FREEPORT-McMoRan COPPER & GOLD INC.

The accompanying unaudited consolidated financial statements have been prepared in accordance with the instructions to Form 10-Q and do not include all information and disclosures required by generally accepted accounting principles (GAAP) in the United States (U.S.). Therefore, this information should be read in conjunction with Freeport-McMoRan Copper & Gold Inc.’s (FCX) consolidated financial statements and notes contained in its 2009 Annual Report on Form 10-K. The information furnished herein reflects all adjustments which are, in the opinion of management, necessary for a fair statement of the results for the interim periods reported. All such adjustments are, in the opinion of management, of a normal recurring nature. Operating results for the three-month and six-month periods ended June 30, 2010, are not necessarily indi cative of the results that may be expected for the year ending December 31, 2010.

FCX’s basic net income per share of common stock was calculated by dividing net income attributable to common stock by the weighted-average shares of common stock outstanding during the period. Following is a reconciliation of net income and weighted-average shares of common stock outstanding for purposes of calculating diluted net income per share (in millions, except per share amounts):

FCX’s convertible instruments are excluded from the computation of diluted net income per share of common stock when including the assumed conversion of these instruments results in an anti-dilutive effect on earnings per share (see footnote b above).

Outstanding stock options with exercise prices greater than the average market price of FCX’s common stock during the period also are excluded from the computation of diluted net income per share of common stock.

Excluded amounts were approximately nine million stock options with a weighted-average exercise price of $75.56 for second-quarter 2010 and approximately six million stock options with a weighted-average exercise price of $77.55 for the six months ended June 30, 2010. Stock options for approximately eight million shares with a weighted-average exercise price of $73.00 were excluded for second-quarter 2009, and stock options for approximately nine million shares with a weighted-average exercise price of $69.73 were excluded for the six months ended June 30, 2009.

The components of net periodic benefit cost for pension and postretirement benefits follow (in millions):

Net periodic benefit costs decreased by $7 million in second-quarter 2010 mainly as a result of an increase in the expected return on plan assets ($4 million) primarily because of the 2009 gains on plan assets.

Net periodic benefit costs decreased by $3 million in the first six months of 2010 mainly as a result of an increase in the expected return on plan assets ($7 million) and a decrease in the amortization of actuarial losses ($4 million) primarily because of the 2009 gains on plan assets. These decreases were partially offset by the absence of the first-quarter 2009 gains on special retirement benefits and curtailments ($9 million) caused by workforce reductions in connection with the fourth-quarter 2008 and first-quarter 2009 revised mine operating plans.

FCX recorded charges for lower of cost or market (LCM) molybdenum inventory adjustments totaling $19 million ($19 million to net income attributable to FCX common stockholders or $0.04 per diluted share) for the first six months of 2009 resulting from lower molybdenum prices.

FCX’s income tax provision for second-quarter 2010 resulted from taxes on international operations ($382 million) and U.S. operations ($51 million). FCX’s income tax provision for the first six months of 2010 resulted from taxes on international operations ($979 million) and U.S. operations ($132 million). FCX’s consolidated effective income tax rate was 35 percent for the first six months of 2010.

FCX’s income tax provision for second-quarter 2009 resulted from taxes on international operations ($538 million) and U.S. operations ($4 million). FCX’s income tax provision for the first six months of 2009 resulted from taxes on international operations ($868 million) and U.S. operations ($5 million). During the first half of 2009, FCX did not record a benefit for losses generated in the U.S., and those losses could not be used to offset income generated from international operations. These factors combined with the high proportion of income earned in Indonesia, which was taxed at an effective tax rate of 43 percent, caused FCX’s consolidated effective income tax rate of 47 percent for the first six months of 2009 to be higher than the U.S. federal statutory rate of 35 percent.

During the second quarter of 2010, FCX purchased in the open market $85 million of its 8.25% Senior Notes due 2015 for $92 million and $193 million of its 8.375% Senior Notes due 2017 for $210 million. These open-market purchases resulted in losses on early extinguishment of debt totaling $28 million ($23 million to net income attributable to FCX common stockholders or $0.05 per diluted share). For the first six months of 2010, FCX purchased in the open market $218 million of its 8.25% Senior Notes for $237 million and $329 million of its 8.375% Senior Notes for $358 million, which resulted in losses on early extinguishment of debt totaling $55 million ($46 million to net income attributable to FCX common stockholders or $0.10 per diluted share).

On April 1, 2010, FCX redeemed all of its $1.0 billion of outstanding Senior Floating Rates Notes due 2015 for which holders received 101 percent of the principal amount together with accrued and unpaid interest. As a result of this redemption, FCX recorded a loss on early extinguishment of debt totaling $22 million ($19 million to net income attributable to FCX common stockholders or $0.04 per diluted share) in the second quarter and the six-month periods of 2010.

Consolidated interest expense (before capitalization) totaled $132 million in second-quarter 2010, $172 million in second-quarter 2009, $283 million for the first six months of 2010 and $348 million for the first six months of 2009. Capitalized interest expense totaled $10 million in second-quarter 2010, $14 million in second-quarter 2009, $16 million for the first six months of 2010 and $59 million for the first six months of 2009. Lower capitalized interest in the 2010 periods primarily reflects the completion of development activities for the initial project at FCX’s Tenke Fungurume mine, which commenced initial copper production in March 2009.

During April 2010, holders of FCX’s 6¾% Mandatory Convertible Preferred Stock elected to convert 787,158 preferred shares into 1,079,615 shares of FCX common stock (conversion rate equal to 1.3716 shares of FCX common stock). On May 1, 2010, the remaining 27,504,512 shares of FCX’s 6¾% Mandatory Convertible

Preferred Stock were automatically converted into 37,725,139 shares of FCX common stock (conversion rate equal to 1.3716 shares of FCX common stock). For the first six months of 2010, a total of 28,749,560 outstanding shares of FCX’s 6¾% Mandatory Convertible Preferred Stock were converted into 39,432,793 shares of FCX common stock (conversion rate equal to 1.3716 shares of FCX common stock).

In April 2010, FCX’s Board of Directors (Board) authorized an increase in the annual cash dividend on its common stock from $0.60 per share to $1.20 per share. On June 24, 2010, FCX declared a quarterly dividend of $0.30 per share, which was paid on August 1, 2010, to common shareholders of record at the close of business on July 15, 2010.

Total comprehensive income attributable to FCX common stockholders totaled $666 million in second-quarter 2010, $654 million in second-quarter 2009, $1,614 million for the first six months of 2010 and $825 million (including a $61 million gain related to the remeasurement of certain defined benefit plans during the first quarter of 2009) for the first six months of 2009.

In May 2000, FCX’s Board adopted a shareholder rights plan. Under the rights plan, each share of outstanding common stock included a purchase right that would become exercisable if a third party acquired (or announced it would acquire) 20 percent or more of FCX’s outstanding common stock without the approval of FCX’s Board. If such acquisition occurred, each purchase right (other than rights held by the third party) entitled its holder to purchase FCX’s securities at a substantial discount. The shareholder rights plan expired in accordance with its terms on May 16, 2010.

FCX does not purchase, hold or sell derivative financial instruments unless there is an existing asset or obligation or if it anticipates a future activity that is likely to occur and will result in exposure to market risks and FCX intends to offset or mitigate such risks. FCX does not enter into any derivative financial instruments for speculative purposes, but has entered into derivative financial instruments in limited instances to achieve specific objectives. These objectives principally relate to managing risks associated with commodity price, foreign currency and interest rate risks. The fair values of FCX’s derivative financial instruments are based on widely published market prices.

A summary of unrealized (losses) gains recognized in income before income taxes and equity in affiliated companies’ net earnings for derivative financial instruments that are designated and qualify as fair value hedge transactions, along with the unrealized gains (losses) on the related hedged item (firm sales commitments) follows (in millions):

A summary of the realized and unrealized gains (losses) recognized in income before income taxes and equity in affiliated companies’ net earnings for derivative financial instruments, including embedded derivatives, which do not qualify as hedge transactions follows (in millions):

A summary of the fair values of unsettled derivative financial instruments recorded on the consolidated balance sheets follows (in millions):

swap contracts that qualified for hedge accounting for 63 million pounds at an average price of $3.06 per pound, with maturities through July 2011.

Embedded derivatives and derivative financial instruments that do not meet the criteria to qualify for hedge accounting are discussed below.

In April 2009, FCX entered into copper forward sales contracts to lock in prices at an average of $1.86 per pound on 355 million pounds of PT Freeport Indonesia’s provisionally priced copper sales at March 31, 2009, which final priced from April 2009 through July 2009. These economic hedge transactions were intended to reduce short-term price volatility in earnings and cash flows. Gains and losses for these economic hedge transactions were recorded in revenues. FCX has not entered into additional forward sales contracts since April 2009 for its provisionally priced copper sales, but may enter into future transactions to lock in pricing on provisionally priced sales from time to time. However, FCX does not intend to change its long-standing policy of not hedging future copper production.

Fair value accounting guidance includes a fair value hierarchy that prioritizes the inputs to valuation techniques used to measure fair value. The hierarchy gives the highest priority to unadjusted quoted prices in active markets for identical assets or liabilities (Level 1 inputs) and the lowest priority to unobservable inputs (Level 3 inputs). The three levels of the fair value hierarchy are described below:

A summary of FCX’s financial assets and liabilities measured at fair value on a recurring basis follows (in millions):

Money market funds and time deposits are classified within Level 1 of the fair value hierarchy because they are valued using quoted market prices in active markets.

Fixed income securities (government and agency securities, corporate bonds, asset-backed securities and U.S. core fixed income fund) are valued using a bid evaluation or a mid evaluation. A bid evaluation is an estimated price at which a dealer would pay for a security. A mid evaluation is the average of the estimated price at which a dealer would sell a security and the estimated price at which a dealer would pay for a security. These evaluations are based on quoted prices, if available, or models that use observable inputs and, as such, are classified within Level 2 of the fair value hierarchy.

Equity securities are valued at the closing price reported on the active market on which the individual securities are traded and as such are classified within Level 1 of the fair value hierarchy.

FCX’s derivative financial instruments for copper futures and swap contracts and forward contracts are classified within Level 1 of the fair value hierarchy because they are valued using quoted market prices in active markets (refer to Note 7 for further discussion).

FCX has organized its operations into five primary divisions – North America copper mines, South America mining, Indonesia mining, Africa mining and Molybdenum operations. Notwithstanding this structure, FCX internally reports information on a mine-by-mine basis. Therefore, FCX concluded that its operating segments include individual mines. Operating segments that meet certain thresholds are reportable segments. Further discussion of the reportable segments included in FCX’s primary operating divisions, as well as FCX’s other reportable segments – Rod & Refining and Atlantic Copper Smelting & Refining – follows.

processes material on a toll basis. Toll arrangements require the tolling customer to deliver appropriate molybdenum-bearing material to FCX’s facilities for processing into a product that is returned to the customer, who pays FCX for processing its material into the specified products. The Molybdenum segment also includes FCX’s wholly owned Climax molybdenum mine in Colorado, which has been on care-and-maintenance status since 1995.

TO THE BOARD OF DIRECTORS AND STOCKHOLDERS OF

FREEPORT-McMoRan COPPER & GOLD INC.

We have reviewed the condensed consolidated balance sheet of Freeport-McMoRan Copper & Gold Inc. as of June 30, 2010, and the related consolidated statements of income for the three- and six-month periods ended June 30, 2010 and 2009, the consolidated statements of cash flows for the six-month periods ended June 30, 2010 and 2009, and the consolidated statement of equity for the six-month period ended June 30, 2010. These financial statements are the responsibility of the Company’s management.

We conducted our review in accordance with the standards of the Public Company Accounting Oversight Board (United States). A review of interim financial information consists principally of applying analytical procedures and making inquiries of persons responsible for financial and accounting matters. It is substantially less in scope than an audit conducted in accordance with the standards of the Public Company Accounting Oversight Board, the objective of which is the expression of an opinion regarding the financial statements taken as a whole. Accordingly, we do not express such an opinion.

Based on our review, we are not aware of any material modifications that should be made to the condensed consolidated financial statements referred to above for them to be in conformity with U.S. generally accepted accounting principles.

We have previously audited, in accordance with the standards of the Public Company Accounting Oversight Board (United States), the consolidated balance sheet of Freeport-McMoRan Copper & Gold Inc. as of December 31, 2009, and the related consolidated statements of operations, cash flows, and equity for the year then ended (not presented herein), and in our report dated February 26, 2010, we expressed an unqualified opinion on those consolidated financial statements and which report included an explanatory paragraph for the Company’s adoption of guidance originally issued in FASB Statement No. 160, Noncontrolling Interests in Consolidated Financial Statements (codified in FASB ASC Topic 810, Consolidation) effective J anuary 1, 2009. In our opinion, the information set forth in the accompanying condensed consolidated balance sheet as of December 31, 2009, is fairly stated, in all material respects, in relation to the consolidated balance sheet from which it has been derived.

/s/ ERNST & YOUNG LLP

Phoenix, Arizona

August 6, 2010

Item 2. Management's Discussion and Analysis of Financial Condition and Results of Operations.

OVERVIEW

In Management’s Discussion and Analysis of Financial Condition and Results of Operations, “we,” “us” and “our” refer to Freeport-McMoRan Copper & Gold Inc. (FCX) and its consolidated subsidiaries. You should read this discussion in conjunction with our financial statements, the related Management’s Discussion and Analysis of Financial Condition and Results of Operations and the discussion of our Business and Properties in our Form 10-K for the year ended December 31, 2009, filed with the United States (U.S.) Securities and Exchange Commission (SEC). The results of operations reported and summarized below are not necessarily indicative of future operating results. References to “Notes” are Notes included in our Notes to Consolidated Financial Statements. Th roughout Management's Discussion and Analysis of Financial Condition and Results of Operations all references to earnings or losses per share are on a diluted basis, unless otherwise noted.

We are one of the world’s largest copper, gold and molybdenum mining companies in terms of reserves and production. Our portfolio of assets includes the Grasberg minerals district in Indonesia, significant mining operations in North and South America, and the Tenke Fungurume minerals district in the Democratic Republic of Congo (DRC). The Grasberg minerals district contains the largest single recoverable copper reserve and the largest single gold reserve of any mine in the world based on the latest available reserve data provided by third-party industry consultants. We also operate Atlantic Copper, our wholly owned copper smelting and refining unit in Spain.

Our results for the second quarter and first six months of 2010, compared with the 2009 periods, primarily reflected higher realized metals prices, partially offset by lower copper and gold sales volumes. Refer to “Consolidated Results” for further discussion of our consolidated financial results for the quarter and six-month periods ended June 30, 2010 and 2009.

On April 1, 2010, we redeemed our $1 billion of outstanding Senior Floating Rate Notes, and during the first six months of 2010, we made open-market debt purchases totaling $547 million (refer to Note 6 for further discussion). In April 2010, our Board of Directors increased the annual cash dividend on our common stock to $1.20 per share. In addition, during second-quarter 2010, our 6¾% Mandatory Convertible Preferred Stock converted into 39 million shares of our common stock. Refer to “Capital Resources and Liquidity – Financing Activities” for further discussion.

We have significant reserves and future development opportunities within our portfolio of assets. At December 31, 2009, we had estimated consolidated recoverable proven and probable reserves of 104.2 billion pounds of copper (determined using a long-term average copper price of $1.60 per pound), with potential for greater reserves at higher prices.

We are undertaking major development projects to extend mine lives at El Abra and Grasberg, and are also advancing development activities at the Climax molybdenum mine. In addition, a number of studies are under way to evaluate expansion options at certain of our mining operations. The advancement of these studies will provide flexibility in initiating expansion projects as market conditions warrant. Refer to “Operations” for further discussion of our current operating and development activities.

We view the long-term outlook for our business positively, supported by limitations on supplies of copper and by the requirements for copper in the world’s economy, and will continue to adjust our operating strategy as market conditions change.

OUTLOOK

Consolidated sales from mines for the year 2010 are expected to approximate 3.8 billion pounds of copper, 1.8 million ounces of gold and 63 million pounds of molybdenum, including 970 million pounds of copper, 410 thousand ounces of gold and 15 million pounds of molybdenum for third-quarter 2010. Mine sequencing at Grasberg is resulting in significant fluctuations in quarterly sales of copper and gold during 2010. These sales volume estimates are dependent on the achievement of targeted mining rates, the successful operation of production facilities, the impact of weather conditions and other factors.

Assuming average prices of $1,200 per ounce of gold and $14 per pound of molybdenum for the remainder of 2010 and achievement of current 2010 sales volume and cost estimates, we estimate our consolidated unit net cash costs (net of by-product credits and including Africa mining) for our copper mining operations would average approximately $0.86 per pound of copper for the year 2010. Quarterly unit net cash costs will vary with fluctuations in sales volumes of copper and by-products. The impact of price changes on consolidated unit net cash costs in 2010 would approximate $0.01 per pound for each $50 per ounce change in the average price of gold for the remainder of 2010, and $0.005 per pound for each $2 per pound change in the average price of molybdenum for the remainder of 2010. Estimated consolidated unit net cash costs are higher, com pared with consolidated unit net cash costs of $0.55 per pound of copper in 2009, primarily because of lower projected copper and gold sales volumes from Grasberg, combined with increases in commodity-based input costs. Refer to “Consolidated Results – Production and Delivery Costs” for further discussion of consolidated unit net cash costs.

Our operating cash flows vary with prices realized from copper, gold and molybdenum sales, our production levels, production costs, cash payments for income taxes and interest, other working capital changes and other factors. Based on projected consolidated sales volumes for 2010 and assuming average prices of $3.00 per pound of copper, $1,200 per ounce of gold and $14 per pound of molybdenum for the remainder of 2010, our consolidated operating cash flows for the year 2010 are expected to exceed $5 billion, net of an estimated $0.2 billion for working capital requirements. The impact of price changes on operating cash flows in 2010 would approximate $150 million for each $0.10 per pound change in the average price of copper, $30 million for each $50 per ounce change in the average price of gold and $25 million for each $2 per pound chang e in the average price of molybdenum.

Capital expenditures for the year 2010 are expected to approximate $1.7 billion, including $0.8 billion for major projects, primarily associated with underground development activities at Grasberg, the sulfide ore project at El Abra and a new sulphur burner facility at Safford. For 2009, capital expenditures totaled $1.6 billion, which included $0.8 billion for major projects. We have resumed certain project development activities at our mining operations and a number of studies are ongoing, which may result in increased capital spending programs. Refer to “Operations” for further discussion. COPPER, GOLD AND MOLYBDENUM MARKETS

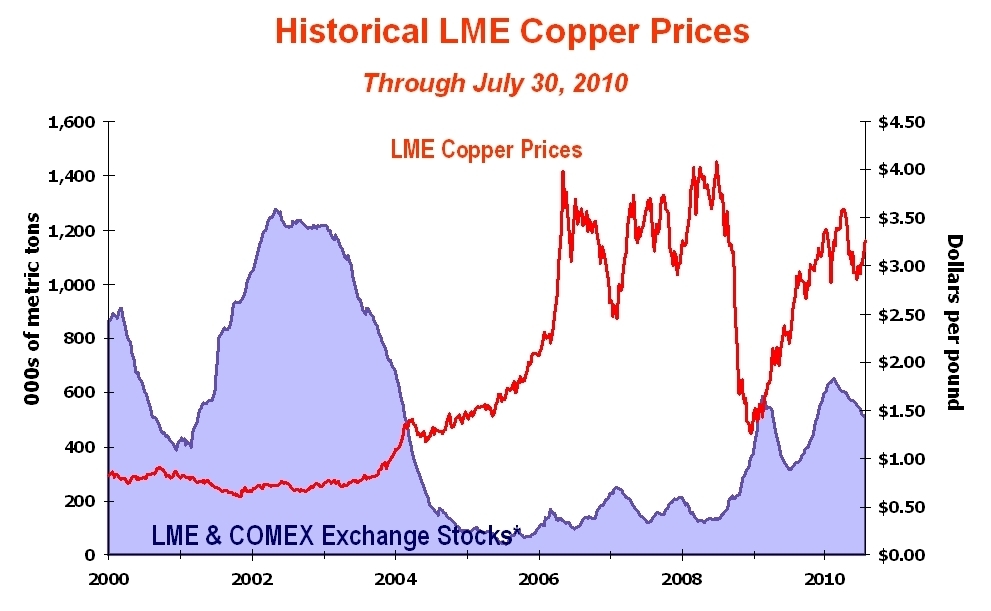

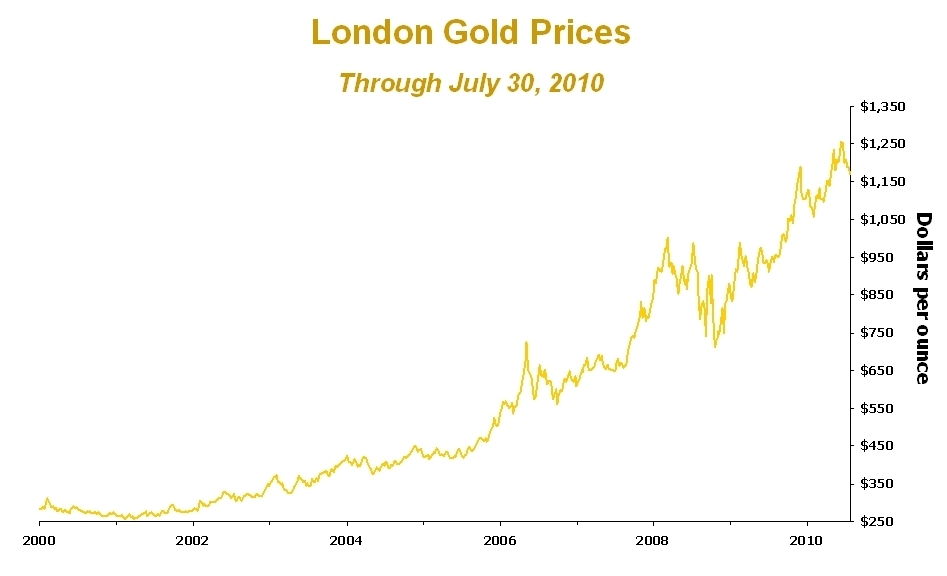

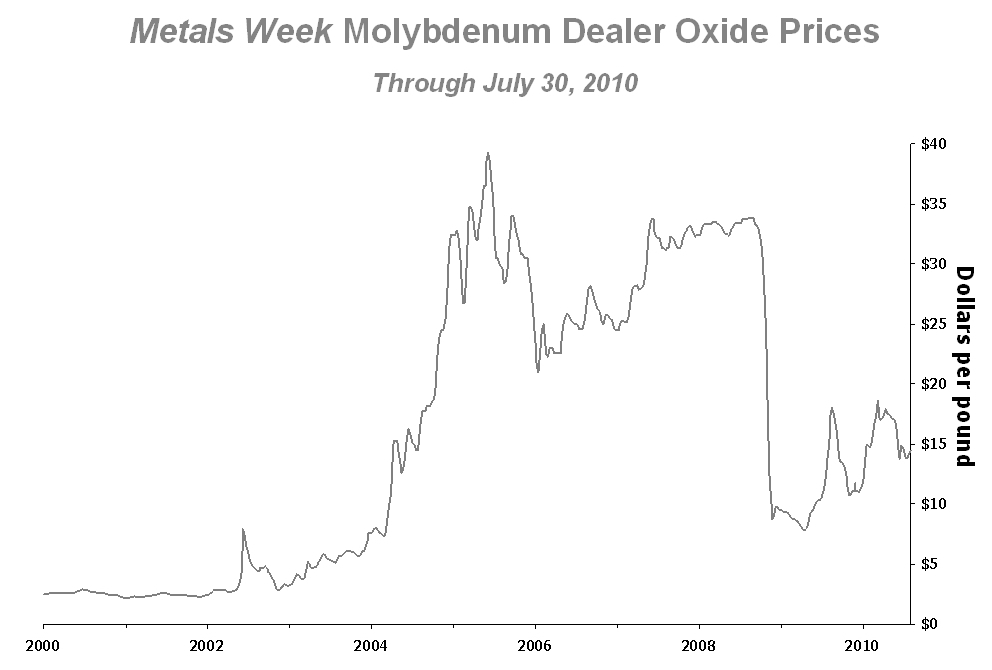

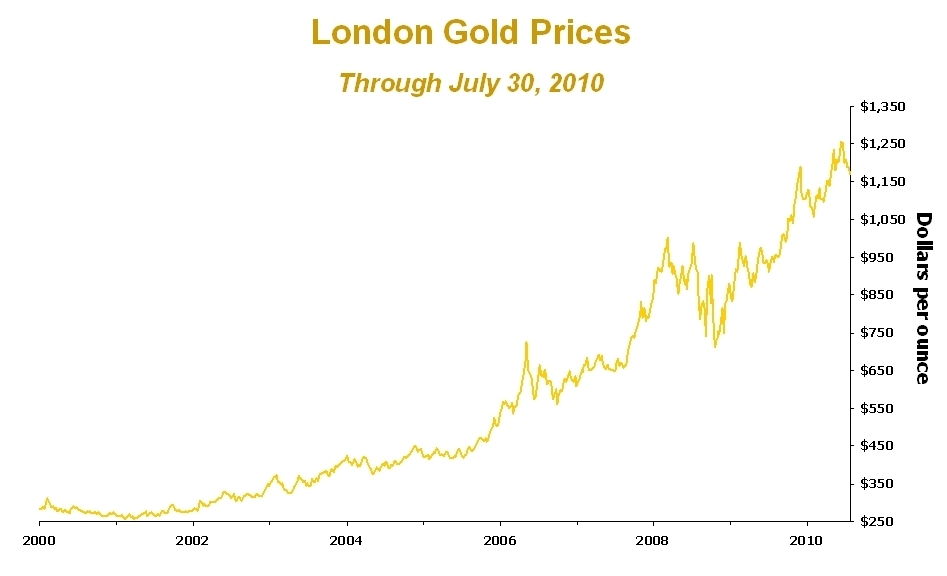

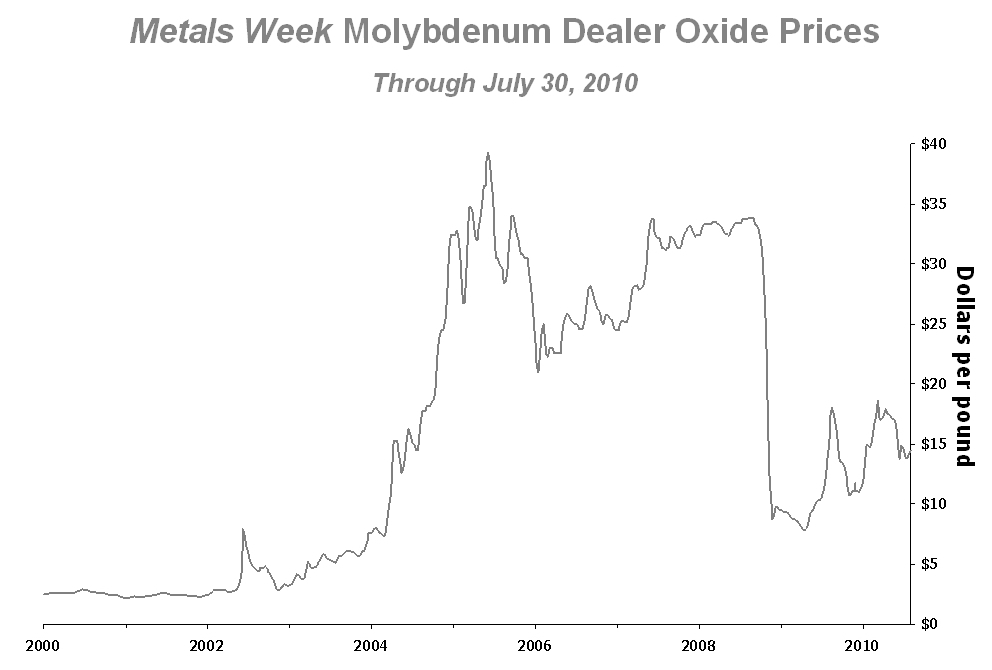

World prices for copper, gold and molybdenum have fluctuated significantly since January 2000. The London Metal Exchange (LME) spot copper price varied from a low of $0.60 per pound in 2001 to a high of $4.08 per pound in 2008, the London gold price fluctuated from a low of approximately $256 per ounce in 2001 to a new high of $1,261 per ounce in June 2010, and the Metals Week Molybdenum Dealer Oxide weekly average price ranged from $2.19 per pound in 2000 to a high of $39.25 per pound in 2005. Copper, gold and molybdenum prices are affected by numerous factors beyond our control as described further in our “Risk Factors” contained in Part I, Item 1A of our Form 10-K for the year ended December 31, 2009.

* Excludes Shanghai stocks, producer, consumer and merchant stocks.

This graph presents LME spot copper prices and reported stocks of copper at the LME and the New York Mercantile Exchange (COMEX) from January 2000 through July 2010. From 2006 through most of 2008, disruptions associated with strikes and other operational issues, combined with growing demand from China and other emerging economies, resulted in low levels of inventory. Beginning in late 2008, slowing consumption led to increases in inventory levels; however, China’s increased buying activity contributed to a decline in exchange inventories during the first half of 2009. After reaching a low for the year in July 2009, inventories grew during the second half of 2009 with combined LME and COMEX stocks ending the year at approximately 592 thousand metric tons. Inventories have decreased since the end of 2009, and at June 30, 2010, combin ed LME and COMEX stocks totaled approximately 544 thousand metric tons, which represents approximately 10 days of global consumption.

Turmoil in the U.S. financial markets and concerns about the global economy negatively impacted copper prices in late 2008, which declined to a four-year low of $1.26 per pound in December 2008; however, copper prices improved during 2009 as a result of strong Chinese import activity and supply limitations. During second-quarter 2010, LME spot copper prices declined compared to first-quarter 2010 levels, because of concerns about the Chinese growth rate, the European debt crisis and global economic recovery. Copper prices ranged from $2.76 per pound to $3.61 per pound and averaged $3.18 per pound in second-quarter 2010. While the near-term outlook is uncertain, we believe the underlying fundamentals of the copper business remain positive, supported by limited supplies from existing mines and the absence of significant new development proj ects. Future copper prices are expected to be volatile and are likely to be influenced by demand from China, economic activity in the U.S. and other industrialized countries, the timing of the development of new supplies of copper and production levels of mines and copper smelters. The LME spot copper price closed at $3.26 per pound on July 30, 2010.

This graph presents London gold prices from January 2000 through July 2010. Continued investment demand and potential weakness in the U.S. dollar are expected to support gold prices, which reached a new high of $1,261 per ounce in June 2010. During second-quarter 2010, gold prices ranged from approximately $1,124 per ounce to $1,261 per ounce and averaged $1,197 per ounce. London gold prices closed at approximately $1,169 per ounce on July 30, 2010.

This graph presents the Metals Week Molybdenum Dealer Oxide weekly average price from January 2000 through July 2010. In late 2008, molybdenum prices declined significantly as a result of the financial market turmoil and a decline in demand; however, molybdenum prices improved during 2009 supported by Chinese imports and supply reductions. During second-quarter 2010, the weekly average price of molybdenum ranged from approximately $13.75 per pound to approximately $17.93 per pound and averaged $16.41 per pound. The weekly average Metals Week Molybdenum Dealer Oxide price was $14.13 per pound on July 30, 2010.

CONSOLIDATED RESULTS

| | Three Months Ended June 30, | | Six Months Ended June 30, | |

| | 2010 | | 2009 | | 2010 | | 2009 | |

Financial Data (in millions, except per share amounts) | | | | | | | | | | | | |

Revenuesa | $ | 3,864 | b | $ | 3,684 | b | $ | 8,227 | b | $ | 6,286 | b |

| Operating income | $ | 1,424 | b | $ | 1,508 | b | $ | 3,472 | b | $ | 2,180 | b |

| Net income | $ | 832 | | $ | 812 | | $ | 2,047 | | $ | 1,019 | |

| Net income attributable to noncontrolling interests | $ | 168 | | $ | 164 | | $ | 438 | | $ | 268 | |

Net income attributable to FCX common stockholdersc | $ | 649 | d | $ | 588 | | $ | 1,546 | d | $ | 631 | |

| Diluted net income per share attributable to FCX common stockholders | $ | 1.40 | d | $ | 1.38 | | $ | 3.40 | d | $ | 1.54 | |

| Diluted weighted-average common shares outstanding | | 473 | | | 471 | | | 474 | | | 426 | |

| | | | | | | | | | | | | |

| FCX Mining Operating Data | | | | | | | | | | | | |

Copper (recoverable) | | | | | | | | | | | | |

| Production (millions of pounds) | | 930 | | | 1,069 | | | 1,859 | | | 2,110 | |

| Sales, excluding purchases (millions of pounds) | | 914 | | | 1,102 | | | 1,874 | | | 2,122 | |

| Average realized price per pound | $ | 3.06 | | $ | 2.22 | | $ | 3.13 | | $ | 2.03 | |

Site production and delivery costs per pounde,f | $ | 1.41 | | $ | 1.04 | | $ | 1.38 | | $ | 1.05 | |

Unit net cash costs per pounde,f | $ | 0.97 | | $ | 0.43 | | $ | 0.89 | | $ | 0.54 | |

Gold (recoverable) | | | | | | | | | | | | |

| Production (thousands of ounces) | | 316 | | | 802 | | | 765 | | | 1,397 | |

| Sales, excluding purchases (thousands of ounces) | | 298 | | | 837 | | | 776 | | | 1,382 | |

| Average realized price per ounce | $ | 1,234 | | $ | 932 | | $ | 1,171 | | $ | 919 | |

Molybdenum (recoverable) | | | | | | | | | | | | |

| Production (millions of pounds) | | 17 | | | 13 | | | 34 | | | 27 | |

| Sales, excluding purchases (millions of pounds) | | 16 | | | 16 | | | 33 | | | 26 | |

| Average realized price per pound | $ | 18.18 | | $ | 10.11 | | $ | 16.62 | | $ | 10.65 | |

| a. | Includes the impact of adjustments to provisionally priced concentrate and cathode sales recognized in prior periods. Refer to “Revenues” for further discussion. |

| b. | Following is a summary of revenues and operating income (loss) by operating division (in millions): |

| | Three Months Ended June 30, 2010 | | Three Months Ended June 30, 2009 | |

| | | | | | Operating | | | | | | Operating | |

| | | | | | Income | | | | | | Income | |

| | | Revenues | | | (Loss) | | | Revenues | | | (Loss) | |

| North America copper mines | $ | 1,044 | | $ | 436 | | $ | 703 | | $ | 176 | |

| South America mining | | 849 | | | 401 | | | 884 | | | 455 | |

| Indonesia mining | | 927 | | | 420 | | | 1,610 | | | 1,095 | |

| Africa mining | | 207 | | | 81 | | | 57 | | | (49 | ) |

| Molybdenum | | 325 | | | 120 | | | 186 | | | 8 | |

| Rod & Refining | | 1,129 | | | 6 | | | 747 | | | 2 | |

| Atlantic Copper Smelting & Refining | | 616 | | | (2 | ) | | 415 | | | (18 | ) |

| Corporate, other & eliminations | | (1,233 | ) | | (38 | ) | | (918 | ) | | (161 | ) |

| Total | $ | 3,864 | | $ | 1,424 | | $ | 3,684 | | $ | 1,508 | |

| | Six Months Ended June 30, 2010 | | Six Months Ended June 30, 2009 | |

| | | | | | Operating | | | | | | Operating | |

| | | | | | Income | | | | | | Income | |

| | | Revenues | | | (Loss) | | | Revenues | | | (Loss) | |

| North America copper mines | $ | 2,098 | | $ | 944 | | $ | 1,321 | | $ | 144 | |

| South America mining | | 1,918 | | | 1,033 | | | 1,586 | | | 719 | |

| Indonesia mining | | 2,386 | | | 1,312 | | | 2,732 | | | 1,784 | |

| Africa mining | | 456 | | | 190 | | | 57 | | | (68 | ) |

| Molybdenum | | 600 | | | 193 | | | 332 | | | 4 | |

| Rod & Refining | | 2,202 | | | 10 | | | 1,366 | | | 7 | |

| Atlantic Copper Smelting & Refining | | 1,249 | | | (13 | ) | | 707 | | | (29 | ) |

| Corporate, other & eliminations | | (2,682 | ) | | (197 | ) | | (1,815 | ) | | (381 | ) |

| Total | $ | 8,227 | | $ | 3,472 | | $ | 6,286 | | $ | 2,180 | |

| c. | After net income attributable to noncontrolling interests in subsidiaries and preferred dividends. |

| d. | Includes net losses on early extinguishment of debt totaling $42 million ($0.09 per share) for second-quarter 2010 and $65 million ($0.14 per share) for the first six months of 2010. Refer to Note 6 for further discussion. |

| e. | Reflects per pound weighted-average production and delivery costs and unit net cash costs (net of by-product credits) for all copper mines, excluding net noncash and other costs, and for the 2009 periods excludes Africa mining. For reconciliations of the per pound costs by operating division to production and delivery costs applicable to sales reported in our consolidated financial statements, refer to “Operations – Unit Net Cash Costs” and to “Product Revenues and Production Costs.” |

| f. | The 2009 periods exclude the results of the Tenke Fungurume (Tenke) mine as start-up activities were still under way; the impact of including the results of the Tenke mine for the 2010 periods was $0.01 per pound of copper in second-quarter 2010 and less than $0.01 per pound of copper for the first six months of 2010. |

Revenues

Consolidated revenues include the sale of copper concentrates, copper cathodes, copper rod, gold, molybdenum and other metals by our North and South America copper mines, the sale of copper concentrates (which also contain significant quantities of gold and silver) by our Indonesia mining operation, the sale of copper cathodes and cobalt hydroxide by our Africa mining operation, the sale of molybdenum in various forms by our Molybdenum operations, and the sale of copper cathodes, copper anodes, and gold in anodes and slimes by Atlantic Copper. Consolidated revenues totaled $3.9 billion in second-quarter 2010 and $8.2 billion for the first six months of 2010, compared with $3.7 billion in second-quarter 2009 and $6.3 billion for the first six months of 2009. Following is a summary of changes in our consolidated revenues between periods (in millions):

| | Three Months Ended June 30, | | Six Months Ended June 30, | |

| Consolidated revenues – 2009 periods | $ | 3,684 | | $ | 6,286 | |

| Higher sales price realizations from mining operations: | | | | | | |

| Copper | | 768 | | | 2,005 | |

| Gold | | 90 | | | 195 | |

| Molybdenum | | 132 | | | 198 | |

| (Lower) higher sales volumes from mining operations: | | | | | | |

| Copper | | (417 | ) | | (511 | ) |

| Gold | | (502 | ) | | (557 | ) |

| Molybdenum | | 8 | | | 82 | |

| Higher purchased copper | | 28 | | | 30 | |

| Lower net adjustments for prior period/year provisionally priced sales, | | | | | | |

| including PT Freeport Indonesia’s 2009 forward copper sales contracts | | (193 | ) | | (62 | ) |

| Higher Atlantic Copper revenues | | 201 | | | 542 | |

| Other, including intercompany eliminations | | 65 | | | 19 | |

| Consolidated revenues – 2010 periods | $ | 3,864 | | $ | 8,227 | |

Consolidated revenues in the 2010 periods were favorably impacted by higher copper, gold and molybdenum prices. Realized copper prices increased to an average of $3.06 per pound in second-quarter 2010 (compared with $2.22 per pound in second-quarter 2009) and $3.13 per pound for the first six months of 2010 (compared with $2.03 per pound for the first six months of 2009). Realized gold prices increased to an average of $1,234 per ounce in second-quarter 2010 (compared with $932 per ounce in second-quarter 2009) and $1,171 per ounce for the first six months of 2010 (compared with $919 per ounce for the first six months of 2009). Realized molybdenum prices increased to an average of $18.18 per pound in second-quarter 2010 (compared with $10.11 per pound in second-quarter 2009) and $16.62 per pound for the first six months of 2010 (compared with $10.65 per pound for the first six months of 2009).

Consolidated sales volumes totaled 914 million pounds of copper, 298 thousand ounces of gold and 16 million pounds of molybdenum in second-quarter 2010, compared with 1.1 billion pounds of copper, 837 thousand ounces of gold and 16 million pounds of molybdenum in second-quarter 2009. For the first six months of 2010, consolidated sales volumes totaled 1.9 billion pounds of copper, 776 thousand ounces of gold and 33 million pounds of molybdenum, compared with 2.1 billion pounds of copper, 1.4 million ounces of gold and 26 million pounds of molybdenum for the first six months of 2009. Lower copper and gold sales volumes in the 2010 periods primarily reflect anticipated lower ore grades at Grasberg resulting from planned mine sequencing. Lower copper

sales volumes were also impacted by decreased volumes at our South America mining operations, partly offset by additional volumes provided by the Tenke mine in Africa. Higher molybdenum sales volumes reflect improved demand in the chemical sector. Refer to “Operations” for further discussion.

During the first half of 2010, approximately 47 percent of our mined copper was sold in concentrate, approximately 27 percent as cathodes and approximately 26 percent as rod from our North America operations. Substantially all concentrate and cathode sales contracts at our copper mining operations provide final copper pricing in a specified future period (generally one to four months from the shipment date) based primarily on quoted LME prices. We receive market prices based on prices in the specified future period, which results in price fluctuations recorded through revenues until the date of settlement. We record revenues and invoice customers at the time of shipment based on then-current LME prices, which results in an embedded derivative on our provisional priced concentrate and cathode sales that is adjusted to fair value through ea rnings each period, using the period-end forward prices, until the date of final pricing. To the extent final prices are higher or lower than what was recorded on a provisional basis, an increase or decrease to revenues is recorded each reporting period until the date of final pricing. Accordingly, in times of rising copper prices, our revenues benefit from higher prices received for contracts priced at current market rates and also from an increase related to the final pricing of provisionally priced sales pursuant to contracts entered into in prior periods; in times of falling copper prices, the opposite occurs.

At March 31, 2010, we had provisionally priced copper sales at our copper mining operations totaling 372 million pounds of copper (net of intercompany sales and noncontrolling interests) recorded at an average of $3.53 per pound. Lower prices during second-quarter 2010 resulted in adjustments to these prior period provisionally priced copper sales and decreased consolidated revenues by $169 million ($72 million to net income attributable to FCX common stockholders or $0.15 per share) in second-quarter 2010, compared with a net increase of $43 million ($13 million to net income attributable to FCX common stockholders or $0.03 per share) in second-quarter 2009. Additionally, adjustments to prior year provisionally priced copper sales at our copper mining operations resulted in a net decrease to consolidated revenues of $23 million ($9 milli on to net income attributable to FCX common stockholders or $0.02 per share) for the first six months of 2010, compared with a net increase of $132 million ($62 million to net income attributable to FCX common stockholders or $0.15 per share) for the first six months of 2009.

LME spot copper prices averaged $3.18 per pound in second-quarter 2010, compared with our average realized price of $3.06 per pound. At June 30, 2010, we had provisionally priced copper sales at our copper mining operations totaling 364 million pounds of copper (net of intercompany sales and noncontrolling interests) recorded at an average of $2.95 per pound, subject to final pricing over the next several months. We estimate that each $0.05 change from the June 30, 2010, average price for provisionally priced copper sales would have a net impact on our 2010 consolidated revenues of approximately $24 million ($12 million to net income attributable to FCX common stockholders). The LME spot copper price closed at $3.26 per pound on July 30, 2010.

In April 2009, we entered into forward sales contracts on certain of PT Freeport Indonesia’s provisionally priced copper sales at March 31, 2009, which final priced from April 2009 through July 2009 (refer to Note 7 for further discussion).

Production and Delivery Costs

Consolidated production and delivery costs totaled $2.1 billion in second-quarter 2010 and $4.0 billion for the first six months of 2010, compared with $1.8 billion in second-quarter 2009 and $3.4 billion for the first six months of 2009. The increase in consolidated production and delivery costs in the 2010 periods primarily reflected higher costs of concentrate purchases at Atlantic Copper associated with higher copper prices and higher commodity-based input costs at our mining operations.

Our copper mining operations require a significant amount of energy, principally electricity, diesel, coal and natural gas. For the year 2010, we expect energy costs (including Africa mining) to approximate 20 percent of our consolidated copper production costs, which reflects purchases of approximately 220 million gallons of diesel fuel; 6,200 gigawatt hours of electricity at our North America, South America and Africa copper mining operations (we generate all of our power at our Indonesia mining operation); 800 thousand metric tons of coal for our coal power plant in Indonesia; and 1 million MMBTU (million british thermal units) of natural gas at certain of our North America mines. Energy costs for 2009, which excluded Africa mining, approximated 20 percent of our consolidated copper production costs.

Consolidated site production and delivery costs for our copper mining operations, excluding net noncash and other costs, averaged $1.41 per pound of copper in second-quarter 2010 and $1.38 per pound for the first six months of 2010, compared with $1.04 per pound of copper in second-quarter 2009 and $1.05 per pound of copper for the first six months of 2009. Higher site production and delivery costs in the 2010 periods primarily reflected lower copper sales volumes at Grasberg and South America. Refer to “Operations – Unit Net Cash Costs” for further discussion of unit net cash costs associated with our operating divisions, and to “Product Revenues and Production Costs” for reconciliations of per pound costs by operating division to production and delivery costs applicable to sales reported in our consolidated financial statements.

Depreciation, Depletion and Amortization

Consolidated depreciation, depletion and amortization expense totaled $249 million in second-quarter 2010 and $520 million for the first six months of 2010, compared with $256 million in second-quarter 2009 and $488 million for the first six months of 2009. Consolidated depreciation, depletion and amortization for the 2010 periods reflected lower expense under the unit-of-production method, offset by higher expense at our Tenke Fungurume mine, which commenced initial copper production in March 2009.

Lower of Cost or Market (LCM) Inventory Adjustments

Inventories are required to be recorded at the lower of cost or market. In first-quarter 2009, we recognized charges totaling $19 million ($19 million to net income attributable to FCX common stockholders or $0.05 per share) for LCM inventory adjustments associated with our molybdenum inventories.

Selling, General and Administrative Expenses

Consolidated selling, general and administrative expenses totaled $101 million in second-quarter 2010 and $196 million for the first six months of 2010, compared with $89 million in second-quarter 2009 and $151 million for the first six months of 2009. Selling, general and administrative expenses for the 2010 periods reflected higher incentive compensation costs and charges associated with relocating our corporate offices.

Exploration and Research Expenses

Consolidated exploration and research expenses totaled $38 million in second-quarter 2010 and $69 million for the first six months of 2010, compared with $24 million in second-quarter 2009 and $54 million for the first six months of 2009. Exploration activities are being conducted near our existing mines with a focus on opportunities to expand reserves that will support the development of additional future production capacity in the large mineral districts where we currently operate. Significantly expanded drilling activities in recent years have been successful in generating reserve additions and in identifying potential additional mineral resources adjacent to existing ore bodies. Results indicate opportunities for future potential reserve additions at Morenci, Sierrita and Bagdad in North America, at Cerro Verde and El Abra in South Am erica and in the Tenke Fungurume district.

For the year 2010, exploration spending is expected to approximate $120 million. Exploration activities will continue to focus primarily on the potential in our existing mineral districts.

Restructuring and Other Charges

For the first six months of 2009, we recognized net charges of $23 million ($22 million to net income attributable to FCX common stockholders or $0.05 per share) associated with revised operating plans, including contract termination costs, other project cancellation costs and charges for employee severance and benefits, partially offset by gains for pension and postretirement special benefits and curtailments.

Interest Expense, Net

Consolidated interest expense (before capitalization) totaled $132 million in second-quarter 2010 and $283 million for the first six months of 2010, compared with $172 million in second-quarter 2009 and $348 million for the first six months of 2009. Lower interest expense in the 2010 periods primarily reflected the impact of debt repayments during 2009 and the first half of 2010.

Capitalized interest decreased to $10 million in second-quarter 2010 and $16 million for the first six months of 2010, compared with $14 million in second-quarter 2009 and $59 million for the first six months of 2009, primarily reflecting the completion of development activities for the initial project at our Tenke Fungurume mine, which commenced initial copper production in March 2009.

Losses on Early Extinguishment of Debt

We recorded losses on early extinguishment of debt totaling $50 million ($42 million to net income attributable to FCX common stockholders or $0.09 per share) in second-quarter 2010 and $77 million ($65 million to net income attributable to FCX common stockholders or $0.14 per share) for the first six months of 2010 associated with the redemption of our Senior Floating Rate Notes and open-market purchases of our 8.25% and 8.375% Senior Notes. Refer to Note 6 for further discussion.

Provision for Income Taxes

Our income tax provision for second-quarter 2010 resulted from taxes on international operations ($382 million) and U.S. operations ($51 million). Our income tax provision for the first six months of 2010 resulted from taxes on international operations ($979 million) and U.S. operations ($132 million). As presented in the table below, our consolidated effective income tax rate was 35 percent for the first six months of 2010.

Our income tax provision for second-quarter 2009 resulted from taxes on international operations ($538 million) and U.S. operations ($4 million). Our income tax provision for the first six months of 2009 resulted from taxes on international operations ($868 million) and U.S. operations ($5 million). During the first half of 2009, we did not record a benefit for losses generated in the U.S., and those losses could not be used to offset income generated from international operations. These factors combined with the high proportion of income earned in Indonesia, which was taxed at an effective tax rate of 43 percent, caused our consolidated effective income tax rate of 47 percent for the first six months of 2009, to be higher than the U.S. federal statutory rate of 35 percent.

A summary of the approximate amounts in the calculation of our consolidated provision for income taxes for the first six months of 2010 and 2009 follows (in millions, except percentages):

| | | Six Months Ended | | Six Months Ended | |

| | | June 30, 2010 | | June 30, 2009 | |

| | | | | | | | Income Tax | | | | | | | Income Tax | |

| | | Income | | | Effective | | (Provision) | | Income | | | Effective | | (Provision) | |

| | | (Loss)a | | | Tax Rate | | Benefit | | (Loss)a | | | Tax Rate | | Benefit | |

| U.S. | | $ | 586 | | | 23% | | $ | (132 | ) | $ | (318 | ) | | (2)% | | $ | (5 | ) |

| South America | | | 1,022 | | | 32% | | | (331 | ) | | 694 | | | 32% | | | (221 | ) |

| Indonesia | | | 1,349 | | | 42% | | | (570 | ) | | 1,759 | | | 43% | | | (749 | ) |

| Africa | | | 142 | | | 30% | | | (43 | ) | | (86 | ) | | 30% | | | 26 | |

| Eliminations and other | | | 50 | | | N/A | | | (24 | ) | | (175 | ) | | N/A | | | 56 | |

Annualized rate adjustment b | | | N/A | | | N/A | | | (11 | ) | | N/A | | | N/A | | | 20 | |

| Consolidated FCX | | $ | 3,149 | | | 35%c | | $ | (1,111 | ) | $ | 1,874 | | | 47% | | $ | (873 | ) |

| a. | Represents income (loss) by geographic location before income taxes and equity in affiliated companies’ net earnings. |

| b. | In accordance with applicable accounting rules, we adjust our interim provision for income taxes to equal our estimated annualized tax rate. |

| c. | Our estimated consolidated effective tax rate for the year 2010 will vary with commodity price changes and the mix of income from international and U.S. operations. Assuming average prices of $3.00 per pound of copper, $1,200 per ounce of gold and $14 per pound of molybdenum for the remainder of 2010 and current 2010 sales volume and cost estimates, we estimate our annual consolidated effective tax rate will approximate 36 percent. |

OPERATIONS

North America Copper Mines

We currently have six operating copper mines in North America – Morenci, Sierrita, Bagdad, Safford and Miami in Arizona, and Tyrone in New Mexico. All of these mining operations are wholly owned, except for Morenci, an unincorporated joint venture, in which we own an 85 percent undivided interest.

The North America copper mines include open-pit mining, sulfide ore concentrating, leaching and solution extraction/electrowinning (SX/EW) operations. In addition to copper, the Sierrita and Bagdad mines produce molybdenum as a by-product. A majority of the copper produced at our North America copper mines is cast into copper rod by our Rod & Refining operations. The remainder of our North America copper sales is primarily in the form of copper cathode or copper concentrate. Refer to Note 11 for further discussion of our reportable segment in the North America copper mines division.

Operating and Development Activities. We have restarted the Morenci mill and have commenced a staged ramp up of Morenci’s mining rates. We have also resumed certain project development activities, including restarting the Miami mine and construction on the sulphur burner at Safford. Operating plans for the North America copper mines continue to be reviewed and adjustments will be made based on market conditions.

Morenci Mill Restart and Mine Ramp-up. In March 2010, we restarted the Morenci mill to process available sulfide material currently being mined. Mill throughput averaged 28,000 metric tons of ore per day during the second quarter of 2010 and is expected to increase to approximately 50,000 metric tons per day by 2011. We have also commenced a staged ramp up at the Morenci mine from the current rate of 450,000 metric tons per day to 635,000 metric tons per day. These activities are expected to expose additional ore and enable Morenci’s annual copper production to increase by approximately 125 million pounds, beginning in 2011. Further increases to Morenci’s mining rate are being evaluated.

Miami Restart. We have initiated limited mining activities at the Miami mine to improve efficiencies of ongoing reclamation projects associated with historical mining operations at the site. During an approximate five-year mine life, we expect to ramp up production at Miami to approximately 100 million pounds of copper per year by the second half of 2011. We are investing approximately $40 million for this project, which is benefiting from the use of existing mining equipment.

Safford Sulphur Burner. We are advancing plans to construct a sulphur burner at the Safford mine, which will provide a more cost effective source of sulphuric acid used in SX/EW operations and lower transportation costs. This project is expected to be complete during 2011 at a capital investment of approximately $150 million.

Chino Restart. We are evaluating the restart of mining and milling activities at the Chino mine, which were suspended in late 2008. The preliminary economics of the project appear attractive and would increase copper production by approximately 150 million to 200 million pounds per year. As reported in our annual report on Form 10-K for the year ended December 31, 2009, Chino’s reserves, excluding metal in stockpiles, totaled 1.1 billion pounds of copper (determined using a long-term average copper price of $1.60 per pound).

Twin Buttes Acquisition. In December 2009, we purchased the Twin Buttes copper mine, which ceased operations in 1994, and is adjacent to our Sierrita mine. The purchase provides significant synergies in the Sierrita minerals district, including the potential for expanded mining activities and access to material that can be used for Sierrita tailings and stockpile reclamation purposes. Studies have commenced to incorporate the Twin Buttes resources in our development plans.

Operating Data. Following is summary operating data for the North America copper mines for the second quarters and first six months of 2010 and 2009:

| | | Three Months Ended June 30, | | Six Months Ended June 30, | |

| | | 2010 | | 2009 | | 2010 | | 2009 | |

| Operating Data, Net of Joint Venture Interest | | | | | | | | | | | | | |

Copper (millions of recoverable pounds) | | | | | | | | | | | | | |

| Production | | | 263 | | | 272 | | | 527 | | | 561 | |

| Sales, excluding purchases | | | 289 | | | 281 | | | 580 | | | 582 | |

| Average realized price per pound | | $ | 3.21 | | $ | 2.18 | | $ | 3.27 | | $ | 1.88 | |

| | | | | | | | | | | | | | |

Molybdenum (millions of recoverable pounds) | | | | | | | | | | | | | |

Productiona | | | 5 | | | 7 | | | 11 | | | 13 | |

| | | | | | | | | | | | | | |

| 100% Operating Data | | | | | | | | | | | | | |

| SX/EW operations | | | | | | | | | | | | | |

| Leach ore placed in stockpiles (metric tons per day) | | | 646,100 | | | 553,700 | | | 624,100 | | | 611,200 | |

| Average copper ore grade (percent) | | | 0.25 | | | 0.31 | | | 0.25 | | | 0.30 | |

| Copper production (millions of recoverable pounds) | | | 182 | | | 201 | | | 384 | | | 423 | |

| | | | | | | | | | | | | | |

| Mill operations | | | | | | | | | | | | | |

| Ore milled (metric tons per day) | | | 195,300 | | | 170,600 | | | 179,200 | | | 175,700 | |

| Average ore grade (percent): | | | | | | | | | | | | | |

| Copper | | | 0.32 | | | 0.31 | | | 0.31 | | | 0.33 | |

| Molybdenum | | | 0.02 | | | 0.03 | | | 0.02 | | | 0.03 | |

| Copper recovery rate (percent) | | | 81.4 | | | 84.8 | | | 83.3 | | | 85.3 | |

| Production (millions of recoverable pounds): | | | | | | | | | | | | | |

| Copper | | | 100 | | | 89 | | | 180 | | | 177 | |

| Molybdenum | | | 5 | | | 7 | | | 11 | | | 13 | |

| a. | Reflects by-product molybdenum production from the North America copper mines. Sales of by-product molybdenum are reflected in the Molybdenum division. |

Copper sales volumes from our North America copper mines totaled 289 million pounds in second-quarter 2010 and 580 million pounds for the first six months of 2010, compared with copper sales volumes of 281 million pounds in second-quarter 2009 and 582 million pounds for the first six months of 2009.

Consolidated sales volumes from our North America copper mines are expected to approximate 1.1 billion pounds of copper for the year 2010, compared with 1.2 billion pounds of copper in 2009. As discussed above in “Operating and Development Activities,” we are increasing mining and milling rates at the Morenci mine and restarting the Miami mine, which are expected to result in higher production in future periods.

Unit Net Cash Costs. Unit net cash costs per pound of copper is a measure intended to provide investors with information about the cash-generating capacity of our mining operations expressed on a basis relating to the primary metal product for our respective operations. We use this measure for the same purpose and for monitoring operating performance by our mining operations. This information differs from measures of performance determined in accordance with generally accepted accounting principles (GAAP) in the U.S. and should not be considered in isolation or as a substitute for measures of performance determined in accordance with U.S. GAAP. This measure is presented by other mining companies, although our measure may not be comparable to similarly titled measures reported by other companies.

Gross Profit per Pound of Copper and Molybdenum

The following tables summarize unit net cash costs and gross profit per pound of copper and molybdenum at the North America copper mines for the second quarters and first six months of 2010 and 2009. Refer to “Product Revenues and Production Costs” for an explanation of the “by-product” and “co-product” methods and a reconciliation of unit net cash costs to production and delivery costs applicable to sales reported in our consolidated financial statements.

| | Three Months Ended June 30, 2010 | | Three Months Ended June 30, 2009 | |

| | By- | | Co-Product Method | | By- | | Co-Product Method | |

| | Product | | | | | Molyb- | | Product | | | | | Molyb- | |

| | Method | | Copper | | denuma | | Method | | Copper | | denuma | |

| Revenues, excluding adjustments | $ | 3.21 | | $ | 3.21 | | $ | 17.34 | | $ | 2.18 | | $ | 2.18 | | $ | 8.43 | |

| | | | | | | | | | | | | | | | | | | |

| Site production and delivery, before net noncash | | | | | | | | | | | | | | | | | | |

| and other costs shown below | | 1.46 | | | 1.31 | | | 8.55 | | | 1.24 | | | 1.13 | | | 5.34 | |

By-product creditsa | | (0.38 | ) | | – | | | – | | | (0.21 | ) | | – | | | – | |

| Treatment charges | | 0.09 | | | 0.08 | | | – | | | 0.09 | | | 0.08 | | | – | |

| Unit net cash costs | | 1.17 | | | 1.39 | | | 8.55 | | | 1.12 | | | 1.21 | | | 5.34 | |

| Depreciation, depletion and amortization | | 0.23 | | | 0.22 | | | 0.64 | | | 0.21 | | | 0.21 | | | 0.36 | |

| Noncash and other costs, net | | 0.19 | | | 0.18 | | | 0.04 | | | 0.15 | | | 0.14 | | | 0.04 | |

| Total unit costs | | 1.59 | | | 1.79 | | | 9.23 | | | 1.48 | | | 1.56 | | | 5.74 | |

| Revenue adjustments, primarily for hedging | | – | | | – | | | – | | | 0.06 | | | 0.06 | | | – | |

| Idle facility and other non-inventoriable costs | | (0.08 | ) | | (0.08 | ) | | (0.01 | ) | | (0.08 | ) | | (0.08 | ) | | – | |

| Gross profit per pound | $ | 1.54 | | $ | 1.34 | | $ | 8.10 | | $ | 0.68 | | $ | 0.60 | | $ | 2.69 | |

| | | | | | | | | | | | | | | | | | | |

| Copper sales (millions of recoverable pounds) | | 288 | | | 288 | | | | | | 281 | | | 281 | | | | |

Molybdenum sales (millions of recoverable pounds)b | | | | | | | | 5 | | | | | | | | | 7 | |

| | Six Months Ended June 30, 2010 | | Six Months Ended June 30, 2009 | |

| | By- | | Co-Product Method | | By- | | Co-Product Method | |

| | Product | | | | | Molyb- | | Product | | | | | Molyb- | |

| | Method | | Copper | | denuma | | Method | | Copper | | denuma | |

| Revenues, excluding adjustments | $ | 3.27 | | $ | 3.27 | | $ | 15.71 | | $ | 1.88 | | $ | 1.88 | | $ | 9.02 | |

| | | | | | | | | | | | | | | | | | | |

| Site production and delivery, before net noncash | | | | | | | | | | | | | | | | | | |

| and other costs shown below | | 1.39 | | | 1.25 | | | 8.00 | | | 1.28 | | | 1.19 | | | 4.85 | |

By-product creditsa | | (0.32 | ) | | – | | | – | | | (0.19 | ) | | – | | | – | |

| Treatment charges | | 0.08 | | | 0.08 | | | – | | | 0.08 | | | 0.08 | | | – | |

| Unit net cash costs | | 1.15 | | | 1.33 | | | 8.00 | | | 1.17 | | | 1.27 | | | 4.85 | |

| Depreciation, depletion and amortization | | 0.25 | | | 0.24 | | | 0.63 | | | 0.23 | | | 0.22 | | | 0.29 | |

| Noncash and other costs, net | | 0.13 | | | 0.13 | | | 0.05 | | | 0.15 | | | 0.15 | | | 0.10 | |

| Total unit costs | | 1.53 | | | 1.70 | | | 8.68 | | | 1.55 | | | 1.64 | | | 5.24 | |

| Revenue adjustments, primarily for hedging | | – | | | – | | | – | | | 0.15 | | | 0.15 | | | – | |

| Idle facility and other non-inventoriable costs | | (0.08 | ) | | (0.08 | ) | | (0.01 | ) | | (0.10 | ) | | (0.11 | ) | | – | |

| Gross profit per pound | $ | 1.66 | | $ | 1.49 | | $ | 7.02 | | $ | 0.38 | | $ | 0.28 | | $ | 3.78 | |

| | | | | | | | | | | | | | | | | | | |

| Copper sales (millions of recoverable pounds) | | 579 | | | 579 | | | | | | 582 | | | 582 | | | | |

Molybdenum sales (millions of recoverable pounds)b | | | | | | | | 11 | | | | | | | | | 13 | |

| a. | Molybdenum by-product credits and revenues reflect volumes produced at market-based pricing and also include tolling revenues at Sierrita. |

| b. | Reflects molybdenum produced by the North America copper mines. |

Unit net cash costs (net of by-product credits) for our North America copper mines were $1.17 per pound of copper in second-quarter 2010 and $1.15 per pound of copper for the first six months of 2010, compared with $1.12 per pound of copper in second-quarter 2009 and $1.17 per pound of copper for the first six months of 2009. Unit net cash costs for the 2010 periods reflected higher site production and delivery costs ($0.22 per pound for the quarter and $0.11 per pound for the six month period) primarily associated with higher input costs from increased mining and milling activities. Offsetting these higher costs were higher molybdenum credits ($0.17 per pound for the quarter and $0.13 per pound for the six month period) resulting from higher molybdenum prices.

Some of our U.S. copper rod customers request a fixed market price instead of the COMEX average price in the month of shipment. We hedge this price exposure in a manner that allows us to receive market prices in the month of shipment while the customer pays the fixed price they requested. Because these contracts previously did not meet the criteria to qualify for hedge accounting, revenue adjustments in second-quarter and the first six months of 2009 primarily reflect unrealized gains on these copper derivative contracts.

Our operating North America copper mines have varying cost structures because of differences in ore grades and ore characteristics, processing costs, by-products and other factors. Based on current operating plans and assuming achievement of current 2010 sales volume and cost estimates and an average price of $14 per pound of molybdenum for the remainder of 2010, we estimate that average unit net cash costs (net of by-product credits) for our North America copper mines would approximate $1.24 per pound of copper for the year 2010, compared with $1.11 per pound in 2009. Each $2 per pound change in the average price of molybdenum during the remainder of 2010 would have an approximate $0.02 per pound impact on the North America copper mines’ 2010 unit net cash costs.

South America Mining

We have four operating copper mines in South America – Cerro Verde in Peru, and Candelaria, Ojos del Salado and El Abra in Chile. We own a 53.56 percent interest in Cerro Verde, an 80 percent interest in both Candelaria and Ojos del Salado and a 51 percent interest in El Abra.

South America mining includes open-pit and underground mines, sulfide ore concentrating, leaching and SX/EW operations. In addition to copper, the Cerro Verde mine produces molybdenum concentrates as a by-product, and the Candelaria and Ojos del Salado mines produce gold and silver as by-products. Production from our South America mines is sold as copper concentrate or copper cathode under long-term contracts. Our South America mines sell a portion of their copper concentrate and cathode inventories to Atlantic Copper, an affiliated smelter. Refer to Note 11 for further discussion of our reportable segment in the South America mining division.

Operating and Development Activities. The molybdenum circuit at Cerro Verde, which had been temporarily curtailed, resumed operations in September 2009. We have also resumed certain project development activities, including the El Abra sulfide project and the Cerro Verde mill optimization project.

El Abra Sulfide. We are engaged in construction activities associated with the development of a large sulfide deposit at El Abra to extend its mine life by over 10 years. Production from the sulfide ore, which will ramp up to approximately 300 million pounds of copper per year, is expected to begin in 2012 and will replace currently depleting oxide copper production. The aggregate capital investment for this project is expected to total $725 million through 2015, of which approximately $535 million is for the initial phase of the project expected to be completed in 2012. Aggregate project costs of $190 million have been incurred as of June 30, 2010, $115 million of which has been incurred during the first six months of 2010.

We have also initiated studies for a potential milling operation at El Abra to process additional sulfide material and to achieve higher recoveries.

Cerro Verde Expansion. We are completing a project to optimize throughput at the existing Cerro Verde concentrator. This project, which is expected to be completed by the end of 2010, is designed to add 30 million pounds of additional copper production per year by increasing mill throughput from 108,000 metric tons of ore per day to 120,000 metric tons of ore per day. The aggregate capital investment for this project is expected to total approximately $50 million.

In addition, we are evaluating the potential for a large scale concentrator expansion at Cerro Verde. Reserve additions in recent years have provided opportunities to potentially more than double the existing facility’s capacity. A feasibility study is expected to be completed in the first half of 2011.

Other Matters. As reported in Note 14 of our report on Form 10-K for the year ended December 31, 2009, Cerro Verde was notified by SUNAT, the Peruvian national tax authority, of its intent to assess mining royalties related to the minerals processed by the Cerro Verde concentrator, which was added to Cerro Verde’s processing facilities in late 2006. In August 2009, Cerro Verde received a formal assessment approximating $50 million in connection with its alleged obligations for mining royalties and fines for the period from October 2006 through December 2007. In April 2010, SUNAT issued a ruling denying Cerro Verde’s protest of the assessment; Cerro Verde plans

to appeal this decision. Also, in April 2010, Cerro Verde received a formal assessment approximating $40 million in royalties for the year 2008.

Cerro Verde is challenging these royalties because its stability agreement with the Peruvian government exempts from royalties all minerals extracted from its mining concession, irrespective of the method used for processing those minerals. No amounts have been accrued for this contingency. If Cerro Verde is ultimately found responsible for those royalties, it will also be liable for interest, which accrues at rates that range from 6 to 18 percent based on the year accrued and the currency in which the amounts would be payable.

In April 2010, there was a major earthquake in Chile that resulted in significant damages in certain regions of the country. The Chilean government proposed a temporary increase in mining royalties to help fund reconstruction activities, but it was rejected by the Chilean congress in July 2010. We will continue to monitor the activity associated with these proposals and their potential impact on our financial results.

Operating Data. Following is summary operating data for our South America mining operations for the second quarters and first six months of 2010 and 2009:

| | | Three Months Ended June 30, | | Six Months Ended June 30, | |

| | | 2010 | | 2009 | | 2010 | | 2009 | |

| | | | | | | | | | | | | | |

Copper (millions of recoverable pounds) | | | | | | | | | | | | | |

| Production | | | 329 | | | 358 | | | 651 | | | 706 | |

| Sales | | | 311 | | | 363 | | | 618 | | | 713 | |

| Average realized price per pound | | $ | 3.02 | | $ | 2.22 | | $ | 3.07 | | $ | 2.10 | |

| | | | | | | | | | | | | | |

Gold (thousands of recoverable ounces) | | | | | | | | | | | | | |

| Production | | | 20 | | | 24 | | | 39 | | | 47 | |

| Sales | | | 20 | | | 25 | | | 39 | | | 48 | |

| Average realized price per ounce | | $ | 1,221 | | $ | 928 | | $ | 1,175 | | $ | 915 | |

| | | | | | | | | | | | | | |

Molybdenum (millions of recoverable pounds) | | | | | | | | | | | | | |

Productiona | | | 1 | | | – | | | 3 | | | 1 | |

| | | | | | | | | | | | | | |

| SX/EW operations | | | | | | | | | | | | | |

| Leach ore placed in stockpiles (metric tons per day) | | | 247,400 | | | 260,200 | | | 251,600 | | | 255,400 | |

| Average copper ore grade (percent) | | | 0.42 | | | 0.44 | | | 0.43 | | | 0.45 | |

| Copper production (millions of recoverable pounds) | | | 130 | | | 141 | | | 263 | | | 278 | |

| | | | | | | | | | | | | | |

| Mill operations | | | | | | | | | | | | | |

| Ore milled (metric tons per day) | | | 187,100 | | | 186,300 | | | 183,600 | | | 184,400 | |

Average ore grade (percent):b | | | | | | | | | | | | | |

| Copper | | | 0.62 | | | 0.67 | | | 0.62 | | | 0.68 | |

| Molybdenum | | | 0.02 | | | 0.02 | | | 0.02 | | | 0.02 | |

| Copper recovery rate (percent) | | | 89.9 | | | 90.2 | | | 89.5 | | | 89.6 | |

| Production (recoverable): | | | | | | | | | | | | | |

| Copper (millions of pounds) | | | 199 | | | 217 | | | 388 | | | 428 | |

| Gold (thousands of ounces) | | | 20 | | | 24 | | | 39 | | | 47 | |

| Molybdenum (millions of pounds) | | | 1 | | | – | | | 3 | | | 1 | |

| a. | Reflects by-product molybdenum production from our Cerro Verde copper mine. Sales of by-product molybdenum are reflected in the Molybdenum division. |

| b. | Average ore grades of gold produced at our South America mining operations rounds to less than 0.001 grams per metric ton. |

Copper sales from our South America mining operations decreased to 311 million pounds in second-quarter 2010 and 618 million pounds for the first six months of 2010, compared with 363 million pounds in second-quarter 2009 and 713 million pounds for the first six months of 2009. These decreases primarily reflected lower ore grades at Candelaria and timing of shipments at Cerro Verde.

Consolidated sales volumes from South America mining are expected to approximate 1.3 billion pounds of copper and 100 thousand ounces of gold for the year 2010, compared with 1.4 billion pounds of copper and 90 thousand ounces of gold in 2009. Projected copper sales volumes for 2010 are lower than 2009 primarily reflecting

anticipated lower ore grades, principally at El Abra in connection with the depletion of the oxide ore resource and the transition to the sulfide deposit.

Unit Net Cash Costs. Unit net cash costs per pound of copper is a measure intended to provide investors with information about the cash-generating capacity of our mining operations expressed on a basis relating to the primary metal product for our respective operations. We use this measure for the same purpose and for monitoring operating performance by our mining operations. This information differs from measures of performance determined in accordance with U.S. GAAP and should not be considered in isolation or as a substitute for measures of performance determined in accordance with U.S. GAAP. This measure is presented by other mining companies, although our measure may not be comparable to similarly titled measures reported by other companies.

Gross Profit per Pound of Copper

The following tables summarize unit net cash costs and gross profit per pound of copper at the South America mining operations for the second quarters and first six months of 2010 and 2009. Unit net cash costs per pound of copper are reflected under the by-product and co-product methods as the South America mining operations also had small amounts of molybdenum, gold and silver sales. Refer to “Product Revenues and Production Costs” for an explanation of the “by-product” and “co-product” methods and a reconciliation of unit net cash costs to production and delivery costs applicable to sales reported in our consolidated financial statements.

| | Three Months Ended June 30, 2010 | | Three Months Ended June 30, 2009 | |

| | By-Product | | Co-Product | | By-Product | | Co-Product | |

| | Method | | Method | | Method | | Method | |

| Revenues, excluding adjustments | $ | 3.02 | | $ | 3.02 | | $ | 2.22 | | $ | 2.22 | |

| | | | | | | | | | | | | |

| Site production and delivery, before net noncash | | | | | | | | | | | | |

| and other costs shown below | | 1.22 | | | 1.14 | | | 1.00 | | | 0.95 | |

| By-product credits | | (0.19 | ) | | – | | | (0.10 | ) | | – | |

| Treatment charges | | 0.11 | | | 0.11 | | | 0.15 | | | 0.15 | |

| Unit net cash costs | | 1.14 | | | 1.25 | | | 1.05 | | | 1.10 | |

| Depreciation, depletion and amortization | | 0.19 | | | 0.18 | | | 0.19 | | | 0.19 | |

| Noncash and other costs, net | | 0.02 | | | 0.02 | | | (0.01 | ) | | – | |

| Total unit costs | | 1.35 | | | 1.45 | | | 1.23 | | | 1.29 | |

| Revenue adjustments, primarily for pricing on | | | | | | | | | | | | |

| prior period open sales | | (0.37 | ) | | (0.37 | ) | | 0.26 | | | 0.26 | |

| Other non-inventoriable costs | | (0.02 | ) | | (0.02 | ) | | (0.02 | ) | | (0.01 | ) |

| Gross profit per pound | $ | 1.28 | | $ | 1.18 | | $ | 1.23 | | $ | 1.18 | |

| | | | | | | | | | | | | |

| Copper sales (millions of recoverable pounds) | | 311 | | | 311 | | | 363 | | | 363 | |

| | Six Months Ended June 30, 2010 | | Six Months Ended June 30, 2009 | |

| | By-Product | | Co-Product | | By-Product | | Co-Product | |

| | Method | | Method | | Method | | Method | |

| Revenues, excluding adjustments | $ | 3.07 | | $ | 3.07 | | $ | 2.10 | | $ | 2.10 | |

| | | | | | | | | | | | | |

| Site production and delivery, before net noncash | | | | | | | | | | | | |

| and other costs shown below | | 1.21 | | | 1.14 | | | 1.00 | | | 0.94 | |

| By-product credits | | (0.18 | ) | | – | | | (0.11 | ) | | – | |

| Treatment charges | | 0.13 | | | 0.13 | | | 0.15 | | | 0.14 | |

| Unit net cash costs | | 1.16 | | | 1.27 | | | 1.04 | | | 1.08 | |

| Depreciation, depletion and amortization | | 0.19 | | | 0.18 | | | 0.19 | | | 0.18 | |

| Noncash and other costs, net | | 0.01 | | | 0.01 | | | – | | | 0.01 | |

| Total unit costs | | 1.36 | | | 1.46 | | | 1.23 | | | 1.27 | |

| Revenue adjustments, primarily for pricing on | | | | | | | | | | | | |

| prior period open sales | | (0.03 | ) | | (0.03 | ) | | 0.15 | | | 0.15 | |

| Other non-inventoriable costs | | (0.02 | ) | | (0.02 | ) | | (0.03 | ) | | (0.02 | ) |

| Gross profit per pound | $ | 1.66 | | $ | 1.56 | | $ | 0.99 | | $ | 0.96 | |

| | | | | | | | | | | | | |

| Copper sales (millions of recoverable pounds) | | 618 | | | 618 | | | 713 | | | 713 | |

Unit net cash costs (net of by-product credits) for our South America mining operations averaged $1.14 per pound of copper in second-quarter 2010 and $1.16 per pound of copper for the first six months of 2010, compared with

$1.05 per pound in second-quarter 2009 and $1.04 per pound for the first six months of 2009. The increase in unit net cash costs in the 2010 periods primarily reflected higher site production and delivery costs ($0.22 per pound for the quarter and $0.21 per pound for the six-month period) mostly associated with lower sales volumes. Partly offsetting higher site production and delivery costs were higher by-product credits ($0.09 per pound for the quarter and $0.07 per pound for the six-month period) primarily associated with higher gold and molybdenum prices, and lower treatment charges ($0.04 per pound for the quarter and $0.02 per pound for the six-month period).

Our South America mines have varying cost structures because of differences in ore grades and ore characteristics, processing costs, by-products and other factors. Assuming achievement of current 2010 sales volume and cost estimates, we estimate that average unit net cash costs (net of by-product credits) for our South America mining operations would approximate $1.18 per pound of copper in 2010, compared with $1.12 per pound in 2009.

Indonesia Mining

Indonesia mining includes PT Freeport Indonesia’s Grasberg minerals district. We own 90.64 percent of PT Freeport Indonesia, including 9.36 percent owned through our wholly owned subsidiary, PT Indocopper Investama.

PT Freeport Indonesia produces copper concentrates, which contain significant quantities of gold and silver. Substantially all of PT Freeport Indonesia’s copper concentrates are sold under long-term contracts, of which approximately one-half is sold to affiliated smelters, Atlantic Copper and PT Smelting (PT Freeport Indonesia’s 25-percent owned copper smelter and refinery in Indonesia) and the remainder to other customers.

We have established certain unincorporated joint ventures with Rio Tinto plc (Rio Tinto), under which Rio Tinto has a 40 percent interest in certain assets and future production exceeding specified annual amounts of copper, gold and silver.