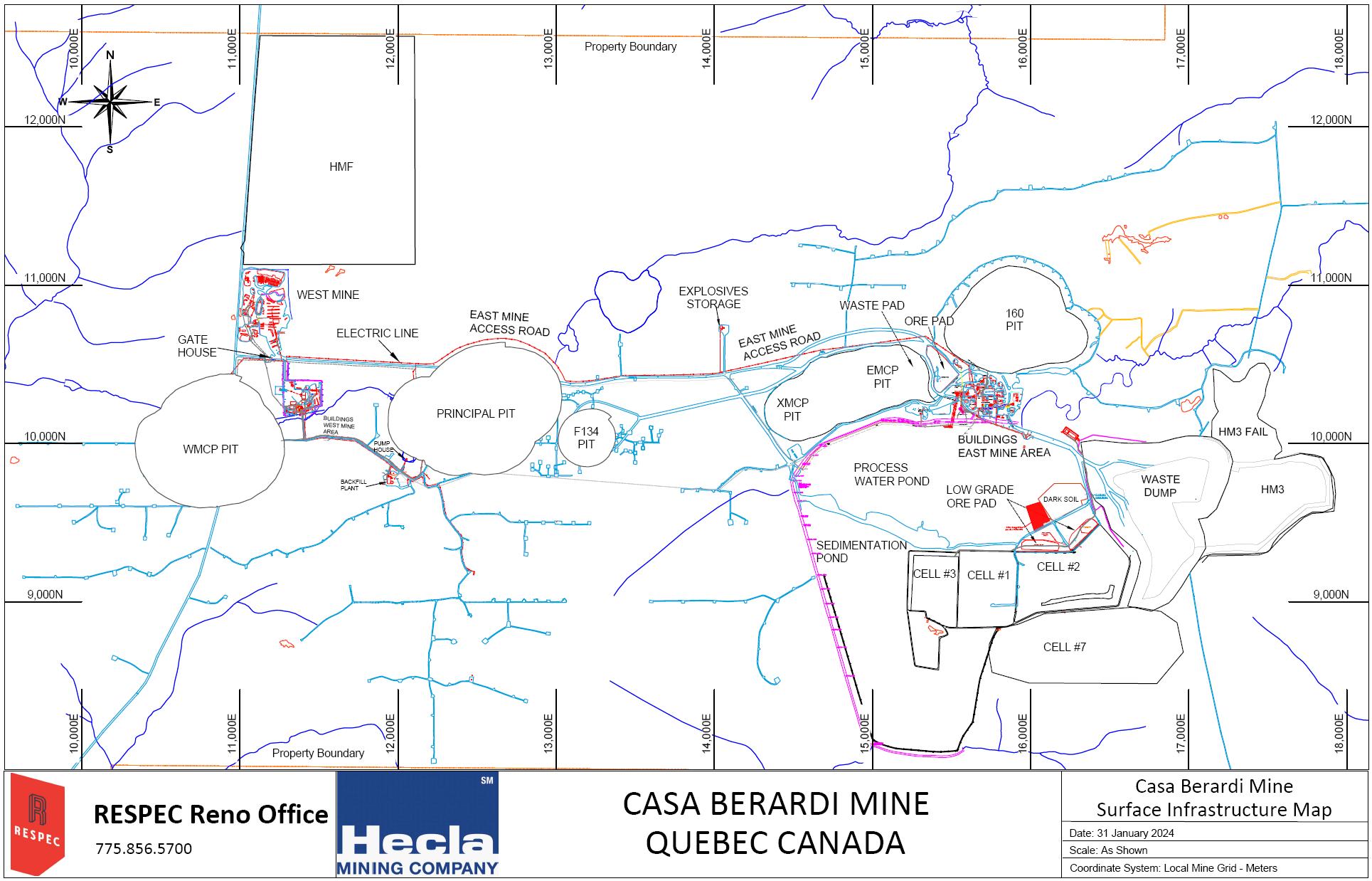

Figure 4‑1. Surface Infrastructure | 31 |

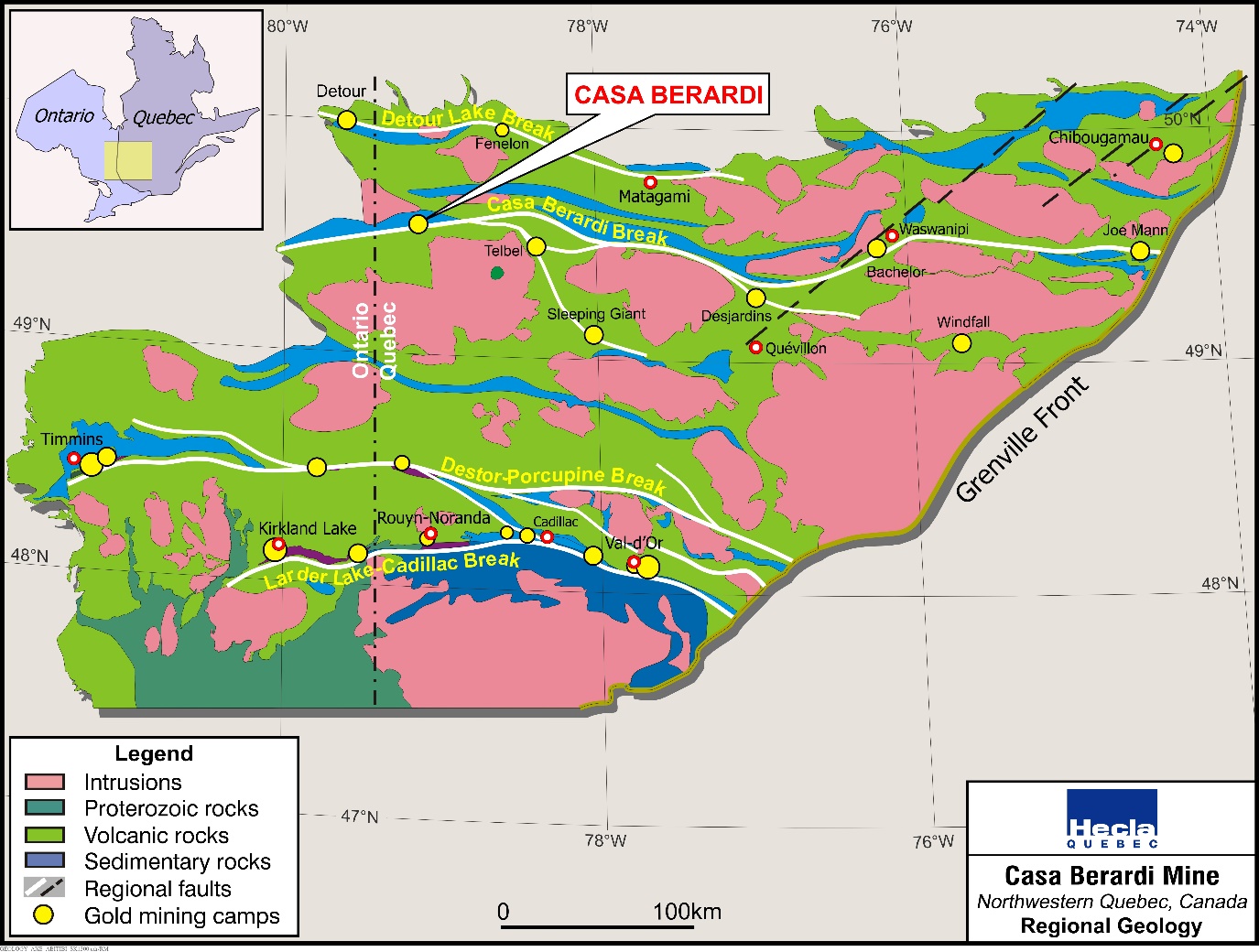

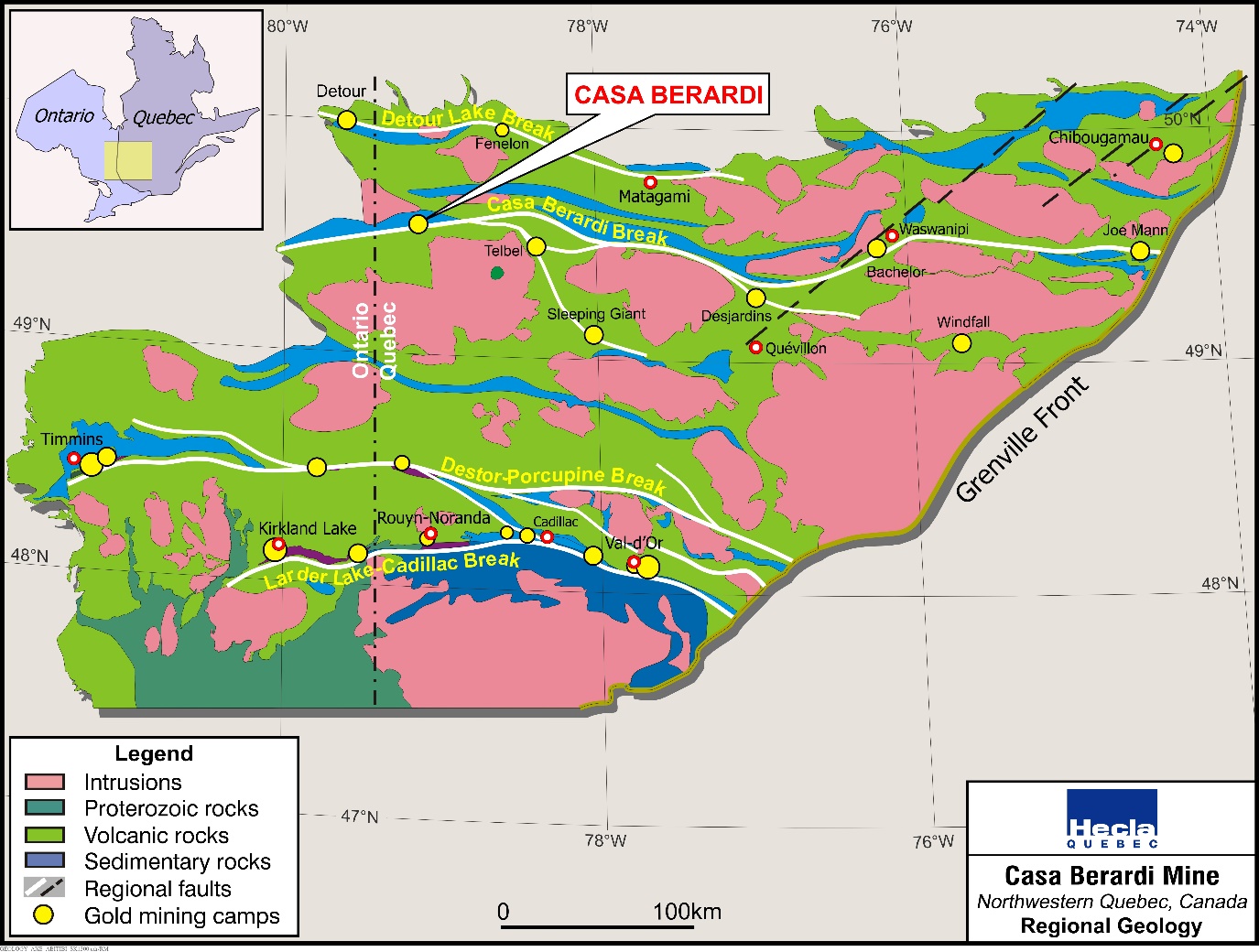

Figure 6‑1. Regional Geology of Northwestern Québec, Canada | 40 |

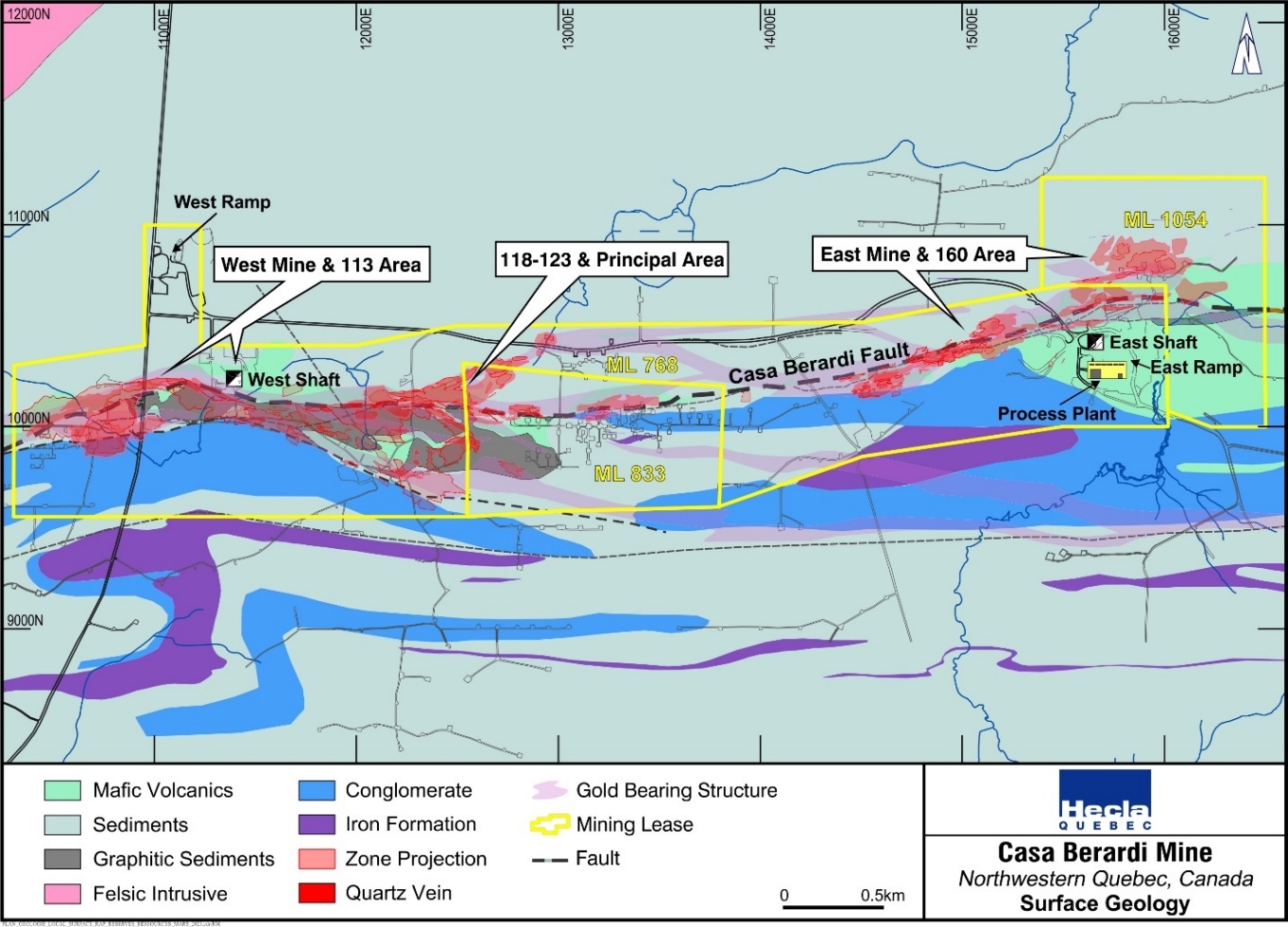

Figure 6‑2. Casa Berardi Property Geology | 41 |

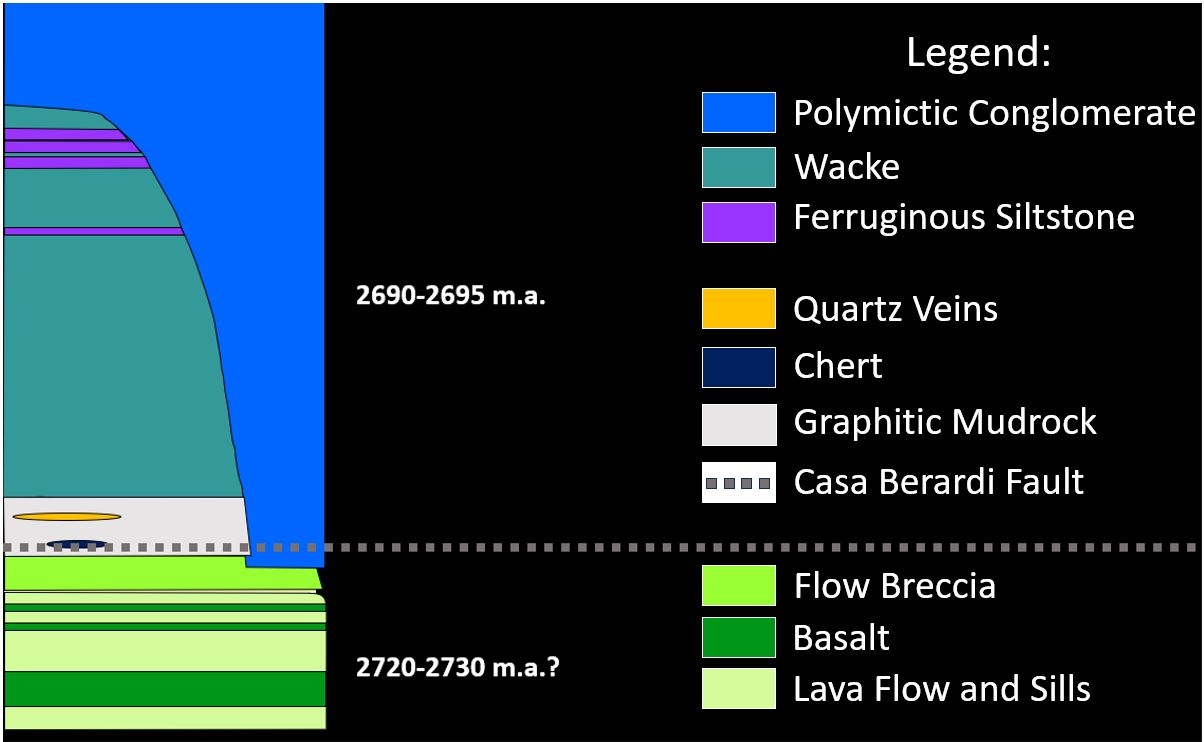

Figure 6‑3. Property Stratigraphic Divisions | 42 |

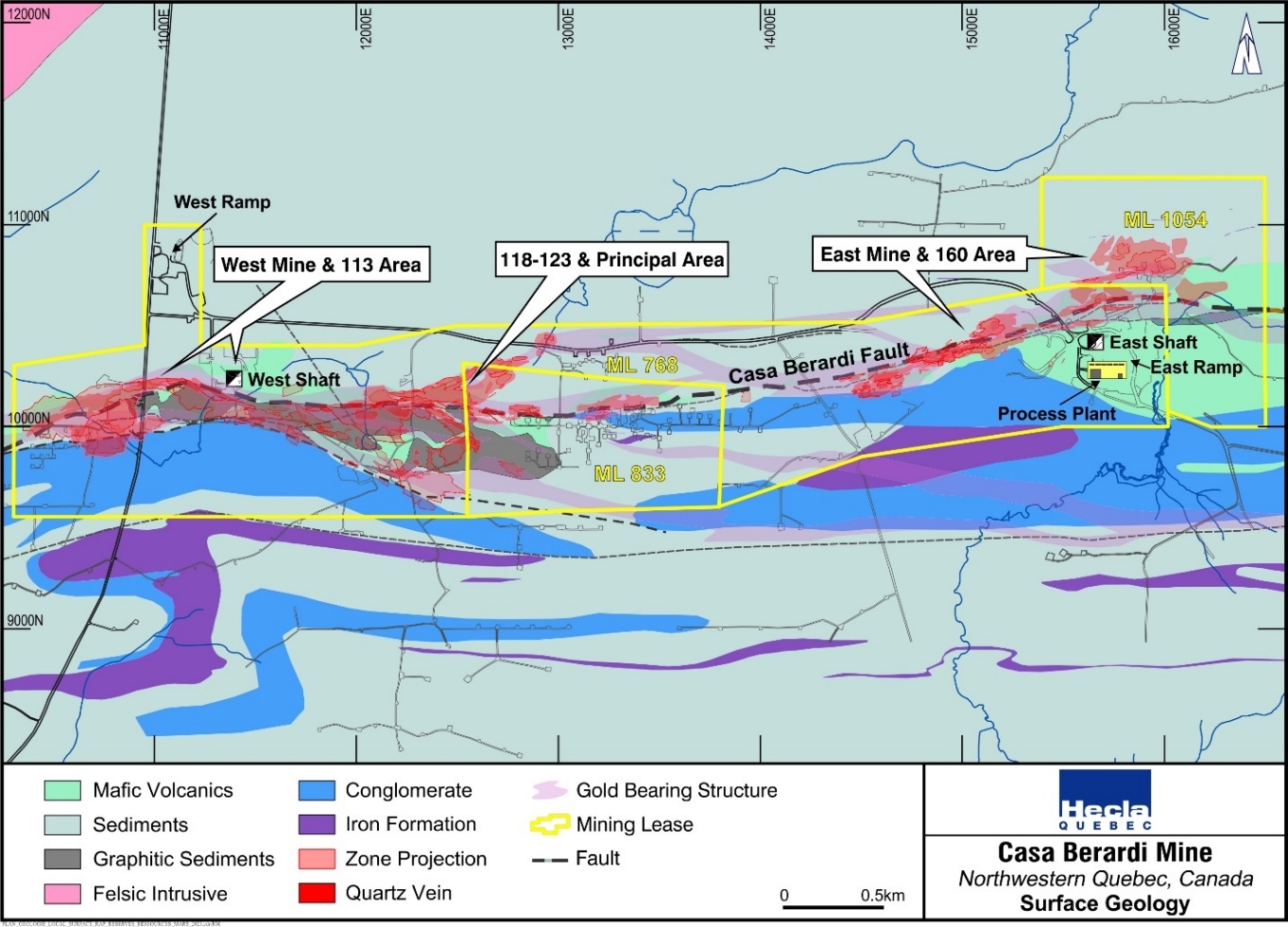

Figure 6‑4. Mine Area Surface Geology | 44 |

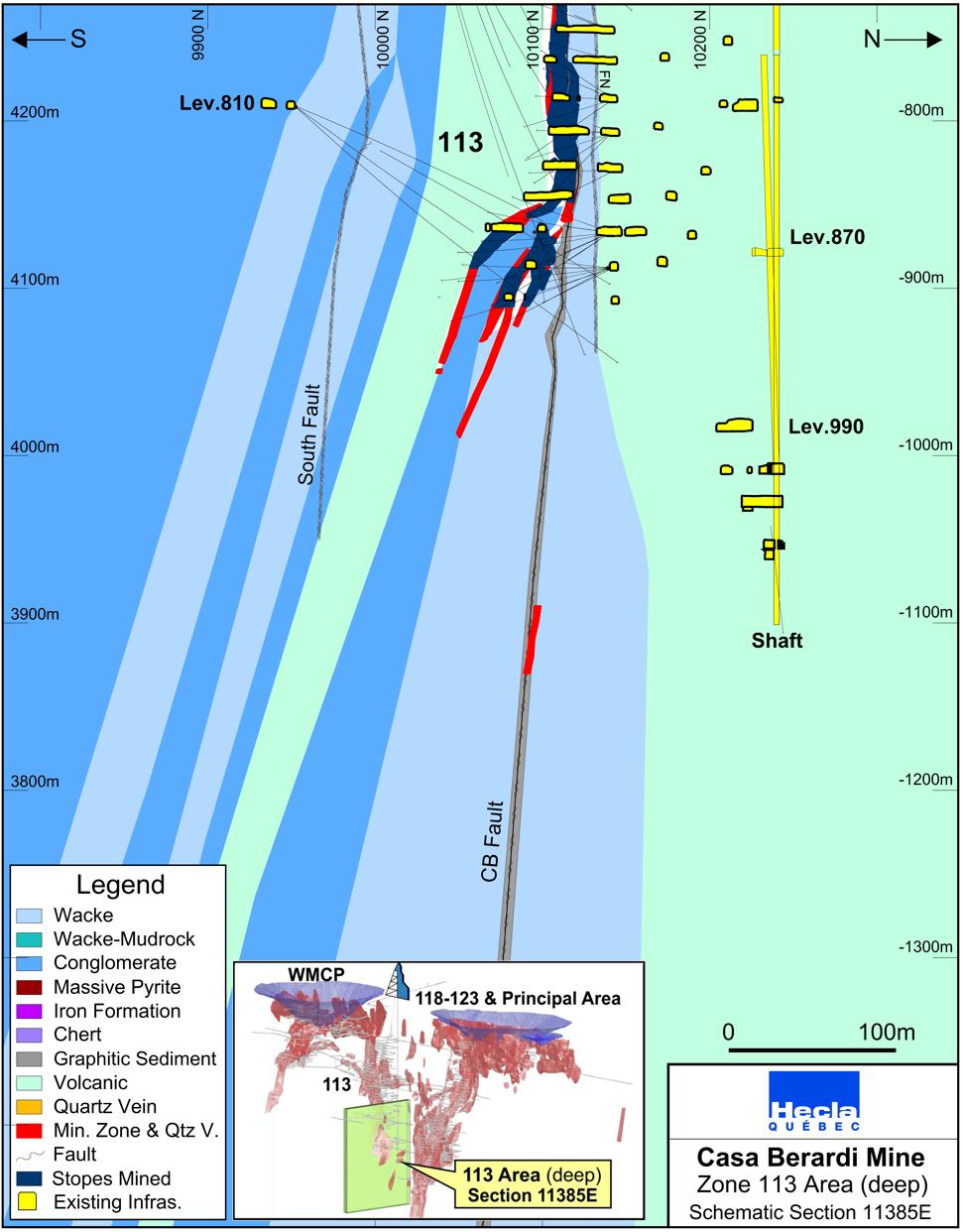

Figure 6‑5. Section 11,385E, West Mine Including the 113 Zone and Casa Berardi Fault | 48 |

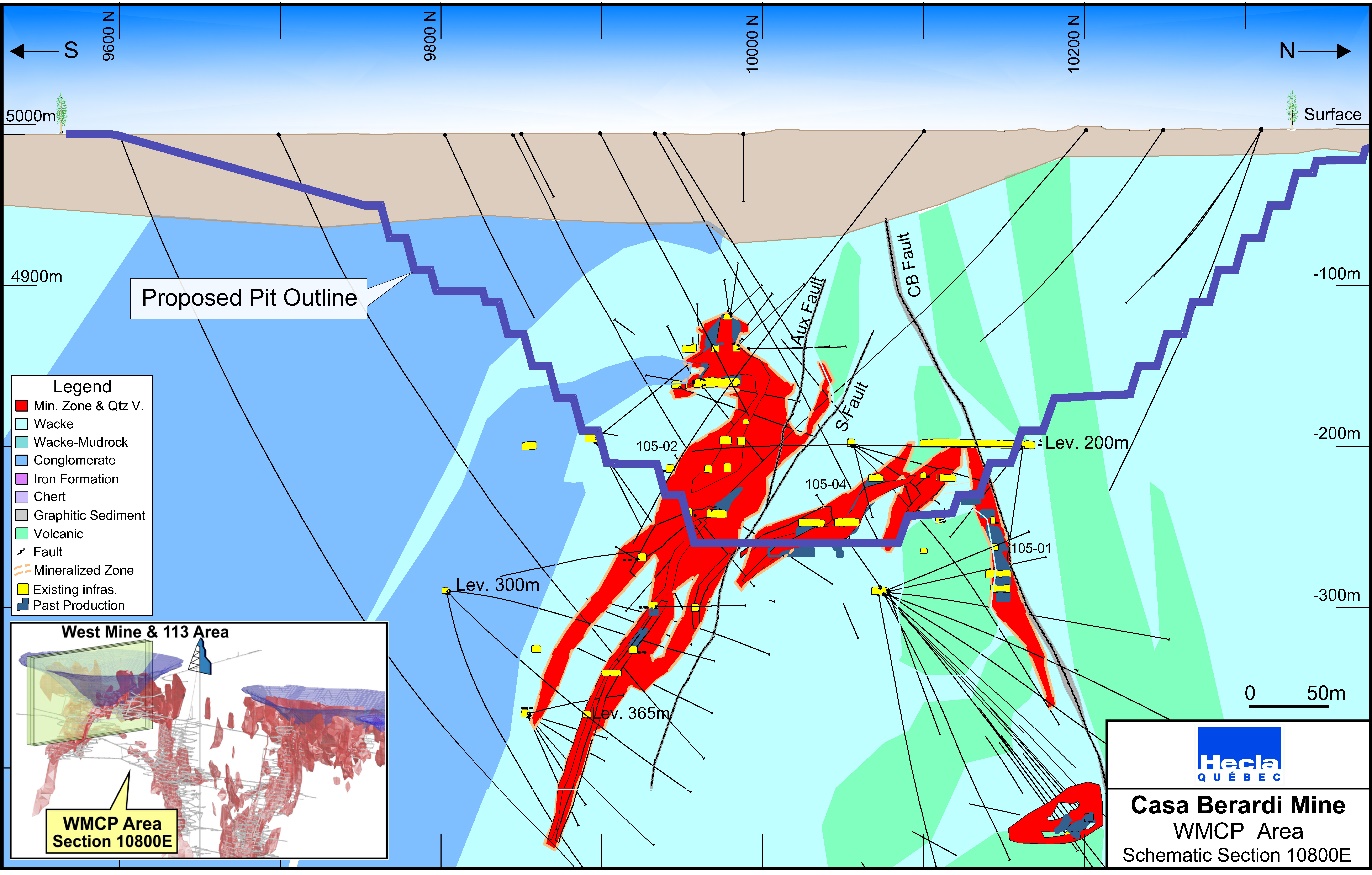

Figure 6‑6. Section 10,800E, West Mine Geology and Mining Infrastructure | 50 |

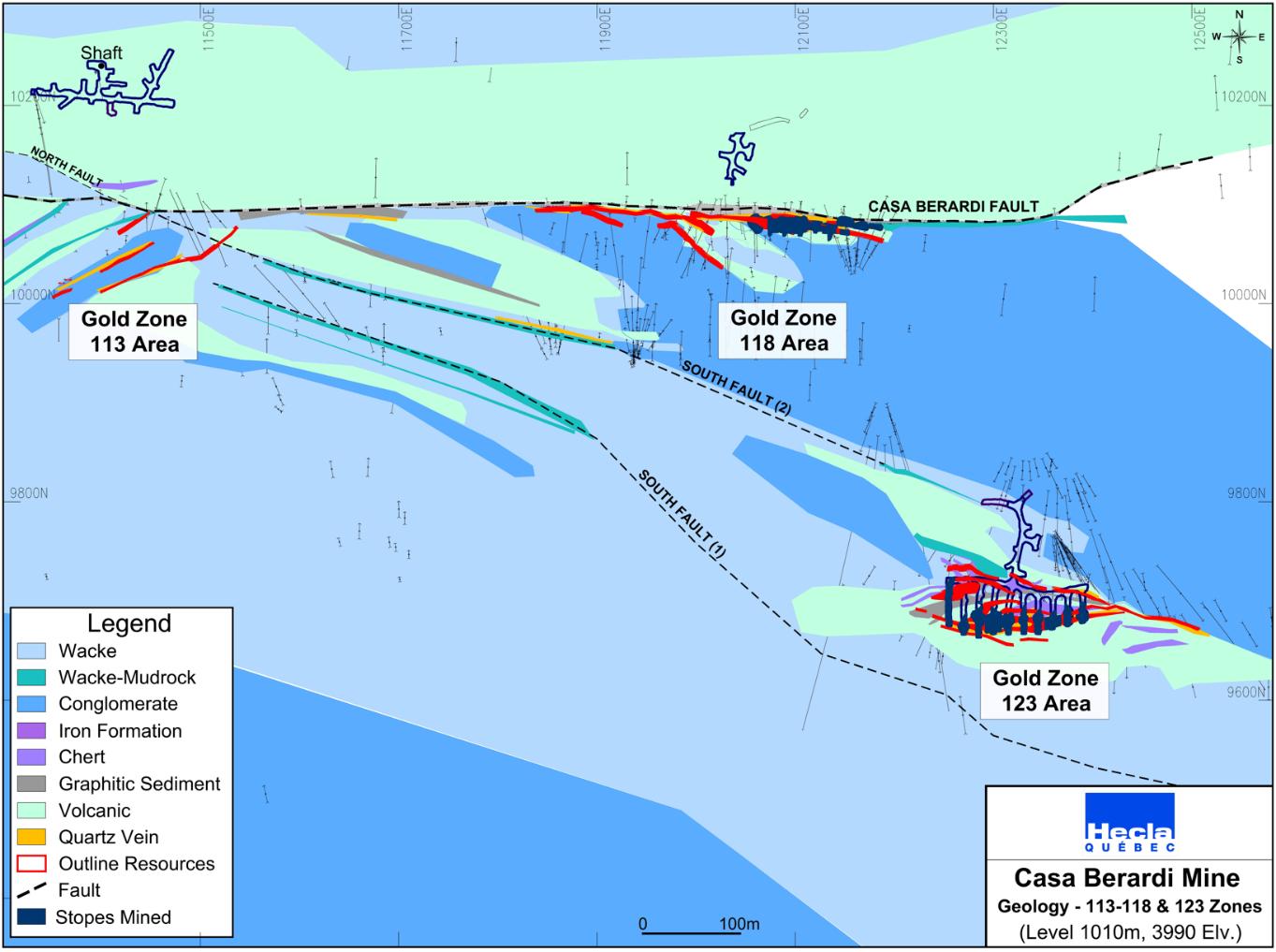

Figure 6‑7. Plan View of the 1,010m Level, Principal Area | 52 |

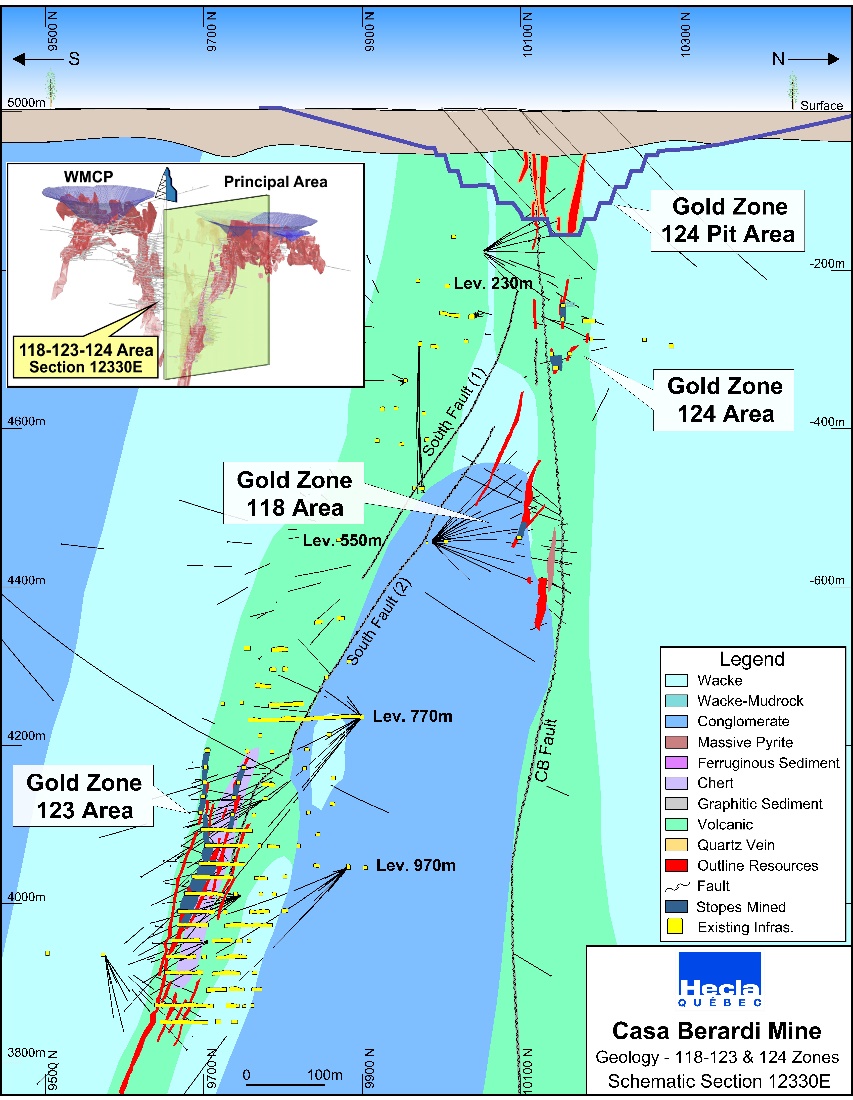

Figure 6‑8. Section 12,330E, Principal Area Geology 118, 123, and 124 Zones | 53 |

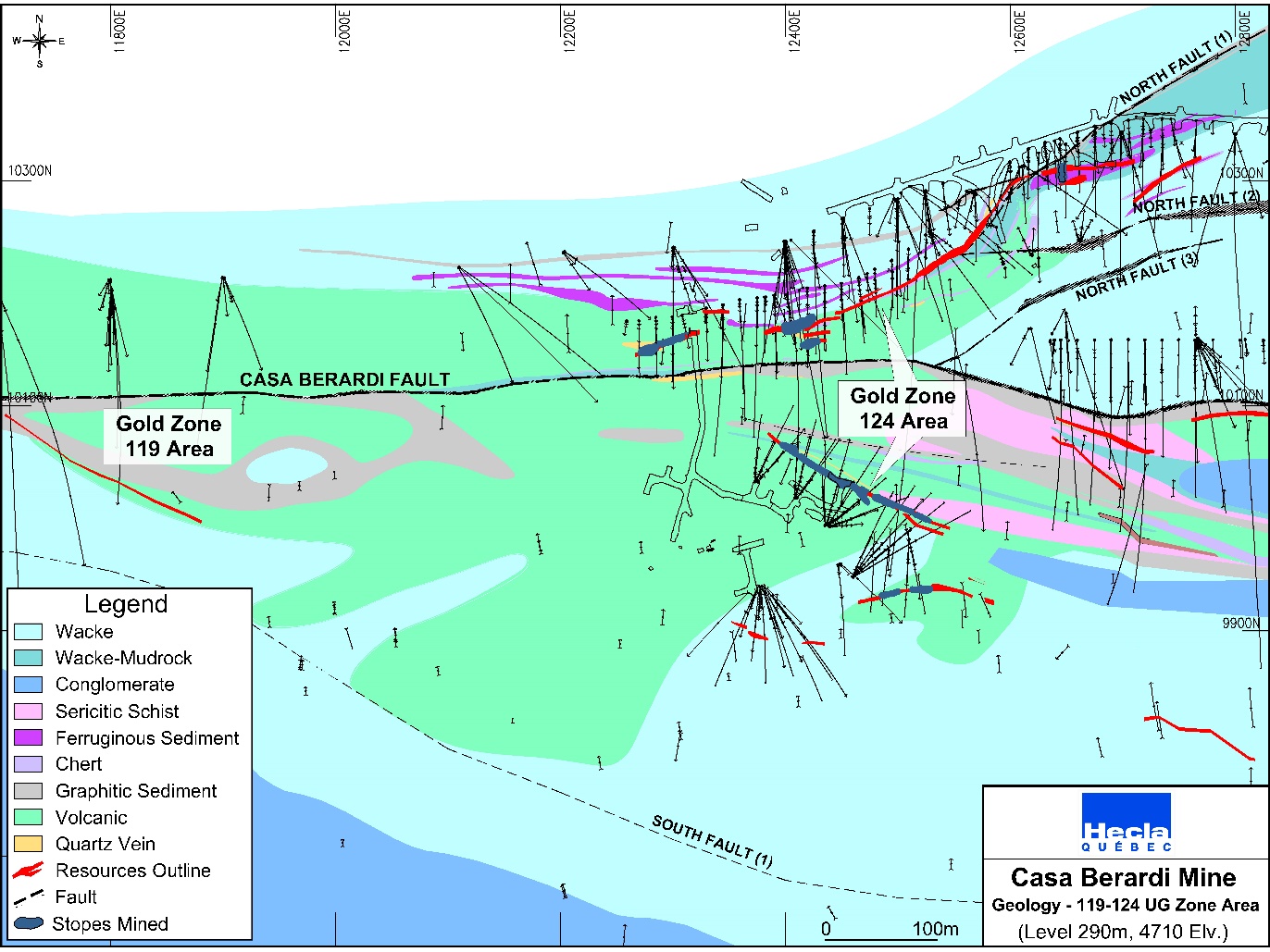

Figure 6‑9. Plan View of the 290m Level, Principal Area Including the 124 Zone Lenses | 55 |

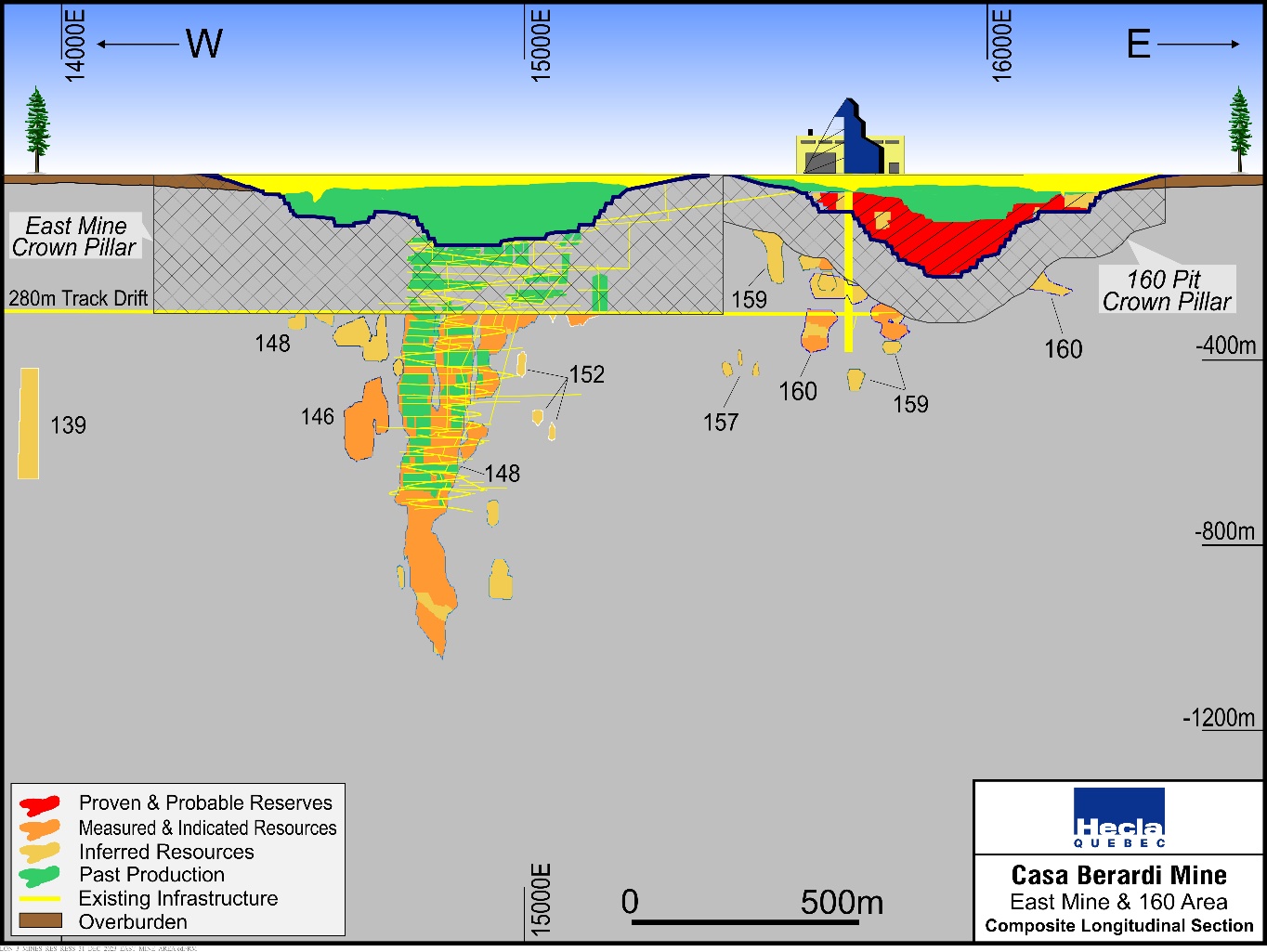

Figure 6‑10. East Mine Composite Longitudinal Section | 57 |

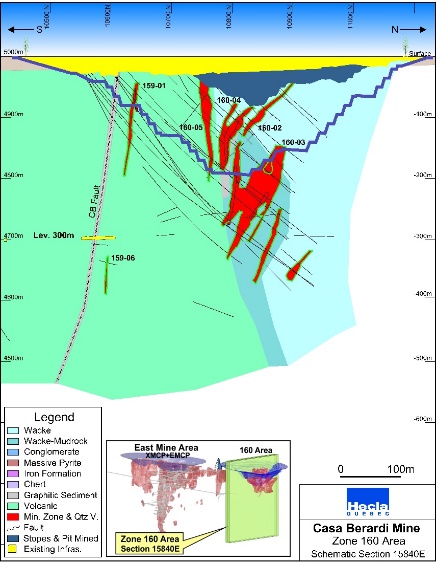

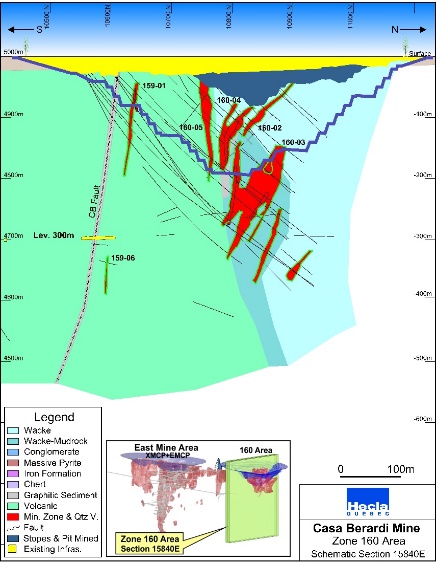

Figure 6‑11. Section 15, 840E, East Mine Geology and Infrastructure – 160 Zone | 58 |

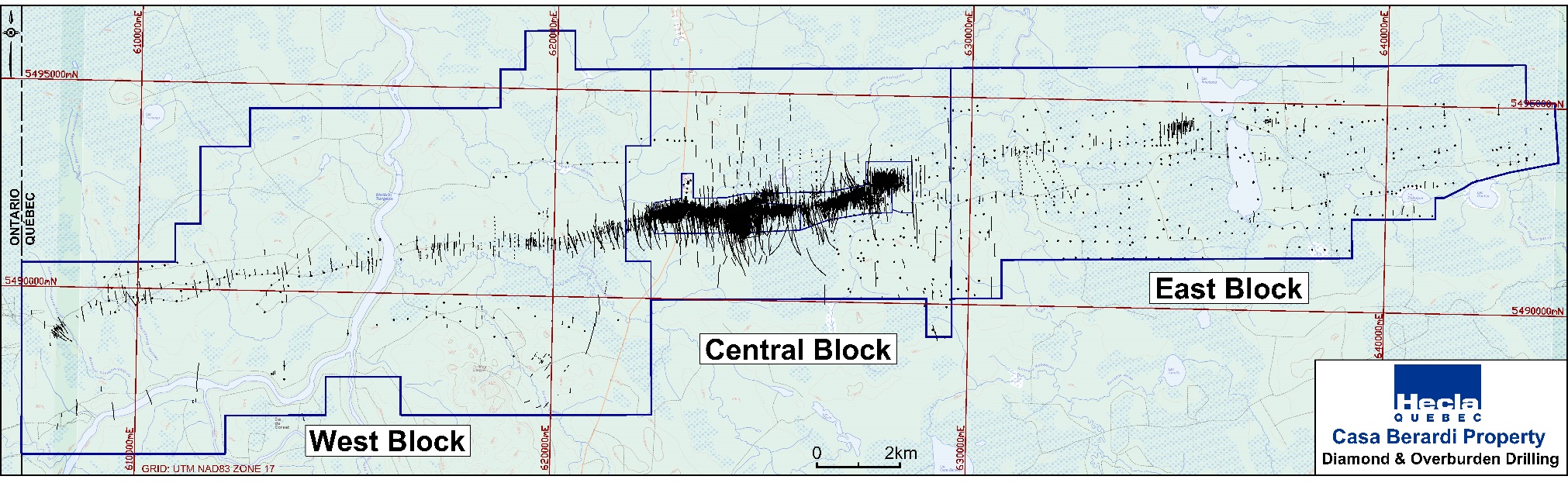

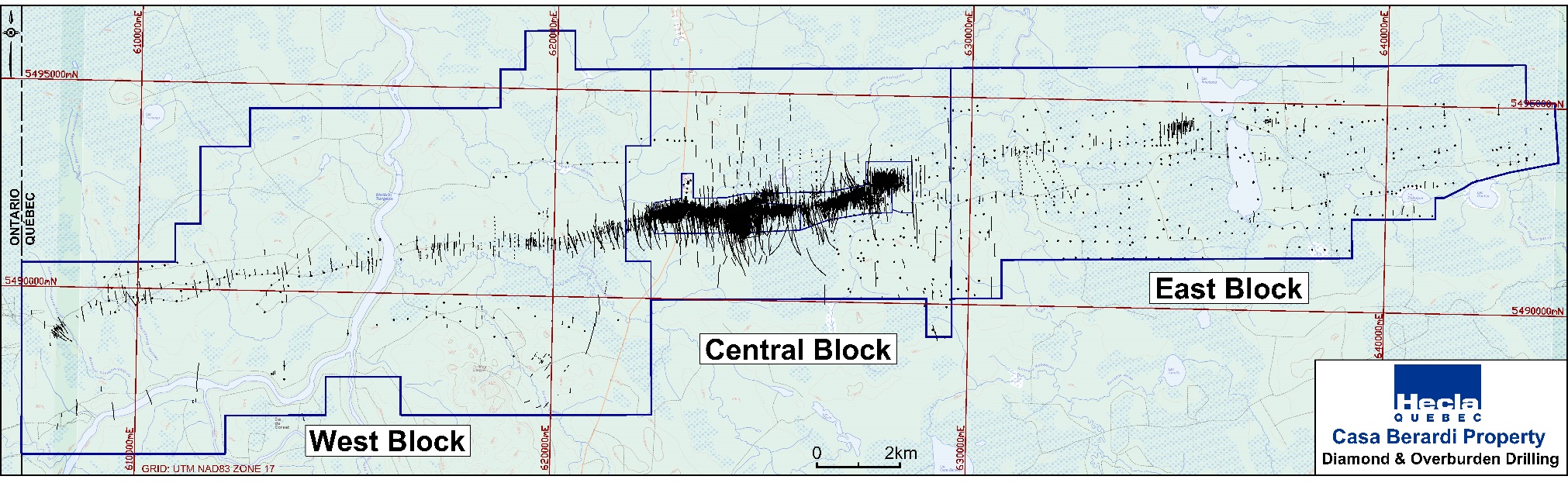

Figure 7‑1. Map of all Historical and Hecla Diamond Core, RC, and Sonic Drilling | 63 |

Figure 8‑1. Mine Laboratory Pulp Duplicate Assays from 2021- 2023 | 77 |

Figure 8‑2. Mine Laboratory Pulp External Check Assays at ALS (2021-2023) | 80 |

Figure 8‑3. Swastika Pulp External Check Assays at ALS (2021-2023) | 80 |

Figure 8‑4. Plot of 2023 CRM Assays from the Mine Lab for OREAS 235 | 83 |

Figure 8‑5. Plot of 2023 CRM Assays from Swastika for OREAS 235 | 84 |

Figure 8‑6. Plots of All CRM Assay Results from 2006 to 2023 | 85 |

Figure 8‑7. Mine and Swastika Blanks – 2023 | 95 |

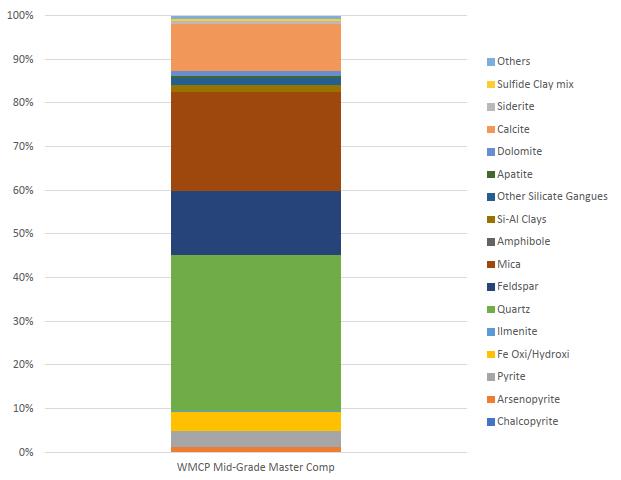

Figure10‑1. Mineralogical Analyses on Composites | 106 |

| |

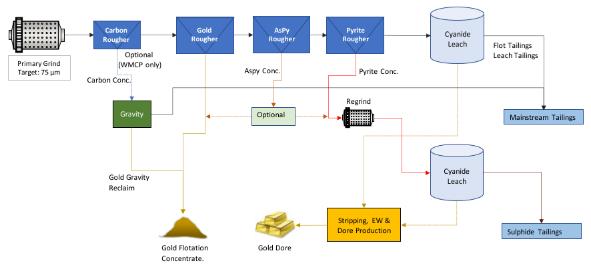

Figure10‑2. Flowsheet Originally Developed | 123 |

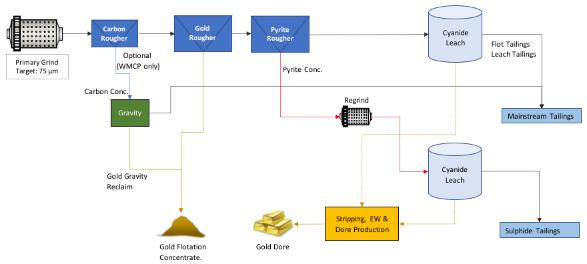

Figure 10‑3. WMCP Blend Simplified Integrated Flowsheet | 128 |

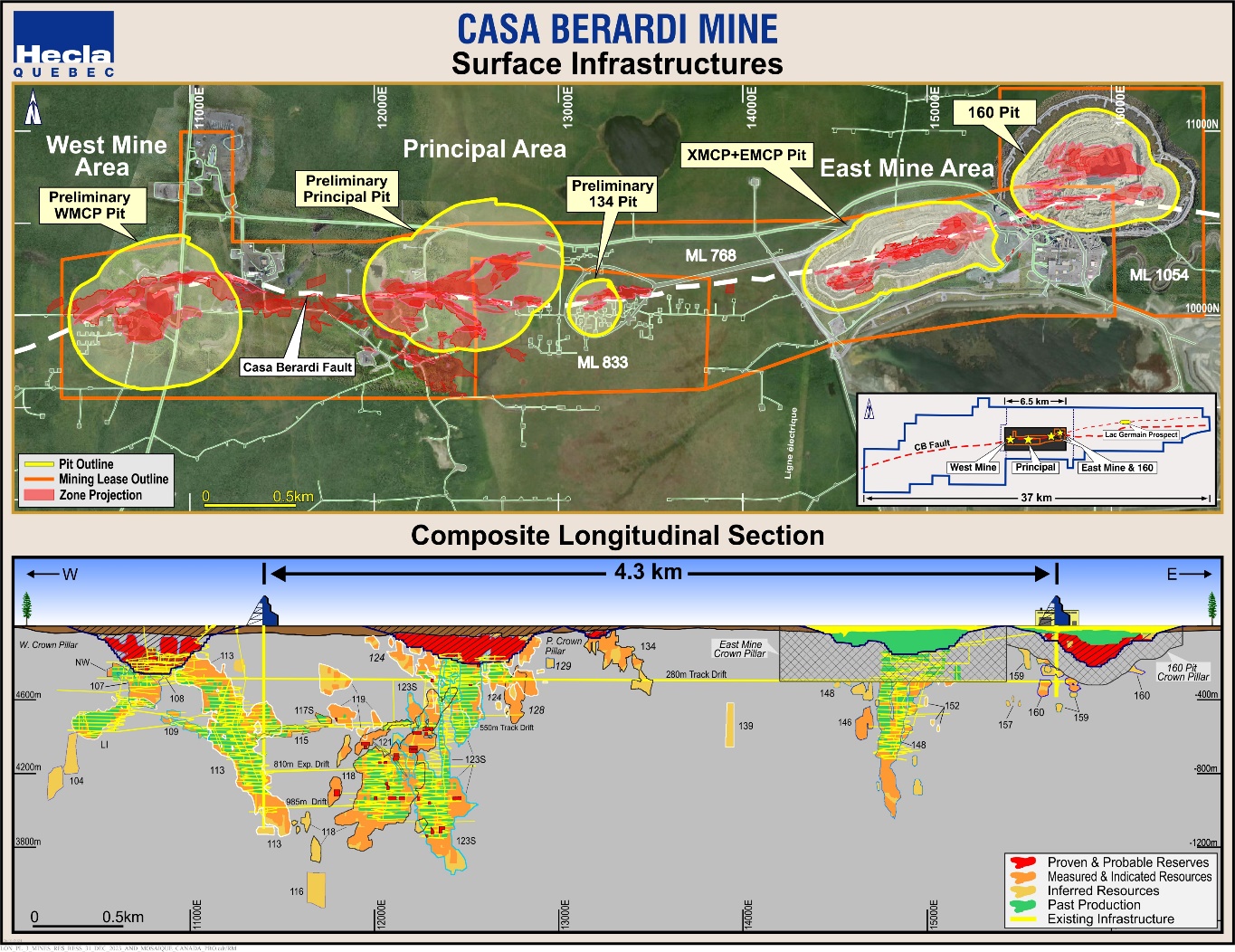

Figure 11‑1. Mine Plan View and Composite Longitudinal Section of Deposit Areas and Infrastructure | 138 |

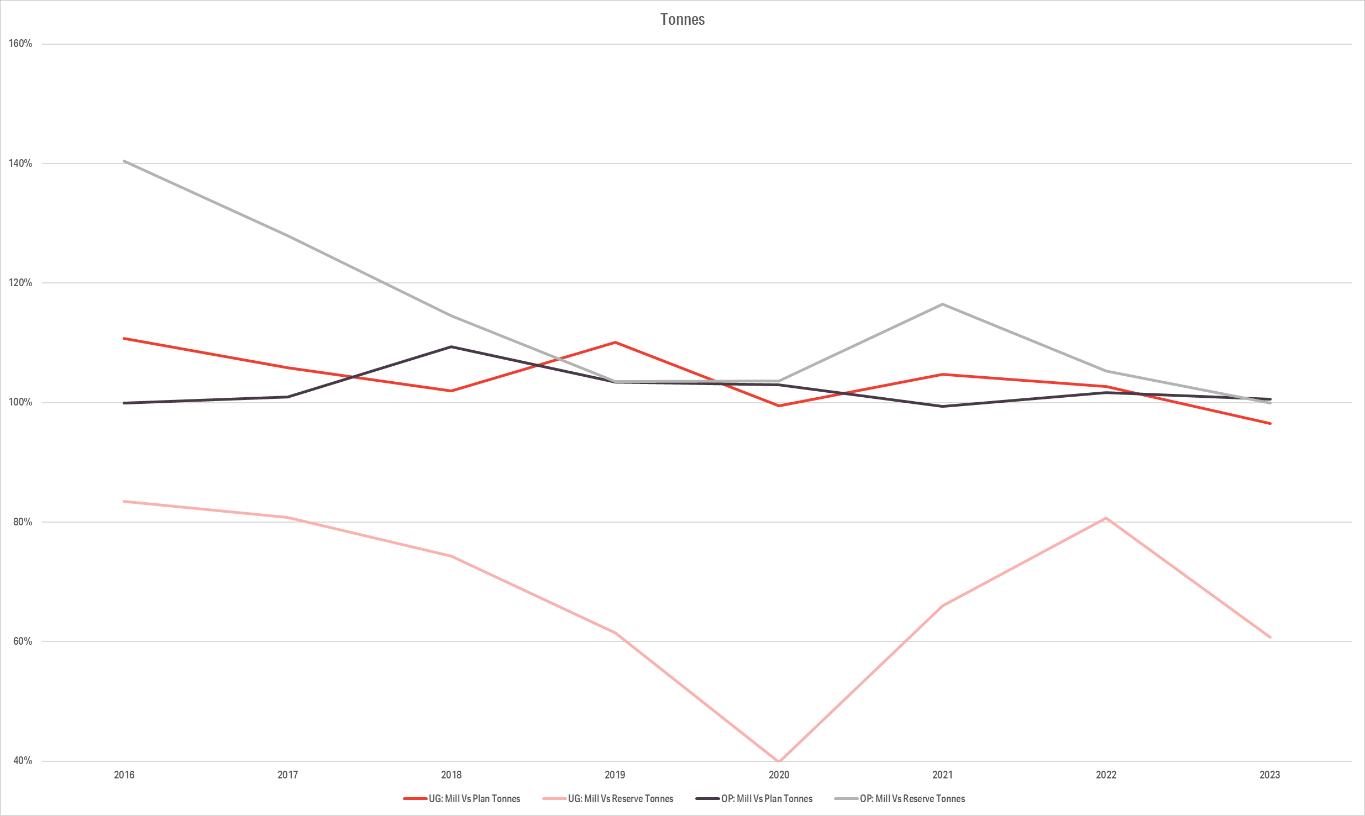

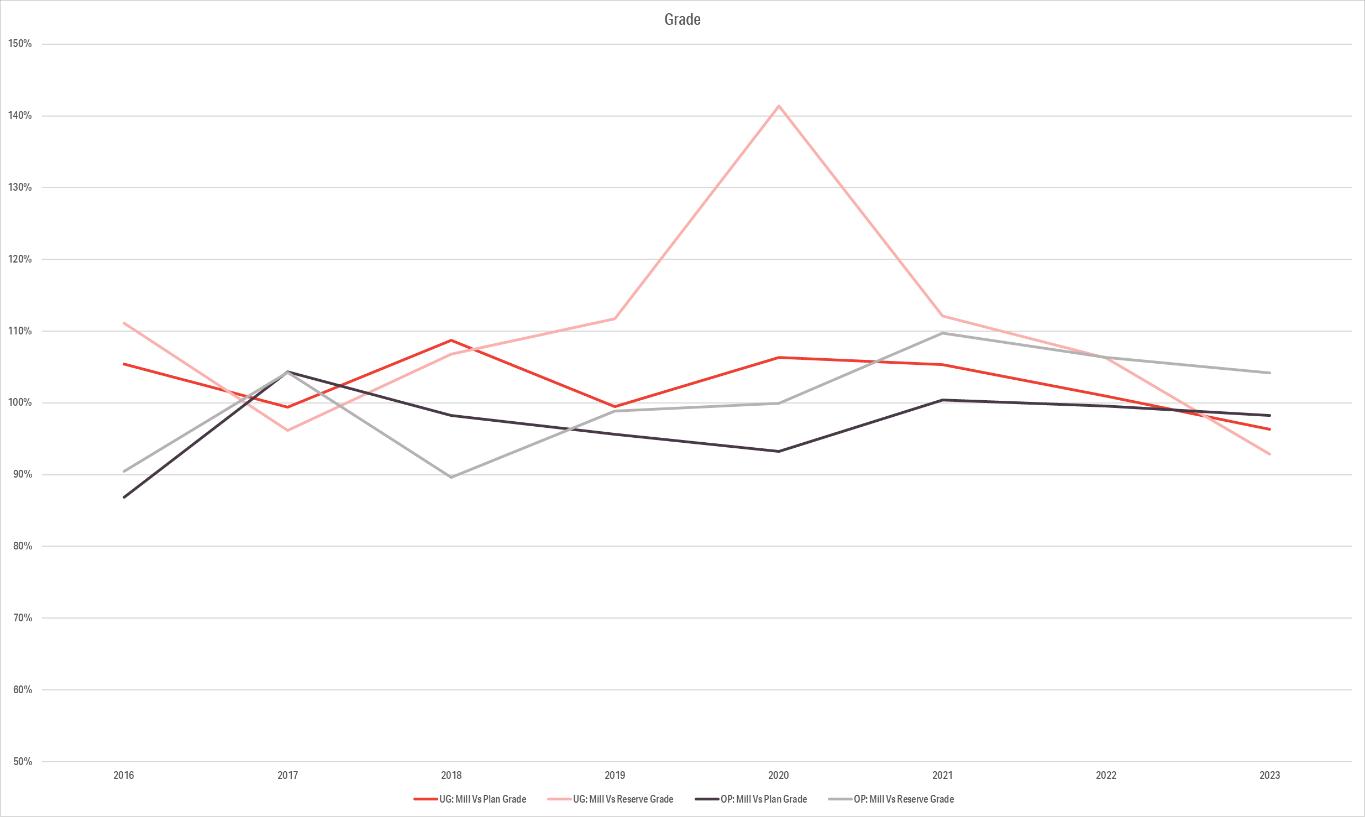

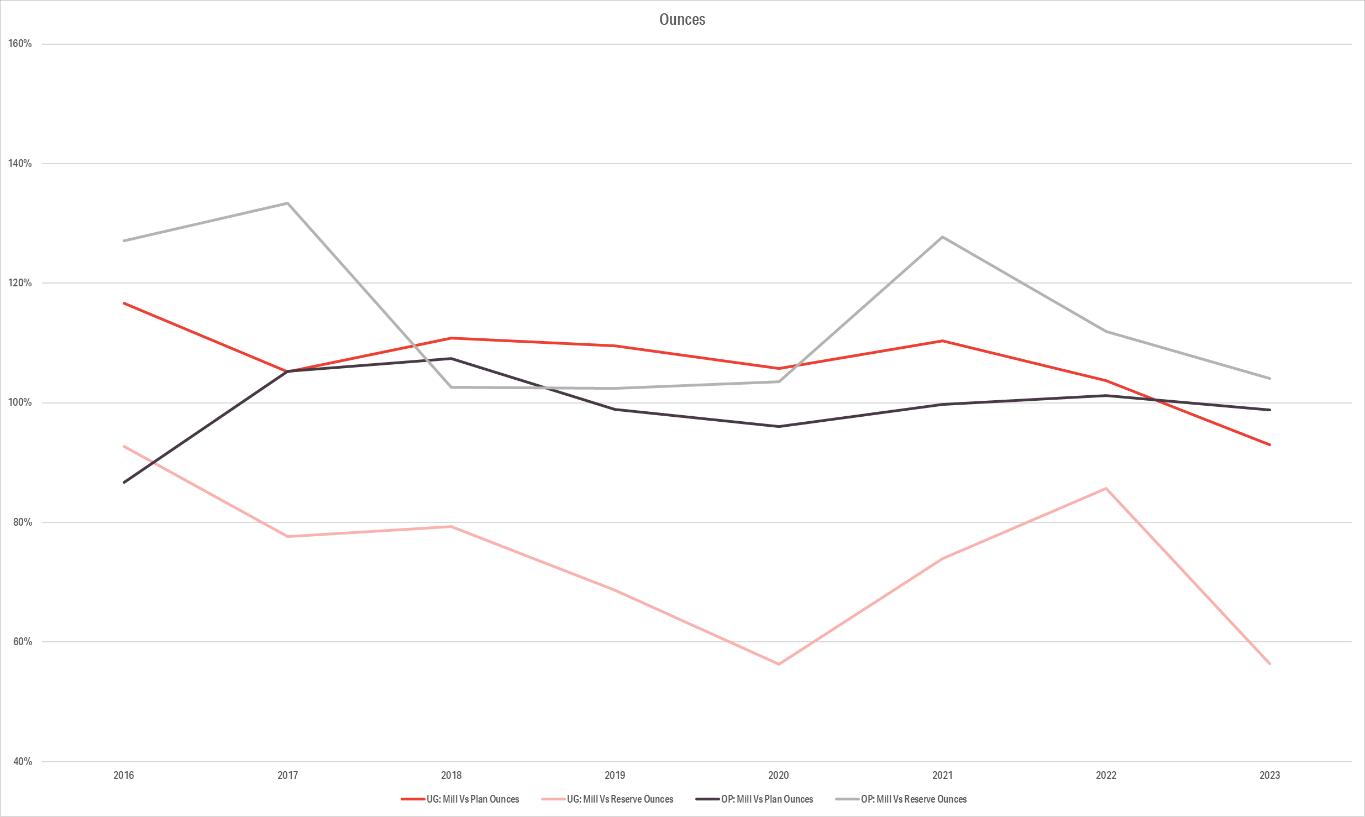

Figure 12‑1. Tonnage Reconciliation 2016 to 2023 Annual | 173 |

Figure 12‑2. Grade Reconciliation 2016 to 2023 Annual | 173 |

Figure 12‑3. Contained Gold Reconciliation 2016 to 2023 Annual | 174 |

Figure 13‑1. Transverse Mining Method | 178 |

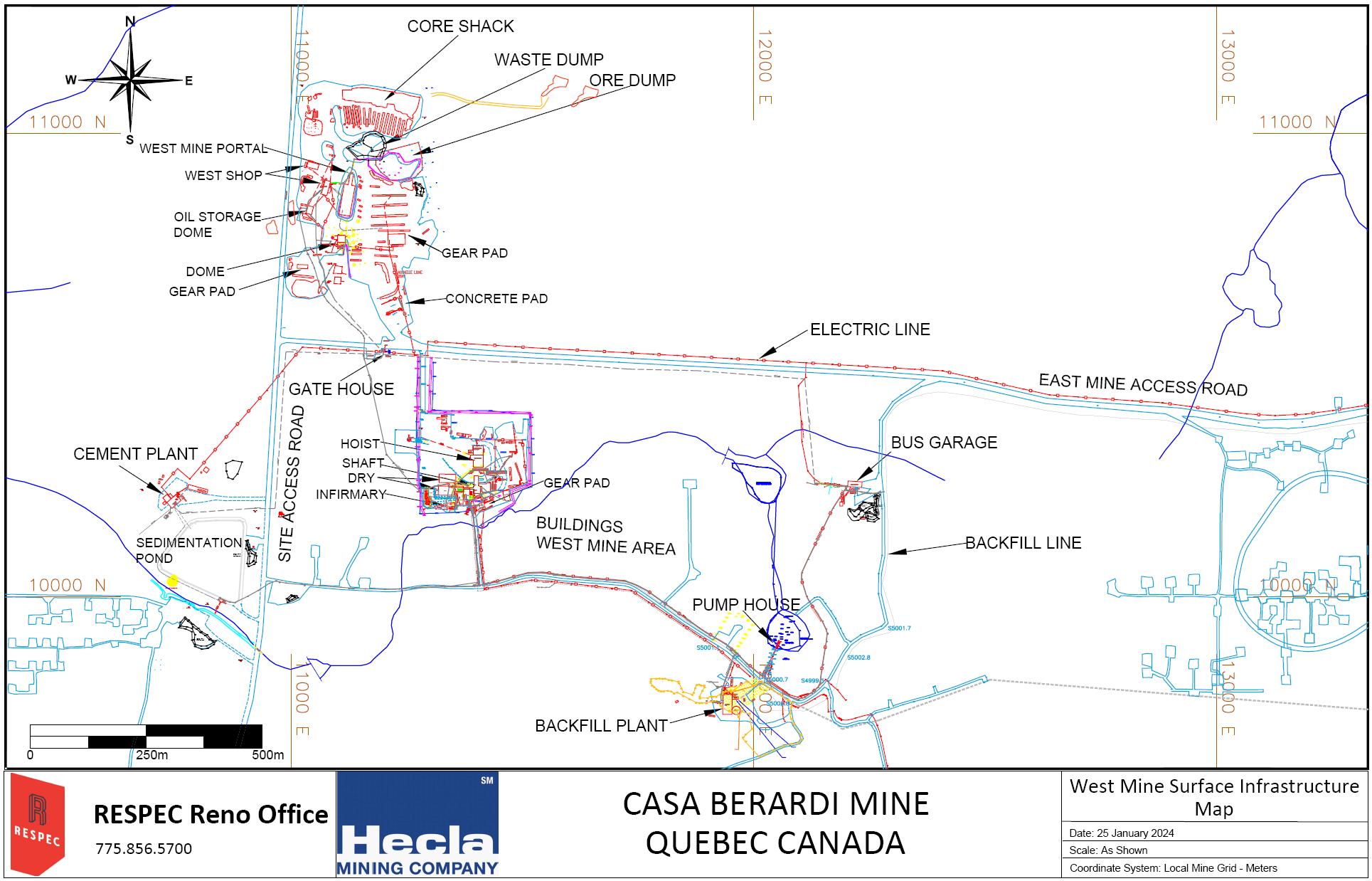

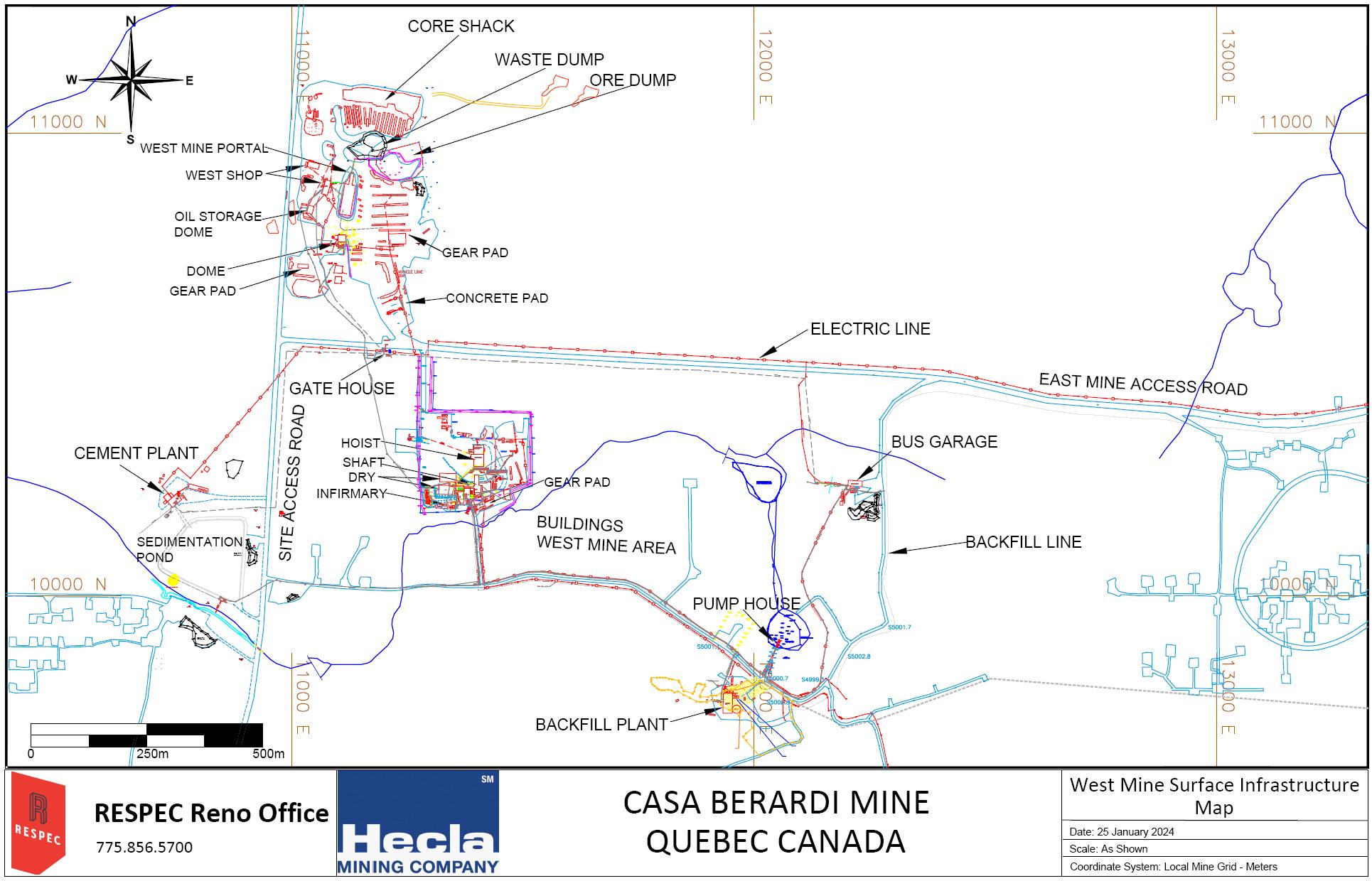

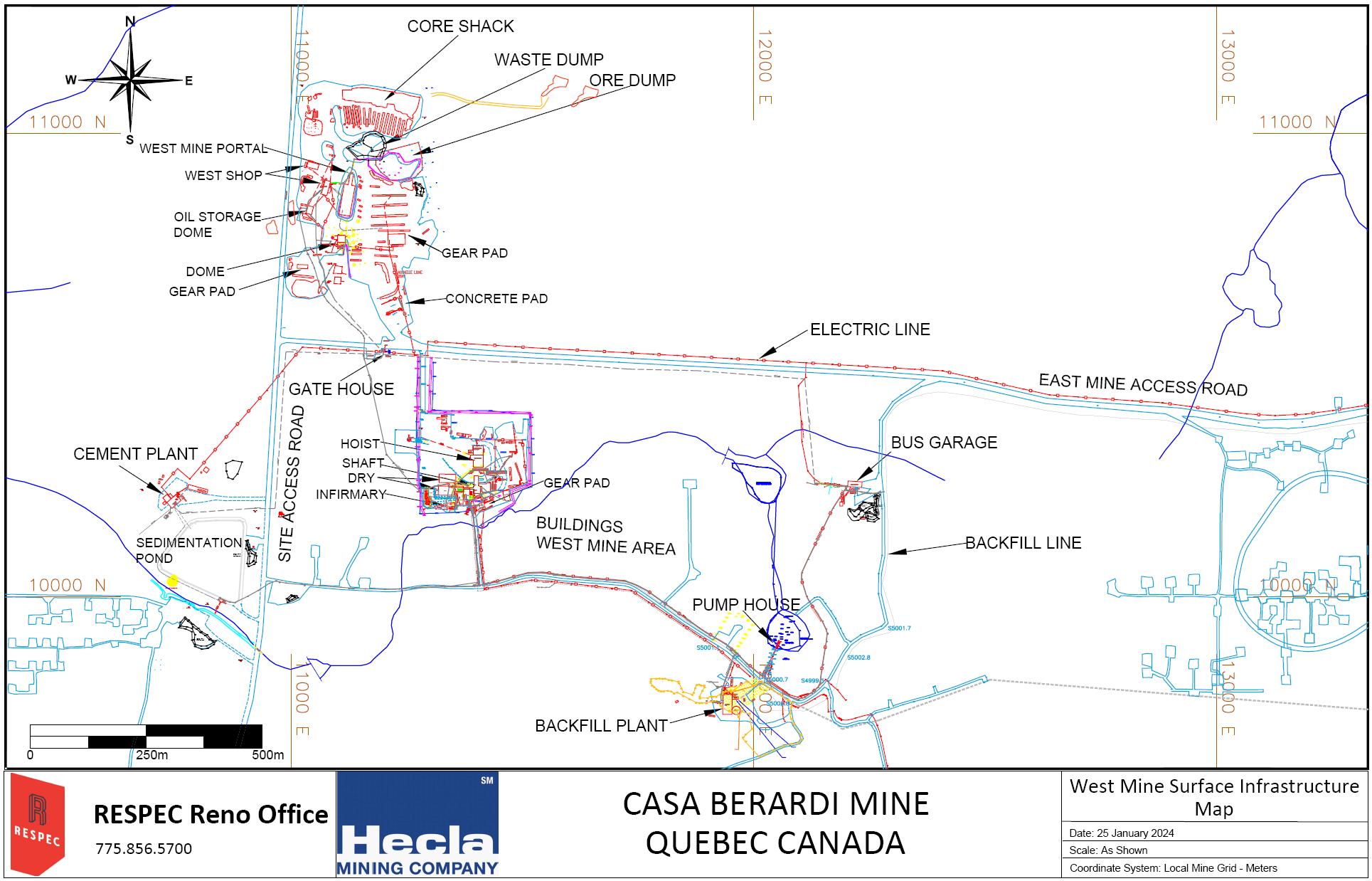

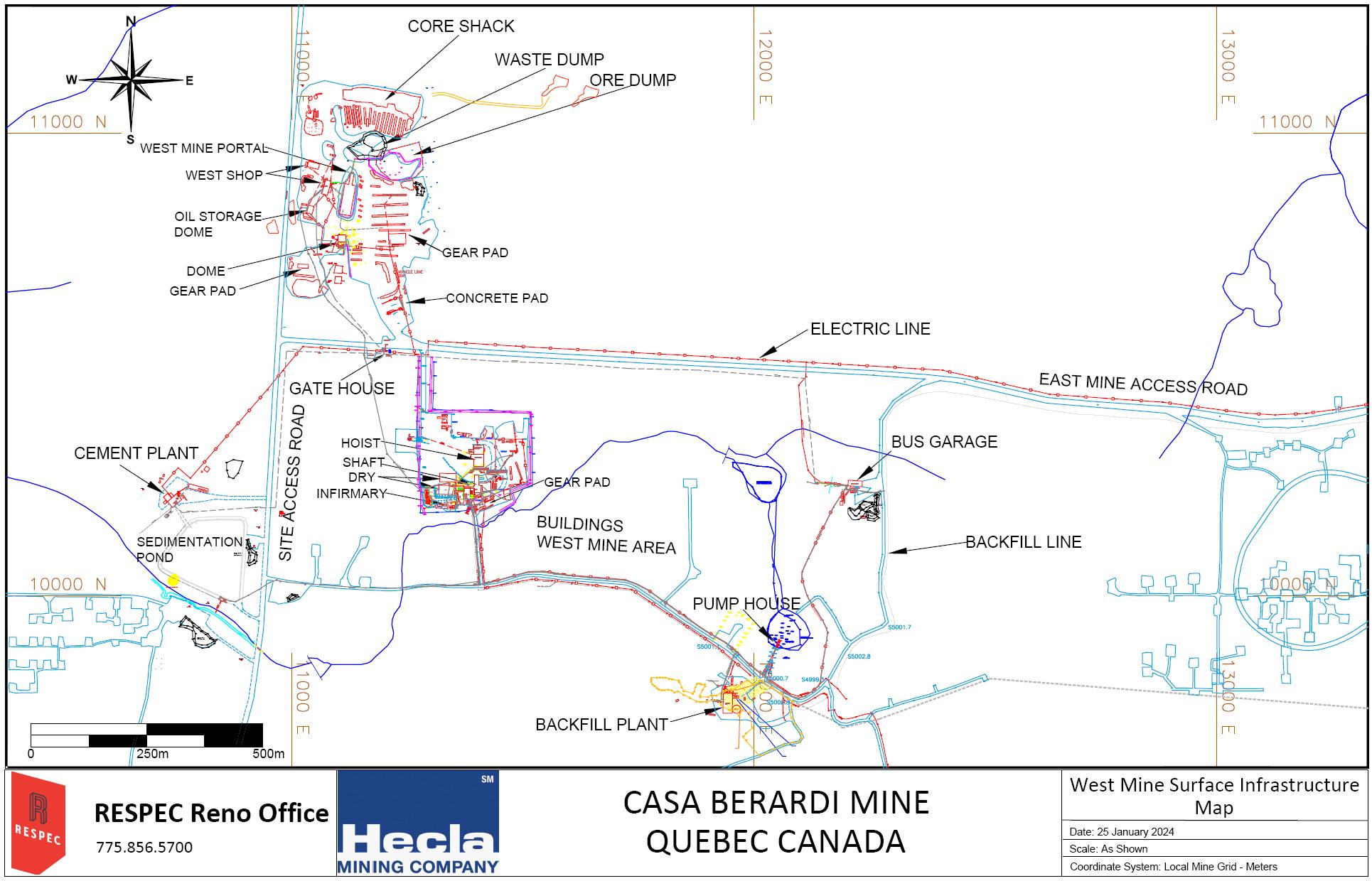

Figure 13‑2. West Mine Surface Infrastructure | 184 |

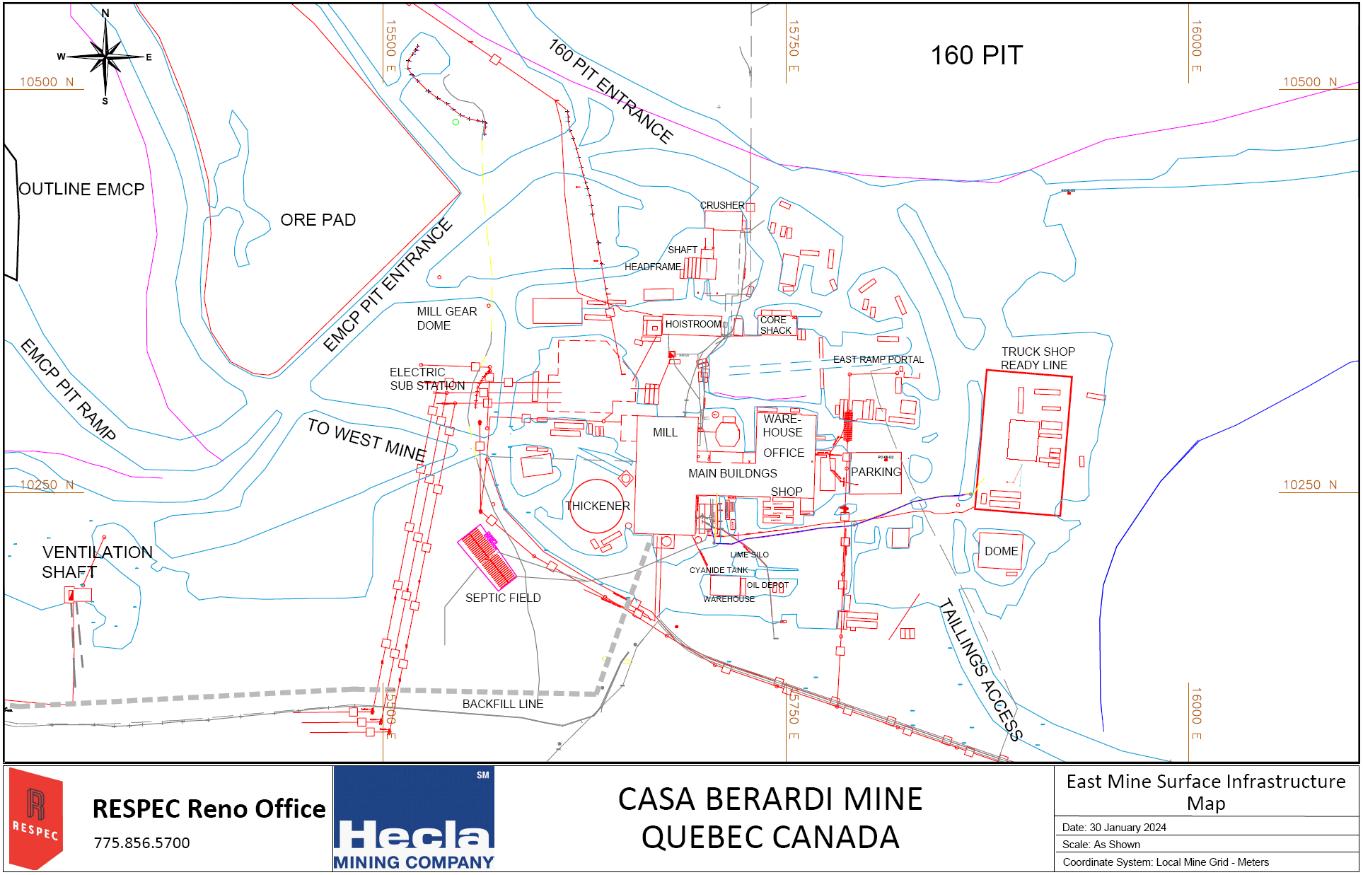

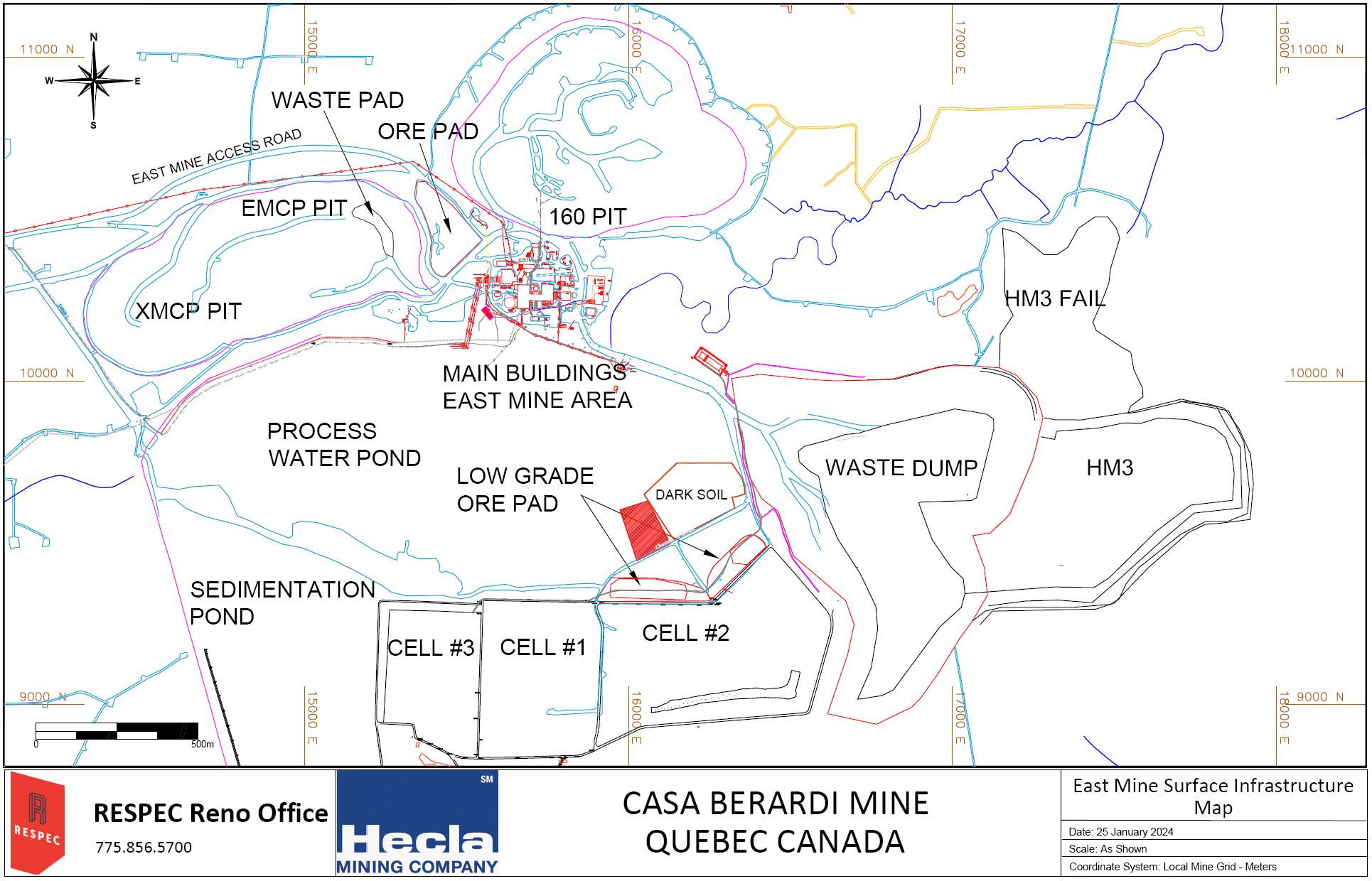

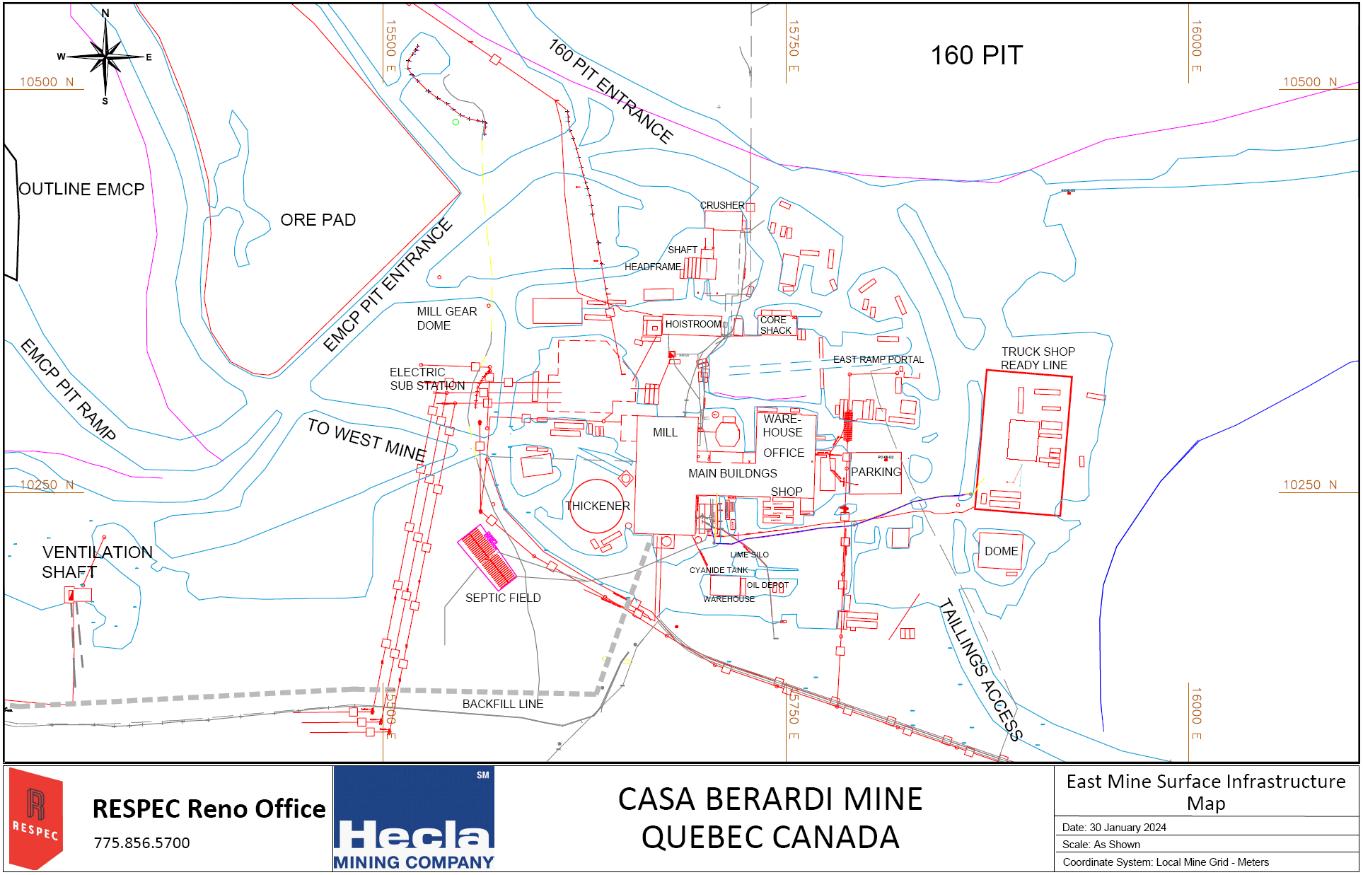

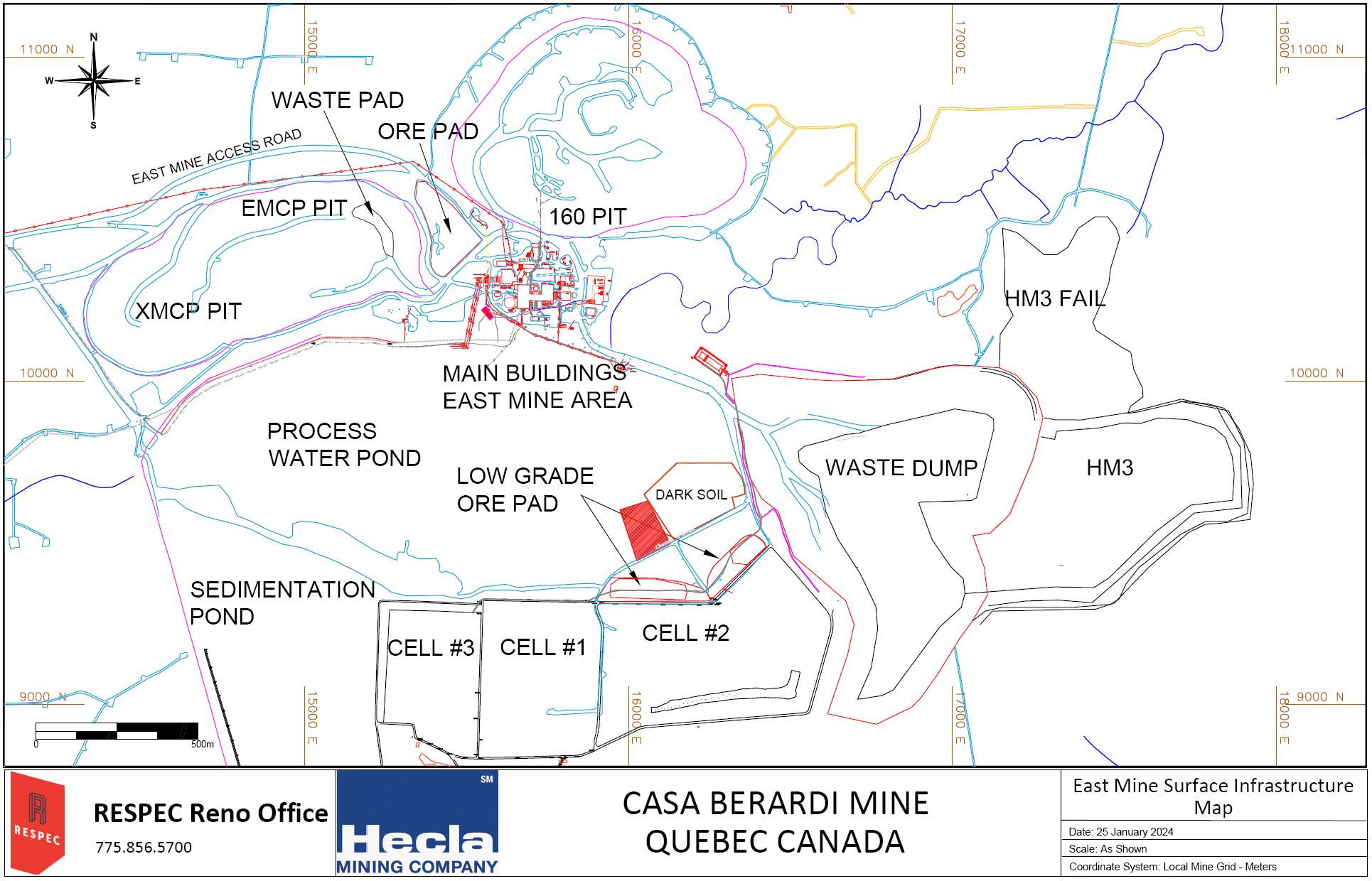

Figure 13‑3. East Mine Surface Infrastructure | 185 |

Figure 13‑4. West Mine - Ventilation Schematic Circuit | 187 |

Figure 13‑5. Casa Berardi Main Station 120kV Flowsheet | 190 |

Figure 13‑6. Open Pit and Waste Rock Locations | 203 |

Figure 13‑7. Plan View of the F160 Pit Project | 206 |

Figure 13‑8. Plan View of the F134 Pit (Ultimate Pit Shell) | 207 |

Figure 13‑9. Plan View of the WMCP Pit Project (Ultimate Pit Shell) | 209 |

Figure 13‑10. Plan View of the Principal Pit Project (Ultimate Pit Shell) | 211 |

Figure 14‑1. Mill Flowsheet | 214 |

Figure 15‑1. Surface Infrastructure (Current and Preliminary) | 221 |

Figure 15‑2. East Mine Surface Infrastructure | 223 |

Figure 15‑3. West Mine Surface Infrastructure | 225 |

Figure 15‑4. Surface Plan Tailings and Waste Rock Facilities | 226 |

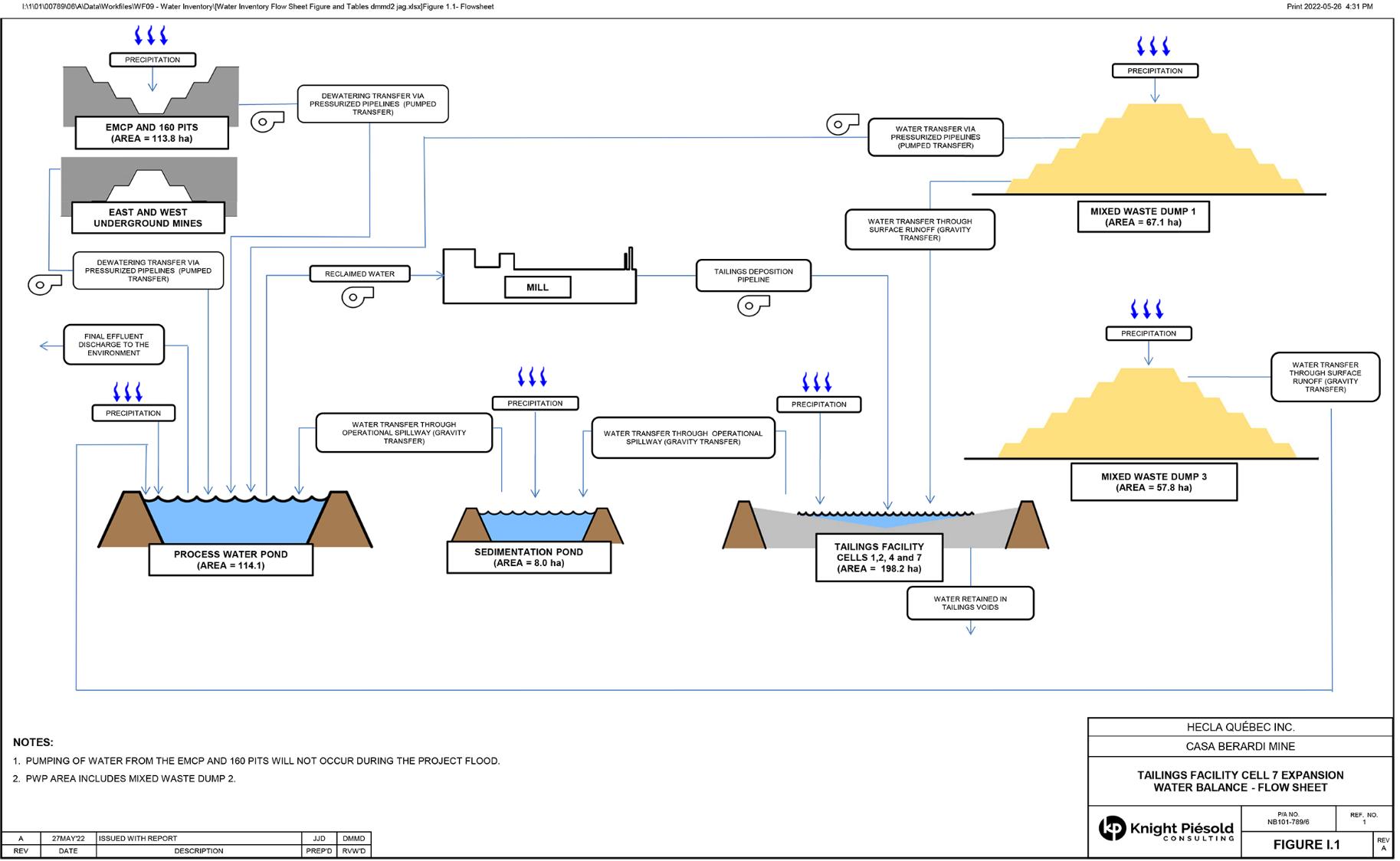

Figure 17‑1. Water Management Flow Sheet | 233 |

Figure 19‑1. After-tax NPV at 5% Sensitivity Analysis | 266 |

1.0 EXECUTIVE Summary

1.1 Summary

RESPEC was retained by Hecla Mining Company (Hecla) to prepare an independent Technical Report Summary (TRS) on the Casa Berardi Mine (Casa Berardi, mine, or the Property), located in Québec, Canada. The purpose of this TRS is to support the disclosure of the Casa Berardi Mineral Resource and Mineral Reserve estimates as of December 31, 2023. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. RESPEC visited the Property on September 19 -21, 2023.

Hecla was established in 1891 and has its headquarters in Coeur d’Alene, Idaho, USA. In June 2013, Hecla acquired Aurizon Mines Ltd. (Aurizon) and renamed the company Hecla Québec Inc. (Hecla Québec). Hecla has an administrative/exploration office in Val‑d’Or, Québec and an office in Vancouver, British Columbia. Hecla holds a 100% interest in Casa Berardi through its wholly owned subsidiary Hecla Québec. The Casa Berardi complex has a 35-year history of surface and underground mining operations.

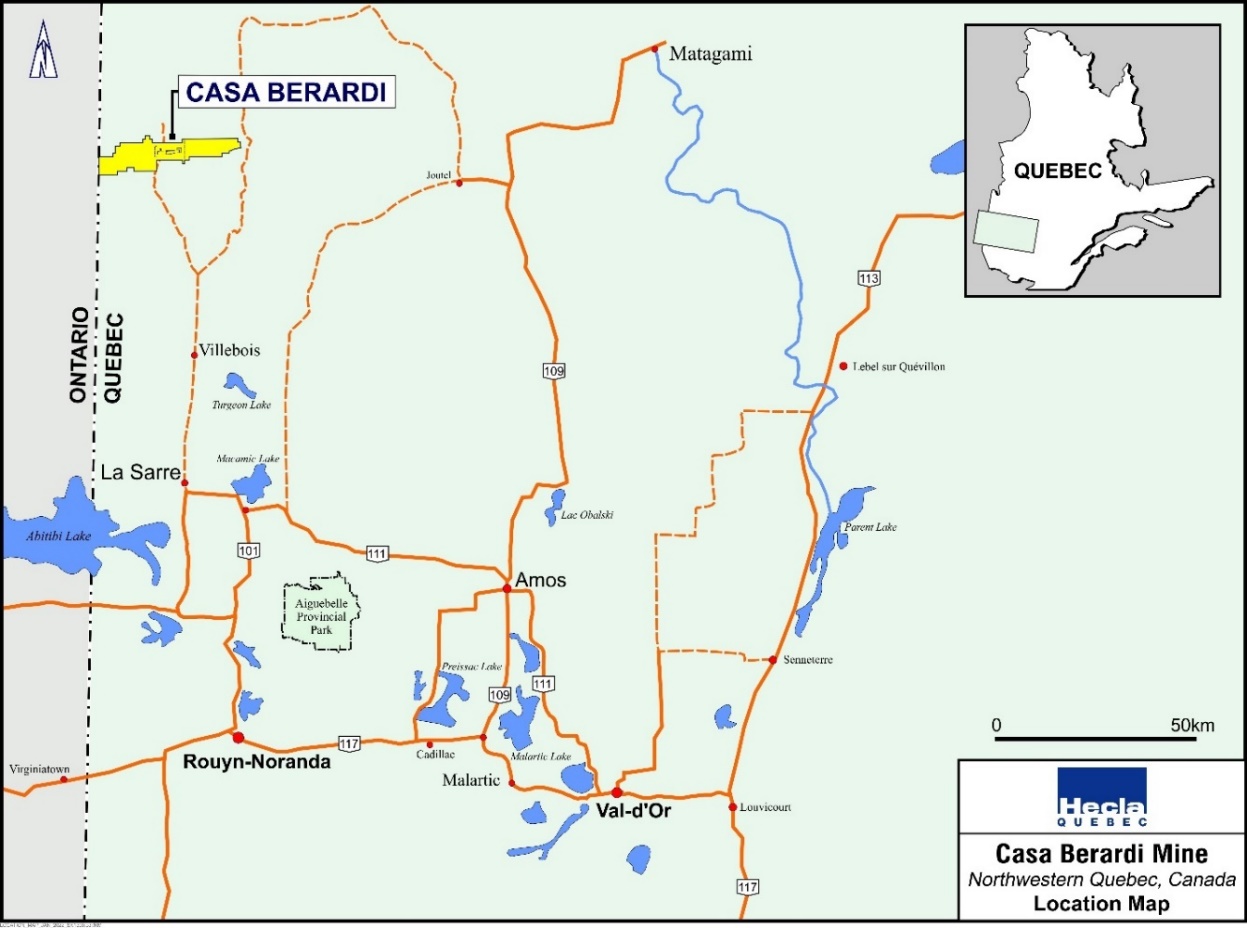

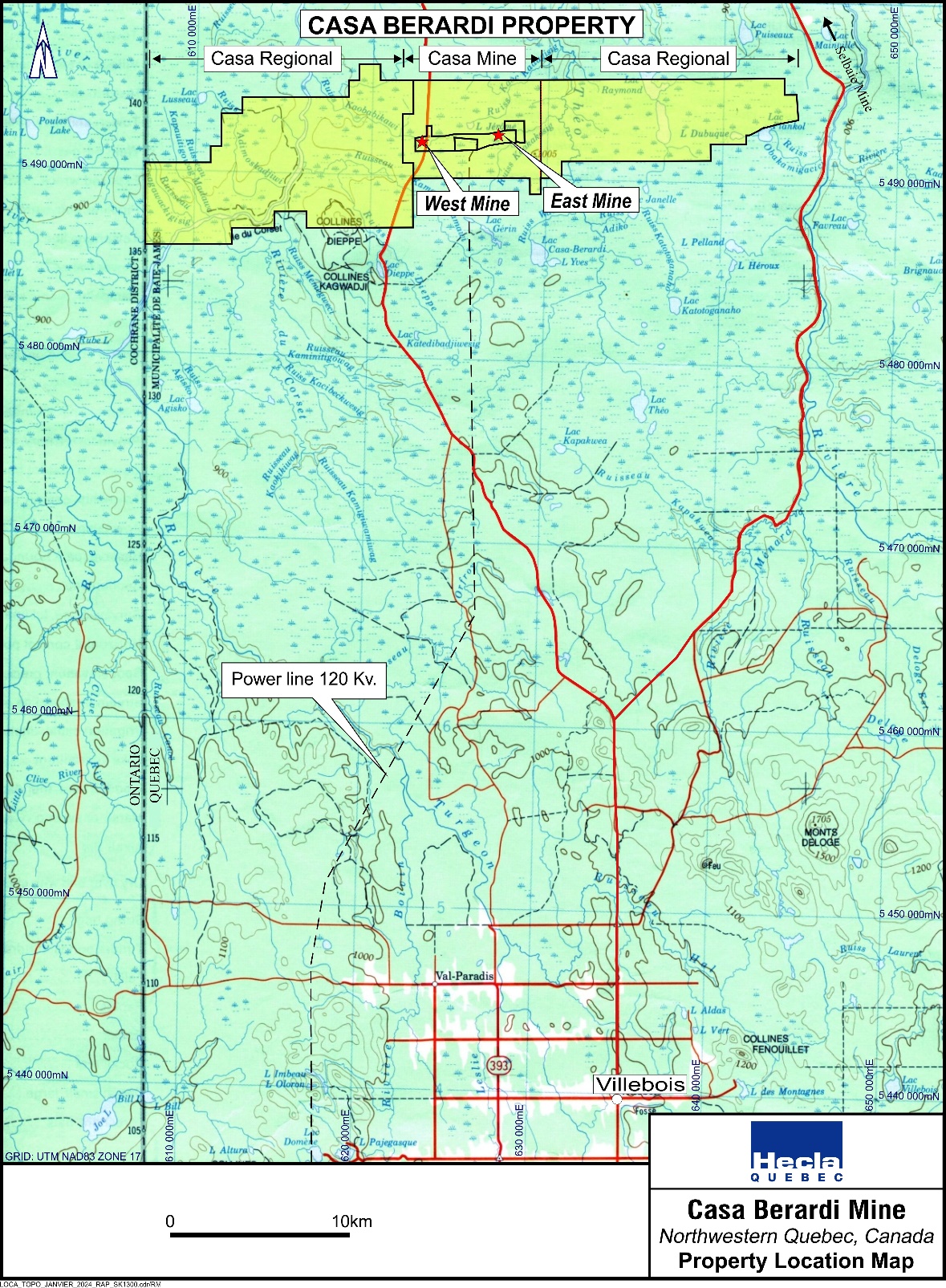

The Property is located in northwestern Québec, approximately 95km north of the town of La Sarre, in the James Bay Municipality. The Property extends east-west for more than 37km and is 3.5km wide in a north-south direction. The Property is bounded to the west by the Québec/Ontario border and covers parts of Casa Berardi, Dieppe, Raymond, D’Estrées, and Puiseaux townships. The Casa Berardi gold deposits are located along a five kilometer east-west mineralized corridor associated with the Casa Berardi Fault. They comprise the West Mine, including the Principal area, and the East Mine.

The Casa Berardi gold deposits can be classified as an Archean sedimentary hosted lode gold deposit. The gold mineralization is superimposed on a continuous graphitic mudrock unit corresponding to the Casa Berardi Fault plane. Gold occurs mainly south of the Casa Berardi Fault, and occasionally on both sides of the fault.

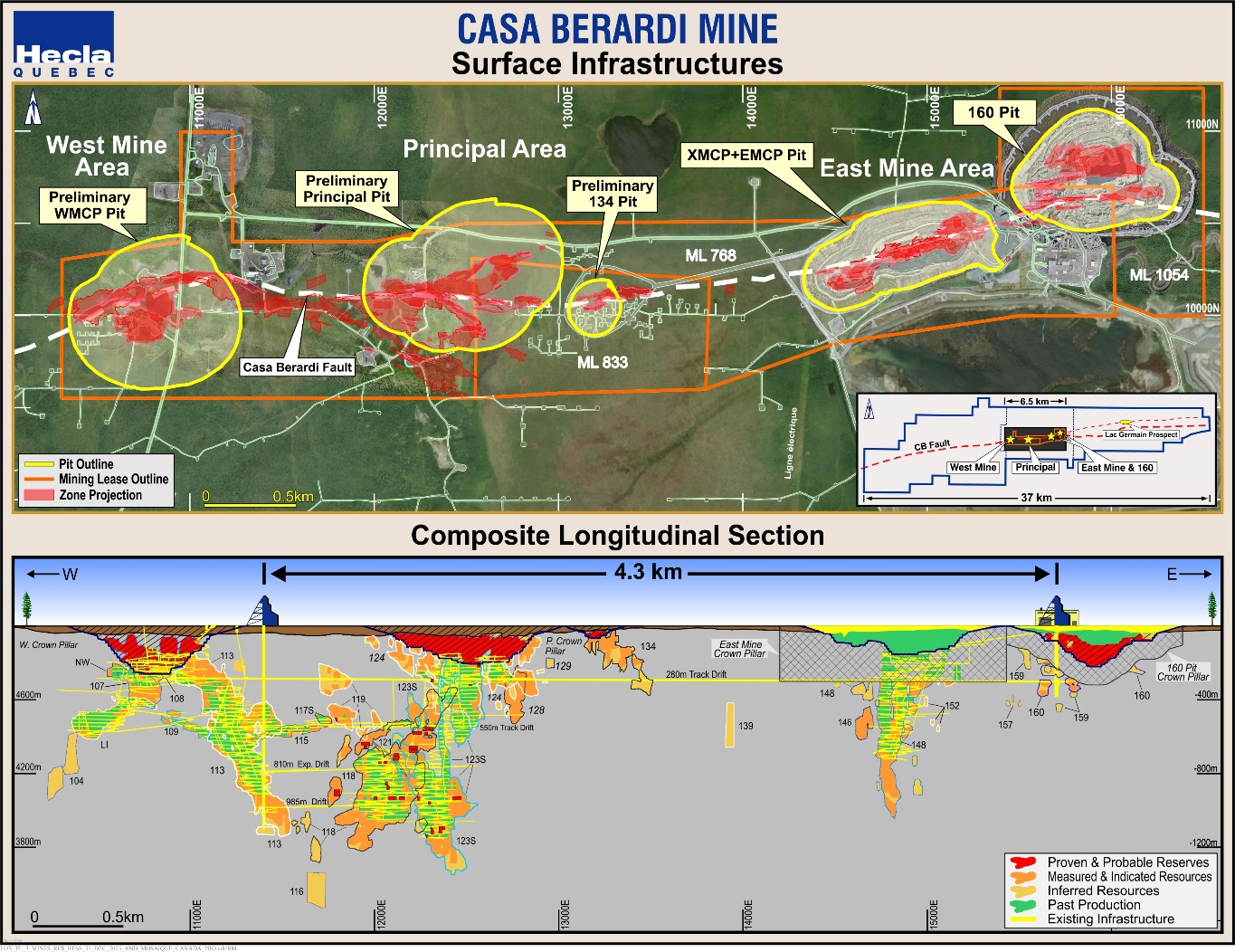

The Casa Berardi operation includes several open pits and two underground mines (Figure 1‑1). The mine has produced approximately 3.06 million ounces (Moz) Au (recovered) since commencing production in 1988, including approximately 2.37Moz Au (recovered) since production recommenced in November 2006.

The Casa Berardi processing facilities consists of a 3,730tonnes per day (tpd) mill, with the ability to process 4,400tpd, and a carbon-in-leach (CIL) process to recover gold from the ore.

Production for Casa Berardi over the current life of mine (LOM), 2024 to 2037, is forecast to be comprised of 209 thousand tonnes (kt) from the underground operations in 2024 and 14.2 million tonnes (Mt) from the open pit operations from 2024 until 2037.

Figure STYLEREF 1 \s 1‑. Mine Plan View of Current and Planned Infrastructure with Composite Longitudinal Section

1.1.1 Conclusions

RESPEC offers the following conclusions and observations by area:

1.1.1.1 Geology and Mineral Resources

/ The Casa Berardi Property is located in the northern part of the Abitibi Subprovince, within the Superior Province of the Archean core of the Canadian Shield. Three principal styles of mineralization have been recognized at Casa Berardi with gold occurring in: 1) quartz veins, 2) stockworks, and 3) banded iron formation. The mineralized zones are closely associated with the Casa Berardi Fault, and the Casa Berardi deposit can be classified as an Archean-age, sedimentary-hosted lode-gold deposit.

/ Compilation and subsequent verification of the Casa Berardi database has been performed by Hecla personnel since 2014. To further evaluate Hecla’s database, RESPEC conducted an audit of all 2021, 2022 and 2023 assay data, with acceptable results. RESPEC is satisfied that the drill-hole database is considered to be sufficient for use in geological and mineral domain modeling, Mineral Resource and Mineral Reserve estimation, and mine planning.

/ Measured and Indicated resources, effective December 31, 2023, consist of a total of 4.11Mt with an average gold grade of 6.39g Au/t containing 0.84Moz Au. Inferred Mineral Resources total 2.09Mt at 5.89g/t Au for

0.40Moz Au. The open pit resources are constrained within the designed pit while underground material was constrained by stope optimizations, reflecting the potential for underground and open pit mining and mill processing of the present Casa Berardi deposits.

/ Hecla considered density and quality of drill-hole data, the established continuity of the auriferous zones, and production experience in classification of the Casa Berardi gold Mineral resources in the open pit and underground block models. RESPEC has evaluated Hecla’s classification for the Casa Berardi Mineral Resources and concludes that their applied methodologies are reasonable and satisfy S-K 1300 requirements.

1.1.1.2 Mining and Mineral Reserves

/ Mineral Reserves have been classified in accordance with the definitions for Mineral Reserves in S-K 1300. Mineral Reserves as of December 31, 2023, total 14.4Mt grading 2.75g/t Au containing 1.27Moz Au.

/ Measured and Indicated Mineral Resources were converted to Proven and Probable Mineral Reserves, respectively. Inferred Mineral Resources were not converted to Mineral Reserves.

/ The mining methods at Casa Berardi are well established with many years of operating experience, providing the necessary expertise to, safely and economically, extract the Mineral Reserves.

/ While both transverse and longitudinal longhole stoping methods are employed underground. Challenging ground conditions require the use of various types of backfill to provide the necessary support.

/ Underground mining will come from the West Mine in 2024 as the East mine was abandoned in 2023 to allow for backfilling the adjoining EMCP pit. Mining from various open pits on surface represents the bulk of the Mineral Reserves to be mined, accounting for approximately 98.5% of the Casa Berardi Mineral Reserves.

/ The current LOM period is estimated to be 14 years ending in 2037. Underground Mineral Reserves totaling 209kt are planned be mined in 2024 while open pit Mineral Reserves totaling 14.2Mt is planned be mined over the entire LOM period.

/ The LOM plan considers a 30-month delay in mining to allow for the expected permitting timeline.

1.1.1.3 Mineral Processing

/ Metallurgical and production models have been developed from extensive baseline sampling and are further adjusted annually to account for process and metallurgical improvements and changes.

/ The test work performed on open pit material was used to estimate gold recovery, while operating data was used for underground material. Extensive test work has been performed by an external laboratory on future open pit material (West Mine Crown Pillar (WMCP) and Principal). WMCP test results were used to inform the long-term mine plan.

/ Test work programs, both internal and external, continue to be performed to support current operations and potential improvements.

/ The current process facilities are appropriate for the mineralization material extracted from the mine. The flowsheet, equipment, and infrastructure are expected to support the current LOM plan.

1.1.1.4 Infrastructure

/ Hecla is currently mining at Casa Berardi and has both open pit and underground infrastructure, as well as a mill. Hecla plans to develop three additional open pits (Principal, WMCP, and F134) and associated waste rock storage facilities, and other surface infrastructure for future mine operations.

/ With the increase of pit production, an expanded maintenance facility will be required. A capital allowance is included in cashflow model.

1.1.1.5 Environment

/ Hecla has sufficiently assessed the environmental impact of the operation, and subsequent closure and remediation requirements such that Mineral Resources and Mineral Reserves can be declared, and the mine plan deemed appropriate and achievable. Closure provisions are appropriately considered, and monitoring programs are in place.

/ Hecla has developed a community relations plan to identify and ensure an understanding of the needs of the surrounding communities and to determine appropriate programs for addressing those needs. Hecla appropriately monitors socio-economic trends, community perceptions, and mining impacts.

/ Current permits held by Hecla for the Property are sufficient to ensure that the planned surface and underground mining activities which will take place into 2026 are conducted in accordance with the local, provincial, and national regulatory frameworks.

/ Beyond 2026, the LOM plan includes the development of three additional open pits along with associated waste rock storage facilities and other infrastructure. This planned development may require an EIA to be performed at the Property. Hecla will submit a project notice to the Provincial MELCCFP in 2024 that describes the proposed development and proposed plan of operations. Hecla expects the EIA process that all necessary permits will be obtained so that mining of the planned open pits can take place in accordance with local, provincial, and national regulatory frameworks.

/ There are currently no known environmental, permitting, or social/community risks that could impact the Mineral Resources or Mineral Reserves.

1.1.2 Recommendations

RESPEC offers the following recommendations by area.

1.1.2.1 Geology and Mineral Resources

/ Continue drilling to expand the near mine open pit Mineral Resources.

/ Convert open pit and underground Inferred Mineral Resources to Indicated, especially material in the Life of Mine Plan.

/ Continue to drill below the F134 and F160 pits.

/ Create resource open pit shells for F134 and F160.

/ Increase regional exploration activities to make new discoveries on the Property.

/ Investigate the potential high gold assay bias at the secondary umpire laboratory.

/ Implement procedures that will help reduce certified reference material (CRM or standard) mislabeling or “swaps”.

1.1.2.2 Mining and Mineral Reserves

/ Review marginal underground Mineral Resources for extraction due to higher spot prices in the near term.

/ Continue to convert Mineral Resources to Mineral Reserves to extend open pit mining where possible.

/ Continue to develop a ramp up plan to reach maximum mining rates after restart.

/ Since the existing cost model is based on contractor rates, an evaluation of a complete haulage model will provide a more comprehensive understanding of late-stage owner operator costs. It would be expected that mining operating costs could be lowered for future studies.

1.1.2.3 Mineral Processing

/ Continue to conduct additional metallurgical testing to better understand the processing of mineralization from the Principal and WMCP pits. This will aid in projecting metallurgical recoveries for these pits and will indicate any variability in gold recovery and grindability of the material.

1.2 Economic Analysis

Please refer to the note regarding forward-looking information at the start of this Report.

The economic analysis contained in this TRS is based on the Casa Berardi Proven and Probable Mineral Reserves material only, economic assumptions, and capital and operating costs provided by Hecla’s technical team in its LOM plan model and reviewed by RESPEC. All costs in this section are expressed in US dollars. Unless otherwise stated, all costs in this section of the TRS are expressed without allowance for escalation or currency fluctuation. All costs received from Hecla’s site technical team in its Casa Berardi LOM 2023 Reserves only model were quoted in Canadian dollars and were converted to US dollars at an exchange rate of US$1 = C$1.350.

A summary of the key project criteria is provided in the subsequent subsections.

1.2.1 Economic Criteria

1.2.1.1 Physicals

/ Mine life: 14 year LOM (between years 2024 and 2037)

/ Open Pit operations

» Open pit mine life: 14 years (between years 2024 and 2037)

» Total ore tonnes mined: 14.2Mt at 2.72g/t Au

» Waste tonnes: 219Mt

» Maximum mining rate: 87ktpd (ore + waste)

/ Underground operations

» Underground mine life: 1 year (2024)

» Total ore tonnes mined: 209kt at 4.84g/t Au

» Maximum mining rate: 1,200tpd

/ Processing of Mineral Reserves:

» Total Ore Feed to Plant: 14.4Mt

Gold grade: 2.75g/t Au

» Maximum milling rate: 4,400tpd

» Contained Metal

Gold: 1.27Moz Au

» Average LOM Plant Recovery 81.5%

» Recovered Metal

Gold: 1.04Moz Au

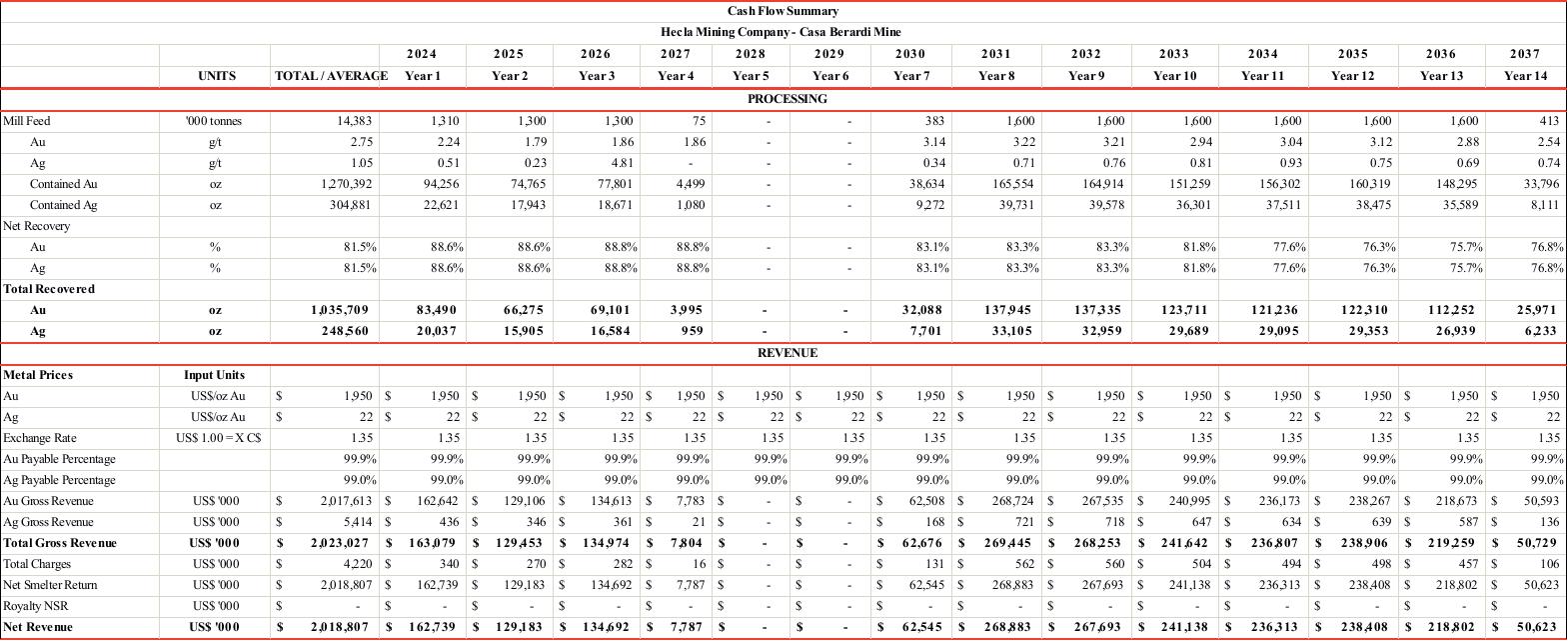

1.2.1.2 Revenue

/ For the purposes of this economic analysis described in this section, revenue is estimated over the LOM with a flat long-term price of US$1,950/oz Au. RESPEC considers this price to be aligned with the latest industry consensus long-term forecast prices. Transportation, insurance, and refining charges are estimated at US$4.07/oz Au over the LOM. Payable metals in the Casa Berardi LOM 2024 plan are estimated at 99.9% for gold and 99.0% for silver. These rates are based on actual figures for refining losses. Silver credits have been estimated based on historical performance of the site.

/ LOM net revenue is US$2,019 million (after Refining Charges).

1.2.1.3 Capital Costs

/ Total operating capital costs total US$498 million

/ Closure costs of US$21.6 million and a salvage value of $19.7 million are included in the analysis at the end of the LOM.

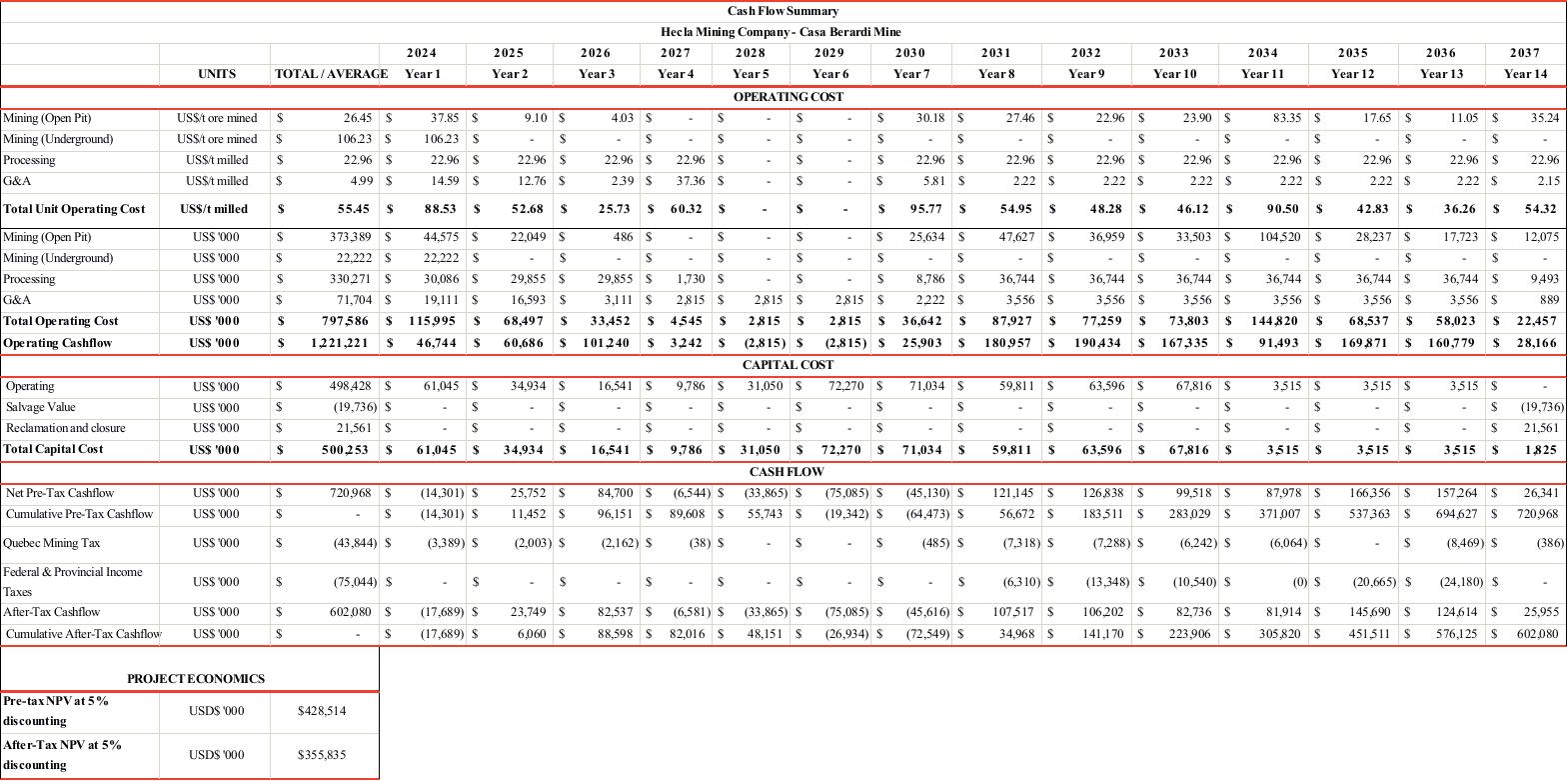

1.2.1.4 Operating Costs

/ Open Pit mining: US$26.45/t ore mined

/ Underground mining: US$106.23/t ore mined

/ Processing: US$22.96/t ore milled

/ G&A US$4.99/t ore milled

/ Total unit operating costs US$55.45/t ore milled

/ LOM total operating costs US$797.6 million

/ Excludes financing and corporate overhead costs

1.2.1.5 Taxation and Royalties

/ Royalties: The current production zones as well as any in the 2024 LOM are not subject to a net smelter return (NSR) or royalty to a third party / previous landowner.

/ Income tax is payable to the Federal Government of Canada, pursuant to the Income Tax Act (Canada). The applicable Federal income tax rate is 15% of taxable income.

/ Income tax is payable to the Province of Québec at a tax rate of 11.5% of taxable income.

/ No income taxes are payable until 2031 as Hecla uses its current tax pools and net operating loss carry forwards. Beginning in 2031, the effective tax rate used is 26.5% (combined federal and provincial).

/ Québec Mining Tax base rate is 16%.

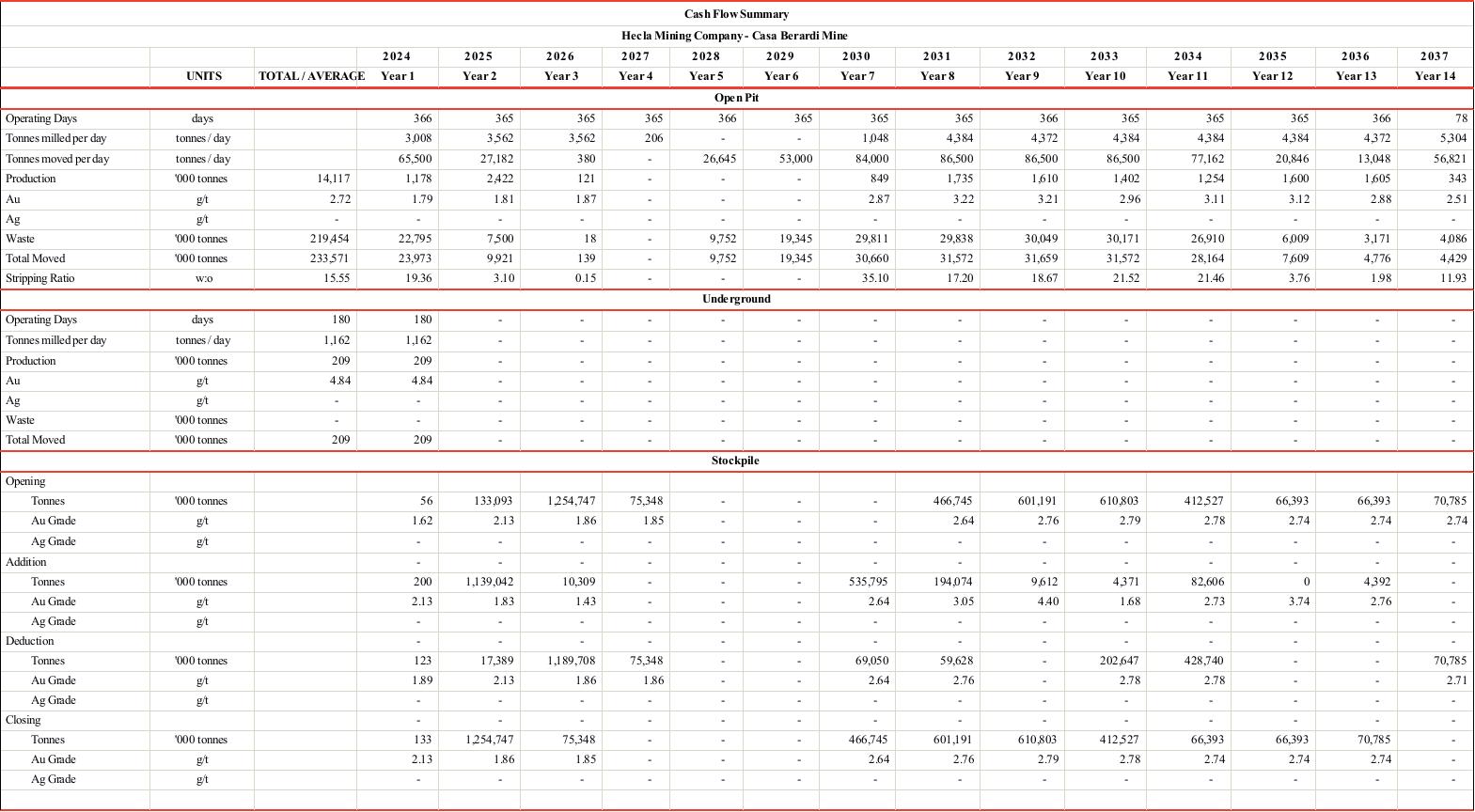

1.2.2 Cash Flow Analysis

RESPEC has reviewed and accepts Hecla’s cash flow model as discussed in this section.

The Casa Berardi economics have been evaluated using the discounted cash flow method by considering annual processed tonnages and grade of ore. The associated process recovery, metal prices, operating costs, refining and transportation charges, and sustaining capital expenditures were also considered.

The full annual cash flow model is presented in Table 1‑1 in US dollars with no allowance for inflation, show a pre-tax and after-tax NPV, using a 5% discount rate, of $429 million and $356 million, respectively. RESPEC is of the opinion that a 5% discount/hurdle rate for after-tax cash flow discounting of long-lived precious/base metal operations in a politically stable region is reasonable and appropriate and commonly used. For this cash flow analysis, the internal rate of return (IRR) and payback are not applicable as there is no negative initial cash flow (no initial investment to be recovered) since Casa Berardi has been in operation for a number of years.

Table STYLEREF 1 \s 1‑. Life of Mine Indicative Economic Results

| | |

| Units | Total LOM |

Production |

LOM | years | 14 |

OP Production | 000t | 14,174 |

Au Grade | g/t | 2.72 |

Waste | 000t | 233,628 |

UG Production | 000t | 209 |

Au Grade | g/t | 4.84 |

Mill Feed | 000t | 14,383 |

Au Grade | g/t | 2.75 |

Ag Grade | g/t | 0.66 |

Ag/Au Conversion Ratio | % | 23.999 |

Total Contained Production |

Contained Au | 000oz | 1,270 |

Contained Ag | 000oz | 305 |

Average Recovery | % | 81.5 |

Total Recovered Production |

Recovered Au | 000oz | 1,036 |

Recovered Ag | 000oz | 249 |

Metal Prices |

Gold Price | US$/oz | 1,950 |

Silver Price | US$/oz | 22 |

Cash Flow |

Gross Revenue | US$ million | 2,023 |

Treatment & Refining | US$ million | -4 |

Operating Costs |

Mining OP Costs | US$ million | -373 |

Mining UG Costs | US$ million | -22 |

Processing Costs | US$ million | -330 |

G&A | US$ million | -72 |

Operating Cash Flow | US$ million | 1,221 |

Growth Capital Costs | US$ million | -421 |

Sustaining Capital Costs | US$ million | -77 |

Salvage Value | US$ million | 20 |

Reclamation & Closure | US$ million | -22 |

| | |

| Units | Total LOM |

Pre-Tax Net Cash Flow | US$ million | 721 |

Québec Mining Tax | US$ million | -44 |

Federal & Provincial Income Taxes | US$ million | -75 |

After-Tax Cashflow | US$ million | 602 |

Project Economics |

Pre-tax NPV at 5% | US$ million | 429 |

After-Tax NPV at 5% | US$ million | 356 |

Operating Metrics |

Maximum Daily OP Mining Rate | t/d mined | 87,000 |

Maximum Daily UG Mining Rate | t/d mined | 1,200 |

Maximum Daily Processing Rate | t/d milled | 4,400 |

OP Mining Cost | US$/t ore mined | 26.45 |

UG Mining Cost | US$/t ore mined | 106.23 |

Processing Cost | US$/t ore | 22.96 |

G&A Cost | US$/t ore | 4.99 |

Total Cost | US$/t ore | 55.45 |

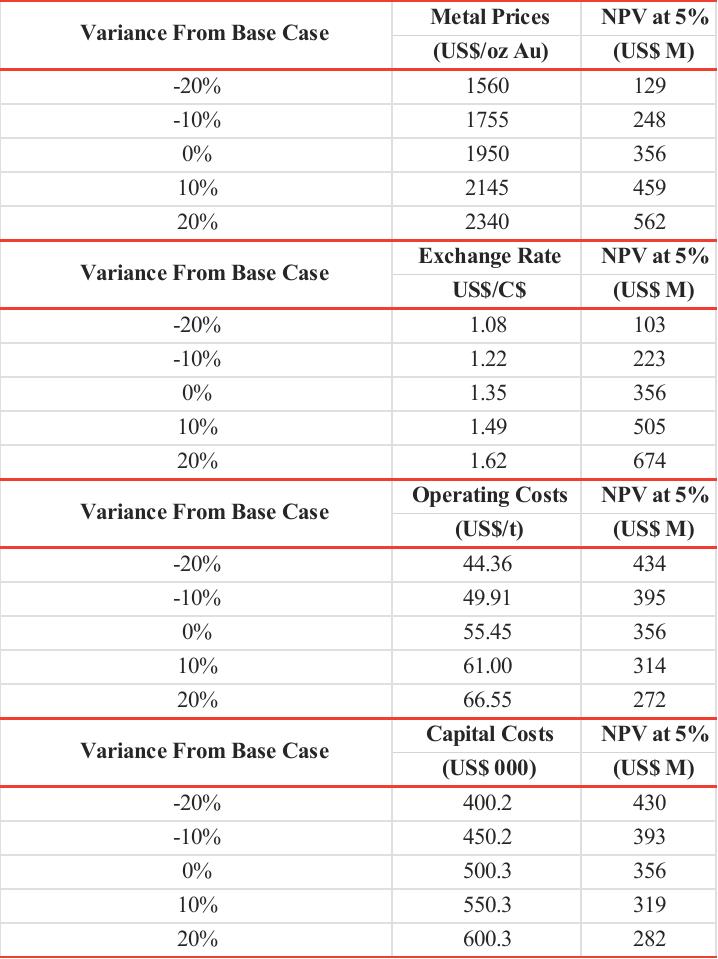

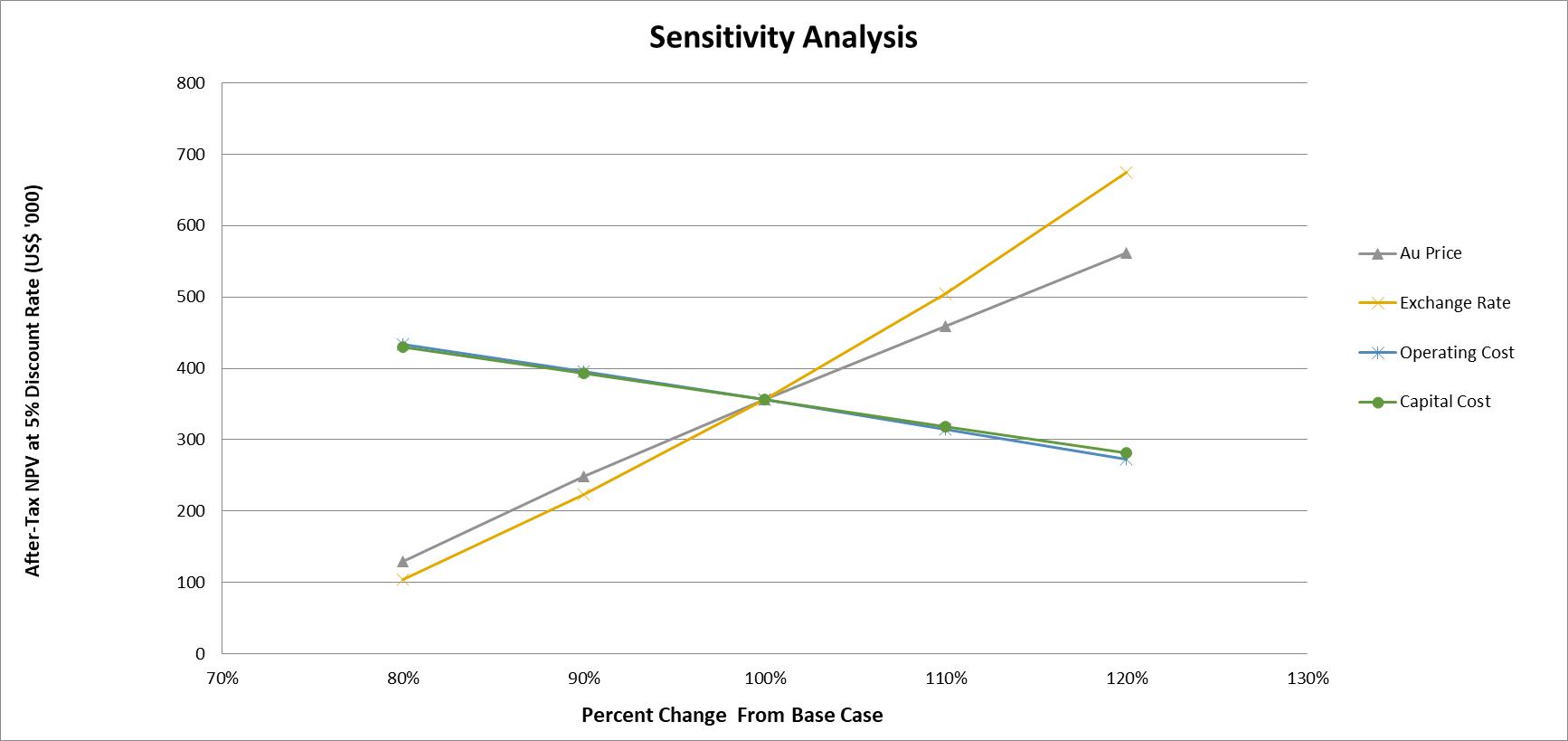

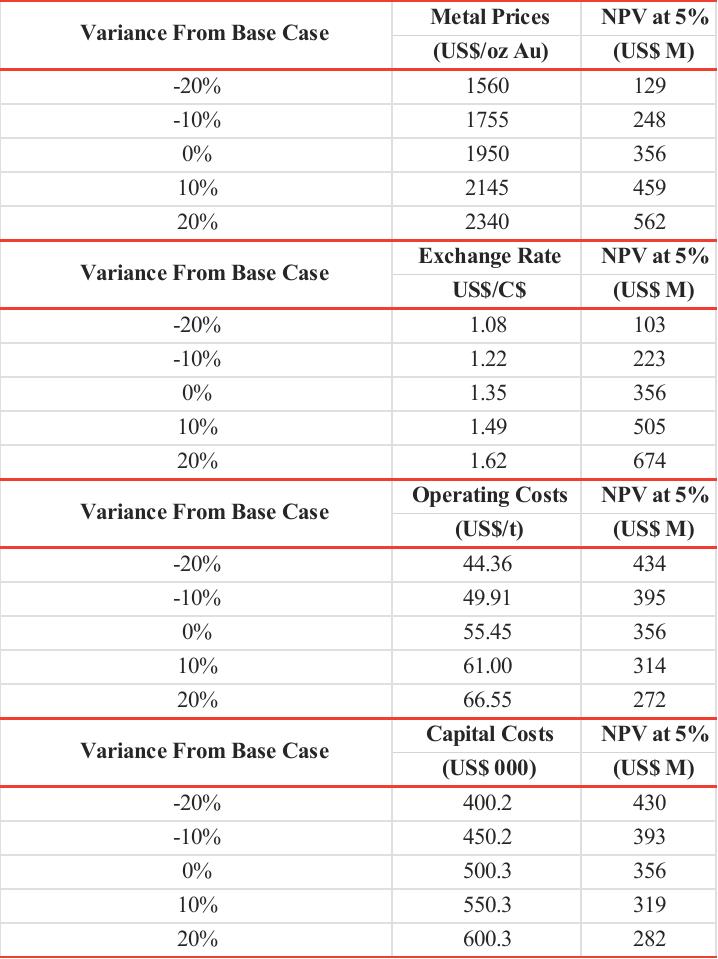

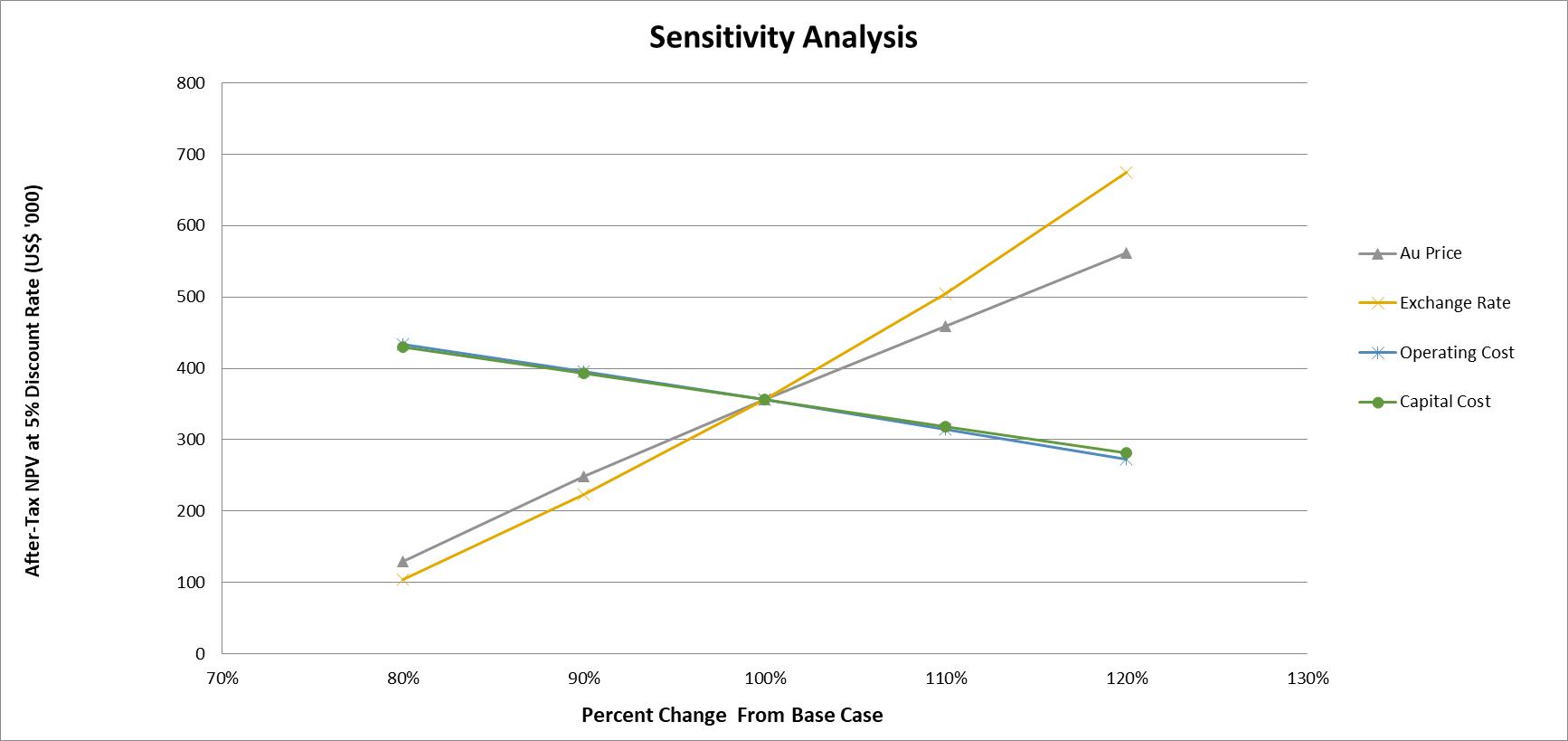

1.2.3 Sensitivity Analysis

Project risks can be identified in both economic and non-economic terms. Key economic risks were examined by running cash flow sensitivities on after-tax NPV at a 5% discount rate. The mine is most sensitive to changes in metal prices and US$/C$ exchange rate, then capital costs and operating costs.

1.3 Technical Summary

1.3.1 Property Description

The Property is located in the Province of Québec, approximately 95km north of the town of La Sarre, in the James Bay Municipality. The mine is located at longitude 79°16’46.4” and latitude 49°33’56.7”.

1.3.2 Land Tenure

The Property consists of 391 contiguous designated claims, covering a total area of 19,151.08ha, and three mining leases, BM 768, BM 833, and BM 1054 covering areas of 397.09ha, 84.35ha, and 92.56ha, respectively. The Property area totals 19,725.08ha. Other legal titles include non-exclusive lease BNE 25938, tailings lease 70218, and two waste rock facility (WRF) leases 192410 and 819410. Legal titles are under the name of Hecla Québec. The Casa Berardi claims are in good standing.

1.3.3 History

Prior to 1974, the Casa Berardi area was explored for base metal deposits. In 1974, the first 13 claims were staked by Inco Gold Ltd. (Inco Gold). The discovery hole was drilled in 1981, and 590 additional claims were staked.

In 1982, Inco Gold (60%) and Golden Knight Resources Inc. (Golden Knight) (40%) formed a joint venture (JV) to operate the Mine, with the East Mine commencing production in 1988 and the West Mine in 1990. In 1991, TVX Gold Inc. (TVX) acquired Inco Gold’s 60% interest in the Property. In 1994, TVX and Golden Knight purchased the remaining interest in the Domex claim block, a part of the Principal (Main) Zone between the West Mine and East Mine, from Teck Corporation. In January 1997, TVX announced the closure of the East Mine due to ground control issues. Two months later, the West Mine was closed. The total combined production for the period from 1988 to 1997 was 3.5Mt at an average grade of 7.1g/t Au. The total gold recovered during the operating years was 688,400toz Au, with an average mill gold recovery rate of 87%.

In September 1998, Aurizon signed an agreement and completed the acquisition of all Casa Berardi assets and mining rights. Aurizon completed exploration diamond drilling programs, feasibility studies, underground development, shaft sinking, and construction.

In early November 2006, Aurizon completed construction and development at the West Mine area and commenced underground mining and milling operations. From November 2006 to May 31, 2013, Aurizon production totaled approximately 4.31Mt at an average grade of 7.7g/t Au for a total of 0.98Moz Au recovered.

In June 2013, Hecla acquired Aurizon and the company was renamed Hecla Québec, a 100% subsidiary of Hecla. By 2012, Lake Shore Gold Inc. (Lake Shore) earned into a 50% interest in certain claims and mineral rights within the Casa Berardi Exploration Property (Casa Exploration Property), but not in areas where production was occurring, pursuant to a 2007 option agreement between the parties. In February 2016, Tahoe Resources Inc. (Tahoe) purchased Lake Shore, and at the end of 2016, they opted to sell their 50% interest in the Casa Exploration Property to Hecla in exchange for C$6 million (US$ 4,433,400 million) and 1% NSR on 227 claims. Hecla Purchased the NSR from Lake Shore in December 2016 and repurchased the related 1% NSR in June 2021. From June 1, 2013 to December 31, 2021, production from Casa Berardi totaled approximately 9.0Mt at an average grade of 4.88g/t Au for a total of 1.17Moz Au recovered.

Since 1988, a total of 19.8Mt at an average grade of 5.49g/t Au have been milled at Casa Berardi for a total recovered gold of 3.1Moz Au and an average gold recovery of 87.8%

1.3.4 Geological Setting, Mineralization, and Deposit Types

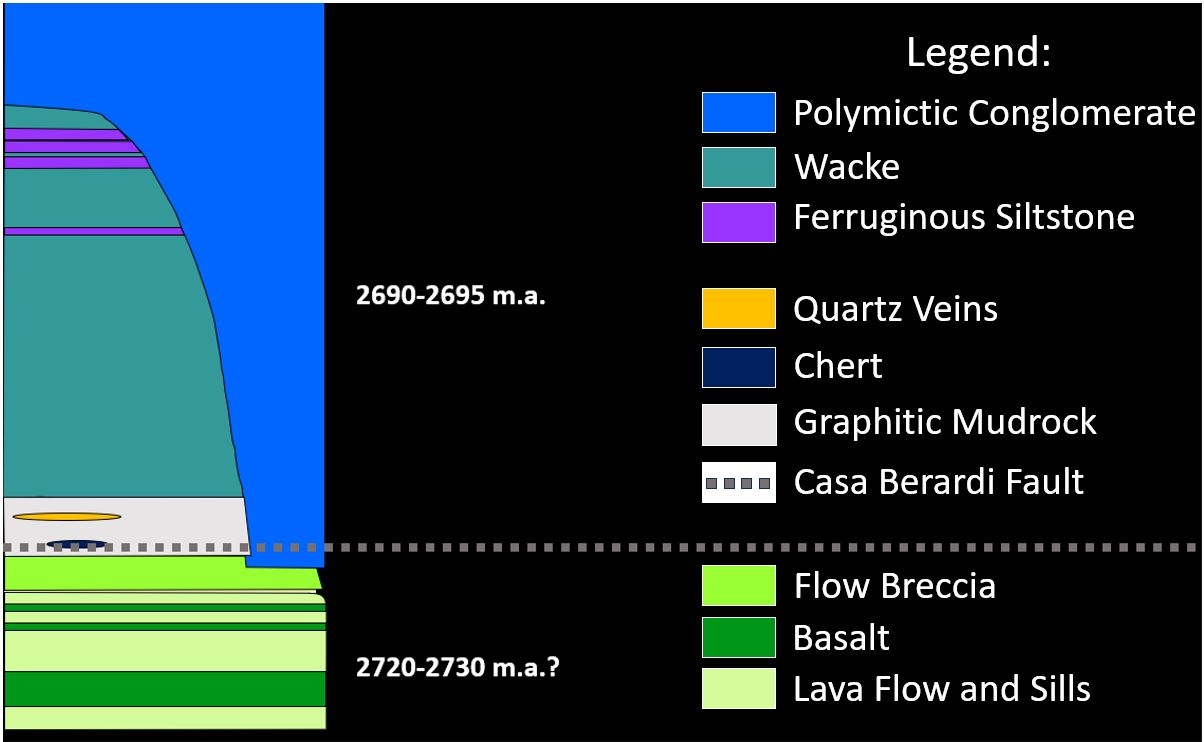

The Casa Berardi Property is located in the northern part of the Abitibi Sub province, within the Superior Province of the Archean core of the Canadian Shield. The regional geology is characterized by generally east-west assemblages of isoclinally folded and variably foliated and metamorphosed mafic volcanic rocks, flysch‑type sedimentary iron formations, graphitic mudrocks, and a large granodioritic to granitic batholith. Structurally, the Property is within the Casa Berardi Break, a 15km wide corridor of strain that can be traced over 200km. The Casa Berardi Fault, which strikes east-west and dips 80° to the south, was active during this stage along an unconformity between graphitic sedimentary and volcanic units.

Three principal styles of mineralization have been recognized at Casa Berardi with gold occurring in: 1) quartz veins, 2) stockworks, and 3) banded iron formation. The mineralized zones are closely associated with the Casa Berardi Fault and are found on both sides of the fault. They are restricted to a 500m wide corridor that is folded and plunges slightly to the west.

The grade of gold mineralization associated with veins generally increases with increasing complexity. Quartz phases include: 1) early grey quartz, with abundant sulfide and fluid inclusions; 2) mosaic micro-crystalline quartz associated with higher grades; and 3) late non-mineralized coarsely crystallized white quartz. Veins contain only 1% to 3% sulfides, predominately arsenopyrite and pyrite, as well as traces of sphalerite, chalcopyrite, pyrrhotite, tetrahedrite, galena, and gold. Arsenopyrite is the main gold-bearing sulfide present in all veins of the Casa Berardi deposit. Stockworks represent nearly the same volume as the large quartz veins. Stockwork mineralization is generally sub-economic, unless they occur in close proximity to larger quartz veins. Gold-bearing banded iron formation is restricted to the highly sheared, brecciated, and altered ferruginous sedimentary units occurring north of the Casa Berardi Fault. Mineralization contains up to 10% chert-magnetite beds, and exhibits high sulfide content which consists of pyrite, arsenopyrite, traces of pyrrhotite, and little or no visible gold.

The Casa Berardi deposit can be classified as an Archean-age, sedimentary-hosted lode-gold deposit. Gold deposits of the Archean Abitibi greenstone belt predominantly consist of epigenetic disseminated and vein-hosted deposits, and syngenetic gold-rich massive sulfides (Robert, et al., 2005; Monecke, et al., 2017). The Casa Berardi gold mining camp contains different styles of mineralization within the same deposit including gold-rich massive sulfides, auriferous pyritic and carbonaceous phyllite and chert, and pyrite-arsenopyrite-gold-quartz veins.

1.3.5 Exploration

Since Hecla’s acquisition of Casa Berardi in June 2013, exploration activities have largely consisted of staking and acquiring new claims, core drilling, geophysical surveys, drill-hole re-logging and drilling data compilation and integration. The majority of Hecla’s exploration and delineation drilling since 2014 was core. No RC holes were drilled by Hecla, although there were 103 sonic holes drilled in 2022.

RESPEC believes that exploration potential remains on the Property along strike and at depth of known gold mineralization along the Casa Berardi Fault, both within and outside the current mine areas. Geophysical studies and drilling will be important exploration tools for making new discoveries at Casa Berardi, particularly for gold mineralization concealed by glacial till and other post-mineral overburden material outside the mine areas.

1.3.6 Mineral Resource Estimates

Hecla considered density and quality of drill-hole data, the established continuity of the auriferous zones, and production experience in classification of the Casa Berardi gold Mineral Resources in the open pit and underground block models (Table 1‑2). Classification was applied based on the average distance of a given block centroid to drill-hole composites used to estimate the block grade, the proximity to mine workings, and the location within modeled mineral envelopes. RESPEC considers Hecla’s use of distances from composites and mine workings to be a reasonable approach to classifying resources. Average and closest distances of composites relative to blocks is commonly used in the mining industry for resource classification and satisfies S-K 1300 requirements.

Table STYLEREF 1 \s 1‑. Mineral Resource Estimate Summary – December 31, 2023

| | | |

Resource Category | K Tonnes | Grade

(g/t Au) | Contained Metal

(k oz Au) |

Underground |

Measured | 997 | 7.30 | 234.0 |

Indicated | 2,861 | 6.55 | 602.5 |

Measured and Indicated | 3,858 | 6.74 | 836.6 |

Inferred | 1,338 | 7.71 | 331.6 |

Open Pit |

Measured | 61 | 0.96 | 1.9 |

Indicated | 186 | 0.81 | 4.9 |

Measured and Indicated | 247 | 0.85 | 6.7 |

Inferred | 751 | 2.65 | 64.0 |

Total |

Measured and Indicated | 4,106 | 6.39 | 843.3 |

Inferred | 2,089 | 5.89 | 395.6 |

Notes:

1. In situ Mineral Resources are classified in accordance with the S-K 1300 classification system.

2. Mineral Resources were estimated by Hecla staff and reviewed and accepted by RESPEC.

3. Mineral Resources are exclusive of Mineral Reserves and do not have demonstrated economic viability.

4. Underground Mineral Resources are reported at cutoff grades ranging from 3.78g/t Au to 5.84g/t Au.

5. Open pit Mineral Resources are reported at cutoff grades ranging from 0.97g/t Au to 1.13g/t Au.

6. Underground and open pit Mineral Resources are reported using US$1,750/oz Au, based on consensus, long-term forecasts from banks, financial institutions, and other sources, and a US$/C$ exchange rate of 1.300.

7. A minimum mining width of three meters was used for the modeled open pit and underground mineral envelopes used to estimate Mineral Resources.

8. Totals may not represent the sum of the parts due to rounding.

9. Mineral Resources potentially amenable to open pit mining methods are reported using a gold price of US$1,750/oz, a throughput rate of 4,400 tonnes/day (combined material from underground and open pit sources), surface mining costs of US$3.46/tonne mined, milling processing costs of US$24.13/tonne processed, and general and administrative and other costs ranging from $9.96-10.34/tonne processed. Metallurgical recoveries were based on metallurgical curves.

10. Mineral Resources potentially amenable to underground mining methods are reported using a gold price of US$1,750/oz and a throughput rate of 4,400 tons/day (combined material from underground and open pit sources). Operating costs are US$183.08/ton mined or US$282.60/ton mined, depending on the underground zone or lens. Mill recoveries also vary by zone or lens and range from 80.10% to 89.90%.

All Mineral Resources reported in Table 1‑2 used a gold price of US$1,750/oz Au, which was chosen based on consensus, long-term forecasts from banks, financial institutions, and other sources, and a US$/C$ exchange rate of 1.300. The reported underground resources are undiluted and are exclusive of Mineral Reserves. The reported open pit resources are diluted by pit and are exclusive of Mineral Reserves. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

The underground Mineral Resources summarized in Table 1‑2 are reported by tabulating all blocks within modeled mineral envelopes with estimated grades that exceed the calculated reporting cutoff grades, which vary for each zone or lens (sub-zone). The cutoff grades range from 3.78g/t Au to 5.84g/t Au, and are calculated based on a gold price of $1,750/oz, and mill recoveries and operating costs that are specific to each zone. The resource estimates are based on a combined open pit and underground mill feed of 4,400tpd.

The reported open pit Mineral Resources in Table 1‑2 are constrained by pit designs generated using cutoff grades that range from 0.97g/t Au to 1.13g/t Au. The gold cutoff grades were calculated at a gold price of $1,750/oz, and using pit area-specific processing, general and administrative costs, recoveries, and refining costs. The mining cost is included in pit optimizations but is not included in the determination of the cutoff grade, as all material in each pit would be removed as either ore or waste.

RESPEC reviewed Hecla’s Casa Berardi open pit and underground models, both visually and statistically. Gold grade and tonne smoothing during estimation is the primary issue in the models. Underground estimates are more tightly constrained by modeled mineral envelopes, so the smoothing is less pronounced compared to the open pit models. The grade smoothing increases risk associated with the Casa Berardi open pit resource models, which diminishes confidence in the local distributions of gold grades and tonnes within the broader wireframes. The homogenization of grade has resulted in models that likely overstate tonnes and understate grade, although the extent and the ultimate effects during mining cannot be fully quantified. However, the uncertainties associated with grade and tonne smoothing in the current models are offset in part by the history of productive mining at Casa Berardi.

1.3.7 Mineral Reserve Estimates

Mineral Reserves have been classified in accordance with the definitions for Mineral Reserves in S-K 1300. Mineral Reserves as of December 31, 2023, are summarized in Table 1‑3.

Measured Mineral Resources were converted to Proven Mineral Reserves, and Indicated Mineral Resources were converted to Probable Mineral Reserves. Inferred Mineral Resources were not converted to Mineral Reserves.

Table STYLEREF 1 \s 1‑. Summary of Mineral Reserves - December 31,2023

| | | | |

Reserve Category | Tonnes | Grade | Contained Metal | Metallurgical Recovery |

| | | | |

| (K t) | (g/t Au) | (K oz Au) | (%) |

Underground |

Proven | 50 | 4.14 | 6.7 | - |

Probable | 159 | 5.06 | 25.9 | - |

Proven + Probable | 209 | 4.84 | 32.6 | 88.7 |

Open Pit |

Proven | 3,846 | 3.07 | 379.4 | - |

Probable | 10,327 | 2.59 | 858.5 | - |

Proven + Probable | 14,174 | 2.72 | 1,237.9 | 81.3 |

Total |

Proven + Probable | 14,383 | 2.75 | 1,270.5 | 81.5 |

Notes:

1. Classification of Mineral Reserves is in accordance with the S-K 1300 classification system. Mineral Reserves are reported as in situ with the exception of mill stockpile volumes as defined in this report.

2. RESPEC is responsible for the statement of Proven and Probable Mineral Reserves.

3. Mineral Reserves are 100% attributable to Hecla.

4. Underground Mineral Reserves are estimated at a cutoff grade of 3.60g/t Au for 124 Zone and a 3.88g/t Au for the 118 and 123 Zones.

5. Open pit Mineral Reserves are estimated at a cutoff grade of 1.02g/t Au for the F160 pit and1.18g/t Au for the WMCP, Principal, and F134 Pits.

6. Underground Mineral Reserves are estimated using short-term gold price of US$1,850/oz Au and open pit Mineral Reserves are estimated using an average long term gold price of US$1,650/oz Au, using a US$/C$ exchange rate of 1.300.

7. A minimum mining width of three meters was used for underground Mineral Reserves.

8. Totals may not represent the sum of the parts due to rounding.

Production for Casa Berardi over the current LOM, 2024 to 2037, includes 209kt from the underground operations in 2024 and 14.2Mt from the open pit operations from 2024 until 2037. Contained gold production over the LOM is forecasted to total 1.27Moz Au.

RESPEC is not aware of any risk factors associated with, or changes to, any aspects of the modifying factors such as mining, metallurgical, infrastructure, permitting, or other relevant factors that could materially affect the Mineral Reserve estimate.

1.3.8 Mining Methods

The mine design and planning processes reflect the previous mining experience at the West and East mines. Currently, the entirety of the production comes from the West Mine which can be accessed by a shaft or a ramp down to the 1,080m level. The East Mine was barricaded off with a bulkhead in 2023 to allow for backfilling of the EMCP pit from the surface.

A combination of longitudinal and transverse blasthole stoping is typically used at Casa Berardi, depending on mineral zone geometry (width and attitude) and development requirements. Timely delivery of backfill plays a crucial role in controlling dilution and maintaining the short stoping cycle. The zones vary in thickness, ranging from over 50m to less than three meters (e.g., minimum mining width). In general, the zones are subvertical (e.g., 55° to 85°).

Open pit mine designs and planning processes reflect previous experience with conventional truck shovel operations.

1.3.9 Processing and Recovery Methods

The Casa Berardi processing facility consists of a 3,730tpd mill, with the ability to process 4,400tpd, and a CIL process to recover gold from the ore. The key unit operations to produce gold include:

/ Crushing

/ Grinding

/ Gravity Circuit

/ CIL Circuit

/ Electrowinning Circuit

/ Smelting

Residual pulp from the CIL mixing tank is pumped to the cyanide destruction tank to which sulfur dioxide and compressed air is added to destroy residual cyanide with agitation. After cyanide destruction, the treated pulp is then pumped to the paste backfill plant or the tailings pond. Ferric sulfate is also added to this material to reduce arsenic content in the solution. Approximately 5% of the Casa Berardi mine tailings are used in the mine backfill cycle. Tailings that are not used for mine backfill are disposed of at the tailings storage facility (TSF).

1.3.10 Infrastructure

Existing surface and underground infrastructure at the East Mine include the following:

/ A nominal 3,730tpd mill, with the ability to process 4,400tpd.

/ F160, EMCP, and XMCP open pits.

/ TSF with five tailings cells, a polishing pond, a sedimentation pond for settling iron arsenate precipitates, and a process water pond.

/ Two-story administrative building with offices, warehouse, dry, laboratory, two heavy equipment maintenance garage, millwright shop, and electrical shop.

/ Two core shacks.

/ Water pumping station.

/ Hoistroom, a headframe, and a 380m deep shaft (with no hoist).

/ Mine access decline and a series of ramp-connected levels.

/ Three petrol tanks with pump gas and fuel.

/ One mineral stockpile.

/ One waste and till-clay pile.

Existing surface and underground infrastructure at the West Mine include the following:

/ Backfill plant, including a compressor room and a ventilation raise intake.

/ Settling ponds.

/ Pumping station.

/ A 380 m2 garage.

/ Two dry houses with offices.

/ Emergency building for mine rescue and infirmary.

/ Warehouse.

/ Core storage area.

/ Gatehouse.

/ Mine access decline providing access to the West Mine and Principal area.

/ Hoistroom, headframe, and mine shaft to the 1,080m level.

/ A 125 tonnes per hour (tph) paste backfill plant and a cement plant with tailings feed line from the mill and distribution holes to the underground.

/ Mine ventilation fans and mine air heater with ventilation raise to the mine workings.

/ One WRF and one ore rock pile.

There is currently no additional surface infrastructure related to the Principal Mine area. A five-kilometer track drift joins the East and West mines and provides access to the Principal Mine at the 280m level. After the East Mine was closed, a bulkhead was constructed on the track drift to control water flow to the West Mine.

The power supply of the site is provided by a 55km, 120kV power line, from the town of Normétal.

1.3.11 Market Studies

Hecla currently has a refining agreement with Asahi Refining Canada (Asahi) whereby the gold and silver is refined and credited to Hecla’s account at Asahi. The doré bars produced at Casa Berardi are refined at Asahi’s facilities in Brampton, Ontario, Canada.

Gold and silver bullion is sold through commercial banks or metal traders via a sale contract at spot prices. Settlement of funds from bullion sales occurs two business days after the contract date.

The terms and conditions of the refining and bullion sales contracts are typical and consistent with standard industry practice and would be similar to contracts for the supply of gold elsewhere in North America.

1.3.12 Environmental Studies, Permitting and Plans, Negotiations, or Agreements with Local Individuals or Groups

Hecla has sufficiently assessed the environmental impact of the operation, and subsequent closure and remediation requirements such that Mineral Resources and Mineral Reserves can be declared, and the mine plan deemed appropriate and achievable. Closure provisions are appropriately considered, and monitoring programs are in place.

Hecla has developed a community relations plan to identify and ensure an understanding of the needs of the surrounding communities and to determine appropriate programs for addressing those needs. Hecla appropriately monitors socio-economic trends, community perceptions, and mining impacts.

Current permits held by Hecla for the Property are sufficient to ensure that planned surface and underground mining activities through 2026 are conducted within the regulatory framework required by regulations.

Beyond 2026, three additional open pits along with associated waste rock storage facilities and other infrastructure are expected to be developed at the Property. This planned development may require an Environmental Impact Assessment (EIA) at the site. Hecla expects to submit a project notice to the Provincial Ministère de l'Environnement, de la Lutte contre les changements climatiques, de la Faune et des Parcs (MELCCFP) in 2024. The notice is planned to include an overview of the proposed development and a description of the plan of operations. The EIA process typically takes several years to complete. Hecla expects that all necessary permits will be obtained, and that mining of the planned open pits can take place in accordance with local, provincial, and national regulatory frameworks.

There are currently no known environmental, permitting, or social/community risks that could impact the Mineral Resources or Mineral Reserves.

1.3.13 Capital and Operating Cost Estimates

The estimated capital costs for Casa Berardi are presented in Table 1‑4. The majority of the growth capital is to be spent over the period 2028-2033.

Table STYLEREF 1 \s 1‑. LOM Capital Cost Summary

| | | | | |

Description | Units | Total | 2024-2027 | 2028-2033 | 2034-2037 |

Growth Capital Costs USD$ | US$(000) | 421,455 | 83,368 | 338,087 | - |

Sustaining Capital USD$ | US$(000) | 76,972 | 38,937 | 27,490 | 10,545 |

Salvage Value | US$(000) | (19,736) | - | - | (19,736) |

Reclamation & Closure | US$(000) | 21,561 | - | - | 21,561 |

Total Capital Costs USD$ | US$(000) | 500,253 | 122,305 | 365,577 | 12,371 |

The capital costs are based on updates from equipment suppliers and verified with engineering companies providing services to Casa Berardi. The capital costs accuracy would be considered +-15% with zero contingency. Major Projects include permitting costs for the LOM which include environmental, hydrogeological, and geotechnical studies, and condemnation drilling. Mine Stripping includes the overburden removal from WMCP and Principal pits. Open pit costs include mobilization of the open pit contractor and capitalized stripping costs. In year 2037 there is a salvage value of approximately US$19.7 million for mine and other equipment that can be sold.

The estimated operating costs over the LOM (2024 to 2035) are presented in Table 1‑5.

Table STYLEREF 1 \s 1‑. LOM Operating Cost Summary

| | |

Item | Total LOM | Total LOM |

(US$000) | (US$/t milled) |

Tonnes Milled (000 t) | 14,383 | |

Mining | 395,611 | 27.51 |

Processing | 330,271 | 22.96 |

Administration | 71,704 | 4.99 |

Total | 797,586 | 55.45 |

Hecla-forecasted operating costs estimates are derived from annual budgets and historical actuals over the long life of the current operation. The operating costs accuracy would be considered +-15% with zero contingency.

2.0 Introduction

RESPEC Company LLC (RESPEC) was retained by Hecla Mining Company (Hecla) of Coeur d’Alene, Idaho, USA, to prepare an independent Technical Report Summary (TRS) on the Casa Berardi Mine (Casa Berardi or the “Property”), located in Québec, Canada. The purpose of this TRS is to support the disclosure of the Casa Berardi Mineral Resource and Mineral Reserve estimates as of December 31, 2023. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. There has been one previous TRS for Casa Berardi prepared by SLR Consulting (Canada) Ltd. (SLR) and dated February 21, 2022 (SLR, 2022). The current TRS herein draws extensively from SLR 2022 and supersedes the SLR 2022 TRS.

In this TRS, the term “RESPEC” refers to Qualified Persons (QPs) employed by RESPEC, as well as RESPEC employees working under the direct supervision of RESPEC QPs.

The Casa Berardi operation includes several open pits and two underground mines. Collectively, these workings produced approximately 3.06 million ounces (Moz) Au (recovered) since commencing production in 1988, including approximately 2.37Moz Au (recovered) since production recommenced in November 2006.

The Casa Berardi processing facilities consist of a mill, with the ability to process 4,100tpd, and a carbon-in-leach (CIL) process to recover gold from the ore.

Production for Casa Berardi over the current life of mine (LOM), 2024 to 2037, is planned to comprise 209 thousand tonnes (kt) from the underground operations in 2024 and 14.2 million tonnes (Mt) from the open pit operations from 2024 until 2037. Gold production over the LOM is forecasted to total 1.04Moz Au (average of 86,000oz Au per annum) while recovered silver is forecasted to total 249,000oz Ag (average of 20,700oz Ag per annum).

2.1 Site Visit

RESPEC visited Casa Berardi September 18-22, 2023. The initial F160 Pit Phase was nearing completion while RESPEC was at site, and underground mining operations were expected to cease within a year. RESPEC held meetings with site personnel and followed up with several teleconference meetings after the site visit.

RESPEC engineering QPs visited the F160, East Mine Crown Pilar (EMCP), western extension (XMCP) Pit, the West Mine underground, tailings storage facilities (TSF), core logging facilities, and surface infrastructure.

The geology of the gold mineralization was observed underground in the Principal and West deposits, in the F160 and EMCP open pits, and in core from various areas by RESPEC’s geology QP. An underground diamond drill in the process of drilling core hole CBW-1223 was also visited. Core processing and sample handling procedures were reviewed in the core shack, and Hecla provided a tour of the mine laboratory. Resource modeling and estimation procedures were discussed in detail with Hecla Québec’s Principal Geologist, Real Parent.

2.2 Sources of Information

Most of the information in this TRS has been drawn from Hecla company files and other sources as cited. Section 10.0 Mineral Processing and Metallurgical Testing, and Section 14.0 Processing and Recovery Methods were contributed by SLR.

During the preparation of this TRS, discussions were held with Hecla personnel to obtain information and data contained in the technical report summary or used in its preparation.

The documentation reviewed, and other sources of information as cited, are listed in Section 24.0 References.

2.3 Units and Abbreviations

Units of measurement used in this TRS conform to the metric system.

Currency, units of measure, and conversion factors used in this report include:

Linear Measure

1 centimeter = 0.3937 inch

1 meter = 3.2808 feet = 1.0936 yard

1 kilometer = 0.6214 mile

Area Measure

1 hectare = 2.471 acres = 0.0039 square mile

Capacity Measure (liquid)

1 liter = 0.2642 US gallons

Weight

1 tonne = 1.1023 short tons = 2,205 pounds

1 gram = 0.03215 troy ounces

1 kilogram = 2.205 pounds

Grade

1 gram/tonne = 0.0292 troy ounces/short ton

Currency in this TRS is in United States dollars (US$) unless otherwise noted. Canadian dollars (C$) have been converted to US$ dollars at an exchange rate of US$1 = C$1.300 unless otherwise noted.

| | | |

Abbreviation | Unit | Abbreviation | Unit |

m | Micron | kVA | kilovolt-amperes |

mg | Microgram | kW | kilowatt |

a | Annum | kWh | kilowatt-hour |

A | Ampere | L | liter |

Ac | Acre |

| | | |

Abbreviation | Unit | Abbreviation | Unit |

AMSL | Above Mean Sea Level | | |

bbl | Barrels | lb | pound |

Btu | British thermal units | L/s | liter per second |

°C | degree Celsius | m | meter |

C$ | Canadian dollars | M | mega (million); molar |

cal | Calorie | m2 | square meter |

cfm | cubic feet per minute | m3 | cubic meter |

cm | Centimeter | m3/h | cubic meters per hour |

cm2 | square centimeter | mi | mile |

d | Day | min | minute |

dia | Diameter | mm | micrometer |

dmt | dry metric tonne | mm | millimeter |

dwt | dead-weight ton | mph | miles per hour |

°F | degree Fahrenheit | MVA | megavolt-amperes |

ft | Foot | MW | megawatt |

ft2 | square foot | MWh | megawatt-hour |

ft3 | cubic foot | oz | Troy ounce (31.1035g) |

ft/s | foot per second | oz/st, opt | ounce per short ton |

g | Gram | ppb | part per billion |

G | giga (billion) | ppm | part per million |

Gal | Imperial gallon | psia | pound per square inch absolute |

g/L | gram per liter | psig | pound per square inch gauge |

Gpm | Imperial gallons per minute | RL | relative elevation |

g/t | gram per tonne | s | second |

gr/ft3 | grain per cubic foot | st | short ton |

gr/m3 | grain per cubic meter | stpa | short ton per year |

ha | Hectare | stpd | short ton per day |

hp | Horsepower | t | metric tonne |

hr | Hour | tpa | metric tonne per year |

Hz | Hertz | tpd | metric tonne per day |

in | Inch | US$ | United States dollar |

in2 | square inch | USg | United States gallon |

J | Joule | USgpm | US gallon per minute |

| | | |

Abbreviation | Unit | Abbreviation | Unit |

k | kilo (thousand) | V | volt |

kcal | Kilocalorie | W | watt |

kg | Kilogram | wmt | wet metric tonne |

km | Kilometer | wt% | weight percent |

km2 | square kilometer | yd3 | cubic yard |

km/h | kilometer per hour | yr | year |

kPa | Kilopascal | | |

3.0 Property Description

3.1 Location

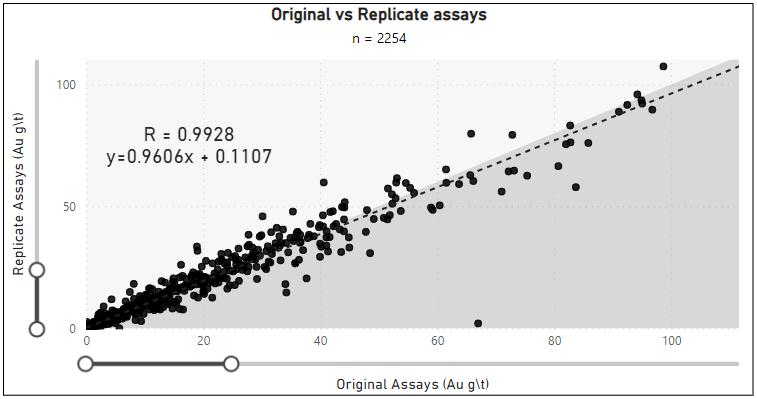

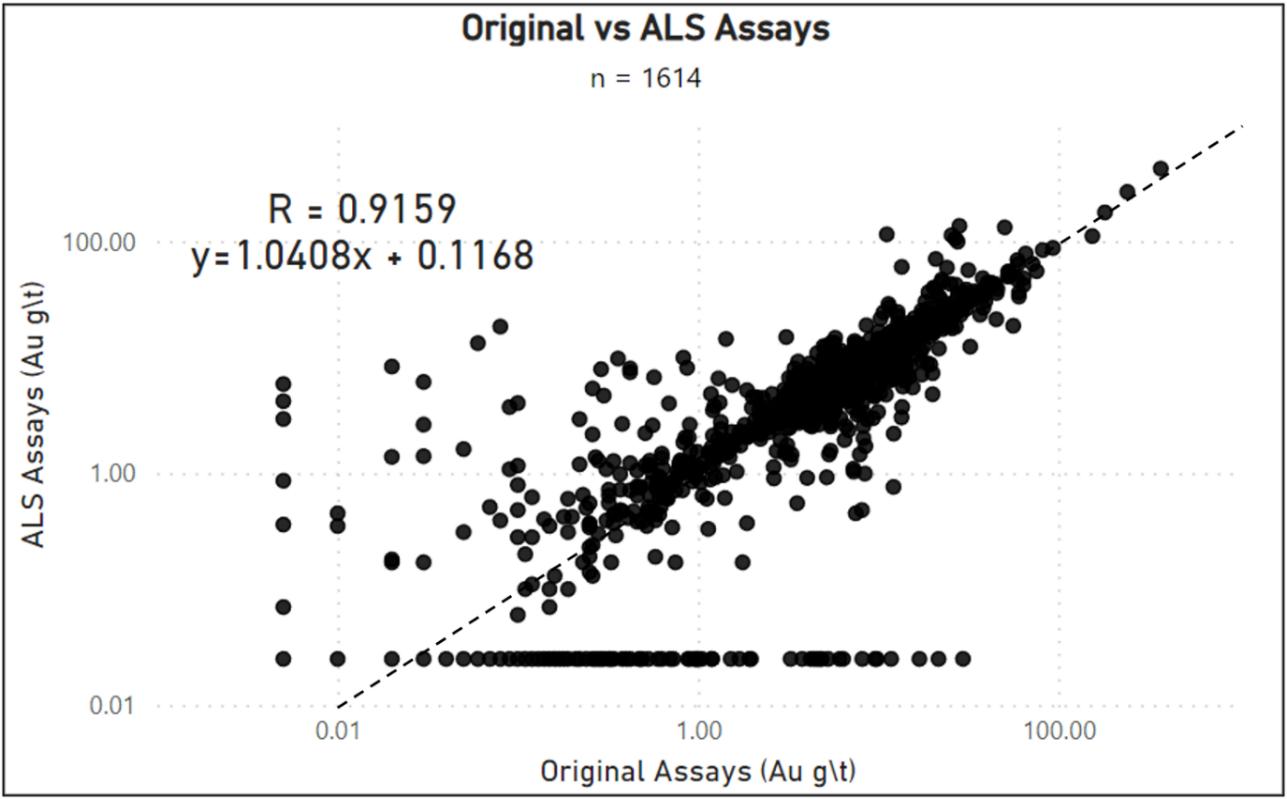

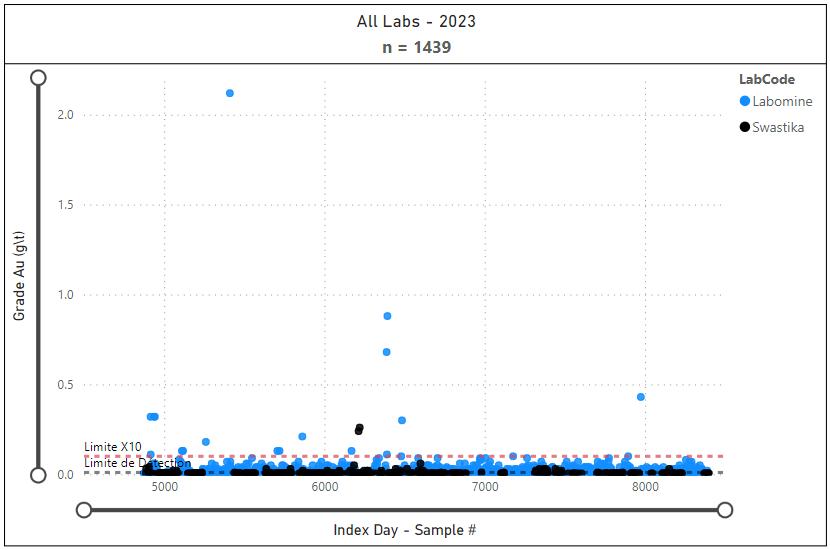

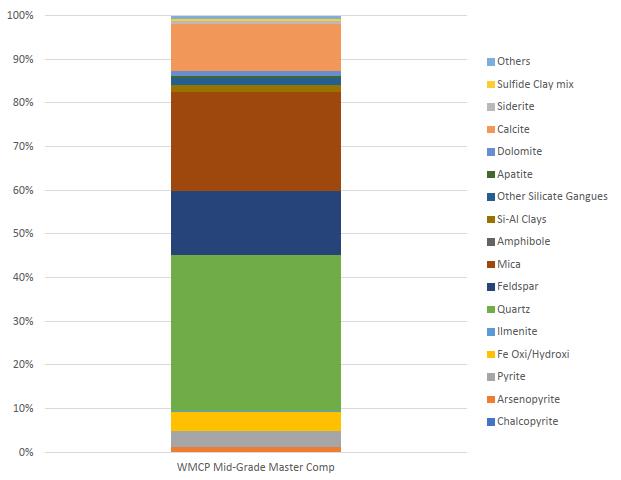

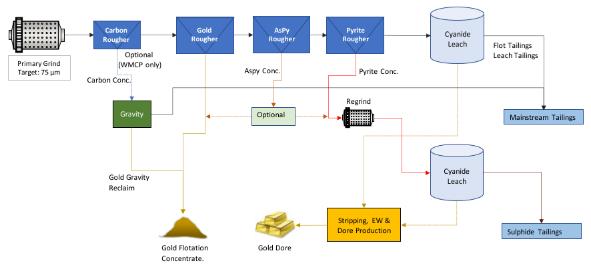

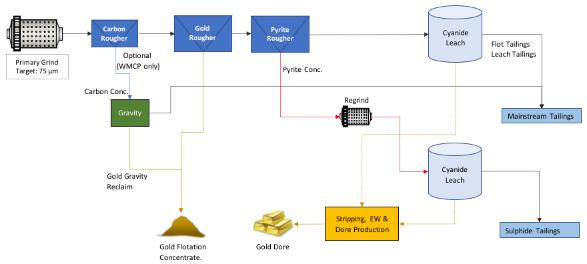

The Property is located in the Province of Québec, approximately 95km north of the town of La Sarre, in the James Bay Municipality (Figure 3‑1). The mine is located at longitude 79° 16’ 46.4” and latitude 49°33’56.7”. The Property is bounded in the west by the Québec/Ontario border and covers parts of Casa Berardi, Dieppe, Raymond, D’Estrées, and Puiseaux townships.