Technical Report Summary, Greenbushes Mine, Western Australia Albemarle Corporation Date: 10 February 2025 Exhibit 96.1 | ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | | | | Page i of vii | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 TABLE OF CONTENTS 1. EXECUTIVE SUMMARY .................................................................................................................. 1 1.1 Report Scope ..................................................................................................................................... 1 1.2 Property Description and Location .................................................................................................... 1 1.3 Geology and Mineralization ............................................................................................................... 2 1.4 Exploration Status ............................................................................................................................. 2 1.5 Development and Operations ............................................................................................................ 2 1.6 Mineral Resources and Mineral Reserves ........................................................................................ 4 1.7 Market Studies................................................................................................................................... 6 1.8 Environmental, Permitting, and Social Considerations ..................................................................... 6 1.9 Economic Evaluation ......................................................................................................................... 7 1.10 Recommendations ............................................................................................................................ 9 1.11 Key Risks ......................................................................................................................................... 10 2. INTRODUCTION ............................................................................................................................. 11 2.1 Report Scope ................................................................................................................................... 11 2.2 Site Visits ......................................................................................................................................... 11 2.3 Sources of Information .................................................................................................................... 11 2.4 Forward-Looking Statements .......................................................................................................... 12 2.5 List of Abbreviations ........................................................................................................................ 12 2.6 Independence .................................................................................................................................. 16 2.7 Inherent Mining Risks ...................................................................................................................... 16 3. PROPERTY DESCRIPTION AND LOCATION .............................................................................. 17 3.1 Location ........................................................................................................................................... 17 3.2 Land Tenure .................................................................................................................................... 19 3.3 Surface Rights and Easement ......................................................................................................... 24 3.4 Material Government Consents ....................................................................................................... 24 3.5 Significant Limiting Factors ............................................................................................................. 24 4. ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY 25 4.1 Accessibility ..................................................................................................................................... 25 4.2 Climate ............................................................................................................................................ 25 4.3 Local Resources .............................................................................................................................. 25 4.4 Infrastructure ................................................................................................................................... 25 4.5 Physiography ................................................................................................................................... 26 5. HISTORY ......................................................................................................................................... 27 5.1 Past Production ............................................................................................................................... 27 5.2 Exploration and Development of Previous Owners or Operators ................................................... 28 6. GEOLOGICAL SETTING, MINERALIZATION AND DEPOSIT .................................................... 29 6.1 Regional Geology ............................................................................................................................ 29 6.2 Local Geology .................................................................................................................................. 29 6.3 Mineralization .................................................................................................................................. 35 6.4 Deposit Types .................................................................................................................................. 35 7. EXPLORATION............................................................................................................................... 37 7.1 Exploration ....................................................................................................................................... 37 7.2 Drilling .............................................................................................................................................. 37

| ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | | | | Page ii of vii | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 7.3 Hydrogeology .................................................................................................................................. 40 7.4 Geotechnical Data, Testing, and Analysis ...................................................................................... 40 8. SAMPLE PREPARATION, ANALYSES AND SECURITY ........................................................... 42 8.1 Analytical and Test Laboratories ..................................................................................................... 42 8.2 Sample Preparation and Analysis ................................................................................................... 42 8.3 Sample Security .............................................................................................................................. 42 8.4 Density Determination ..................................................................................................................... 43 8.5 Quality Assurance and Quality Control ........................................................................................... 43 9. DATA VERIFICATION .................................................................................................................... 47 10. MINERAL PROCESSING AND METALLURGICAL TESTING ..................................................... 49 10.1 Mineralogy ....................................................................................................................................... 49 10.2 Metallurgical .................................................................................................................................... 49 10.3 LOM Plan ......................................................................................................................................... 50 11. MINERAL RESOURCE ESTIMATES ............................................................................................. 51 11.1 Resource Areas ............................................................................................................................... 51 11.2 Statement Of Mineral Resources .................................................................................................... 51 11.3 Initial Assessment ........................................................................................................................... 52 11.4 Resource Database ......................................................................................................................... 55 11.5 Geological Modelling ....................................................................................................................... 55 11.6 Basic Statistics ................................................................................................................................ 57 11.7 Treatment of High Grade ................................................................................................................. 57 11.8 Geospatial Analysis ......................................................................................................................... 58 11.9 Kriging Neighborhood Analysis ....................................................................................................... 61 11.10 Block Model ..................................................................................................................................... 63 11.11 Grade Dependent Search ............................................................................................................... 64 11.12 Bulk Density ..................................................................................................................................... 64 11.13 Block Model Validation .................................................................................................................... 64 11.14 Resource Classification ................................................................................................................... 68 11.15 Mining Depletion .............................................................................................................................. 70 11.16 Reconciliation .................................................................................................................................. 70 11.17 Comparison to Previous Mineral Resource Estimate...................................................................... 71 12. MINERAL RESERVES ESTIMATES .............................................................................................. 72 12.1 Summary ......................................................................................................................................... 72 12.2 Statement of Mineral Reserves ....................................................................................................... 72 12.3 Approach ......................................................................................................................................... 73 12.4 Planning Status ............................................................................................................................... 74 12.5 Modifying Factors ............................................................................................................................ 74 12.6 Comparison to Previous Mineral Reserve Estimate ........................................................................ 80 13. MINING METHODS ........................................................................................................................ 81 13.1 Mine Method .................................................................................................................................... 81 13.2 Mine Design ..................................................................................................................................... 81 13.3 Geotechnical Considerations .......................................................................................................... 81 13.4 Hydrogeological Considerations ...................................................................................................... 84 13.5 Mining Strategy................................................................................................................................ 84 13.6 Life of Mine Plan .............................................................................................................................. 89 13.7 Mining Equipment ............................................................................................................................ 91 | ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | | | | Page iii of vii | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 14. PROCESSING AND RECOVERY METHODS ............................................................................... 92 14.1 Process Overview............................................................................................................................ 92 14.2 Technical Grade Plant ..................................................................................................................... 95 14.3 Chemical Grade 1 Processing Circuit ............................................................................................. 99 14.4 Chemical Grade 2 Processing Circuit ........................................................................................... 102 14.5 Chemical Grade 3 Processing Circuit ........................................................................................... 105 14.6 Tailings Reprocessing Plant .......................................................................................................... 108 14.7 Final Product ................................................................................................................................. 110 14.8 Plant Yield ..................................................................................................................................... 111 15. INFRASTRUCTURE ..................................................................................................................... 113 15.1 Site Access .................................................................................................................................... 115 15.2 Power Supply ................................................................................................................................ 116 15.3 Water Supply ................................................................................................................................. 116 15.4 Highway Crossing Infrastructure Option ....................................................................................... 122 15.5 Flood Risk ...................................................................................................................................... 122 15.6 Maintenance Service Area ............................................................................................................ 122 15.7 Propane ......................................................................................................................................... 123 15.8 Diesel Storage and Dispensing ..................................................................................................... 124 15.9 Site-Camp Accommodation Facilities ........................................................................................... 124 15.10 Communications and SCADA Systems ........................................................................................ 124 15.11 Tailings Storage ........................................................................................................................... 124 16. MARKET STUDIES ...................................................................................................................... 129 16.2 16.1.4 Lithium prices ..................................................................................................................... 134 17. ENVIRONMENTAL STUDIES, PERMITTING, AND PLANS, NEGOTIATIONS OR AGREEMENTS LOCAL INDIVIDUALS OR GROUPS .................................................................................................... 138 17.1 Environmental Studies .................................................................................................................. 138 17.2 Environmental Management ......................................................................................................... 147 17.3 Mine Waste and Water Management ............................................................................................ 147 17.4 Operation Permitting and Compliance .......................................................................................... 148 17.5 Social or Community Requirements .............................................................................................. 160 17.6 Mine Closure Requirements .......................................................................................................... 163 18. CAPITAL AND OPERATING COSTS .......................................................................................... 164 18.1 Capital Costs ................................................................................................................................. 164 18.2 Mine Closure and Rehabilitation ................................................................................................... 165 18.3 Operating Costs............................................................................................................................. 165 18.4 Safeguard Mechanism .................................................................................................................. 167 19. ECONOMIC ANALYSIS ............................................................................................................... 168 19.1 Economic Criteria .......................................................................................................................... 168 19.2 Cash Flow Analyses ...................................................................................................................... 168 19.3 Sensitivity Analysis ........................................................................................................................ 171 20. ADJACENT PROPERTIES ........................................................................................................... 172 21. OTHER RELEVANT DATA AND INFORMATION ....................................................................... 173 21.1 Standalone Ore Sorting Plant ........................................................................................................ 173 21.2 Underground Mine ......................................................................................................................... 173

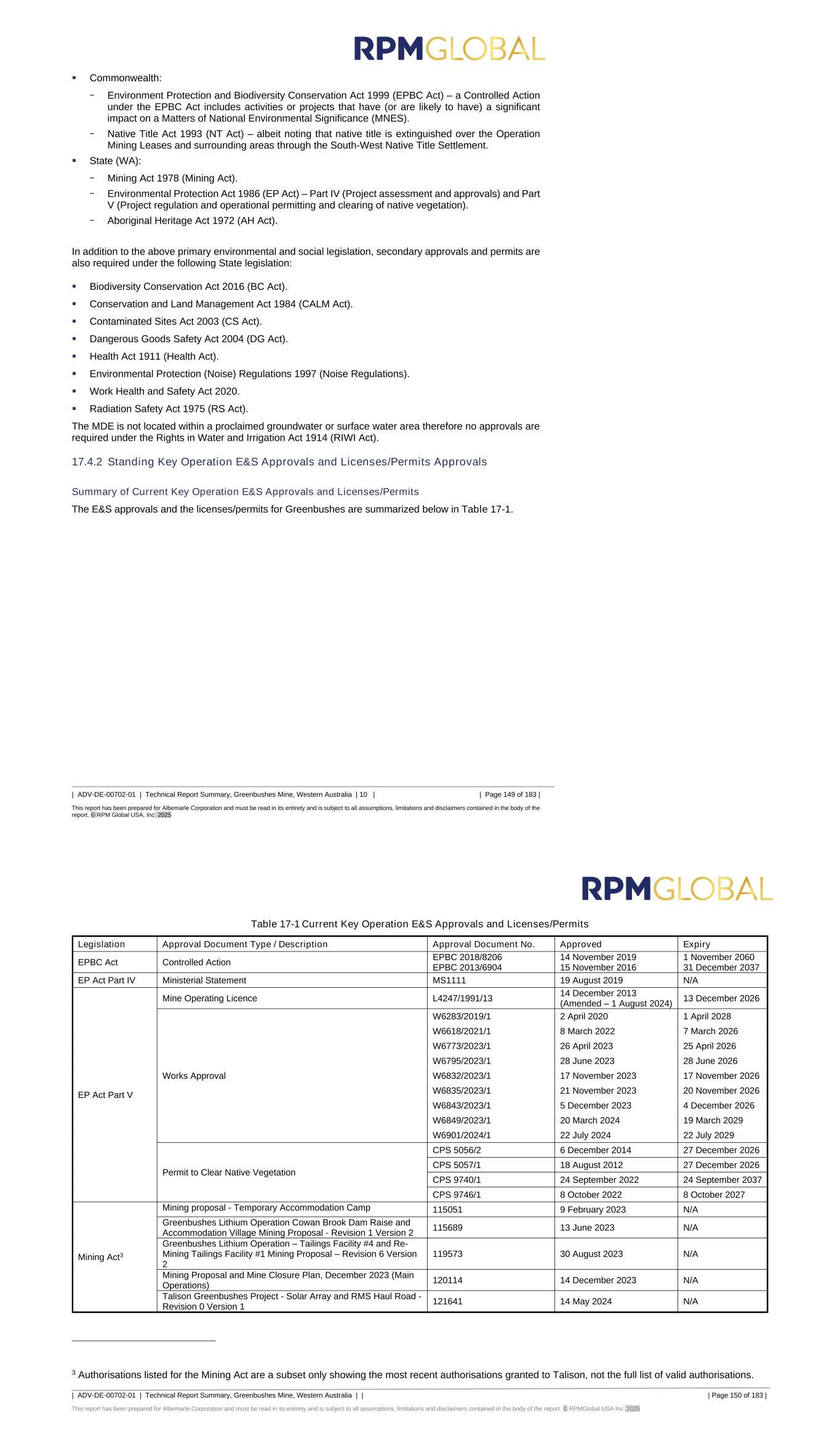

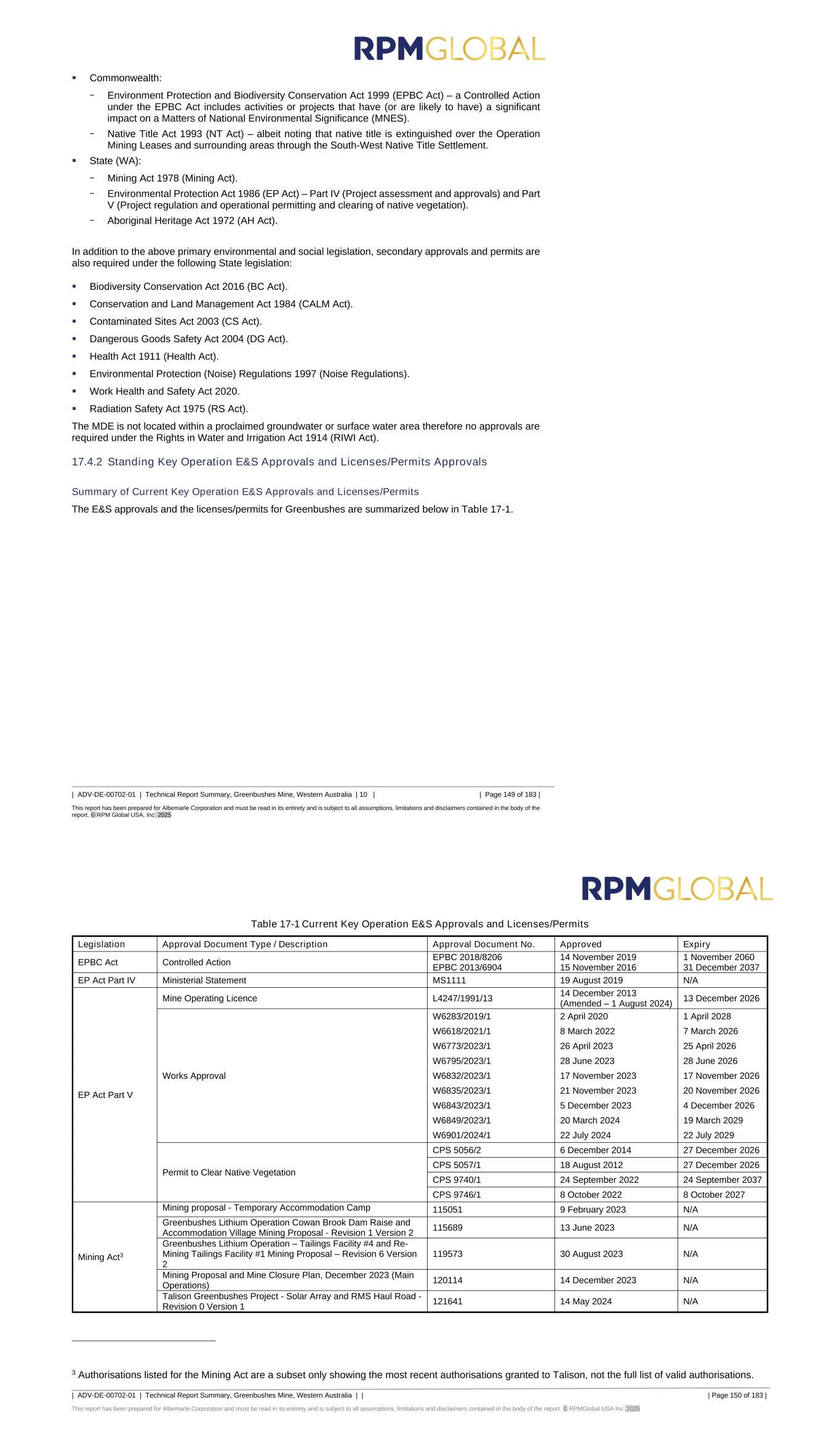

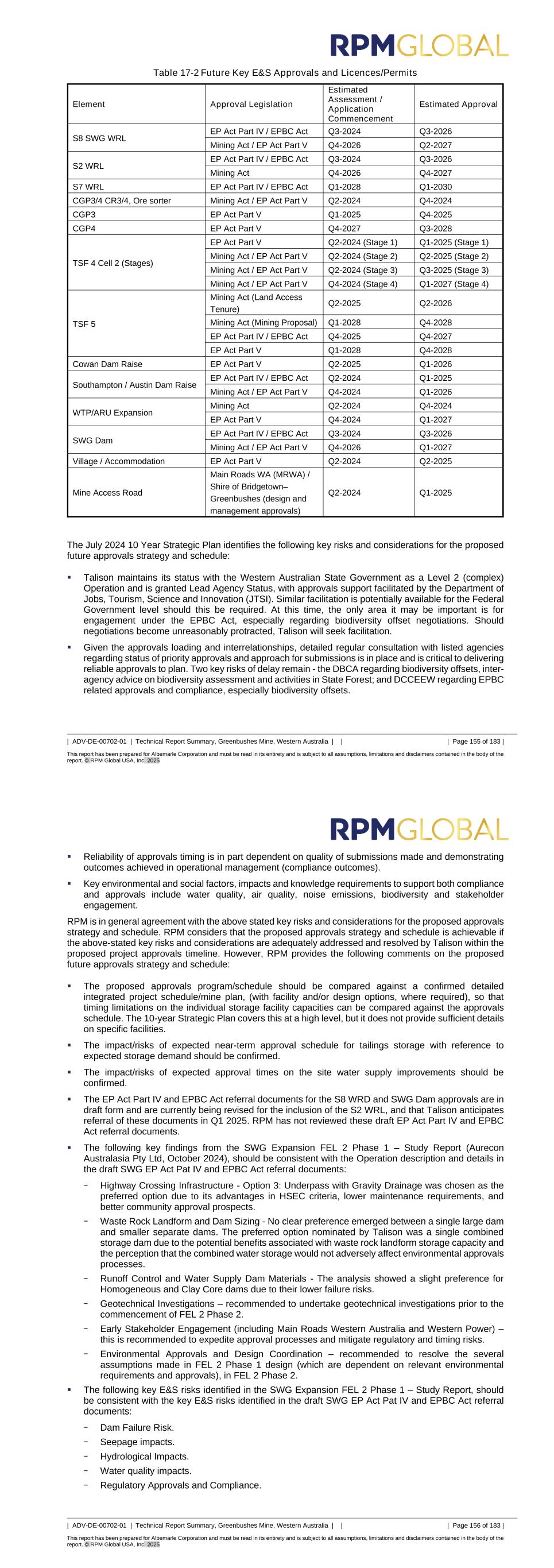

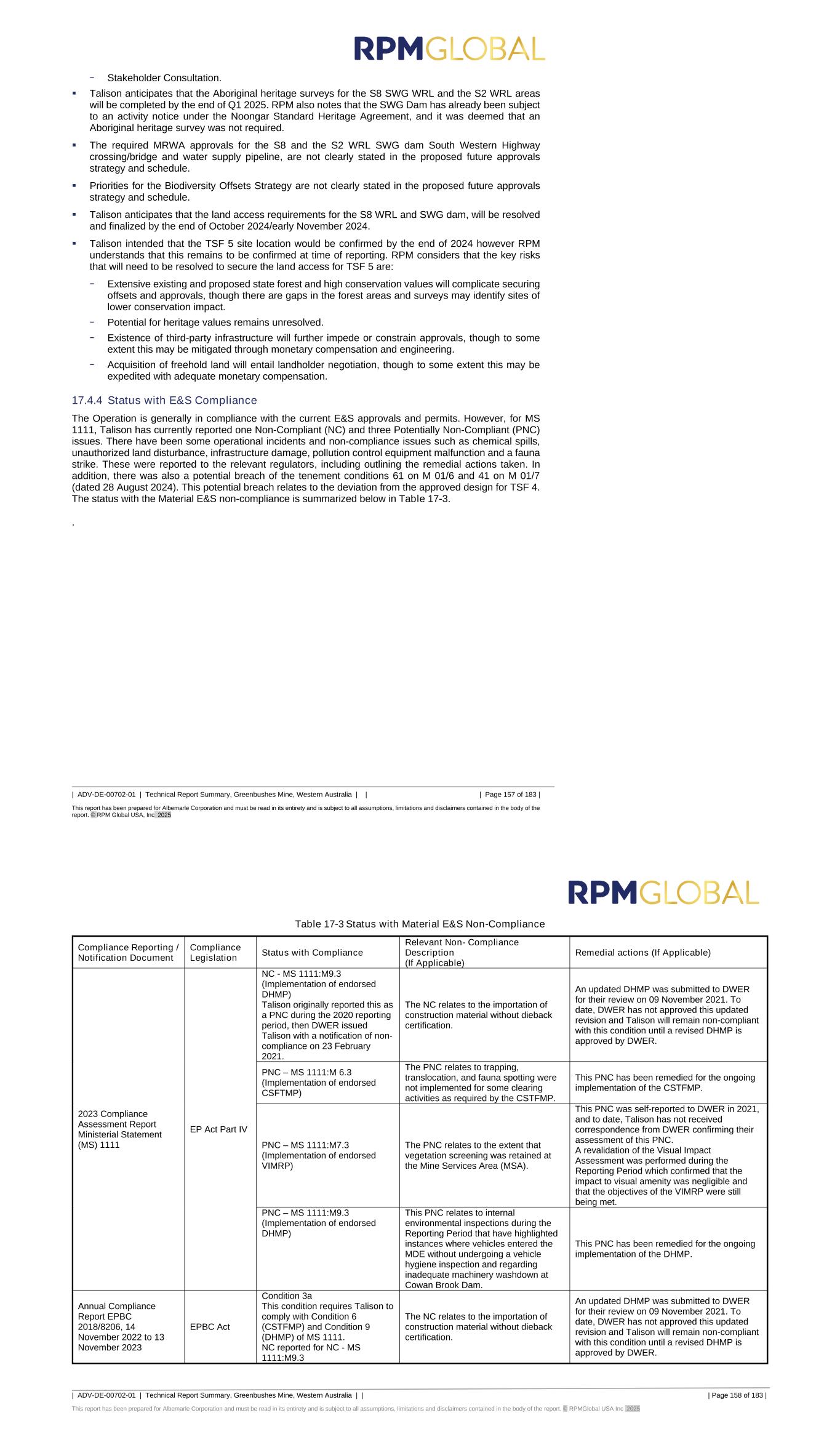

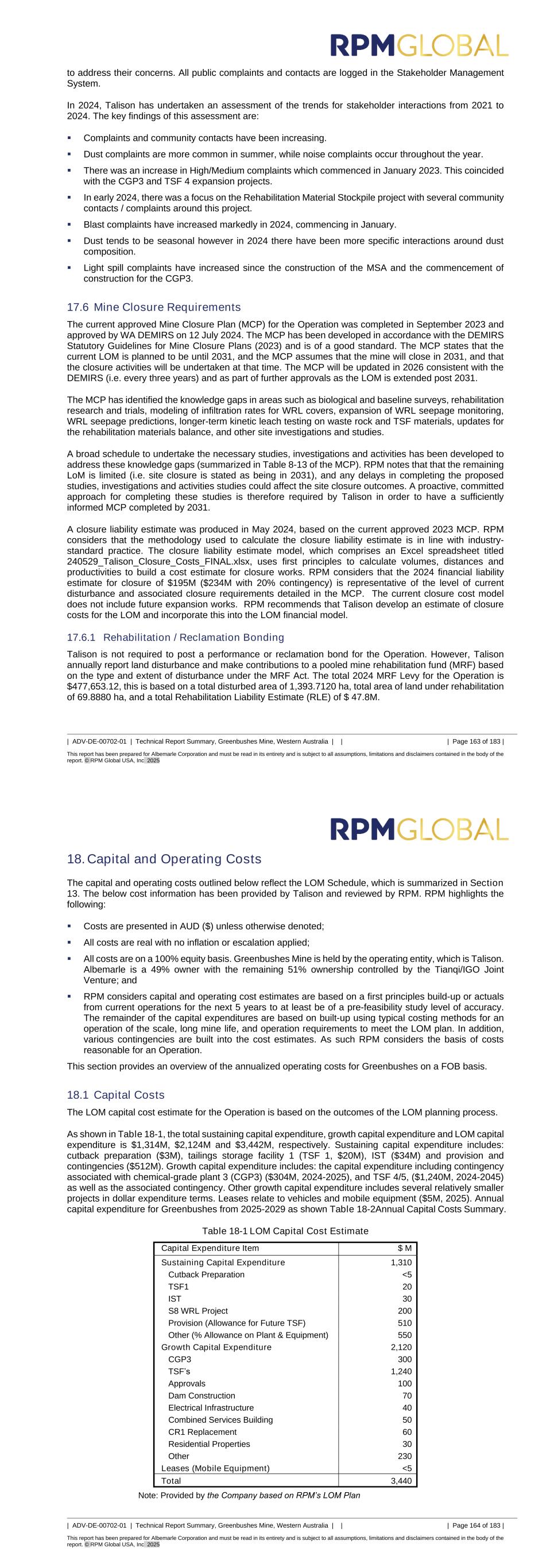

| ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | | | | Page iv of vii | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 22. INTERPRETATION AND CONCLUSIONS .................................................................................. 174 22.1 Geology ......................................................................................................................................... 174 22.2 Mining ............................................................................................................................................ 174 22.3 Processing ..................................................................................................................................... 174 22.4 Environmental, Social, and Governance ....................................................................................... 174 22.5 Water ............................................................................................................................................. 175 23. RECOMMENDATIONS ................................................................................................................. 176 23.1 Geology and Mineral Resources ................................................................................................... 176 23.2 Mining ............................................................................................................................................ 176 23.3 Processing ..................................................................................................................................... 176 23.4 Infrastructure ................................................................................................................................. 177 23.5 ESG ............................................................................................................................................... 177 23.6 Tailings Storage............................................................................................................................. 177 23.7 Water ............................................................................................................................................. 177 24. REFERENCES .............................................................................................................................. 178 25. RELIANCE ON INFORMATION PROVIDED BY REGISTRANT ................................................. 181 25.1 Macroeconomic Trends ................................................................................................................. 181 25.2 Marketing ....................................................................................................................................... 181 25.3 Legal Matters ................................................................................................................................. 181 25.4 Environmental Matters .................................................................................................................. 181 25.5 Stakeholder Accommodations ....................................................................................................... 181 25.6 Governmental Factors ................................................................................................................... 182 26. DATE AND SIGNATURE PAGE .................................................................................................. 183 | ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | | | | Page v of vii | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 LIST OF TABLES Table 1-1 Nameplate and LOM Plant Capacities .................................................................................... 3 Table 1-2 LOM Physicals ......................................................................................................................... 4 Table 1-3 Statement of Mineral Resources at 30 June 2024 .................................................................. 4 Table 1-4 Statement of Mineral Reserves as at 30 June 2024 ............................................................... 5 Table 1-5 Summary of Capital Costs ....................................................................................................... 8 Table 1-6 Summary of Economic Evaluation ........................................................................................... 8 Table 2-1 Site Visit Summary ................................................................................................................ 11 Table 2-2 List of Abbreviations .............................................................................................................. 12 Table 3-1 Greenbushes Mine Land Tenure ........................................................................................... 21 Table 7-1 Lode Resource Drilling Summary .......................................................................................... 38 Table 8-1 Central Lode Density Statistics .............................................................................................. 43 Table 8-2 Summary of CRM Submissions for Li2O ............................................................................... 44 Table 10-1 Greenbushes Mineralogical Report Summary .................................................................. 49 Table 10-2 Greenbushes Metallurgical Testwork Summary ................................................................ 50 Table 11-1 Statement of Mineral Resources at 30 June 2024 ............................................................ 52 Table 11-2 Mineral Resources Marginal Cut-off Grade Assumptions ................................................. 53 Table 11-3 Interpreted Variogram Models ........................................................................................... 60 Table 11-4 Block Model Size and Extents ........................................................................................... 63 Table 11-5 Bulk Density Assigned ....................................................................................................... 64 Table 11-6 Global Statistical Comparison of Grades of Blocks and Composites by Domain ............. 68 Table 11-7 Comparison with Previous Mineral Resources Estimates ................................................. 71 Table 12-1 Statement of Mineral Reserves as at 30 June 2024 ......................................................... 73 Table 12-2 Pit Optimization Parameters .............................................................................................. 75 Table 12-3 Pit Design Parameters ....................................................................................................... 77 Table 12-4 Ramp and Pit Standoff Parameters ................................................................................... 77 Table 12-5 Mineral Reserves Mass Yield ............................................................................................ 79 Table 12-6 LOM Plant Feed Yield ........................................................................................................ 79 Table 12-7 Reserves Marginal Cut-off Grade Assumptions ................................................................ 79 Table 12-8 Comparison with Previous Mineral Reserve Estimates ..................................................... 80 Table 13-1 Waste Dump Capacity ....................................................................................................... 86 Table 13-2 LOM Physicals ................................................................................................................... 89 Table 13-3 LOM Schedule as at 30 June 2024 ................................................................................... 90 Table 13-4 Major Production Mine Fleet .............................................................................................. 91 Table 13-5 Major Mining Fleet Summary ............................................................................................. 91 Table 14-1 Nameplate and LOM Plant Capacities .............................................................................. 92 Table 17-1 Current Key Operation E&S Approvals and Licenses/Permits ........................................ 150 Table 17-2 Future Key E&S Approvals and Licences/Permits .......................................................... 155 Table 17-3 Status with Material E&S Non-Compliance ..................................................................... 158 Table 18-1 LOM Capital Cost Estimate ............................................................................................. 164 Table 18-2 Annual Capital Costs Summary ....................................................................................... 165 Table 18-3 Annual Operating Costs Summary .................................................................................. 166 Table 18-4 LOM Opex Excluding Royalties ....................................................................................... 166 Table 18-5 LOM Average Annual Cost Excluding Distribution .......................................................... 167 Table 19-1 Summary of Economic Evaluation ................................................................................... 169 Table 19-2 Annual Cashflow .............................................................................................................. 170 Table 19-3 Sensitivities Applied to NPV Sensitivity Analysis ............................................................ 171

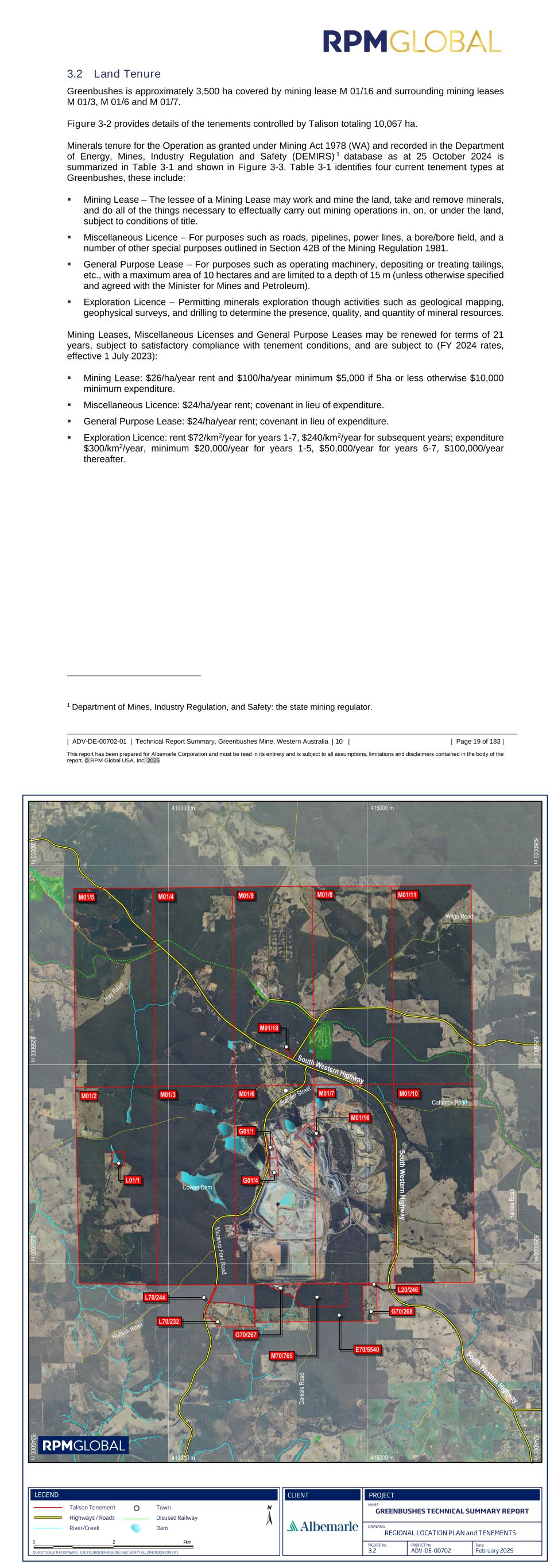

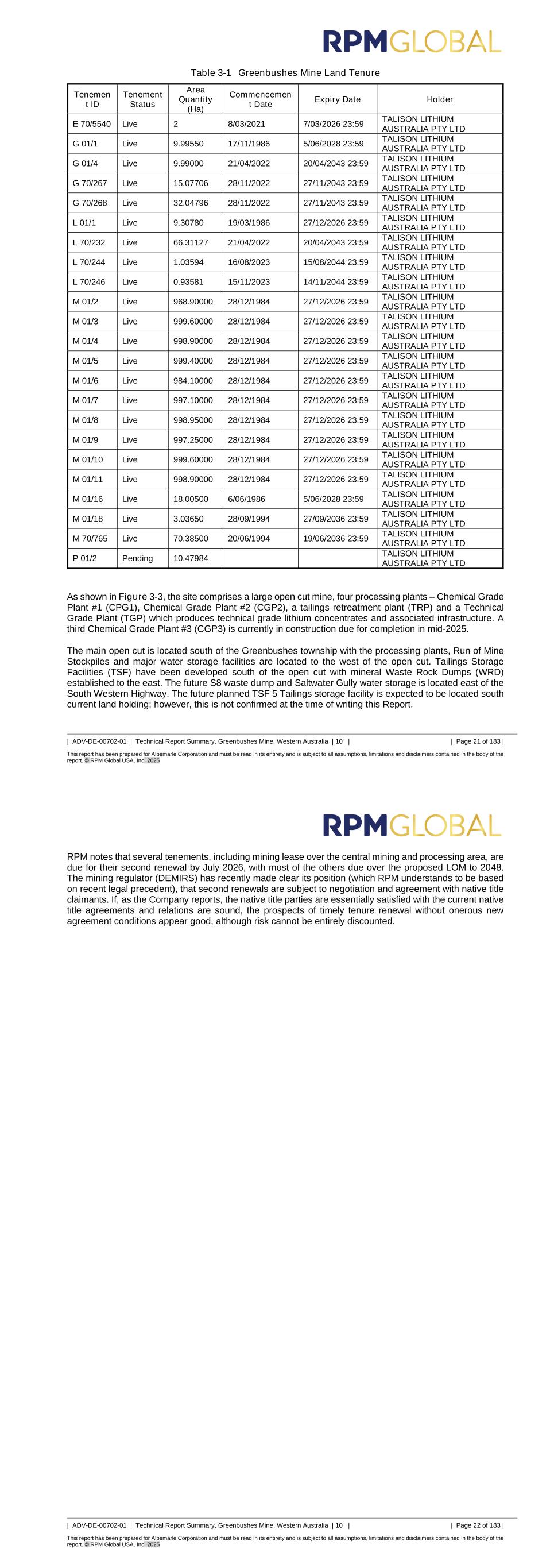

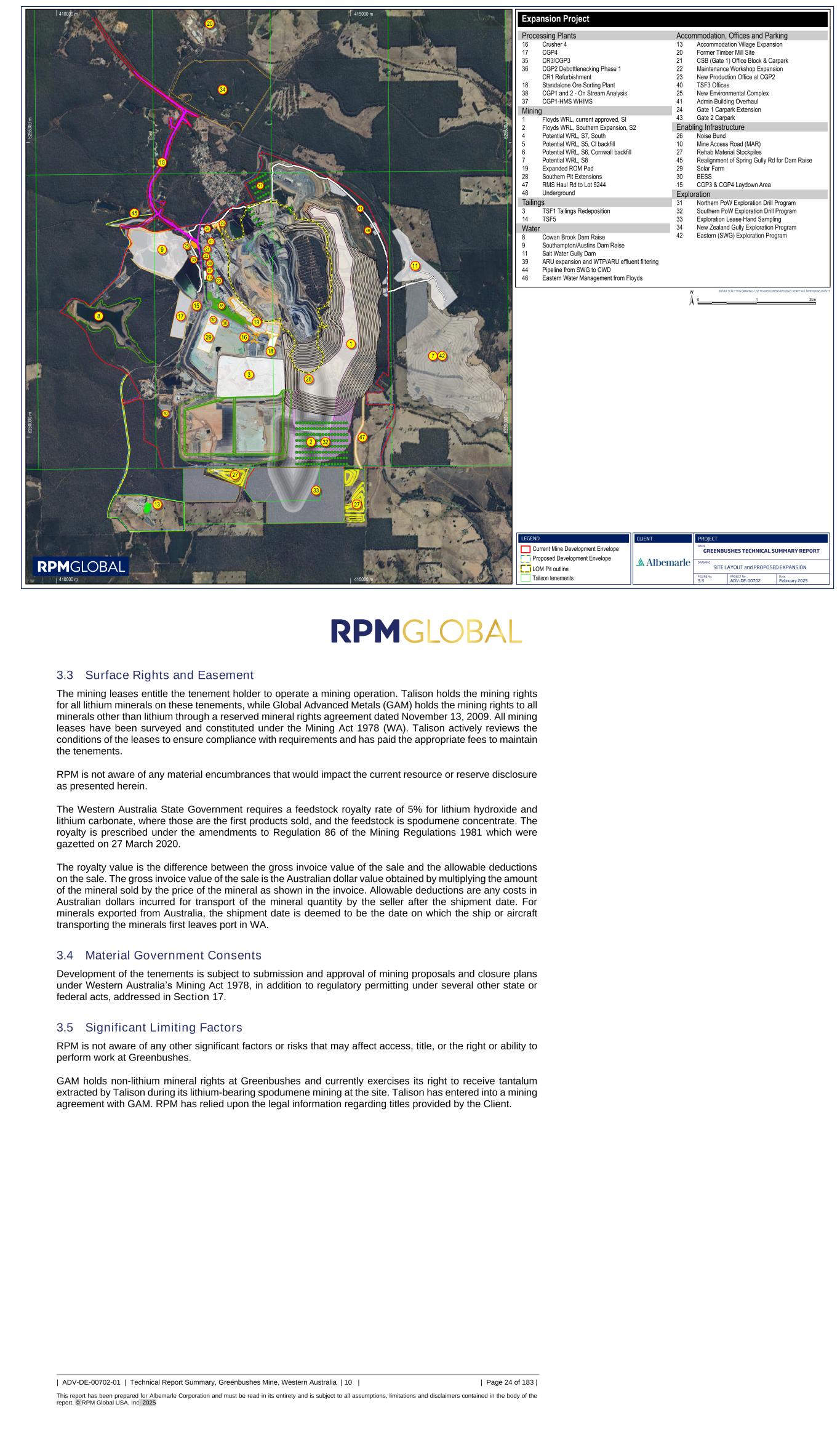

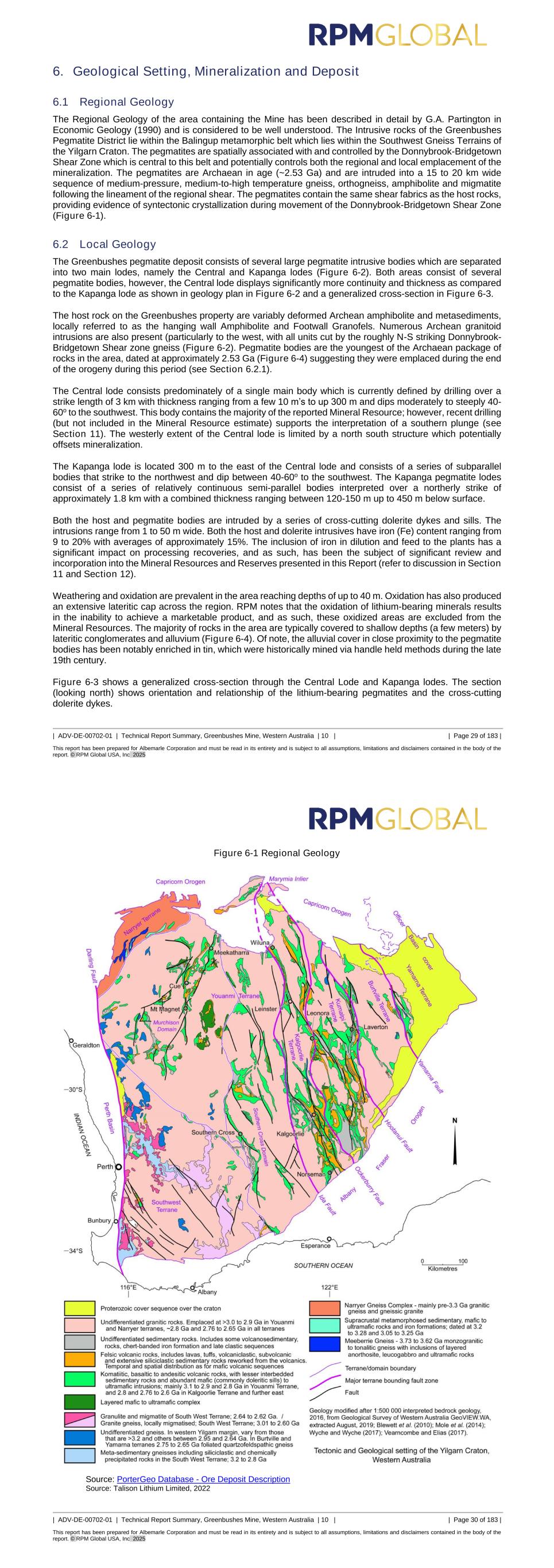

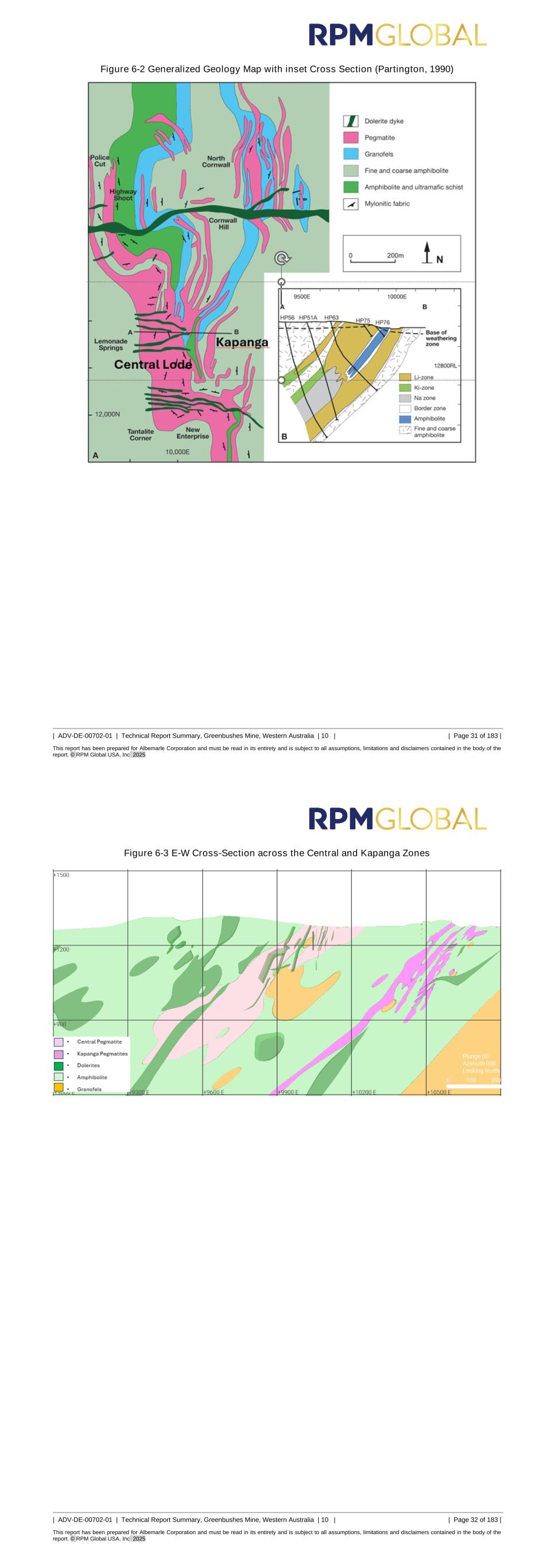

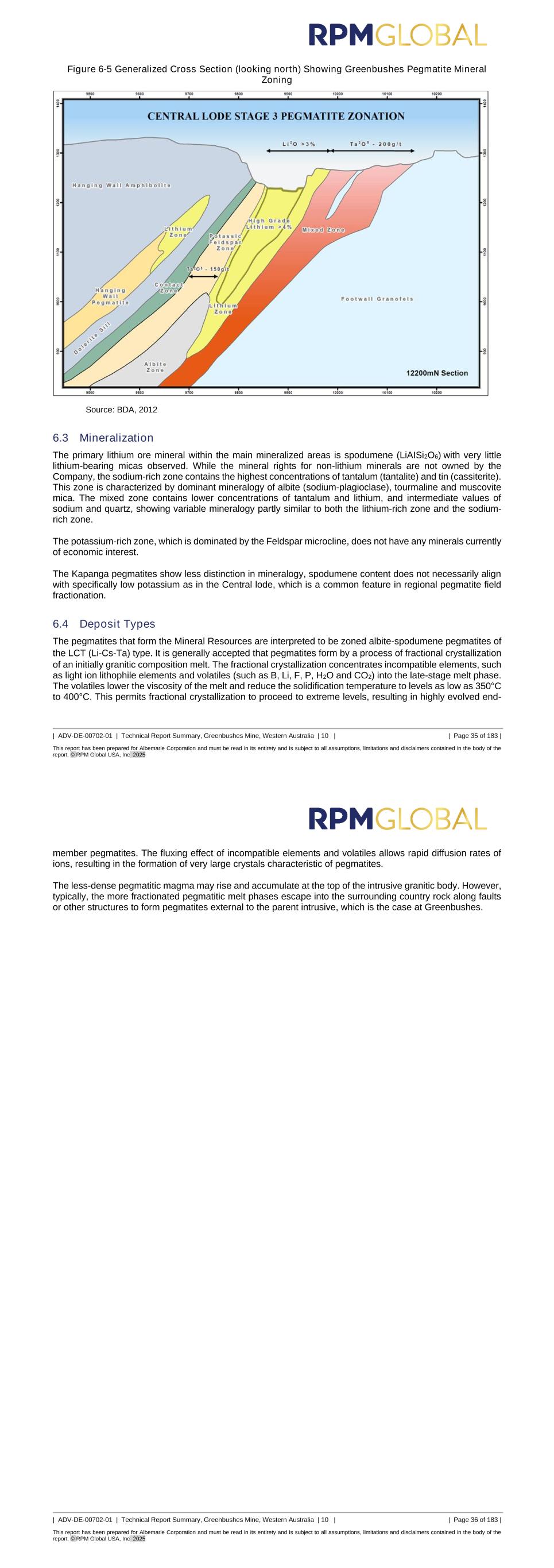

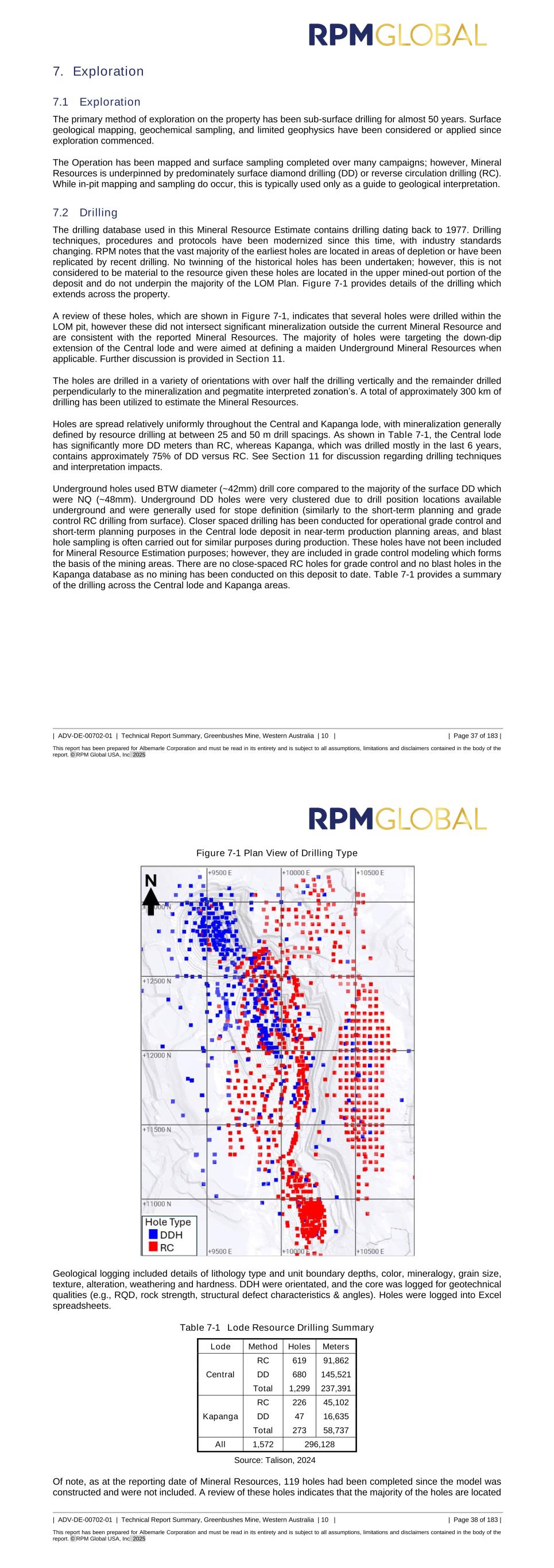

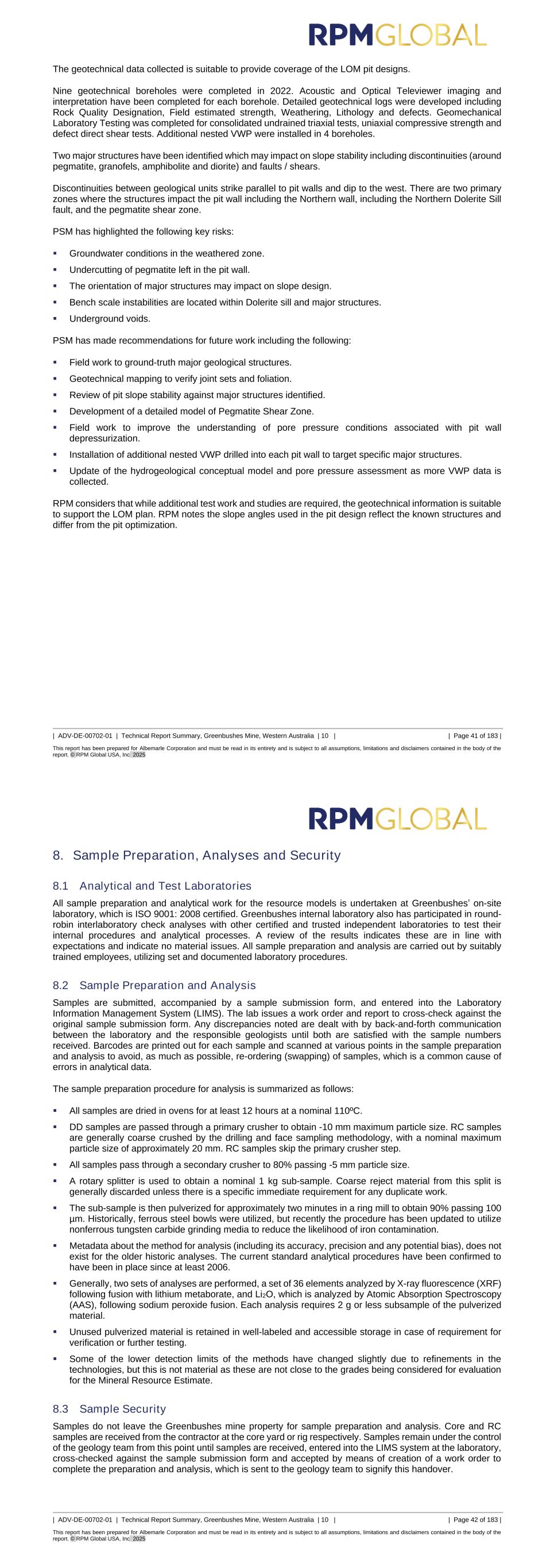

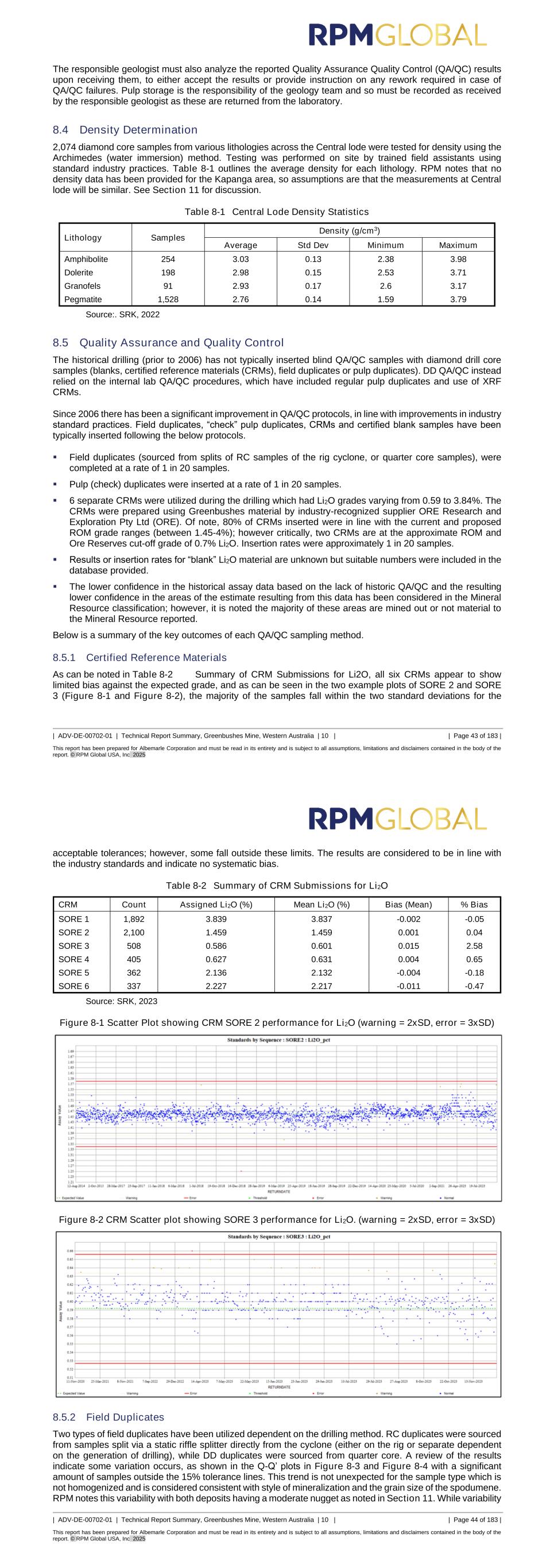

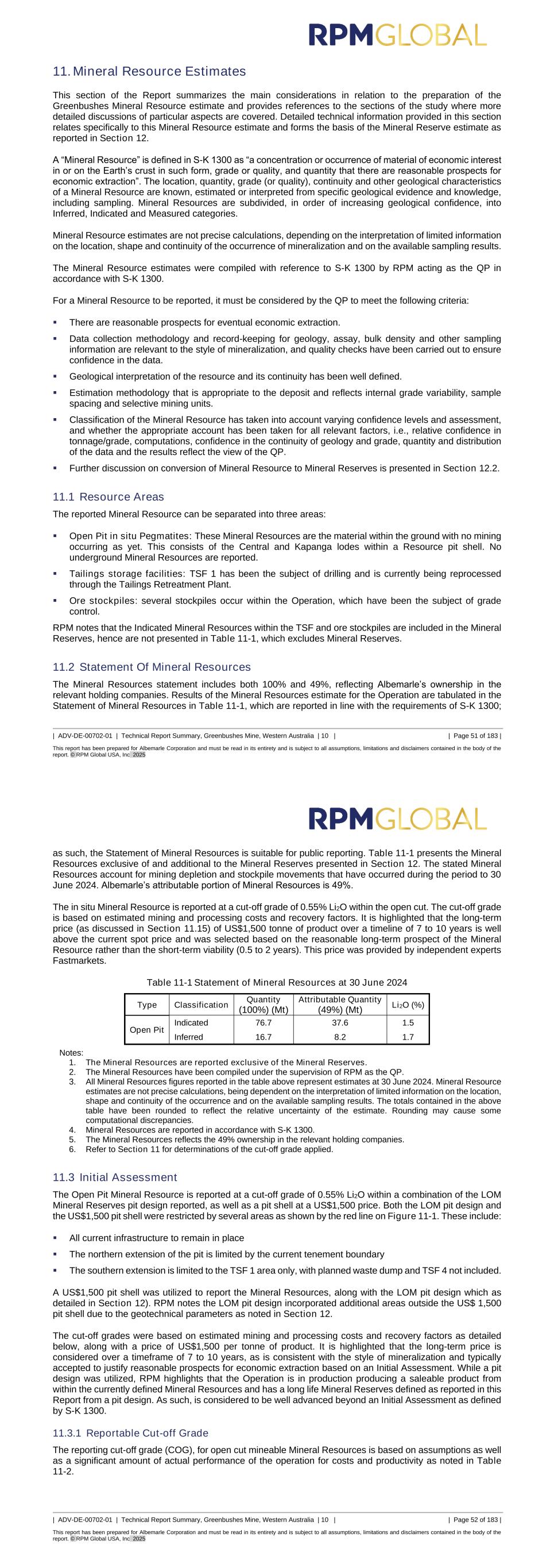

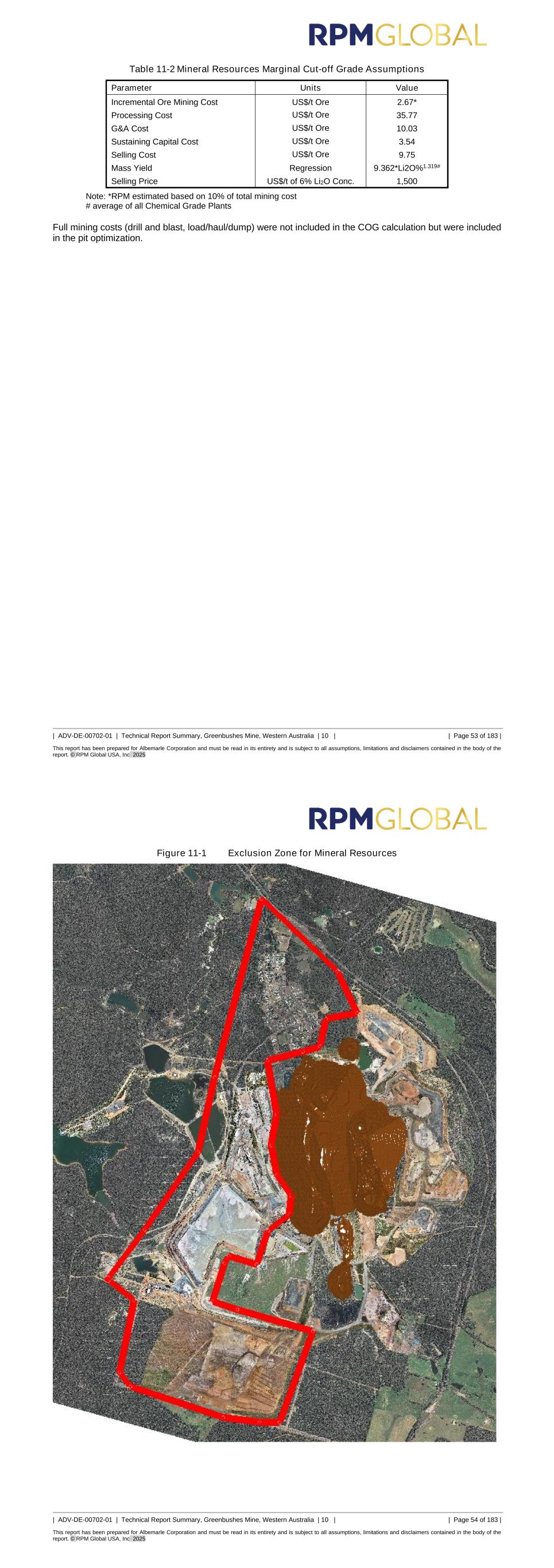

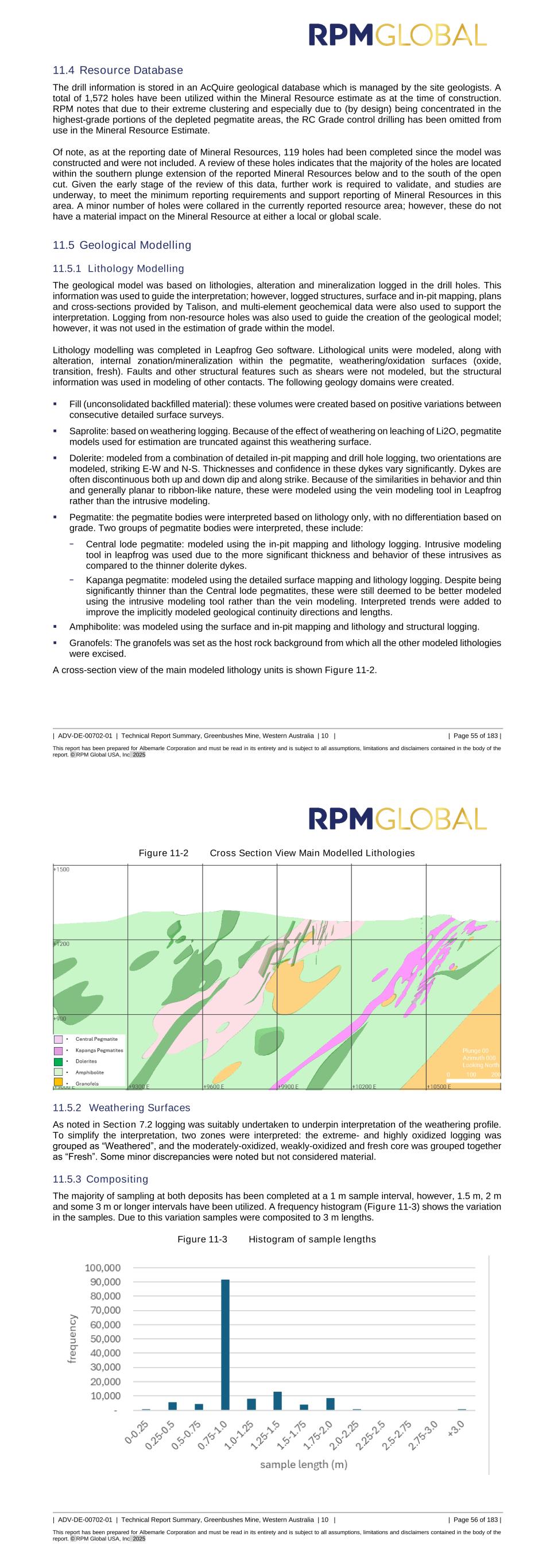

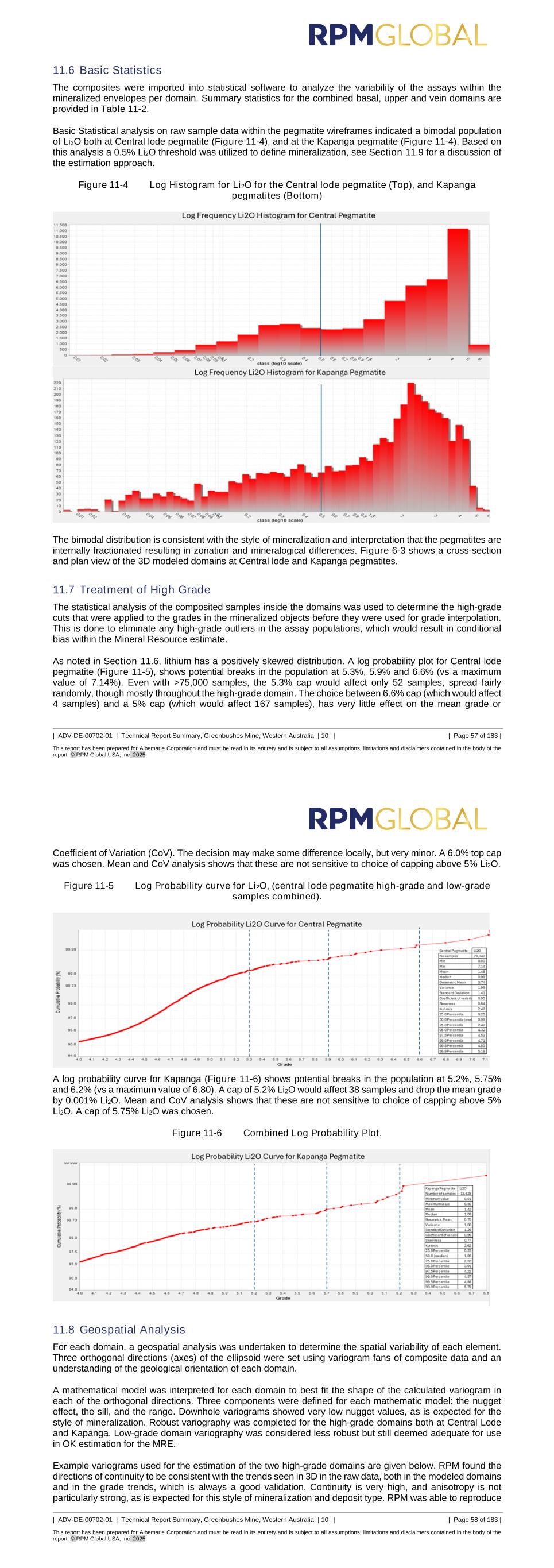

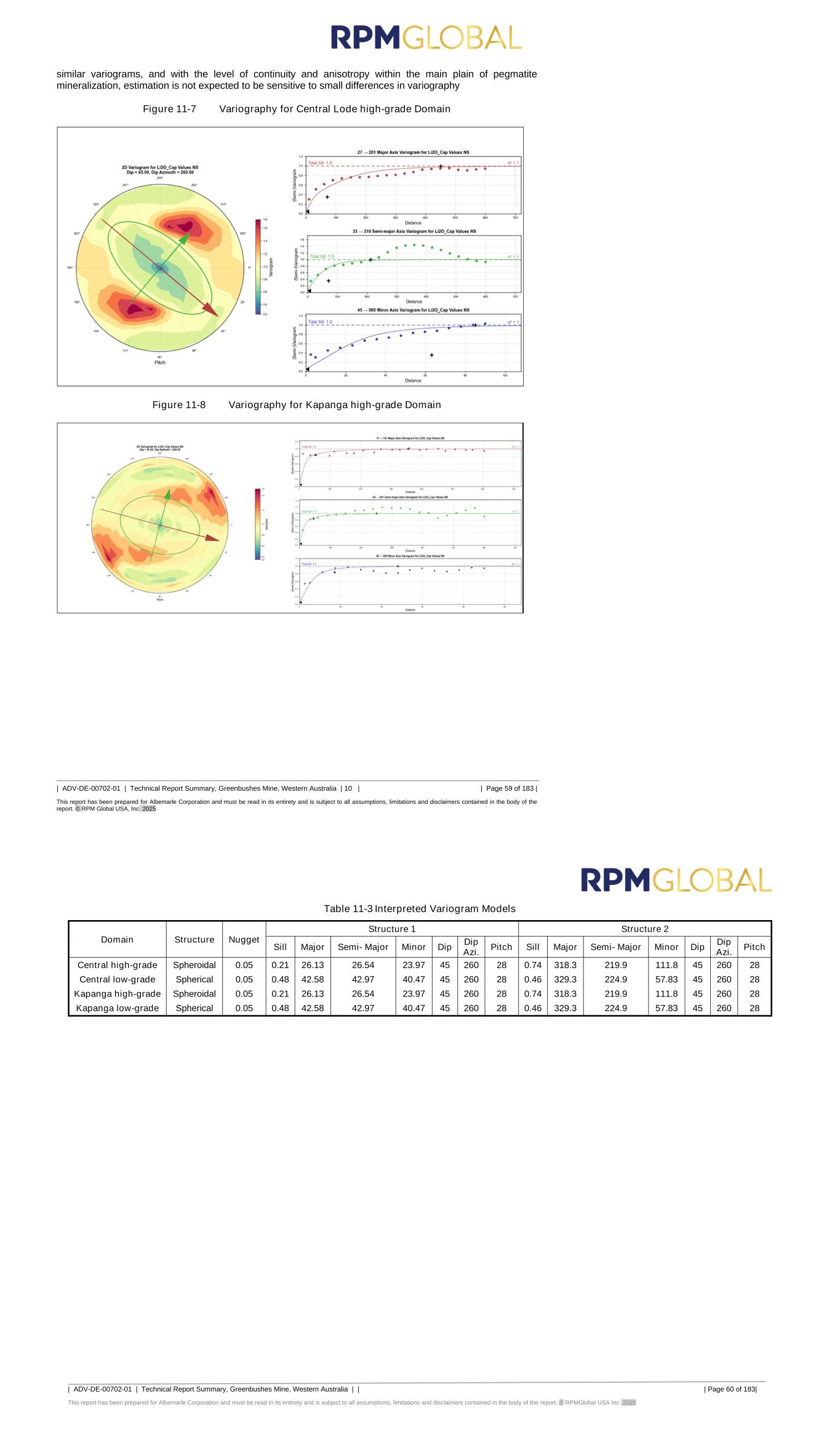

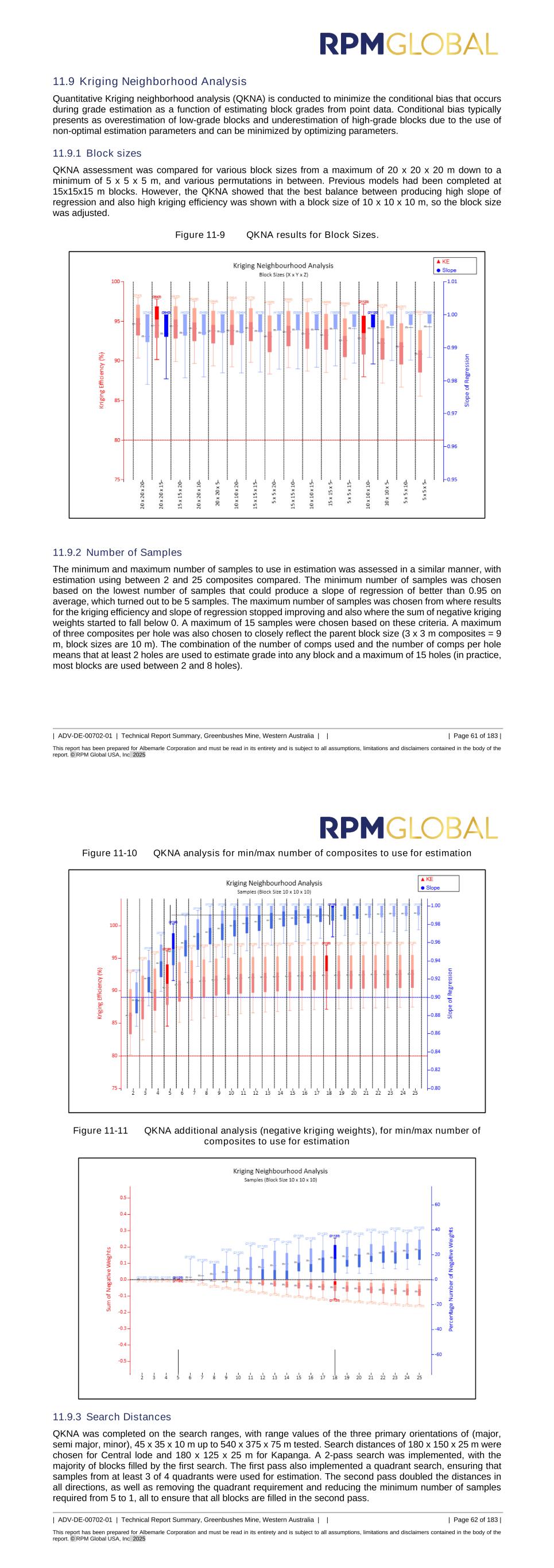

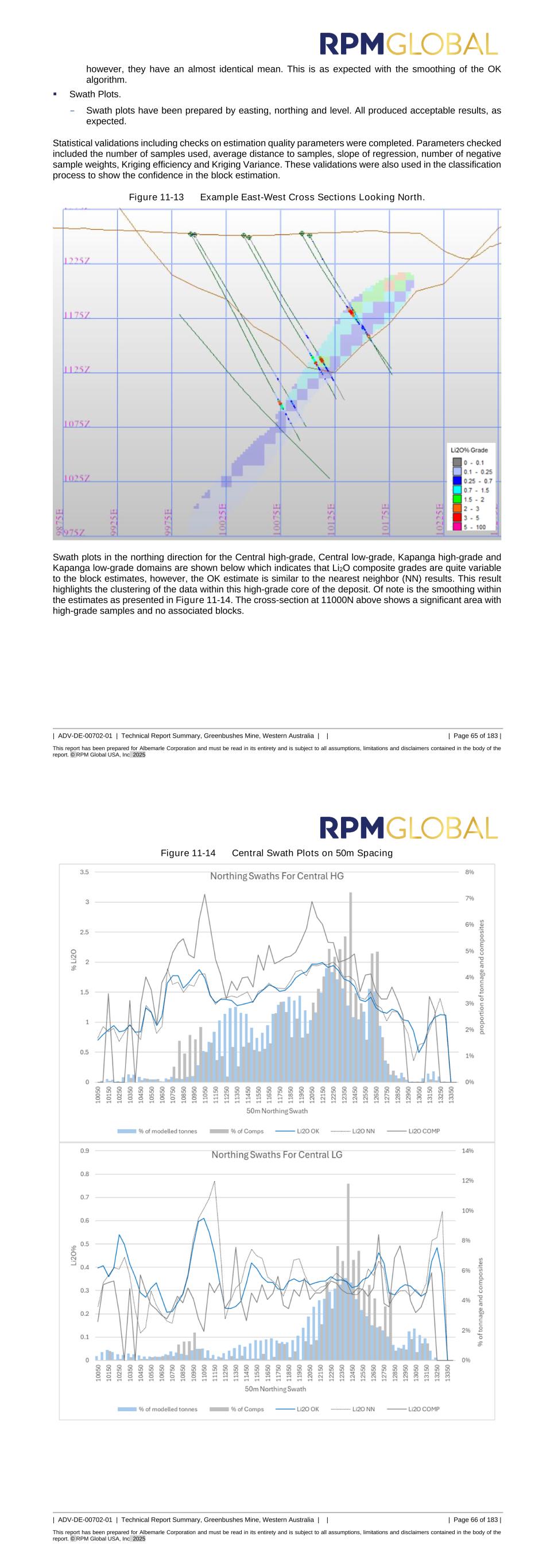

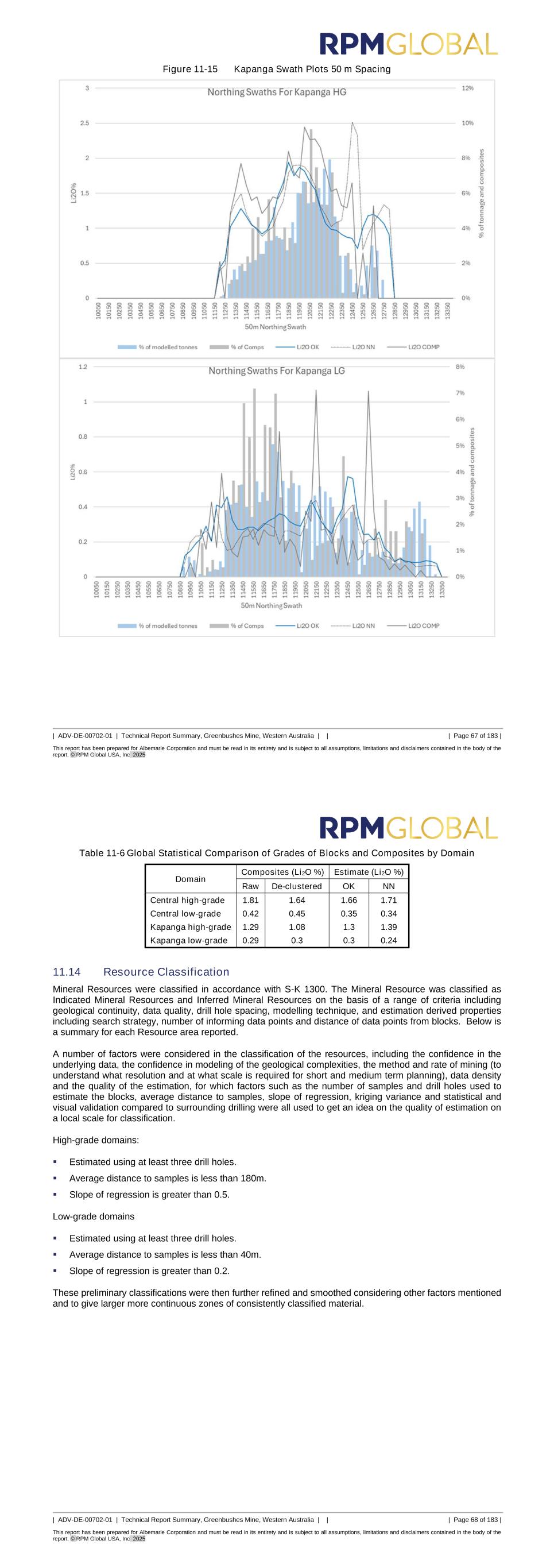

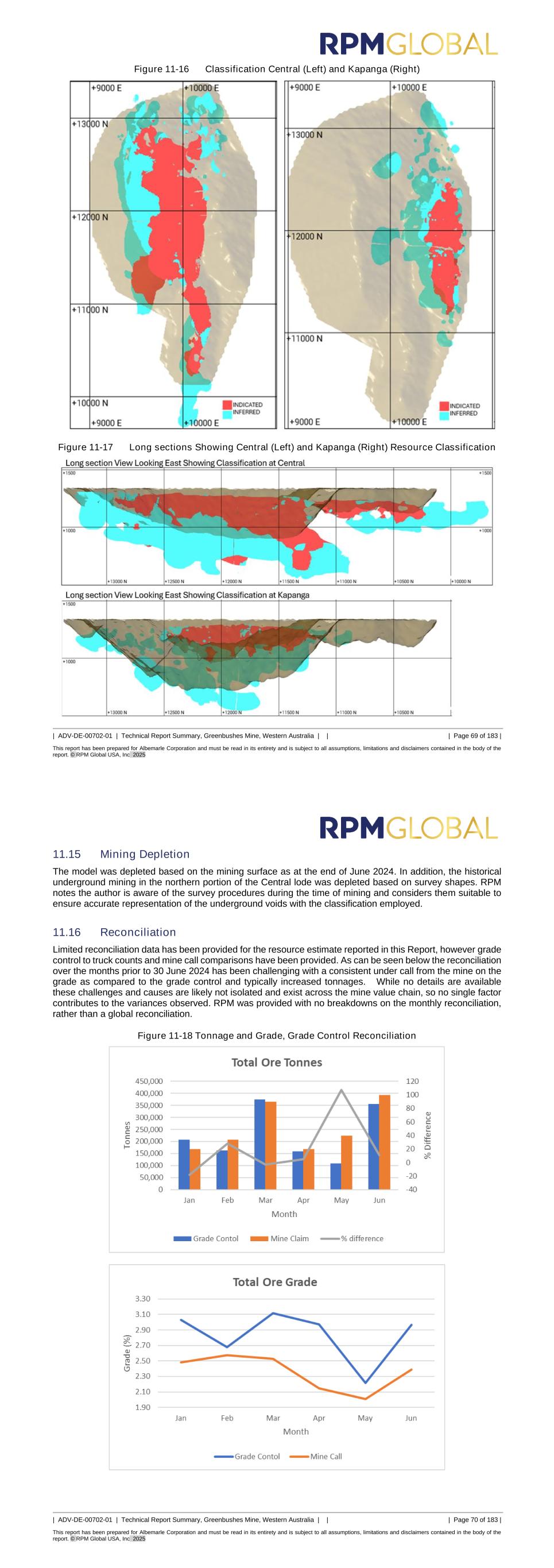

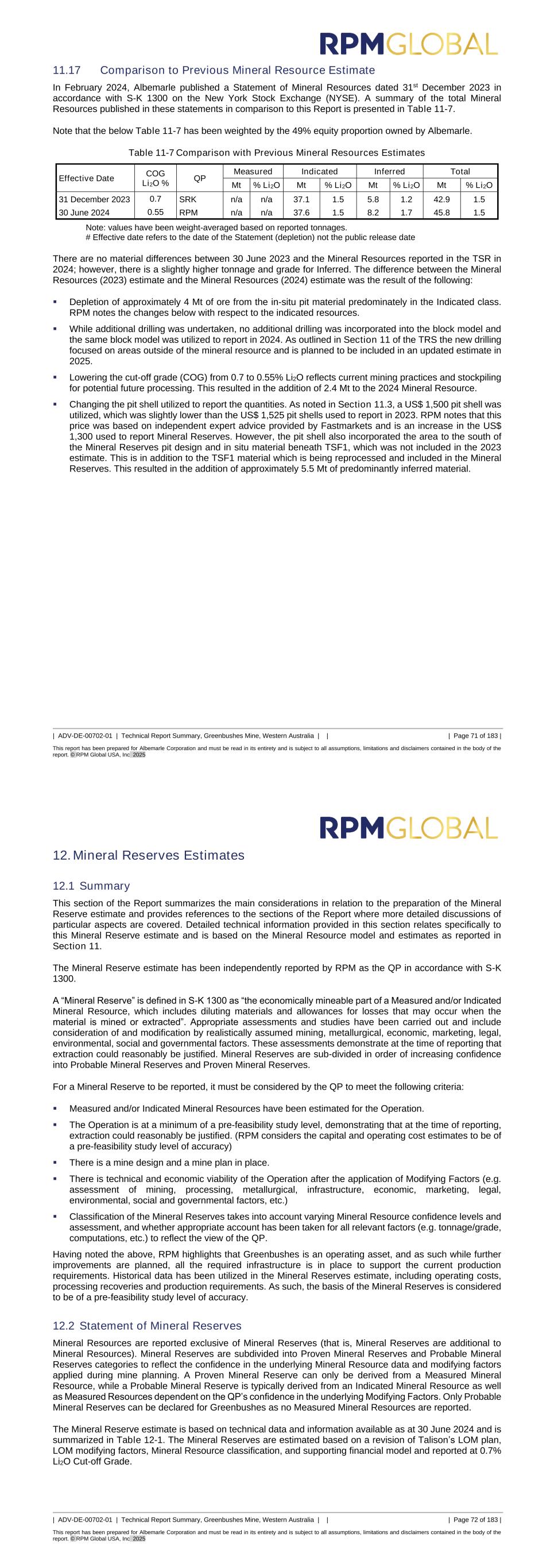

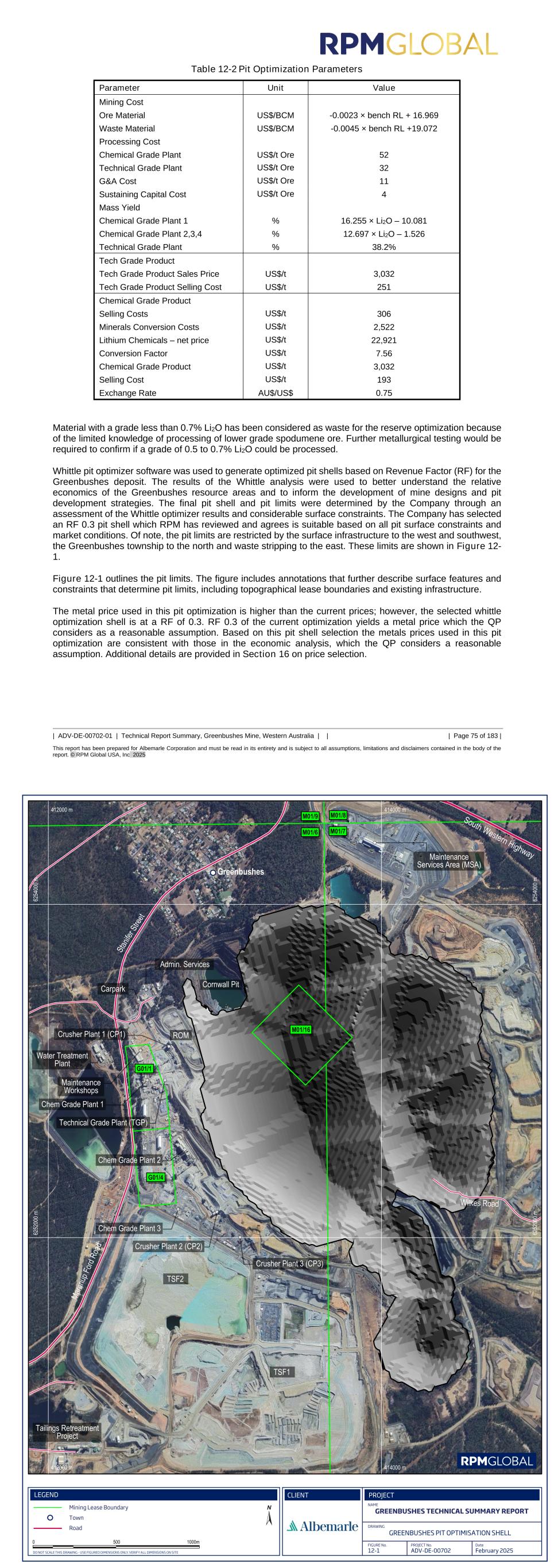

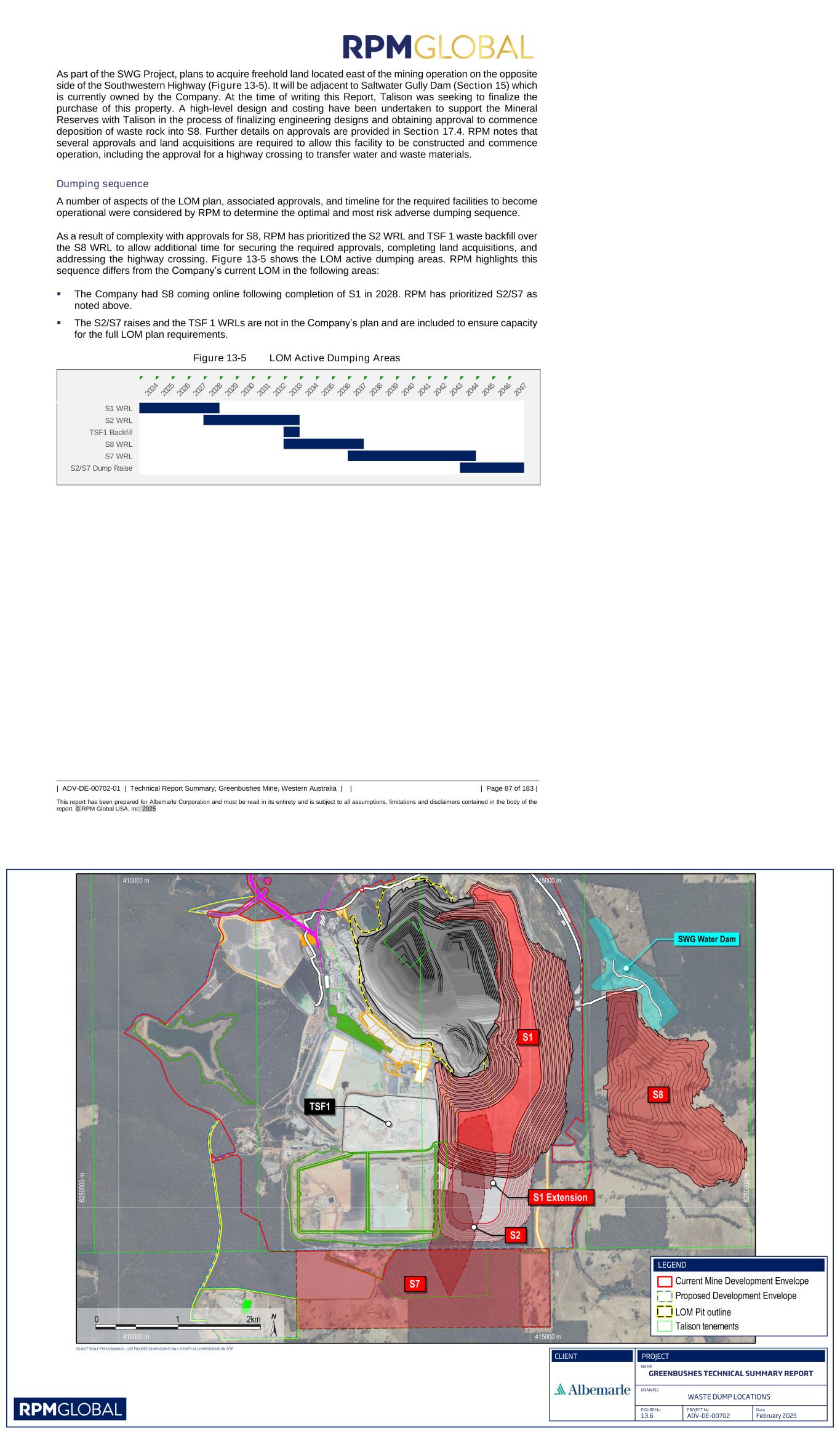

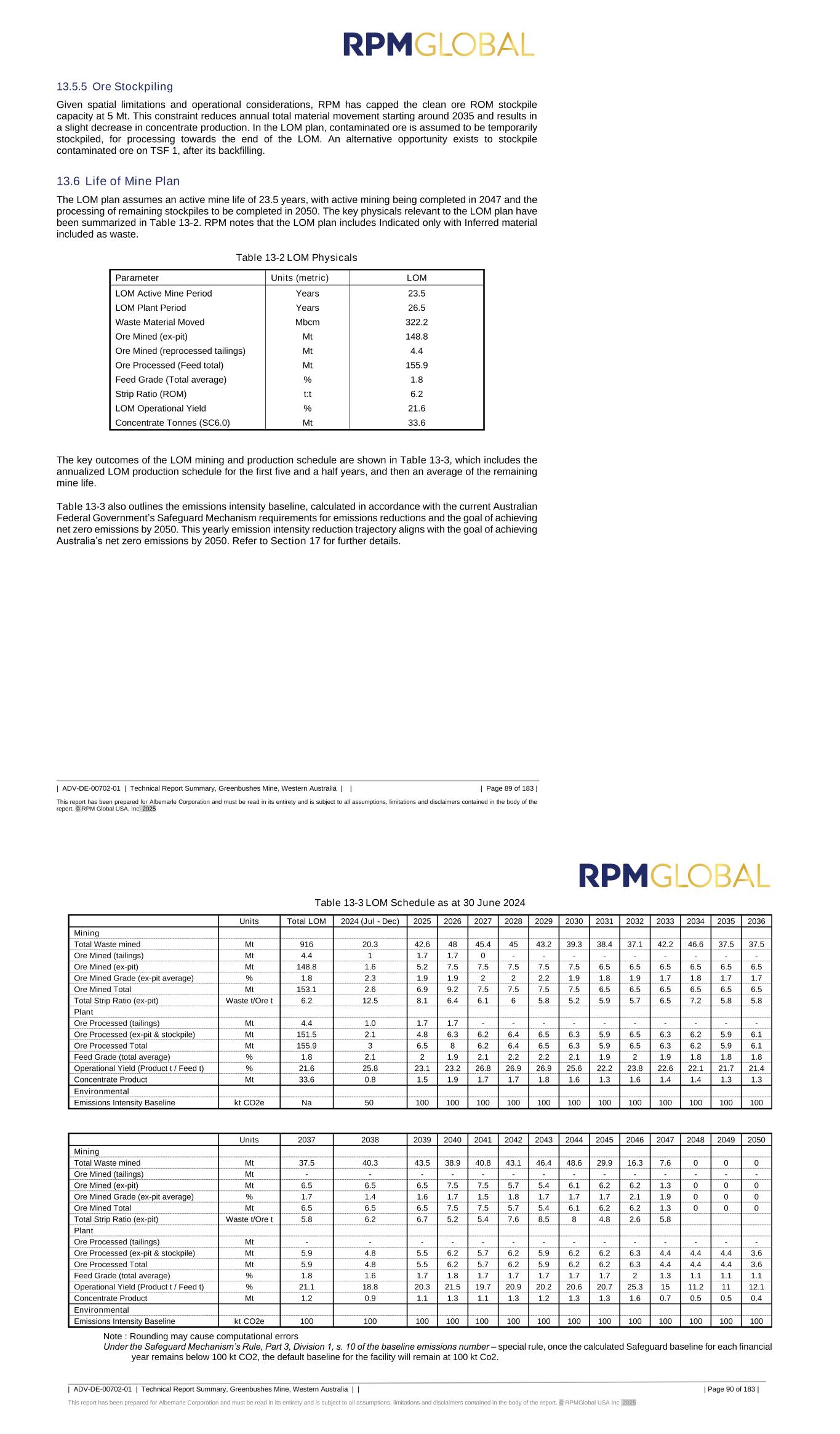

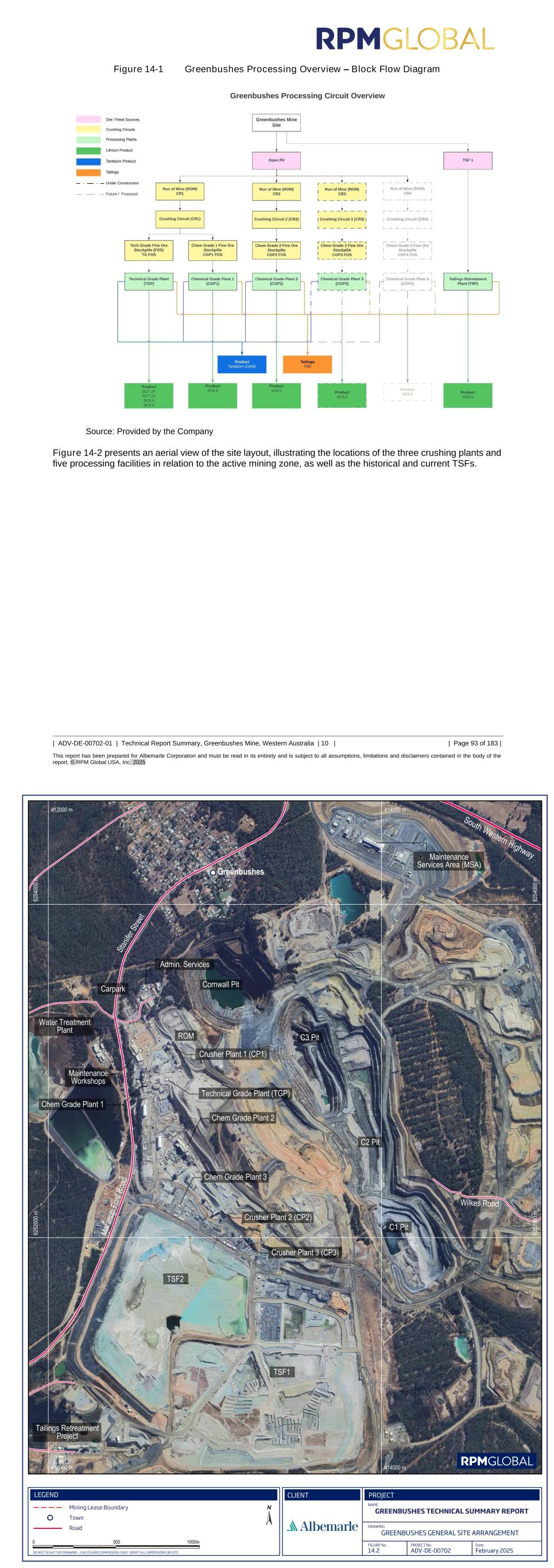

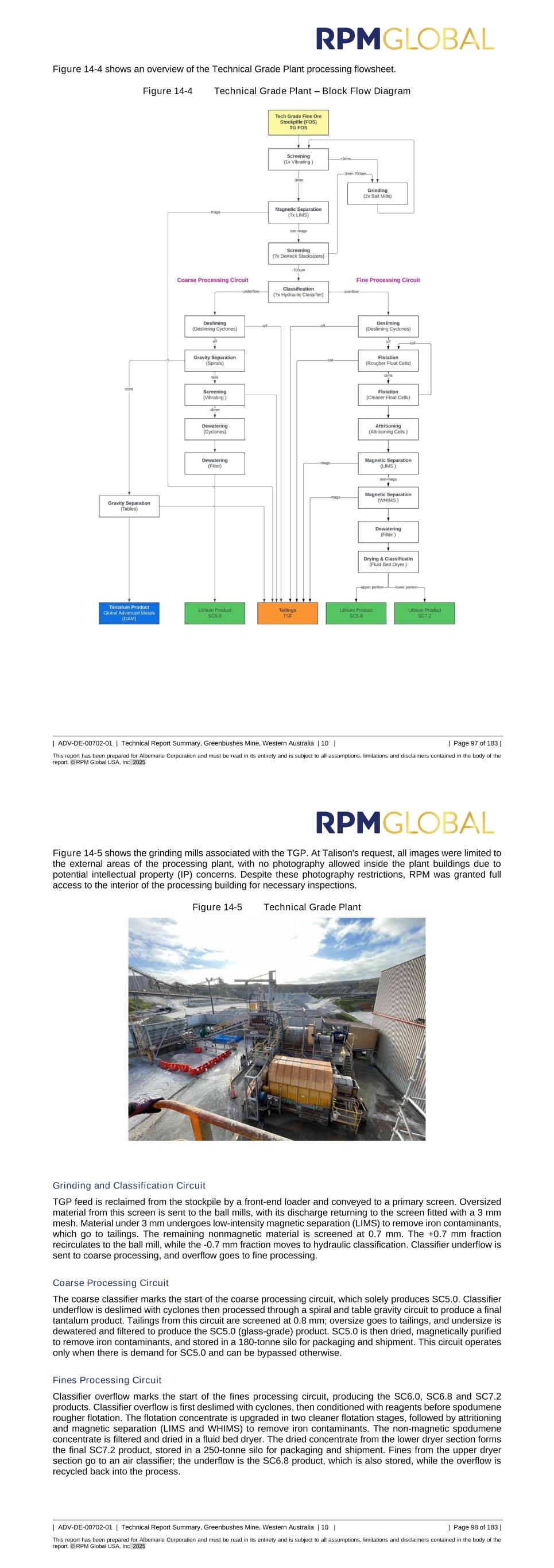

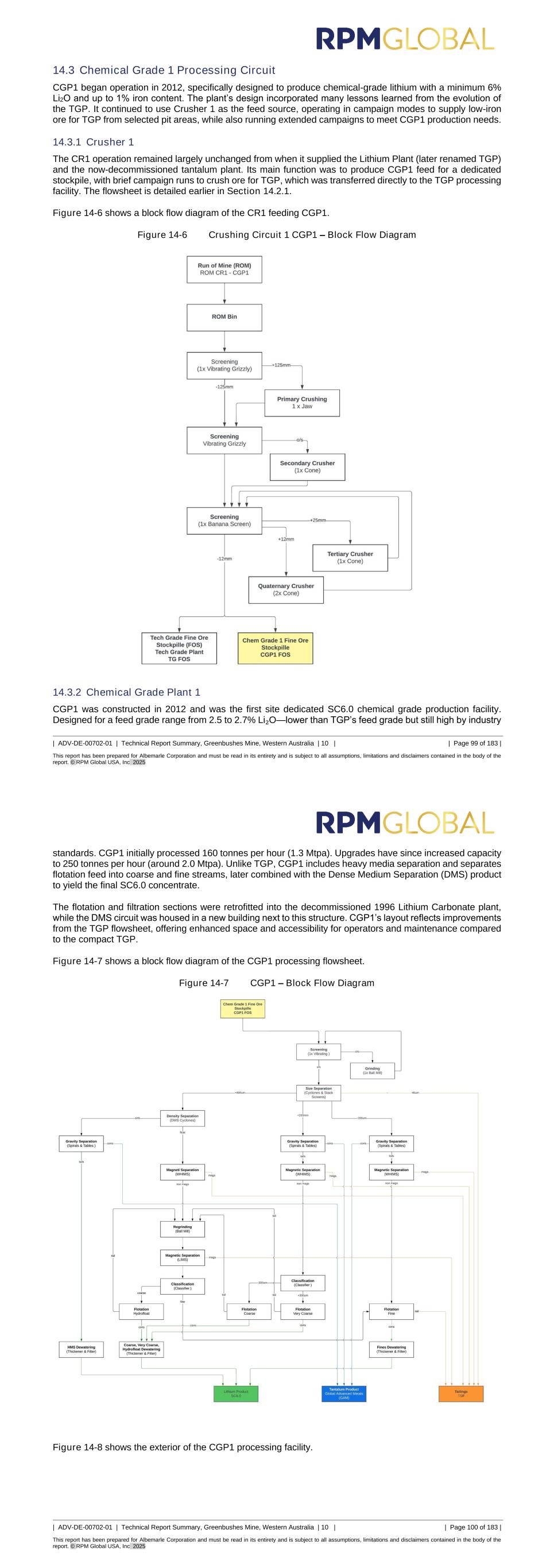

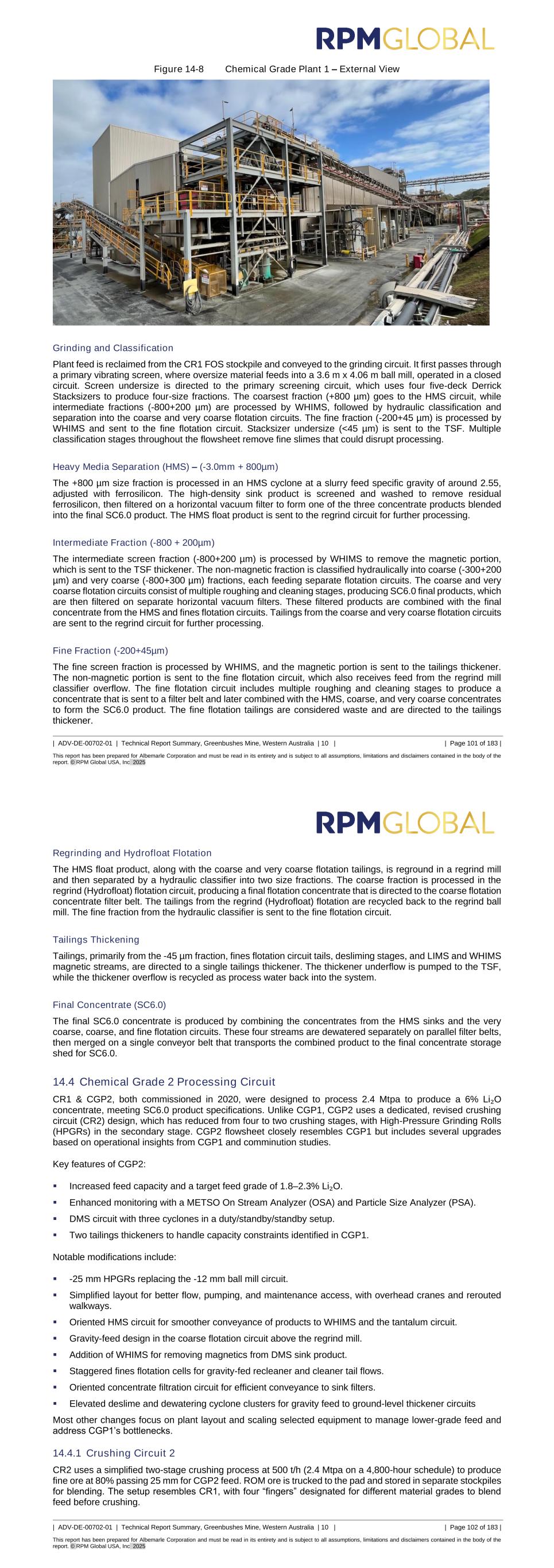

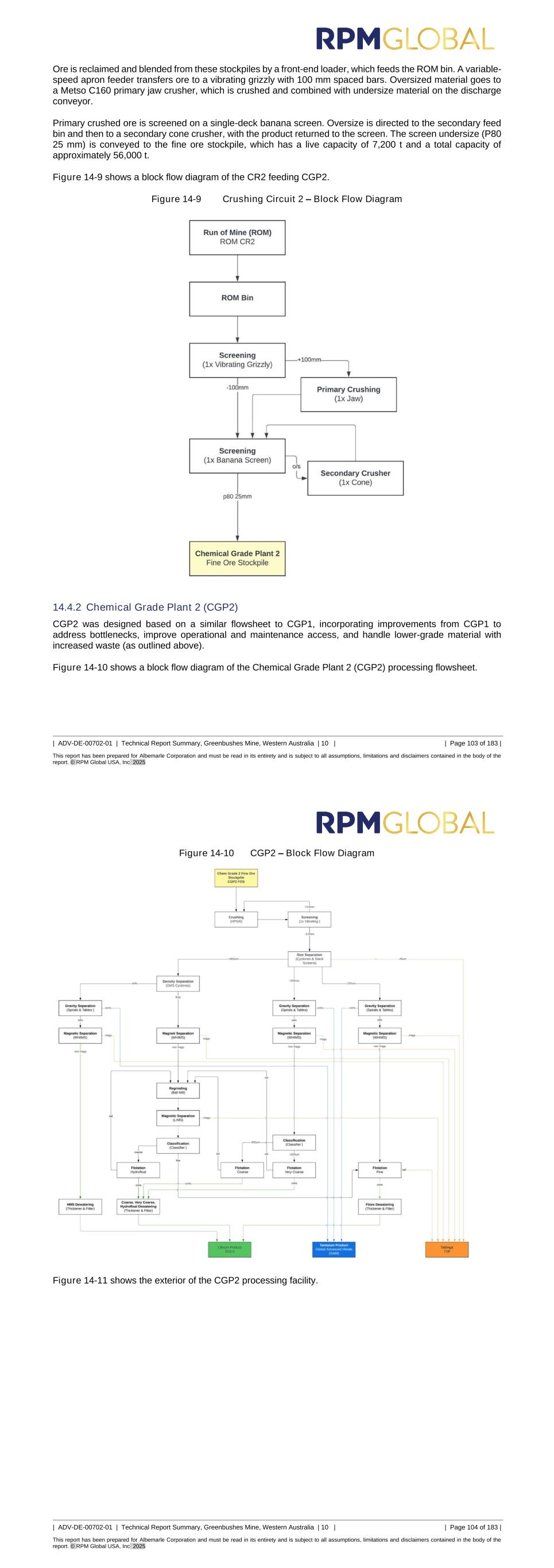

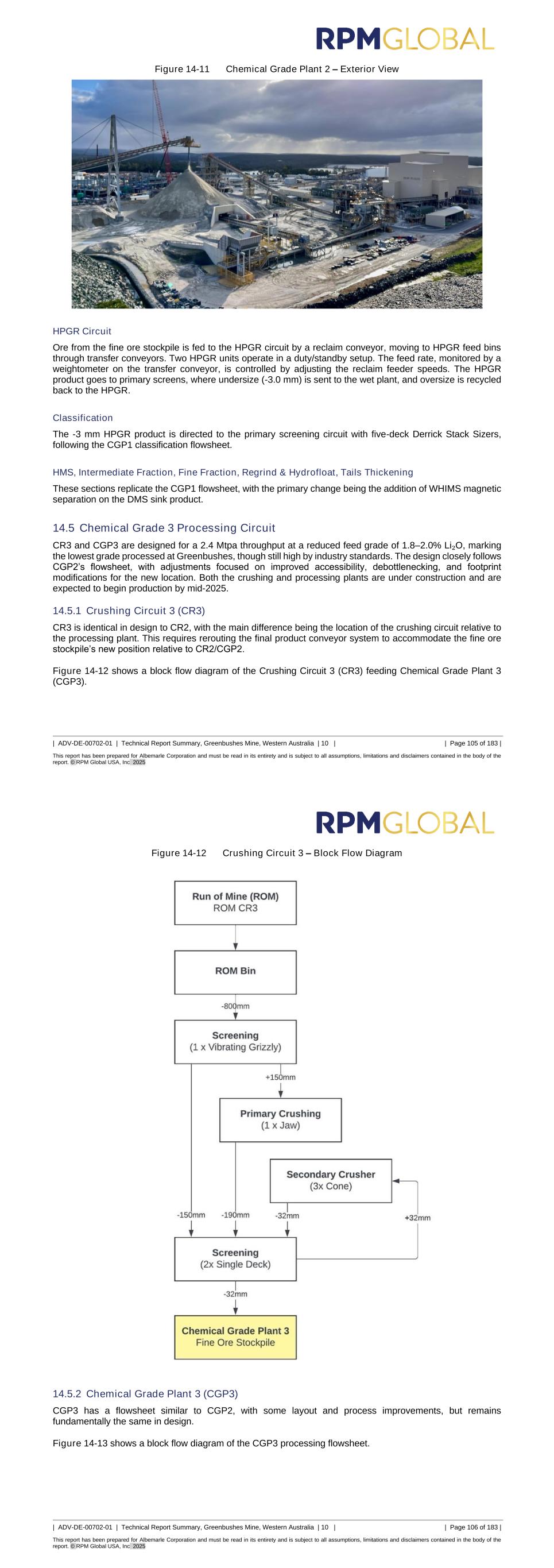

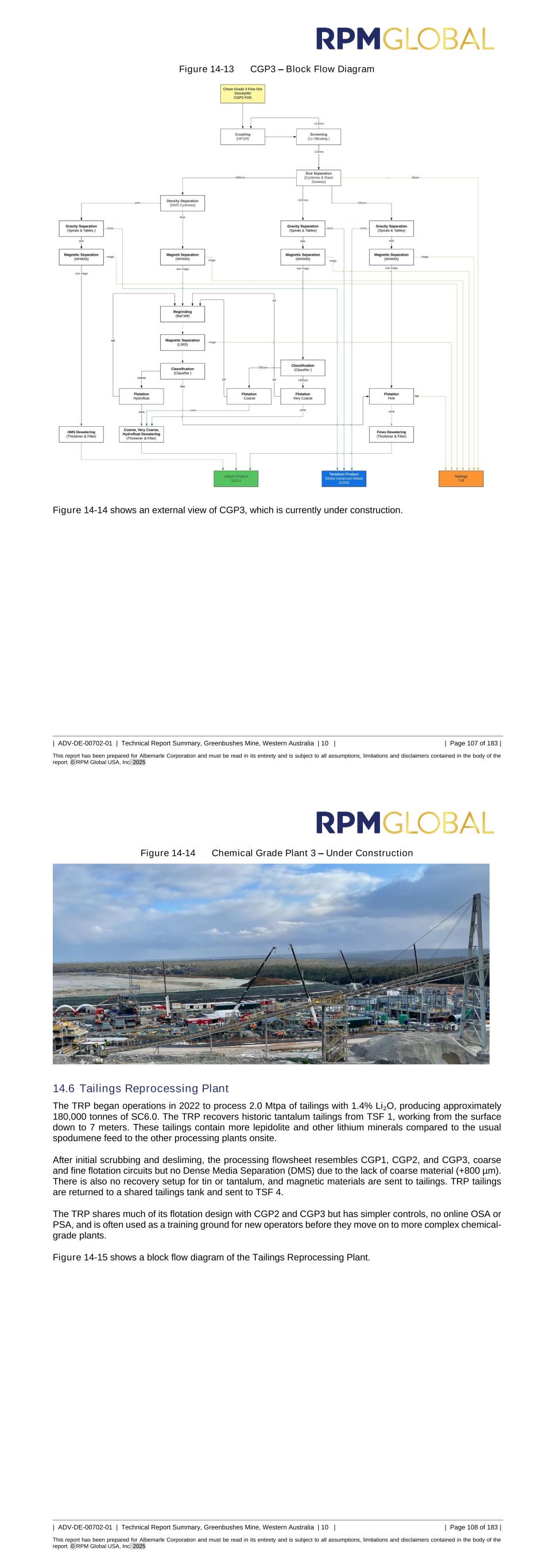

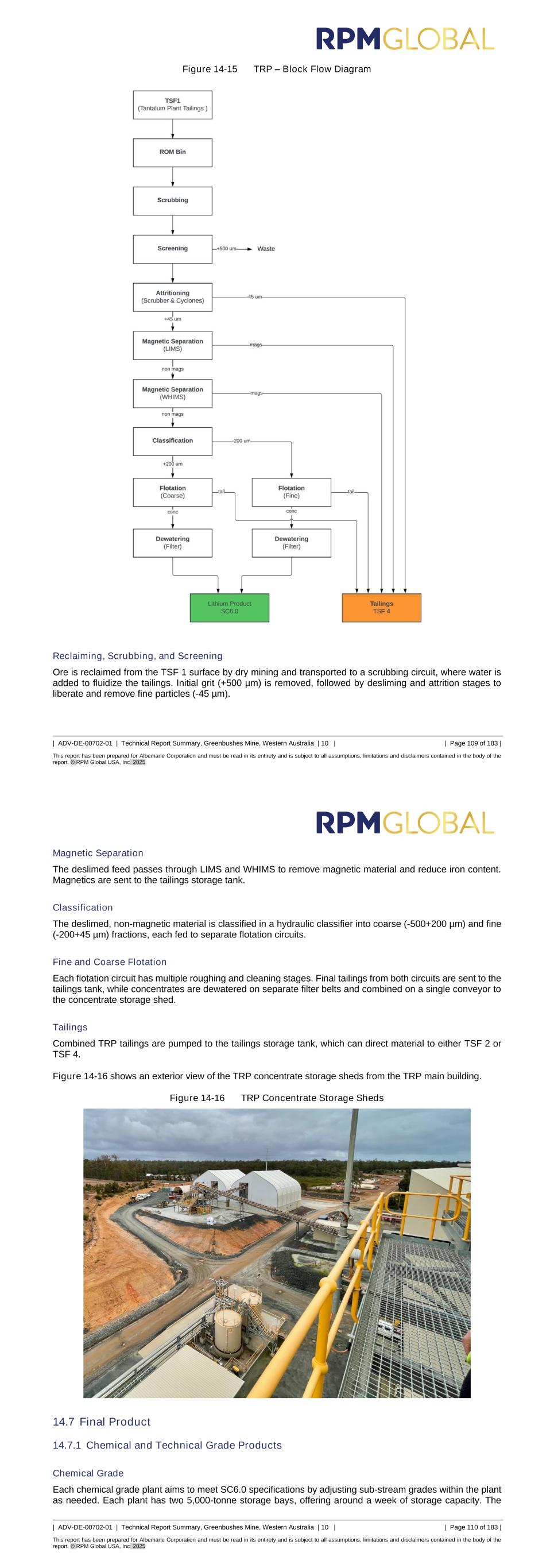

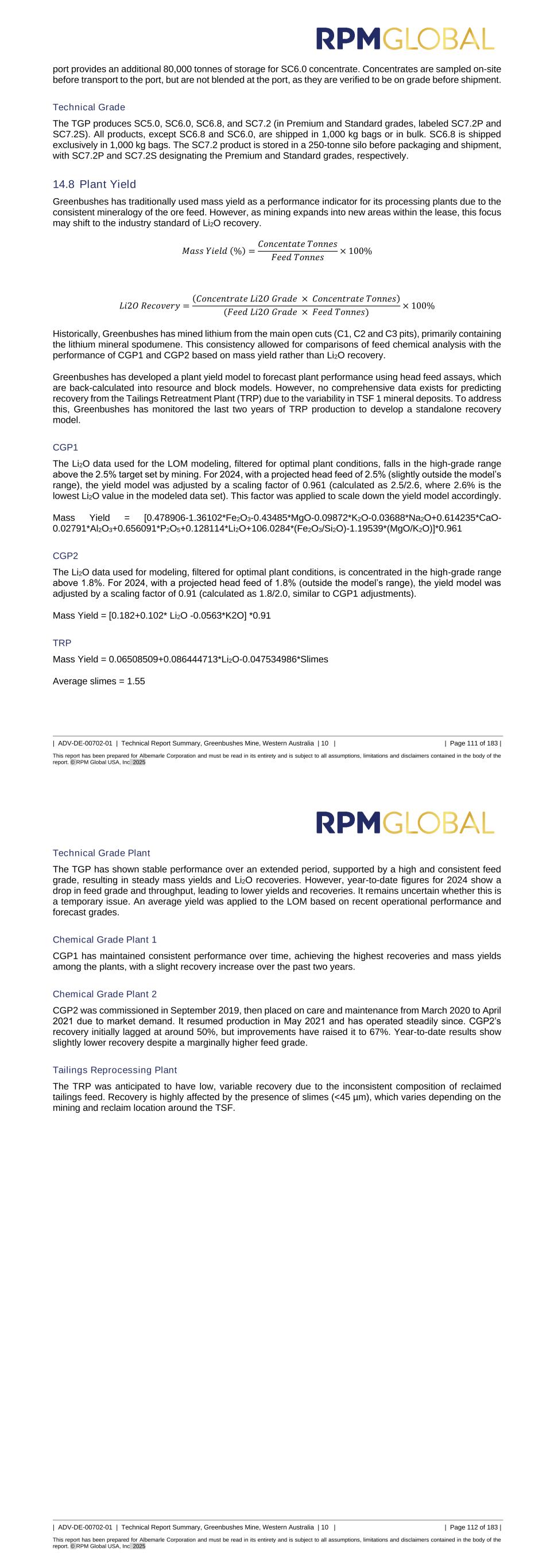

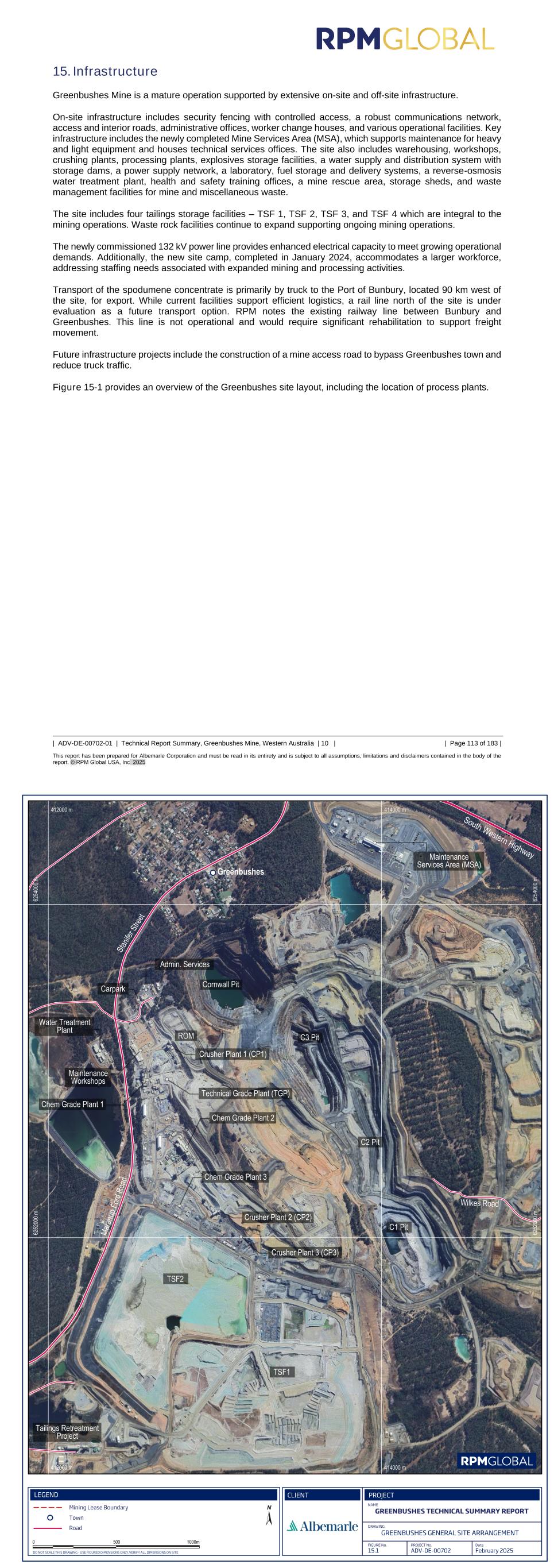

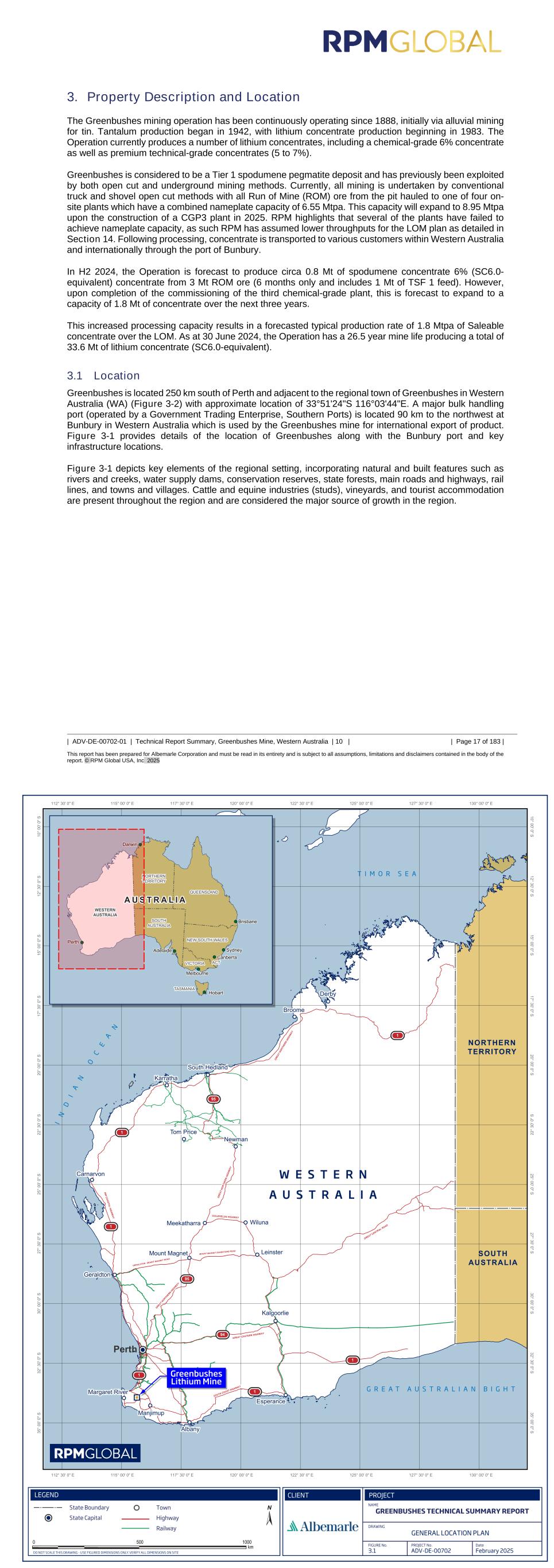

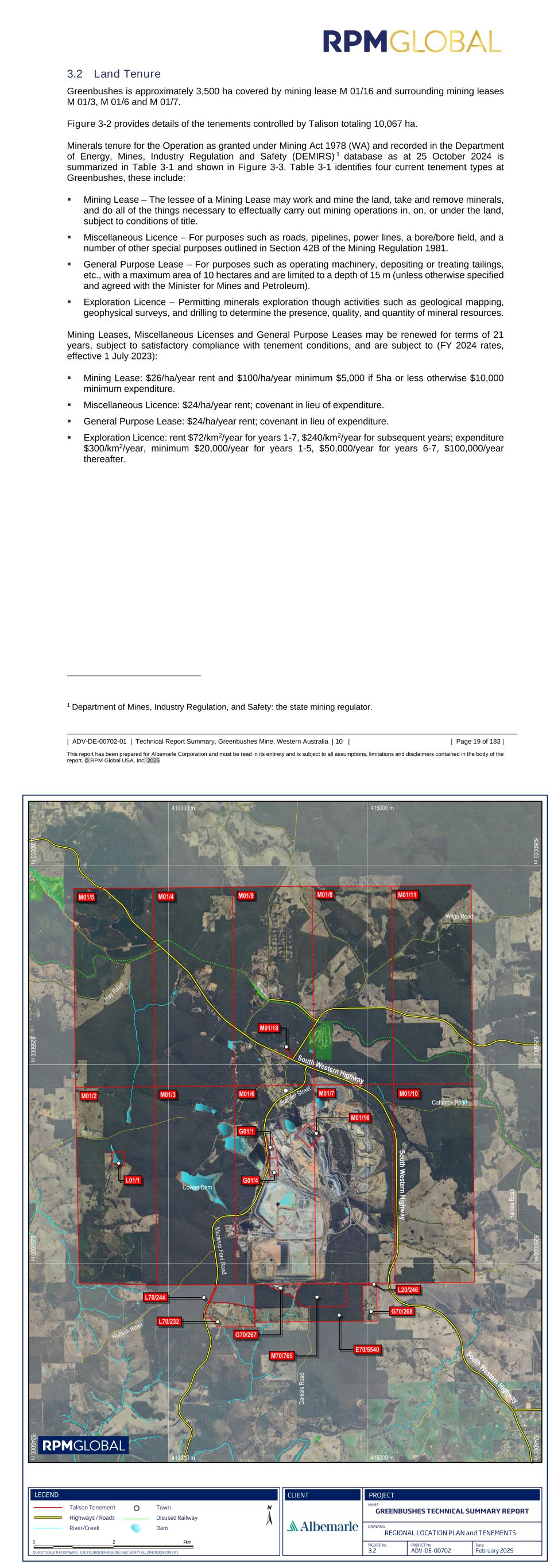

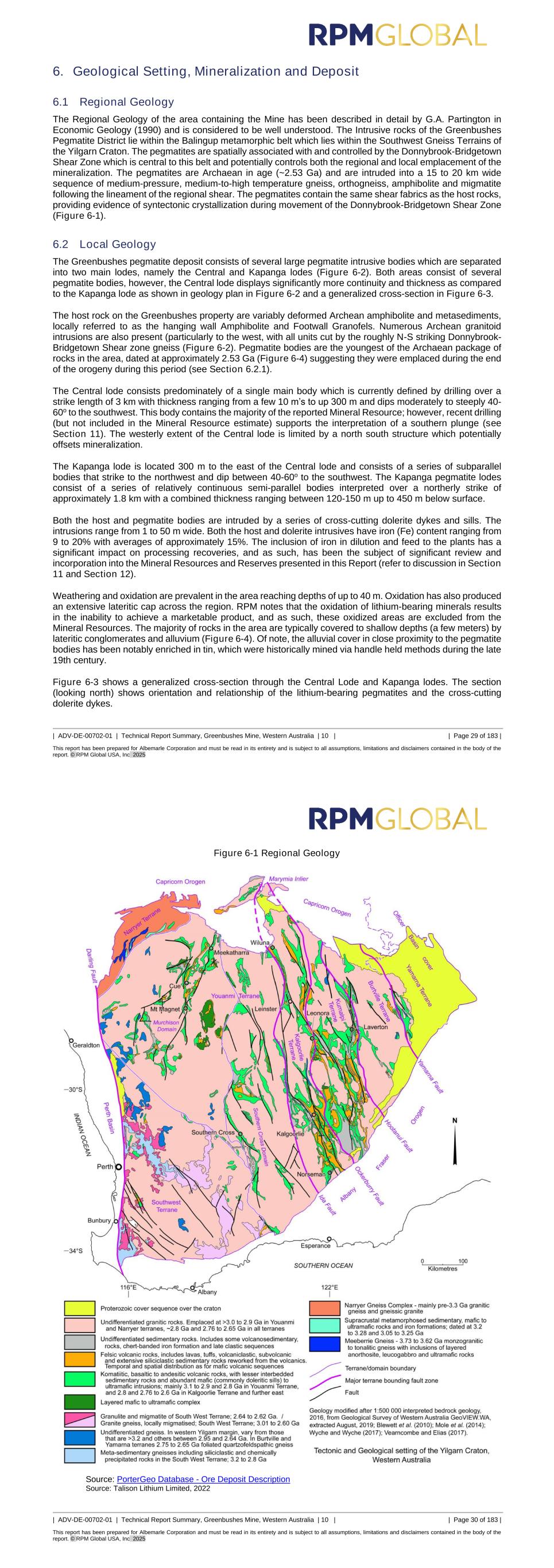

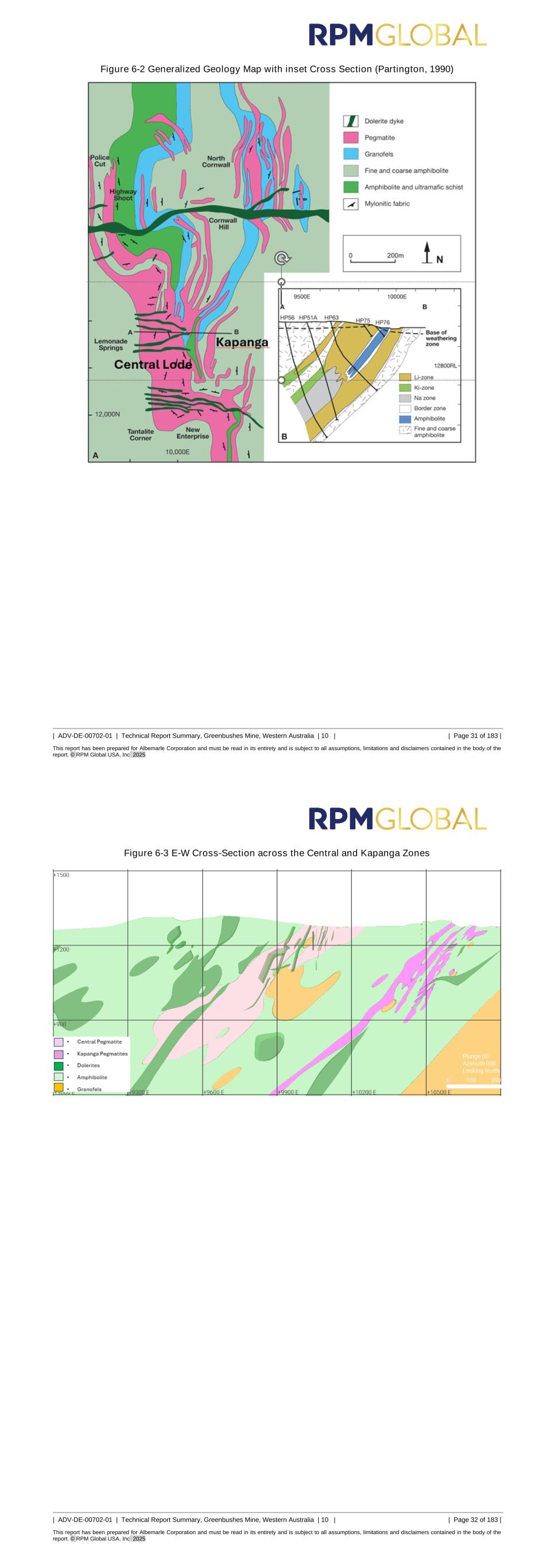

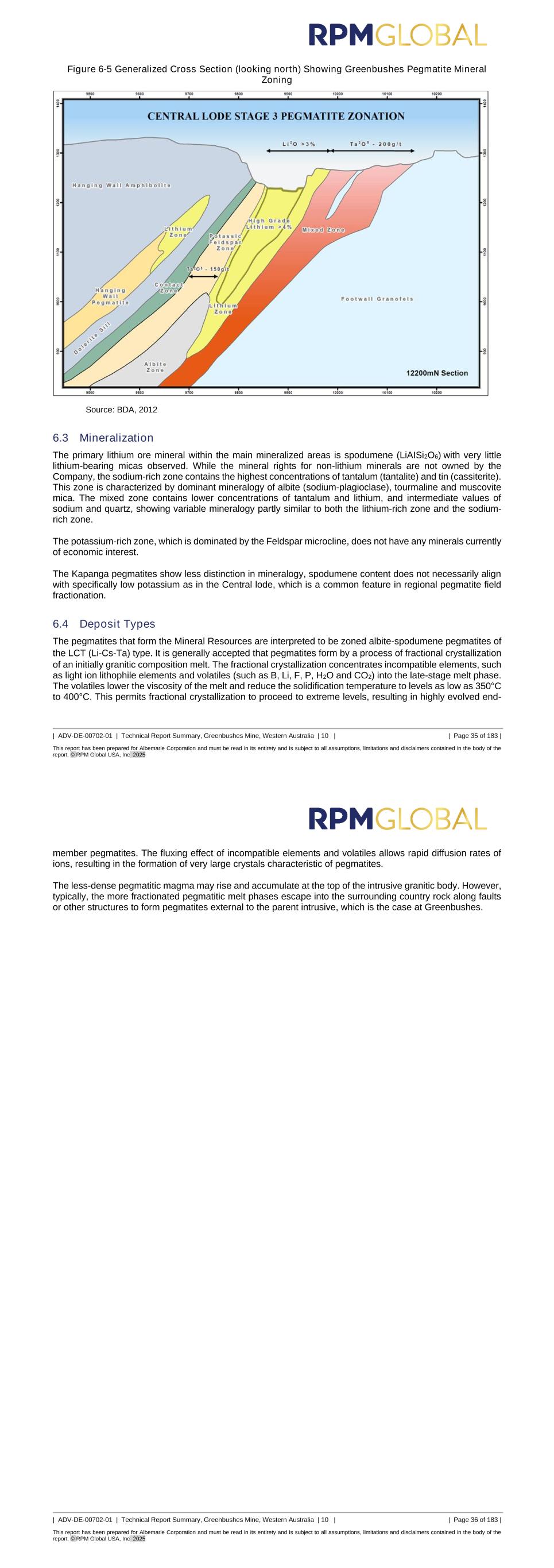

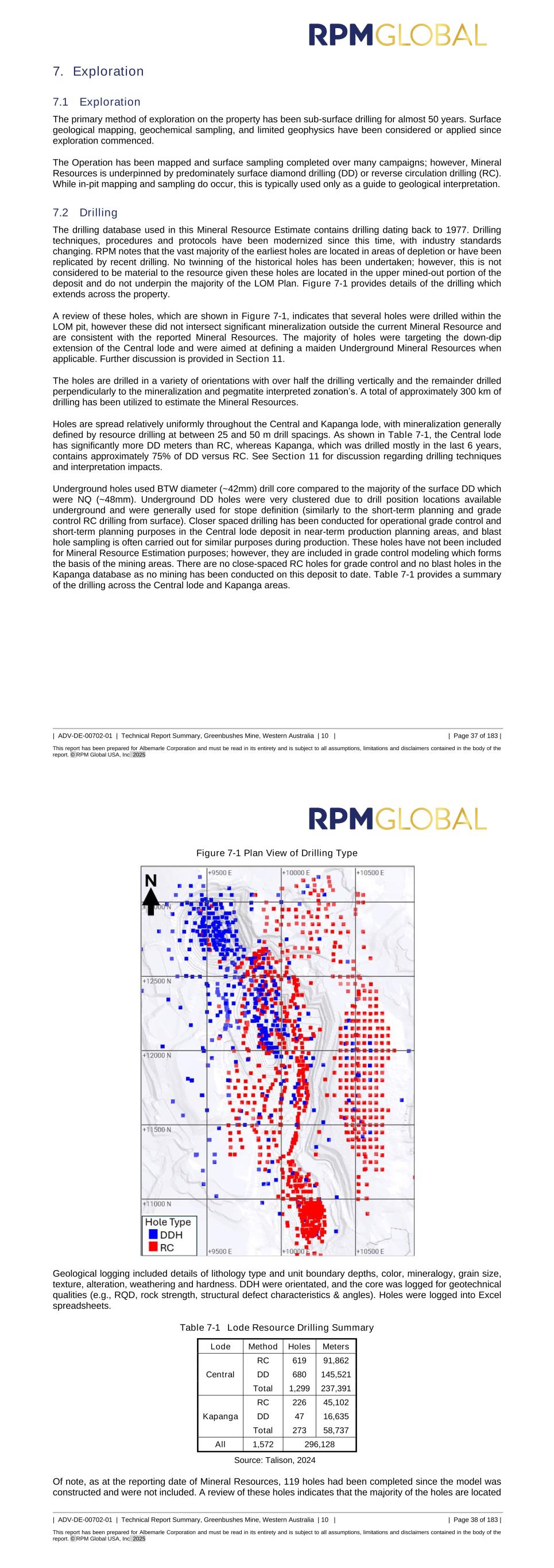

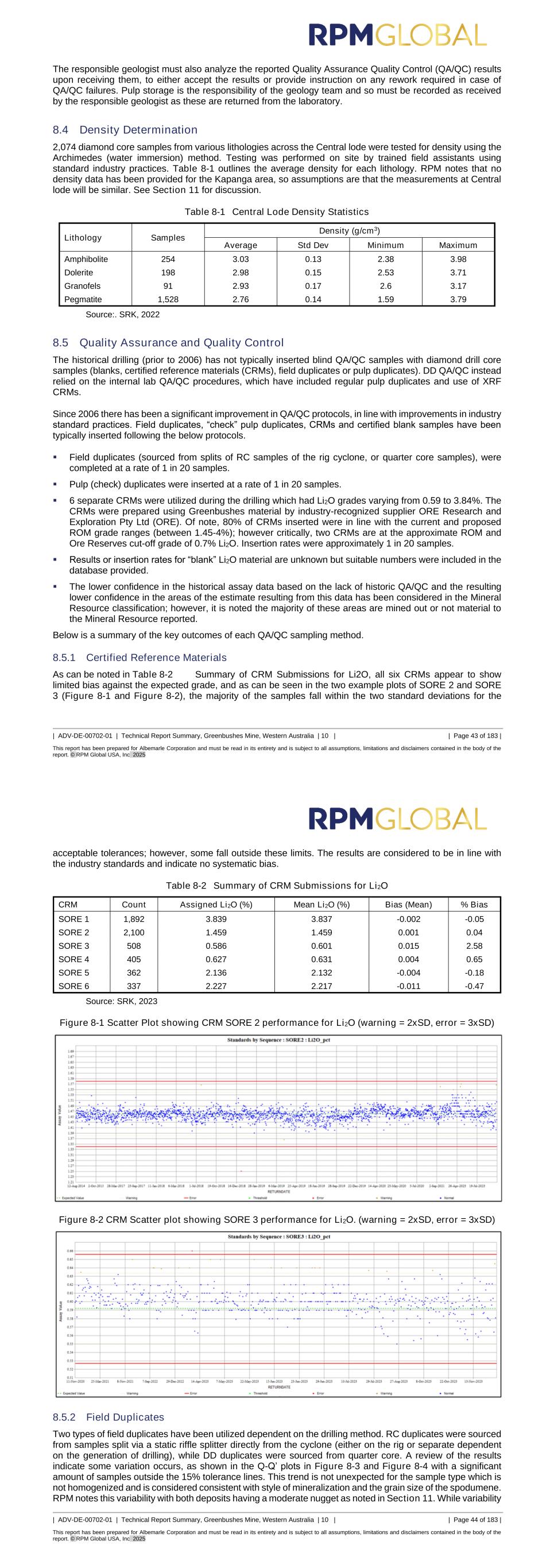

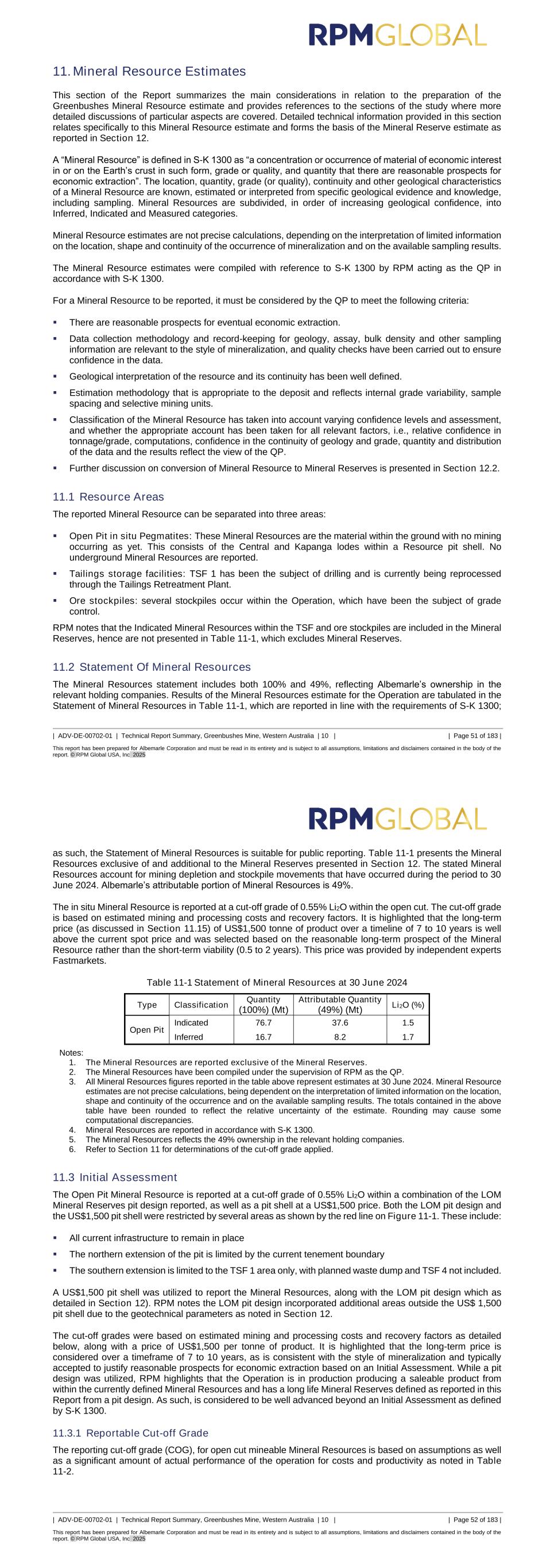

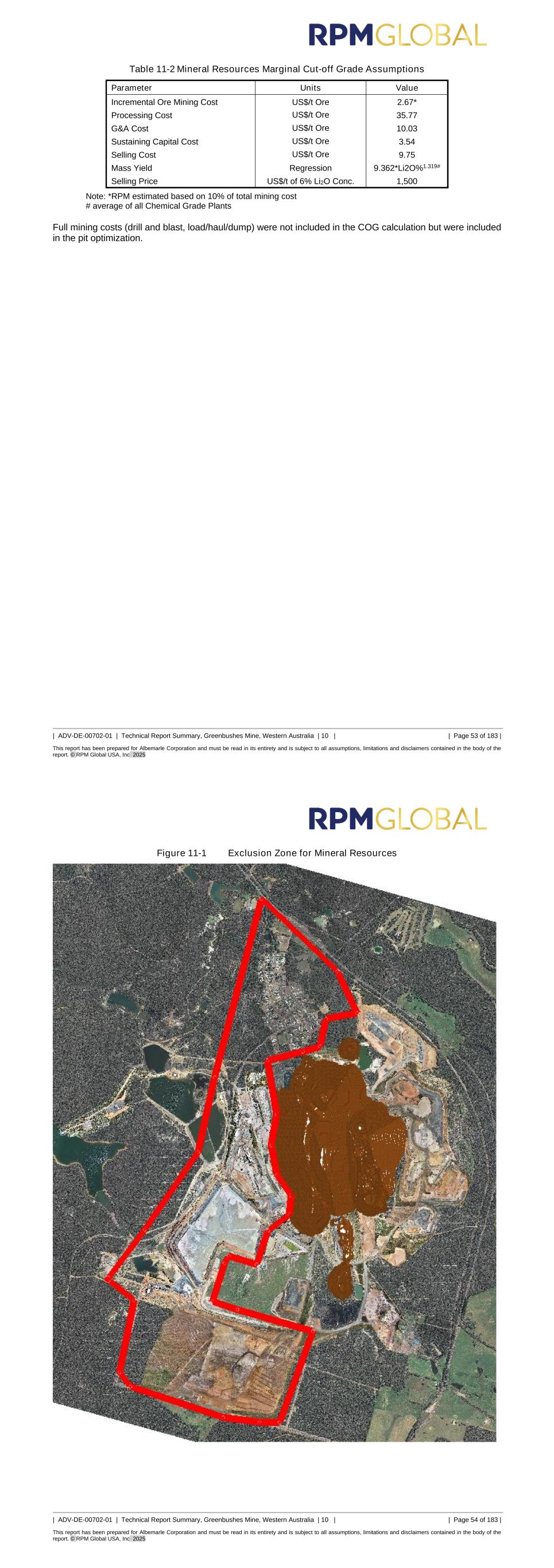

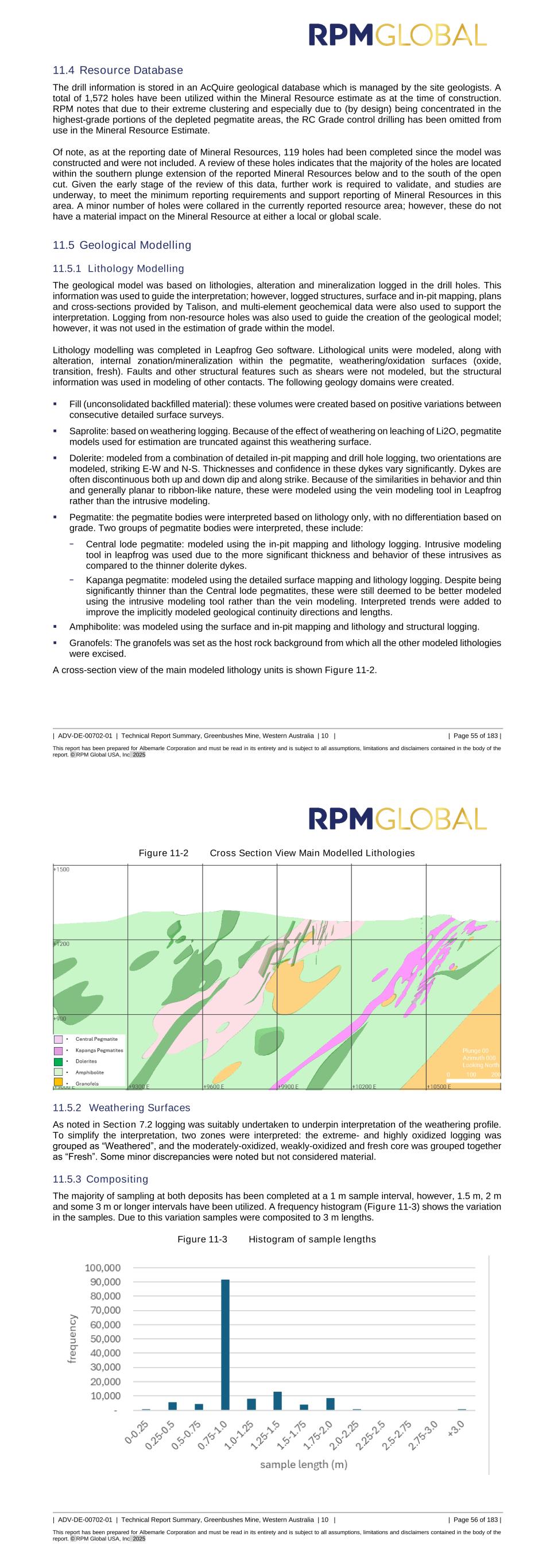

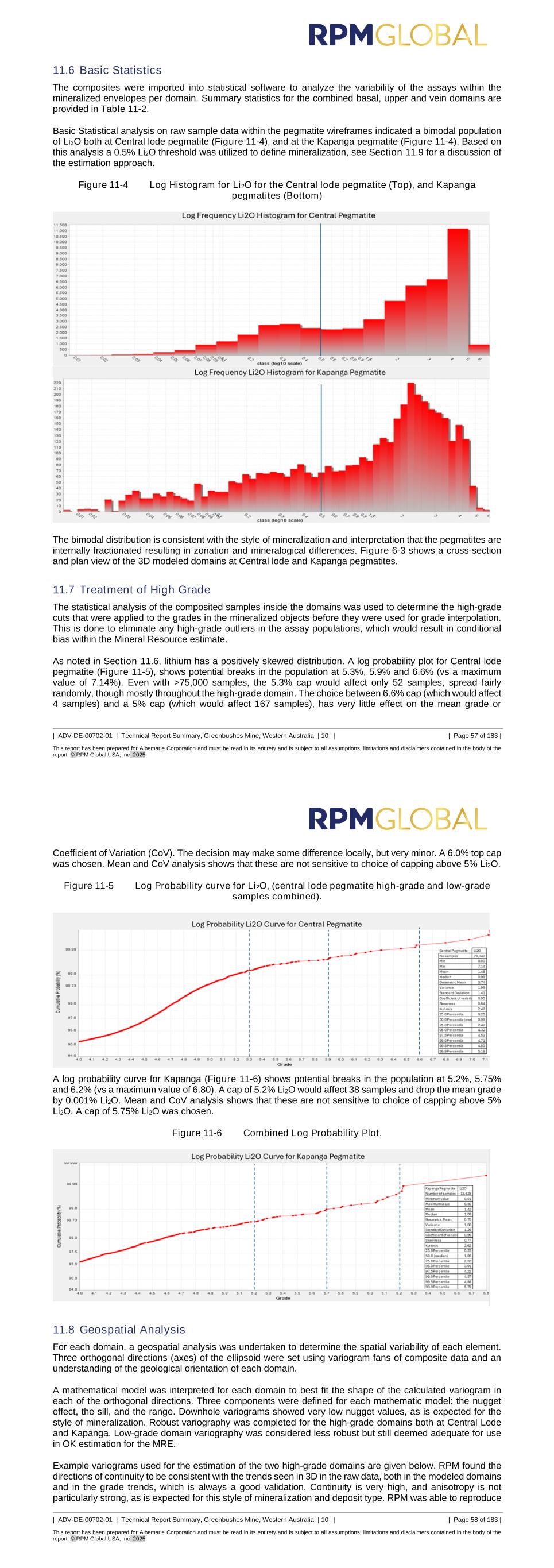

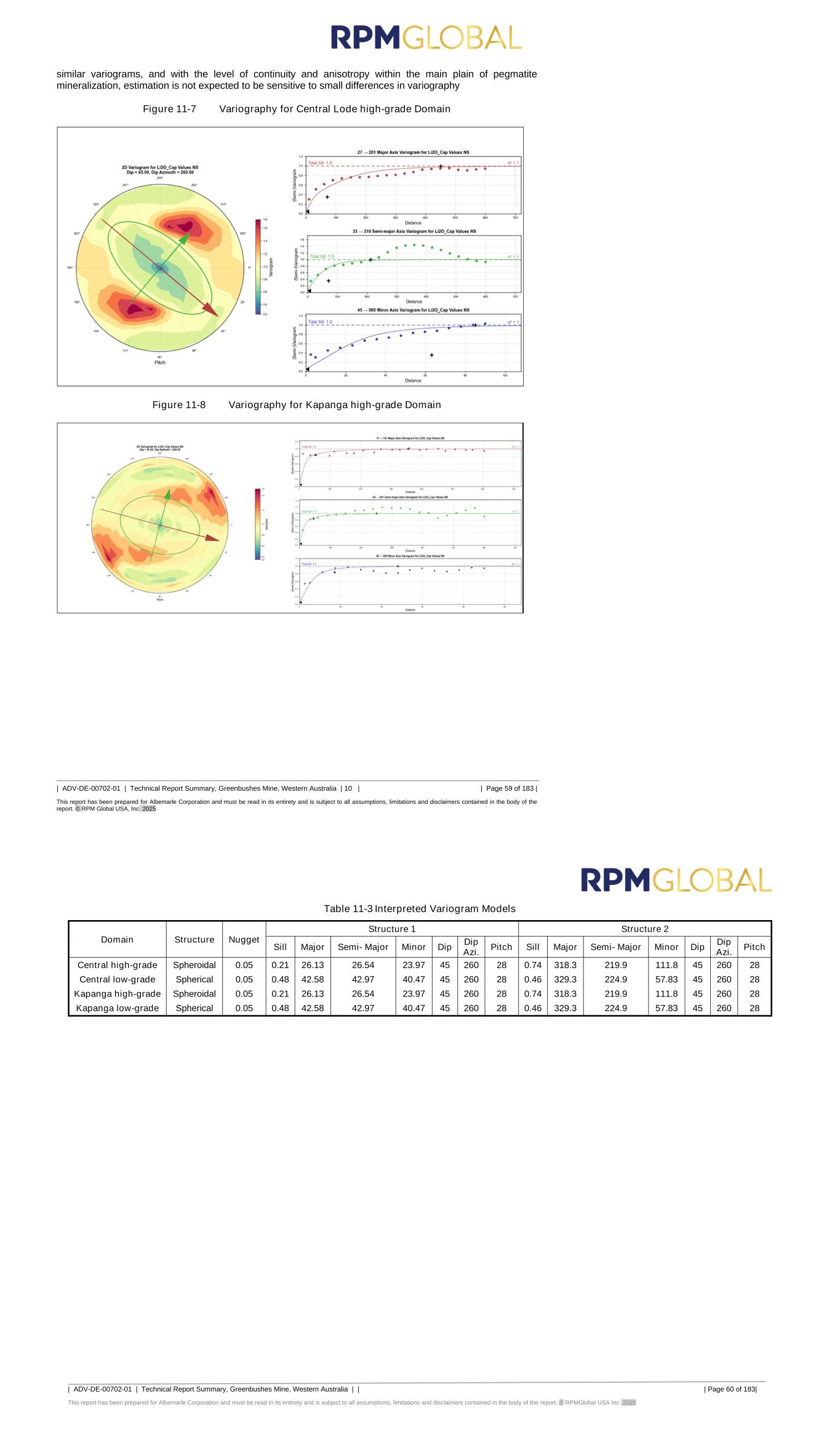

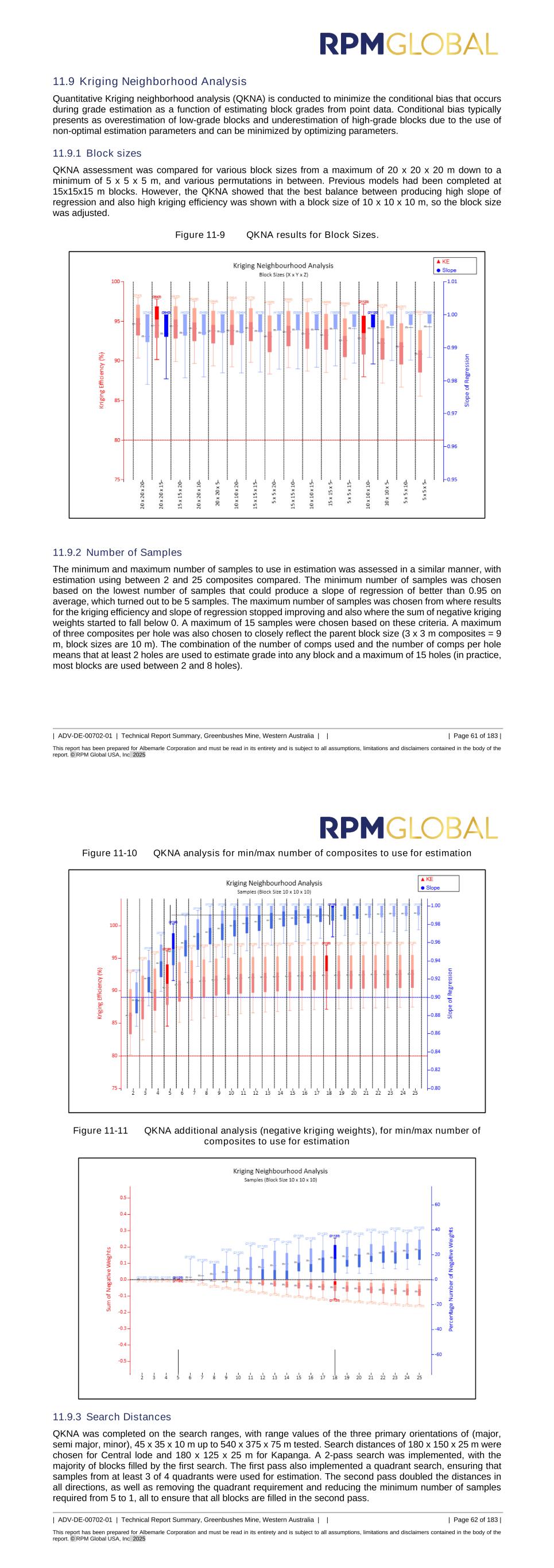

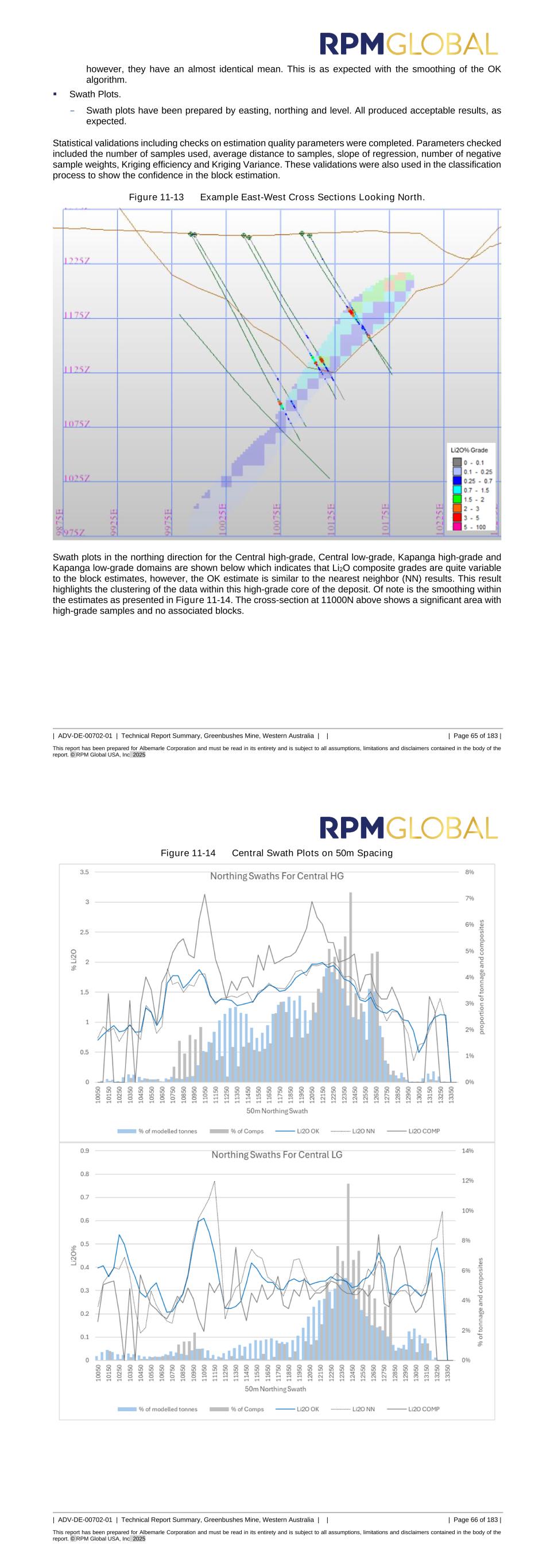

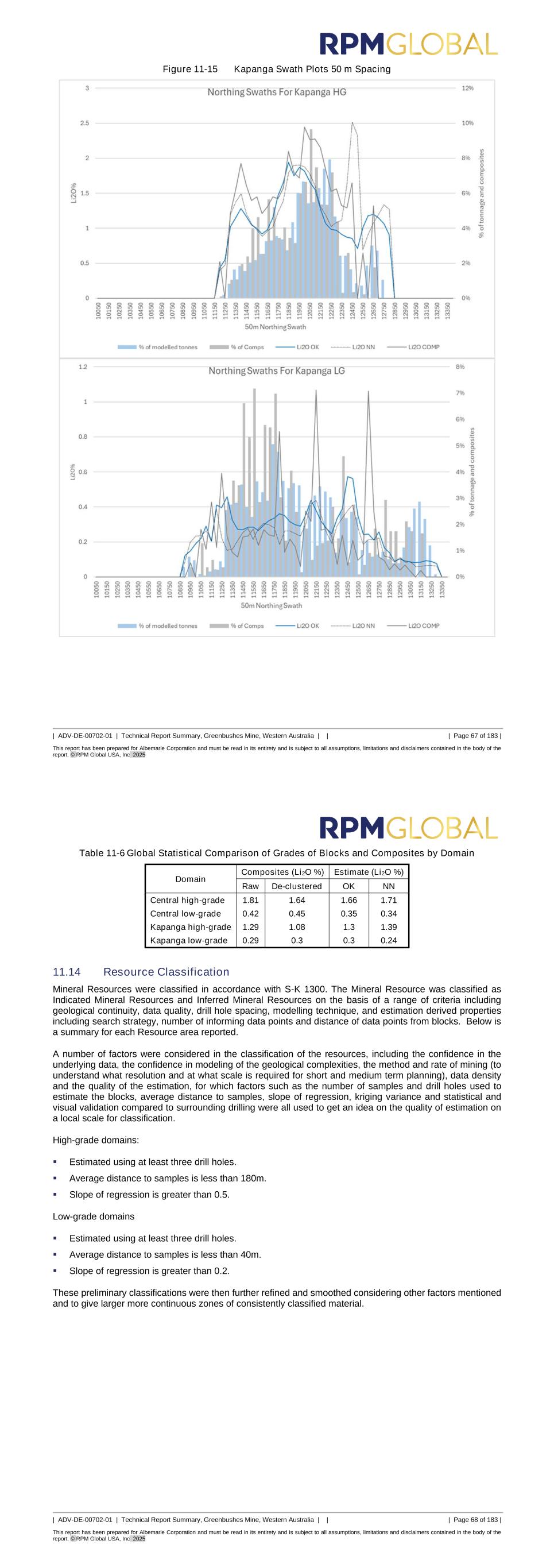

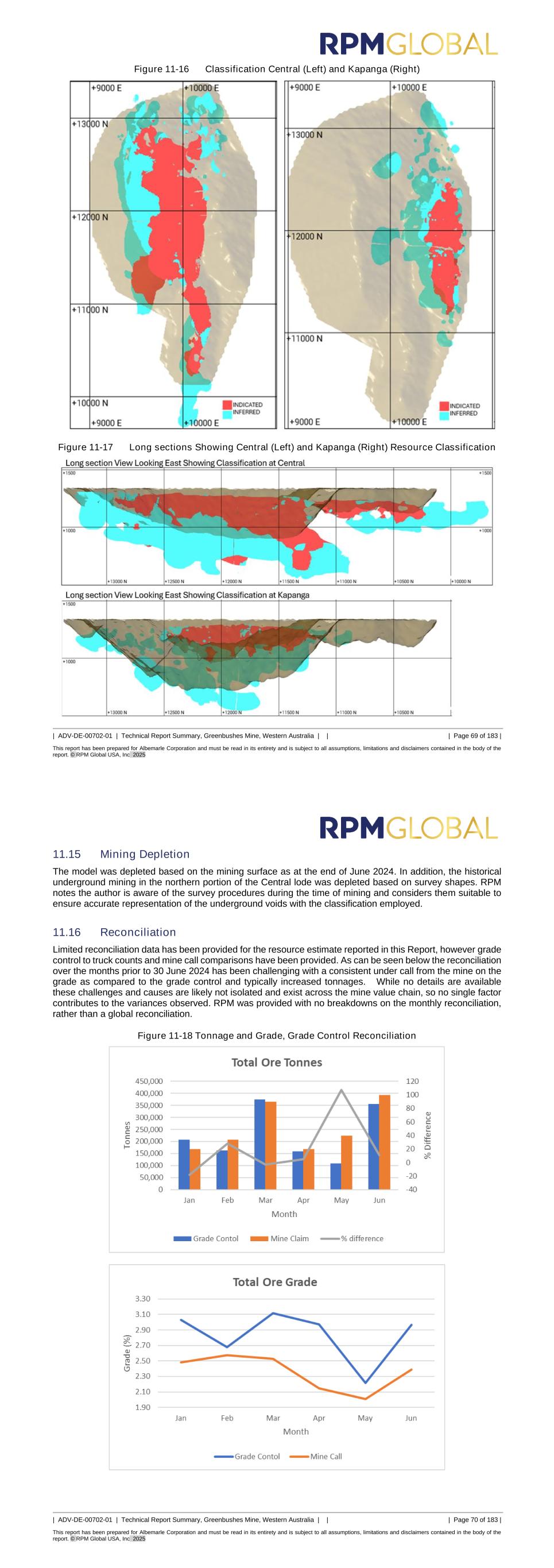

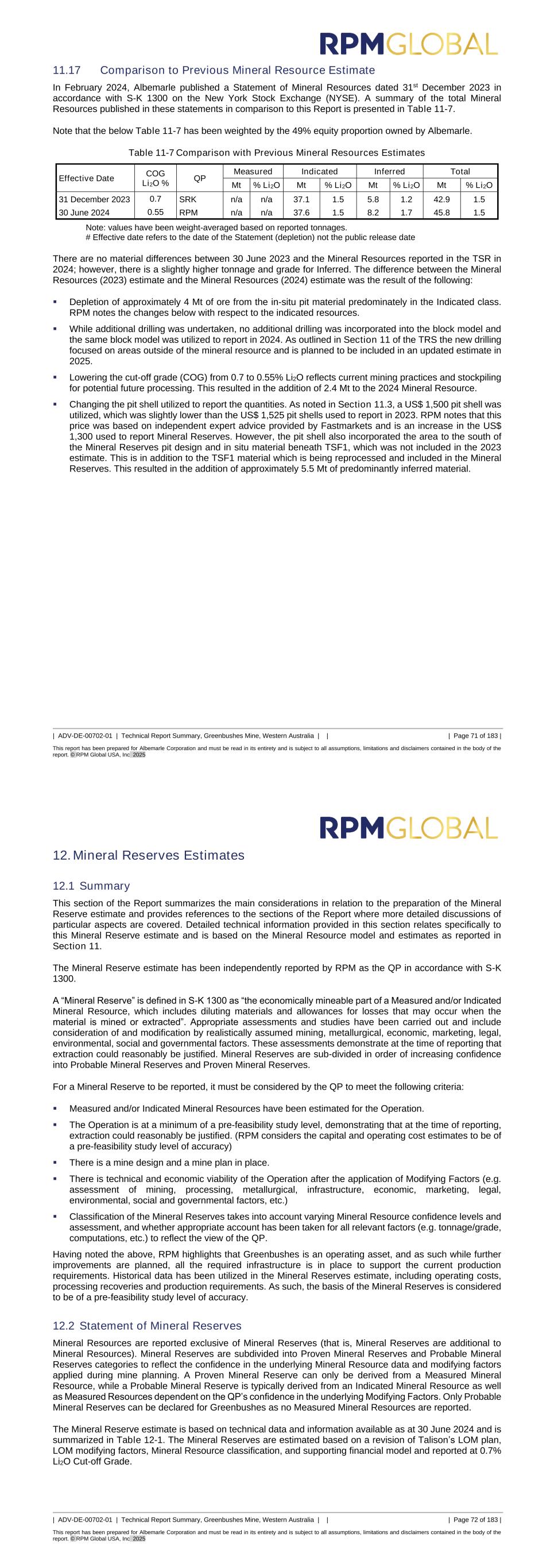

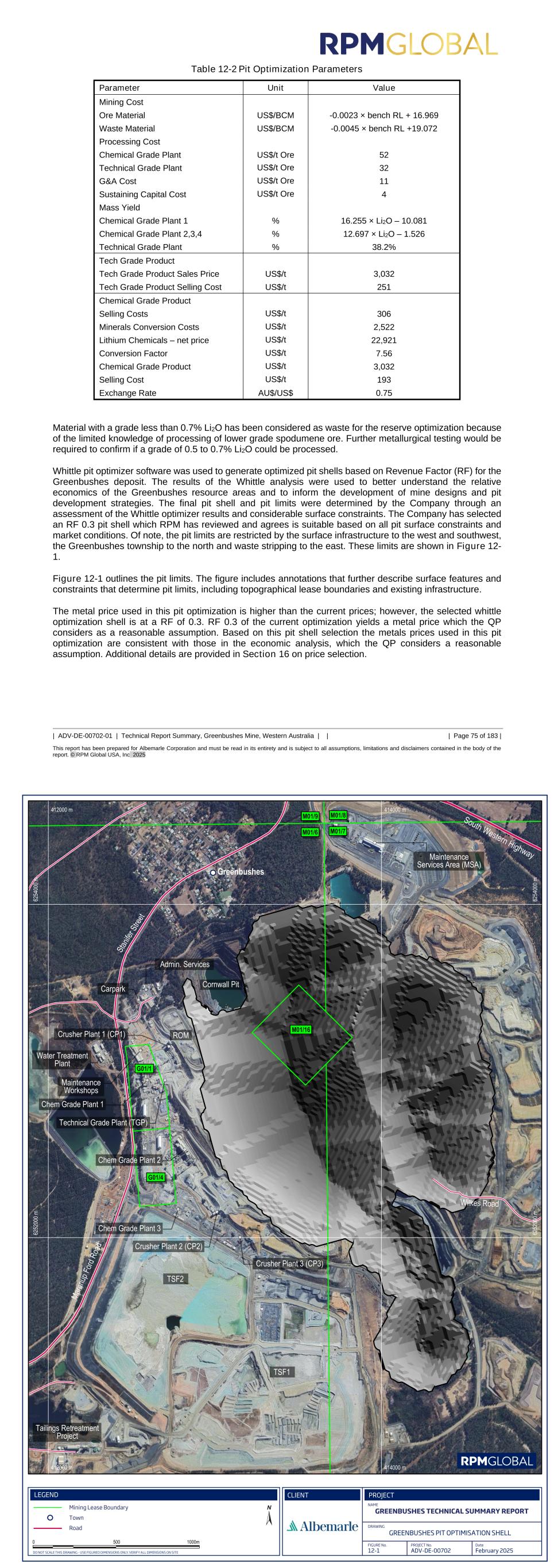

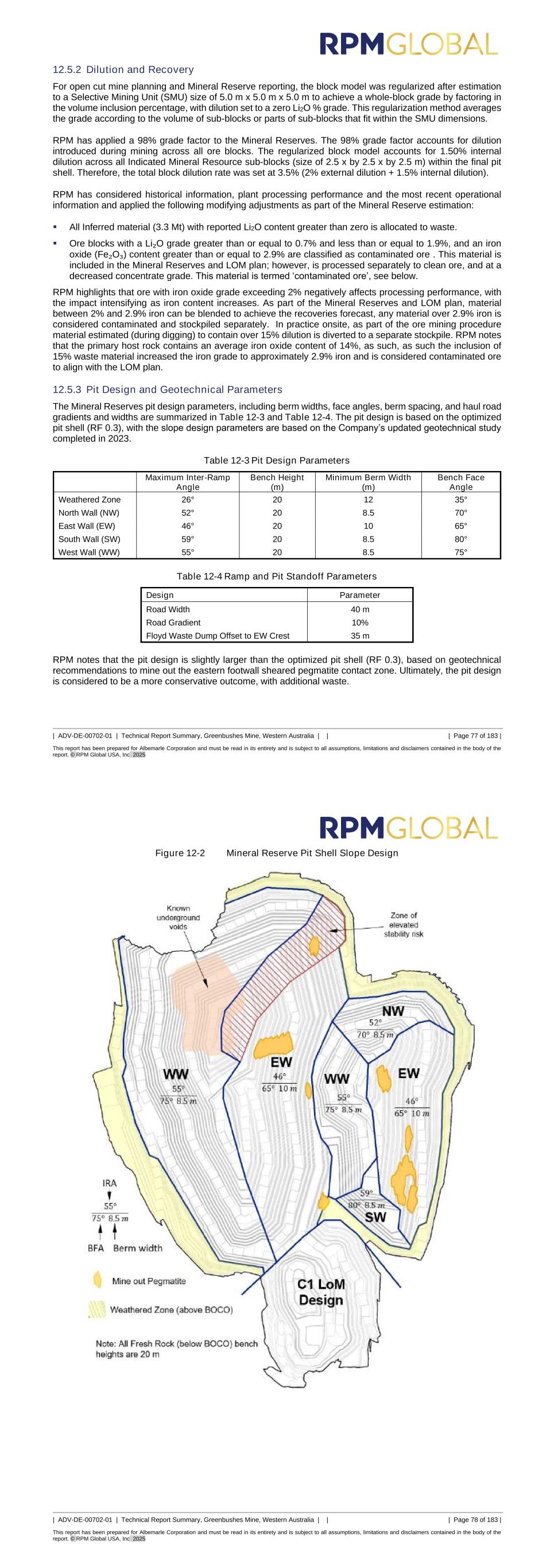

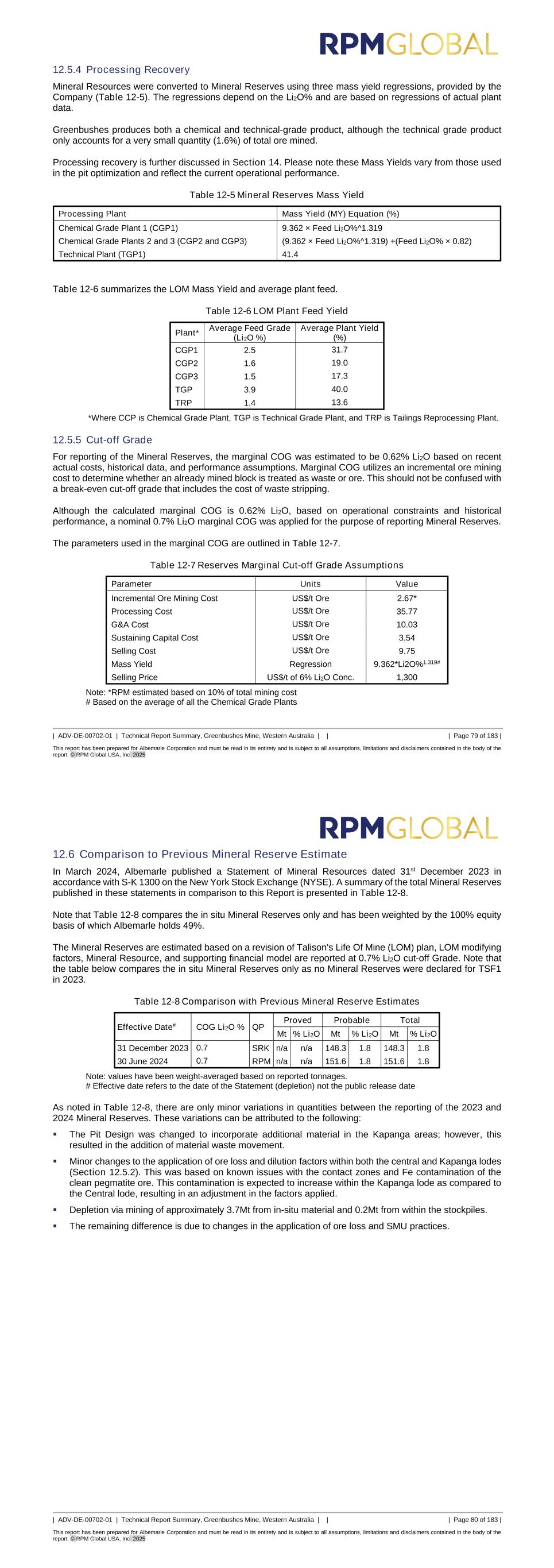

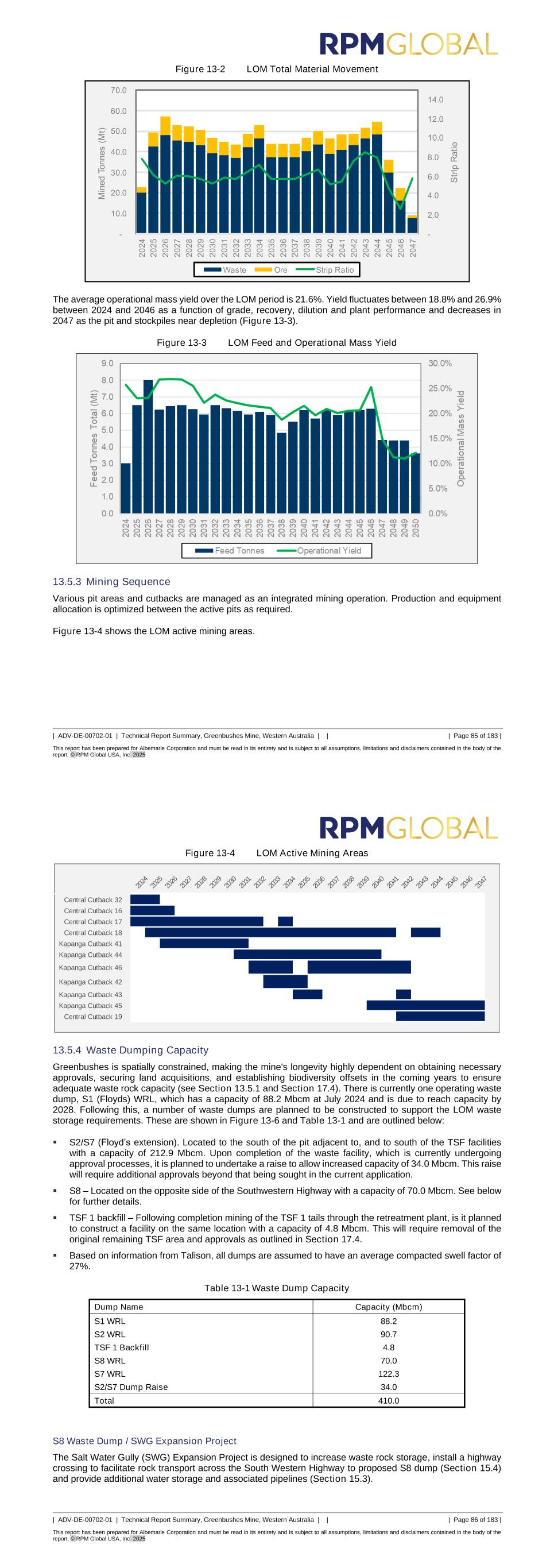

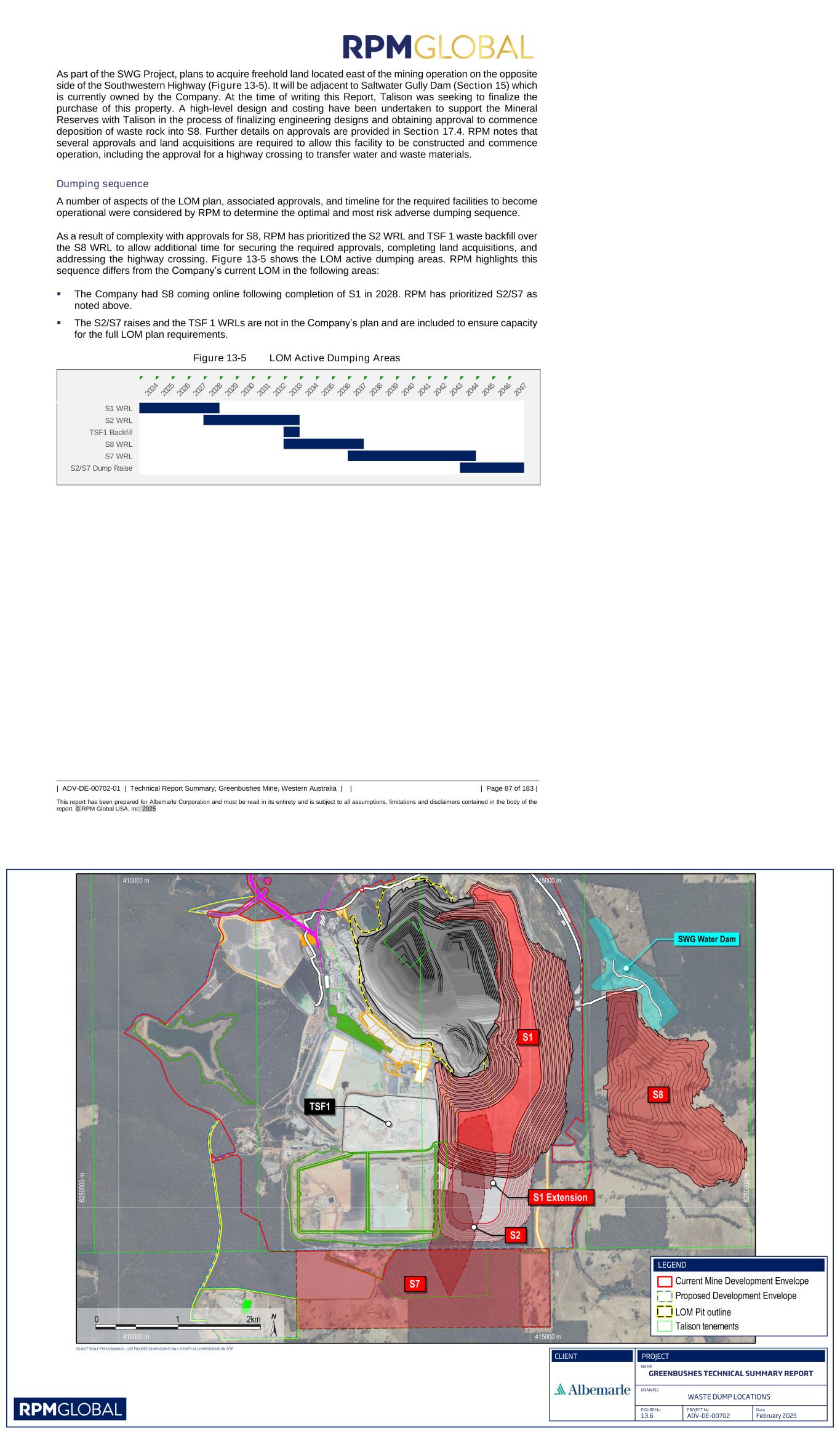

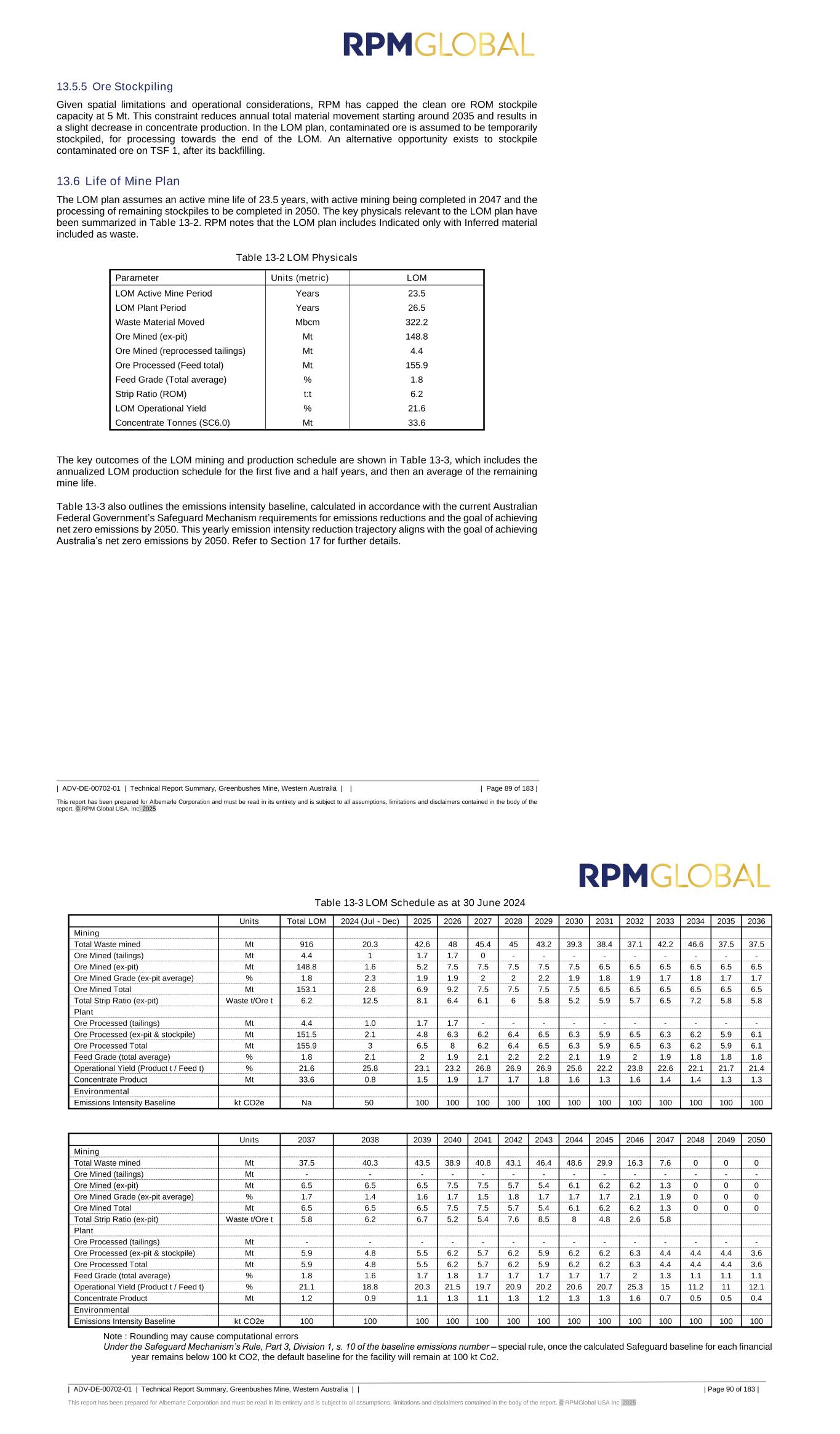

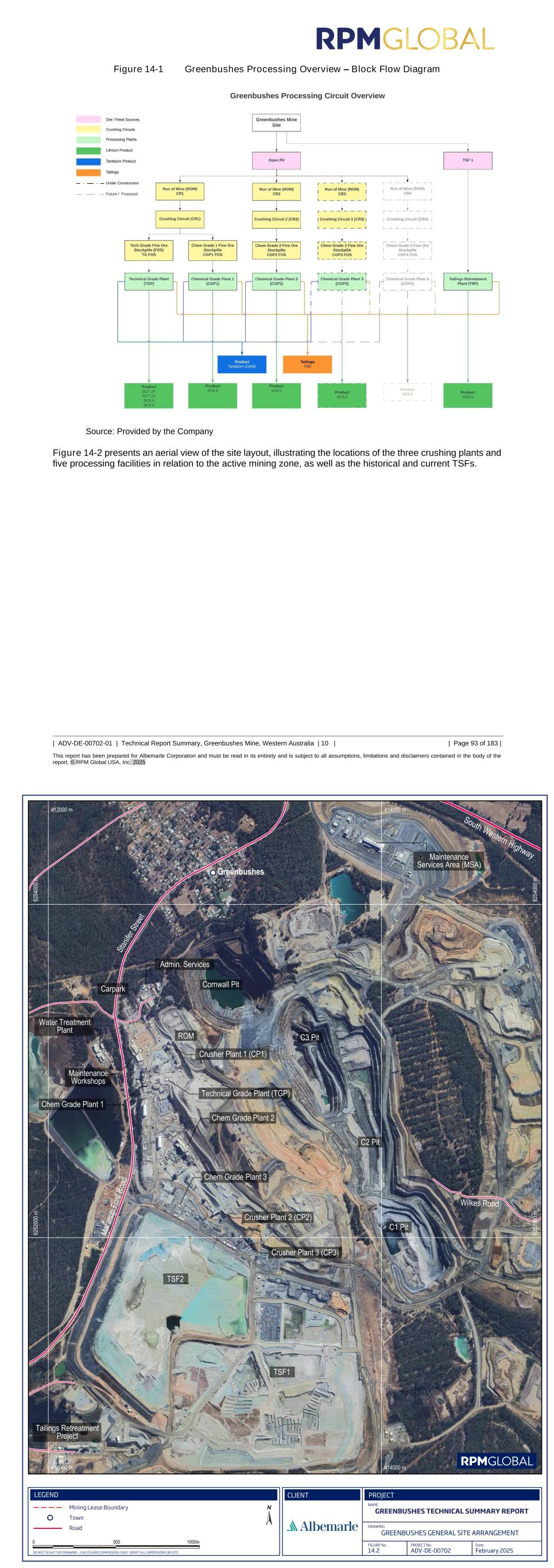

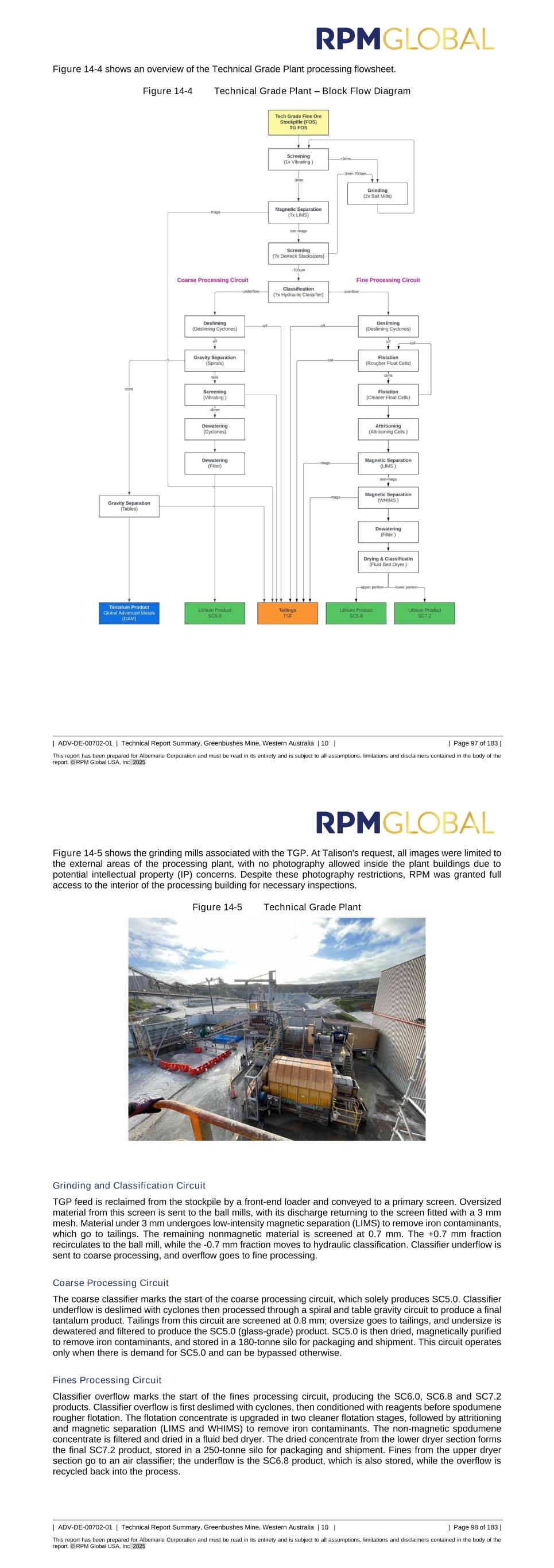

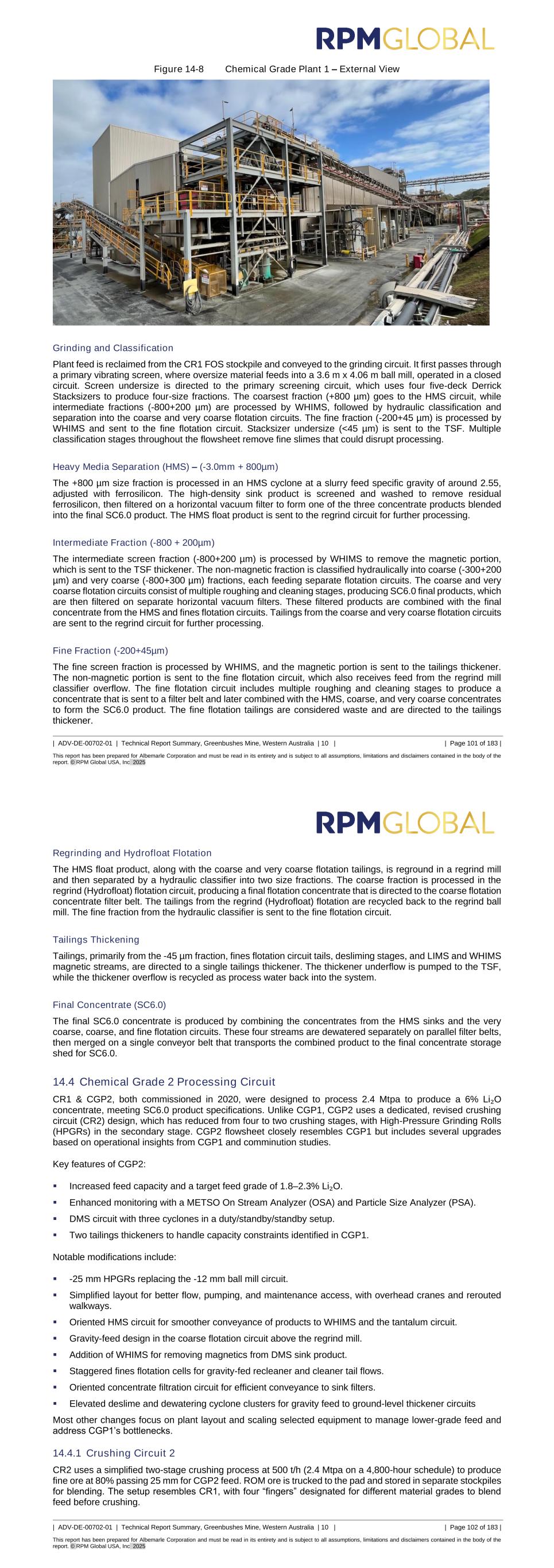

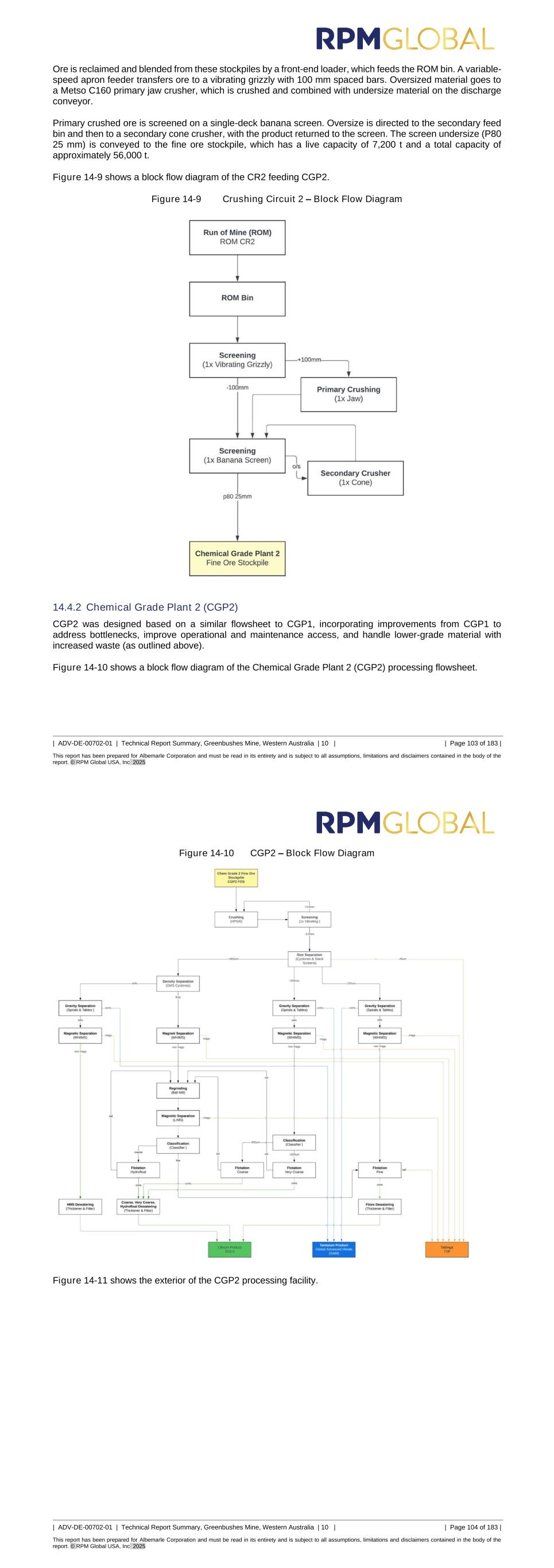

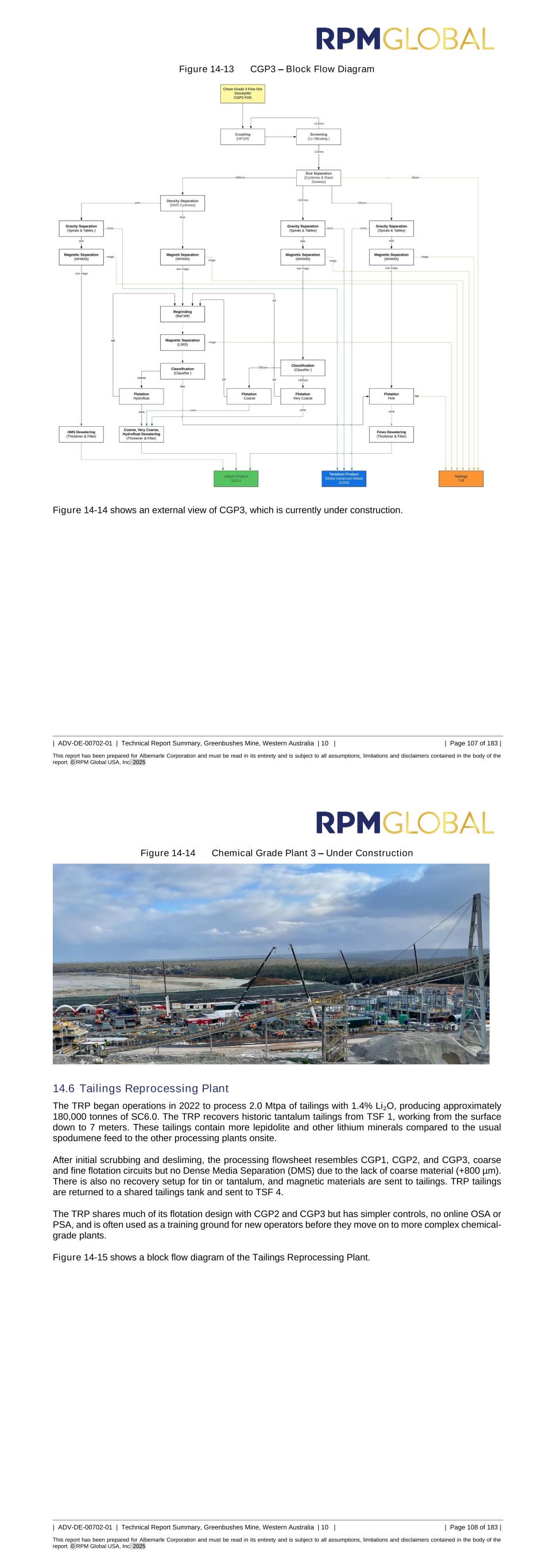

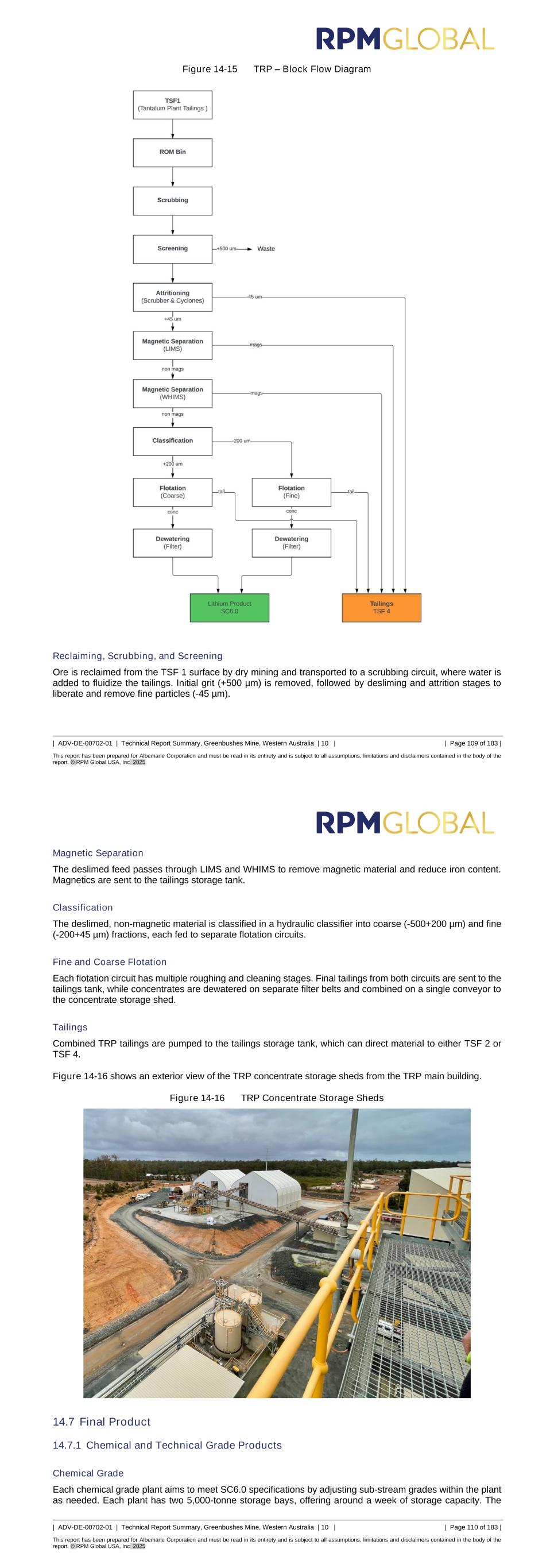

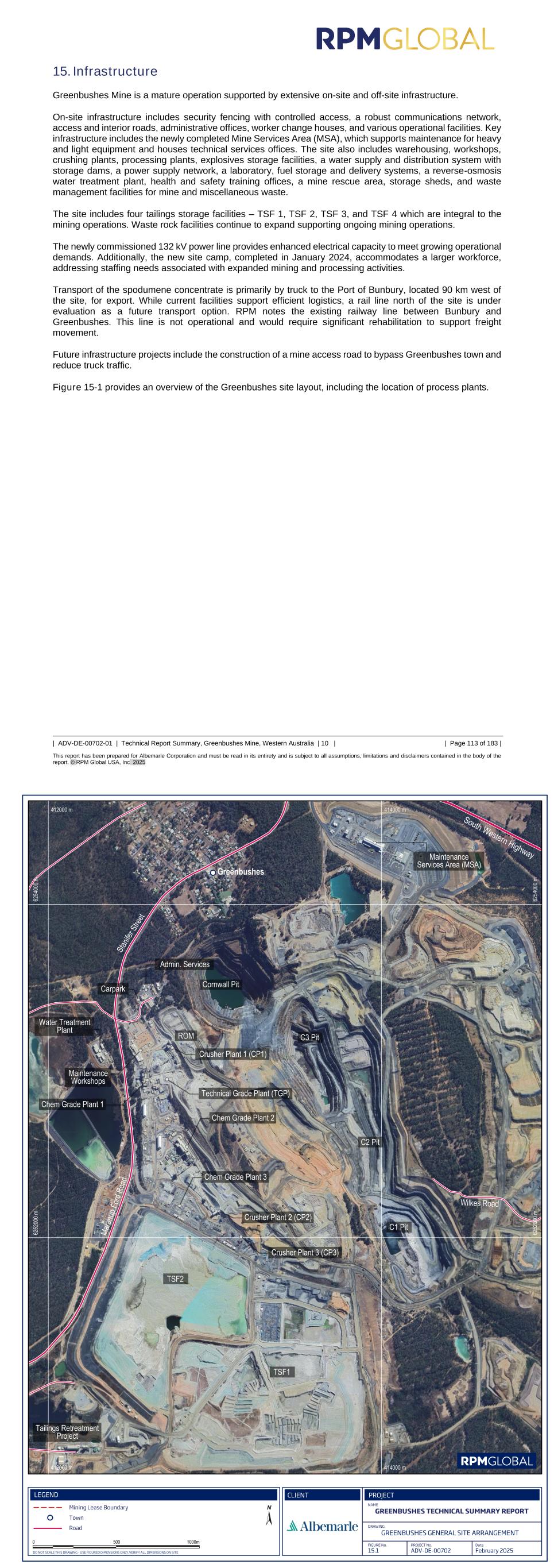

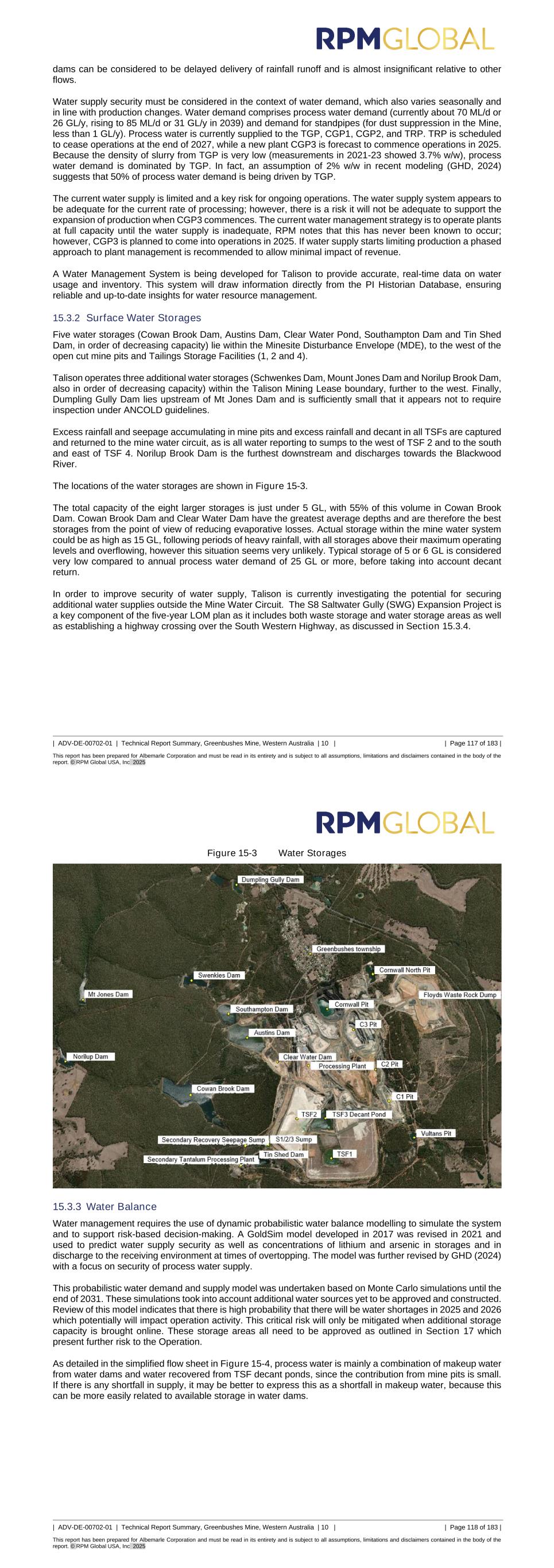

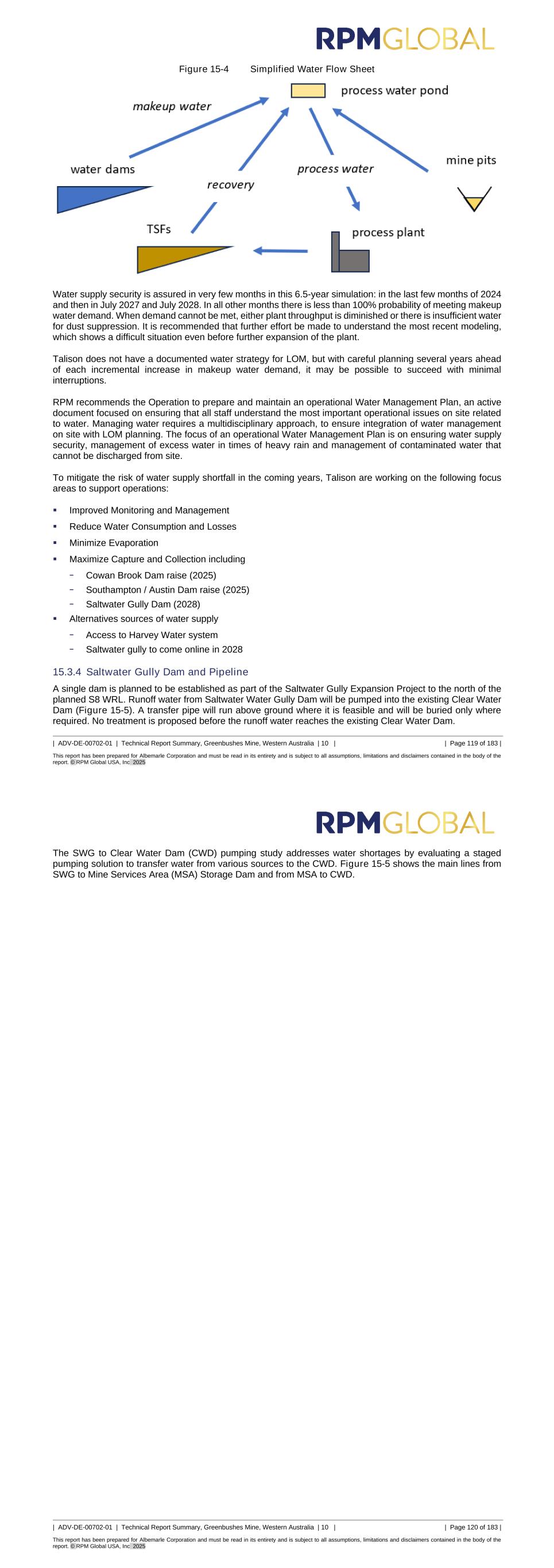

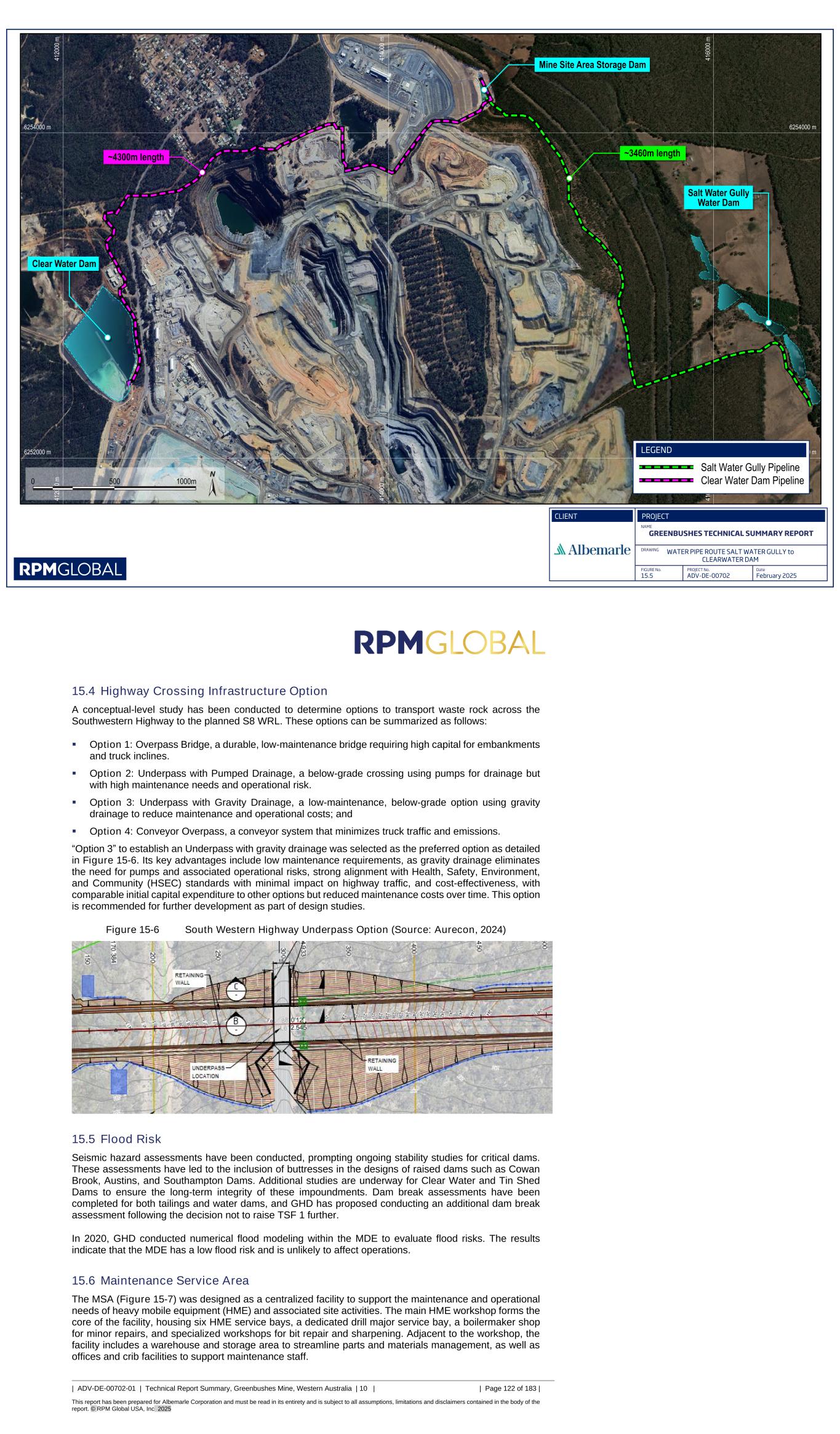

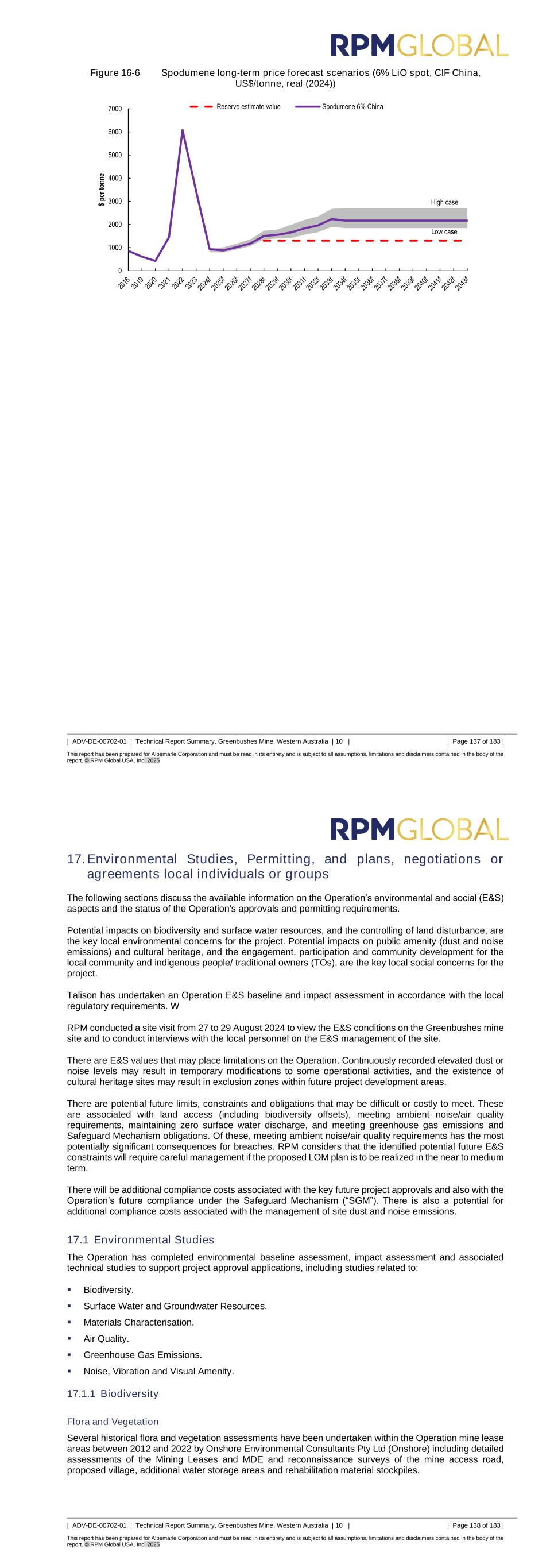

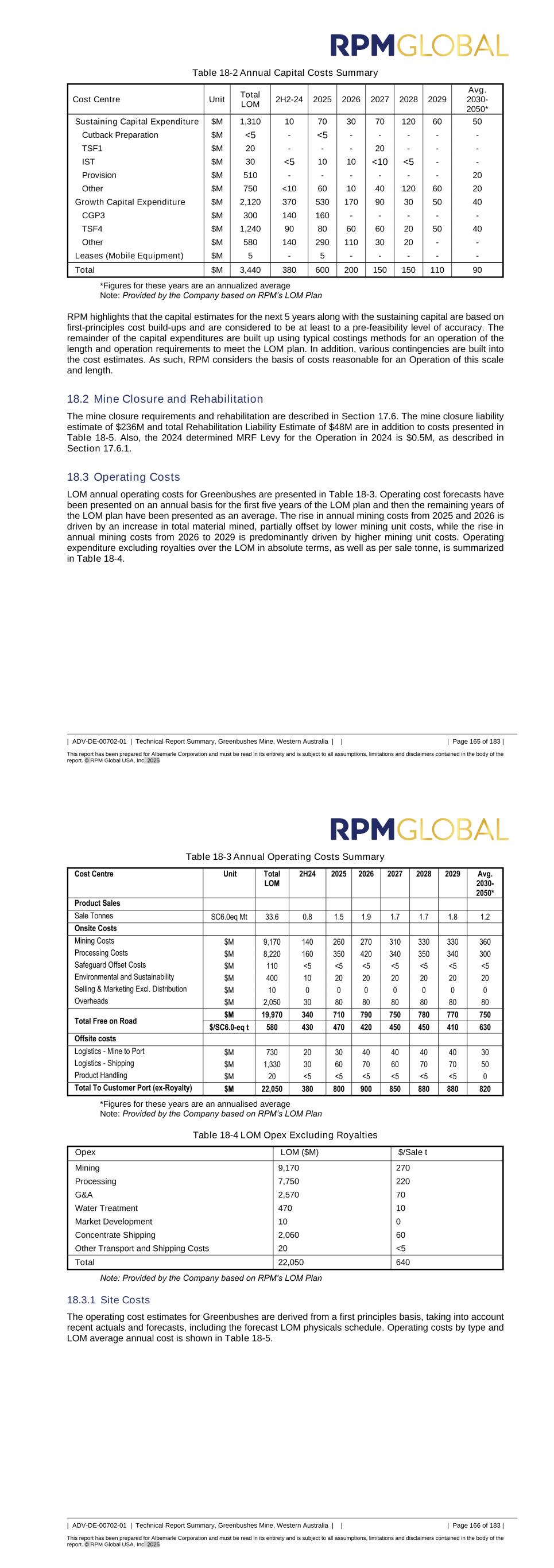

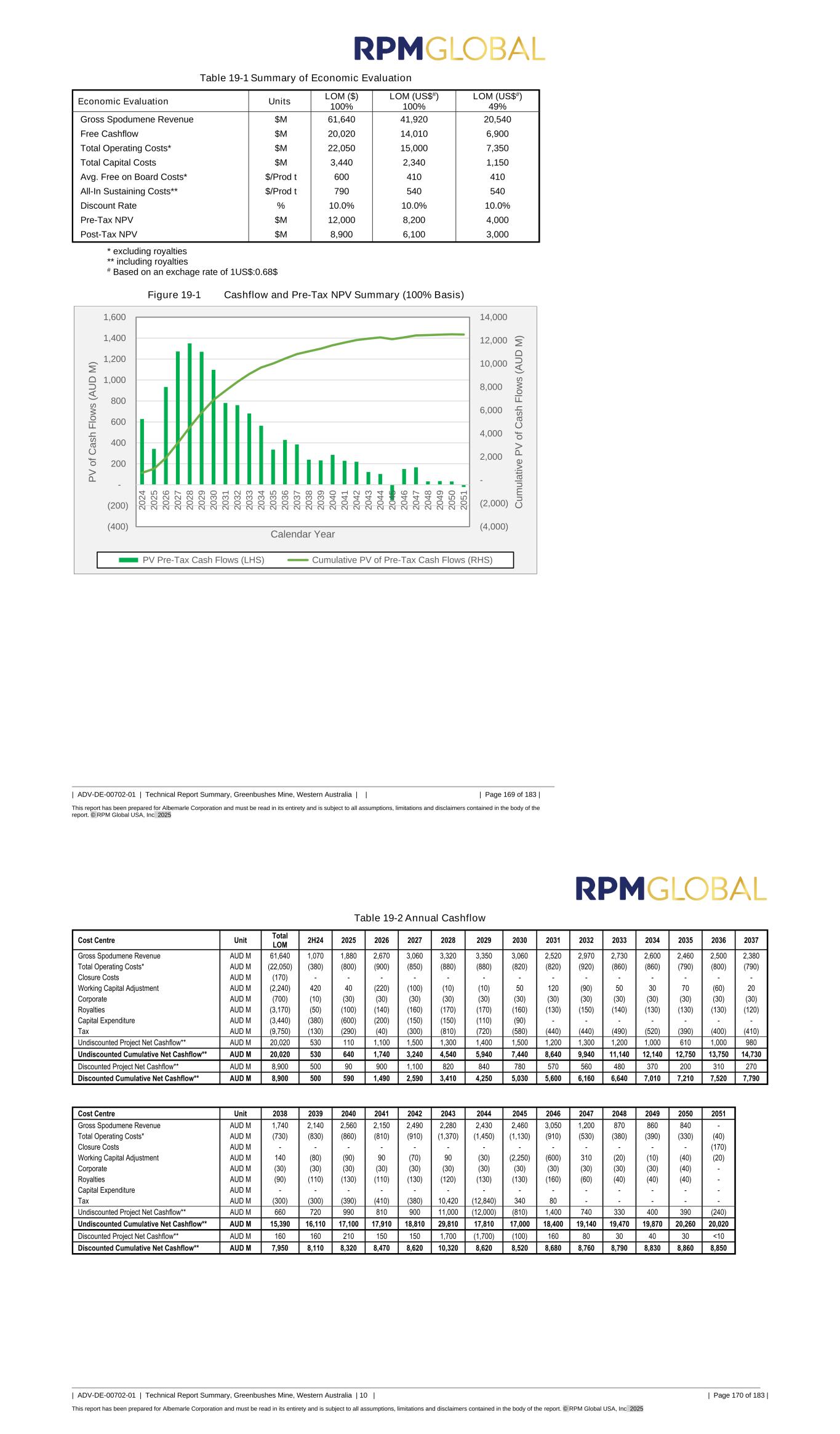

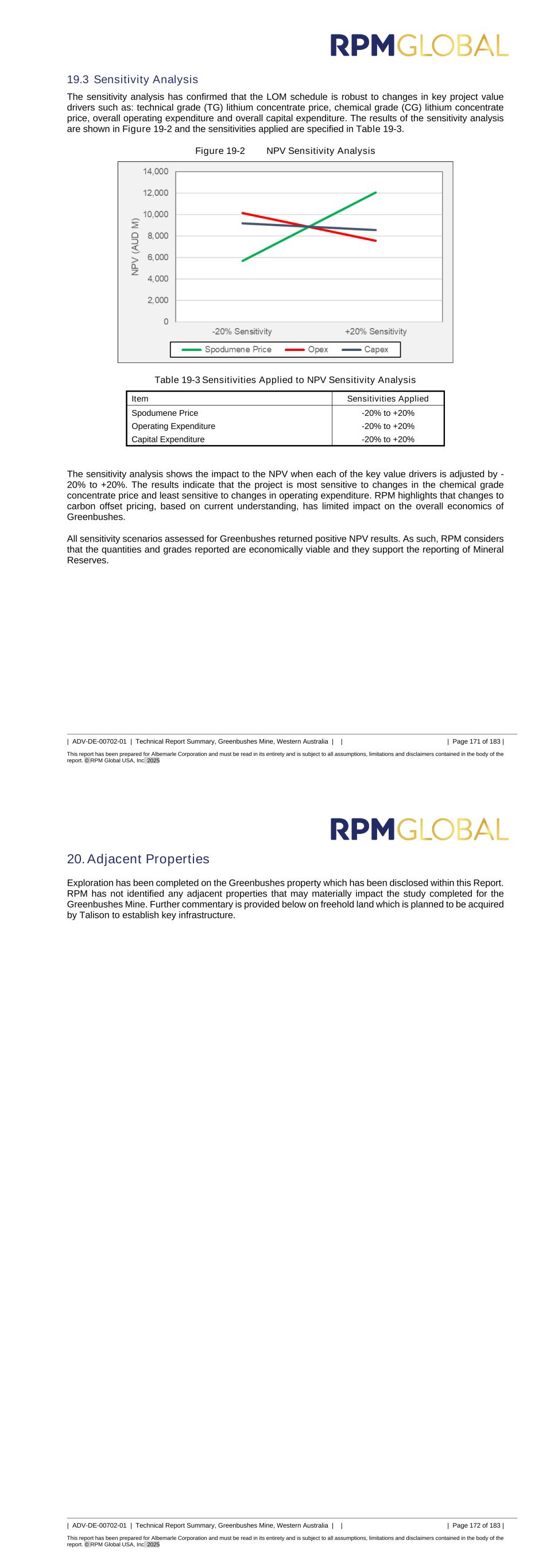

| ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | | | | Page vi of vii | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 LIST OF FIGURES Figure 1-1 Lithium supply-demand balance ('000 tonnes LCE) ................................................................ 6 Figure 3-1 Greenbushes General Location Plan .................................................................................... 18 Figure 3-2 Greenbushes Regional Location Map ................................................................................... 20 Figure 3-3 Greenbushes Mine Operation Layout .................................................................................... 23 Figure 6-1 Regional Geology .................................................................................................................. 30 Figure 6-2 Generalized Geology Map with inset Cross Section (Partington, 1990) ............................... 31 Figure 6-3 E-W Cross-Section across the Central and Kapanga Zones ................................................ 32 Figure 6-4 Simplified Stratigraphic Column ............................................................................................ 33 Figure 6-5 Generalized Cross Section (looking north) Showing Greenbushes Pegmatite Mineral Zoning 35 Figure 7-1 Plan View of Drilling Type ...................................................................................................... 38 Figure 8-1 Scatter Plot showing CRM SORE 2 performance for Li2O (warning = 2xSD, error = 3xSD) 44 Figure 8-2 CRM Scatter plot showing SORE 3 performance for Li2O. (warning = 2xSD, error = 3xSD) .. 44 Figure 8-3 Scatter plot of RC Field Duplicates ........................................................................................ 45 Figure 8-4 Scatter Plot of DD Field Duplicates ....................................................................................... 46 Figure 8-5 Q-Q' Plots for RC Pulp Duplicate ........................................................................................... 47 Figure 8-6 Q-Q' Plots for DD Pulp Duplicate ........................................................................................... 47 Figure 11-1 Exclusion Zone for Mineral Resources .............................................................................. 54 Figure 11-2 Cross Section View Main Modelled Lithologies ................................................................. 56 Figure 11-3 Histogram of sample lengths ............................................................................................. 56 Figure 11-4 Log Histogram for Li2O for the Central lode pegmatite (Top), and Kapanga pegmatites (Bottom) 57 Figure 11-5 Log Probability curve for Li2O, (central lode pegmatite high-grade and low-grade samples combined). 58 Figure 11-6 Combined Log Probability Plot. ......................................................................................... 58 Figure 11-7 Variography for Central Lode high-grade Domain ............................................................. 59 Figure 11-8 Variography for Kapanga high-grade Domain ................................................................... 59 Figure 11-9 QKNA results for Block Sizes. ........................................................................................... 61 Figure 11-10 QKNA analysis for min/max number of composites to use for estimation ........................ 62 Figure 11-11 QKNA additional analysis (negative kriging weights), for min/max number of composites to use for estimation .................................................................................................................................. 62 Figure 11-12 QKNA assessment for search ellipsoid distances ............................................................. 63 Figure 11-13 Example East-West Cross Sections Looking North. ......................................................... 65 Figure 11-14 Central Swath Plots on 50m Spacing ................................................................................ 66 Figure 11-15 Kapanga Swath Plots 50 m Spacing ................................................................................. 67 Figure 11-16 Classification Central (Left) and Kapanga (Right) ............................................................. 69 Figure 11-17 Long sections Showing Central (Left) and Kapanga (Right) Resource Classification ...... 69 Figure 11-18 Tonnage and Grade, Grade Control Reconciliation ............................................................. 70 Figure 12-1 Pit Optimization Shell ......................................................................................................... 76 Figure 12-2 Mineral Reserve Pit Shell Slope Design ............................................................................ 78 Figure 13-1 LOM Final Pit Design (Adopted from 2023) ....................................................................... 83 Figure 13-2 LOM Total Material Movement .......................................................................................... 85 Figure 13-3 LOM Feed and Operational Mass Yield ............................................................................ 85 Figure 13-4 LOM Active Mining Areas .................................................................................................. 86 Figure 13-5 LOM Active Dumping Areas .............................................................................................. 87 Figure 13-6 Location of S8 Waste Dump .............................................................................................. 88 Figure 14-1 Greenbushes Processing Overview – Block Flow Diagram .............................................. 93 Figure 14-2 Greenbushes Process Plants – Aerial Image .................................................................... 94 Figure 14-3 Crushing Circuit 1 TGP – Block Flow Diagram.................................................................. 96 Figure 14-4 Technical Grade Plant – Block Flow Diagram ................................................................... 97 Figure 14-5 Technical Grade Plant ....................................................................................................... 98 Figure 14-6 Crushing Circuit 1 CGP1 – Block Flow Diagram ............................................................... 99 Figure 14-7 CGP1 – Block Flow Diagram ........................................................................................... 100 Figure 14-8 Chemical Grade Plant 1 – External View ........................................................................ 101 Figure 14-9 Crushing Circuit 2 – Block Flow Diagram ........................................................................ 103 Figure 14-10 CGP2 – Block Flow Diagram ........................................................................................... 104 Figure 14-11 Chemical Grade Plant 2 – Exterior View ......................................................................... 105 Figure 14-12 Crushing Circuit 3 – Block Flow Diagram ........................................................................ 106 Figure 14-13 CGP3 – Block Flow Diagram ........................................................................................... 107 | ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | | | | Page vii of vii | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 Figure 14-14 Chemical Grade Plant 3 – Under Construction ............................................................... 108 Figure 14-15 TRP – Block Flow Diagram.............................................................................................. 109 Figure 14-16 TRP Concentrate Storage Sheds .................................................................................... 110 Figure 15-1 Overall Layout (Source: Google Earth, 2024) ................................................................. 114 Figure 15-2 Port of Bunbury - Berth 8 ................................................................................................. 116 Figure 15-3 Water Storages ................................................................................................................ 118 Figure 15-4 Simplified Water Flow Sheet ........................................................................................... 119 Figure 15-5 Water Pipe Route Saltwater Gully to Clearwater Dam .................................................... 121 Figure 15-6 South Western Highway Underpass Option (Source: Aurecon, 2024) .......................... 122 Figure 15-7 Mine Services Area (MSA) .............................................................................................. 123 Figure 15-8 TSF 2 ............................................................................................................................... 125 Figure 15-9 Greenbushes TSFs .......................................................................................................... 127 Figure 16-1 EV sales and penetration rates (000 vehicles, %) ............................................................... 130 Figure 16-2 Lithium demand in key sectors ('000 LCE tonnes) .............................................................. 130 Figure 16-3 Forecast mine supply ('000 tonnes LCE) ............................................................................. 133 Figure 16-4 Lithium supply-demand balance ('000 tonnes LCE) ............................................................ 134 Figure 16-5 Spodumene prices (6% lithia, spot, CIF China, US$/tonne ................................................. 135 Figure 16-6 Spodumene long-term price forecast scenarios (6% LiO spot, CIF China, US$/tonne, real (2024)) 137 Figure 19-1 Cashflow and Pre-Tax NPV Summary (100% Basis) ...................................................... 169 Figure 19-2 NPV Sensitivity Analysis .................................................................................................. 171

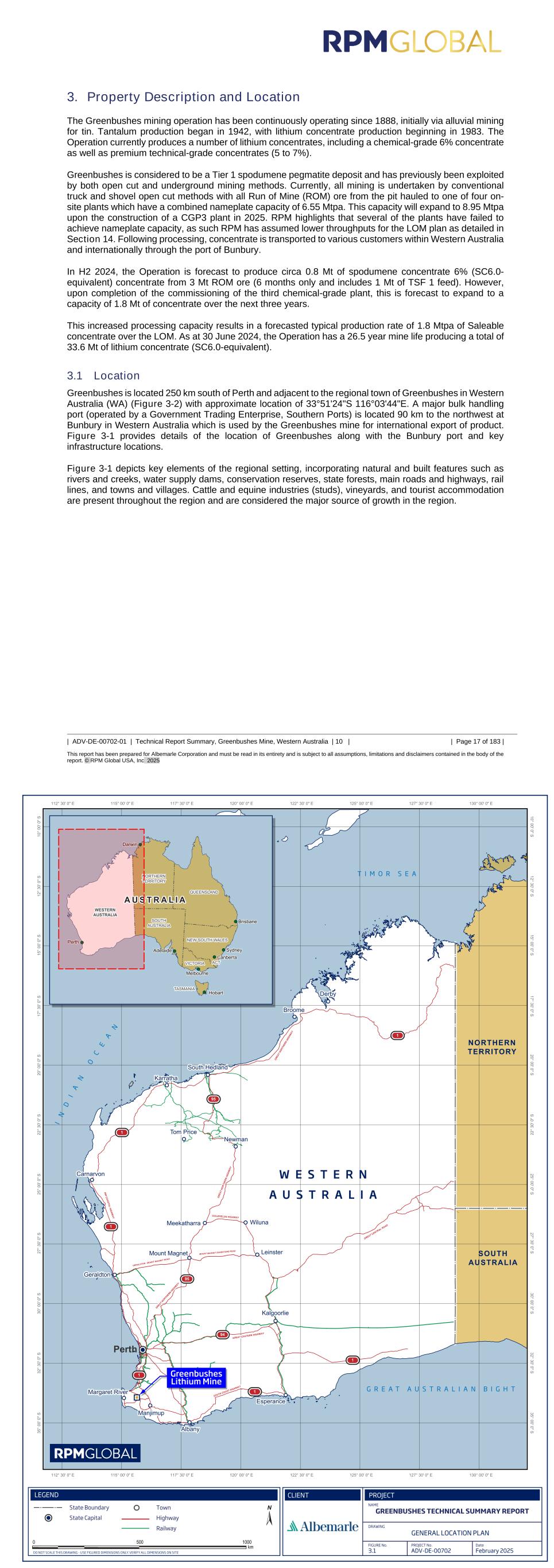

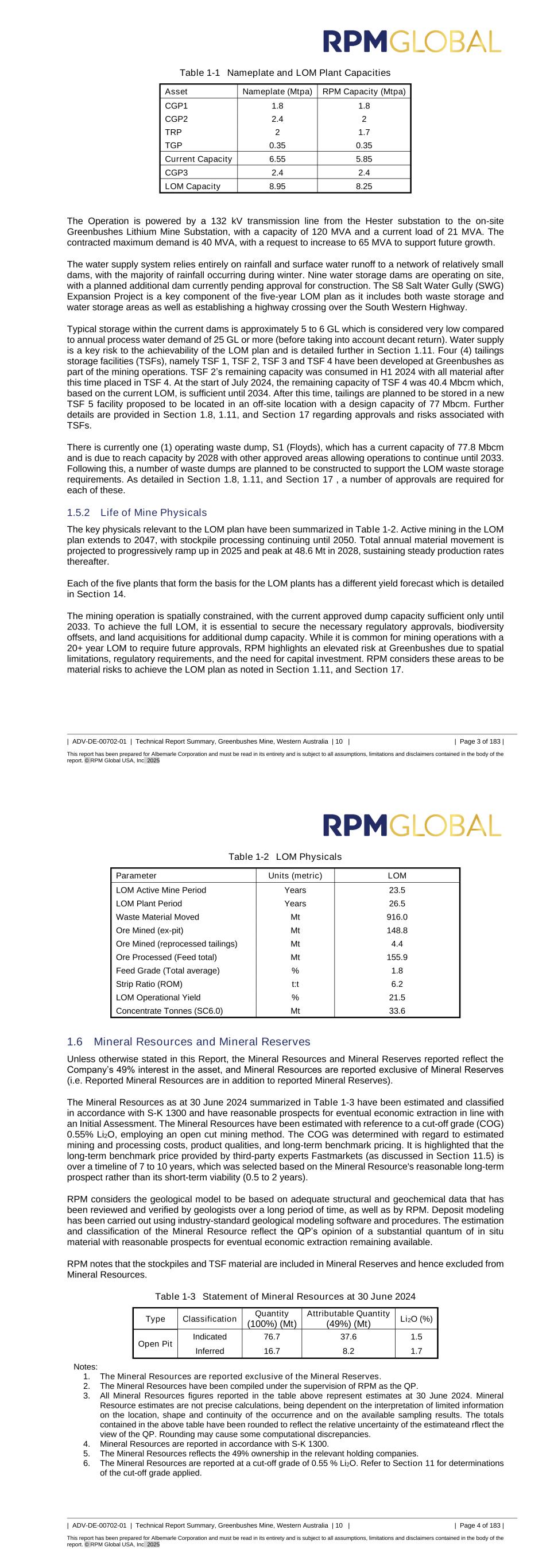

| ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | 10 | | Page 1 of 183 | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 1. Executive Summary Greenbushes is held within the operating entity, Talison Lithium Australia Pty Ltd (“Talison” or the “Company”) of which Albemarle is a 49% owner, with the remaining 51% ownership controlled by the Tianqi/IGO Joint Venture (JV) between Tianqi Lithium (Tianqi) and IGO Ltd (IGO) with ownership of 26.01% and 24.99%. Talison engages in and carries out work at the Operation, while each party manages the marketing and sales of its attributable share of spodumene concentrate. RPM’s technical team (the Team) consisted of Senior, Principal, and executive-level Consultants in geology, mining, processing, infrastructure, environment, health, safety, and social (EHSS) relevant experience in the project's styles of mineralization, mining methods, and regional setting. RPM, as the QP, was responsible for compiling or supervising the compilation of this Report and the Statements of Mineral Resources and Mineral Reserves stated within. It should be noted that all costs are presented in Australian dollars ($) unless otherwise stated, the economics have been detailed and evaluated on a 100% equity basis, and no adjustment has been made for inflation (real terms basis). 1.1 Report Scope The purpose of this Report is to provide a Technical Report Summary for Greenbushes, which includes a statement of Mineral Resources and Mineral Reserves at Greenbushes as at 30 June 2024, reported to reflect the ownership in the relevant holding companies that own the Project. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Title 17 Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. The Report was prepared by RPM as a third-party firm in accordance with S-K 1300. References to the QP are references to RPM and not to any individual employed or engaged by RPM. In addition to work undertaken to generate independent Mineral Resources and Mineral Reserves estimates, the TRS relies largely on information provided by Talison or the Client, either directly from the site and other offices or from reports by other organizations whose work is the property of the Talison or the Client or its subsidiaries. The data relied upon for the Mineral Resources and Mineral Reserves estimates independently completed by RPM have been compiled primarily by the Client and Talison and subsequently reviewed and verified as well as reasonably possible by RPM. The TRS is based on information made available to RPM as at 30 June 2024. Neither the Client, nor Talison has advised RPM of any material change, or event likely to cause material change, to the underlying data, designs, or forecasts since the date of asset inspections. It is noted that references to quarterly, half-yearly or annual time periods are based on a calendar year commencing 1 January each year, unless otherwise noted. 1.2 Property Description and Location Greenbushes is a medium-scale open cut mining operation located 250 km south of Perth in Western Australia directly adjacent the Southwest Highway. The highway allows access to a third-party-owned and operated major bulk handling port capability located 90 km to the northwest at Bunbury. Greenbushes is one of the largest known high grade spodumene pegmatite resources in the world and extracts lithium and tantalum products. The Operation’s property area is approximately 3,500 hectares (ha), which is a smaller subset of a larger 10,067 ha land package controlled 100% by Talison. RPMGlobal USA, Inc., acting as the Qualified Person (“QP”), has been engaged by Albemarle Corporation (“Albemarle” or the “Client”) to prepare a Technical Summary Report on the Greenbushes Lithium Mine (“Greenbushes” or the “Operation” or the “Mine”) located in Western Australia (Figure 3-1). The purpose of this Report is to provide a Technical Report Summary (“TRS” or the “Report”) in accordance with the United States Securities and Exchange Commission (SEC) S-K Regulations. | ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | 10 | | Page 2 of 183 | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 The Operation is accessible year-round via sealed bitumen roads, and there is sufficient road, air and port infrastructure in place with sufficient capacity to support the planned mining operations. The climate is characterized as temperate, and RPM considers there to be no limitations on mining or exploration at the site due to the climate. 1.3 Geology and Mineralization The intrusive rocks of the Greenbushes Pegmatite District lie within the Balingup metamorphic belt which lies within the Southwest Gneiss Terrains of the Yilgarn Craton. The pegmatites are spatially associated with and controlled by the Donnybrook-Bridgetown Shear Zone which is central to this belt, and potentially controls both the regional and local emplacement of the mineralization. The Greenbushes pegmatite deposit consists of several large pegmatite intrusive bodies which are separated into two main lodes, namely the Central and Kapanga lodes. Both areas consist of several pegmatite bodies; however, the Central lode displays significantly more continuity and thickness as compared to the Kapanga lode. Five distinct mineralogical zones have been defined in the Greenbushes central lode pegmatite. Generally, the pegmatite shows a contact zone, a K-feldspar (Potassium)-rich zone, an albite (sodium)-rich zone, a mixed zone and a spodumene (Lithium)-rich zone. The bulk of the lithium in the deposit is contained within the spodumene-rich zone, generally towards the center of the Central lode pegmatite. 1.4 Exploration Status The Greenbushes deposit is well explored and understood, with exploration drilling programs completing 1,572 holes since drilling commenced in the early 1970s. Exploration has been continuous throughout the life of the Operation, with recent exploration focused on the mining areas within the Life of Mine (LOM) pit limits. These exploration programs have gathered geological and geochemical data, with the bulk of this data collected from surface drilling activities. However, some drilling has been undertaken via underground methods. Greenbushes’ forward-looking exploration strategy focuses on increasing the geological confidence within the footprint of the tenement holdings to expand the current resource base. 1.5 Development and Operations The Operation utilizes conventional open-cut mining techniques optimized for the deposit's geological characteristics, with targeted extraction from the Central Lode and Kapanga pegmatite zones. Mining is forecast to be within a single open cut with the final pit design incorporating staged cutbacks to balance cost efficiency, recovery and safety. The mining fleet is expected to remain fully contractor-operated, consisting of a mixed fleet of hydraulic excavators and 140-tonne haul trucks. Contractors manage equipment supply, maintenance, replacement, and workforce logistics, subsequently, all mining costs are based on unit rates. 1.5.1 Key Site Infrastructure The Operation currently has four operating processing plants and associated infrastructure – Chemical Grade Plant #1 (CGP1), Chemical Grade Plant #2 (CGP2), a Tailings Retreatment Plant (TRP) and a Technical Grade Plant (TGP). Combined, these plants produce various technical-grade lithium concentrates and a 6% lithium-grade concentrate (SC6.0). As outlined in Table 1-1, the plants combined have a total nameplate processing capacity of 6.55 Mtpa producing up to 1.5 Mtpa of lithium mineral concentrate. A third Chemical Grade Plant #3 (CGP3) is currently being constructed and is forecast to commence commissioning in mid-2025, which will increase nameplate processing capacity to 8.95 Mtpa. RPM highlights that several of the plants have failed to achieve nameplate capacity, as such RPM has assumed lower throughputs for the LOM plan as noted in Table 1-1.

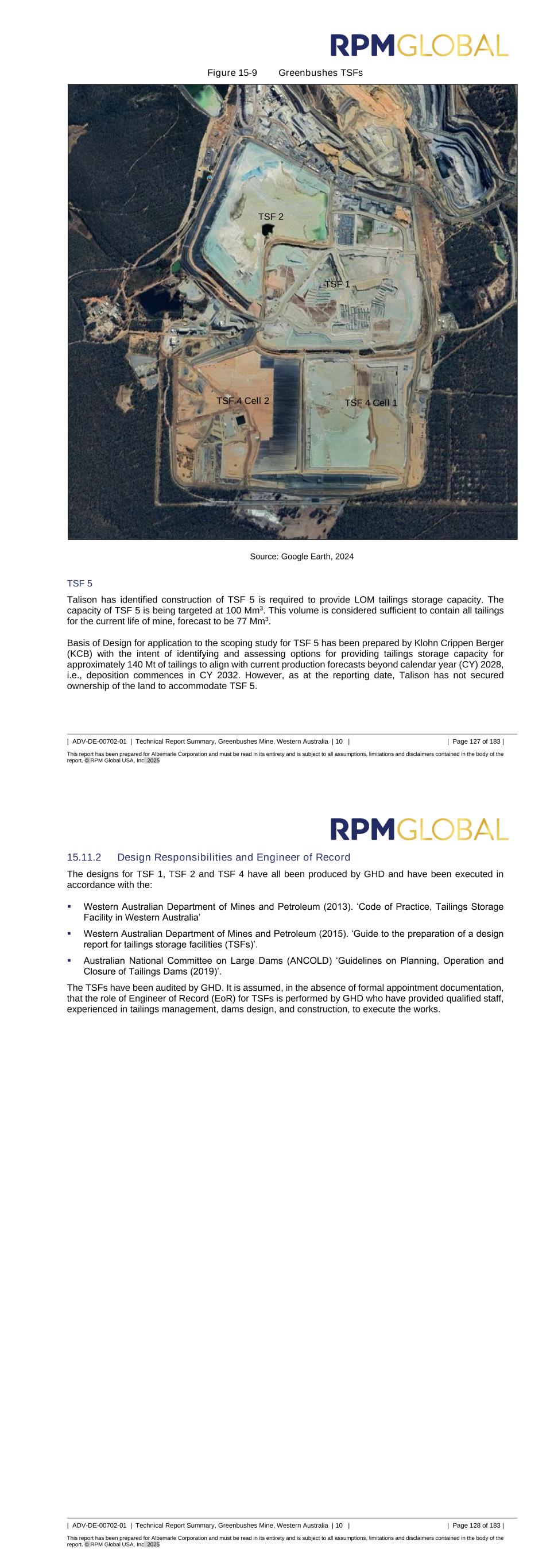

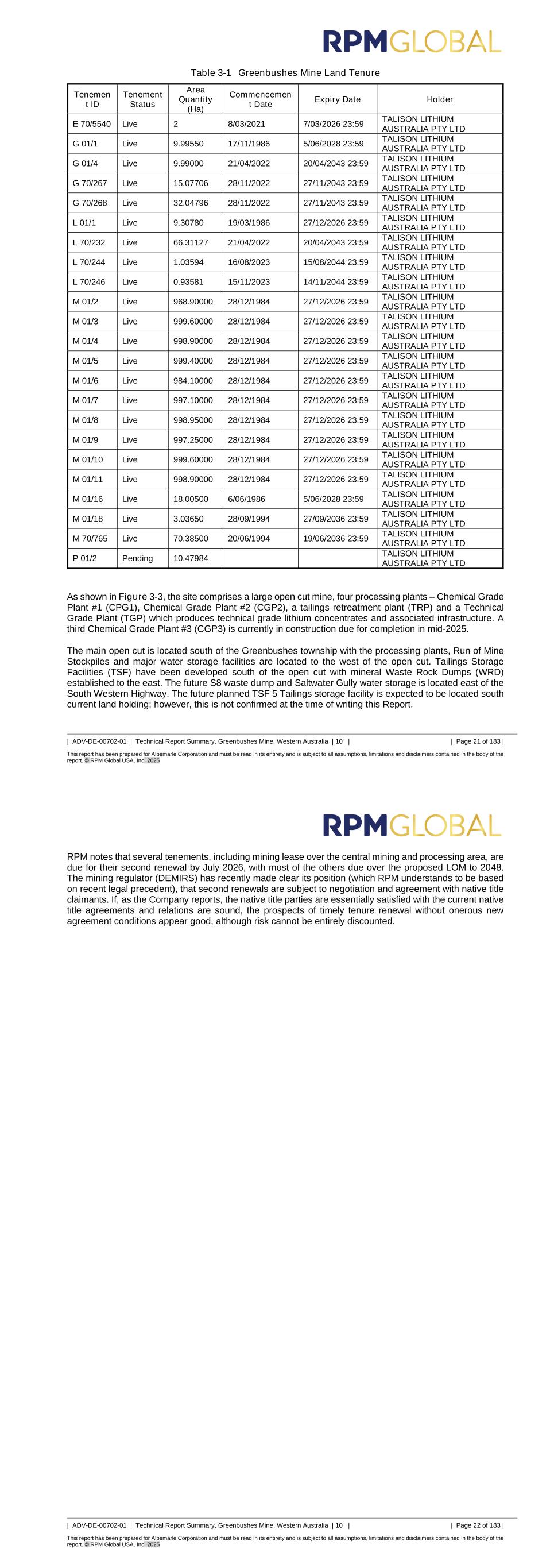

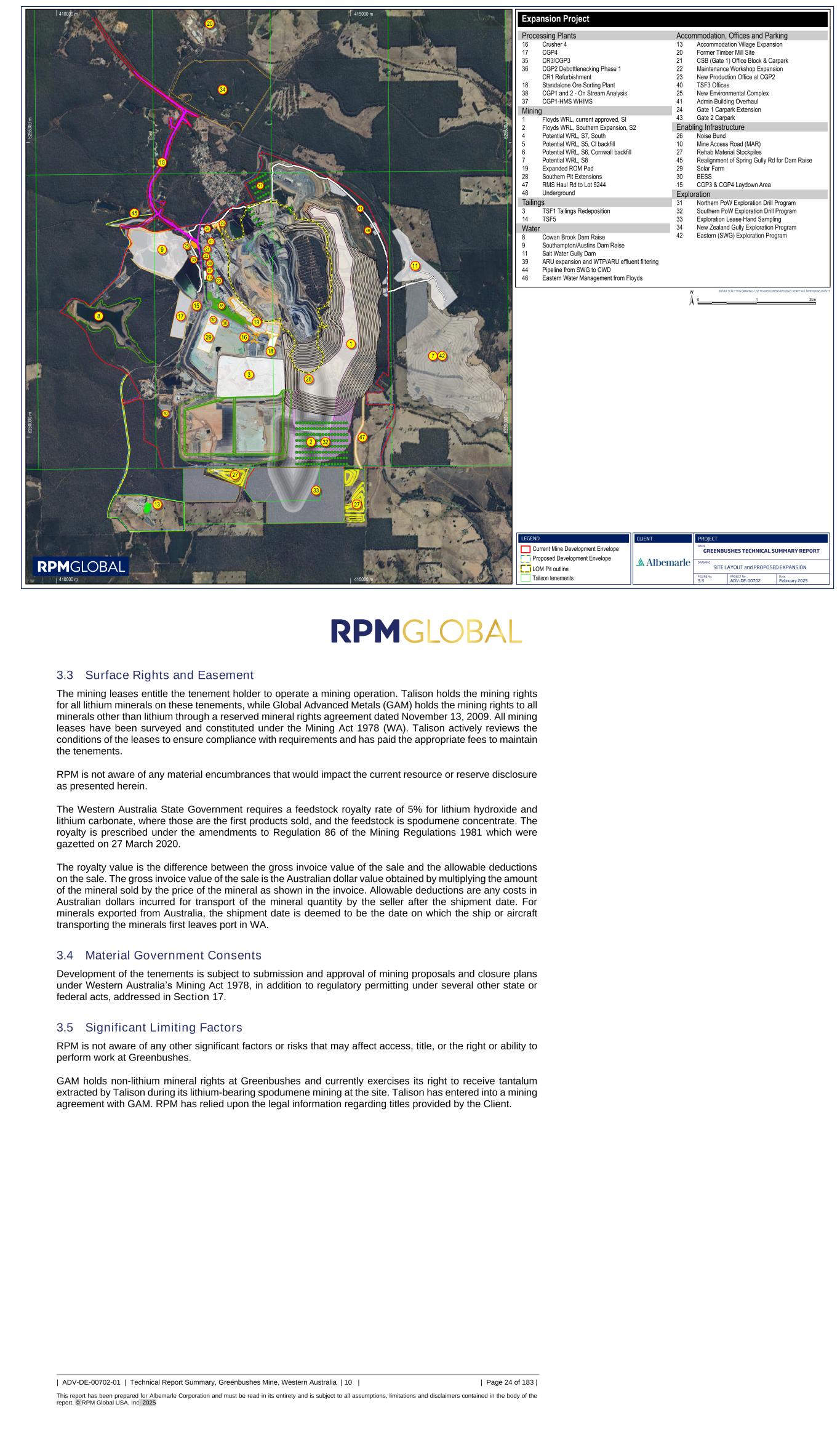

| ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | 10 | | Page 3 of 183 | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 Table 1-1 Nameplate and LOM Plant Capacities Asset Nameplate (Mtpa) RPM Capacity (Mtpa) CGP1 1.8 1.8 CGP2 2.4 2 TRP 2 1.7 TGP 0.35 0.35 Current Capacity 6.55 5.85 CGP3 2.4 2.4 LOM Capacity 8.95 8.25 The Operation is powered by a 132 kV transmission line from the Hester substation to the on-site Greenbushes Lithium Mine Substation, with a capacity of 120 MVA and a current load of 21 MVA. The contracted maximum demand is 40 MVA, with a request to increase to 65 MVA to support future growth. The water supply system relies entirely on rainfall and surface water runoff to a network of relatively small dams, with the majority of rainfall occurring during winter. Nine water storage dams are operating on site, with a planned additional dam currently pending approval for construction. The S8 Salt Water Gully (SWG) Expansion Project is a key component of the five-year LOM plan as it includes both waste storage and water storage areas as well as establishing a highway crossing over the South Western Highway. Typical storage within the current dams is approximately 5 to 6 GL which is considered very low compared to annual process water demand of 25 GL or more (before taking into account decant return). Water supply is a key risk to the achievability of the LOM plan and is detailed further in Section 1.11. Four (4) tailings storage facilities (TSFs), namely TSF 1, TSF 2, TSF 3 and TSF 4 have been developed at Greenbushes as part of the mining operations. TSF 2’s remaining capacity was consumed in H1 2024 with all material after this time placed in TSF 4. At the start of July 2024, the remaining capacity of TSF 4 was 40.4 Mbcm which, based on the current LOM, is sufficient until 2034. After this time, tailings are planned to be stored in a new TSF 5 facility proposed to be located in an off-site location with a design capacity of 77 Mbcm. Further details are provided in Section 1.8, 1.11, and Section 17 regarding approvals and risks associated with TSFs. There is currently one (1) operating waste dump, S1 (Floyds), which has a current capacity of 77.8 Mbcm and is due to reach capacity by 2028 with other approved areas allowing operations to continue until 2033. Following this, a number of waste dumps are planned to be constructed to support the LOM waste storage requirements. As detailed in Section 1.8, 1.11, and Section 17 , a number of approvals are required for each of these. 1.5.2 Life of Mine Physicals The key physicals relevant to the LOM plan have been summarized in Table 1-2. Active mining in the LOM plan extends to 2047, with stockpile processing continuing until 2050. Total annual material movement is projected to progressively ramp up in 2025 and peak at 48.6 Mt in 2028, sustaining steady production rates thereafter. Each of the five plants that form the basis for the LOM plants has a different yield forecast which is detailed in Section 14. The mining operation is spatially constrained, with the current approved dump capacity sufficient only until 2033. To achieve the full LOM, it is essential to secure the necessary regulatory approvals, biodiversity offsets, and land acquisitions for additional dump capacity. While it is common for mining operations with a 20+ year LOM to require future approvals, RPM highlights an elevated risk at Greenbushes due to spatial limitations, regulatory requirements, and the need for capital investment. RPM considers these areas to be material risks to achieve the LOM plan as noted in Section 1.11, and Section 17. | ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | 10 | | Page 4 of 183 | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 Table 1-2 LOM Physicals Parameter Units (metric) LOM LOM Active Mine Period Years 23.5 LOM Plant Period Years 26.5 Waste Material Moved Mt 916.0 Ore Mined (ex-pit) Mt 148.8 Ore Mined (reprocessed tailings) Mt 4.4 Ore Processed (Feed total) Mt 155.9 Feed Grade (Total average) % 1.8 Strip Ratio (ROM) t:t 6.2 LOM Operational Yield % 21.5 Concentrate Tonnes (SC6.0) Mt 33.6 1.6 Mineral Resources and Mineral Reserves Unless otherwise stated in this Report, the Mineral Resources and Mineral Reserves reported reflect the Company’s 49% interest in the asset, and Mineral Resources are reported exclusive of Mineral Reserves (i.e. Reported Mineral Resources are in addition to reported Mineral Reserves). The Mineral Resources as at 30 June 2024 summarized in Table 1-3 have been estimated and classified in accordance with S-K 1300 and have reasonable prospects for eventual economic extraction in line with an Initial Assessment. The Mineral Resources have been estimated with reference to a cut-off grade (COG) 0.55% Li2O, employing an open cut mining method. The COG was determined with regard to estimated mining and processing costs, product qualities, and long-term benchmark pricing. It is highlighted that the long-term benchmark price provided by third-party experts Fastmarkets (as discussed in Section 11.5) is over a timeline of 7 to 10 years, which was selected based on the Mineral Resource's reasonable long-term prospect rather than its short-term viability (0.5 to 2 years). RPM considers the geological model to be based on adequate structural and geochemical data that has been reviewed and verified by geologists over a long period of time, as well as by RPM. Deposit modeling has been carried out using industry-standard geological modeling software and procedures. The estimation and classification of the Mineral Resource reflect the QP’s opinion of a substantial quantum of in situ material with reasonable prospects for eventual economic extraction remaining available. RPM notes that the stockpiles and TSF material are included in Mineral Reserves and hence excluded from Mineral Resources. Table 1-3 Statement of Mineral Resources at 30 June 2024 Type Classification Quantity (100%) (Mt) Attributable Quantity (49%) (Mt) Li2O (%) Open Pit Indicated 76.7 37.6 1.5 Inferred 16.7 8.2 1.7 Notes: 1. The Mineral Resources are reported exclusive of the Mineral Reserves. 2. The Mineral Resources have been compiled under the supervision of RPM as the QP. 3. All Mineral Resources figures reported in the table above represent estimates at 30 June 2024. Mineral Resource estimates are not precise calculations, being dependent on the interpretation of limited information on the location, shape and continuity of the occurrence and on the available sampling results. The totals contained in the above table have been rounded to reflect the relative uncertainty of the estimateand rflect the view of the QP. Rounding may cause some computational discrepancies. 4. Mineral Resources are reported in accordance with S-K 1300. 5. The Mineral Resources reflects the 49% ownership in the relevant holding companies. 6. The Mineral Resources are reported at a cut-off grade of 0.55 % Li2O. Refer to Section 11 for determinations of the cut-off grade applied.

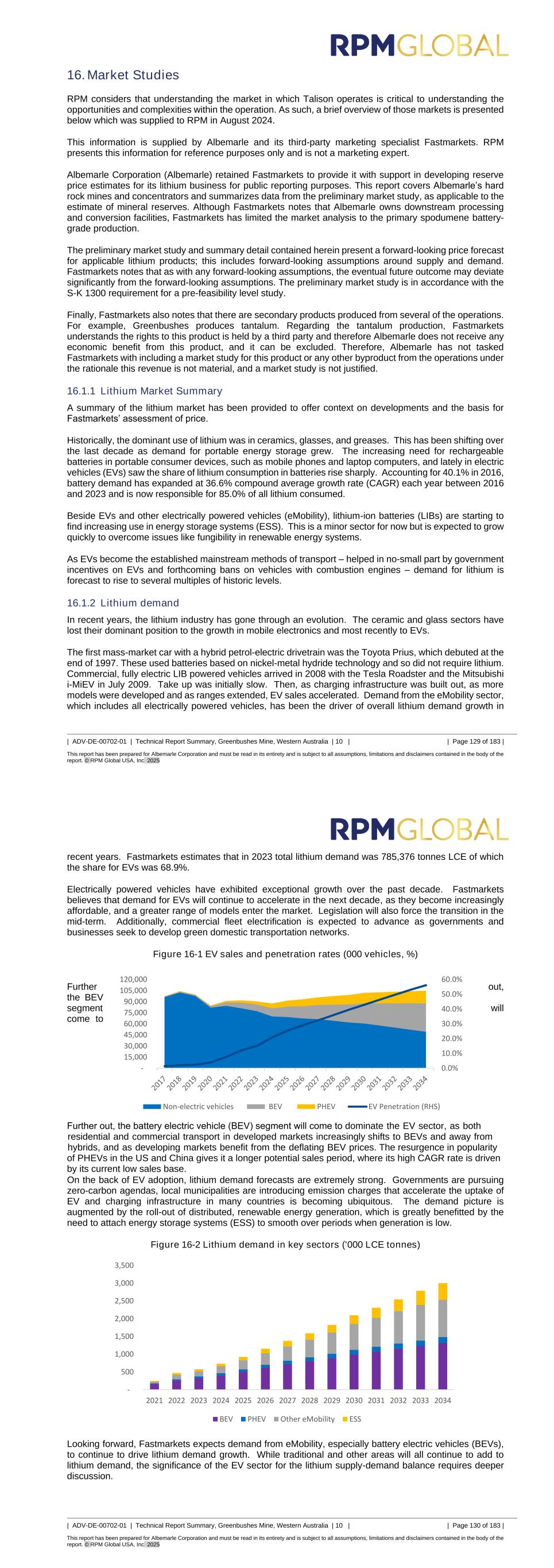

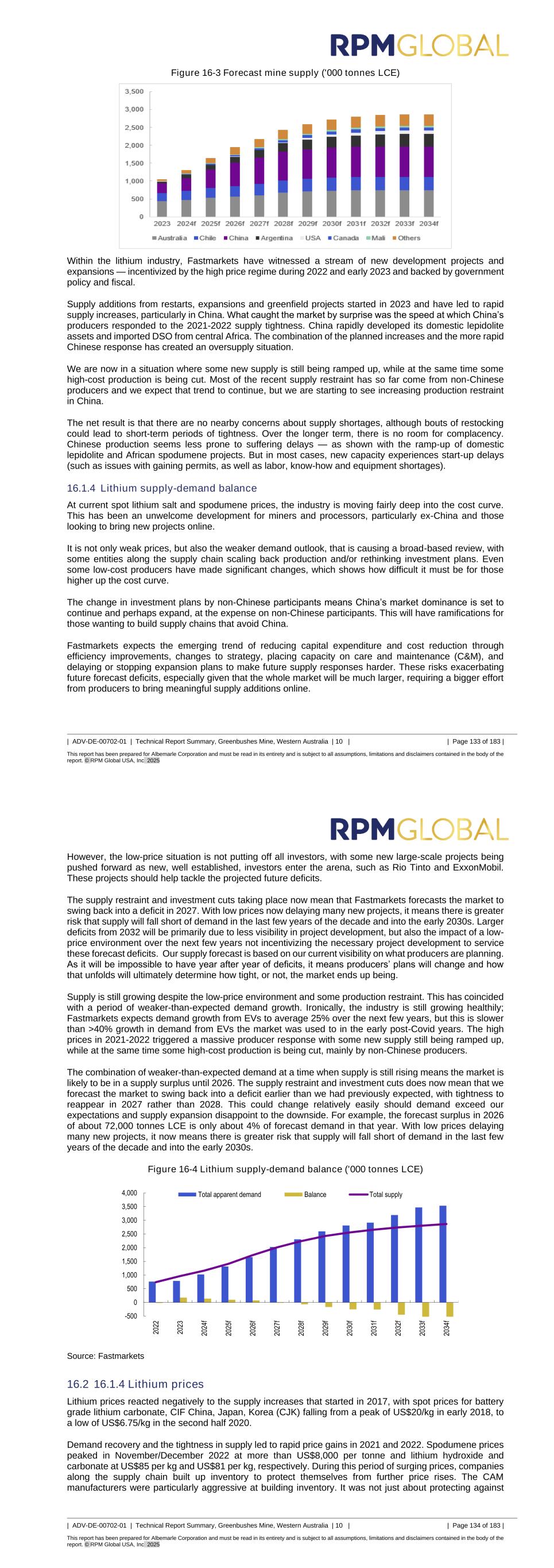

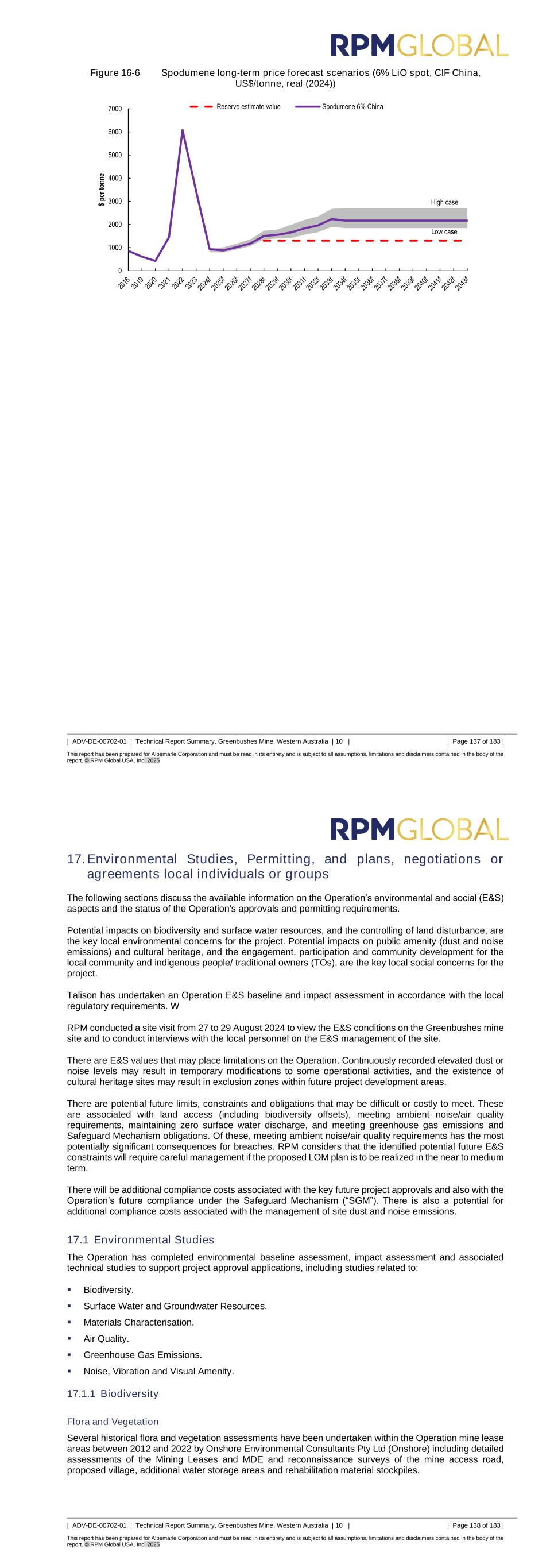

| ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | 10 | | Page 5 of 183 | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 The Mineral Reserves have been estimated as at 30 June 2024 as summarized in Table 1-4 Statement of Mineral Reserves as at 30 June 2024. Mineral Reserves are subdivided into Proven Mineral Reserves and Probable Mineral Reserves categories to reflect the confidence in the underlying Mineral Resource data and modifying factors applied during mine planning. A Proven Mineral Reserve can only be derived from a Measured Mineral Resource, while a Probable Mineral Reserve is typically derived from an Indicated Mineral Resource as well as Measured Resources dependent on the QP’s confidence in the underlying Modifying Factors. No Measured Mineral Resources have been reported for the Operation, as such no Proven Mineral Reserves are reported. The conversion of Mineral Resources to Mineral Reserves incorporated systematic mine planning and analysis, including pit optimization, detailed pit design, the application of modifying parameters, LOM scheduling, and cost analysis. All Mineral Reserve calculations are in metric units, with Li2O grades reported in percentage (%). Mineral Reserve quantities were estimated using a marginal cut-off grade of 0.7% Li2O and a selling price of US$ 1,300, based on Fastmarkets Market Study Guidance in Section 16. Table 1-4 Statement of Mineral Reserves as at 30 June 2024 Classification Type Quantity (100%) (Mt) Attributable Quantity (49%) (Mt) Li2O% Probable In situ 148.8 72.9 1.8 Probable Stockpiles 2.8 1.4 2.4 Probable TSF 1 4.3 2.1 1.4 Total 155.9 76.4 1.8 Notes: 1. The Mineral Reserves are additional to the reported Mineral Resources. 2. The Mineral Reserves have been estimated by RPM as the QP. 3. Mineral Reserves are reported in accordance with S-K 1300. 4. The Mineral Reserves have been reported at a 49.0% equity basis. 5. Mineral Reserves are reported on a dry basis and in metric tonnes. 6. The totals contained in the above table have been rounded with regard to materiality. Rounding may result in minor computational discrepancies. 7. Mineral Reserves are reported considering a nominal set of assumptions for reporting purposes: - Mineral Reserves are based on a selling price of US$1,300/t for chemical grade concentrate (6% Li2O), and concentrate transport and selling cost of US$9.75/t. RPM has relied on third-party and expert opinions and notes the selling price is below the Fastmarkets CIF China, Japan, Korea (CJK) low-case 10-year average price of US$1,333 . - Mineral Reserves assume a 98% global grade factor. - Mineral Reserves are diluted by approximately 3.5% (2% grade reduction + 1.5% internal dilution). - All Inferred material (3.3 Mt) with reported Li2O content greater than zero, is allocated to waste. - Ore blocks with a Li₂O grade greater than or equal to 0.7% and less than or equal to 1.9%, and an iron oxide (Fe₂O₃) content greater than or equal to 2.9% are classified as contaminated ore . This material is included in the Mineral Reserves and LOM plan; however, is processed separately to clean ore, and at a decreased concentrate grade. Material above 1.9% Li2O is considered clean or irrespective of the Iron grade. - Costs estimated in Australian Dollars were converted to U.S. dollars based on an exchange rate of AU$1.00:US$0.68. - The economic CoG calculation is based on an estimated US$2.67/t-ore incremental ore mining cost, US$35.77/t-ore processing cost, US$10.03/t-ore G&A cost, and US$3.54/t-ore sustaining capital cost. - The price, cost and mass yield parameters produce a calculated economic COG of 0.62% Li2O. However, due to the internal constraints of the current operations, an elevated Mineral Reserves COG of 0.7% Li2O has been applied. - The mass yield for ore processed through the Chemical and Technical plants is estimated based on formulas that vary depending on Li2O%. For CGP1, the formula is MY%=9.362 × Feed Li2O%^1.319. For CGP2 and CGP3, the formula is MY%=(9.362 × Feed Li2O%^1.319)+(Feed Li2O% × 0.82). The TGP formula is MY%=41.4 and the TRP formula is MY%=13.6. - Waste tonnage within the reserve pit is 916.0 Mt at a strip ratio of 6.2:1 (waste to ore – not including reserve stockpiles). | ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | 10 | | Page 6 of 183 | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 1.7 Market Studies Fastmarkets has developed a marketing study on behalf of Albemarle to support lithium pricing assumptions utilized in this Report. This market study does not consider by- or co-products that may be produced alongside the lithium production process. Battery demand is now responsible for 85.0% of all lithium consumed. Looking forward, Fastmarkets expects demand from eMobility, especially battery electric vehicles (BEVs), to continue to drive lithium demand growth. Supply is still growing despite the low-price environment and some production restraint. This has coincided with a period of weaker-than-expected demand growth. Ironically, the industry is still growing healthily; Fastmarkets expects demand growth from electric vehicles (EVs) to average 25% over the next few years, but this is slower than >40% growth in demand from EVs the market was used to in the early post-Covid years. The high prices in 2021-2022 triggered a massive producer response with some new supply still being ramped up, while at the same time, some high-cost production is being cut, mainly by non-Chinese producers. The combination of weaker-than-expected demand at a time when supply is still rising means the market is likely to be in a supply surplus until 2026. Based on supply restraint and investment cuts, Fastmarkets forecasts the market to swing back into a deficit in 2027. This could change relatively easily should demand exceed expectations and supply expansion disappoint to the downside. Fastmarkets recommends that a real price of US$1,300/tonne for spodumene SC6.0 CIF China should be utilized by Albemarle for Mineral Reserve estimation. Recommended prices are on the lower end of Fastmarkets' low-case scenario. Figure 1-1 Lithium supply-demand balance ('000 tonnes LCE) Source: Fastmarkets Based on the Fastmarkets report, RPM has adopted the following to support Mineral Resource and Mineral Reserve Estimation: ▪ Mineral Resources: US$1,500/t for spodumene SC6.0 CIF China ▪ Mineral Reserves: US$1,300/t for spodumene SC6.0 CIF China; and ▪ Financial Modelling: US$1,300/t for spodumene SC6.0 CIF China from 2027, increased from spot price in line with the Fastmarkets forecast. 1.8 Environmental, Permitting, and Social Considerations The Operation is generally in compliance with the current E&S approvals and permits. However, there have been some operational incidents and non-compliance issues such as chemical spills, unauthorized land disturbance, infrastructure damage, pollution control equipment malfunction and a fauna strike. In addition, the Department of Energy, Mines, Industry Regulation and Safety (DEMIRS) issued a notification of a

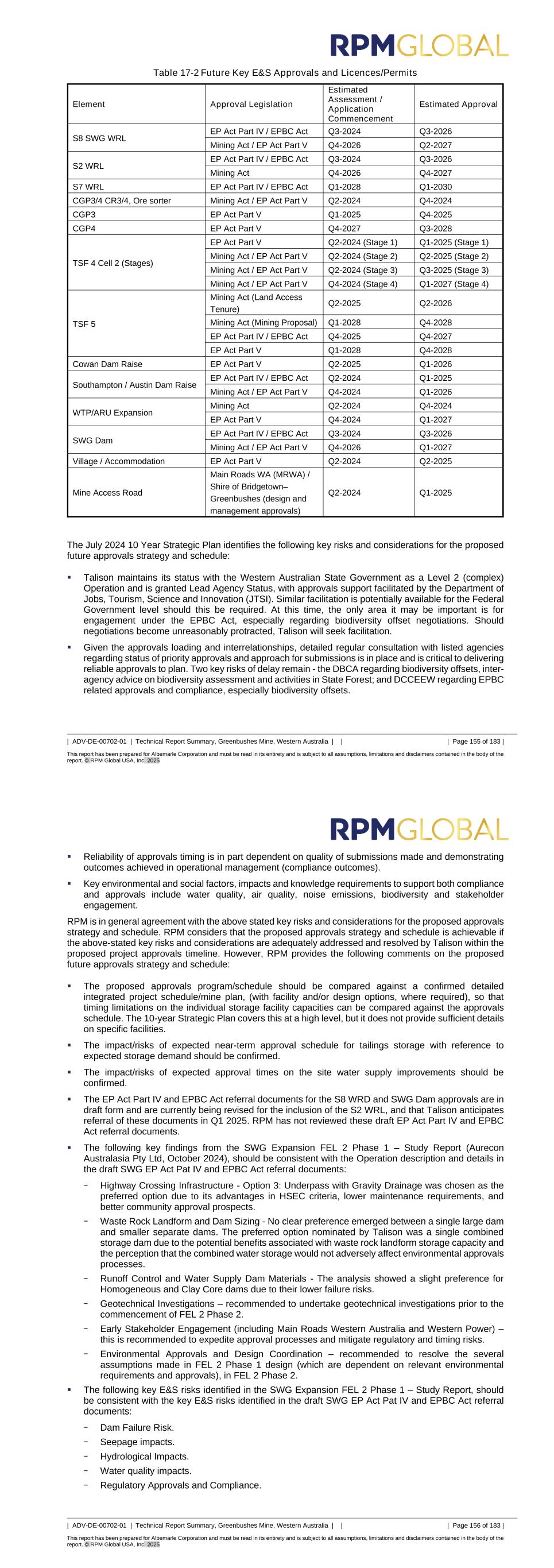

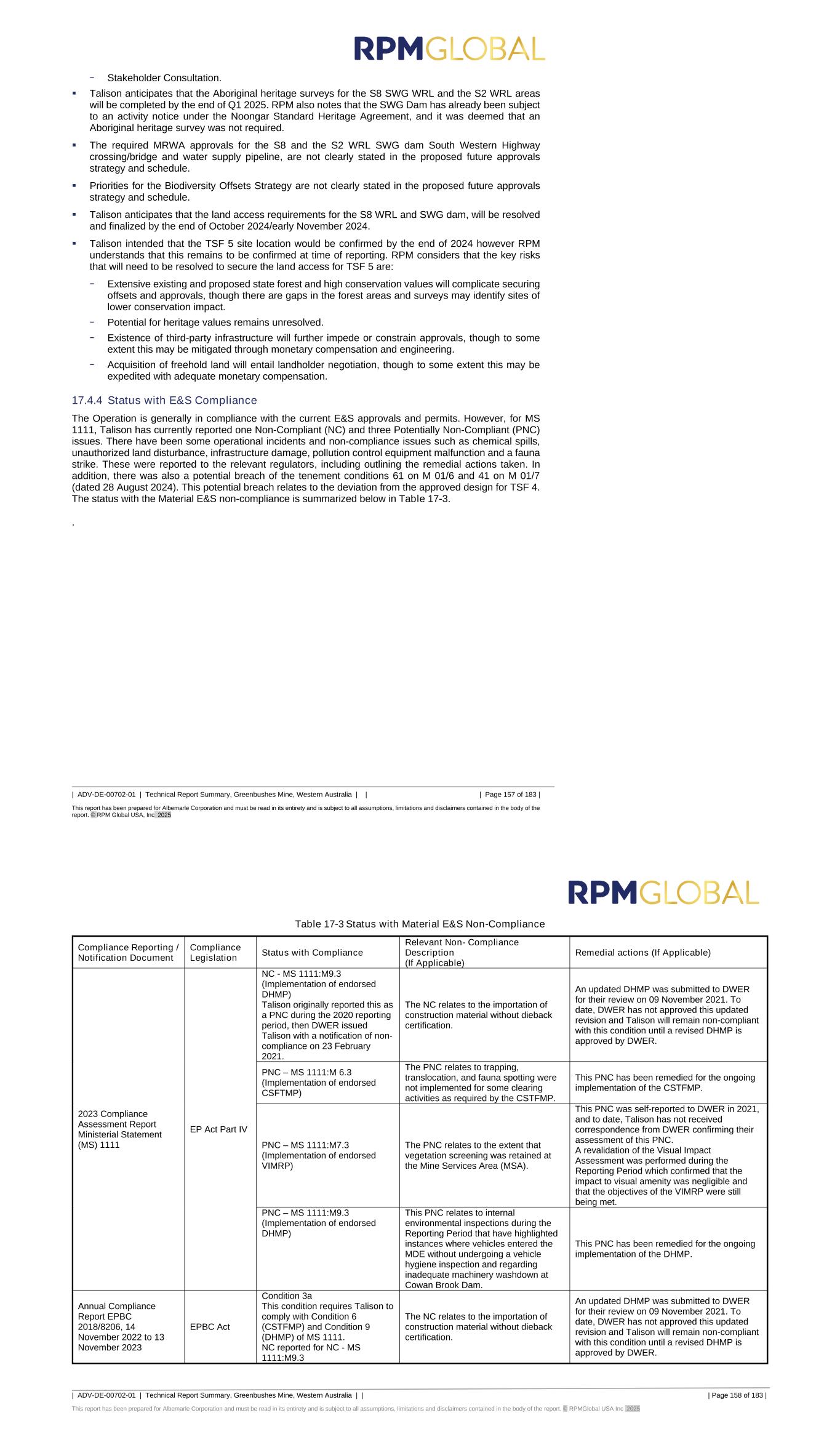

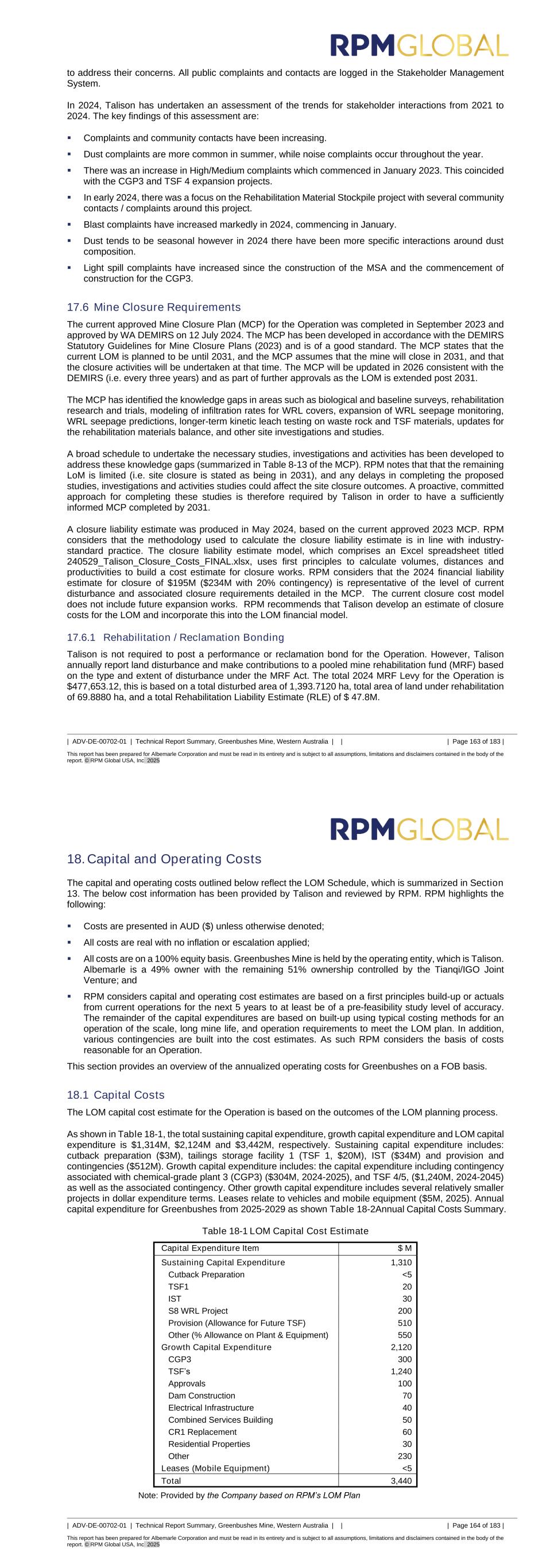

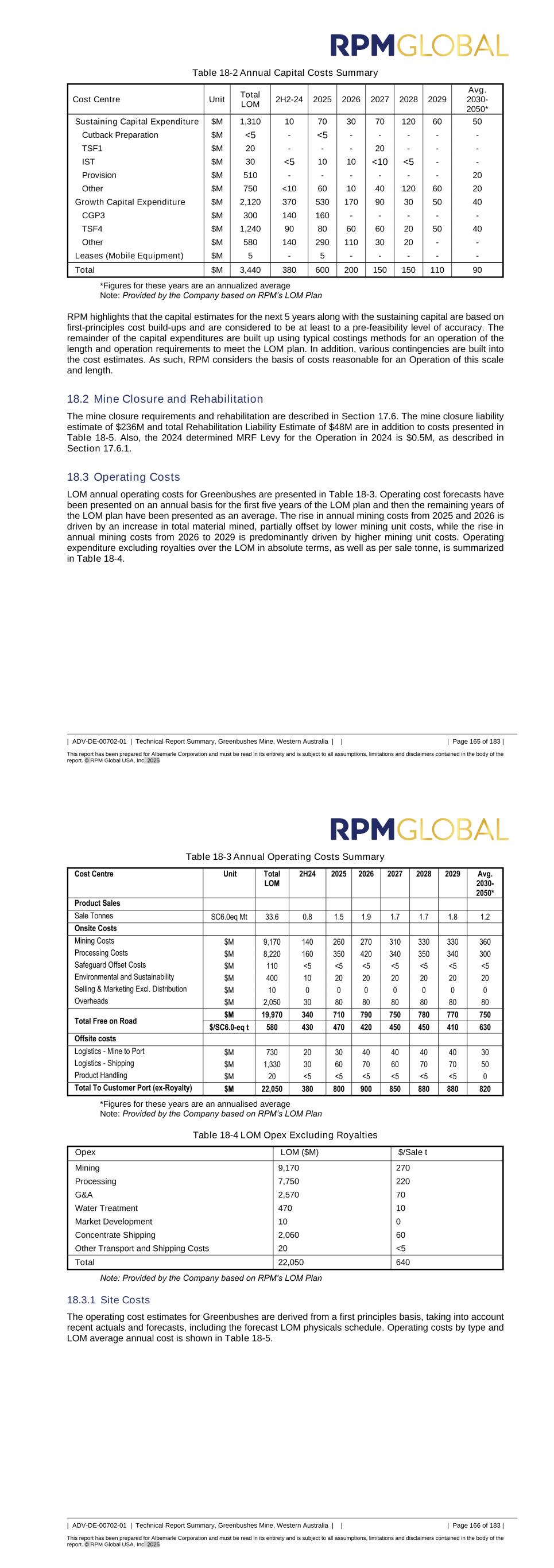

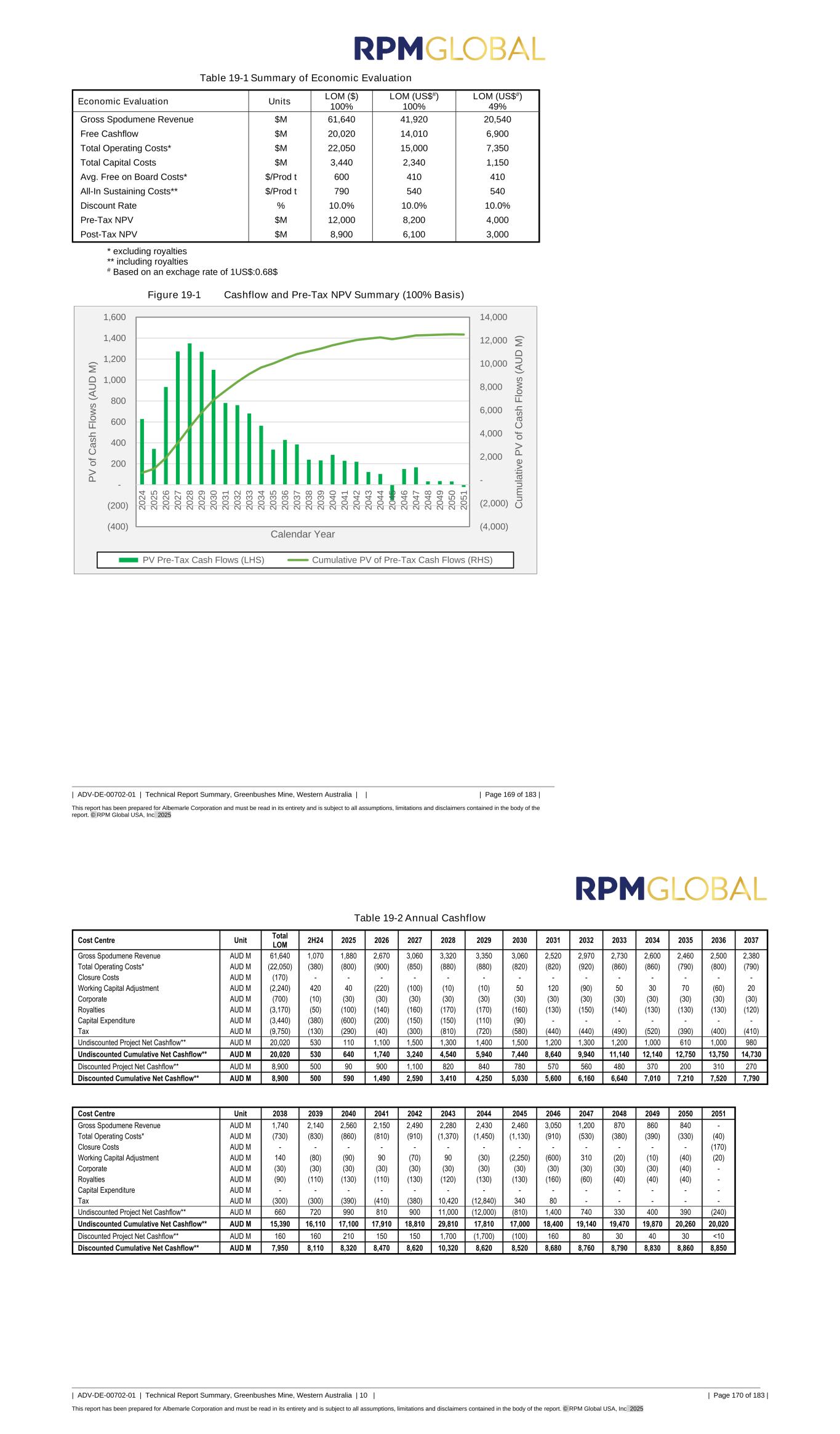

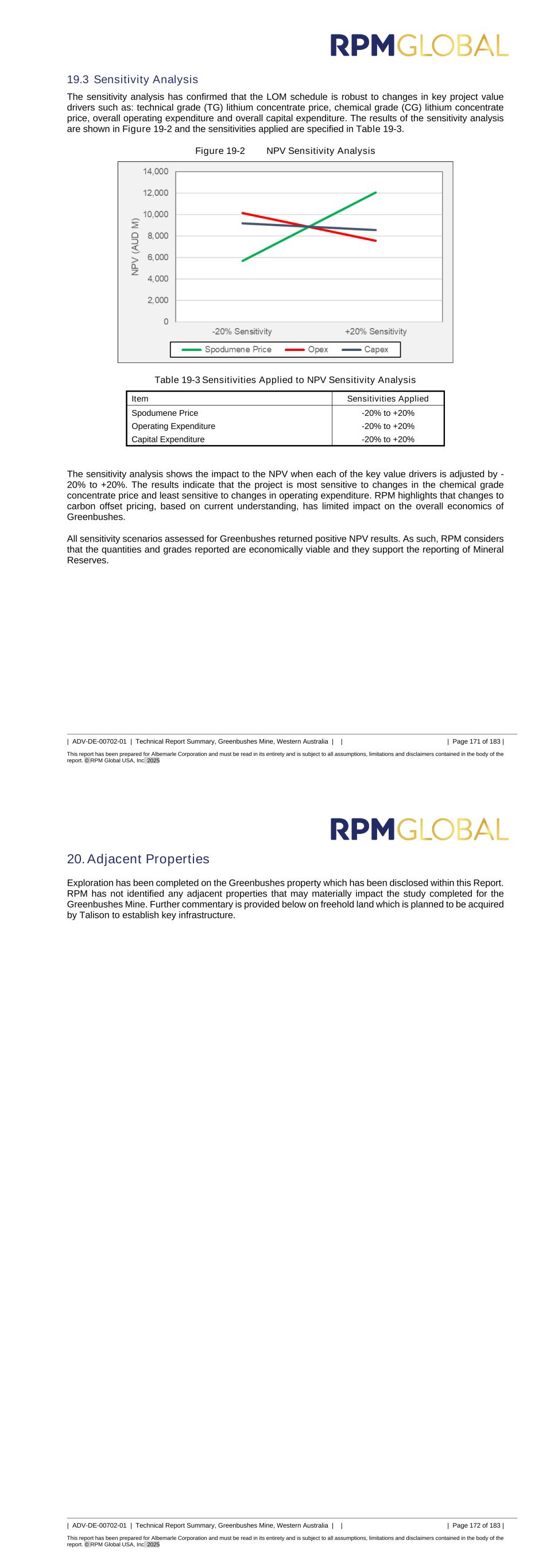

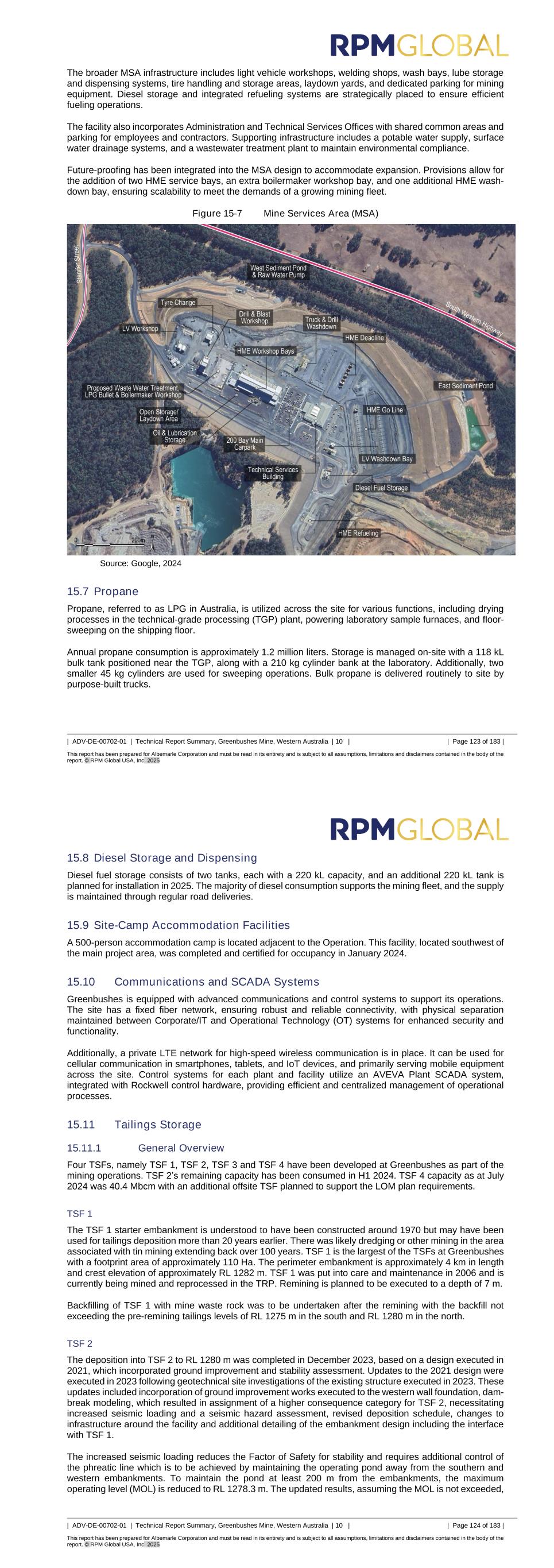

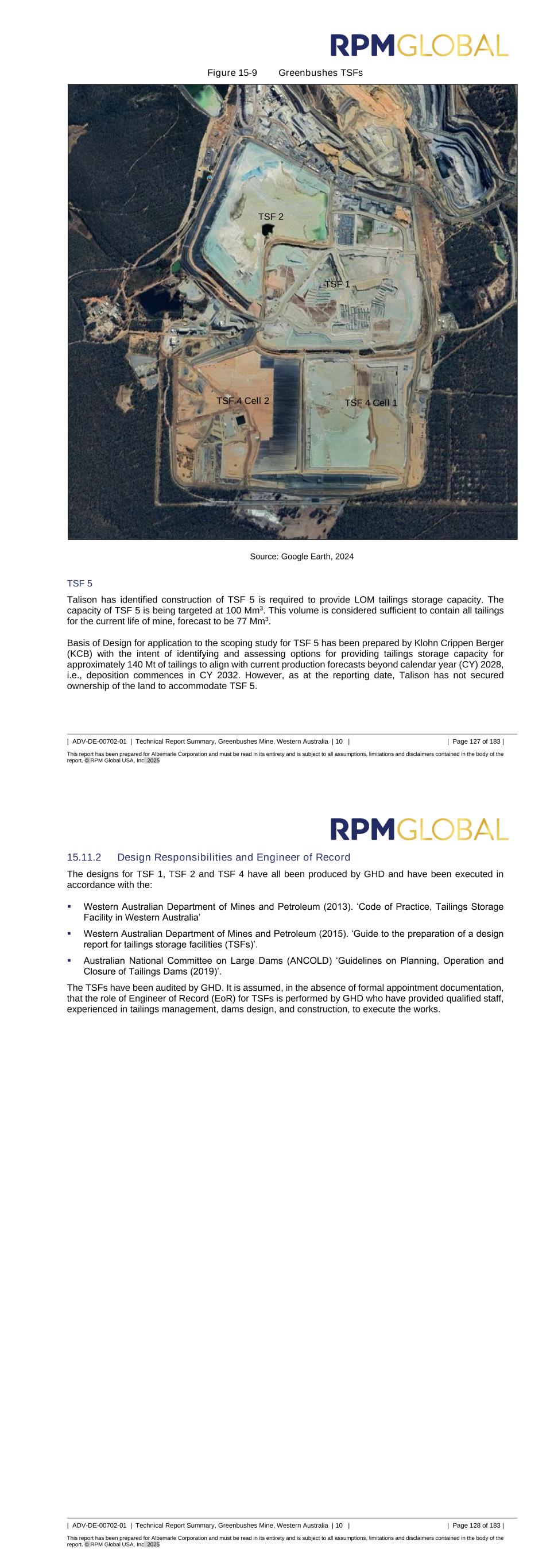

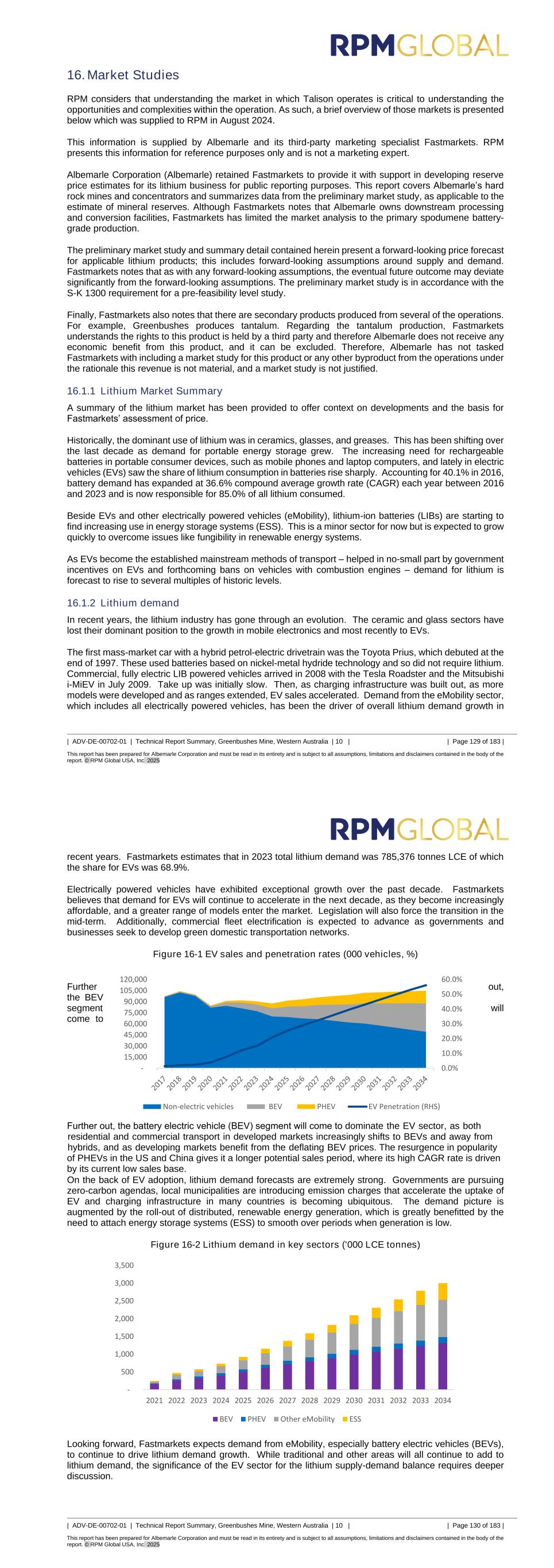

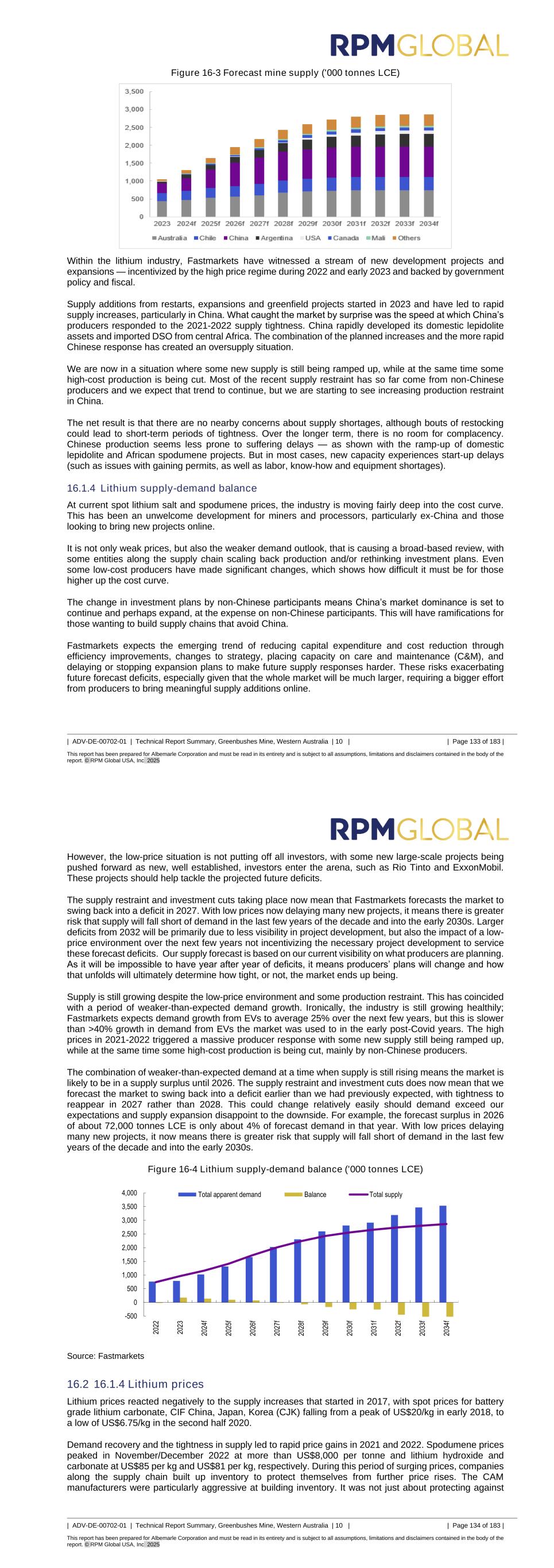

| ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | 10 | | Page 7 of 183 | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 potential breach of the tenement conditions 61 on M 01/06 and 41 on M 01/07 (dated 28 August 2024). This potential breach relates to the deviation from the approved design for TSF 4. Talison submitted its response to this notification to DEMIRS on 24 September 2024. Talison provided a detailed justification as to why it does not consider tenement conditions have been breached, which is supported by proposed corrective action measures. The reply from DEMIRS is pending. There are several key project approvals required for near to medium term mining in the LOM Plan, including the S8 Saltwater Gully Water (SWG) waste rock landform (WRL), (SWG) Dam, S2 WRL, S7 WRL, CGP3 CR3, CGP3, TSF5, TSF 4 Cell 2 (wall lifts), Cowan Dam Raise, Southampton / Austin Dam Raise, WTP/ARU Expansion and TSF 5. Further details are provided in Section 17. RPM notes there are three (3) potential sites for TSF 5 and Talison anticipates the site location to be confirmed by the end of 2025. RPM considers that the key risks that will need to be resolved to secure land access for TSF 5 are: ▪ Extensive existing and proposed state forest and high conservation values will complicate securing offsets and approvals. ▪ Potential for heritage values have not been evaluated. ▪ Potential existence of third-party infrastructure on the selected area will further impede or constrain approvals, though to some extent this may be mitigated through monetary compensation and engineering. This is expected to be only farm related infrastructure. ▪ Acquisition of freehold land will entail landholder negotiation, though to some extent this may be expedited with adequate monetary compensation. There are environmental and social (E&S) values that may place limitations on the Operation. Continuously monitored elevated dust or noise levels may result in temporary modifications to some operational activities, and the existence of currently unknown cultural heritage sites or biodiversity values may result in exclusion zones within future project development areas. RPM notes that the known areas are excluded from the LOM plan and native title studies have been completed. There are potential future E&S limits, constraints and obligations that may be difficult or costly to meet. These are associated with land access (including biodiversity offsets) for tails and waste storage areas, meeting ambient noise/air quality requirements, maintaining zero surface water discharge, and meeting greenhouse gas emissions/safeguard mechanism obligations. RPM considers that the identified potential future E&S constraints will require careful management if the proposed LOM plan is to be realized in the near to medium term. Talison has assessed and is managing the Aboriginal cultural heritage issues associated with the Operation. Talison has Heritage Agreements in place with the local indigenous groups, which will facilitate and guide any future required heritage surveys for the Operation. With the renewal of the mining leases pending, in 2026, renegotiation of these agreements may potentially be required. Talison has established an extensive stakeholder engagement and community development program. The stakeholder engagement is guided by an overarching Stakeholder Engagement Plan (SEP) and Stakeholder Management System, which is managed by a dedicated Stakeholder Engagement Team (SET). Talison has also developed the 2024 Stakeholder Engagement & Community Relations Business Plan, which outlines and guides the current specific stakeholder engagement and community development activities for future plans. A current approved Mine Closure Plan (MCP) is in place, and RPM considers that the 2024 financial liability estimate for closure of $195M ($236M with contingency 100% basis) is representative of the level of disturbance and associated closure requirements detailed in the MCP. 1.9 Economic Evaluation RPM highlights that the opex and capital estimates for the next 5 years, along with the sustaining capital, are based on first principle cost build-ups and are considered to be at least to a pre-feasibility level of accuracy. The remainder of the capital expenditures are based on built-up using typical costing methods for an operation of the scale, long mine life, and operation requirements to meet the LOM plan. In addition, | ADV-DE-00702-01 | Technical Report Summary, Greenbushes Mine, Western Australia | 10 | | Page 8 of 183 | This report has been prepared for Albemarle Corporation and must be read in its entirety and is subject to all assumptions, limitations and disclaimers contained in the body of the report. © RPM Global USA, Inc 2025 various contingencies are built into the cost estimates. As such RPM considers the basis of costs reasonable for an Operation. Operating Costs The LOM operating costs are built up from first principles with reference to historical actuals (cost and production performance), the LOM physical schedule, and forecast product estimates. The total Free on Board (FOB) operating costs (which exclude royalties and shipping costs) are $20,723M over the LOM and the average LOM FOB cost is $599/t product. Mine Closure of $236M is included in addition to the operating costs and allows for the total planned closure costs, ongoing closure holding costs and workforce redundancy. Capital Costs The economic evaluation summarized in Table 1-5 includes: ▪ Sustaining capital for equipment purchase and replacement, and other general sustaining capital costs, which are typical for an operating asset of this scale. ▪ Growth capital to support the LOM production ramp up, CGP3 and upgrades, TSF 5 and other mine infrastructure projects, EPCM and associated contingency. ▪ Mobile equipment leases Table 1-5 Summary of Capital Costs Capital Expenditure Item $ M Sustaining Capital Expenditure 1,310 Growth Capital Expenditure 2,120 Leases (Mobile Equipment) 5 Total 3,440 RPM highlights that the majority of operating infrastructure is in place to support the 26.5-year Operation’s life which includes 3 years of processing stockpiles. 1.9.1 Economic Evaluation The economic evaluation of the asset was completed using a discounted cash flow analysis and confirmed the robust economics of Greenbushes. Table 1-6 Summary of Economic Evaluation provides a summary of the economic evaluation. Table 1-6 Summary of Economic Evaluation Economic Evaluation Units LOM ($) 100% LOM (US$#) 100% LOM (US$#) 49% Gross Spodumene Revenue $M 61,640 41,920 20,540 Free Cashflow $M 20,020 14,010 6,900 Total Operating Costs* $M 22,050 15,000 7,350 Total Capital Costs $M 3,440 2,340 1,150 Avg. Free on Board Costs* $/Prod t 600 410 410 All-In Sustaining Costs** $/Prod t 790 540 540 Discount Rate % 10.0% 10.0% 10.0% Pre-Tax NPV $M 12,000 8,200 4,000 Post-Tax NPV $M 8,900 6,100 3,000 * excluding royalties ** including royalties # Based on an exchange rate of 1US$:0.68$